25 minute read

News

Time for Timber campaign highlights net zero

With the threat of missing critical environmental targets a very real danger in the post Covid-19 economy, the Time for Timber campaign has launched a new drive that directly targets the financial and insurance sectors – one of the biggest stumbling blocks in the path of sustainable development.

With ambitious targets set for the UK to reach net zero by 2050, combined with an increasingly urbanised population, there is an urgent need to change how we build high density and single-family housing. The obvious solution is using renewable, sustainable and environmentally positive materials such as timber but, historically, the insurance industry has been unwilling to support such initiatives. Misconceptions around timber’s suitability as a major project construction material have meant that this versatile solution is considered a risk by many insurers and finance houses. This basic misunderstanding of the facts could be jeopardising the future of the economy and the environment.

Bringing together leading voices from around the construction industry, the Time for Timber campaign has been founded with the express intention of challenging these misconceptions within the financial and insurance sectors. The campaign launched with a major advertising campaign at Bank underground station, in the heart of London’s financial district. The bold move will see the hard-hitting campaign message dominating the advertising space within the station, in a bid to kick-start engagement with this important issue. A programme of webinars with financial sector media partners and a new whitepaper will follow, to begin strengthening the dialogue between the timber construction industry, insurers and investors.

Underpinning the communication campaign is a groundswell of support that is building throughout the industry, which is showcased in a new Time for Timber documentary. The film features compelling interviews with figures such as: British Green Party economist, Molly

Scott Cato, architect and Chair of the Good Homes Alliance, Lynne Sullivan, Technical and Innovation Director at Barratt Homes, Oliver Novakovic and Chief Executive of the UK Sustainable Investment and Finance Association, Simon Howard. Andrew Orriss from the Time for Timber campaign commented:

“We are at a crossroads in the UK and on a global basis: we need to act now if we are going to meet our environmental obligations and timber is the primary building material that will help us do this. As well as being sustainable, replenishable and easily re cycled, the adoption of timber within offsite construction and MMC techniques would have a profound effect on the wider construction market and a demonstrable reduction in the carbon footprint of projects. “This is in harmony with the Government’s agenda of Building Back Better, with its emphasis on green initiatives, which clearly recognises that there is a need to create jobs to avoid a financial downturn. But we should be creating those jobs to ensure the green transition happens as quickly as possible, to propel us towards net zero carbon – as well as protecting communities from future environmental and economic hazards.”

More at www.timefortimber.org

Norbord ready to help builders’ merchants sector through challenging times

“It’s obvious, and well-documented, that the nature of lockdown, furlough, safe distance protocol and new remote ways of working have meant that all companies must adapt and operate new practices in order to succeed in today’s new world,” says Sanjit Dosanjh, Norbord’s National Sales Manager for UK & Ireland. “But what exactly does this mean for Norbord as a supplier to the merchant and building industry?

“In essence, we are very talkative and communicative, speed of response-driven, efficient and “modern” in communications, as have our customers. In turn, our customer base is reaping the reaping the rewards of changing the way we work together. Of course, nothing is the same as a face-to-face meeting, but we are all adapting to the new norm across the building industry – and everywhere.

“It has been challenging at times for all of us as any change is; but we have

moved forward, as has the industry, and the building world is a really positive place to be. Due to the lockdown, and subsequent limitations on travel and staff levels, customers have not been on site or available for physical meetings. Yet we are talking more.

“Norbord’s base of merchants has reacted and we are working in tandem very well. We keep in touch with Zoom or Teams meetings – we are communicating much more, with more people in one place, and in much less time which is good for everyone. Merchants and suppliers alike now seem easier to access and results are quicker to realise. As the customers now order on a click-and-collect basis in the main, their online presence is crucial. In turn, we are supporting our customers with online sales and product training and, if a conversation is needed, our team is ready.”

