June 2024 - Vol 50 - No 6 ISSN : 2031-9193 www.ien.eu INDUSTRIAL ENGINEERING NEWS 12 16 24 26 Automation: Maximizing Automation Efficiency in Small Spaces with Robots Ensuring Safety and Efficiency in the Process Industry with the Right HMI Electronics & Electricity: Cable Carriers for Control Stations and Control Rooms Electronics & Electricity: Effective Cooling of Hot Spots with LiquidCooled Heat Sinks JUNE Monitored Changeover for Process Reliability in Tube Production page 8 PCN Europe Supplement page 16 to 21 22 Impact without Rebound: Miniature Shock Absorbers for Drop Test Construction Solving the Battery Problem of the IoT with Energy Harvesting Page 25

TIM Global Media BV

140 Rue de Stalle - 3ème étage, 1180 Uccle-Brussels, Belgium o.erenberk@tim-europe.com - www.ien.eu

Editorial Director: Orhan Erenberk o.erenberk@tim-europe.com

Editor: Kay Petermann k.petermann@tim-europe.com

Editorial Support Flavio Steinbach

Energy Efficiency: f.steinbach@tim-europe.com

Associate Publisher: Marco Marangoni m.marangoni@tim-europe.com

Production & Francesca Lorini

Order Administration: f.lorini@tim-europe.com

Website & Marco Prinari

Newsletter: m.prinari@tim-europe.com

Marketing Manager: Marco Prinari m.prinari@tim-europe.com

President: Orhan Erenberk o.erenberk@tim-europe.com

ADVERTISING SALES OFFICES

EUROPE

AUSTRIA/SWITZERLAND

Monika Ailinger

Tel.: +41 41 850 44 24 m.ailinger@marcomedia.ch

BENELUX, NORWAY, SWEDEN

Nadia Liefsoens

Tel.: +32-(0)11-224397

Fax: +32-(0)11-224397 n.liefsoens@tim-europe.com

FRANCE

Roxanne Akbulut

Tel: + 33 06 52 31 41 56 r.akbulut@tim-europe.com

M’fumu Tiya Mindombe

Tel: +32 465 443 530 m.mindombe@tim-europe.com

GERMANY

Simone Ciolek

Tel: +49-(0)9771-1779007 s.ciolek@tim-europe.com

ITALY, SLOVENIA

Andrea Rancati

Tel: +39-02-7030 0088 arancati@rancatinet.it

TURKEY

Onur Dil

Tel: +90 212 366 02 76

Fax: +90 212 366 58 02

E-mail: o.dil@tim-europe.com

UNITED KINGDOM/DENMARK/ FINLAND

Dave Harvett

Tel: +44 (0)121 705 21 20 daveharvett@btconnect.com

NORTH AMERICA

Hamilton-Murphy Global, LLC

John Murphy

Tel: +1 616 682 4790 Fax: +1 616 682 4791 john@hamiltonmurphymedia.com

JAPAN

Ichiro Suzuki Incom Co. Ltd. Tel: +81-(0)3-3260-7871 Fax: +81-(0)3-3260-7833 isuzuki@INCOM.co.jp

OTHER COUNTRIES

Cristian Son

Tel: +39 027030631 c.son@tim-europe.com

Dear Readers,

k.petermann@tim-europe.com

k.petermann@tim-europe.com

Space in a production environment can also be a resource. If it is not available in sufficient quantities, a smooth production process is jeopardised or not possible. And as with other commodities, a solution must be found - as quickly, easily and cost-effectively as possible. As this is often not possible, reserves should be planned for when planning new projects and space should be saved from the outset. The article on page 12 shows the role that certain SCARA robots can play in automation projects. On page 8 you can read how efficiency gains can be achieved by integrating monitored changeover solutions in machines. The article in the PCN Europe supplement on page 16 explains how safety and efficiency can be realised by using the right HMI concept in the difficult environment of the process industry.

Batteries on one hand are very practical if you want to place sensors or equipment in positions that are not easy to reach or remote. But maintenance-wise and from the ecological standpoint they are not the ideal solution. What energy harvesting could do to get rid of these problems, you can read on page 25.

As always, I wish you an interesting read.

KayPetermann

Editor IEN Europe

Digital File Requirements available at: www.ien.eu/technical-guidelines/

© 2024 TIM Global Media BV Production by design3, Milano, Italy Printing by Logo Srl - Padova, Italy

POSTMASTER

Send address changes to:

Industrial Engineering News Europe

Marco Prinari - m.prinari@tim-europe.com

N° 6 - JUNE 2024 FREE DIGITAL SUBSCRIPTION

FREE Digital Subscription 3

KayPetermann

editorial

Industry News

New Products

Automation: Monitored Changeover for Process Reliability in Tube Production

Automation: Rugged Panel PCs for Manufacturing, Logistics, and Energy Management

Automation: Cloud Platform for Remote Management of Edge Devices

Automation: Maximizing Automation Efficiency in Small Spaces with Robots

Processing & Control News Europe Supplement

Measurement & Instrumentation: Ensuring Safety and Efficiency with the Right HMI

Measurement & Instrumentation: Better Cleaning and Protection for Reliable Sterile Processes with Electronic In-line Pressure Measurement

New Products

Test & Measurement: Impact without Rebound: Miniature Shock Absorbers for Drop Test Construction

Electronics & Electricity: Cable Carriers for Control Stations and Control Rooms

Electronics & Electricity: Solving the Battery Problem of the IoT with Energy Harvesting Electronics &

Effective Cooling of Hot Spots with Liquid-Cooled Heat

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 4

Sinks New Products Index & Events 5 6 8 10 11 12 15 16 18 20 22 24 25 26 28 30 6 24 28 12 8 contents In the next issue: WebMag July: Condition Monitoring & Intelligent Maintenance Smart Handling Automation N° 6JUNE 2024 21

Electricity:

Specialised Imaging Ltd Starts with New Division on Image Sensor Market

SI Sensors based in Cambridge, UK will focus on the development of advanced CMOS image sensors. Drawing upon a team of specialists with a broad range of experience in image sensor design – SI Sensors is creating custom image sensor designs with cutting edge performance. In particular, the company’s in-house experts have specialist knowledge of visible and non-visible imaging technologies, optimised light detection and charge transfer, radiation-hard sensor design, and creating CCD-in-CMOS pixels to enable novel imaging techniques such as ultra-fast burst mode imaging. Philip Brown, General Manager of SI Sensors said, “In addition to developing new sensors for Specialised Imaging’s next generation of ultra-fast imaging cameras utilising the latest foundry technologies, we are developing solutions for other customers with unique image sensor design requirements including for space and defence applications”. He added “SI Sensors team also use their skills and experience to develop bespoke image sensor packages that accommodate custom electrical, mechanical, and thermal interface requirements. Our aim is always to achieve the best balance between image sensor performance and cost (optimised value) for customers.

Strategic Technology Partnership Formed Between Festo and Phoenix Contact

Heilind Expands European Presence with New Distribution Center

Festo, manufacturer of pneumatic and electrical automation technology, will use PLCnext Technology, Phoenix Contact’s open ecosystem for modern automation, in future intelligent devices. This will combine the innovative strength of both companies with the aim of taking industrial automation to a new level. The new product generation is expected to be launched by year-end. The integration of PLCnext technology opens up a wide range of opportunities for Festo and its customers. PLCnext Technology is based on an open architecture that allows individual solutions to be developed and existing systems to be seamlessly integrated.The common goal of Festo and Phoenix Contact is to meet the requirements resulting from the convergence of IT and OT in industry with open automation solutions. “In a rapidly changing world, it is becoming increasingly important to enter into partnerships and work together within the framework of open technology platforms. A paradigm shift is clearly noticeable. Together with Festo, we will continue to work on generating new solutions for our customers. Because sustainable innovation can only be achieved through close cooperation," emphasizes Frank Stührenberg, CEO of Phoenix Contact.

Heilind Electronics Europe, a leading global distributor of interconnect, electromechanical components and fasteners, has opened a new state-of-the-art distribution center in Hanau near Frankfurt, Germany. This new center will strengthen the company’s position in Western Europe whilst supporting growth in Central and Western Europe, namely the DACH region, Benelux, Italy and France for Industrial and MIL/Aero business. Located in Hanau near Frankfurt, a major logistics hub in Europe, the new distribution center spans over 8 000 m², including a Value-Add Center and offices. This large surface area allows for increased storage capacity, accommodating more inventory to meet demand fluctuations. The facility offers Value-Added Distribution (VAD) services including kitting, re-reeling, special packaging, connector assembly and more – all tailored to meet the diverse needs of Heilind’s customers across Europe. “Our expansion in Germany reflects our dedication to providing unparalleled service and support to our customers” comments Stefan Barrig, Sales Director of Heilind Electronics Europe. “At Heilind, accessibility and proximity to key logistics hubs are paramount. With our new extensive capabilities including VAD services, our solution-oriented approach, and a global distribution network, Heilind truly connects everywhere.”

Endress+Hauser Joins the Single Pair Ethernet System Alliance

SPE is a game-changer, especially for the food & beverage and life sciences industries. In highly automated process environments without extensive hazardous protection, SPE delivers a variety of benefits. High speed and volume of transmitted data to and from field level with a simple two-wire cable transmitting both data and energy. SPE proves its worth as an open, costefficient and future-proof technology that is ready for the Industrial Internet of Things (IIoT). By joining the Single Pair Ethernet System Alliance Endress+Hauser is demonstrating its trust in the members that are committed to shaping the future of automation together. Customers benefit from interoperability by driving business with the members of the SPE System Alliance. Close to 75 members are creating the largest ecosystem of SPE products, creating freedom of choice for customers. Endress+Hauser’s entrance into the partnership opens the door for sharing knowledge and expertise to deliver superior solutions. To offer customers the chance to grow their digitalization capabilities and realize all the benefits of SPE, Endress+Hauser is now working on its portfolio of field devices with SPE. A clear goal is to create a harmonized approach, comparable to the manufacturer’s Ethernet-APL devices.

