• CHARGING INNOVATION

• ARCC'S

• CHARGING INNOVATION

• ARCC'S

Safety in vehicles is a controversial subject, not the least because most of us think we are safe drivers. However the reality is that all of us make silly mistakes, have a lapse of judgement or just plain stuff up at least once in a lifetime of driving vehicles. Anyone who says they have never made a mistake or had an accident is almost certainly bending the truth.

The reality is we are all just human and we are open, nay prone to making errors and mistakes, which only serves to make you realise that any sort of safety tech we can include in vehicles is going to either prevent accidents or at the least ameliorate the effects of and crash you might have.

As we so graphically saw in the recent Hunter Valley bus crash, when things go wrong in a bus they can go dreadfully wrong.

It’s not for us to second guess or presuppose exactly what happened in that particular incident because as we know these things will be before the courts. However one does wonder if a bus with stability control may have enabled that crash to have been avoided or reduced in its dreadful consequences.

There are no guarantees when it comes to these things and we can’t say for sure. If safety tech would have prevented it but there is a reasonably good chance it would have. Many safety engineers believe that the reason our road tolls have largely remained static in recent years, which actually mean they are falling in real terms, given the increase in population, is because of the waves of safety technology that have rolled in over the last 20 years or so.

When we talk safety tech what we mean is the electronic systems that keep the vehicle stable to prevent roll overs via ESP electronic stability programs, stop it via ABS anti-lock brakes, help it maintain its place in the lane its travelling in with lane keep assist and most importantly stop the vehicle crashing into things in front via autonomous emergency braking or AEB.

AEB is a remarkable technology and the first time we tried it was on a test track with a heavy vehicle fitted with

the technology. Ahead of it on the track was a ‘dummy’ vehicle, in fact a life size cardboard cut out of a car rear and sides and we were asked to drive along at 50 km/h and not touch the brakes as we approached the dummy vehicle. The system sensed the vehicle ahead, sounded a number of loud chimes and warning lights on the dash and since we didn’t respond it applied the vehicle brakes and brought our heavy vehicle to a complete halt less than a metre from the stationery dummy car.

Just imagine those incidents we have seen in recent times where inattentive truck drivers have ploughed into the back of a row of stopped cars at road works ahead. Engineers tell us that even if the system fails to bring the vehicle to a complete halt in time, which would be rare, the system will slow it enough to dramatically reduce the damage and to almost certainly prevent fatalities.

A momentary lapse of attention and a number of people’s lives are ruined, or alternatively some electronic wizardry, which never stops paying attention, makes up for that lapse and prevents these life altering consequences.

Problem of course is that this technology is fitted to new buses but there are also a huge number of older buses on our roads. So how do you get those new buses into fleets without sending the operators broke.

This is where our government has to step in and provide some attractive incentives to get old buses off fleets and to be replaced by new ones with strong levels of safety tech built into them from the word go. That is going to cost a huge amount we know, but what do road fatalities and major road trauma cost us as a society, not to mention the emotional cost.

We need some innovative and clever ways to renew our fleets and to put newer high tech vehicles on the road and we need it sooner rather than later.

In this issue of Coach & Bus we head to Germany to drive the latest zero emission propulsion systems from Daimler, both battery electric and hydrogen fuel cell power systems and this gives us a window

into the future of how our heavy vehicles will be driven in the not too distant future.

We also take a look at a couple of Queensland fleets, one a Volvo operation in Brisbane, another in outback country transporting personnel to and from the many resource facilities around the state.

In Sydney we take a look at a new manufacturer, ARCC, which has a pretty strong pedigree in the bus business, and which is now manufacturing a very advanced hydrogen fuel cell and battery electric bus range locally.

As well as this we also have a story on a new charging system being pioneered by Scania as well as also taking a look at a new incarnation for British based bus builder Optare which has changed its name to become Switch Mobility and which will now focus on zero emission technology and may well come back to Australia sometime soon.

All that and a whole lot more in this issue of Coach & Bus so take it easily drive safely and enjoy the mag.

PO Box 7046

Warringah Mall NSW 2100 www.truckandbus.net.au admin@truckandbus.net.au

Enquiries

02 9938 6408

Follow us on Twitter #truckandbusnews

Follow us on Facebook at Truck and Bus Australia

Publisher Jon Thomson admin@truckandbus.net.au

Editor in Chief Peter Barnwell peter@truckandbus.net.au

Art Director Fiona Meadows fiona@kududesign.com.au

Advertising Sales

Jon Thomson Mobile: 0418 641 959 admin@truckandbus.net.au

Contributing Writers

Barry Flanagan, Sven Erik Lindsrand

Contributing Photographers

Mark Bean, Cristian Brunelli, Jan Glovac

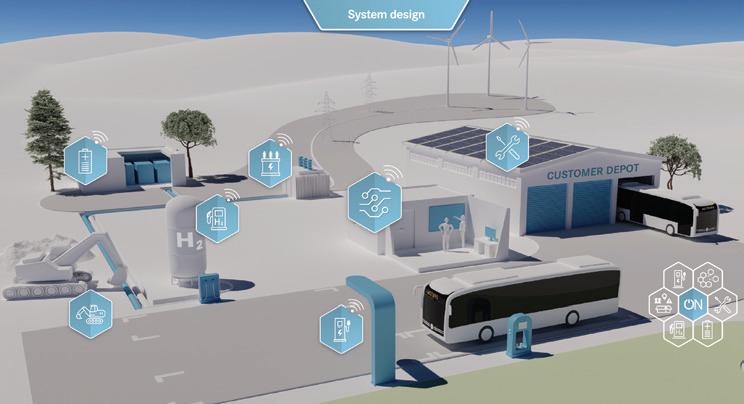

Coach & Bus headed to Stuttgart in Germany recently to have a guided tour around the epicentre of hydrogen fuel cell technology and research for both Daimler and its rival Volvo, who have pooled resources in a joint venture that aims to make it a zero sum game when it comes to bus emissions.

Out on the Western Plains of Queensland it’s easy to visualise the words from Peter Allen’s iconic Tenterfield Saddler, but for Queensland based coach operator Palmer’s, the black cockatoo is not just it’s logo but also a symbol that has significant releveance in outback Queensland. We take a look at Palmer’s operations and in particular its strong reliance on Scania.

Forty five years is a long time in any business and that is exactly how long Brisbane’s Kangaroo Bus Lines has been transporting people around South east Queensland and beyond. After recently taking deliver of some new Volvos the company reckons it might just have jumped to the next level.

One of the most asked questions at the moment when it comes to talk of zero emission vehicles, particularly commercial vehicles, is, “how will we charge them”? Swedish commercial vehicle maker, Scania and fellow Swede ABB E Mobility are collaborating to make charging the next gen zero emission vehicles easier and more efficient. We take a look at what the two companies are up to.

Long, long ago the legend of the Ark was born, a receptacle for animal life on the planet to save species from the coming flood. In Sydney in the year 2023 an ARCC is something very different, but like Noah the people at ARCC hope their new aluminium frame hydrogen fuel cell bus may enable them to stay ahead of the coming flood of zero emission buses to Australian roads. We visited ARCC to see what is floating this zero emission organisation.

Remember Optare, the bus maker that grew out of the ashes of the Leyland bus brand? Well Optare has changed its name and is now known as Switch Mobility .It remains part of the giant Hinduja Group and the new brand recently launched its first new European city bus, the e1, which it unveiled at the recent Paris trade show. We take a look at this new bus brand and delve into see if it might come down under.

On-Demand Buses have taken public transport by storm! Buses have been operating in a similar fashion since the early 1900’s. But now with to technological advancement, transit agencies and providers have an opportunity to create a new and agile experience for the bus industry. We take a look at how it might pan out.

Coach & Bus Magazine is published under licence by Transport Publishing Australia and is distributed to road transport professionals, fleets, business professionals and the industry throughout Australia.

All material contained herein including text, photography, design elements and format are copyright and cannot be reproduced by any means without the written permission of the publisher. Grayhaze Pty Ltd is a member of the Copyright Agency Limited (1800 066 844).

Editorial contributions are welcome for consideration. Contact the Editor or Publisher for guidelines, fees and level of interest. All unsolicited manuscripts must be accompanied by a stamp, addressed envelope for their return. We will not be held responsible for material supplied electronically.

Proudly printed in Australia

Single copy price $9.50 incl. GST

Mitsubishi’s ageing Triton is a conundrum. On one hand it represents excellent value and stands out from the other dual cab utes while delivering good performance and comfort, but on the other hand it is an ageing platform with some distinct handicaps compared with newer rivals. We climbed aboard the Triton GSR for a 2000km drive and tow test and found this ageing Diamond is still a valued heirloom of the ute market.