More at www.norbord.co.uk

Port responds to fears of 7,000 trucks delayed at Dover

Peel Ports, the major UK port and terminals operator, has said its Port of Liverpool facility is ideally placed to contribute to the ‘Team UK Approach’ needed to overcome major Brexit delays at Dover, following a stark warning from cabinet minister Michael Gove in September. In his letter to haulage associations, Mr Gove warned that 7,000 trucks could be queuing for up to two days in Kent due to delays caused by Brexit, impacting ‘category one’ goods such as food, medicine and hospital equipment. Peel Ports group commercial director Stephen Carr said: “We have long argued the UK is too reliant on a few key pinch points in the South-East and today’s announcements demonstrates the risks to UK businesses of this strategy.

“We have been preparing rigorously for many months and have invested heavily at our Liverpool, Heysham and Sheerness ports to ensure they have the capacity to accommodate cargo switch routes and modes. All three ports have already taken steps to improve resilience ahead of Brexit, with increased throughput capacity for HGV trailers, containers and storage to support smooth operations by RORO ferries and other shipping services.” The Dover Straits now accounts for roughly three-quarters of all RORO trade with the continent – whereas prior to the signing of the Maastricht treaty it was less than half – despite the fact much of the UK’s warehousing is situated in the Midlands and North of Britain. The Port of Liverpool has seen in recent weeks new ferry routes commence with Spain and Portugal with CLdN in addition to more capacity being added to existing services. “Potential delays and holdups post-Brexit underline the advantage of using ports closest to the origin or destination of goods,” added Stephen Carr. “Every minute that goods are delayed waiting for border checks incurs greater costs to businesses and stops the flow of vital goods such as food and medicines – an issue which has been brought sharply into focus by the Covid-19 pandemic. “The Port of Liverpool is uniquely positioned to offer this proximity to market, which allows goods to reach their end destination more reliably and with less reliance on increasingly scarce truck drivers. This is a need which has never been more critical considering the changes in demand patterns we’ve seen this year, with added pressure of anticipated queues at Dover and long onward journeys from the South to the North of the country. A port’s proximity to markets has other indirect benefits, not only acting as a strategic gateway, but as a facilitator of supply chain activity and as a catalyst for reducing carbon emissions of a journey. “Whether it’s full processing, product finalisation or implementation of storage solutions, being close-by means a port can fulfil a wide range of logistics activities, as well as minimises the risk of disruption as a result of transport congestion. It additionally offers environmental benefits given shipping’s relatively low carbon emissions when measured on a per tonne KM basis.

“All businesses will be impacted by the changes Brexit will bring, but the preparations undertaken by UK’s ports industry will relieve pressure on traditional routes, increase capacity and introduce new trade routes. The Port of Liverpool is an obvious, sustainable port of choice for those looking to avoid costly delays and future proof their supply chains.”

LIGNIA® set to be distributed in Australasia

LIGNIA Wood Company, the award-winning modified timber business based in Barry, Wales has signed a distribution agreement with Australian timber experts Hurford Wholesale, who will be distributing LIGNIA products to the Australian and New Zealand markets. Hurfords was established in 1932 and is a leading Australian third-generation family business dedicated to the native hardwood timber industry. With its HQ (pictured) in Stapylton in Queensland, it covers the entire supply chain from the management and harvesting of forest resources, processing, manufacturing, sales and distribution of wood products in Australia and around the world. LIGNIA Wood Company produces modified timber at its base in Barry. It uses real softwood from responsibly sourced FSC® certified plantations which is then modified through a unique process. This gives LIGNIA the beauty, performance and appearance of popular hardwoods. Neil Ryan, CEO of LIGNIA Wood Company said: “LIGNIA continues to go from strength to strength across the globe and we are now delighted to welcome Hurfords as a world-class distributor and partner of LIGNIA for Australasia. Hurfords has a track record of success going back nearly 90 years and an expertise that will help us take LIGNIA into a bright future, especially as they are close to the end users and can therefore provide solutions for specific projects.” Ryan Chipperfield, group marketing manager of Hurfords added: “We are excited to welcome LIGNIA to our growing range and offering for our customer base. Adding a product with many new features and benefits

alongside the fact it is produced with sustainability in mind is a source of pride for our business. We look forward to a long relationship with LIGNIA.” LIGNIA is manufactured from a fast-growing FSC® certified softwood modified to become LIGNIA, a timber with excellent durability, stability and physical properties, making it suitable as a substitute for tropical hardwoods. The timber is designed to be ‘wood made for life’ with greatly improved performance against decay and rot in ‘above ground’ applications with a 50-year warranty.