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024

industry news 5

IP67HMIPANELDISPLAYS

FlexiblymountablemultitouchHMIinfoursizes KEB Automation haslauncheda newrangeofHMIpaneldisplays. TheC6X1HMIpanelcanbe flexiblyattachedanywhereona machinewithvariousmounting options.Thiseliminatestheneed formountinginacontrolcabinet,allowinguserstofreelyposition theHMInearthemachine.TheIP67-protectedHMIisavailablein fourdifferentsizes.TheWebHMIC6X1isequippedwithcapacitivemulti-touchandcanbeinstalledanywhereintheenvironment ofthemachineaccordingtotheindividualrequirementsofthe machinebuilderorsystemsintegrator.Anadvantagehereisthe particularlysimpleconnectivityofthedevices,asthepanelsupportsPower-over-Ethernet(PoE).Thepossibilityofinstallingthe WebHMIoutsideofthecontrolcabinetismadepossibledueto thehighprotectionclassratingofIP67,whichenablesuseinan extendedtemperaturerangeof-20°Cto+55°Cwithoutanadditionalhousing.Userscanchoosebetweenfourdifferentpanelsizes: 7,10.1,15.6or21.5inches. TheHMIsystemshaveaLinuxoperatingsystemandareequippedwithaChromium-basedHTML5 browser.ThismakesthemidealforIIoTedgeapplications.Machine buildersandsystemsintegratorsarethereforeprovidedwithallthe basicrequirementsforthefutureofdigitalmanufacturingandcan benefitfromtheadvantagesofIndustry4.0.TheWebHMIsare designedforlongtermavailability.

64851atwww.ien.eu

COMPACTLASERDIFFUSESENSOR

Objectdetectionforarangeofupto2meters

WiththenewODT3CL1-2Mlaser diffusesensorLLeuze extendsthe operatingrangeoftheir3Cseries distancesensors.Thankstoinnovativetime-of-flight(TOF)technology,theswitchingandmeasuringsensorwithbackgroundsuppressionworkswithanoperating rangeofuptotwometers.Thismakesthesensorsuitableforall applicationsinintralogisticswherelongdistancesneedtobe bridged:e.g.inautomatedguidedvehiclesformonitoringthe positionofgoods,forcontrollingrobotgrippersorinqualitycontrol.WiththeIP69Kprotectionreliableuseisguaranteedeven underharshconditions. Withitstwoindependentswitchingpoints, itisabletoperformdetectionandmeasurementtasksatthesame time.Systemoperatorscanthereforesolvebothrequirements usingjustonesensor.Thisisanadvantageif,forexample,shuttles areused:Theycanoptimallysetandvarytheirspeedviathe independentswitchingpoints.IO-Linkcanbeusedtotransmit measurementvaluesandprocessdataofthesensortothemachine control.Thisallowsuserstoeffortlesslyevaluatethecomprehensivediagnosticdatafromthediffusesensor-e.g.temperature information,informationonsignalqualityandwarnings. Thanksto itscompactdesign(11.4x34.2x18.3mmWxHxL),thelaser diffusesensorcanalsobeusedwherespaceislimited.

64839atwww.ien.eu

NEWFUNCTIONSFORVISIONSENSOR

SoftwareUpdateenhancesapplicationalpossibilities SensoPart introducesthelatest softwareupdateforitsVISOR® series.Withthisfreeupdatetopnotchfeaturesforprecisecontour checksandindividualmarkings, previouslyonlyavailablein significantlymoreexpensiveand complexvisionsystemsare availabletousers. The"Contour Check"detectorallowsfortheprecisecomparisonofobject contourswithapreviouslytaughtreferencecontour,ensuringfast andreliableerrordetection.Thissignificantlycontributesto improvingproductionqualityandreducingwaste.Thedetectoris applicableacrossawiderangeofindustrialapplications-from plasticsprocessingandmetalworkingtoassemblytechnology.The new"IndividualOverlays"functionenablesVISOR®usersto displayrelevantinformationandresultsdirectlyintheimage.For instance,itallowsforcoloringbasedontheresult,whichcanbe easilysetupwithjustafewclicks.Theimmediatevisualizationof allessentialdatafacilitatessystemmaintenanceandpromotes rapiderrordetectionandcorrection.Additionally,thefunction enhancestransparencyintheproductionprocess,leadingto greateroverallacceptance. Thereleasealsoincludesexpanded resultprocessingfunctions,includingnewoperatorsforrobotics applicationsandnewmeasurementfunctions.

64840atwww.ien.eu

COLLABORATIVEROBOTSERIES

Preciseandfastmovementswithupto30kgPayload Delta Electronics announceda significantmilestoneinitsdevelopmentofsmartmanufacturing solutionswiththelaunchofsix highlyversatilemodelsintheD-Bot seriesofcollaborativeindustrial robots(Cobots).TheportfoliofeaturesCobotswithpayloadcapacitiesupto30kg,reachspansupto1800mm,compatibilitywith EtherCAT,ModbusandCODESYS,aswellastheintegrationof 24-bitencoderstoensureoptimallevelsofprecision,especiallyin pick&place,weldingandpalletizingapplications.TheD-Botseries includessixversatilemodelswithpayloadcapacities from6to30 kg.Featuringsixaxesforunmatchedflexibilityandprecision,these modelsofferspeedsupto200degreespersecondandaccuracy within±0.02mm.Theintegrationof24-bitencodersenhances precision,ensuringconsistentperformance. Theseriesisdesigned withIP66protectionandadvancedsafetyprotocols.With"Plug& Play"setupandintuitiveprogrammingviaauser-friendlyinterface, theD-Botseriesareaccessibletooperatorsofallskilllevels,promotinghuman-robotcollaborationinsectorssuchasautomotive, logisticsandelectronics.Thesystemfacilitatesteachingthrough drag&drop,Python,ROS1,orC++,andthemoderngraphicaluser interface(GUI),featuringimmersive3Dvisualization,allowsusers ofalllevelstoquicklyprogram.

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 6 64759atwww.ien.eu

TWINCATRUNTIMEFORREAL-TIMELINUX

Newpossibilitiesforreal-timecontrolwithindustrialPCs Beckhoff'sTwinCATruntimefor real-timeLinux® isopeningupnew applicationpossibilitiesforrealtimecontrol.Theabilitytoexecute severalTwinCATruntimesona singleindustrialPCmeansusers cannowcombinedifferentsystem partsononehigh-performancecomputertostreamlineprogramminganddiagnostics.ItalsomakesitpossibletoaccessaGPUfrom thereal-timeenvironment,providingahardwareacceleratorfor particularlycomputing-intensiveapplicationssuchasvision-and muchmorebesides.TwinCATruntimeforreal-timeLinuxisbased onBeckhoff'sownLinux®distribution,whichexpandstheexisting spectrumofoperatingsystemsbeyondWindowsandTwinCAT/ BSD.ThisdistributionwasdevelopedusingthefreeDebianoperatingsystemandincludesaLinux®real-timekernelasstandardfor real-timeexecutionoftheruntime.Usingcontainertechnologies suchasDocker®,Podman,orLXC,severalTwinCATruntimescan beexecutedonasingleIPCtoachievemodularityinmachineand othercontrolapplications.TheindividualexecutionofseveralruntimesonasingleindustrialPCfacilitateshardwareconsolidation withcorrespondingcostadvantagesduetotheimprovedutilizationoftheavailablecomputingcapacity. TwinCATruntimefor real-timeLinux®willinitiallybeavailableforthenewARM-based CX82x0andCX9240EmbeddedPCs(withARMCortex™A53CPU).

64777atwww.ien.eu

GEAR-ANDSHAFTLESSDIRECTDRIVE

Forlowerelectricityconsumtionincoolingtowers

ThecoolingtowerofASSANAluminumisequippedwiththe3KMF18 modelandMF18-1.200filltype.This designfeaturesacapacityof12mill. Kcal/h,awaterflowrateof1,200 m³/h,awaterinlettemperatureof 40°C,andawateroutlettemperature of30°C.However,theinefficiencyand lackofdurabilityoftheexisting system'smotoranddrivecomponents(gearbox,coupling,shaft) duetotheirtraditionalstructurewereaproblem. Toincreasethe efficiencyofASSAN'scoolingtowerandensurelong-termsustainability,thecompanycollaboratedwith EMF Motor.WiththeintroductionofEMFMotor,allcomponentsthatcouldcausemalfunctionswereeliminated,andonlythedirect-driveEMFMotorwas usedinstead.Additionally,thesystembecamequieter,vibration levelswerereduced,andwithminimalgreasereplenishment,the annualmaintenancerequirementbecamemuchsimpler.This collaborationwasasignificantstepintermsofbothtechnological innovationandoperationalefficiency.Itincreasedtheperformance ofcoolingtowerswhilereducingoperatingcostsandenvironmentalimpact.Suchinnovationshaveincreasedthecompetitivenessof industrialfacilitiesandcreatedamoresustainablebusinessmodel. Thisgroundbreakingworkinthefieldofindustrialcoolingisajoint projectofEMFandCenkIndustrialPlantsManufacturing.