Electric cars are the topic de jour it seems. Every second person we speak to says their next car will be electric, but price and supply appear to be the biggest hurdles standing in the way of many more people steering down the zero emission route. We take Hyundai’s superb Ionic 5 for a spin and find a car that is fabulous to drive and live with, if only we could easily secure one to buy.

HINO AUSTRALIA has announced it has made the decision to pause Bus sales due to a lack of suitable products being available to it at the moment, and for the foreseeable future.

Hino’s vice president of brand and franchise development said that it was a difficult decision as Hino has been selling buses in Australia since 1965.

“However, we will continue to monitor the Australian bus market against future product opportunities from our parent company, Hino Motors, Ltd in Japan,” said Emery.

“It is important to note that we will continue to provide our customers with parts, service, and technical support via our

extensive dealership network and through our Product Support division,” he added.

“Our dedicated network of 60 dealerships and service centres across the country nationally will provide ongoing aftersales support to Hino bus customers,” he said.

The announcement of the pause in bus sales follows Hino’s decision in March 2023 to withdraw its Poncho buses from sale in Australia after they were voluntarily suspended from importation and sale in August 2022 due to concerns around Hino Motors processes in relation to vehicle homologation and certification results in Japan.

“While we continue to believe that the Poncho Bus meets the

relevant regulatory requirements for the vehicle, the decision was made considering the regulatory processes that apply to the recommencement of sales for a small volume of vehicles,” Emery added.

Hino’s pause also follows a similar stance from Daimler earlier this year when it withdrew from new bus sales in Australia due in part to restrictive commercial vehicle width and weight rules in this country.

SCANIA AUSTRALIA’S director of sales for bus and power solutions, Julian Gurney has reacted to news that the company has ceased bus production at its production facility in Poland, saying that the major move will have no effect on supply for Australia.

“The recent announcement of the cessation of the production of Scania complete bus bodies at the production facility in Poland, including production of the full Low Floor C-Chassis will have no effect on the supply of chassis for the Australian market,” said Gurney.

“Australia has always been a Low Entry City Bus Market, and

Scania’s modular K-chassis range has filled the requirements for the industry since its introduction in 2006 to meet the requirements of Euro 4 emission legislation requirements.

“Now available with Hybridelectric and Euro 6-compliant diesel powertrains, and with the first 100% battery electric chassis poised to hit the road in South Australia, Scania has a full range of Low Entry City Bus options for all Australian states and territories, and will continue to offer these. In fact, our Battery Electric Vehicle range futureproofs our customers well into the

next decade and beyond,” Gurney said.

“The Scania New Bus Generation city, school and coach product are all based on the Scania K-chassis, and we look forward to the continuing support and acceptance of the NBG range in Australia, which we have seen since launch in the summer of 2022.

“The pressure on the body building industry at both

global and local levels is well documented, with the BIC’s recent paper on the challenges facing the industry highlighted to the various State and Federal government departments with a view to raising awareness of the seriousness – across all areas of government – of the severity of the impact of the cost increases across the entire supply chain,” he said.

At Volvo Buses, sustainability is about more than just care for the environment – it also extends to social and ethical responsibility. Our Volvo BZL Electric product is a testament to our broader sustainability commitment, as we work towards the UN Development Goals with our trusted global partners, ensuring our electric offering is sustainable in more ways than one. From committing to supply chain audits to uphold responsible material sourcing and ethical labour, to encouraging remanufactured parts and battery circularity, to maintaining stringent data and cyber security, we are striving to ensure our Volvo BZL Electric is sustainable in every sense of the word. So, not only do you get clean, silent and efficient cities when you Go Electric With Volvo, but you contribute to a brighter, more sustainable future for everyone.

With the Volvo BZL Electric

With the Volvo BZL Electric

U-Go

NSW TRANSPORT minister Jo Haylen said that Transport for NSW has stepped in to manage day-to-day operations in Region 10 alongside the contractor, U-Go Mobility.

“Everything we are doing is about making sure bus services are more reliable for the community and that we are supporting our bus drivers,” said Minister Haylen.

“I’ve directed Transport for NSW to step in to improve bus services in Region 10 and to fix up the former government’s failures. There have been some improvements to services but there is still more to do to improve performance,” said the Minister.

“I want to make this arrangement work but services in Region 10 must improve. All options remain on the table if we don’t see further improvements to services from the operator.”

Transport for NSW claims that since the intervention, service cancellations have declined from

28 per cent to 13 per cent, but that the number is still too high and there is still more to do to get bus services in Region 10 back on the road.

According to the government the U-Go Mobility, has failed to deliver the expected level of service for the community and added that the Region 10 contract was signed weeks before the election by the old state government and added that the winning bid for the Region 10 contract was determined by which operator could deliver for the lowest price, instead of focusing on an improved level of service for passengers.

Transport for NSW also said that it has taken responsibility for other bus service operations including, scheduling and implementing a more reliable timetable for customers from Monday 31 July, re-working current turn-around times for routes to ensure an adequate pre-trip brief is given to drivers,

with the hope that this will help eliminate stops being missed or taking the wrong route They also believe that meeting with U-Go Mobility management several times a week is making progress in ensuring adequate resourcing and the operator is making progress in improving performance.

Minister Haylen also directed Transport for NSW to give some school service routes to another operator to run in the short term to ensure that these key community services are prioritised.

Under the new arrangement, the previous managing director has departed U-Go Mobility and is no longer be working for the operator.

Minister Haylen and Transport for NSW said they also reserves the right to further exercise the step in rights and fully take over the contract if more improvements are not made.

In the statement it was revealed that U-Go Mobility has also

adopted a range of measures to address the driver shortage, to retain staff and to attract drivers, including a $5000 retention and sign on bonuses.

Transport for NSW has already put in place a number of other day-to-day measures to support bus operations in Region 10 including a system of dedicated Transport staff monitoring region 10 bus services in real time to identify and report issues directly to the operator and Transport Management Centre. In addition there will be dedicated Transport staff responding to customer enquiries and liaising with key stakeholders including schools, local councils and local members. It also says it will have Transport commanders deployed to key interchanges to help customers on the ground and a dedicated timetable team to ensure the adjusted timetable is prioritising dedicated schools services and regular route services that carry a large cohort of school students.

With Caltex Delo’s ISOSYN Technology, fleet owners and drivers can rely on extended service protection, maximised engine durability and minimised operating costs.

Talk to your local distributor or find out more about Caltex fuels and lubricants. www.caltex.com/au/business-solutions

BUS OPERATOR Busways has revealed it has been selected to deliver bus services for the NSW Central Coast community for a further eight years, following the competitive open tender process.

Busways has won the Outer Metropolitan Bus Services Contract 6 by the NSW Government commencing in July next year (2024), and the bus company says this was a result of having demonstrated its capabilities ‘delivering high-quality bus services for more than 53.7 million passenger journeys a year across Australia’.

Busways says it is expert in operating route, school, on-demand hub-to-point services, emergency buses and special services through its contracts in NSW and SA with more than 1,300 buses and a 2,800 strong workforce.

Managing director of Busways, Byron Rowe said he welcomed the news as recognition of Busways’ proven performance, with capabilities to implement the NSW Government’s Future Transport vision and

continue to improve customer outcomes and bus service quality throughout the region.

“Busways has operated bus services in NSW for 80 years, and on the Central Coast since 1990, and been highly adaptable to the changing needs of the region, seeing 44% population growth in that time,” Rowe said.

“It’s great to see the NSW Government backing home grown business - we are thrilled to continue our productive partnership with Transport for NSW and our committed focus on providing an exceptional customer experience for Central Coast customers, and secure jobs for our experience local team,” he said.

Busways chief operating officer, Chris Wolf, said the company had proven advanced scheduling and operational capabilities to efficiently deliver growth services, whilst maintaining high levels of reliability, customer experience, safety and service innovation on the Central Coast.

“We have maintained consistently high standards in

service delivery and our customers tell us we are getting it right, with 95 per cent customer satisfaction in TNSW’s May 2022 Customer Satisfaction Index,” Wolf said.

“Our focus on safety and maintenance was recognised by our Central Coast fleet achieving an average 97% pass rate over the last five years of HVIS Inspections safety audits. We have also invested in sustainable depot infrastructure, now powering our Gosford bus depot completely on solar power,” he said.

For the next eight years, Byron Rowe said Busways will continue to focus on delivering quality bus passenger services to the growing and evolving Central Coast region. The Central Coast population is forecast to grow 23 per cent by 2036 to more than 415,000 residents.