More at www.lignia.com

Advertise with Timber Media’s Products & Services

For more information call Terry Hanlon on 01925 270093 or email terry.hanlon@timbermedia.co.uk

SO Modular moves closer to energy self-sufficiency

SO Modular, the Neath-based specialist in timber frame construction, has unveiled a new biomass boiler at its headquarters, the result of a significant investment which moves it closer to becoming completely self-sufficient in terms of its energy and production process. The cutting-edge waste wood biomass boiler was installed by energy specialist Novalux Energy. It is fuelled by timber offcuts and wood shavings, a natural by-product of the production process and will re-use 90% of the fuel into usable heat.

The 2MW waste wood boiler works by burning the fuel at high temperatures to produce heat, or thermal energy. This thermal energy is transferred to a heat exchanger which provides you with heat for space or processes. Excess heat from the boiler is diverted to an Organic Rankine Cycle (ORC) which converts the heat into power through a twin screw expander. One of the most important aspects of the boiler to SO Modular is that the technology utilises carbon filters to filter out impurities in its emissions to ensure they are not harmful to the local environment. The installation means that the company is now recycling a very high percentage of its waste material, converting it into heat and energy. The site is now almost self-sufficient in its energy needs during production and even has surplus at some points in time, which it sells to the grid. All of SO Modular’s timber is sourced locally. The majority comes from its doorstep in the Neath Valley, milled by Pontrilas Sawmills, just over an hour away in Hereford. Founded in 1947, Pontrilas is one of the largest independent sawmills in the UK. SO Modular now uses enough

wood every year to build more than 1,000 timber frame homes. This amount is set to increase exponentially as the business grows rapidly and demand for timber frame solutions soars. In 2019, SO Modular invested some £6.5m in acquiring and regenerating a large part of the iconic industrial site in Neath. Since its investment, it has capacity to make more than 3,500 homes a year. As such, it is seeking new sources of timber in Wales. Charlotte Hale, Director of SO Modular, said: “We are embracing sustainability in all aspects of what we do and the biomass boiler is just the first of several initiatives we have planned, including solar panels. We believe this will be a fantastic case study for the benefits of the circular economy. “Our aim is to sustainably redefine the buildings we construct and restore our new facility to its former glory but in an innovative and ecofriendly way; we want it to be a landmark of the town again, which the community can be proud of, while also benefiting the local supply chain and keeping jobs and money in the region.” Joseph Allcott, Managing Director of Novalux Energy, added: “Renewable energy systems can fit a variety of applications and in the case of SO Modular, the 2MW waste wood boiler and 100kW ORC works to utilise waste product as a fuel. This is a great example of a renewable system offsetting fossil fuels and benefitting from the Renewable Heat Incentive.”