64820atwww.ien.eu

COMPACT

CONTROL FOR BRUSHLESS MOTORS

12-bit encoder and controller with only 18 mm length

64712atwww.ien.eu

MAGNETICFIELDANDTEMPERATURESENSOR Three-axisconditionmonitoringsensorwithIO-Link TheCMMT3-axismagneticfield/ temperaturesensorwithIO-Linkis thethirdsensortypethatTTurck has developedspecificallyforeasy-touseandretrofittableconditionmonitoringapplications.Itcomplements theexistingrangeoftheCMVT vibration/temperaturesensorand theCMTHforhumidityandtemperaturemeasurements.Thecombinedmeasurementofmagnetic fieldandtemperaturewiththeCMMTenablessimpledetectionof faultsonmotorsorinprocesseswithmagneticcomponents.The newsensoralsoopensupapplicationsthatwerepreviouslyimpossible,suchasthecontactlessdetectionoftherotationandmovementofmetalobjectswithoutvisualcontact. Thankstoitshigh sensitivityoffivemicrotesla,thesensoralsodetectstheearth's magneticfield,butcanhidethisifrequiredbysettingtheparameters.Thedeviceoutputsmeasuredvaluesindividuallyorasvector sumviaIO-Link.Userscanalsoassigntwoindependentswitching outputs.TheCMMTsupportstheSmartSensorProfile4.1.4. When commissioningtheCMMT,usersaresupportedbytheTurckAutomationSuite(TAS)MagneticFieldMonitorapp.Thisapplication visualizesthesensordataliveinthewebbrowserandcanbeused viaanyTurckIO-Linkmasterwithoutadditionalsoftware.The devicefunctionsarealsosetviaTASorotherIODDinterpreters.

Integratedinthepowerfulbrushlessmotorsofthe F FAULHABER 22xx...BX4family,thenew IntegratedMotionController 22xx...BX4IMC,impresseswithits extensiverangeoffunctionsand outstandingperformance. Extensioninlengthcomparedto themotoraloneis18mmonlyincludingafullfeaturedservo controlleranda12-bitencoder.Totopthis,thefullperformanceof themotorscanbeusedinalldifferentexecutions. Theversionwith RS232interfaceisidealforintegrationbothfromaPCorviaan embeddedmaster.TheCANopenversionistheperfectmatchfor industrialautomationnetworks.BeingfullycompliantwiththeCiA 402servodrivestandardallowsdirectsupportfromtypicalPLCs. ButevenusingtheRS232versionseveraldrivescanbecontrolled usingasingleportofthemaster.Typicaltaskslikehomingadrive candirectlybeexecutedbytheintegratedMotionControllerusing itslocaldigitalandanalogI/Os. Alternatively,bothversionscan alsobeoperatedwithoutamasterin"stand-alone"mode.Its digitalandanalogI/Oscanthenbeusedveryflexibleforlocal controltasksorfordiscreteset-pointandactualvalues.The compact22xx...BX4IMCcanbecombinedwithmanyproducts fromtheFAULHABERproductrangesuchasthecompactGPT gearheadsandthenewFAULHABER22Llinearactuators. 64713atwww.ien.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 7

Process Reliability in Tube Production

Monitored changeover is an opportunity to optimise machines, reduce sources for potential errors and making them intuitive and quick to operate.

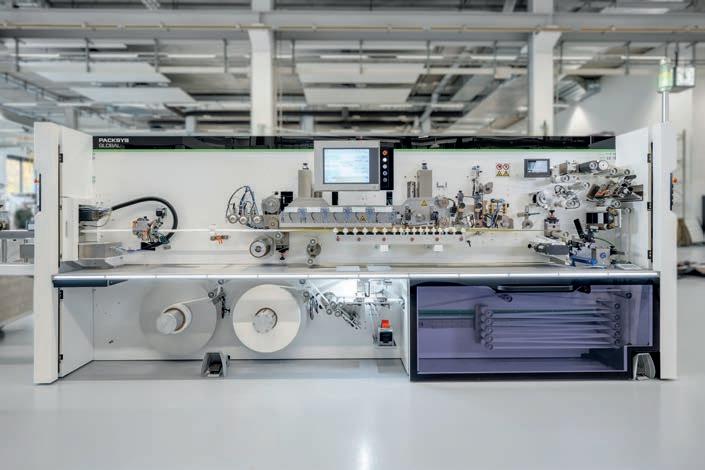

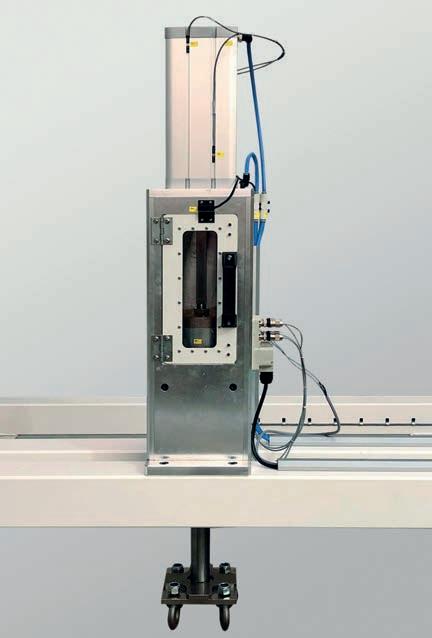

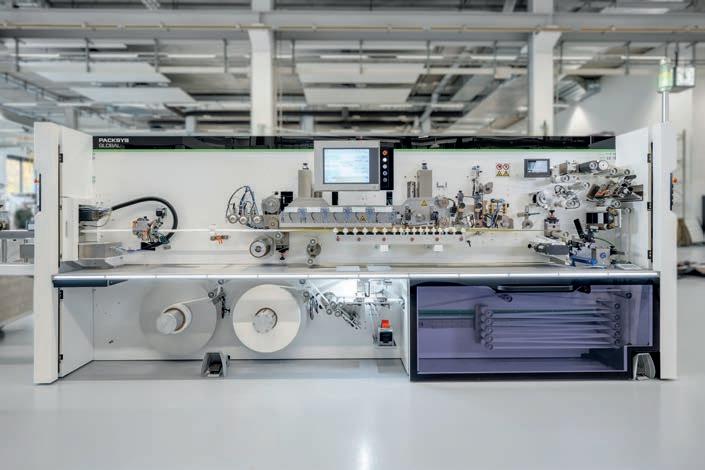

Large tubes, small tubes, long tubes, thick tubes, flat tubes, miniature tubes—tubes are produced in countless sizes and formats for oral care, cosmetics, and in the pharmaceutical industry. The machines that produce the packaging for toothpaste and cosmetic products come from PackSys Global AG in Rüti, Switzerland. PackSys has integrated a monitored changeover solution from SIKO GmbH in order to increase the ease of use of its tube welding machines and ensure the safe adjustment of the various units. PackSys Global AG, which belongs to the Brückner Group, is specialized in systems for the production of plastic tubes. PackSys Global also supplies hot stamping machines for applying decorative metallized coatings, roll cutting and folding machines for plastic closures, as well as packaging machines for cans, tubes, and closures to transport them from the manufacturer to the filler.

Monitored Changeover

Many of the company’s machines require regular changeovers. The most common method to accomplish this is to use mechanical position indicators that are manually set to a position value stored in the documentation. This has a high potential for error, as values may be read and set incorrectly. Especially in the case of frequent adjustments for different tube variants at several positions, the integration of digital position indicators for monitored changeovers is worthwhile as an alternative. The switch to digital position indicators was tested during the development of a new tube welding machine, the FlexSeamer. The choice for the digital AP05 position indicator with IO-Link interface from SIKO was made for several reasons: It stood out due to its compactness, universal applicability regardless

of the axis orientation (vertically or horizontally), and intuitive readability thanks to two LED lights. The displays are used at approximately ten positions throughout the system, for example, to check settings like the thickness or length of the plastic laminates or a varying print image. Another SIKO position indicator, the AP10S, is used to monitor the positioning during linear movements.

From Laminate to Tube

The FlexSeamer is used to unwind a flat belt material, a plastic laminate, from a large roll of material. Depending on the product requirements, the plastics processed are usually material blends that must have good barrier properties in order to minimize the amount of oxygen reaching the product inside and limit the diffusion of aromatic substances out of the tube.

The plastic sheet is folded lengthwise, formed into a tube, and then provided with a longitudinal weld seam, transforming the flat material into an endless tube. The plastic tube is cut into individual sections by a rotary blade. This is the actual body of the tube into which the cosmetic, toothpaste, or pharmaceutical product will later be filled. In a subsequent machine, known as the “Header & Capper,” a so-called shoulder with threaded and capped ends is placed on one of the two sides. The other side is left open so that the contents can be inserted through this opening during filling process and a final transverse weld seam can be applied.

FlexSeamer: High Speed and Reliable Operation

What sets the new welding machine apart is that it features a high speed of 250 tubes per

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 8 automation

The FlexSeamer tube welding machine from Packsys Global offers high speed and reliable operation. Image: PackSys Global

minute, long heating and cooling sections designed for modern laminate types, and intuitive, fast, and reliable operation thanks to the digital capture of most settings. While mechanical position indicators only display the actual value of a position, digital position indicators also show the target value of a setting. For example, the dimensions for a particular type of tube are stored as a recipe in the machine control system and are then transferred to the respective indicators via IO-Link. An operator must then adjust the setting to match the actual and target values. This is the only way to continue with the production process. Reliable indicators here include the two LED lights, which illuminate green only when the values match. As long as a red light remains illuminated on the system, the process must be stopped and readjusted. Emanuel Heusser, Group Manager Automation Engineering in R&D, emphasizes an aspect that is relevant to quality: “It is often only when products are subjected to random destructive testing, which requires a great deal of effort, that the effects of an incorrect setting become apparent. However, if the digital position indicators ensure that the same settings are used throughout the production process, there is no need for downstream quality control. This is a significant added value of monitored changeovers. There are many factors to consider when de-

ciding on a monitored changeover. Positions requiring frequent adjustments are ideal for such an investment in digital monitoring. Another argument can be the costly downtime associated with format changeovers. Reducing setup times can be critical. For rare adjustments or situations where incorrect settings are immediately noticeable, PackSys Global continues to use mechanical position indicators from SIKO. These indicators allow for easily controlled position values. Another option from SIKO’s range of solutions are compact, fully automatic positioning drives. These allow size adjustment at the touch of a button. Furthermore, they are also easy to use in hard-to-reach areas of a machine.

