PROJECT STUDY

Life on the Edge

The Observation Deck at 30 Hudson Yards Stands Out

At 101 floors and 1,270 feet, 30 Hudson Yards is the tallest building in the largest private real-estate development in U.S. history. And at 1,131 feet up, protruding sharply from the 100th floor, the Edge is the highest open-air observation deck in the western hemisphere. It cantilevers 80 feet from the main structure to its tip. A glass floor in the deck’s center lets visitors enjoy views straight down.

The unique triangular terrace represents a spectacular feat of engineering ingenuity. But this awe-inspiring deck wasn’t always part of the building plan.

“Early in the tower’s design,” said Project Manager Jeff Callow, “the developer decided they wanted an iconic place-marking feature near the top – something that was one of a kind.”

(continued inside)

Location: New York, New York

Developer: The Related Companies

Architect:

Kohn Pedersen Fox Associates (KPF)

When KPF and Related developed a design that added an open-air observation deck, the primary challenge became how to build a structure that was light and elegant, and could also cantilever so far out from the building at such a high elevation.

With nothing at that level to support falsework, gaining access to the area was a primary concern, particularly for installing the cladding on the underside of the deck. Together, the engineers, fabricators and façade consultant devised a solution that was nothing short of ingenious.

The

Solution

To accommodate crane capacities, wind loads, scheduling and other considerations, the team split the portion of the deck that extends beyond the building’s footprint into 15 prefabricated modules, which included structural steel, secondary cladding support and soffit cladding. The steel fabricator and façade consultant carefully coordinated every detail, including installation of access panels at the bottom of the soffit, and rigs with rails that enable maintenance workers to access remote areas of the deck.

To guarantee a precise fit, steel fabricator Cimolai laid out the complete deck, fully connected, on their grounds in Italy. This ensured that all the holes and pairings between the modules would line up perfectly – before the deck was shipped to New York.

Each module was lifted individually, in a single crane lift, or pick, and installed in a planned sequence. To minimize crane

time, specially designed connections allowed the modules to be connected in the air. At weights ranging from 35,000 to 100,000 pounds, with a total structural weight of about 765,000 pounds, most of the modules were so large and heavy that they required two tower cranes working in tandem to lift them into place. At one pick per module, installation took about 15 nonconsecutive days.

“Instead of building a series of temporary trusses or falsework that cantilevered off the tower, or trying to walk our way out and construct it in small pieces, we managed to build it in 15 picks,” said Principal in Charge and Co-CEO Mike Squarzini. “But what’s really impressive is the collaboration between designers, fabricators and erectors that enabled this signature element to seem to suddenly appear on the side of the building.”

In a tandem pick, two tower cranes lift one of 15 modules that make up the Edge at Hudson Yards. Each module was lifted and installed in a single day.

What do you get when you marry creativity with innovation? An approach that’s unbounded by preconceptions, but is grounded in reality – and backed by solid science. We call it ingenuity. And we believe this quality sets the everyday apart from the extraordinary.

Building an Enduring Organization

Our leadership team in front of the Thornton Tomasetti-engineered Vessel at New York City’s Hudson Yards. From left: President Wayne Stocks, Co-CEO Mike Squarzini, Executive Chairman Tom Scarangello, Managing Director Gary Panariello, and Co-CEO Pete DiMaggio. See page 27 for Wayne’s thoughts on how we’re advancing inclusion and diversity at the firm and page 12 for Gary’s views on the firm’s decarbonization initiative.

Every five years, we tap the brakes on the daily race, set aside time to look down the road and prepare our next five-year vision. We ask a lot of questions: Where are our clients headed? What will they need in five years? Where is the industry going? Where should we invest our R&D dollars? What should be our big bets?

This year’s answers spurred us to center our 2020 to 2025 vision on four main ideas.

Vitality: We will focus on exploring new options, renewing our strategy and growing sustainably. We’re freeing up project teams to drive creativity, and to match our progress and success with initiatives in artificial intelligence and machine learning.

Ingenuity: By evolving to take advantage of the rapid rate of change in our industry, we’ll ensure that our offerings remain fresh and relevant, and continue to promote the success of our clients (see roundtable discussion, page 8). This is how we’ll achieve sustained ingenuity – which we define as the combination of creativity (freshness of ideas) and innovation (how those ideas are put to work).

Opportunity: We will invest in the next generation of talent, provide our people with challenging opportunities and stay ahead of client expectations (see page 12 for decarbonization, page 30 for application of computational fluid dynamics and page 35 for dronebased condition assessment).

People: We will set and achieve targeted, data-driven goals to increase inclusion and diversity – of our staff, leaders, owners and board of directors (see page 24). We’ll also invest in a powerful leadership development program. We know diversity drives innovation, so we’re making sure that everyone at Thornton Tomasetti is empowered to transform our industry.

In His Own Words: New Co-CEO Mike Squarzini

Education: MSSE, University of Minnesota; BSCE, Manhattan College Years with Thornton Tomasetti: 27 Fun Fact: Mike has played guitar since he was 14, and once dreamed of touring the world with his own band.

What motivates him: What has always driven me is the pursuit of excellence. I never do things halfway. I hate losing, and I hate failure, but those are natural in life. It’s how you recover from failure that shapes you as a person.

How he wants to be seen by others: I identify myself as approachable. I’ve always tried to be authentic. People can generally figure me out quickly, because what you see is what you get.

How to grow as a leader: Listen, listen, and listen some more . . . and then act.

Outside of work: I’m never not at work – I’m always thinking of the firm. But when I want to relax, I like playing golf with my wife and boys.

Ingenuity: Engineers are solution-oriented – “here’s the problem, here’s the solution.” Ingenuity requires you to surround yourself with people who have skills you don’t have – who have better technical expertise or are more creative thinkers. Getting those people in a room and letting the ideas clash always produces the best outcomes. Our ingenuity initiative is all about that.

His goals as new co-CEO: I want to touch this organization in a way that leaves it stronger, more people-focused and even more inspiring than the organization where I spent my career.

In His Own Words: New Co-CEO Pete DiMaggio

Education: MSCE, BSCE and B.A., Columbia University Years with Thornton Tomasetti: 26

Fun Fact: While attending Columbia, Pete was a star midfielder for the Lions soccer team. In 1991, he was named Ivy League Player of the Year and First Team All-American.

What inspired him to pursue an engineering career: I’ve always been drawn to science and math. Solving problems through the application of science is one of my favorite kinds of puzzles.

Where the firm is headed: We’re evaluating a lot of opportunities. I think, in addition to building on our existing practices, you’ll see continuous growth into areas that I refer to as “applied mechanics,” addressing some of the most difficult challenges the world is facing, such as sustainability, security, resilience and decarbonization.

Ingenuity: It’s important to understand our clients’ challenges and come up with the best ways to address them. That’s why ingenuity is so crucial. Once we figure out the solution – conceptually, artistically, creatively – we use the power of technology to bring it to life.

Outside of work: I train in the martial art of Brazilian jiu-jitsu, and enjoy being outside, doing something exciting with my wife and three boys.

His new role as co-CEO: We have an extraordinary company, with so many talented people doing amazing things. Our role is to empower, motivate and inspire them, and to make sure we are operating collaboratively across the firm worldwide. This is an evolution. The firm is in an amazing place right now, and our job as leaders is to gently guide it into the future.

Our vision is tuned for the agility needed to thrive in the midst of rapid change. To be an enduring organization, we have to anticipate and embrace change. And we have to address the new challenges facing our people and our planet. This year, in support of industry initiatives to reduce carbon emissions, we released BeaconTM, an embodied carbon calculator we developed using real-world project data we’ve been collecting for nearly a decade (see page 28).

Ultimately, our goal is to remain a driver of change and innovation in our industry, building on our decade-long track record. CORE, our innovation and R&D incubator, has invented solutions that let us work faster and smarter for our clients. TTWiiN, our innovation accelerator, has launched four companies based on Thornton Tomasetti intellectual property development. This year, we launched TTWiiN II to bring our continuing stream of IP to market.

We invite you to explore this report for the results of our prior five-year vision and join us in sowing the seeds for a new period of growth and ingenuity.