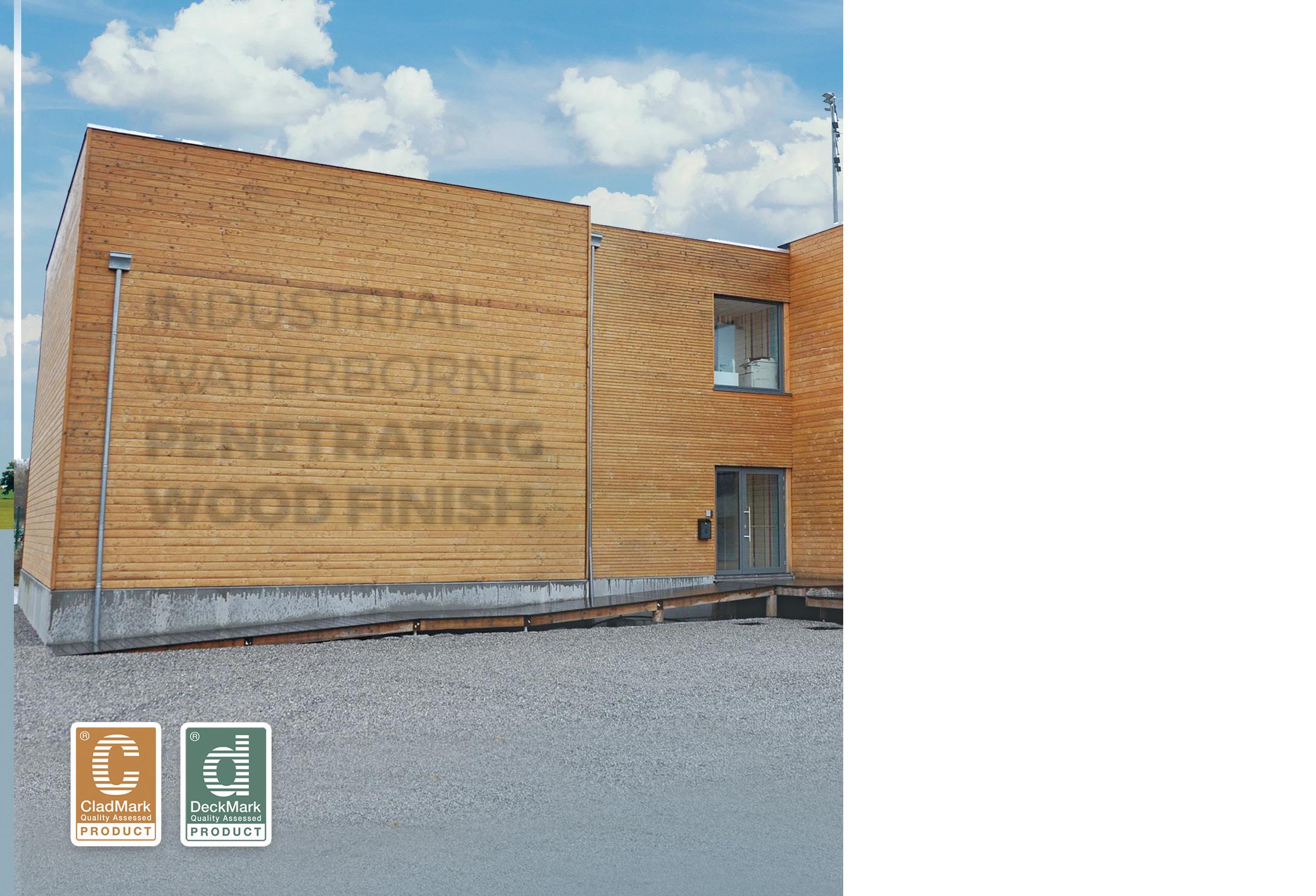

Freedom to design with complete peace of mind

MAXimum Design Possibilities

MAXimum Flame Retardance*

MAXimum Environmental Commitment

Let’s do the right thing!

*Maximum Euroclass rating for a timber panel

With SMARTPLY MAX FR B, we’ve produced an OSB panel that is even better than B-fore. SMARTPLY MAX FR is now SMARTPLY MAX FR B!

Comprising all the properties you would expect from a SMARTPLY OSB panel – strength, moisture resistance, high load-bearing capacity and no added formaldehyde – SMARTPLY MAX FR B now offers increased levels of fire protection for the creation of safer, more resilient buildings. With a Euroclass B flame retardance rating, SMARTPLY MAX FR B offers reliable assurance to specifiers, of its ability to suppress fire growth in the critical early stages of development, making it an appropriate consideration for timber frame and offsite construction projects, especially during the construction phase. Smart, consistent and strong, with even greater fire retardance, ‘B’ sure to do the right thing with SMARTPLY MAX FR B.