Example Settings for Print Mark Sensors

The added value of the monitored changeover can be illustrated using an example setting, the print mark sensor: To cut the tube section, the cut must be made in the correct position relative to the print image. This is done by applying printed marks to the laminate, which are detected by sensors. The mark is located in a different place on the circumference of the tube depending on the print image. Therefore, the position of the sensor on the circumference must always be slightly different in order to detect this print mark. The position of the print

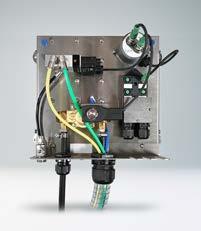

The AP05 (left) and AP10S (right) position indicators always guarantee reliable machine settings for the production of a wide range of tube variants. Image: SIKO GmbH / Istock.com

mark sensor can now be recorded in degrees and stored in the recipe thanks to the AP10S position indicator. This means that the operator does not have to go into the machine to position the sensor relative to the print mark. Instead, the target positioning values are stored for each print image.

Integration of the SIKO Position Indicators

For Emanuel Heusser, the universal applicability of the AP05 on both vertical and horizontal axes was a major plus: “The display is angled at 45 degrees and can be configured via the software in regard to how it should be positioned. This also makes it easier for us to stock different products for vertical and horizontal axes. The actual integration proved to be straightforward, both regarding the mechanical design and the electronic integration.”

Heusser’s assessment of the cooperation with SIKO is also positive: “There has always been a great deal of goodwill. SIKO aims to make wishes and suggestions a reality. For example the AP05 was specially designed with IO-Link for our FlexSeamer project.”

Looking ahead, Aitor Henao sees a clear trend towards digitization and automation of systems, especially in the area of changeovers: “These small details, such as the LED display, make all the difference. They improve the quality of our machines and services, helping customer companies to focus on their business.”

64822 at www.ien.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 9

From the plastic laminate to the finished tube: The FlexSeamer is easy to operate and reliable thanks to monitored changeovers from SIKO (markings). Image: PackSys Global

Rugged Panel PCs for Manufacturing, Logistics, and Energy Management

New modular all-in-one solutions have thousands of configuration options to provide reliable data access and visualization in challenging environments

OnLogic introduced their new Tacton Series of rugged panel PCs and industrial touchscreen displays, designed to empower innovators with the tools they need for advanced automation, industrial control, and data visualization. Tacton was developed from the ground up as a reliable, highly-configurable, secure, and easy to install HMI solution for manufacturing, warehousing, energy management, and transportation applications.

"The Tacton Series gives users the best of both worlds in an all-in-one touchscreen computer," said David Zhu-Grant, Product Management Lead at OnLogic. "We heard from users that they needed a system that was highly configurable, but didn't lock them into paying for features they didn't need. We took that input and designed a solution that can be customized to the unique requirements of a given project, is easy to install, and built to last. We're excited

to see how innovators put Tacton Panel PCs to use empowering next generation edge solutions."

Highly-configurable

Rugged Panel PCs & Industrial Displays

The Tacton is a rugged all-in-one Panel PC with integrated AI acceleration capabilities provided by a range of Intel® 12th Gen Alder Lake-N processors.

An extensive I/O coastline is augmented by customization capabilities via OnLogic's proprietary ModBay™, which can be used to add additional connectivity to support specific user application requirements.

Engineered for Challenging Environments

To help ensure reliability in a wide range of installation environments, Tacton Series displays are UV and vibration resistant, have a wide input power and wide operating temperature range, and are available with ignition sensing for in-vehicle installations. The projected capacitive screens offer a 7H hardness, multi-touch support, optical bonding, and anti-water technology to prevent unintended inputs during washdown. The modular design of the Tacton Series allows the TC401 and TN101 to be configured with one of 18 high-resolution displays. Screens are available in 3 sizes, regular or high brightness, resistive or projected capacitive touch interface, with IP66 or IP69K water

and dust ingress protected front bezels, and can be configured with an optional integrated front facing camera.

Built-in Security Features

To deter unauthorized access, the Tacton TC401 has built-in intrusion detection, which allows users to be notified when the control cabinet in which Tacton is installed is opened. An optional port blocking and cable securing bracket with onboard power supply mounting points helps to protect against access to unused ports and secure cables to reduce the risk of accidental disconnection. Onboard TPM 2.0 hardware security helps protect data by providing secure boot, platform integrity monitoring, and remote attestation capability. The Tacton Series can be installed via standard VESA mount, or panel mounted using OnLogic's patent pending toolless, ruggedized, locking panel mounting clips, which help prevent the clips from unscrewing in vibration-prone installations.

64856 at www.ien.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 10 automation

Cloud Platform for Remote Management of Edge Devices

Private cloud architecture for secure industrial deployment Aetina announced the launch of the EdgeEye cloud-based management platform. The platform aims to simplify edge computing device management, helping enterprises improve operational efficiency.

Edge devices often face challenges such as system instability and crashes, especially when operating in harsh outdoor environments such as earthquakes or extreme temperatures. Therefore, real-time system monitoring and prompt effective troubleshooting are crucial. EdgeEye adopts a browser-based platform, providing an intuitive and user-friendly management dashboard accessible via smartphones, tablets, or laptops. The platform supports out-of-band (OOB) management, allowing management even in offline situations, while continuously monitoring device operation status through in-band management

technology. With both in-band and out-of-band management, EdgeEye enables remote data collection, system monitoring, remote troubleshooting, and power cycling, thus avoiding the risk of prolonged device downtime. Moreover, as awareness of cybersecurity and protection of business confidentiality increases, many enterprises are turning to private cloud architectures to prevent data leaks. Built on a private cloud architecture, EdgeEye allows enterprises to deploy EdgeEye servers within their own domains to ensure data security and privacy. In smart city scenarios, such as traffic surveil-

Who Can Breathe New Life into Your Processes?

Visit us at ACHEMA. June 10 to 14, 2024 in Frankfurt, Germany, Hall 11.1, Booth E 43

#digital innovation

→ IO-Link and Single Pair Ethernet lead to the factory of the future

lance devices spread across the city or the rapid rise in recent years of large-scale green energy devices like solar and battery equipment, troubleshooting and system rebooting by technicians incur not only manpower costs but also difficulties in responding to device downtime in real-time. EdgeEye can simultaneously monitor multiple devices. Once system abnormalities are detected, EdgeEye will proactively send warning notifications, enabling real-time remote rebooting and troubleshooting.

64757 at www.ien.eu

#pharma innovation

→ Perfect growth conditions in the bioreactor through precise automation and sensor technology

#hydrogen innovation

→ Certified sensor and automation technology for electrolyzers, fuel cells, hydrogen refueling stations, and H2 storage

#process innovation

→ We are a leading solution provider that simplifies processes through innovative technologies and customized solutions

Visit our booth to see how state-of-the-art products can be turned into integrated systems as well as complete solutions through comprehensive engineering and service. This saves you time, money, and resources. Our experts will be happy to advise you on process technologies, hydrogen infrastructures, pharmaceutical applications, digital transformation, and many other applications. Get your free ticket now: ↗ achema-en.jumo.info

JUMO

has the right solutions for you!

MORE THAN SENSORS AND AUTOMATION

64764 at www.ien.eu 11

Maximizing Automation Efficiency in Small Spaces with Robots

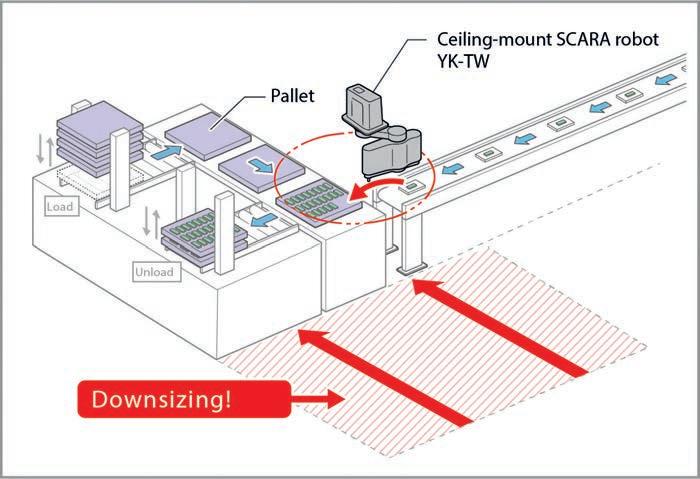

While automating processes using robots is a reliable way to increase production throughput and productivity, the savings in floorspace can vary depending on the type of robot chosen. Where space is at a premium, a ceiling-mounted orbital robot can offer a suitable solution.

Utilising factory floorspace efficiently is as important to productivity as choosing the best equipment. Like human workers, machines such as pick-and-place robots for tasks including packing and palletising need room to move. A keep-out area may also be required to ensure the safety of any human staff who may be working in the vicinity of the robot. The total working area can be significantly larger than the robot itself, preventing factory floorspace from being used for other purposes.

Where incoming items must be moved from a pallet onto a conveyor, a vertically articulated robot can provide a fast and repeatable solution. These are relatively easy to select, install, and program. A secure base is required and can be large depending on the moving masses and payload. The robot is usually positioned to the side of the work area, far enough

from structures such as conveyors to allow the robot to articulate and reach the target positions for picking and placing objects. The size and construction of this is determined according to the moving masses and payload. The complete automation solution, as installed, can occupy a large area.

Effective use of space is key

After some time, inevitably, factory real-estate needs to be reorganised to introduce new equipment and processes, and as business requirements change. An extra production line may be needed, or more space for storing inventory. Expanding or extending the factory may be practically impossible; moving to larger premises expensive and disruptive. Reclaiming the floorspace around a large, heavy robot can appear an attractive alternative. Indeed, there are some options to consider.