Tom Scarangello Pete DiMaggio Mike Squarzini Executive Chairman Co-CEO Co-CEO

ingenuity

During our preparation of this report, a novel coronavirus spread around the world and upended life as usual.

No one alive had experienced anything like it, and there was no playbook. The outbreak required extraordinary measures and sacrifices to protect the communities around the world in which we live and work.

It also required ingenuity, a combination of creativity (freshness of ideas) and innovation (how those ideas are put to work). And ingenuity, mixed with agility, flexibility and goodwill, moved our entire industry to work and collaborate virtually.

The challenges of the outbreak caused us all to seek and apply the most ingenious ideas – to look beyond business as usual and find opportunities to keep moving forward.

We hope the exploration of ingenuity in the following pages sparks ideas that go beyond just project work. Because the creation, cultivation and distribution of ingenious ideas will enable us all to make lasting contributions to our industry and our communities.

In the absence of any standardized code approach, we used our expertise in high-fidelity analytical models to design the iconic steel connections for Dubai Expo 2020’s Al Wasl Trellis (see inside back cover).

How Can Our Industry Build a Culture of Ingenuity?

The architecture, engineering and construction (AEC) industry ranks near the bottom in speed to innovation and digitization of many processes. What are the hurdles, and how can we overcome them?

Phil Bernstein, FAIA, RIBA, LEED AP

Associate Dean and Senior Lecturer

Yale School of Architecture

New Haven, Connecticut

Dominique Davison, AIA, LEED AP, NCARB Principal

DRAW Architecture + Urban Design

Founder, PlanIT Impact

Kansas City, Missouri

MaryAnne Gilmartin

Co-Founder and CEO

L&L MAG

New York, New York

Ray Levitt, Ph.D.

Operating Partner

Blackhorn Ventures Denver, Colorado

Phil: If we define ingenuity as the creative application of innovation, does the AEC industry have an ingenuity shortage?

Dominique: In AEC, we underinvest in technology and innovation, spending about half as much on technology as other industries. This leads to a lack of ingenuity. Our designs are innovative, but our processes or delivery are less so.

MaryAnne: The development industry aids and abets this lack of ingenuity. Developers operate within a rigid framework that is defined by capital constraints, the political environment, process constraints and risk profile. We are therefore loath to innovate, mainly because the risk is so great. Sustainability only became such a big part of our business because people wanted to live in healthy buildings, and consumers were demanding it, so we changed because we had no choice.

Phil: What are the hurdles to innovation?

MaryAnne: It’s about the money. When we wanted to do a modular building in Brooklyn, an idea we were passionate about, I needed to sell the idea to capital partners and lenders. An idea like modular construction – innovative for Brooklyn! – can be generated by the development community, but to make it a reality, there are a lot of other people you need to persuade.

Phil: That’s true across the supply chain. Developers need bankers.

Architects need an insurance company. Contractors need a bonding agent. It’s a high coefficient for all of us. Is that a main constraint, or is it our thin margins, or something else?

MaryAnne: Developers can still make money without innovating, so there is no imperative. When the market demands innovation – like the surging interest in sustainability – we’ll make the change because it’s for survival, but we tend to follow rather than lead. A developer can still eke out some success with a series of forgettable buildings that are not contributing to the community and the built environment in any ingenious way.

Ray: In construction, the drastic demand fluctuation at the local and regional levels makes it difficult for contractors to invest in anything, especially R&D. And fixed-price contracts that force them to bid competitively don’t allow them to try new things. Combine that with the fact that we have 50 times as many lawyers per capita as Japan does.

Phil: Is there a locus of ingenuity? What’s the source?

Ray: Real innovation is coming from the people who employ all the labor and all the equipment – the specialty trade contractors, like plumbing and electrical. But they can only innovate within their own lane. And if there is an innovation that requires the next lane to make a change – if the mechanical people want to do something that requires a different structure, or different plumbing, or a

different something else – then everyone needs to agree to evolve. You also need some repetition so you can learn how to do it. A big problem is not having the same team members from one project to the next, because we often select people by competitive bid.

But there is a slow diffusion of automation across the industry, which is starting to pay dividends. You pay subcontractors net 30 days, and you can take 5 percent out of the cost of building right there, and so you’ve got to automate the lien releases. You’ve got to automate the bank’s construction-loan payment processes. All those things are starting to happen. Technology has paved the path,

and now people are finding more creative ways to drive on it. I bet that if somebody studied labor productivity in the industry right now, the curve would be starting to bend up.

Phil: Who is doing it right?

Ray: The Googles, Facebooks and Apples care about their carbon footprints, and they’re focused on offices that are healthy for their workers. They’re competing for talent and have to build premium workplaces. Google, for example, is interested in trying alternative cements that are low in embedded carbon, as well as new window walls and different air-conditioning systems.

MaryAnne: Companies like that will drive innovation, as huge consumers of space. They’ll drive the development community to a certain place, because they’re willing to pay for it.

Phil: Despite their interest in creating an optimal workplace and being leaders in carbon footprint reduction, the Googles, Apples and Facebooks of the world don’t show as much interest in process innovation. Some of those iconic facilities they’ve been building were delivered as straight construction-management at-risk jobs. It’s all lowest-cost procurement, with zero innovation on the process side.

Dominique: It’s hard to drive innovation when you don’t have everybody lined up behind a clearly defined outcome. When everybody agrees on what success looks like – in terms of building performance, operational cost, quality of the space, financial outcomes, etc. – then it’s easier for people to innovate toward those goals. Integrated project delivery (IPD) allows everybody to align their goals and derisk innovation. The people for whom this is valuable are owneroccupiers, who aren’t going to flip their buildings. That’s why Google cares about life-cycle costs.

Phil: Ray, you mentioned the productivity curve. Whether or not it’s bending up, we still lag behind many industries. Would focusing on productivity be an organizing principle to get us to begin innovating? Would it interest you, MaryAnne, if you could build your buildings for 35 percent less?

MaryAnne: I went down that rabbit hole at 461 Dean Street in Brooklyn, part of the Pacific Park megaproject. We knew we had scale, so it was time for us to figure out the most efficient way to put a building together.

Chasing 15 to 20 percent in cost savings came down to modular construction. We put 65 percent of the process in a factory a mile and a half from the site, where every floor was built on the ground, and it was safe and protected from weather. We found ourselves in an R&D mode as a public real-estate company, which was difficult. It took 18 months to get the unions on board, and we wound up with a partner that didn’t understand how to build prefab.

In the end, the building was highly successful financially, even though our process faced many hurdles. There were hurdles, but it was a step in the right direction.

Phil: This raises a bigger process question. Does our linear way of working – concept, design, procurement, construction, closeout and litigation (no kidding!) – make sense anymore?

Dominique: That’s interesting to think about in terms of the bidding phase. How do you carve out bidding as a phase? We’re pricing things continually, every step of the way, looking for potential value engineering based on

that constant cost information. There is a continuing, iterative push-pull between design and pricing. If we try to design and then price, we want to do it early enough that we’re on the right track and avoid big surprises later. It means we have to be more agile, running in loops rather than in a straight line.

MaryAnne: As a client, I need that process for a few reasons. One, what we think we want in schematics really needs to evolve. You sometimes can’t get to certain finish details if you don’t know what the guts of the building are. Two, the pricing at certain milestones is important to me. I want to know where I am so I don’t get a surprise at 50 percent design development or at construction documents. And third, I can’t get the money unless I have 80 percent CDs. I need some point where the music stops and I say to my bank, “This is how much it’s going to cost.” And I say to my contractor, “We’re doing a GMP right now, and you’re going to lock these down.” I would be open to another process, but to me, that process is like my insurance policy, to make sure I don’t have a pool on the roof and a garage in the basement that I can’t afford.

Phil: When you ask engineers about ingenuity and innovation, they often think the solution is to be more efficient and free up resources to do more interesting things. Do you buy that argument?

Ray: Working more efficiently doesn’t mean you’re doing the right thing. And so I think it’s really important to keep on balancing efficiency versus effectiveness. And that’s hopefully what you get when you have these multidisciplinary teams, and when the client is represented by someone who’s actually going to operate the building, not just get the cheapest capital cost and then flip the building.