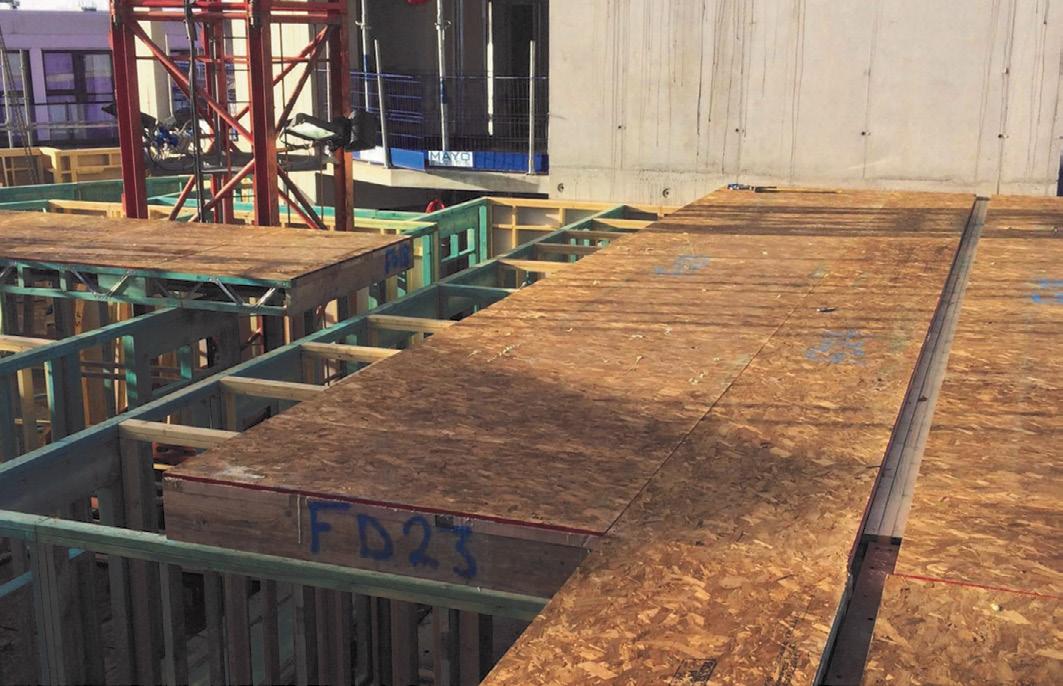

Introducing SMARTPLY MAX FR B

MEDITE SMARTPLY has now launched SMARTPLY MAX FR B, the brand new Euroclass B OSB3, a market innovation bringing increased safety and reliability to an industry contingent on safety and predictability. SMARTPLY MAX FR B is the first Euroclass B board—the maximum Euroclass rating for a timber panel—manufactured in the UK and Ireland to feature wood flakes treated with flame retardant solution before pressing. This ensures its flame retardance is integral and maintains its structural integrity, unlike many post-treated alternatives, making it the safer choice for use within timber frame construction, or projects that will require a large amount of timber product. “We are extremely excited to introduce SMARTPLY MAX FR B to the marketplace, expanding our already extensive SMARTPLY OSB range,” comments Richard Allen, Sales Director at MEDITE SMARTPLY. “In SMARTPLY MAX FR B, customers can expect all the fantastic benefits of a SMARTPLY OSB board, with the addition of ZeroIgnition® solution, a water based and environmentally friendly flame retardant which is added during panel production.

“This is a solution that has potential in a huge range of applications and industries, encompassing many modern methods of construction such as offsite and timber frame construction, light gauge steel and modular construction systems, as well as temporary structures. Whatever the sector, all customers can rest assured that this board’s flame retardance will hold to Euroclass B standard, even when cut to size, which makes it different to other FR boards out there.”