“With the certainty provided by this new contract, we look forward to partnering with Transport for NSW in planning and designing improvements to bus services for the Central Coast community as it grows,” Rowe said.

Byron Rowe went on to say how privileged Busways has been to grow strong community ties in the region.

“Across the past seven years, Busways donated over $150,000 in-kind bus shuttle services to support Central Coast community events and groups who help the disadvantaged,” Rowe said.

“Just two weeks ago we supported the 5 Lands Walk for the seventh year with shuttle bus services to enable people of all abilities to take part in this celebration of people, place and Aboriginal culture. We also provide bus safety travel training for primary school students and people with disabilities and support many other community initiatives such as Camp Toukley, which provides fun and respite for foster children.”

Under the OMBSC6 contract, Busways says it will transport more than 4.5 million passengers on nearly 400,000 bus trips a year, operating over 160 buses, with 260 employees at the Gosford and Wyong bus depots.

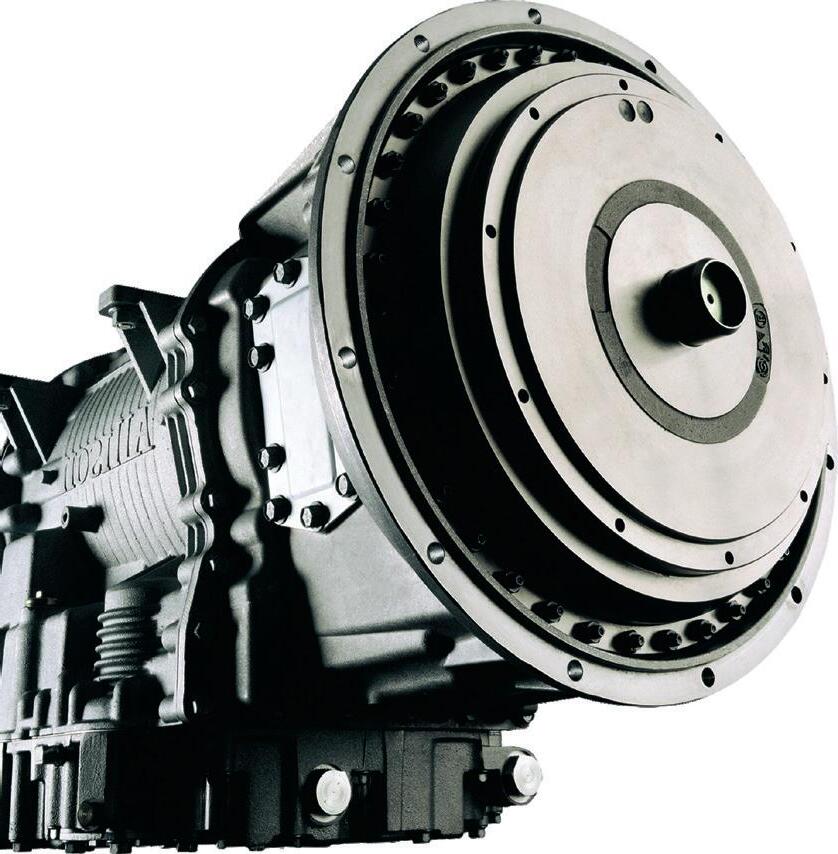

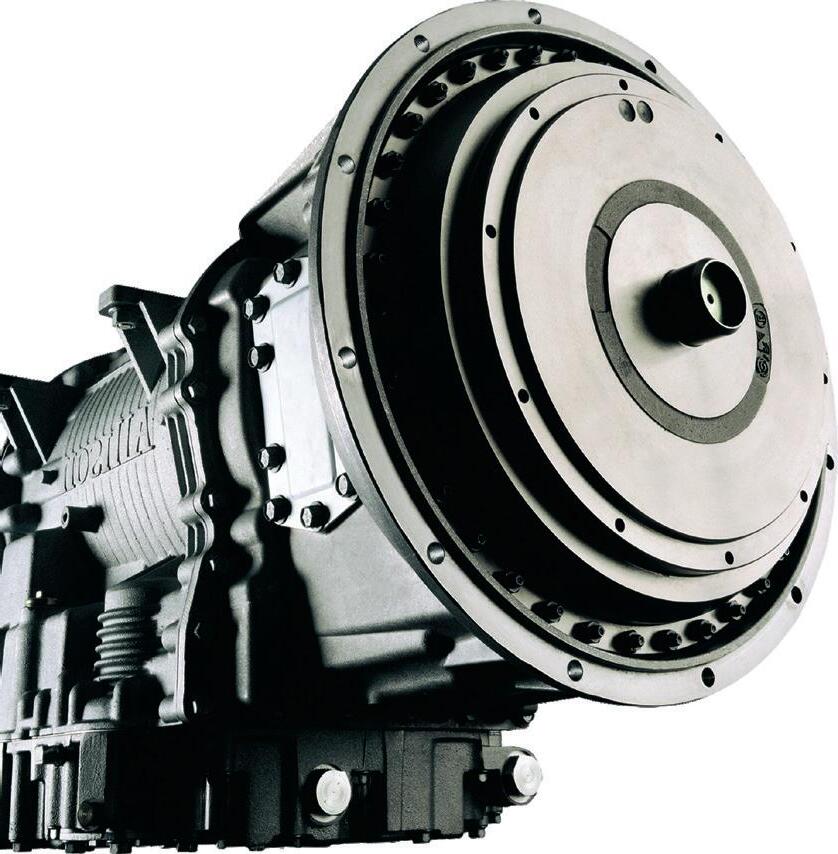

PROVEN QUALITY AND PERFORMANCE FOR OVER 20 YEARS

Engineered for Allison Transmission by Castrol, the technology and market leader for over 20 years.

Builds on the outstanding performance of the original TranSynd formula with enhancements that include: improved wear protection, extended anti-shudder durability and extended clutch-friction durability.

Engineered for Allison Transmission® by Castrol®

Busways has announced it has expanded its Sydney electric bus fleet to 18 zero emissions buses now on the road enabling the company to claim it now operates the second largest electric bus fleet in NSW.

Busways says it purchased the first 12 NSW-built Custom Denning Element electric buses in 2021 and has invested heavily in charging infrastructure at its Penrith depot over the past two years.

Managing director, Byron Rowe, says adding six new Yutong E12 electric buses to the Busways fleet in Penrith continues the

journey to decrease carbon emissions.

“These new ZEBs are part of our plan to increase sustainable outcomes for local communities and contribute to NSW’s objectives of cutting emissions by 70% by 2035,” Rowe said.

“One electric bus saves up to 34 tonnes of Co2 emissions per annum locally – with 18 buses, each year we are preventing 620 tonnes of Co2 from entering the local atmosphere in Western Sydney, compared to a diesel bus.”

The news follows Busways’ recent trials of various electric bus makes, including Volvo,

BYD and Yutong.Chris Wolf, chief operating officer, said Busways will continue to work closely with a range of manufacturers as electric vehicles are constantly evolving.

“We’ve always taken a partnership approach with manufacturers, providing advice and feedback from our employees and customers and working with manufacturers to improve aspects like drivability, dashboards, security and accessibility,” Wolf said.

“The Yutong’s have the ability to recharge in around three hours - we will closely monitor charging

and range of these vehicles in Western Sydney conditions,” he said.

“Efficient ZEB fleets are all about charging management. The scalable charging infrastructure we installed over the last two years at Penrith is the key to being able to add these and future new electric buses.”

Busways has already trained more than 80 drivers and seven mechanics on the new vehicles with more drivers undergoing training in late May.

Four of the Yutong electric buses also started service in May with the rest to be running soon.

NEW FOR WINTER 2021/2, AND AVAILABLE WITH WHITE OR AMBER POSITION LIGHT FUNCTION, SENTINEL IS A RANGE OF 9” ROUND LED SPOTLIGHTS COMBINING THE BEST AND LATEST IN TERMS OF ELECTRONICS AND MATERIAL DESIGN, TO DELIVER UNRIVALLED LIGHTING PERFORMANCE WITH HEAD-TURNING CONTEMPORARY PRODUCT DESIGN.

Like all Lazer products, the Sentinel range is designed and manufactured in-house, in the UK. Product quality is assured and backed up by a comprehensive 5 year guarantee. For a safer, more comfortable night driving experience, look no further.

SEE MORE GO FURTHER GO SAFER

THE SOUTH AUSTRALIAN Government has started what it is describing as a ground-breaking, two-year hydrogen bus trial involving two vehicles based at the Morphettville bus depot which will be deployed on routes across Adelaide from late August.