Dominique: We define success at the outset of a project. Then we push the boundaries of what we can achieve in long-term operational efficiency, but also in process efficiency. If you’re checking along the way against that benchmark, then I think the argument makes sense. The catch is, even if technology is helping you work more efficiently, you might not necessarily fill your time with more valuable, creative activities.

We use the 4DX process1 to protect time for higher-value efforts. This process recognizes that 80 percent of what you do is the everyday, tactical, must-get-done work and only 20 percent is higher-level strategic work. The process provides a framework to protect that 20 percent.

Phil: The industry lacks common platforms. The only way it does anything together is when clients convene some kind of forum. Academics, software providers, architects, engineers – we’re constantly talking amongst ourselves. It’s an echo chamber.

MaryAnne: The federal government convened a forum for embassies. They brought in people from different industries, and we would sit around and talk

Sowing Seeds of Ingenuity

Engineering is an act of ingenuity. It happens at all scales – on projects large and small, simple and complex, and for all our clients. But it’s often hidden in plain sight. At any moment, Thornton Tomasetti has more than 4,000 active projects. How can we find, celebrate and share lessons from our most ingenious projects? To answer that question, we launched our first annual Ingenuity Awards, judged by a panel of our leaders. Nominations from across the firm

show creative and innovative ideas put into practice. Creativity? That’s fresh ideas. Innovation? That’s how those ideas are put to work. So project delivery, as well as conceptual thinking, qualified. “The standard was high, and the judges had a tough job,” said Managing Principal Bruce Gibbons, who oversees the awards program. “The value of reflecting on how we infuse ingenuity into our work will benefit our clients and future projects.”

Of the 59 projects submitted for our ingenuity competition, the judges chose the Al Wasi Trellis, built for Dubai Expo 2020, as the overall winner. See pages 32-33 and the inside back cover of this report for more winners and nominees.

about the U.S. embassy in Lebanon. I was on it for two years. It gave me hope that my federal government was thinking, “We don’t want to just hire a fancy architect. We want to understand the best way to build this building.” These forums are too few and far between.

We developers will change because we have to. We’re not necessarily going to be on the forefront. You’ll be dragging us toward it, but if we don’t change, it’s going to be a problem. We can’t continue to do things the way we’ve been doing them.

1 Chris McChesney, Sean Covey and Jim Huling, The Four Disciplines of Execution (New York: Free Press, 2012).

Decarbonization: Advances in Energy & Industry

Decarbonizing the world economy isn’t just necessary; it’s also good business. Our deep experience in the energy industry and our track record of helping it optimize products and processes put Thornton Tomasetti at the forefront of decarbonization. We invest heavily in practical innovation that can reduce greenhouse gas emissions.

New energy storage concepts. Battery design improvements. Safe and efficient hydrogen-production technology. Carbon capture and storage. We’re working on all of these and more. And we’re actively involved in developing the next generation of transportation, from lighter road and rail vehicles to game changers like hyperloop systems.

Building Better Batteries

“Massive change is underway as the world transitions from burning hydrocarbons to producing and applying cleaner energy. This will fundamentally affect the world economy in ways we’re only starting to imagine. It means adopting new methods of energy production, storage and use, as well as rethinking manufacturing processes and transportation. We’re applying our ingenuity to help a wide range of energy and industrial clients solve these problems and become leaders in the next generation of technological frontiers.”

– Gary Panariello Managing Director and Executive Committee Member

Expanded use of renewable energy is a critical piece of the decarbonization puzzle. Using renewable energy to power transportation will require dependable storage. We recently worked with the U.S. Federal Aviation Administration to improve the functioning of lithium-ion (Li-ion) battery packs.

When a Li-ion cell fails, it creates high-temperature gases. If these gases are not vented quickly, they can damage nearby cells, kicking off a cascading failure – and the possibility of fire or explosion. Our thermofluids experts performed computational fluid dynamics and hot-gas flow modeling to understand and optimize the client’s venting system. The result? Safer and more reliable batteries that can bring us one step closer to decarbonization.

This graph shows the evolution and time lag of temperature propagation through a four-millimeter intumescent layer on a battery pack.

The HyperloopTT Quintero 1 passenger capsule features a fuselage made from cutting-edge composite materials.

Putting the Genie Back in the Bottle

Since 2006, our engineers have been working to support the development of carbon capture and storage (CCS) technologies. We’ve helped clients with both pre- and post-combustion CO2 capture for projects in the U.S. and the U.K.

Our involvement has included hazard analysis, site layouts, pipeline routing, and experimental release work that enables validated dispersion analysis.

We helped BP develop dispersion analysis tools to support CCS projects, such as this experimental dense-phase CO2 release vessel.

More Than Just Hype

Earlier this year, we signed a partnership agreement with Hyperloop Transportation Technologies (HyperloopTT) to assess aspects of their hyperloop system.

Our specialists in advanced material modeling, characterization and failure are focusing on fire dynamics and battery safety, impact and crashworthiness, tube vulnerability, and the thermal, chemical and mechanical characterization of structural and nonstructural materials used in the system.

“CCS is not only a critical component of the blue hydrogen production process –in which hydrogen is extracted from natural gas – it also helps reduce the carbon footprint of industries such as energy, cement, steel and chemical manufacturing. It is a key bridging technology in the pursuit of world CO2 reduction targets.”

– Pawel Woelke Principal

University of Oregon’s Knight Campus for Accelerating Scientific Impact

To lead global advancements in science and technology, the University of Oregon must attract world-class companies, researchers, faculty and students. And it needs a state-of-the-art facility to encourage their best work.

Envisioned as a tech hub where startups can grow and stay, the Knight Campus aims to redefine how research is conducted. In its modern approach, collaboration fosters innovation, diversity is supported and the public is engaged.

Cutting the time it takes for scientific discoveries to impact society means starting now. For this campus expansion, fast-tracking its design and construction was the first step.

To meet the ambitious schedule, we combined the strengths of our structural engineering, specialty structures and façade engineering specialists.

The team focused on structural design first. We used tools like Revit to aid collaboration, consulted with other disciplines, and coordinated with the contractor early on. By doing so, we devised

modern, efficient solutions that made construction faster and easier – without compromising the project’s contemporary architecture.

We split the program into two L-shaped buildings – 75,000 square feet each –and rested them on a concrete podium base that offers solid support in this seismically active area. A 15-foot-wide connector between the four-story buildings also buffers sound from the site’s surroundings and uses a sliding end connection to accommodate movement between buildings during earthquakes.

Location: Eugene, Oregon

Architects: Ennead Architects; Bora Owner: University of Oregon Contractor: Hoffman Construction

The third floor, where mezzanines maximize the 16-foot floor-to-floor height, is suspended from locally sourced cross-laminated timber. The floors below are column-free. A steel roof and penthouses allow lighter, longer spans and a faster build.

One façade features a cantilevered glass rainscreen evocative of the cascading waterfalls of the Pacific Northwest. Another reveals the exposed interior structure within a transparent aluminum and glass curtain wall system. A 120-foot-long cable-supported canopy with a lightweight and transparent ETFE skin shelters the terrace café below from inclement weather and solar heat gain.

To connect the new campus to the existing one, we designed a lightweight, self-supporting pedestrian bridge over a busy roadway. The all-steel long-span structure resists seismic, wind and traffic forces with a symmetrical arched butterfly design. Tension cables along each side carry loads to a common point on either side of the road, and support SPS-panel decking and a glass enclosure.

A Closer Look at a Stunning Façade

As students and faculty approach the campus, the first thing they’re likely to notice is how its façade redistributes sunlight, casting angular shadows and patterns onto every surface. But this façade is more than just a pretty face.

For starters, the facility has not one, but five façade types. The main façade is the most complex – a unitized curtain wall that supports a cantilevered glass rainscreen composed of laminated, fritted glass panels. The fritting serves two practical purposes: cutting glare and improving thermal comfort for occupants. The triangular glass panels face each

A lightweight ETFE canopy spans the area between the main buildings, shielding the outdoor terrace.