Manufactured using advanced resin technology that results in a high performance, no added formaldehyde panel, SMARTPLY MAX FR B can help specifying architects, contractors and fabricators contribute to the creation of safer, healthier environments. This includes not only the built environments actively created but the natural environments left behind: SMARTPLY MAX FR B is sustainably produced using timber from sustainably managed Irish forests. “At MEDITE SMARTPLY, we want to support a safer, wider future for timber buildings, that will enable the wider construction industry to work more sustainably and more efficiently, truly building for the future,” adds

Richard Allen. “This has been one of our main motivations in developing SMARTPLY MAX FR B.” SMARTPLY MAX FR B also complies with the performance requirements in the Structural Timber Association’s FR BUILD “Design guide to separating distances during construction” for timber frame buildings above 600m² total floor area. SMARTPLY MAX FR/FR BUILD can be used in a timber frame building when mitigation measures are required due to the distance from neighbouring buildings. There are wall and floor systems outlined within the guide which give points towards the overall building, this satisfies any mitigation that may be required. Please refer to the STA guide for more information. Finally, SMARTPLY MAX FR B meets with the requirements of European Standards EN 300 and EN 13986, while also complying with the European reaction to fire class B-s2,d0 and Bfl-s1. Boards can be manufactured in largescale formats of up to 2.8m wide by 7.5m long, making it ideal for offsite manufacturing, alongside traditional building.

More at

www.mdfosb.com/en/smartply/ products/smartply-max-fr-b

Fast Growth 50 award for Premier Forest Group

Premier Forest Group, one of the UK’s fastest growing timber groups, has been recognised with a special award at this year’s Fast Growth 50 event in Cardiff. The Fast Growth 50 is in its 20th year of celebrating the fastest growing firms in Wales. The awards, established by Professor Dylan Jones-Evans in 1999 use sales as the main indicator, looking at a business’ percentage increase in turnover over three accounting periods.

This year, the awards acknowledged ‘super growth’ firms for the first time. These are companies whose turnover has surpassed £100m since they first appeared on the list. Only ten firms that have made the Fast Growth 50 list in the past twenty years have passed the critical £100m mark, and Premier Forest Group is one of them. Terry Edgell (pictured), CEO and co-founder of Premier Forest Group, said: “To pass £100m

turnover was a goal of ours for a number of years and to be recognised for passing this significant milestone is very rewarding. To be on the stage with household brands like Admiral and GoCompare was a real honour and showed us just how far Premier Forest Group has come.” Professor Dylan Jones-Evans said: “When I first established Fast Growth 50 it was to celebrate companies like Premier Forest Group who prove that you can set up, run, and grow hugely successful businesses right here in Wales. What Premier Forest has achieved is testament to a lot of hard work and a successful business strategy.”

