DESIGN & ENGINEERING

Standout Custom Packaging for the World’s

Leading Brands and Emerging Companies

Standout Custom Packaging for the World’s

Leading Brands and Emerging Companies

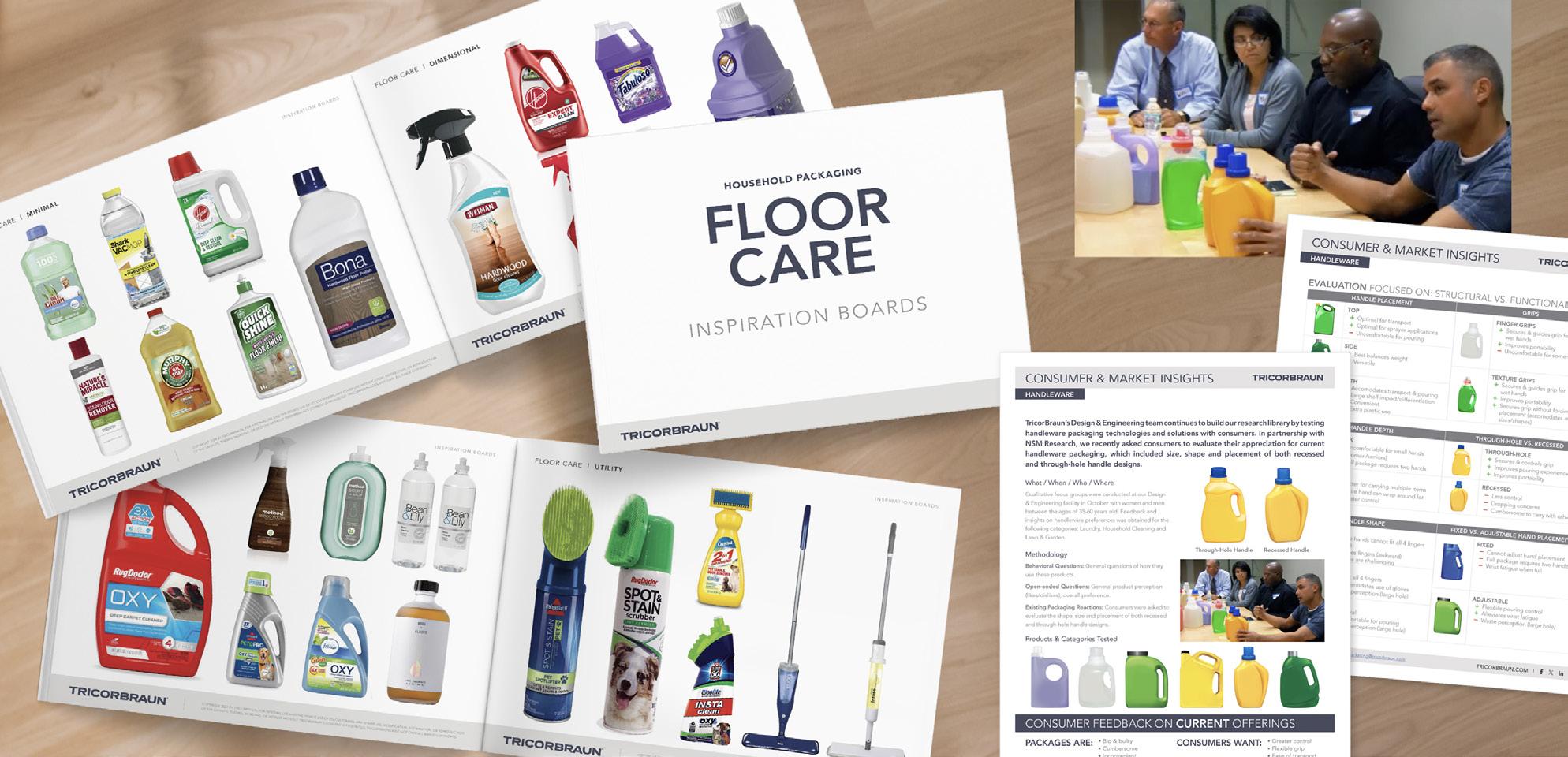

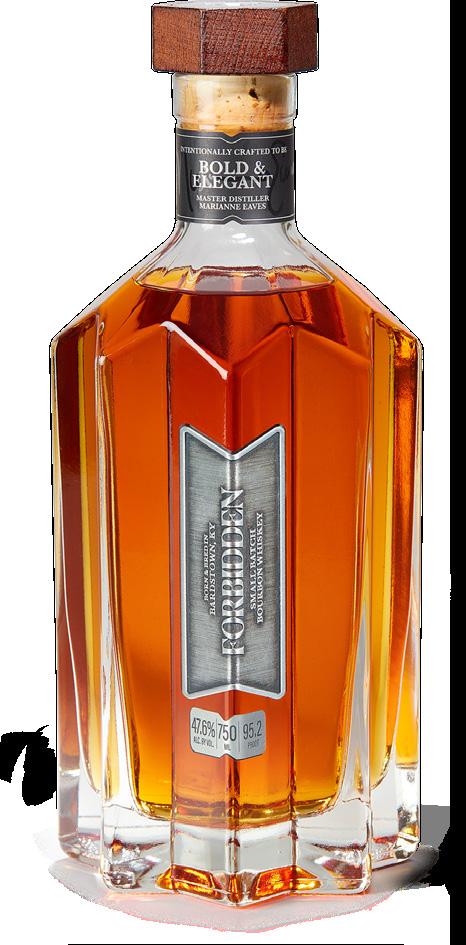

Differentiate your package from the competition and get the features and functionalities that matter most to your customers when you leverage our industry trends and consumer insights.