A signature pedestrian bridge with wing-like supports connects the old and new sections of the campus.

other at angles that create a dynamic interplay of light and shadow. The rainscreen hangs from tension rods attached to cantilevered steel outriggers that are anchored to the roof slab. It is laterally braced by a series of stainless-steel wind struts attached to the unitized curtain wall.

One of the greatest façade-design challenges was figuring out how to maintain thermal and weather performance. Since the university is in an earthquake-prone region, seismic performance was also critical. Some early design iterations included larger penetrations that would transfer loads directly to the building structure. But the size of the penetrations and the amount of steel required would have caused thermal bridging and increased the risk of air and water infiltration.

So with a heavy glass rainscreen cantilevering out from the building, how can you safely and efficiently transfer loads back to the main structure? After considering a number of options, we

decided to distribute the forces across the façade through wind struts at each of the vertical mullion joints. This transferred loads through the curtain wall framing to architecturally exposed, mid-span steel beams that connect to concrete columns. To minimize breakage during seismic events, glass clamp supports allow the panels to rotate slightly.

A Flexible Future

The $225 million project is the first phase of the Knight Campus. Phase 2 will add another 65,000-square-foot research building, while a 10-year, billion-dollar master plan identifies future projects.

Straightforward yet sophisticated, the phase 1 buildings will act as a hub of collaboration and innovation. Several dozen researchers will work in open and flexible layouts that foster greater interaction among groups. The facility offers classrooms, office and meeting space, and vibration-controlled labs.

Resilience: Cities Reimagined

What happens to this building when we’re done with it? An introduction to Circular Economic Principles

How can we rethink the way cities are designed, built and operated to address social, environmental and economic needs? We convened members of the Urban Design Forum’s 2019 Class of Forefront Fellows to explore this question. Their fellowship project is investigating how design can address a social or political challenge in New York City in which race, class and climate change intersect. Here, they focus on the potential of circular urban systems.

Michael Izzo

Vice President of Construction Hines

Amy Macdonald

Resilience Practice Leader

Thornton Tomasetti

Rebecca Macklis

Senior Urban Designer

New York City Public Design Commission

Autumn Visconti

Senior Landscape Architect

Bjarke Ingels Group

What is a circular economic principle?

Amy: Since the Industrial Revolution, we’ve been operating in a linear economy: we extract resources, make a product, use it and then throw it out, so it ends up in a landfill or the ocean. This is a wasteful and leaky way of operating. The circular economy upends this entire approach. It has three components. The first is to reduce consumption; the second is to design out the production of waste and pollution and enable reuse. Burning waste to generate energy for a city or community, and capturing the waste heat for heating, for example. Everyone more or less gets that idea. This helps keep products and materials in use at their highest value for as long as possible. And the third component is to regenerate natural systems

Measuring reduction in consumption is often straightforward. How do you measure the other benefits?

Michael: Circular systems form a Venn diagram of equally weighted economic, environmental and social benefits. We

do a good job of quantifying economic values, such as dollars saved or energy consumed. You can demonstrate environmental benefits with a life-cycle analysis to show the amount of water saved, waste reduced, pollution eliminated, etc. Environmental, economic and social benefits are often interwoven. By flipping the linear “take-make-waste” way we operate now, we can design all our systems to give waste a similar financial value. A simple example: this weekend I bought a waterproof beach pouch made of used bicycle tubes.

Key to the circular approach is considering ease of recycling at the time of design or production. If we begin a product design with the question “what is the second and third life of this product?” we might make different decisions. It’s

taking more of a systems view than just “what do we do with this product next?”

Manufacturers don’t have any liability for dealing with waste. One approach is having manufacturers become responsible for the waste related to their products. New York, for example, spends $300 million per year to cart out waste and shifts the environmental liability to a location thousands of miles away.

Rebecca: The fashion industry has been a leader in this expanded circle of responsibility, because it’s become a marketing tool. At Patagonia, “this sweater used to be plastic bottles” is one example, as is their program to repair and recycle worn-out clothing. Consumers are more aware than ever about transparency in the manufacturing supply chain – where is the factory? Under what conditions are people working? Where is the waste going?

For the average person, understanding that life cycle for the building stock might be harder. The prevalent mindset is to design buildings to last forever in their current use. Instead, what would it mean to design in the agility to accommodate future building systems or programs?

Amy: One area ripe for revision is how we deal with water in the built environment. Water is collected in drains and during heavy rains and floods can combine with sewage and discharge

into our waterways. It’s also piped great distances. One opportunity is to capture rainwater on-site and use it locally for irrigation instead of piping in water from reservoirs to water our green spaces. It means thinking “how can we use this?” instead of “how can we get rid of this?”

How do you persuade a skeptical owner or developer that these approaches are worth the investment?

Michael: People often assume there’s an insurmountable up-front cost. Once they see that circular systems are self-incentivizing and apply them, they realize the up-front costs decrease and intrinsic value increases. A study done in Stockholm showed that circular systems led to 25 percent increases in residual property values.

Doing Good Business in Panama

How can we make urban revitalization both profitable and equitable for people at all income levels? This is the challenge we face with partners undertaking a large-scale urban infill project in Santa Ana, a historic neighborhood in Panama City. Developer Conservatorio wants to create a vital and inclusive mixed-income neighborhood that provides for the needs of all while achieving returns for investors.

The mixed-use development – comprising multiple buildings of up to 15 stories – includes retail and commercial, attainable residential and public plaza space.

Working through Doing Good Business – our social impact initiative – with Practice for Architecture Urbanism, we provided more than just structural engineering solutions. We dug deep to understand the team’s mission-driven core values and support them at every step of our work. We applied our experience in complex mixed-use projects and used specialized tools –including programs custom-built by our CORE R&D team to maximize design efficiency and minimize structural embodied carbon – to help the team devise smarter and faster ways to achieve its vision.

Autumn: On the design side, there is no shortage of innovative approaches. The real effort goes into guiding the conversation with the public, so they can visualize what we’re proposing. Many people mistakenly equate recycling with circular systems and think “we’re already doing this,” when in fact that’s only the tip of the iceberg. The real answer is to reduce and reuse first. Recycling is an option only when there is no other use for the product.

Amy: Cornell Tech’s Tata Innovation Center in New York is an example where clever use of data changed behavior. The main structure used passive house design, and there’s a data board in the lobby that shows students each unit’s energy use for the past week. It’s become a weekly competition – and an effective way to raise awareness and change behavior. To an owner or developer, these kinds of feedback loops can help prove the value of the effort.

What’s one circular principle you’re applying to a project now?

Amy: We’re working on a master plan for a major development in New York City, and circularity has been part of the conversation from the outset. We’re looking at water capture and reuse across the entire development to reduce pressure on the already overwhelmed city drainage infrastructure. The idea is to reuse captured water not just for landscape irrigation, but also for laundry and flushing toilets. Building codes need modification for that to become the norm. It’s done in other cities, but will require some work to get it accepted in New York. We’re also encouraging the use of mass-timber construction instead of automatically going with steel and concrete. That’s important for using a renewable resource and significantly reducing the carbon footprint.

Autumn: We recently worked with the United Nations on a conceptual design and prototype for a floating city, in

Making Airports More Resilient

How can we make airports function better and more productively? To find out, we studied operations at three U.K. airports on behalf of Resilience First, an industry organization. We looked at best practices and areas for improvement in resilience, and conducted data reviews, interviews and an agility survey.

Our top five key findings?

Link Resilience to Business Outcomes

Use consistent measures to assess the benefits of resilience and the impact of disruptions.

Include Resilience in Policy, Strategies and New Developments

Embed resilience in strategic, tactical and operational planning.

Look Further Ahead

Use horizon scanning and scenario planning to understand potential disruptors, for example, automated vehicles and electric aircraft.

Harness Technology and Boost Productivity

Acquire and share real-time data and exploit new technologies such as AI in control systems, automated vehicles and security systems.

Apply a Community/Systems Approach

Resilience cannot be managed by operating in silos, but collaboration can be a force multiplier.