The first of the new hydrogen buses has already arrived in Adelaide, and has been wrapped in a striking green.

Bus operator Torrens Transit will begin internal testing of the two Foton Hydrogen Fuel Cell Buses in collaboration with Foton Mobility, BOC gases and H2H Energy, with the trial buses operating from the Morphettville depot, before they will be released for operation.

The SA Government says that hydrogen fuel cell technology significantly reduces fuel use and environmental impact buses (HFCB) represent a rapidly emerging, green alternative technology.

SA Transport minister Tom Koutsantouris said that the ground-breaking trial of two hydrogen buses, which demonstrate the real-world application of South Australia’s investment in hydrogen technology through the Hydrogen Jobs Plan as well as the HFCBs

the government has also invested in hydrogen for its rail services.

“This innovative trial will place South Australia as an Australian leader in applying hydrogen technology across our public transport network. The hydrogen buses will be fuelled with the assistance of the Tonsley Innovation Facility,” said the Minister.

“The State Government will continue to work with partners and stakeholders to adopt any technology and develop solutions that reduce emissions and provide a superior passenger experience,” he said.

“We will leave no stone unturned in the quest to employ cleaner, greener and more efficient technologies across the public transport system that help achieve net zero emissions by 2050 - or even earlier,” he concluded.

Michael McGee, the CEO of Transit Systems which is the company that will operate the hydrogen buss on trial said the company committed to relentless investment into researching green technology, while having the expertise and knowledge to deploy efficient change to decarbonise public transport.

“These hydrogen buses are a perfect example of this, as we are bringing our global experience from operating hydrogen buses in London to the streets of South Australia,” McGee said.

“It’s an exciting opportunity to incorporate the Premier’s vision to turn South Australia into a world-class producer, user and exporter of hydrogen. This vision is critical to help combat climate change and transform South Australia’s industry into a major global player in the renewable energy market,” he added.

“These hydrogen buses will utilise hydrogen that has been proudly produced at the Tonsley Innovation District. This trial will exploit innovative local supply chain solutions, gauge the economic benefits of renewable energy and harness local talent as part of the South Australian Government’s pioneering work to support local industry into a green future,” he added.

The SA Government said that the HFCB trials and fleet implementations are increasingly occurring across public transport networks globally from London to Beijing and Cologne – which has a similar population size to Adelaide.

It added that the benefits of hydrogen-powered vehicles over battery electric buses include faster refuelling and greater range, which may be critical to delivering services to the outer metro areas and into the regions and that hydrogen complements battery electric vehicle technology by providing a viable cleaner, greener, emissions-free technology that can power buses, trains or other heavy vehicles carrying heavy loads.

As well as the the hydrogen bus trial the SA Government has implements a new hybrid train system which it says offers a better customer experienceparticularly at Adelaide Railway Station - where the train engine can remain off, reducing noise and pollution for those on board and in the station.

It says that the rail trial complements its commitment to embrace hybrid and fully electric solutions on Adelaide’s bus fleet, with South Australia’s first full battery electric bus already being tested, along with 24 electric hybrid buses already in operation.

The SA government said that hydrogen fuel carries significantly more energy than the equivalent weight of batteries, which it says

is important as it evaluates future technology options, including powering trains on its Belair, Outer Harbor lines and Grange and Port Dock connections.

The government says that Initial testing of the prototype hybriddiesel railcar is progressing well, with a second railcar fitted with a new Energy Storage and Recovery System. These railcars have been coupled together and the testing of the two-car train set is now underway. This two-car train set is the first of 44 diesel railcars expected to be fitted with the hybrid system, with the trains to run on the Outer Harbor, Grange and Belair lines.

This new system works by storing kinetic energy generated when the train brakes to an onboard battery, converting it into electrical energy to power normal train operations – decreasing stress on the engine and fuel consumption by approximately 16 per cent.

The battery will also be used instead of the diesel engine to supply auxiliary loads (power for lighting and air-conditioning, for example) at the train platform within Adelaide Railway Station to reduce noise, emissions and air pollution, with the first train is

WANTED:

PANEL BEATER / BODY BUILDER / SPRAY PAINTER

We specialise in Coach and Bus repairs and have over 30 years of industry experience Our business is growing, and we are currently seeking a skilled panel beater / body builder / spray painter with experience in the heavy vehicle industry.

REQUIREMENTS:

expected to be introduced into passenger service in coming weeks.

Installation of the Energy Storage and Recovery System on the remaining trains will be progressively rolled out, with all trains expected to be in passenger service with the new system by mid-2024. Once fully installed, Adelaide Metro will save an estimated 2,400 tonnes of CO2 emissions annually.

Adelaide Metro also continues to make significant steps towards a zero-emissions future across its bus fleet, with testing of the state’s first full battery electric bus already well underway. As well as being better for the environment, full battery electric buses offer a range of benefits for passengers. They offer more space and better comfort and accessibility, while eliminating noise and fuelbased pollution.

A further five full-battery electric buses are on order, pending the results of this trial underlining Adelaide Metro’s committment to transitioning to a zero-emissions public transport system to support the State Government’s net zero emissions by 2050 target.

Previous experience in vehicle panel beating, preferably with heavy vehicles including Fibreglassing, Sheet Metal Work folding/making panels, general vehicle body repairs, Spray Painting, etc.

Must possess a Licensed Trade Certificate and a current Driver's License.

Fuel Allowance provided for distance travel with own vehicle.

Strong work ethic, punctuality, and excellent communication skills.

Competitive compensation for individuals experienced in all three trades.

Opportunities for career advancement.

CONTACT US

24hr Mobile: 0478 637 430

Address: 180 Kingsgrove Road, Kingsgrove, NSW

Email: paul@sydneycoachesbusrepairs.com

Website: www sydneycoachesbusrepairs com

As a kid in the 1960s and 70s, there always seemed to be numerous spasmodic articles in magazines like Pix and People or in the more raffish Sunday papers, about vehicles that could run on water. They were of course articles that had as much credence as large pile of bullock poo, and naturally we have never actually seen it happen.

So here we are in 2023 and we stand on the edge of a precipice, with climate change pushing us inexorably closer to

the drop and we look toward zero emission transport as a safety barrier to hopefully prevent us from going over the edge.

Hydrogen fuel cells are part of what all the big manufacturers tell us will be a multi prong solution to de carbonising the world’s transport networks. In essence hydrogen fuel cells will enable us to power our vehicles using water. That is pretty simplistic but the basic concept is that we extract or split hydrogen from H2O or water as we know it, then the hydrogen

is used to generate electricity in a fuel cell aboard the vehicle. It is a complex process but essentially that is what happens. So maybe those snake oil salesmen in People magazine in the ‘70s may have been visionary, but then again probably not. We found ourselves on a particularly hot and oppressive day in Germany, with the thermometer nudging 40 and the locals wilting in a heat wave so intense that no one could remember anything like it, driving up to a large white office block on an industrial

estate outside Stuttgart. The building is in fact the nerve centre for a major joint venture between Daimler Truck and Bus and its global rival Volvo Group, to take hydrogen fuel cells for heavy commercial vehicles to a commercially viable position before the end of this decade.

The joint venture is known as Cellcentric and inside that big white building, are some of the best and brightest minds on the planet when it comes to the hydrogen fuel cell industry.

The actual facility and operation was a Daimler entity up until it joined forces with Volvo on the 1st March 2021. It was a move that surprised many in the industry, except for ones in the know. The fact is those who understand, realised that commercialising hydrogen fuel cells was going to be vastly expensive. Volvo’s buy in to Cellcentric was around €650 million or close to $1 billion Australian. Given Daimler’s contribution would have had to have been much the same, that means

a $2 billion investment between the two biggest heavy commercial makers in the world. That is a lot of money, even for corporates of the size and breadth of Daimler and Volvo.

To emphasise that this is a big investment and an even bigger play in the global commercial vehicle market, some close to the industry point to the understanding that Volvo global chief , Martin Lundstedt ordered his managers around the globe to sell down inventory, sell as much as

Coach & Bus headed to Stuttgart in Germany recently to have a guided tour around the epicentre of hydrogen fuel cell technology and research for both Daimler and its rival Volvo, who have pooled resources in a joint venture that aims to make it a zero sum game when it comes to bus emissions.

possible, reduce staffing levels and to pour as much revenue as possible into the corporate funnel to enable the Swedish giant to afford the buy in. No one at Volvo will confirm that, however Coach & Bus understands that is what happened.

The drive to get Hydrogen FCEV buses on the road and running cost effectively, efficiently and reliably is of course being forced by the EU, which wants a 98 per cent reduction in emissions from heavy road transport by 2050. This is going to take some decisive and intense action to achieve, and that means zero emission is the only option.

