4 minute read

Cladding and Decking Substructures

Deck Substructures: Prepare for New Specification Levels

As the specification requirements for pressure treated softwood deck substructures are set to change, Janet Sycamore at the Timber Decking and Cladding Association (TDCA), explains how this will improve performance for timber decking.

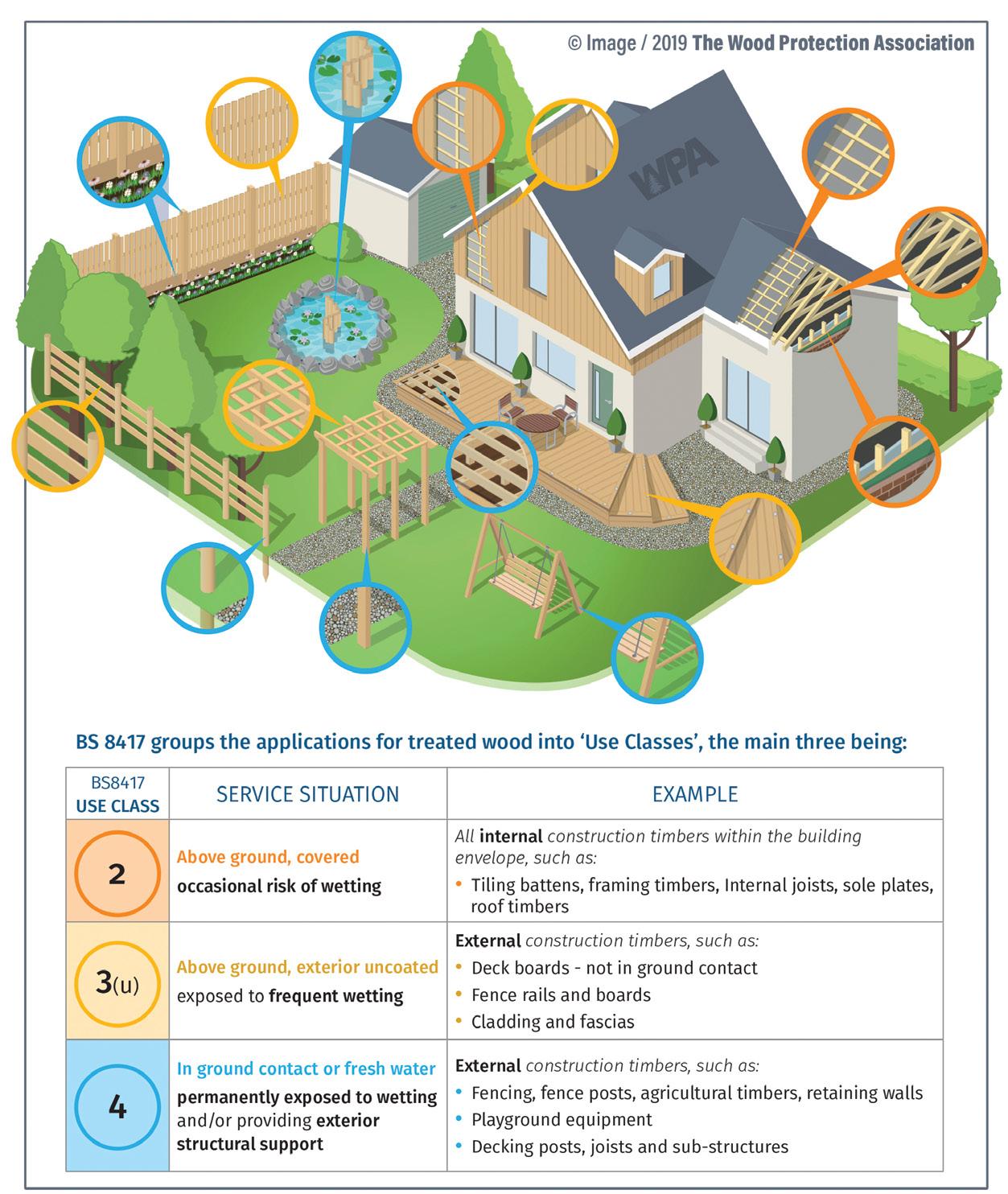

BS8417, the British Standard for wood preservation, when it is next revised later this year will mean that all softwood components used for the structural sub-frame of a deck will have to be treated to the same level as components in permanent contact with the ground, referred to as Use Class 4. Pressure treated softwood is commonly used to build decking substructures to support timber and composite deck boards. Preservative treatment provides wood with added durability and BS 8417 requires that the loading and penetration of preservative, impregnated into the wood, is tailored to the desired end use.

End uses are grouped into five categories: Use Class 3 relates to exterior above ground use whereas Use Class 4 relates to exterior ground contact use. Ground contact use presents a higher biological risk to timber and therefore, in order to work well in this situation, a higher level of wood preservative needs to be impregnated into the timber. The ‘Use Class’ system is important because it indicates the scale of the biological threat faced by a wood product in a specific end-use situation and determines the preservative loading and penetration required to deliver the service life required.

Clear information about using wood correctly for decking and landscaping projects has been promoted widely in the UK for many years with organisations like the TDCA leading the way in providing supply chain and end-user good practice guidance.

Despite this, mistakes and shortcuts are still being made in constructing timber deck substructures – which compromise both the performance of the finished deck and the reputation of wood. This is made worse as once a deck is completed the substructure is typically not visible with the consequences of bad practice not evident until it’s too late. For example, if vegetation and/or debris is allowed to accumulate beneath a deck, this restricts air movement and traps water, increasing the exposure risk. Likewise, it is common for deck joists to be set directly on or very close to the ground.