London Stansted Airport in the U.K. was one of eight resilience study sites.

response to climate change and rising sea levels. The biggest challenge was rethinking many things we take for granted. How could we generate energy? Not only wind and solar, but could we use tidal or wave energy? What does one person consume in a day? What do they need in order to survive? How much water do they use? How much do they need? What kind of food do they need? How much waste does each person produce, and how can we reuse it to benefit the community? For example, we couldn’t have a meat-based diet, because where can we have floating farms with cattle and pigs? So we looked at a fish-based diet, and that was more sustainable than livestock or poultry.

Michael: People look to renewables, but it’s not always the answer, unless we can reduce energy consumption at the building level. The numbers suggest significant energy reductions within the built environment. We’ve been working on a project with the help of some Nordic partners who are currently required by code to design their buildings to net-zero. There are more water-based systems, and electrical energy is being taken from the grid and stored as thermal energy within the building. This keeps the thermal energy as local as possible.

Rebecca: Within New York City, a prime example is the partnership between the Department of Environmental Protection (DEP) and the Department of Sanitation (DSNY) on composting food scraps, which account for about a third of garbage. The aim is to reduce landfill use and generate

energy. Compost from DSNY, along with scraps collected through other partnerships, goes to the digester eggs at the Newtown Creek Wastewater Resource Recovery Facility in Brooklyn. They are used to create and capture methane, which is then fed back to power the plant and into the ConEd pipelines for our daily use at home.

Do circular systems require a certain scale to be effective?

Michael: It depends. Energy efficiency can be achieved at the smallest scale possible, water at the same or slightly larger scale, and waste at a large scale. For example, at the level of an individual building, it’s difficult to make a lot of energy out of the waste you generate. But if you aggregate waste across a number of buildings, then it becomes something powerful. On the energy side, you can easily store electrical or thermal energy at the building level and provide some resilience benefit, because you’re not relying on a continuous external source.

The biggest hurdle is how to derisk innovation. A key is having the academic community lead the charge with research on circular systems, now that some cities and states are pushing climate-change goals. As an impartial third party, a university can conduct research for designers, owners and developers to help derisk being the first adopter.

Rebecca: Academia needs to be part of the conversation, but I wouldn’t burden them with leading it alone. At the Public Design Commission, we recently held a roundtable discussion on the future of prefabrication in New York City. We weren’t looking for a solution, but wanted to get all involved parties – from the Department of Buildings, from design teams, from the fabricators – to openly discuss roadblocks and find a path forward. We didn’t reach a conclusion, but it was valuable in that it exposed the different risks of each stakeholder. Each has a certain level of decision-making they are doing for themselves behind closed doors. In our case, exposing the risk assessments they’re making before coming to the table with a broader audience can help move everyone forward.

In circular design, where is innovation coming from?

Michael: There are many places throughout the world. The Nordic countries definitely, with the help of Sweden; India recently announced plans to build their first climate-neutral city.

Autumn: Another area of innovation is in retrofitting. Many buildings from the last mid-century will still be around in 2050.

Michael: We have a large building portfolio, so we’re looking into that. But I wouldn’t look to a product – I would look to design thinking for the innovation. Different buildings will have different problems, so it won’t be one solution fits all. We’re trying to form a collaborative with academic and legislative partners to develop some of these ideas.

Rebecca: Changes are happening now in academia. This fall, Columbia University’s Urban Design Studio was based on the Green New Deal, and looked at urban design through that lens. All the projects revolved – consciously or unconsciously – around circular design themes.

Ascent Takes Timber to New Heights

Location: Milwaukee, Wisconsin

Developer: New Land Enterprises LLP

Architect: Korb + Associates Architects

Fire Consultant: ARUP

Lighter and more sustainable than concrete or steel, mass timber is gaining ground as a primary structural material. We’re providing structural engineering for Ascent, a new residential tower in Milwaukee, Wisconsin. When completed, it will be the tallest mass-timber structure in the world.

Rising above a six-level concrete parking garage, the 284-foot-tall tower will feature 19 floors framed with glulam columns and beams, with CLT floors.

We sat down with Senior Principal John Peronto, Senior Associate Jordan Komp and Senior Project Engineer Alejandro Fernandez to talk about some of the ways ingenuity helped shape this project.

John Peronto Senior Principal

Jordan Komp Senior Associate

How was designing with timber different from designing a conventional structure?

Alejandro: First of all, because of its height, this project pushed code boundaries. It’s being permitted under an alternative provision of the Wisconsin Commercial Building Code, which is based on IBC 2015, so the rules are similar to the IBC’s alternative materials requirements. This provision allows for mass-timber construction to extend beyond the standard height limits for heavy timber or stick construction –if the design team can verify the structure’s equivalent performance meets or exceeds the code’s intent.

of variances. This reflects the trend –already approved for IBC 2021 – toward allowing taller mass-timber buildings.

Jordan: A big part of proving equivalent safety was fire-testing the glulam columns (see page 22). The results confirmed that the current National Design Specification formulae provide conservative results for up to three hours, even though the current specs were only intended for two hours.

Alejandro Fernandez Senior Project Engineer

John: The verification process involved a combination of calculations, certifications, existing test data, and additional material testing. All of this together allowed us to demonstrate fire performance equivalent to a Type IA construction, which is the most restrictive. Interestingly, the City preferred to approve the building as a Type IV (heavy timber) construction with a number

John: It was crucial to engage the City very early, to have a constant dialogue so they could be comfortable every step of the way. We listened to their concerns and preferences and made sure our plans addressed them. We also met with the fire department. It wasn’t part of the approval process, but it helped us understand their concerns.

Alejandro: One of the benefits of timber construction is the warm, comfortable atmosphere you get from the exposed wood. It was important to the architect and the developer to incorporate that into the interior space, so covering the structural elements with fireproofing

What Is Mass Timber?

Unlike the more familiar timber-frame and post-and-beam systems, mass timber uses larger, prefabricated components made of multiple layers. There are several types in regular use.

Cross-Laminated Timber (CLT) boards are stacked in layers of alternating directions and glued together.

Nail-Laminated Timber (NLT or nail-lam) boards are stacked on edge and fastened with nails or screws.

Glue-Laminated Timber (glulam) boards are stacked and glued together with the grain running parallel to the length of the member.

Dowel-Laminated Timber (DLT) boards are stacked on edge and fastened together with wooden dowels. This is the only mass-timber product that is nearly 100 percent wood, with minimal adhesives.

Mass timber has a high strength-to-weight ratio and is quick to erect, fireresistant and aesthetically warm. It also has the potential to dramatically reduce the embodied carbon in buildings (see page 28).

The 26-story tower will have 259 apartments, a pool on the sixth floor and a top-floor resident amenity level. The use of mass timber for the building’s structure will allow it to exceed Milwaukee’s energy conservation requirements.

would defeat the purpose. The new IBC 2021 allows for taller mass-timber buildings, but for buildings over 12 stories, it requires the structure to be fully concealed. That’s why the team pushed for proving performance through the alternative provision.

Jordan: At Ascent, we have a six-level parking podium below the timber-framed residential floors. For economical design, the timber framing required tighter column spacing, but garages need larger column grids for drive aisles and parking layouts. To merge the two systems, we used a series of post-tensioned transfer beams. The design took advantage of the timber structure’s light weight, which allowed for reasonable transfer-beam sizing.

John: We also put a lot of effort into understanding and designing the timber connections. In addition to structural performance, we had to consider fire performance, aesthetics and cost. These

Trial by Fire

drivers led the team to come up with a combination of timber-to-timber bearing and custom-made steel connections.

Jordan: It was important to acknowledge that there isn’t a lot of research or historical data on how tall mass-timber systems behave, so we needed to know what we didn’t know, which was actually our starting point.

Alejandro: Exactly! So we got creative with the connections. We did a lot of analysis and developed a series of connections that can handle the movements and construction tolerances we expected. But we also designed them to accommodate a range of unexpected movement. Then we kept working to refine the connections to make them economical as well.

What do you see as the most important factor in the success of Ascent’s design?

John: Collaboration was key, with the developer, the design team and the City. Ascent is much taller than the nexthighest timber building in the U.S., so we were all in the avant-garde. Everyone had to be willing to push boundaries and keep an open mind. We couldn’t have done it without great communication.