Simply put, both Martin Daum at Daimler and his counterpart at Volvo, the other Martin, Martin Lundstedt, knew that it would cost a lot more to delay or hope that others would develop the technology and that it would be better for both to join together to achieve it.

Cellcentric is what one might call a ‘skunk works’ full of the best and brightest minds when it comes to that long promised but rarely achieved proposition of running a vehicle on water, for that is pretty much what hydrogen fuel cells do, with a bit of a stretch.

Cellcentric’s fuel cell technology is running in prototypes in Europe already. While in Germany with Daimler we did actually get to ride in a prototype truck powered by a hydrogen fuel cell and electric motors. The truck boasted a 42 tonne mass and a claimed range of around 1000 kilometres using about 100 kilograms of hydrogen, most importantly emitting only

water vapour as its one and only emission into the atmosphere.

Daimler has had purely battery-electric Mercedes-Benz eCitaro city buses in series production since 2018. From this year, the vehicle will also be available with a hydrogenbased fuel cell as a range extender.

In addition, by 2030 Daimler Buses says it aims to offer battery or hydrogen-based CO2-neutral models in every segment. The initial focus will be on the core markets of Europe and Latin America, but by 2039, only locally CO2-neutral new vehicles are to be sold in the core market of Europe.

In other segments: Daimler says it plans to launch the first all-electric intercity bus from the second half of the decade and, by the end of this decade, coaches with hydrogen-based fuel cell drives.

There is still some time before this ‘miracle’ technology will be widely adapted and utilised on the world’s roads.

What does ‘Some time’ in this instance mean? Well the boffins at Daimler and at Cellcentric reckon that we will start to see its first commercial hydrogen fuel cell powered trucks and buses available before the end of the decade, maybe a bit earlier, depending on how fast technology moves.

The challenges that are exercising the best and brightest minds at Cellcentric, focus around how best to store and use the hydrogen and various relatively minor engineering questions, mainly to do with efficiency and packaging. But have no doubt hydrogen fuel cells work, and when it comes to heavy buses travelling long distances, it will almost certainly

be the way we will power them as the 2030s unfold. Conservative companies like Daimler and Volvo don’t bet close to $2billion on a prospect they aren’t reasonably certain will deliver a win.

Cellcentric is based in a plain, uninspiring building in the middle of a small industrial park around 60km from Daimler HQ in Stuttgart and although externally uninspiring, what is revealed inside Cellcentric is anything but uninspiring. This really is a centre of serious brain power, that is exploring the frontiers of hydrogen fuel cell tech that will take us deep into the 21st Century.

This is a partnership between the two global superpowers of commercial vehicle manufacturing. It is the equivalent of NASA and its Russian equivalent RosCosmos joining forces in the midst of the 60s space race. Arguably what the scientists and engineers discover and develop at Cellcentric will have an even more important influence on the future of our planet than putting a man on the moon ever did.

In fact Cellcentric already lays claim to about 700 patents around hydrogen fuel cell development, which in many ways serves to underline the technical superiority of the operation, and the sort of advantages that will flow to Daimler and Volvo products as we advance to hydrogen fuel cell buses and coaches.

Management at Cellcentric has been drawn from the ranks of both Daimler and Volvo. They also go out of their way to emphasise that it is independent of both

its shareholders, and that the fruits of what it develops will flow equally to both companies. It employs several hundred scientists, engineers and technicians across its four engineering laboratory centres, three of which are based in Germany with the fourth in Canada.

The joint venture’s stated goal is to ‘become the number one supplier of fuel cells to support Daimler Truck and Volvo Group’s vision of CO2 neutral transportation’. A visit to the company’s Stuttgart operation leaves you in no doubt that they are determined to achieve that goal.

Our host on the visit to Cellcentric HQ was chief tech officer, Nicholas Loughlan who not surprisingly is a total hydrogen enthusiast.

Loughlan, emphasised that the biggest advantage hydrogen delivers is that it is relatively easy to transport and that storage and refuelling infrastructure is similar to what’s needed for current diesel trucks, and much easier than building charging infrastructure for battery-electric.

“Australia is in fact perfectly placed, both environmentally and geographically to make the most of hydrogen technology and to become a world leader in green hydrogen,” Loughlin said.

Hydrogen, while being the most abundant element on earth, is still tricky to extract from water, and requires significant amounts of energy. Green hydrogen is ‘electrolised’ from water using renewable electricity from solar, wind and hydro electric generation. Blue hydrogen is derived using gas fired electricity, while

brown hydrogen is derived using electricity from coal fired power stations.

Before we go any further, let’s just underline exactly how hydrogen fuel cells actually work. The biggest falsehood is that the hydrogen is ‘burnt’ in some sort of internal combustion engine, similar to petrol or diesel. That is not how a fuel cell works.

Hydrogen fuel cell buses, are electric vehicles, simple as that. Instead of requiring a massive bank of batteries to power a heavy coach over long distances, a hydrogen Fuel Cell Electric Vehicle, an FCEV, to use the accepted acronym, has a much smaller battery bank supplying power to electric axle motors, just like a battery electric bus. What the hydrogen fuel cell does is produce electricity by passing hydrogen and oxygen across an electrochemical cell similar to that of a battery, which produces electricity, water and small amounts of heat.

Consequently there is a regular supply of electricity to power the e-axle motors and keep the batteries charged across a long journey hauling a heavy load. For a large 56 seat interstate coach travelling from say Sydney to Melbourne, expectations are that it will need about 50 to 80 kgs of hydrogen, give or take. That tank of Hydrogen should take about 15 minutes to easily refuel at a station similar to current fuel stations. That is a very simple explanation, certainly one that we can get our tiny mind around.

Inside a fuel cell there are positive and negative electrodes – anodes or negatives and cathodes or positives. These are

positioned

On each of those panels hydrogen is fed to the anode and oxygen is fed to the cathode. A catalyst on the anode separates the hydrogen into protons and electrons, with the electrons creating a flow of electricity while the protons migrate through electrolyte to the cathode producing water and heat, but not other emissions.

That electricity provides power to the electric motors with enough torque to make diesel engine vehicles look and perform like 50kg weaklings by comparison. However more of that later.

Daimler has already stated that it wants to have all its new buses in the major markets of Europe, Japan and North America, CO2-neutral while driving by 2039’ and its aim was to have series production battery-electric vehicles on the road in all core regions by last year, which it was able to declare that it has achieved

Not all major corporations always get it right, however remember Daimler, invented the automobile and has been in business for around 130 years. So the evidence is that this is a company that has endured, and is still a leader in an industry that has seen many come and go over the past 13 decades.

The interesting background to Daimler’s (and Volvo’s) bet on hydrogen for long distance and high mass buses is that, unlike a capital hungry start up, such as Tesla or Nikola, development of the new zero emission technologies can be funded

from the established company’s ongoing revenue, selling internal combustion engine (ICE) buses. The start-ups have to spend the money of backers and shareholders to develop the tech, build the plants, make the prototypes, test them, fund marketing for awareness and positioning, before series production even begins and any revenue comes in.

It underlines just how high the stakes are, but also emphasises just how well positioned Daimler is, particularly as the largest commercial vehicle maker in the world. Daimler global boss, Martin Daum has been quite emphatic that the company is committed to the decarbonisation of the transport industry, and he has put his money where his mouth is.

“Truly CO2-neutral transport only works with battery-electric or hydrogen-based drive,” Daum has said.

While some may think this is a bet each way, it is, to continue the gambling theme, actually horses for courses.

If the path to zero emission was a horse race then the Daimler Volvo horse, Hydrogen Hero is part way down the back straight trailing their other entrant , let’s call it, Battery Bravo, by a few lengths. We reckon

that by the time they reach the winning post around 2030 that it will be a photo finish and both will be judged winners.

Far from being fortune tellers or hopeful tipsters, we are basing these forecasts on the commitments and enormous funds Daimler and Volvo have invested and will continue to invest in these technologies.

While it seems as though everything is focussed on zero emission, the reality is that diesel has some years to play yet, because infrastructure, incentives and all manner of other factors will mean that it will take time for the industry to adopt and adapt to the new drive technologies.

Our visit to Germany came in the midst of a major heatwave and climatic conditions that were extreme, with the mercury climbing into the 40s, water levels in the mighty Rhine dropping significantly, with farmer’s crops coming under the sort of drought pressure we are familiar with Down Under. Back home in Australia of course our winter and spring were waterlogged disasters, with flooding across vast areas of the country.