The failure of the substructure is clearly safety critical. In Sweden, Finland, France and north America, the whole deck substructure system (posts, beams and joists) is categorised as Use Class 4. Subsequently the decision has been taken to follow this best practice in order to ensure substructures are robust and perform better. In addition this should raise confidence in the market and help to maintain timber’s position as the most popular and cost effective solution when building decks. Going forward this means that in the UK the whole substructure will be categorised as Use Class 4, whereas previously, only the posts were categorised as Use Class 4. Following a full review of the issues outlined, the Wood Protection Association (WPA) Technical Committee, which includes representatives of the BRE and TRADA adopted these changes as WPA policy and were subsequently ratified by both the WPA and TDCA Boards.

These changes have also been adopted by the BSI committee managing BS8417 (B/515) and so will be incorporated into the full standard review (probably later in 2020). In due course the WPA, TDCA and Timber Trade Federation (TTF) will be working to adopt this change in policy across the membership of all three partner associations, so as to help them transition to the new requirements in time for the publication of the revised BS8417 towards the end of 2020. In fact TDCA members Hoppings Softwoods and BSW Timber have already introduced products that meet the new guidance.

Checklist When Buying Substructure Components For Timber Decking

Establish if the component has been impregnated with a wood preservative in an industrial treatment plant and that it is suitable for outdoor use

Determine what service life is claimed – it should be similar or better than the deck boards you have chosen

Ask your supplier to verify that the timber meets a Use Class 4 specification – on the delivery note or with a treatment certificate

Never substitute wood that has been treated for an indoor application for use in an external application – early failure is inevitable

When cross-cutting, notching or boring treated timber products during installation, always apply an end grain preservative treatment to freshly exposed areas, to maintain the integrity of the protection. Never put cut ends in the ground, even if end grain coated.

Grow your business with Timber Media Timber Media Ltd, publisher of Timber Construction magazine, is delighted to announce the launch of our brand new e-marketing service for advertisers.

With over 4,500 timber industry business professional contacts, we can send your bespoke, solus e-newsletter to top decision makers in our industry... but be quick, the service is limited to one e-newsletter per week which will be mailed on a Monday to our mailing list.

A second e-newsletter will be sent the following Thursday to engage contacts who opened but did not click the hyperlinks. You’ll then receive a statistics report for the two e-newsletters the following Monday.