Alejandro: And trust. One of the ways we developed that trust was by being able –and willing – to iterate a lot of design options. We have several programs and tools that help us iterate quickly and efficiently. The team actually explored a range of designs in several different materials – CLT, NLT, DLT – and we looked at these options in different kinds of wood, all with different material properties and behaviors.

John: Yes. It was really that combination of creative thinking and technological capabilities that allowed us to make the structural design work. And more than that, to make it efficient.

As part of the approval process, the design team was tasked with confirming a three-hour fire-resistance rating for all exposed glulam columns. However, current timber codes and available test data are primarily limited to two-hour ratings. To bridge the gap, we partnered with the USDA’s Forest Products Laboratory, located in Madison, Wisconsin, where multiple three-hour fire tests were conducted.

Each specimen was instrumented with a series of sensors, at varying depths throughout the member, to track the internal temperature of the timber.

After reassembling, the samples – three each of domestic Douglas fir, black spruce and European spruce –went into the furnace for three hours.

After the three-hour test, the columns were removed from the furnace. Once cooled, the char was removed

The samples were cut into sections for visual inspection, and sensor results were processed. The test results will be published in 2020, paving the way for future projects, codes and provisions, as well as further testing.

This Revit model of the tower shows mass-timber elements in yellow and concrete in gray. The elements shown in red are 450-ton concrete-filled steel-pipe piles.

Inclusion + Diversity

The link between diversity and innovation is well established. We believe diversity also fosters creative thinking, as different perspectives and assumptions mix, mingle and spark new ideas. We’re continuing to pursue a variety of initiatives to increase inclusion and diversity (I+D) at Thornton Tomasetti. And we’re building on past successes to support and empower every one of our people.

The Next Generation of I+D

We launched our first formal I+D program in 2016. It began with a committee of executives and leaders from our Talent Team (human resources) and Communications departments. The focus was on establishing benchmarks, setting goals and developing corporate-level strategies. In the years since, this approach has been successful in building awareness, formulating metrics and making progress toward reaching our goals.

This year, as part of a larger leadership transition, oversight of the I+D program passed from former President Ray Daddazio to current President Wayne Stocks, who is guiding the initiative

in new directions. He and Senior Principal Peggy Van Eepoel restructured the I+D committee to focus on our grassroots employee network groups (ENGs) and empower the ingenuity of their leaders.

ENGs are composed of employees who are linked by social factors such as gender, culture, sexual orientation, or a common interest or goal. They serve as a resource for both their members and the larger organization. ENGs are bottom-up, formed by employees who recognize the needs of an underrepresented group. Their leaders develop strategic plans that are consistent with the firm’s purpose and values.

The I+D committee consists of two executive advocates, an I+D coordinator, and the leaders of our current ENGs: Women@TT; specTTrum, a group focusing on the LGBTQIA+ community; and Mosaic, a multicultural network.

At a committee meeting in January, members spoke about how the new approach will work – and how it’s supporting the firm’s overall goals.

“As we reimagined our approach to I+D, we looked at the success that Women@TT has had over several years – not just in their mission, but in elevating the women involved. We thought carefully about how to build on that success and about how to make the I+D committee employee-driven. So we’ll be supporting them, not directing them.”

“As executive advocates, Wayne and I are here to enable the ENGs. We can use our visibility as leaders in the firm to give them a platform from which they can speak and be heard. We’re also looking to the ENG leaders to connect us to what their members are thinking, what they need. Then we can help them secure resources to help make it happen.”

“ We also keep an eye on how this is promoting overall business goals. The ENG leaders aren’t necessarily focused on that – and they shouldn’t be, really. But we can help them shape what they’re doing, so that while they make strides from an I+D perspective, they are also strengthening the business.”

– Peggy Van Eepoel Senior Principal I+D Executive Advocate

“In the last year, we’ve outhired the market in women. Our percentage of female hires is greater than the percentage of women in available candidate pools. Having programs like Women@TT is definitely helping us achieve this successful outcome. We’re hoping to see similar results from the specTTrum and Mosaic teams.”

“The Talent Team is in place to support and create success for our business. To do that, we have to ensure that everyone in the company is comfortable and encouraged to succeed in their roles. We started I+D with a group of executives who were driven to do the right thing. Now, we’ve infused this approach into all levels of the organization. That sets us apart from other firms in the industry.”

– Aoife Quinn Vice President, Global Talent Partner

“So much of what Women@TT does is grassroots, coming from individual chapters. Most events are organized largely by local staff – they’re not driven by corporate Business Development or Talent Team or Marketing. So we have corporate support, not a corporate mandate.”

“ We changed the Women@TT structure in early 2019. We got creative, especially with the formation of our leadership board. It lets us do more, but distributes the work so we don’t burn anyone out.”

“Involvement in Women@TT has already had tangible career benefits for some of our participants. One example is Angela Heinze, our TT Women Advancement committee leader, who just won a Purpose and Values award (see page 36).”

– Jennifer Greenawalt Senior Engineer, Women@TT President

Launched in 2013, Women@TT is our oldest ENG. It sponsors mentoring programs and leadership development activities to support the advancement of women to senior leadership positions. Its 22 local chapters also host educational programs and business-development networking events.

25 in 2020

100 %

Retention of participants from the 2018 inaugural Mast-Her-Mind leadership retreat

56 % men

LGBTQIA+ Employee Network Group

“ We’re seeing more clients ask for information about I+D issues as part of our qualifications, and not just EEO (equal employment opportunity) data. They want to know about our programs and metrics; they’re taking that into account.”

“The idea for specTTrum began with a project to engage employees around Pride two years ago, right after I joined the firm. That started a conversation that has gradually grown into a formal group. Our goal is to engage our LGBTQIA+ employees from across the firm in a global network where they can feel good about discussing topics that pertain to them.”

“The new I+D structure creates an ‘express lane’ for communication between the leaders of the new ENGs and Women@TT, and between all the ENGs and our executive advocates, Wayne and Peggy. It removes barriers, so we can share and act quickly on what works and what doesn’t.”

– Quinton Turner I+D Coordinator, specTTrum Leader

Clients and industry colleagues who

2,000

Offices that participated in our International Women’s Day celebration employees attended 160 chapter-hosted events

“ We’re working to finalize the goals for Mosaic and developing strategies. How do we focus attention on some of the less represented groups within the company? How do we help our members move up into positions of leadership?”

“An early question we had to answer was whether to have one umbrella group or several targeted ENGs. Other companies have separate groups for African Americans, Hispanics and Native Americans, for example. But we were concerned about creating a heavy administrative burden, and each group might not have enough critical mass to have the impact – that amplifying effect – we’re aiming for.”

“The way we’re structured now is flexible, so we’re open to subgroups forming in the future. But there’s strength in starting as a more encompassing organization. We can identify and really see who’s here already, and we can make connections through a larger, more diverse group – and that ties back to innovation and ingenuity.”

– Humberto Estevez Senior Project Engineer, Mosaic Co-Leader

“As executive advocates, we don’t just want to enable; we want to empower. The ENG leaders are smart and creative. It’s our job to make sure they have direct access to whatever they need to make the ENGs successful – whether that’s help from corporate support or face time with the Executive Committee.”

“Our ENG leaders have volunteered to do this work on top of their regular responsibilities. They’re incredibly enthusiastic, so we want to make sure they don’t burn out. Women@TT has done a great job spreading responsibility across several active and effective committees. We’re looking to replicate that success, in the I+D committee and the new ENGs.”

“ We intentionally built our I+D strategies into the firm’s latest five-year plan (see page 3), because it’s not ‘just’ the right thing to do – there’s a strong business case for it too. The benefits to creativity from diverse teams is one factor. Retention is another. And it’s great training: ENG leaders are learning skills that translate exactly to how we run projects and offices. So we’re doing what’s right for our people, but at the same time, we’re building strong leaders and a stronger organization.”

– Wayne Stocks President I+D Executive Advocate

“ With Mosaic, our first challenge is to figure out what this group could be. What does ‘multicultural’ mean for us? But we’re pushing for this group because it’s needed. We’ve talked to employees and heard what kinds of needs there are.”