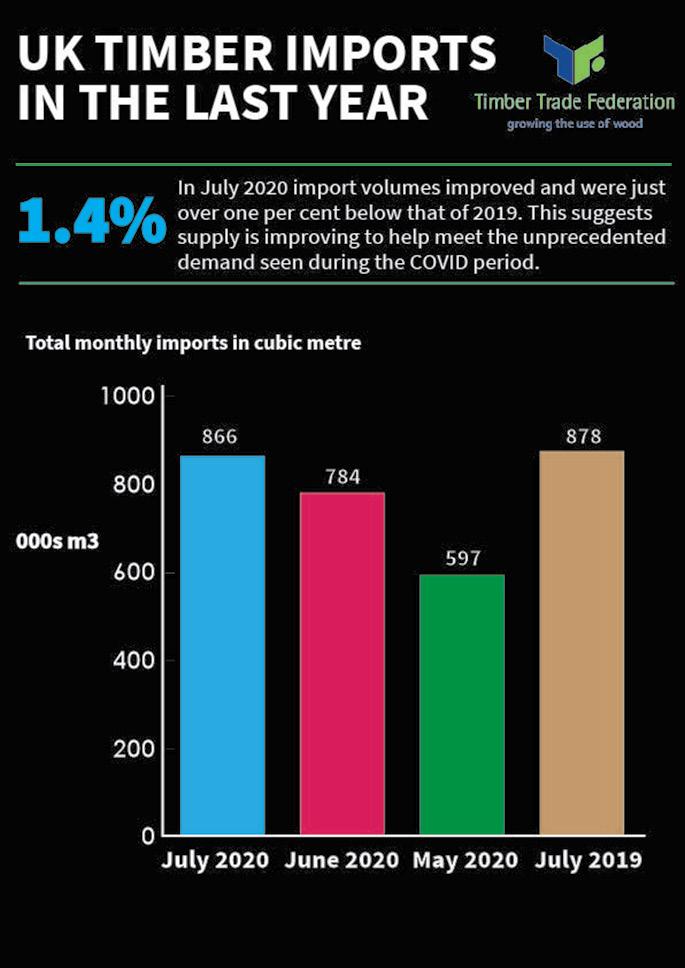

Timber and panel import volumes ‘back on track’ for 2020

A recent Timber Trade Federation (TTF) report reveals total import volumes for main timber and panel products were approximately 1% below July 2019 levels, with 866,000m3 arriving in the UK. The 1% difference in volumes between the two months (July 2020 and July 2019) was the lowest percentage reduction in volume since April 2019.

These volumes were higher than the TTF originally predicted and raise the TTF’s forecast for total timber imports to the UK in

2020 to around 8.4 million m3 (approx. 19%

lower than 2019). Imports across all major

individual product categories, softwood, hardwood, and panel products, have been on the rise. For the first time in 2020, softwood import volumes exceeded 2019 levels as 580,000m3 were imported in July 2020 compared to 514,000m3 in July 2019. Hardwood imports increased to 40,000m3 in July 2020, which while still 5,000m3 below July 2019 figures, represents a 54% increase over June 2020.

Imports for panel products have increased during June and July, with OSB and

MDF leading the way. OSB imports in July

2020 were 46,000m3, a 48% increase from

the volumes seen in June 2020, and 8,000m3

more than July 2019 (38,000m3). MDF imports

for June and July are almost double May’s imports (27,000m3), reaching 57,000m3 in June and 52,000m3 in July 2020. David Hopkins, TTF CEO, said: “These figures are a good signal of a strengthening market. They will go some way to helping rebuild stocks and meet rising demand for timber products. The huge surge we’ve seen in DIY projects along with increased global demand has been unprecedented and caused spikes and longer lead times across certain product categories. This rise in imports should start to help ease that pressure, especially if the trend continues over the coming months.”

More at www.ttf.co.uk

INTRODUCING

PROTECTION FOR CONSTRUCTION TIMBERS

VACSOL 6118 - metal free wood preservative that can be used in both low and high pressure treatments Can be used to protect Use Class 1, 2, 3 Coated and now Use Class 3 Uncoated timbers Can have colours added Simple conversion from existing preservative product

lonzawoodprotection.com/eu

Use wood preservatives safely. Always read the label and product information before use.

UK Government urged to put tree planting targets into legislation

In its response to the England Tree Strategy consultation, forestry and wood trade body Confor says tree planting targets should be enshrined in legislation to display a clear commitment to meeting them and could be done with an amendment to the Environment Bill.

Confor also wants a review of application and approval processes for planting, similar to the Mackinnon Review in Scotland, which kick-started a tree planting surge north of the border. In its wide-ranging consultation response, Confor – which represents 1,500 forestry and wood-using businesses – said: “The Tree Strategy needs to be joined up, from the forest to the end product, supporting three main and very closely linked objectives, which bring together the entire forestry and wood supply chain: plant more trees, manage more of our existing woodland and use more home-grown wood.” Confor urges the Government to understand the importance of forests to people during lockdown and how the industry can deliver environmental, economic and social value to lead a green recovery from Covid-19. Its response says: “The consultation presents an excellent opportunity to produce a strategy for our economy, environment and society at a time when policy interventions delivering multiple benefits must be prioritised. As the UK plots a way forward beyond the pandemic, our forests and woods have a vital role in delivering a Green Recovery – as well as a crucial part to play in meeting longer-term targets, including the UK’s ambition to be Net Zero by 2050 to tackle the climate emergency.”