All of this has only served to strengthen the resolve of Daimler management to address this existential crisis.

The day after our visit to Cellcentric, we travelled to Wörth for the next revelation in our Daimler future tech odyssey with a hydrogen fuel cell powered truck. It wasn’t a bus but the power train principal was the same.

Daimler Truck Advanced Engineering engineer, Andreas Hoefort, who heads up the zero emission technology program for the commercial vehicle giant walked us around the truck and how the FCEV system works within the vehicle framework.

Aside from the whirring of various electric pumps and cooling fans, the Hydrogen vehicle was ‘idling away’ next to us, but without the rumble that would accompany a diesel bus or truck. There was, however, plenty of water dripping from various places, the by-product of that chemical reaction in the fuel cell. At least it is clear, clean water and as Hoefort explained, it is an aspect that is exercising the minds of the Daimler engineers in terms of capturing and potentially using the H2O in some way.

In the passenger seat of the prime mover, hauling a gross of around 42 tonnes, we departed silently and smoothly. No jerks as gears were changed, because there is no

gearbox per se. In its place is a two speed e-axle set up, that seamlessly shifts up as we accelerate away.

A few smooth and silent laps of the banked oval with various bursts of acceleration to illustrate that pushing the throttle further does not produce a roar as an ICE powered vehicle would. Then it was off the banked oval on to a small network of connecting roads for what turned out to be the piece de resistance.

Hoefort pulled the truck on to a steep incline, which was labelled as being an 18 per cent grade. He stopped midway up the hill, paused for a moment or two and then moved off. There was no fuss, no bother and no noise, just pure unadulterated torque. The 40 tonne rig moved away like an empty truck on a flat surface, such was the smooth silent turbine of torque the electric motor produces. In reality it’s no different to any other electric bus or truck we have driven, however, in this instance, instead of having to find a rapid charger a couple of hundred kays down the highway, the driver will be able to cover 1000km or more, without having to refill the hydrogen tank. No range anxiety, no uncertainty and no large scale

loss of payload due to having to carry a vast battery array.

Some may see all this as a pipe dream, a future as uncertainly predicted as jet cars, hoverboards and more leisure time, things promised to us in the ’60s, but which never materialised. However, rest assured, this is technology that is coming, and Daimler is very certain it will be here before the end of this decade.

My colleagues and I shared glances in the cab of the hydrogen fuel cell truck at Wörth, as the various hill starts and manoeuvres were tackled, glances that we would later confirm in discussion were about the future of long distance transport and any scepticism and disbelieve was melting as fast as an ice cream in that hot German sun.

On the test track the Daimler engineer explained the energy frugality of the fuel cell which he told us was programmed to conserve energy whenever it can, sensing and understanding the truck’s power needs, whether it is on a steep hill start, tackling hilly terrain, on the flat, descending hills or delivering just partial power while crawling in heavy traffic, or if manoeuvring in depots or

restricted space. Hoefort explained that the battery and fuel cell outputs adjust to the changing power demands of the truck while working.

One of the major aspects of the fuel cell technology that Daimler and Cellcentric engineers are yet to make a final decision on is the way to store and carry the hydrogen fuel on vehicles.

At the moment the truck we rode in was one of just two prototype fuel cell powered trucks running, with the one we sampled having been in trials for around a year and having covered about 24,000km on public roads and on test tracks. It used hydrogen stored under pressure as a gas and as Hoefort explained this was the starting point.

The intense research and development program is aiming to have a production Hydrogen on roads by around 2028.

The newer prototype truck utilises a different hydrogen storage concept with the fuel stored as liquid under higher pressure and at a temperature of 250 degrees below zero. The Daimler engineers say that this system will provide significantly better range than the gas storage version.

THIS IS TECHNOLOGY THAT IS COMING, AND DAIMLER IS VERY CERTAIN IT WILL BE HERE BEFORE THE END OF THIS DECADE

Start looking around the back of the cab and it is soon obvious that there is more going on here than with an ICE vehicle. There are lots of pipes, storage tanks electric pumps and fans supplying cooling for the high voltage batteries and the fuel cell.

Of course there is no big engine sitting under the cab, just batteries and the fuel cells supplying the electricity to the e Axle with its integrated electric motor, differential and two-speed hub gears.

Interestingly Hoefort tells us that the GenH2 Mercedes is in fact 300mm longer in the wheelbase than an equivalent 4x2 diesel prime mover, enabling the fitment of all of the necessary systems and components. The Gen H2 machine is also around two tonnes heavier than its diesel counterparts, but Hoefort is confident that Daimler will achieve its goal of weight parity by the time FCEV buses and trucks hit production later this decade

Hoefort says that the goal is for the Hydrogen fuel cell vehicles to have a life expectancy of around 10 years or 1.2

million kilometres in European operating conditions, but said that this was a conservative estimate and reckoned that it could be a little on the conservative side. Only time will tell.

It is certainly clear from our visit to the nerve centre of Daimler’s future development, that Hydrogen is going to be the future for long distance and heavy operations, while rechargeable battery electric vehicles will meet the major part of the transport task in and around major cities.

In fact later that day down the road at the giant Daimler factory we were shown battery electric eActros truck coming down the line to the point where the chassis and cab are mated together. After that electric versions are rolled to the specialised Future Truck Centre to be ‘finished’ off with high voltage wiring and battery packs.

Daimler’s intention is to eventually have battery electric, hydrogen fuel cell and conventional diesel buses produced on the

same production lines.

Across the road from the factory an eActros 300 model truck awaited. This was a two axle 4x2 rigid electric truck, featuring three batteries, and loaded to a gross of 15 tonnes. There is also a three axle version of the, eActros which is rated at a GVM of 27 tonnes.

Of course Mercedes Benz stopped selling new buses in Australia in late 2022, thanks to the misalignment of width and weight rules in our country. But don’t be surprised if Benz buses make a comeback in a more width and zero emission friendly local environment. Although the ‘up start’ start-ups will trumpet the fact that they are debuting or signalling they’ll debut zero emission vehicles, the fact is that Daimler has been leading the scene working on battery electric vehicles for the past 13 years and debuted its first series production BEVs back in 2017, in the form of the Fuso eCanter.

It was hard to know what to expect from the eActros. Would it be a bigger version of the eCanter ? Or would it have its own

character and identity? And how would it cope with a much larger GVM?

In those searing conditions we didn’t have to wait long to discover that in every way it was a very different proposition to its Fuso sibling.

In the searing temperatures, with sun baked turf of the nature strips, it felt more like the western suburbs of Sydney than central Germany as we climbed aboard the eActros.

Again, just like the Gen H2 hydrogen truck earlier in the day, the eActros delivered seamlessly smooth and quiet acceleration, quite literally blasting away from traffic lights and stops signs with car like performance.

All the while we were cossetted in the eActros cabin with the air conditioning keeping us cool as we snaked along German country roads, through villages and suburbs as well as a blast down an Autobahn. The performance of the eActros could not be faulted, and we feel confident, knowing Daimler’s track record, that

evolution will further improve the breed further over coming years.

German customers can already buy the eActros, while that option will not be available to Australian truck buyers until early in ’24.

Another part of the Daimler BEV strategy will be the eEconic specialty electric waste truck, which recently commenced series production at Wörth.

As inner city residents we are eagerly anticipating the arrival of not only an electric waste disposal truck like the eEconic, but also electric buses for our early morning sleeping habits if nothing else. The fact is that the inner city sector is one that is ideally suited to a battery electric model, given the relatively short distances, stop-start activity and the sensitivity to noise and pollution in high density population areas.

While skyrocketing oil prices and the Euro push to zero emission is driving demand for the electric commercial vehicles, real numbers are still relatively small, given

the electric is three times the price of the conventional ICE model. However with increased volume, the cost of purchasing electric buses and trucks, like the other Daimler zero emission vehicles will drop in time, while fuel costs will continue to weigh heavily on company balance sheets making the switch to electric even more attractive.

Pressure from not only national and regional politicians but also in local government are driving the move to electric commercial vehicles, not to mention the pressure from Daimler’s own culture and its goal to reduce CO2, which is also driving the move to a zero emission model.

Ever the conservative corporation, Daimler suggests that the battery life for an electric bus should be about six to eight years, but that errs on the side of the pessimism. Under promise and over deliver, is Daimler’s philosophy, clearly. That a three day trip to Germany could reveal as much as this one did about the future of road transport is quite remarkable.

Out on the Western Plains of Queensland it’s easy to visualise the words from Peter Allen’s iconic Tenterfield Saddler, but for Queensland based coach operator Palmer’s, the black cockatoo is not just it’s logo but also a symbol that has significant releveance in outback Queensland. We take a look at Palmer’s operations and in particular its strong reliance on Scania.