“It will be really interesting to see how the ENGs develop. I think they will all be unique. We’ll all be influenced by the Women@TT model at the start, but down the line, each group will develop its own mission and form unique formats and structures. I don’t know what Mosaic is going to look like in a year or two, but it’s probably going to be something we haven’t even thought of yet.”

“Humberto and I are looking at how Mosaic can serve employees internally and how it can be positioned externally, in recruiting or business development. And we’re thinking about how Thornton Tomasetti functions as a worldwide company. How can we take the most advantage of that global and cultural diversity? How can it help us all thrive?”

– Jennifer Mahan (left) Senior Engineer, Mosaic Co-Leader

MULTICULTURAL Employee Network Group

Cutting Carbon from the Built Environment

With research showing that buildings generate nearly 40 percent of global greenhouse gas emissions, dramatically reducing the carbon footprint of the buildings we design is an important part of addressing the climate crisis.

Our sustainability practitioners, structural engineers and façade designers are using a variety of creative strategies and innovative tools to cut both operational and embodied carbon in our projects.

A Beacon for Embodied Carbon Reduction

Building designers have made strides toward reducing the carbon emissions caused by building operations. Embodied carbon, however – the CO2 footprint of the physical components of new buildings and their production, transport and installation – hasn’t been a focus for reductions until recently. Embodied carbon now accounts for 11 percent of global CO2 emissions. It represents a huge challenge for architects, engineers and contractors. But it’s also a tremendous opportunity to reduce emissions.

Sustainability

As with most problems, you can’t manage embodied carbon until you measure it. A collaboration between our Corporate Responsibility department, Sustainability practice and CORE R&D team has developed a series of everimproving tools to measure embodied carbon. Over the past nine years, we’ve calculated the embodied carbon of more than 600 of our structural design projects.

Now we’ve used that experience – and our extensive collection of real-world data – to launch BeaconTM. This innovative

tool will help structural engineers across the industry understand and manage embodied-carbon optimization. A free, easy-to-use plug-in for Revit, Beacon gives engineers quick, high-level feedback and clear visualizations of a design’s embodied carbon quantities. It categorizes calculations by material type, building element and floor level, then rates each model against Carbon Leadership Forum benchmarks. Beacon gives designers a simple way to identify exactly where the embodied carbon is –and where even small changes can have a big overall effect.

“Structural engineers have the opportunity to be leaders in sustainable design because structural materials are the largest contributors to embodied carbon in new construction. Our long-term effort to measure embodied carbon in our projects is helping us understand the impact design and material choices have on the environment.”

– Amy Seif Hattan Corporate Responsibility Officer

City of Boston, Zero-Carbon Housing

Last year, the City of Boston launched Carbon Free Boston, an initiative to become carbon-neutral by 2050. Their first step toward achieving that goal? Committing to zero net carbon (ZNC) for all new city-funded affordable housing.

Boston’s housing crisis requires 15,000 new affordable units by 2030, so going carbon-neutral will have a significant impact. We partnered with Placetailor Architects to develop new ZNC standards and construction guidelines. A key concern was making the standards developer-friendly without compromising outcomes.

Analysis & Insight

We performed large-batch analyses of housing typologies and energy-conservation standards related to carbon emissions. We found that short buildings could easily produce more power than they need with rooftop photovoltaics, but taller buildings don’t have enough roof area to fully offset their electricity use. So we developed the concept of a carbon-per-person “budget.” Developers could build carbon-neutral portfolios that combine smaller, energy-positive buildings with taller buildings. This encourages density, providing housing for more people within a limited footprint.

Our team then analyzed more than 80,000 iterations of four multifamily building types – small, three-story, four-to-five story, and six-story – to tease out the most cost-effective “recipe” of windows, HVAC and insulation for achieving the per-person carbon target. Placetailor designed construction details and reviewed them with contractors to ensure they wouldn’t increase costs. Then we published a first-of-its-kind guidebook that can serve as a road map for other cities as they pursue their carbon-emissions goals.

were instrumental in the project’s success.

Cutting (Carbon) Edge Tools

Thornton Tomasetti has developed or improved several powerful tools that enable the design of more sustainable projects.

Asterisk Developed as a way to speed schematic- and concept-level structural designs, Asterisk allows engineers to quickly – almost instantaneously – iterate, explore and compare the impact of different design choices, such as materials, bay sizes or floor heights. Our CORE team included an embodied energy calculator, so sustainability can be a driver in the earliest design decisions.

Thread The latest version of our Design Explorer web application, Thread is a data-exploration platform tailored to iterative decision-making processes.

It can clearly show which combinations of parameters will yield high-efficiency buildings.

Water Balance Calculator This tool aids in water conservation by quickly calculating a building’s water demands and estimating the availability of on-site supplies (see below). It provides a water-balance summary, which helps project stakeholders balance the trade-offs of different approaches to water use.

Tools That Enable Ingenuity

“Ingenuity really does require both creativity and innovation. You might have an idea you think is crazy. But you share it with someone who becomes inspired, and suddenly that crazy idea’s not so crazy anymore. Then you follow through with the hard work to make it happen.”

– Robert Otani, Chief Technology Officer

Technology has always provided fertile ground for innovation at Thornton Tomasetti. Here are some of the emerging tools and methods that are inspiring us to new levels of creativity, innovation and ingenuity.

Jasso: Shock Testing That Comes to You We’ve long been a leader in nonexplosive shock testing, using seismic airguns to evaluate the performance of naval equipment. But until now, clients had to transport their equipment to our testing site.

Jasso – winner of a 2020 Business Innovation Award from the U.K. Institute of Physics – condenses our airgun capabilities into a portable shock machine that fits into a 20-by-8-foot shipping container. The machine can be tuned to match a range of shock and dynamic inputs, mimicking conditions that occur when an underwater explosive detonates. It also expands our testing capabilities beyond naval shock to cover environmental transport requirements and robustness tests. Jasso can test equipment up to six meters long and five tons in weight. And its small size allows it to go wherever our clients need it.