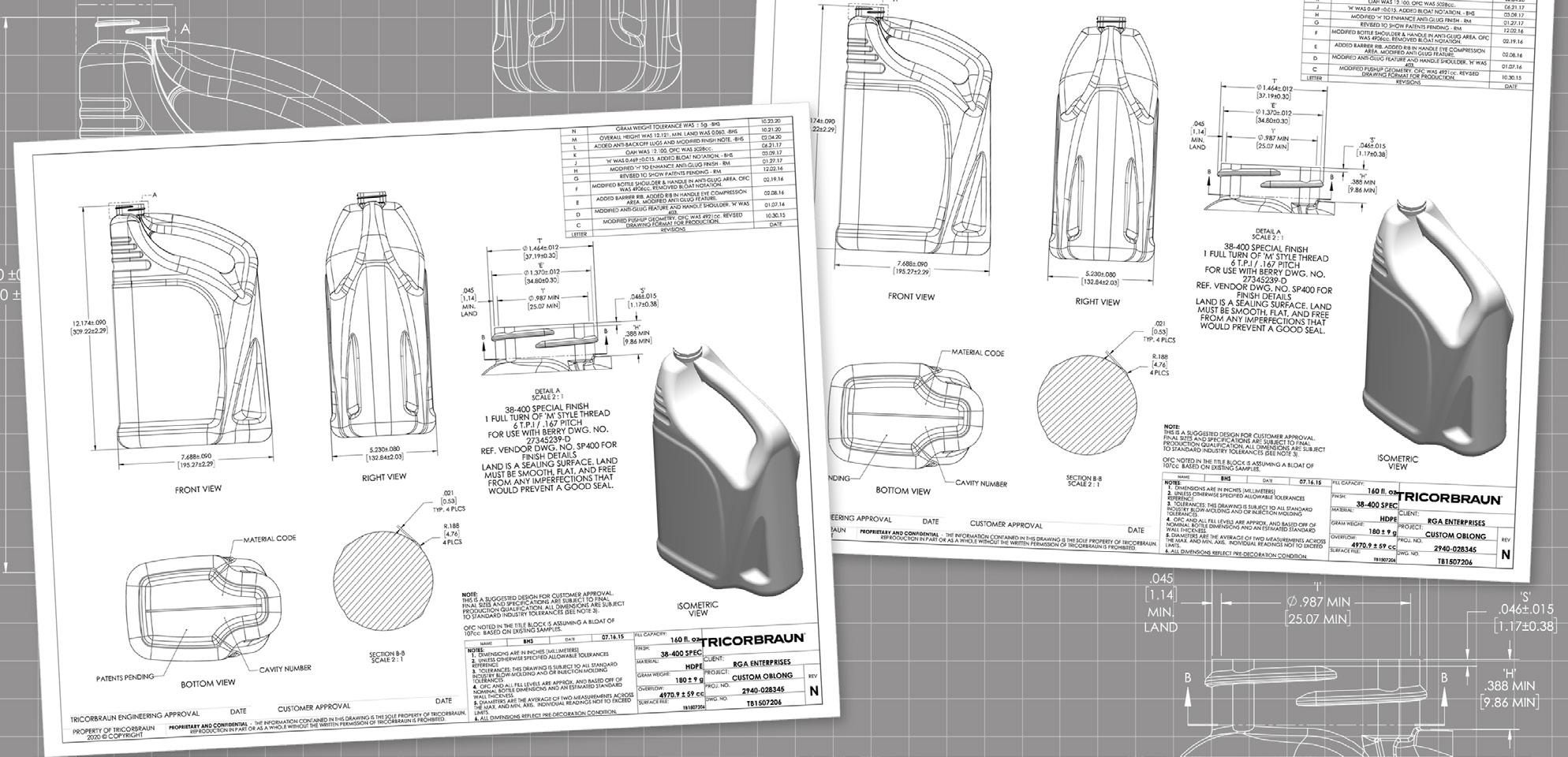

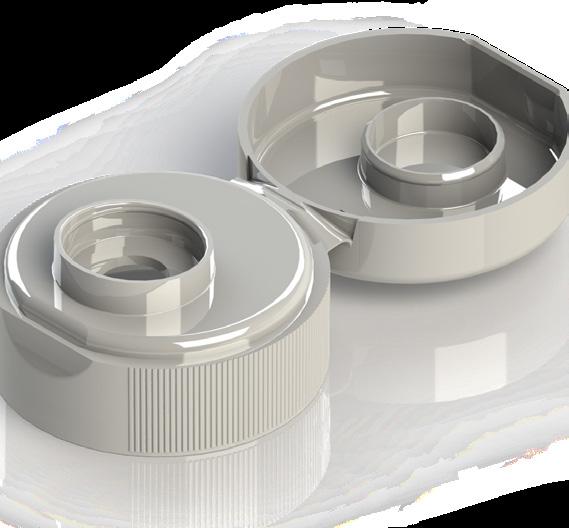

Take advantage of the depth and breadth of our expertise across packaging formats and materials. Our knowledgeable and experienced team supports all aspects of your custom packaging development, including industrial design, graphic design, packaging engineering, mold development, and quality engineering.

Get the innovative and high-quality custom packaging you need based on your brand requirements and the latest in customer insights and industry trends. We prioritize your budget, quality requirements, sustainability initiatives, filling location, and product features and functionality when designing and commercializing your package.

Gain speed to market with our in-house mold shop—where we manage the schedule, control the process, and ensure the commercial viability of our designs. We also directly manage the development process and ensure the quality of your packaging components.

Our proven custom development process ensures we successfully execute our package designs into commercialized products. With a comprehensive understanding of your brand requirements, we manage every step necessary—from design to mold development to supply chain logistics—to bring your design to market.

We strategically invest our cash and capital to support our Design & Engineering process and the customers we serve. Doing so minimizes your required investment and brings value-added resources to your project, including rapid prototyping, inhouse mold production, commercialization support, tooling, and lifecycle analysis. This enables you to focus on what matters most: launching an innovative packaging solution that propels your growth. Because when you succeed, we succeed.

Our proven development process leverages our over 30+ years of experience to focus on supporting our customers to deliver commercializable designs that win in the marketplace.