For many of us living in the big cities mines are far off things, that these days mostly fly their workers in and out of the remote locations where the digging and blasting goes on.

However FIFO or Fly In/Fly Out is not the only way miners access their workplaces across this wide brown land. In fact buses and coaches play a vital role in delivering valuable and hard to find workers to mines across the country.

The reality is that contracts to transport mine workers have kept Rick Palmer’s Scania-powered coaches busy, particularly during those devastating COVID disruption through 2020,’21 and ’22. The business for Palmer’s certainly went some way toward off-setting some of the decline in tourism and charter work that blighted the entire

industry during those wretched three years of pandemic.

Rick and Kim Palmer have their bus and coach business based in Miles, around five hours west of Brisbane, along with offices at Burleigh on the Gold Coast, where the premium-class transport business operates 30 vehicles, including 14 Scania coaches.

The Palmer’s fleet comprises four fitted with Coach Concept bodies and three with IRIZAR i6, three IRIZAR Century 3900, three Coach Design and one Mills Tui.

Adding to Rick Palmer’s happiness with the efficient way the Scania’s perform is the opening of a Scania independent authorised dealer, Equipment & Transport Specialists, located nearby in Chinchilla.

“I love my Scanias and one of the biggest advantages of Scania ownership is the

Maintenance Contract,” Rick said.

“Having a local Scania dealer saves me from sending a bus to Brisbane for service, saving potentially two days if for some reason a service is due, but I don’t have a run to there,” Rick says. “The local dealer is a big bonus.”

Kim and Rick started Palmer’s Coaches back in 2012 with just one coach and since than they have grown the business to a significant mid-range fleet of just over 30 vehicles.

Rick inherited his love of coaches from his father and spent the majority of his youth driving passengers all over Australia.

With a passion for coach travel and a focus on safe, reliable and comfortable transport, Palmer’s Coaches says it prides itself on having some of the newest

vehicles on the road, backed by equally passionate and knowledgeable teams.

Rick says that the company has built a reputation for quality and reliable transport solutions particularly in the mining industry, but also in the education sector, as well as with sporting and special interest travel the company also services tourism and corporate functions through Brisbane, the Gold Coast and Outback Queensland.

Palmer’s says that as a proud and active member of the Outback community, it has adopted the iconic black cockatoo as its official logo.

“The black cockatoo in flight is an iconic symbol of freedom in the Outback, and represents endurance, good luck, new beginnings, accomplishment and journeys of all distances,” said Rick.

Aside from COVID decimating the tourism business across Australia, Rick says that after 10 years in business his biggest problem is finding staff, particularly drivers.

“It would be my number one concern, and it is putting a brake on expanding my business. It is hard to get drivers on the Gold Coast, but it is even harder out west.

“But with the Scanias, I know I have a hook to keep the drivers happy,” he said.

“I received a text message at 3.00am a while ago, and that is not a time you want to get an SMS. But it was just the driver telling me the Scania coach was the best one he’d ever driven. I was happy to hear that, but it was news that could have waited till daylight,” he says.

“While the charter work has been slow, we have had contracts to shuttle mine

workers from outback Queensland to Brisbane to fly home, and then bring in the new group. This has kept us going. The mines tend to work on a 19-day swing, and we can field up to 11 vehicles to transport the workers to and from the airport. Just before COVID hit I had acquired a bus company near Gosford and we have a business on the Gold Coast and they have been very quiet, but the mining work has carried us through,” he says.

“We usually have a couple of the coaches away on tours, there’s one now about to head up the middle from Adelaide to Alice Springs, and there’s usually one in for service. Our five new coaches are all on Scania’s Repair and Maintenance Contracts, but the older Scanias and other brands we still service ourselves.

“THE BLACK COCKATOO IN FLIGHT IS AN ICONIC SYMBOL OF FREEDOM IN THE OUTBACK, AND REPRESENTS ENDURANCE, GOOD LUCK, NEW BEGINNINGS, ACCOMPLISHMENT AND JOURNEYS OF ALL DISTANCES”

The Scania R&M takes the risk off our shoulders, it’s a predictable cost and I anticipate getting better resale values when I come to trade them or sell them, because they have been on the Scania maintenance programme,” Rick says.

Rick’s K 450 Coach Concepts flagship features a steerable tag axle for increased manoeuvrability, and a powerful Euro 6 450 hp in-line six cylinder engine mated to Scania’s 12-speed Opticruise transmission.

“The new coaches are very quiet and easy to drive, and they are very good on fuel. So far, they have covered around 200,000 km. This is less than usual given they are around four years old, so we will probably keep them longer to get as much from them as we can. We have pared the fleet back from close to 40 to around 20 and we have added a few trucks as well to broaden our offering.

“Our New Vehicle Account Manager at Scania, Brian Thompson, knows how fussy I am about my vehicles, and we have developed a very good relationship over the years. When I was deciding about the two Coach Concept bodies, he told me it would be a good decision, and it has been. Aside from the positive driver acceptance, the bodies are very tight, with no rattles or squeaks, which also keeps the passengers happy. I like very short front overhangs as the bodies can be damaged quite easily when manoeuvring, and the driveways of the motels on the Gold Coast are notoriously tight to get in and out of. The IRIZAR i6 has a short front overhang, so that is a benefit,” Rick says.

“Knowing how particular Rick and Kim are, and the pride they take in their fleet, it was great to be able to work with them on updating their fleet based on their requirements,” said Brian Thompson, Scania Bus and Coach Account Manager for Queensland and northern NSW.

Forty five years is a long time in any business and that is exactly how long Brisbane’s Kangaroo Bus Lines has been transporting people around South east Queensland and beyond. After recently taking deliver of some new Volvos the company reckons it might just have jumped to the next level.

Kangaroo Bus Lines, like a lot of transport start-ups, was born of humble beginnings. Back in 1978 the family owned and operated bus company began operations with six buses run from a private house on the edge of Moreton Bay.

From those humble beginnings the Brisbane based bus line has grown to have more than 140 vehicles on the road and has become one of the leading bus operations in South East Queensland.

Over the past 40 or more years Kangaroo has evolved to encompass a range of transport solutions and experiences

throughout Queensland and beyond and has historically been a leader in the industry, particularly with its innovation and sustainability.

These days Kangaroo boasts a head office just to the north of Brisbane between the CBD and the Sunshine Coast at a purpose built facility which is home to more than 100 immaculately presented, modern buses along with a state-of the art workshop and a staff of passionate and dedicated people.

It is fair to say that the company is an integral part of the to the passenger transport industry in Queensland these days

and it takes pride in moving people and connecting communities around the region. Kangaroo Bus Lines is also strongly immersed in the tourism and education sectors with extensive offerings in transport, logistics and experiences.

The company says it offers complete, personalised transport solutions tailored to customer needs and has identified the need to embrace shifts within the industry. The milestone handover of ten city buses late last year marked start of a whole fleet transition for KBL.

Until recently, the bulk of KBL’s city route city buses used a US sourced

drive train with Cummins and Allison on board. However KBL’s CEO, Darren Webster said the transition to a European chassis with the acquisition of Volvo buses, marks the start of a much bigger transition for the company.

“Seeing that Volvo has a very steady product range in Euro 6, as well as Hybrid and Electric, really reiterated to us that they were the right choice for a long term business partner,” said Webster.

“As our industry evolves quickly, we knew we wanted to work closely with a manufacturer who could show their consistency in terms of product quality

and service support,” he said.

Following the delivery of a range of Volvo B11R coaches over the past two years, KBL says it has been consistently impressed with the level of customer care shown by the Volvo team, who are headquartered close by in Brisbane.

“We saw an opportunity to move to a Partner that could offer the full package –not only coaches, but the next generations of vehicles too,” said Webster.

“We could see through our experience working with Volvo on our coaches, that they had the product range and support

services to really be good business partners,” he added.

KBL revealed that local support also means a lot as well, which is why it says that local body build partner Volgren was an obvious choice.

Volvo Bus Australia agrees with this, and having partnered with the local team at Volgren Brisbane for years, which has delivered more than a thousand buses as partners, including a major contract for the Brisbane City Council, Volvo and Volgren knew that a quality, locally built product would be a solid solution for the KBL operations.

“We’ve worked closely with the team at Volgren for several years now, and were confident in delivering a quality product to KBL in the Volvo-Volgren low-bodied units”, said Volvo Bus Australia’s general manager, Mitch Peden.

Reflecting further on the partnership, Peden is clearly quite proud of the work the company has done with, and for, KBL.