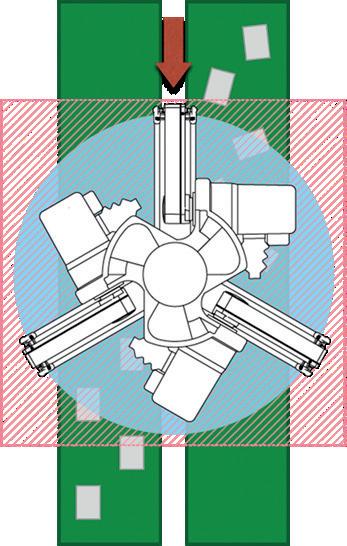

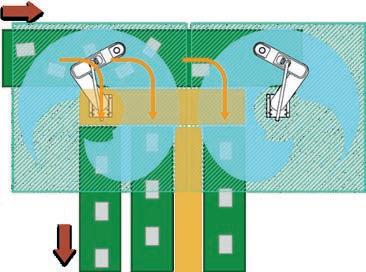

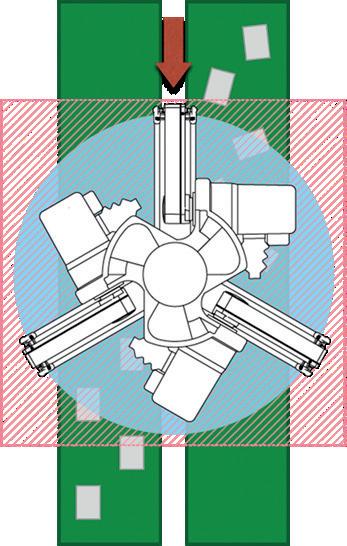

Figure 2: Although the parallel link robot can save floorspace, the total area remains large and the installation can be tall if a long reach is required. Figure 3: Two conventional SCARA robots can sort and conveyorise at high speed, although some floorspace remains unused. © Yamaha Robotics

Some robots, such as parallel link machines, are designed to be installed directly above their working area and can liberate the space to the side of a conveyor otherwise occupied by a vertically articulated robot. However, these can be tricky to setup. A strong frame is needed to handle the robot’s weight, and the robot may be tall if a long reach is required. The savings gained are comparatively small. The example in figure 2 shows a parallel link robot which is installed above a pair of conveyors to pick and align randomly positioned workpieces that are moving at a high flow rate. The robot can operate at high speed, and realises a worthwhile saving in floorspace compared to a vertically articulated machine, as the diagram shows. However, an even more economical use of space would be desirable.

A SCARA robot can allow a smaller footprint, particularly in relation to its load carrying capacity. Choosing a SCARA can deliver other advantages such as easier programming, greater z-axis accuracy, and high speed and acceleration. The example shown in figure 3 illustrates how two SCARA robots can be arranged to pick random items from a single conveyor and place them on separate conveyors according to type. The orange shading shows areas that may be saved if a more space-efficient solution can be found. To achieve the greatest possible savings in floorspace, an orbital SCARA robot may be considered. These can utilise space more efficiently than vertically articulated, parallel link, and conventional SCARA machines. The orbital motion allows access to all points in a circular area beneath the robot and high speed as well as high accuracy are both achieved. The arm movement range can be

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 12 automation

Fig. 2

Fig. 3

limited if required, to allow use in extremely small spaces.

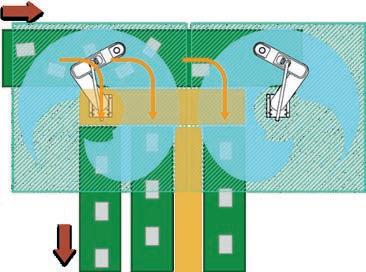

Compared to conventional SCARA robots, a centrally positioned orbital SCARA can do the work of two machines when moving items from one conveyor onto three. The orbital machine occupies considerably less floorspace

Saving space the right way

A system integrator working with Yamaha Robotics found that the YK-TW series orbital SCARA series expanded the company’s opportunities to build more compact solutions to fulfil end-users’ requirements. Choosing a YK-TW model with a payload of 5 kg and a large movement range of φ1,000mm ensured enough reach to pick items from large pallets while occupying a compact overall working area. The chosen model has extremely low height of just 392 mm and weighs just

Yamaha YK350TW

orbital SCARA with high footprint/reach ratio

© Yamaha Robotics

The orbital SCARA saves floorspace, eliminates safety guards, and achieves a low overall height. © Yamaha Robotics

27 kg. Taking advantage of the properties of this orbital SCARA, the team was able to deliver a uniquely space-efficient solution that led, ultimately, to a winning tender.

As picture 4 shows, the range of motion allows the orbital SCARA to be installed within the area of the conveyor thereby eliminating any need for safety guards. With the conveyor height of 900 mm and the 600 mm total height of the robot mounted on its gantry, the total height of the installation is about 1.5 metres. Assuming a typical human-worker’s height of 1.7 metres, the orbital robot contributes towards a more comfortable environment for people to work in without feeling dominated by large robots.

In addition, Yamaha can supply a dedicated mounting bracket for YK-TW robots that relieves engineering teams of laborious strength calculations and significantly reduces project development time.

Conclusion

Orbital SCARA robots can help save space in factories and also permit a lower overall equipment height compared to vertically articulated robots as well as other space-saving options such as parallel link and conventional SCARA robots. In projects where saving floorspace has a high priority, orbital SCARA can be operationally efficient and permit a fast project turnaround.

64838 at www.ien.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 13

Scaling Roll-Out of Generative AI for Industrial Engineering

The aim is to speed up the generation of complex automation code for the engineering process in industrial environments

At Hannover Messe 2024, Siemens presented their first generative artificial intelligence (AI) product for engineering in an industrial environment. The Siemens Industrial Copilot, the generative AI-powered assistant, is now seamlessly connected to the Totally Integrated Automation (TIA) Portal. This will enable engineering teams to find the right help topic and to generate a basic visualization and code faster for programmable logic controllers (PLC). The Siemens Industrial Copilot for TIA Portal Engineering will be available for download from the Siemens Xcelerator marketplace starting in summer 2024.

From theory to scale

At Hannover Messe 2023, Siemens and Microsoft jointly unveiled their vision for a

generative AI-powered assistant: The Siemens Industrial Copilot, that includes automation and process simulation information from Siemens’ digital business platform Siemens Xcelerator. It has been enriched with the large language models in Microsoft Azure OpenAI Service, for example to augment the creation and optimization of code in software for factory automation. At the Smart Production Solutions (SPS) trade show in the fall of 2023 and in collaboration with Schaeffler AG, Siemens presented a generative AI-enhanced production machine for the first time. Siemens is now moving from theory to scale with its first generative AI-powered product for engineering.

The Siemens Industrial Copilot will enable industrial customers of all sizes to harness the power of industrial-grade generative

AI to transform their operations. Industrial automation solution provider Grenzebach Group, a family-owned business and an early adopter of the Siemens Industrial Copilot, is testing how generative AI can augment industrial automation engineering and support engineers to reduce time, effort and probability of errors.

Dr. Steven Althaus, CEO Grenzebach Group, says: “Generative AI is a must have. At Grenzebach, we’re committed to harnessing its power to stay ahead of the game. The Siemens Industrial Copilot will allow us to make the most of the rapidly increasing amount of data available in a factory. And it will take human-machine collaboration to the next level. With Siemens, we can address the skilled labour shortages, boost innovation, and significantly increase the productivity of our workforce.”

Huge benefits for engineering

Features of the new Siemens Industrial Copilot for TIA Portal Engineering include automated code generation in structured control language (SCL): The TIA Portal can take the code suggestion directly from the AI, eliminating the need to copy and paste. It’s also possible for the Siemens Industrial Copilot to explain SCL code blocks or to guide and easily create an initial machine or plant visualization in WinCC Unified. In addition, engineering teams can search Siemens manuals in natural language. Customers will have the option to access their private instance of Azure OpenAI Service which doesn’t use customer data to retrain models.

64837 at www.ien.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 14 automation

Ensuring Safety and Efficiency with the Right HMI

18 MEASUREMENT & INSTRUMENTATION: Better Cleaning and Protection for Reliable Sterile Processes with Electronic In-line Pressure Measurement.

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024

ISSN : 2031-9177 June 2024 - Volume 21 JUNE 20 New Products and Solutions for the Processing Industries

Page 16

measurement&instrumentation

Ensuring Safety and Efficiency with the Right HMI

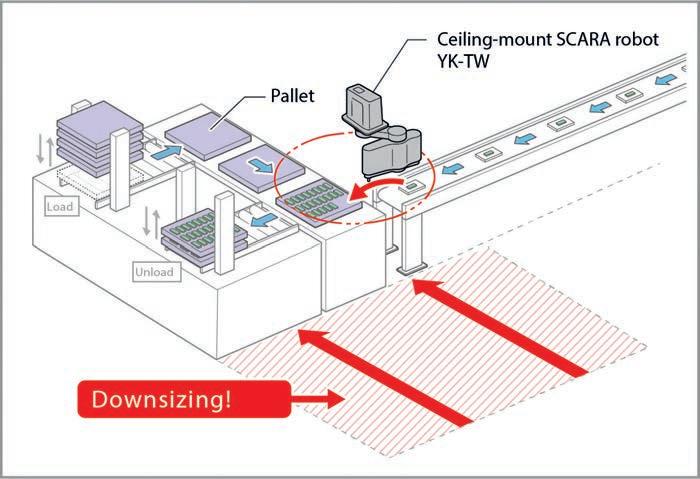

The VisuNet GXP and VisuNet FLX series HMIs from Pepperl+Fuchs set new standards for safety and efficiency in hazardous industrial environments, meeting rigorous explosion protection requirements while offering sleek designs and flexible adaptability. Featuring modular designs and advanced technologies, these HMIs ensure operational excellence and compliance with industry standards, making them a smart investment for industries prioritizing safety and productivity.