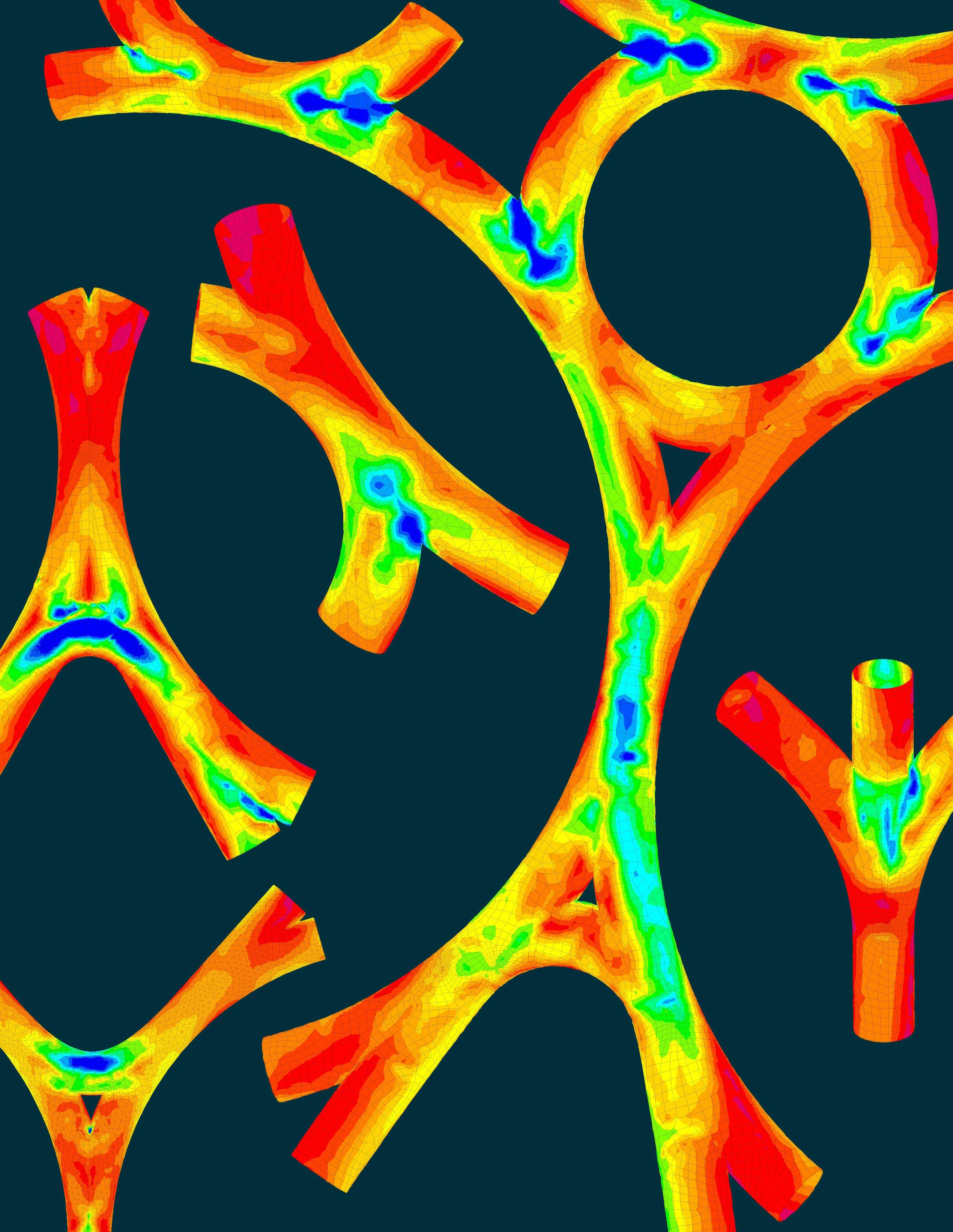

Computational Fluid Dynamics: Going with the Flow

The movement of air around a room. The sloshing of a liquid inside a tank. The interactions between winds and high-rise structures. The dispersion of gas from an explosion. From the mundane to the dramatic, anything that flows falls into the realm of computational fluid dynamics (CFD).

Using state-of-the-art CFD software, our experts can predict the thermal comfort of pedestrians in a retail development. They can model explosives detonations in the air and underwater. Or they can visualize vapor cloud explosions, hemodynamics or shock and wind loading on structures. We’re exploring new areas of problem-solving using CFD, and working with our CORE R&D team to find ways to optimize it – making it faster and more economical for our clients to reap its benefits.

MMICast: Improved Oil-Rig Fire & Explosion Safety

When you’re working on an oil rig, fires and explosions are omnipresent risks. You need your fire and gas detectors to provide complete coverage. And you need to minimize the likelihood of false alarms. MMICast ray-casting software is our innovative solution to these problems and more.

Here’s how it works: After locating all fire and gas detectors, engineers associate them with a comprehensive 3D model of the rig, including the positions of potential obstructions. MMICast then sends rays outward from the detectors to determine their fields of view and identify where detection is

(Above) CFD visualization of turbulent wind flowing around the Palace of Westminster in London. This cross section shows the instantaneous wind speed, with blue representing low-speed flow and red, high-speed flow.

(Left) Sectional view of a Jasso simulation. In the internal tank, a single airgun fires beneath a floating strike plate, just before impacting the test table.

interrupted. We can then advise operators on the best placement and orientation of detectors for optimum coverage. Our software also accounts for any overlap in detectors’ fields of view, which helps reduce false alarms.

MMICast model of flame detector coverage for a congested offshore module. Regions visible to one detector are blue; regions visible to two detectors are green.

. . . and That’s Not All!

Those are just a few of the technologies we’re developing and using. There are many others, some of which are described elsewhere in this report.

See page 28 for BeaconTM and page 35 for T2D2 (left) and Swarm (below).

Innovation Tournaments: A Small Step Becomes a Giant Leap

In November 2016, our CORE R&D team sponsored our first innovation tournament, based on a deceptively simple concept: “Let’s get together for a day and see how many innovative ideas we can come up with.” It was conceived as a yearly event, held in New York. But over time, it grew into a semiannual program that moves from office to office, around the world.

Although the tournaments attract mostly technical experts, software developers and engineers, anyone in the firm is welcome to participate. Organizers encourage participants to give every idea equal and unbiased consideration.

In the morning, attendees have one hour to generate three to five ideas and choose two to present to the group. During lunch, attendees vote, and teams form around the six highest-ranking entries. Teams spend two hours collaborating on business plans and technical road maps, identifying the resources they need to make the idea a reality. This documentation then goes to our CORE oversight committee, which assigns each idea to a technical expert to determine which will receive funding.

The tournament program was an early component in the development of the firm’s R&D program. CORE soon began calling for more entries on Spark, our social intranet. Now, judges consider Spark entries along with the tournament submissions.

This program has proven hugely successful, generating 150 to 200 ideas a year. Of those, an average of 24 receive funds for further development and 6 to 10 result in tools that we use within the firm or offer to external users.

Ingenuity Everywhere

We’re fusing creativity and innovation into elegant solutions around the globe. Many of the projects described here were nominated for our Ingenuity Awards program (see page 11 and inside back cover). Category runners-up are identified by and denotes nominees

Seattle Center Arena, Temporary Roof Support

Seattle, Washington

We raised the roof – literally – on the expansion of the former KeyArena. Our construction engineers devised a first-of-its-kind system to lift and support the historic roof for two years while the rest of the stadium is demolished and rebuilt.

Intensive collaboration with architect Populous and contractor Mortenson yielded a sequencing plan to ensure the temporary supporting structure won’t conflict with construction.

The Arbour, George Brown College Toronto, Ontario

This 10-story, naturally ventilated building will be Ontario’s first low-carbon mass-timber institutional building. Our acoustics, noise and vibration specialists designed systems to allow passive ventilation while maintaining acoustic separation between classrooms and corridors, and to control footfall noise through the raised-floor system.

Wrigley Field Renovations

Chicago, Illinois

A triple play helped us update this iconic ballpark. We repurposed the lower seating bowl’s concrete deck as a continuous diaphragm, performing a detailed thermal expansion/contraction study, and adding carbon-fiber reinforcement to bring the lateral system up to code. We encased steel raker beams in concrete to add strength. And we buried the spalling ends of precast seating risers in the encasements to stop falling-concrete hazards.

Pittsburgh International Airport – Terminal Modernization Program

Pittsburgh, Pennsylvania

Our structural engineers and CORE R&D experts used genetic algorithms to search for the grouping of branch angles that would minimize the number of unique castings needed to transition from branches to trunks of the tree columns that support the undulating roof.

Our sustainability team analyzed environmental conditions and provided design advice for the overhanging roof to best protect pedestrians from rain and snow.

Cable Dehumidification for the Benjamin Franklin Bridge

Philadelphia, Pennsylvania

Our bridge engineers collaborated with mechanical and electrical specialists to preserve the 94-year-old suspension bridge’s giant cables. An inspection showed that moisture had begun to cause deterioration. The fix? Wrapping the cables in an elastic membrane and pumping in dry air. Monitoring equipment will record humidity levels and listen for future wire breaks.

U.S. Embassy Facilities

We’re taking an ingenious approach to keeping U.S. diplomatic facilities and personnel safe around the world.

Algiers

Aluminum-Sheet Damage Simulation

New York, New York

When Novelis, a leading aluminum-sheet manufacturer, needed better models of damage from combined bending and tension loads, we devised a more accurate method. Then we worked with the developer of LS-DYNA finiteelement software to implement the validated improvement to its GISSMO modeling program. Widely used by the automotive industry, this innovation has potential applications in many fields.

Arter

Istanbul, Turkey

Carefully planned internal divisions in this contemporary art museum’s layout created unobtrusive lateral and vertical structural support. Inventively clad perimeter walls increased resistance to seismic forces. The integrated efforts of our façade, structural and civil engineering experts helped architect Grimshaw make a very strong building appear light and welcoming – all within strict local code requirements.

Puerto Rico Ports

Authority Post-Maria Roof Assessments

Puerto Rico

After Hurricane Maria, our FAAlicensed drone pilots deployed to the island to assess several airport and pier facilities, swiftly and safely collecting data on roof conditions.

Using a commercial program (Pix4D) that was adapted by our CORE team, we transformed the point-cloud data collected by the drones to create high-resolution photomosaics of each property.

Wimbledon No. 1 Court

London, England