Caroline Ayre, Confor’s National Manager for England, said: “The England Tree Strategy represents an excellent opportunity to ‘turn the dial’ and really puts forests and wood at the heart of our environmental and economic future. We have seen a very positive approach from Lord Goldsmith since he became Minister and will continue working closely and constructively with him to deliver this exciting agenda. “The benefits of forestry and wood are not either/or options – creating jobs and economic growth can go hand in hand with tackling the climate and nature emergencies and providing beautiful places for people to enjoy the natural world. Seizing this opportunity can set the UK on a path to a net-zero economy by 2050, and a long-term sustainable rural future.

“We are very clear in our response – this is not just about tree planting, but about better management of the forests we have, and greater wood use. The three must be approached together in a joined-up way: that’s how we will see multiple benefits delivered. However, planting trees is the starting-point and targets are just numbers on a page, when it is about trees in the ground. That’s why we think enshrining the targets in legislation is a great first step for the UK Government to show its commitment, combined with an external review of the approvals process.”

HSE Dust-free insulation could help prevent lung disease says Actis, as HSE launches respiratory risk campaign. Building workers are around a hundred times more likely to die from a disease caused or exacerbated by their workplace than through a construction accident. That’s the shocking news the Health and Safety Executive is sharing during a month-long campaign to raise awareness of lung diseases caused by workplace dust. The Dustbuster campaign will see HSE officials checking up on construction firms across the country to help protect workers from the dangers of dust caused by certain materials and working practices.

Using power tools, sweeping and working with products such as gypsum and wood are among activities which can be extremely harmful, without protection, say HSE experts. The initiative is aimed at helping businesses find ways to minimise dust production.

Insulation specialist Actis says one change which could help is to switch from using traditional, solid insulation products which create dust when cut to those which generate no irritants or dust whatsoever. Indeed, users of Actis’ flexible honeycomb insulation Hybris and insulating vapour control and breather membranes H Control Hybrid, Boost R Hybrid and Boost R Hybrid Roof say their cleanliness and complete absence of dust is precisely one of the reasons they use them. Tony Byron-Cooper, site manager at PCR Projects’ recently completed 43-home development in Kent says he will be using Actis products on all his future developments. “Most importantly, health and safety wise for our installers, it is light, easy to handle and there’s no dust to contend with,” he said. Derek Dawson, MD at timber frame specialist Scandia-Hus said: “The Hybrid range doesn’t produce irritant and messy dust when installing.” Canterbury builder Simon Day added: “There are no fibres and no dust is created when you cut it, which means I didn’t need a respiratory mask or any special clothes.”

Avoiding dust has health as well as cleanliness implications, which is one of the reasons so many customers choose Actis. The fact that there’s no need for specialist PPE or masks and it only requires a saw or a hand operated cutter to trim it are some of the reasons builders return to Actis again and again. The HSE campaign, which launched in October focuses on respiratory risks and occupational lung disease and looks at the measures businesses can take to protect their workers’ lungs from certain materials. HSE’s chief inspector of construction, Sarah Jardine, said: “Around a hundred times as many workers die from diseases caused or made worse by their work than are actually killed in construction accidents. We want businesses and their workers to avoid creating dust by working in different ways to keep dust down and wear the right mask and clothing.”

More at www.insulation-actis.com

NOW HIRING BRANCH MANAGERS

TIMBER & BUILDERS MERCHANTS

UK WIDE

Contact Specialist Consultant, Fiona Hamilton for more information on opportunities in your region