In the complex and often hazardous landscape of industrial operations, ensuring maximum safety while maintaining operational efficiency is not only a goal, but a necessity. Human-machine interfaces (HMIs) are the critical link between the human operator and the sophisticated machinery used in today's industry. The VisuNet GXP and VisuNet FLX HMIs from Pepperl+Fuchs represent a significant step forward in the field of explosionprotected HMIs. Developed with precision and foresight, these series are an example of how cutting-edge technology can meet strict safety standards to protect human lives and infrastructure investments.

Explosion protection is more than compliance and safety

The inherent risks of operating in environments with explosive atmospheres - whether

due to flammable gases, vapors or combustible dusts - require HMIs that do more than just meet safety standards. The VisuNet GXP and FLX series not only meet ATEX, IECEx and NEC requirements, as well as other global standards, but also offer a sleek design. Thanks to the innovative design, these HMIs ensure that there is no ignition source, providing safety for operators and safety managers alike. The integration of intrinsically safe circuits and sand-encapsulated enclosures illustrates the holistic safety approach of these series.

Slim design and flexible adaptability up to Zone 1/21 and Div. 2

Unlike the bulky and heavy designs often associated with explosion-proof devices, the VisuNet GXP and VisuNet FLX series feature a lightweight and compact form factor without compromising on safety or functionality. This

design innovation not only simplifies installation and mobility, but also opens up new possibilities for system integration and customization. The adaptability of the two HMI series is also underlined by the fact that they allow for a variety of customized modifications, from mobile trolley solutions to a wide range of mounting options, ensuring that all operational requirements are met precisely.

Precision in hygiene and safety in the pharmaceutical industry

The strict regulatory environment in the pharmaceutical industry makes the development and operation of HMIs even more complex. The VisuNet GXP and VisuNet FLX series take up this challenge with features that meet the special requirements of the pharmaceutical industry: GMP-compliant design, easy cleaning and minimized risk of contamina-

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 16

Versatile HMI portfolio for different requirements. Picture: Pepperl+Fuchs

tion. These HMIs feature an edgeless design and an antibacterial keypad, housed in an IP66-rated stainless steel enclosure (or alternatively aluminum) to withstand aggressive cleaning agents. The integration of VisuNet Control Center add-on software also increases operational efficiency by enabling remote management and maintenance of all HMIs, reducing the need to physically enter cleanrooms, which is often preceded by a time-consuming decontamination process. VisuNet Control Center makes it possible to install updates on all devices simultaneously from a central location. This guarantees quick and easy management of HMIs and ensures that cybersecurity standards are always up to date.

Customized solutions for demanding industries

In industries where the environment itself presents considerable challenges, the VisuNet GXP and VisuNet FLX series are characterized by their ruggedness. The new extended temperature variant of the VisuNet FLX HMI series has a marine-grade aluminum housing and can withstand even extreme temperature fluctuations from -20 to +50 °C. Together with suitable sunshields, they are therefore perfect

for outdoor applications, for example in ship and truck loading and filling applications. The option of attaching additional sunshields to protect against sun, rain and environmental influences further underlines the adaptability of these HMIs to any application scenario.

Convenient maintenance thanks to modular design

The concept of modularity is at the heart of the VisuNet HMI series and not only enables

Modularity means flexibility: The VisuNet HMI systems consist of 3 modules: Display Unit, Computing Unit and Power Supply Unit. Picture: Pepperl+Fuchs

flexible customization, but also simplifies maintenance. The division into three main components - the Display Unit (DPU), the Computing Unit (PC Unit or Thin Client Unit) and the Power Supply Unit (PSU) - enables parts to be replaced and upgraded quickly, even in hazardous areas. This design approach minimizes downtime and logistical issues associated with repairs and demonstrates an understanding of the operational realities of the industry working in hazardous areas.

Setting new standards for HMIs in hazardous areas

Manage all thin client HMIs from a central location with VIsuNet Control Center. Picture: Pepperl+Fuchs

The VisuNet GXP and VisuNet FLX series from Pepperl+Fuchs are more than just HMIs; they are proof of the ability to combine safety, efficiency and flexibility in the most demanding industrial environments. By integrating advanced technologies, meeting the strictest safety standards and offering exceptional customization options, these series set new standards for what can be expected from HMIs in hazardous areas. For industries looking to improve their operational capabilities while ensuring the safety of their employees and equipment, the VisuNet series is a smart and future-proof investment.

64824 at www.pcne.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 17

measurement&instrumentation

Better Cleaning and Protection for Reliable Sterile Processes

Absolute sterility, optimised processes and lower operating costs – the food industry is challenged to align its production procedures amid these conflicting interests. The measurement technology employed to check individual process parameters plays a decisive role here. WIKA has now opened up a new chapter in pressure instrumentation: an in-line process transmitter with a “dry” measuring cell takes monitoring of this variable in sterile applications to a higher level.

Hench, WIKA Alexander Wiegand SE & Co. KG, Product Management Process Instrumentation Pressure

Production under aseptic conditions is the most vital prerequisite of flawless product quality. The ability to clean pipelines and tanks without residue is a central task in the sequence of individual steps. That sounds easier than it is in practice. All processes are instrumented throughout with heterogeneous components, peppered with shut-off valves, pumps and measuring devices of assorted origins. Not surprisingly, this enormous di versity entails considerable effort for cleaning. Several cycles are necessary involving dif ferent substances such as citric acid and lye, with sterile saturated steam to finish off. This final step in the clean ing process is also a critical moment. If steam at a temperature of up to 150°C comes together with water particles from previous cleaning cycles, explosive reactions are inevitable. These hydraulic shocks –also known as “water hammer” – take the form of pressure surges that make plant opera tors’ hair stand on end. The force unleashed by water hammer can dam age the pressure measuring instruments installed in the process to the point of failure. The only option in this situ ation is to stop the process and re place the affected devices.

Faster detection of damages

However, since not all damage results in failure, it may not be detected immediately, in which case the impact of water hammer could well be even more severe – for example, if the product is contaminated. This is because some of the measuring points in food production are equipped with diaphragm seal systems with integral pressure or process transmitters. If their diaphragms on the process side are damaged, the transmission fluid will leak from the diaphragm seal and contaminate the product. Contamination can also occur with ceramic sensors. If damaged, these immediately go into error mode, yet detached ceramic particles get into the medium nevertheless. Here, too, product purity is no longer ensured. In most instances, the affected batch must subsequently be destroyed. The economic con-

DMSU21SA diaphragm seal system with built-in diaphragm monitoring. Source: WIKA

sequences are devastating: since such plants generally run 24/7, a large amount of product will already have been turned over before counteraction is taken. In the past, loss on this scale could only be avoided by using a diaphragm seal system with built-in diaphragm monitoring (a patented WIKA solution). This works with a double diaphragm: if the diaphragm on the process side is damaged, the system simultaneously outputs an alarm signal. The second diaphragm then seals off the process until the problem has been fixed. WIKA’s new development for monitoring pressure in sterile processes is aimed at further reducing the potential hazards outlined above while at the same time optimising the cleaning process. As the name suggests, the DMSU22SA in-line process transmitter with the HART®7 communication protocol and a flanged connection becomes an integral part of the pipeline. Its design enables better flow behaviour than conventionally mounted instruments.

Process optimisation with hermetically sealed sensor elements

An advanced hygienic design concept makes the measuring element many times more resistant to water hammer and other extreme process conditions. The DMSU22SA also records the pressure without transmission fluid, so that in the event of damage contamination is avoided. This is the chief difference compared to traditional in-line measuring arrangements with in-line diaphragm seals or flush mounted process transmitters. At the heart of the new device is a hermeti-

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024

18

Author: Tobias

cally sealed sensor element made of 316L stainless steel. Similar to a Bourdon tube, it is elliptical and is accordingly deformed under pressure. A Wheatstone bridge attached to the sensor body allows pressure-induced changes in the electrical resistance to be accurately detected and sent to the transmitter. The DMSU22SA also has a PT sensor for active temperature compensation between 10°C and +80°C. Error compensation is up to ten times better than with conventional devices, so that more precise process control is possible.

Although the pipeline and the pipe sensor have different diameters, a drag coefficient measurement has confirmed that the new measuring instrument exhibits significantly better flow behaviour than other solutions, including those with hygienic connections. In other words, the dead space-free design means less energy is needed to maintain the process pressure or for CIP / SIP processes and reduces the consumption of water and cleaning agents.

The pipe sensor has an extra-robust wall for enhanced process reliability. Depending on the version, it is up to ten times thicker than a standard diaphragm seal (0.05 mm). Yet persistently unfavourable process conditions

DMSU22SA in-line process transmitter with HART®7 communication protocol and a flanged connection for improved product safety.

Source: WIKA

can cause leaks in spite of this, with the result that product gets into the space between the sensor and the support tube. This space is evacuated and has built-in vacuum monitoring, with a sensor that reacts at a pressure of just 50 mbar. The plant operator receives

Solutions for retrofitting and new installations

Pressure monitoring implemented using an in-line process transmitter is primarily recommended for new plants. Retrofitting an existing plant with the new system gives rise to disproportionately high costs for the operator. To minimise the risk of product contamination, manufacturers can opt for a retrofit comprised of WIKA’s DMSU21SA diaphragm seal system with built-in diaphragm monitoring. WIKA’s in-line process transmitter with a “dry” measuring cell and built-in sensor monitoring makes processes in food production more reliable. This new development with the model designation DMSU22SA prevents product contamination and enables more precise process control thanks to active temperature compensation. Its flow behaviour reduces the consumption of operating fluids. The device is primarily designed for use in new plants with digitised processes.