1

PROJECT KICKOFF

2

MARKET & CONSUMER INSIGHTS

3

DESIGN & DEVELOPMENT

PACKAGE

4

5

6

• Understand project parameters

• Define success criteria

• Align project with sustainability initiatives and goals

• Expectations and the timing of deliverables are established

• Criteria are defined for successful commercialization

• Leverage applicable primary and/or secondary research to further define packaging implications and ensure package designs resonate with and delight consumers

• Project is in line with the customer’s aesthetic preferences and target demographic

• Project is in line with distribution channel and competitive environment

• Intellectual property review

• Ideate based on project brief, global market, and consumer insights

• Concept development and refinement

• Engage with Supply Chain team to assess ideal vendor partners for customer’s needs

• Initial production timeline analysis

• Manufacturable designs are rendered for customer review

• Packaging costs are estimated for commercialization

• Manufacturing partner is identified

• Final design is achieved

• Finalize engineered CAD and part drawings

• Engineering review with manufacturer and mold builder

• Prototype tooling assessment for form, fit, and function (FFF)

• Formal timeline established

• Project timelines are finalized

• Final design files are submitted for tooling to be initiated

• Evaluation of prototype tooling (if conducted)

• Production tool build

• Final qualification for FFF

• Support production

OUTCOME

• Distribution and retail requirements are met

• Package is validated for successful commercialization and product launch

• Continuous Improvement Planning (CIP)

• Packaging Optimization

• Postmortem Analysis

OUTCOME

• Our expansive resources are leveraged to support ongoing production and identify growth opportunities for our customers

When best suited to your project, we will build molds in-house for speed to market, quality control, and cost savings.

As sustainability becomes a business imperative, a wide range of factors can shape your sustainable packaging strategy, including legislative mandates, retailer requirements, and what consumers want. Plus, of course, your brand goals, your budget, your timeline, and your product protection requirements.

87 %

of consumers agreed that companies have a responsibility to protect the planet and its people.

– WUNDERMAN THOMPSON

The design process typically influences 80 % of a product’s sustainable impact on the environment.

– MCKINSEY AND COMPANY

We explore multiple options, including paper, plastic PCR, aluminum, glass, biodegradable additives, alternative resins, and advanced recycled resins to identify the material that’s best for your custom solution.

We design for recyclability and incorporate refillable/reusable formats where appropriate.

From materials to circularity to optimization, we use Life Cycle Analysis (LCA) tools throughout our design process to evaluate the impact of different choices and ensure that your package is optimized to your sustainable packaging strategy.

From the shape of your package (e.g., square, round) to nesting, lightweighting, and the location of your manufacturing partners, we look at design elements and other factors that can make a sustainable difference.

“Our unit consumption has increased 20% year-over-year since the rebrand and new packaging launch. We are thrilled with this outcome.

TIM SCHAEFFER CEO Seaweed Bath

“TricorBraun’s extensive experience and creativity were the catalysts in bringing our vision to life. As a result, the function of the bottle changed entirely, allowing us to evolve from being a one-anddone product to a refillable solution that is more innovative and sustainable.

MICHAEL KOVENDI CFO and COO WHOOSH!®

“TricorBraun came highly recommended to the NERDS® Candy team. And after our first meeting, we were very impressed with their custom packaging solution capabilities, their manufacturing connections, and that they have an on-site Design & Engineering team.

JUDY LEE Senior Manager, Industrial Design Ferrara USA

““Our team spent many months creating, researching, and testing a very effective formula, and I wanted branding and packaging that delivered the same impact. The TricorBraun Design & Engineering team and I spent a lot of time talking about what was possible. We were pushing the limits of design and blow molding capability.

ROBERT PARKER Owner Roar Ambition

Between TricorBraun’s exemplary knowledge and timely responsiveness and the Design & Engineering team’s ability to execute our vision from a few sketches we provided, TricorBraun well-exceeded our goals. The company went above and beyond to fix an issue that we were trying to figure out, and they nailed it.

RANDY GROFF Director of Operations Kelly

Products, Inc.

“

TricorBraun helped our project come to life from a photo and concept to a bespoke and refined package we are truly proud of, one that is worthy of the exquisite rum inside.

LINDSEY KOPS MUNDY Vice President Hemingway Rum Company

It’s not enough to have a pretty package—it must also wow customers and win in the marketplace. When you partner with us and leverage our expertise, you can confidently embark on a journey that merges creativity, functionality, and marketability, leading to the success and growth of your brand.

To learn more please visit our website tricorbraun.com or find us on Facebook, X, LinkedIn, or Instagram