“Working closely with Kangaroo Bus Lines to truly understand their business

needs has been an excellent experience for my team,” Peden said.

“We’ve been able to problem solve together, and show KBL that we’re in it for the long term – from service, to training, to body build support – my team have been on the ground to work through this low floor transition with the KBL crew,” he said.

“Its another excellent example what true business partnership means to us here at Volvo Bus,” Peden said.

Webster echoed these sentiments, saying that the service and support it received on the coaches delivered of in 2021, and on every bus since, has just reconfirmed that it has partnered with the right chassis provider.

“We have been so pleased with the support we’ve received from Volvo, and are really reassured we’ve chosen the right manufacturer for our ever-growing fleet,” said Webster.

TRP® offers a comprehensive range of washes for all types of applications. No matter what your preferred washing style, we have a wash to suit!

All our washes are formulated and manufactured in Australia. They are all non-acidic, biodegradable, triple interceptor safe and inhibit corrosion.

So how do you choose which TRP® wash is right for you? It’s quite simple - go for the colour of your existing wash. If you are used to using a blue wash, go for the TRP® blue wash, If you prefer a green wash, go for the TRP® green wash. If you prefer a gold wash & wax combination, go for the TRP® gold alternative.

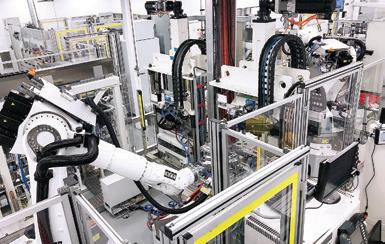

One of the most asked questions at the moment when it comes to talk of zero emission vehicles, particularly commercial vehicles, is, “how will we charge them”? Swedish commercial vehicle maker, Scania and fellow Swede ABB E Mobility are collaborating to make charging the next gen zero emission vehicles easier and more efficient. We take a look at what the two companies are up to.

How do we charge them?

That is a very good question and one that is exercising some of the best and brightest minds in the automotive and electrical engineering universes right now.

For Scania, which as part of the giant VW controlled Traton heavy vehicle corporation, is a flag waving proponent for electric vehicles, it is not leaving the charging situation to chance and has aligned itself with global engineering company and fellow Swede ABB to forge a collaboration that will be key in driving

electrification of heavy duty transport.

Recently a Next generation electric Scania truck completed its first charging test with a pilot Megawatt Charging System (MCS) which has been developed by ABB E-mobility

Scania says that the testing represents a global milestone in development of charging system for heavy duty vehicles not only in Europe but also here in Australia.

Scania has so far successfully installed and tested a pilot ABB E-mobility megawatt charging system that it says

represents the next milestone in the development of an efficient, high-power charging solution for heavy-duty vehicles. The technology will enable charging times to be halved for heavy-duty buses.

“This could be a significant step towards the realisation of longer distance battery powered coach and bus travel which would be ideal for Australian conditions,” said Scania Australia’s director of sales for bus and power solutions, Julian Gurney.

“At present, the Australian landscape does not permit the use of zero emission buses and coaches for long-distance

running due to the limited range of the batteries and more specifically, the time taken to recharge,” Gurney explained.

“But as battery cell technology improves range and Megawatt charging systems are developed and initiated, this represents a huge opportunity for deploying our battery electric buses and coaches over distances that are more in line with school and charter bus operators in our regional and extra urban areas,” he added.

“This could also be ideal for tourism operators, giving them an extra advantage, by appealing to inbound tourists visiting our areas of natural beauty in the comfort of zero emissions vehicles,” he said.

“We welcome the news of the successful testing of this system by ABB and Scania in Europe and look forward to the implementation stage of this technology in Australia which could literally open the door to unimpeded zero emission bus and

coach travel for a much larger scope in application and appeal to a wider group of the travelling public,” Gurney added.

“Furthermore, with zero emission bus transport growing in scope, we could conceivably reduce the numbers of cars on the roads, as travellers switch to BEV buses, which additionally enjoy the bonus of being near silent in operation, providing and even more comfortable and appealing journey options,” he said.

“Scania and ABB’s Megawatt charging trials bode well for the introduction of battery electric long distance coach travel – further cementing Scania’s push to be the leader in sustainable transport solution in Australia,” said Julian.

Both Scania and ABB say they are committed to enabling a zero-emission transport future and taking the lead in developing tomorrow’s technology today. Developing a solution to fast charge these

commercial electric vehicles, which will also deliver significant range, is a major step towards increasing sales of heavyduty vehicles that can be driven fossil-free.

The initial testing, to prove the technical viability of high current charging, is a first important step towards the future MCS system from ABB E-mobility. This will result in the progressive deployment of high-power chargers, starting from 1,500 Ampere and eventually extending to the full MCS scope of up to 3,000 Ampere. This is a charging standard that Scania and ABB E-mobility have both invested in and have been instrumental in developing in collaboration with CharIN (the MCS standard is expected in 2024).

MCS technology is critical for Scania’s long-haul electric trucks, where both driving time and resting time are regulated by law. The vehicle can be driven for a maximum of 4.5 hours before the driver

needs to take a 45-minute break and during this time the truck needs to charge enough power to operate another 4.5 hours. Due to the size of the batteries, both fast and high-power charging is essential.

“We see momentum for electric transport and our goal is that 50 percent of all vehicles we sell annually by 2030 are electric. To achieve this goal will require infrastructure and MCS is a crucial piece of the puzzle for the infrastructure going forward,” said Fredrik Allard, Scania’s head of E-mobility.

ABB E-mobility is a global leader in EV charging solutions, and is at the forefront of delivering the reliable charging infrastructure and robust service capabilities which fleets require in order to successfully transition to electric.

Chris Nordh, ABB E-mobility’s global head of the fleet and transit business said that the company was delighted to be collaborating with Scania on this milestone

pilot, which he says, will set a precedent for the sector and identifies one of the ways they can collaboratively approach OEM charging partnerships, effectively verticalizing the technology stack to create great end-user experiences.

“Today is an exciting day and we look forward to many more milestones to come as we further develop a quality, reliable, and seamless charging experience for fleets,” said Nordh.

Scania says it can now offer trucks with the MCS pre-standard connector to customers with specific and pronounced needs, with production set to begin in 2024. ABB E-mobility will introduce the next iteration of its MCS technology in late 2024/early 2025.

ABB claims to be a global leader in electric vehicle charging solutions, saying it boasts the highest uptime and largest installed base of DC fast chargers in the

market globally.

It’s vertically integrated offering includes wide portfolio of AC and DC charging hardware, a range of digital services and advanced energy and fleet management solutions, using critical cloud-based connectivity, to provide 24/7 remote monitoring and diagnostics.

ABB claims more than 13 years of experience in DC fast charging and boasts sales of more than one million electric vehicle chargers across more than 85 markets, including more than 50,000 DC fast chargers and more than one million AC chargers.

ABB says that to continue its leadership in the fast-moving space of electric vehicle charging it has created a platform for future growth, by transitioning its E-mobility Division into a stand-alone business. With E-mobility as separate legal structure, we create a platform for accelerated growth and value creation in this business.

“ WE WELCOME THE NEWS OF THE SUCCESSFUL TESTING OF THIS SYSTEM BY ABB AND SCANIA IN EUROPE AND LOOK FORWARD TO THE IMPLEMENTATION STAGE OF THIS TECHNOLOGY IN AUSTRALIA”

Long, long ago the legend of the Ark was born, a receptacle for animal life on the planet to save species from the coming flood. In Sydney in the year 2023 an ARCC is something very different, but like Noah the people at ARCC hope their new aluminium frame hydrogen fuel cell bus may enable them to stay ahead of the coming flood of zero emission buses to Australian roads. We visited ARCC to see what is floating this zero emission organisation.

Peter Murley founded ARCC, or Aluminium Revolutionary Chassis Company to spell out the acronym, after selling out his interests in the Malaysian based bus builder, Gemilang to an investment group, which evolved into Nextport, as it is today.

It was while Murley was still with Gemilang Australia, that he set up the ARCC business to satisfy the vision he had that things were transitioning away from the internal combustion engine to zero emissions.

“We only do zero-emission vehicles and we are looking to go into the full mobility sector including things like trucks, aviation tugs and buses, and we are a 100 per cent Australian owned,” Murley explained to us when we visited the ARCC facility in Wetherill Park in Sydney ‘s West.

“Everything that we’ve developed, we’ve done with Australian talent, in terms of the software, the hardware etc. and we actually went into the bus sector initially, purely because it’s regulated and the government controls that consumption, so from a funding

perspective that is important,” he continued.