64827 at www.pcne.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 19

OPTIMISEDRADIATION-RESISTANTLENSES

Non-browninglensesfordifferentCMOSsensorsizes Withrecentadvancesintechnology-CMOSsensorsare beingdevelopedcapableof withstandinghigherlevelsof radiationthanwaspreviously possiblemakingthemaviable optionforamuchlargerrange ofnuclearapplication.Inordertotakeadvantageofthehigher resolutioncolourimagesprovidedbyaCMOSsensor,morenuclear cameramanufacturesarelookingtousethemasanalternativeto traditionaltubes.Asaresult- Resolve Optics hasnotedagrowing demandforcustomnon-browninglensesoptimisedforthelarge varietyofdifferentformatsthatCMOSsensorsareproducedin. To fulfilthegrowingdemandfromdifferentmanufacturersofradiation tolerant,colourCMOScamerasResolvedevelopeda10xnonbrowningzoomlensdesigntoprovidebetterHDcolourimagesfor nuclearapplications.TodateResolveproducedversionsofthis non-browninglensoptimizedfor¼-inch,1/3-inchand2/3-inch CMOSsensorformats. TheHDzoomlensdesignusesnon-browning glasses,speciallyselectedtoproduceclearsharpimagesfreeof thestrongyellowtintthathastraditionallybeenalimitingissue whenusingnonbrowninglensesoncoloursensors.Theglassused intheselensescanwithstandlong-termexposuretoradiationup toanaccumulativedoseofonehundredmillionradandtemperaturesupto85°Cwithouttransmissionloss.

64816atwww.pcne.eu

IO-LINKCONDUCTIVITY-ANDPH-SENSOR

Foreasieraccesstodiagnosticdataofsensors

Bürkert isprovidingcustomerswith morediagnosticdatafromitsType 8222conductivitysensorsandType 8202pHsensorsbyembeddingthe IO-LinkandBürkertbüSindustrial protocolsintoitsELEMENTNeutrino rangeofproducts.Thedigitisationof theseproductsallowsmaintenance andoperationstobestreamlined throughremotemonitoringcapabilities,supportingprocessuptimeinwaterqualityorchemicalapplications. Operatorsarenolongerlimitedtoafewoutputs,buthave accesstoawealthofdiagnosticdataonmanyotherfactorsthat affecttheperformanceandconditionofthesensors. Andallofthis canbeaccessedremotely.Theabilitytostreamlinemaintenance throughremotemonitoringisakeybenefit.Diagnosticscanbe carriedouttodeterminetheconditionofequipmentandthenature ofpotentialrepairsbeforevisitingthesite.Thisallowstheright sparestobepreparedbeforeleavingtheworkshop,avoiding multipletrips.ThisgivesOEMstheopportunitytoofferproducts thatactivelyreducemaintenancerequirementsandcosts. Forend users,accuratereal-timesensorandprocessdataenablesamore proactiveapproachtoequipmentmaintenancewhich,combined withreducedmaintenance,significantlyimprovesuptimeand productivity-allwhilereducingoperatingcosts.

64668atwww.pcne.eu

DIGITALPROCESSANDTEMPERATUREMETER

Shallow-depth1/8''casingwithIP65frontprotection Moore Industries announcesthe 330R21/8DINprocessand temperaturepanelmeterto replacethediscontinued330R processmonitor.The330R2 coversawiderangeofprocess andtemperatureapplications withitsuniversalinputanddualprocessrelays.Itfeaturesa UV-resistant,sunlight-readable4-digitdisplay.Withanoperating temperaturerangeof-40to65°C,the330R2isidealforharsh outdoorenvironments.The330R2ishousedina1/8DINcaseand acceptsawiderangeofanalogueinputsincludingprocessvoltage (0-5V,1-5V,0-10V,±10V)andcurrent(0-20mA,4-20mA,±20mA) inputs,100OhmRTDsandthefourmostcommonthermocouples. Highlightsofthe330R2includetheabilitytoprovide24VDCto powerthetransmitter's4-20mAsignalwiththehigh-levelinput poweredunits,simplifyingwiringandreducingoverallinstallation costs.Inaddition,anisolated4-20mAoutputoptionisavailablefor retransmissionofprocessandtemperatureinputs.The330R2isa versatileanddurablepanelmeterinashallow1/8DINhousing withaNEMA4X&IP65frontpanelwithadjustabledisplay intensityforoutdoorapplications. With2SPDTFormCrelays,the 330R2providesalarmandcontrolflexibilityforcriticaltemperature andprocessloops,includingpumpcontrolapplications.Themeter canbequicklyandeasilyprogrammedfromaPCorinthefield.

64705atwww.pcne.eu

FREQUENCYINVERTERSOLUTIONSFORPUMPS

Minimisingdowntimeswithpredictivemaintenance

TheKKostal InveorMPPandMPMfrequencyinvertersolutionsarenow equippedwiththe"VibrationMonitoring"functionasstandard.Duringoperation,thesystemcanbemonitoredfor irregularitiescausedbyvibration.The dataiscollectedandcanbefurther processedviaMQTT.Fortheuser,thisis thegatewaytopredictivemaintenance, whichenablesthemtopreventunexpectedfailuresandminimisedowntime costs. TheInveorgivestheuserthegreatestpossibledegreeof freedomwhenconfiguringthedrivesystem,asthedrivecontroller issuitableforalltypesofmotor.Thismeanstheycanplanforthe futureandarelessdependentonrareearths.Savingscanalsobe madeonacquisitioncosts,astheInveorcanoptimallycontrolany brandofmotor,meaningthatusersarenotforcedtobuyamore expensivesystemconsistingofmotorandinverterfromthesame supplier. TheInveorfrequencyinverterisdesignedtobemounted directlyontothemotor.Plug&Playcreatesamodularunitconsistingofmotor,gearboxandinverter.Costsavingsareachievedby eliminatingtheneedforacontrolcabinetandlongmotorcables withappropriateshielding. Thesensorlesscontrolprocessisable tooptimallyrecognisetherotorpositionandreliablycontrolthe motor,evenatlowspeedsrightuptostandstill.

64752atwww.pcne.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 20

MODULARSENSORCLEANINGSYSTEM

Flexibleusewithstaticandretractablefittings

WiththeUniclean700series,KKnick introducesamodularcontrolsystem thatcanbeinstalledveryquicklyand cost-effectivelyasaflexibleentrylevelsolutionforautomatedsensor cleaning.Withitsinnovativeconcept andfocusedfunctionality,theUniclean 700complementsexistingportfolioof KnickcontrollersusedintheestablishedcCaresystemforfullyautomatedcleaningandcalibration.Themodulardesignoftheindividual componentsgivesthecustomerahighdegreeofflexibility. However,thecompactdesignmakesinstallationveryeasy.With theUniclean700controlsystems,Knickofferstheuseraflexible andexpandablesolutionthatissuitableforusewithbothstatic andretractablevalves. Thecost-effectivesolutionisusedinwaste watertreatmentplantsandinthemetalprocessingindustry.Thisis whereheavysoilingandhighsensorwearareencountered.The newseriesalsoexcelsinthefoodindustry.Insugarfactories,for example,sensorsoftenbecomeencrusted. Withthenewseries, Knickoffersanentry-levelsystemforautomaticcleaningofpH sensors,whichisvaluableinmanyindustries.Italsoworkswith thirdpartytransmittersorfittings. Themodulardesignallowsfor easyconversionswhenneeded.Thismeansthatcleaningcontrol systemscanbequicklyadaptedtoprocesschanges.

64688atwww.pcne.eu

SAFETYFEEDERSYSTEM

Forcontinuousorbatchprocessesinbatteryproduction

ThenewCS+loss-in-weightfeeder systemfrom S Schenck Process perfectlymeetsthe different requirementsinbatteryproduction. It canbecustomizedtomeet individualcustomerrequirements. Themodulardesignmakesitpossible tocoveralargefeedingrangewith justonefeedertype:CS+issuitable forsmallquantitiesfrom30litresperhouraswellasforhigh feedingcapacitiesofupto3,000litresperhour.Toprevent metal-to-metalcontact,componentscanbeoptionallycoated. Smoothsurfacesandlimitedrelativespeedsoftheagitatorand screwminimizemetalabrasion.ThepatenteddesignoftheCS+ combinesthiswithaquick-actingflapthatpreventsmaterialfrom tricklingoutduringthebatchprocess. TheCS+loss-in-weight feedersystemalsoofferstheuserpermanentlyhighaccuracyfor consistentlyhighproductquality.Intelligentpressuremanagement preventstheingressofambientairandmoisture.Thisprevents pressurefluctuationsfromhavinganegativeimpactonthedosing accuracy.Atthesametime,thesystemimpresseswithitssimple andpracticaldesign,whichalsoallowsseveraldosingunitstobe installedinthesmallestofspaces.Lastbutnotleast,CS+fits seamlesslyintosystemconceptsthatrelyonaconsistentcontainmentconcepttolimitdustemissions.

WIDE-RANGEAIRQUALITYSENSOR

Real-timeinsightsfortheidentificationofpollutants Vaisala announcedthelaunchof theAirQualityTransmitter560 (AQT560)acompactairquality sensorwithawidedetection range—PM1,PM2.5,andPM10— andauniquecalibrationsystem andalgorithmsthatenableunmatcheddetectionaccuracyand efficiency.TheAQT560standsout asthemostdependablecompact air quality sensor for measuring particle matter (PM). Its precision in detecting aerosol number concentration of particles within the size range of 0.3 to 10 microns is unparalleled. As a result, the sensor excels in accurately providing PM1 concentrations for sources primarily influenced by combustion (such as traffic, residential wood burning, and wildfires), PM2.5 concentrations dominated by long-range transport, and PM10 concentrations driven by abrasive processes (such as road dust, sandstorms, construction, and mining). Leveraging Vaisala's intelligent humidity control system and algorithms, the sensor detects the most important pollutant gases in ambient air, such as NO, NO2, CO, and O3. The sensor is designed for highest dependability with cutting-edge optical components and a rotary vane pump to provide optimal flow management and control, delivering trustworthy intelligence. It can be used standalone or with existing networks.

64689atwww.pcne.eu

3D-PRINTEDMAG-DRIVEPUMPSHROUD High-techshroudavoidsdisadvantagesinoperation Oneofthetechnicalhighlights from K KSB fortheACHEMA 2024willbethenew3D-printedcontainmentshroudfor mag-drivepumpsofthe Magnochemtypeseries. NamedMagnoProtect,the componentoffersthesamesafetyasadouble-walledcontainment shroud-withoutthelatter'sdisadvantagesofheatingupand havinghigheddycurrentlosses. Whileprovidingcomparable safety,theoverallefficienciesofthenewmag-drivedesignsclearly exceedthoseofcannedmotorpumps.Designedwithastructureof channels,thenewcontainmentshroudoffersasecond,redundant, staticsafetybarrierpreventingleakageofthefluidhandled. A pressuretransmittermonitorsthevacuumgenerated,whichis presentduringnormaloperationinthechannelsofthecontainmentshroud.Thecontainmentshrouddesignischaracterisedby highmechanicalstrengthandgoodwearproperties.Ithasbeen optimisedtominimiseheatlossesandeddycurrents. Convertinga standardisedchemicalpumpwithmechanicalsealtoamagnetic driveiseasierandmorecost-efficientthanretrofittingitwitha cannedmotor.ThegeometryanddimensionsofthenewcontainmentshroudareintegratedinthemodularsystemofMagnochem, allowingmetallicorceramiccontainmentshroudstobereplaced easily. Thisenablesoperatorstoupgradeolderpumpsets.

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 21

64706atwww.pcne.eu

64758atwww.pcne.eu

22 test & measurement

Impact without Rebound: Miniature Shock Absorbers for Drop Test Construction

When testing wheelchairs, manufacturers play it safe for understandable reasons. That is why three aspiring mechanical engineers took no risks when they developed a drop test construction for wheelchairs on behalf of the renowned German company MEYRA. They relied on miniature shock absorbers made by ACE to protect the inner life of their construction.

Recently, Arne Hankemeier, Julian Raimann and Tobias Ridder completed their training as state-certified technicians in the field of mechanical engineering at Felix-FechenbachBerufskolleg, a vocational college in Detmold, Germany. Volker Geise, responsible for educational management there, states that the proportion of practice-oriented work is very important in the mechanical engineering department at the technical college. Therefore, he welcomed right from the start that his three graduates wanted to work closely

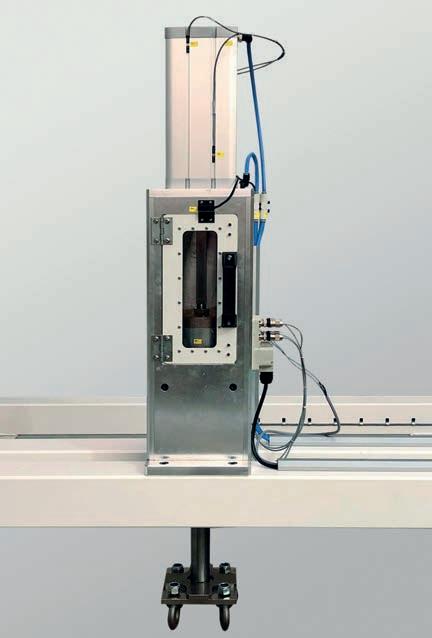

Drop test unit for testing the stability of wheelchairs with controls in the foreground on the right and the pneumatically operated construction for engaging and disengaging the wheelchairs at the top. (Felix-Fechenbach-Berufskolleg)

with nearby company MEYRA GmbH as part of their final thesis.

As a member of internationally operating MEYRA Group from Kalldorf, Germany, the company is one of the leading manufacturers of high-quality wheelchairs and has also made a name for itself as a supplier of rehabilitation equipment. Following their claim “We move people”, MEYRA supports and motivates many people with disabilities around the world to achieve more mobility and independence. It is also constant exchange with those affected as well as with medical experts and those in therapy and care that enable MEYRA to develop practice-oriented products, last not least in close cooperation with medical supply retailers. This holistic, practical approach was very suitable for the learning group at the German college, although another connection existed: Tobias Ridder, one of the three young talents, was already working as a designer for custommade products at MEYRA when he decided together with Arne Hankemeier and Julian Raimann to develop a professional drop test unit for wheelchairs as his final thesis at the college. With full support from his employer, they embarked on building a construction that is mainly intended to test the load capacity of MEYRA’s new wheelchair models.

Requirement: High load capacity

The testing unit is designed in such a way that each wheelchair is loaded at first with the maximum permissible weight and then gets moved into the construction. Each model is then latched onto a gripper and raised using pneumatics and, after being latched, dropped from a previously defined height. To dampen the force of the lifting device's impact plate

The wheelchairs are latched, pneumatically lifted, unlatched and dropped, with the sensitive inner workings of this device being hydraulically dampened. (Felix-FechenbachBerufskolleg)

and to protect their whole structure the three technicians considered installing shock absorbers. This plan was backed by their goal that not only the stability of the wheelchairs should be proven, but the test device itself should also be as stable as possible and not have to be re-

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024

Self-adjusting miniature shock absorbers from the MC5 to MC75 series made by ACE with thread sizes from M5x0.5 to M12x1 for the reduction of effective weights between 0.5 kg and 72 kg.

paired after just a few cycles of use. In an interview the students said, they were familiar with one of the main advantages of hydraulic damping elements in that they work without rebound effects due to their linear characteristics. “Thanks to a presentation by ACE Stoßdämpfer GmbH, which we were able to join as part of our lessons, we knew that certain shock absorbers can not only solve the tasks of deceleration better in terms of their damping properties, but they also help ensure that testing is carried out more quietly than before, especially when comparing the damping tasks to the performance of steel springs or rubber buffers,” remembers Arne Hankemeier. Since ACE offers tools for sizing on their homepage www.acecontrols.co.uk/uk/sizing.html and since many other helpful services accompany the products, the students turned to ACE’s European headquarter in Langenfeld, Germany. To their delight the sales engineers not only confirmed the design data of the young engineers on the phone, they also sampled them with four miniature shock absorbers free of charge. This support of young engineers has been ACE's practice for years, as the company has experienced that sponsoring young academics and technical schools often result in innovative solutions and even new product series.

Problem solvers: Hydraulic damping elements

After the team received the four MC25EUM miniature shock absorbers from ACE everything happened very quickly: Due to their compact design the hydraulic components are predestined to be quickly integrated, also into already existing designs. Available in ver-

sions with and without diaphragm seal technology, the shock absorbers optimize a variety of machines by decelerating masses quickly and non-destructively. Customers can choose between adjustable and self-compensating versions. The latter were used in this case. The outer bodies of the miniature shock absorbers are produced from one solid piece of steel and are filled with temperature-stable special fluids. These hydraulic machine elements also come with integrated positive stops and are maintenance-free, having been developed and perfected by ACE, the technology and market leader for industrial shock absorbers for more than 60 years. The models used in this application provide a stroke of 6 mm and are suitable for energy capacities of 2.8 Nm per cycle. The teamwork of the three college graduates worked perfectly throughout the entire project. Tobias Ridder took over the design, while Arne Hankemeier and Julian Raimann were responsible for design and documentation. In the end, the integration of the four components sponsored by ACE was a small exercise, says Arne Hankemeier and draws this positive conclusion: “We were able to make the adjustment precisely using the continuous thread of the components and reliably hold it in the preset positions using the supplied lock nuts. These dampers really absorb the permissible load reliably, quietly and quickly and fulfill their purpose to the fullest extent. We have also noted very happily in our test series that quite a variety of large masses can be decelerated almost without any noise and certainly with no rebound within the small space of our construction.”

64821 at www.ien.eu

FREE DIGITAL SUBSCRIPTION N° 6 - JUNE 2024 64745 at www.ien.eu

(ACE)

24 electronics & electricity

Cable Carriers for Control Stations and Control Rooms

Cooperation to provide high-quality 24-h workspace systems for a variety of industries

BRAND® CONTROL ROOMS is known for its customized workplace systems, for example in alarm response rooms, control rooms, trading rooms, and control centers. The company offers turnkey solutions for all industries that make intensive use of control and monitoring technologies. The references range from projects for police and fire service control rooms to the monitoring of complex industrial processes. When developing their systems, BRAND® CONTROL ROOMS places a special focus on health & safety, ergonomics, and durability. Control rooms and control centers are designed for a service life of at least 10 to 15 years with intensive 24/7 use. The requirements for third-party components are therefore accordingly high. A challenge that TSUBAKI KABELSCHLEPP was ready to accept.

Cable management for up to 14 screens

The monitors, which play a crucial role in process control and monitoring, are a key element of the workplace systems from BRAND® CONTROL ROOMS. In addition to individual 24-inch up to 55-inch monitors, the systems offer space for up to two rows with seven screens each. The split-level design of the desk allows the monitors to be electrically adjusted to seated and standing height independently of the tabletop. Desks with a straight tabletop also offer the option for electrical depth adjustment of the monitors.

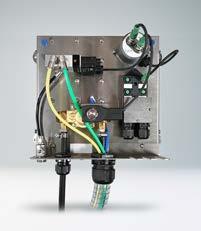

BRAND® CONTROL ROOMS uses TSUBAKI KABELSCHLEPP cable carrier systems to supply its workplace systems with power and data continuously and reliably. The plastic cable carriers from the next generation of EasyTrax® are particularly suitable for this complex application thanks to their compact design.

“The particularly compact ET1455 cable carrier used here has been nicknamed the ‘speedy lamella’ because of its flexible lamellas that allow cables and hoses to simply be pressed in,” explains Werner Eul from KABELSCHLEPP.

Modular system for the furniture industry

In addition to EasyTrax®, TSUBAKI KABELSCHLEPP also offers the PROTUM® Office series for the furniture industry – either as standardized sets for OEM production or as individual configurations for special projects.

Cables are simply pressed into the cable carriers from the EasyTrax® series manufactured by TSUBAKI KABELSCHLEPP – the fast installation saves time and money. Image: TSUBAKI KABELSCHLEPP