SPECIFICATION Magazine

You may just see a roof. But by specifying a complete Marley Solar Roof System, you can be sure of a secure and robust solution, that also delivers more desirable, energy efficient homes. It’s more than a roof, it’s building to make a difference.

As 2025 starts around 1 in 5 households across the UK are living in poorly insulated homes, according to research from the Building Services Research and Information Association (BSRIA).

The UK has the oldest and least efficient housing stock in Europe. BSRIA commissioned a study of 2,000 UK homeowners and tenants to investigate the factors holding back the energy efficiency of homes.

The research revealed that poor or inadequate insulation in walls, roofs, or floors is the primary challenge for 20% of homes, while a quarter (23%) of homeowners flagged drafty doors and windows as a concern. 22% identified a lack of smart heating controls as a key issue affecting energy efficiency.

Moreover, nearly a fifth (18%) said they were worried about poor ventilation in their home leading to condensation or mould.

Only one in five people consider their home energy efficient, with over-55s most likely to stay warm this winter.

Tom Garrigan, Technical Director at BSRIA said: “EDF figures indicate that the average semi-detached homeowner could save up to £235 a year if they upgraded their cavity-wall insulation, £225 by having a well-insulated loft, or £315 a year if they updated their solid wall insulation. However, it’s clear from this research that, despite the energy crisis, little progress has been made in educating the British public on ways to improve the efficiency of their home, meaning millions are missing out on significant savings on their energy bills.”

According to the research, over half of British homeowners (55%) are unfamiliar with the term retrofit in relation to buildings. This involves taking steps to make homes more self-sufficient, through energy-efficiency measures like loft insulation, cavity wall insulation and double-glazing.

Lisa Ashworth, CEO at BSRIA said: “Improving the energy efficiency of homes is important to tackling fuel poverty and reducing emissions, but it’s also crucial for the long-term physical and mental wellbeing of the population. The health implications of poorly insulated homes are staggering, and we urgently need to improve our building stock to safeguard people and ensure that everyone has a warm and comfortable place to live.”

Introducing Impact - the theme driving Futurebuild 2025. Impact reflects our shared commitment to positive change in the built environment, with a focus on sustainability and innovation. By visiting Futurebuild 2025, you'll not only experience this transformation but also take part in it.

Discover cutting-edge solutions, connect with industry leaders, and gain the tools and insights to make a meaningful impact in your work and beyond.

After

manufacturer Russell Roof Tiles

developed a revolutionary concrete roof tile suitable for a wide range of applications. The new roof tile, called Bute3® is 33 per cent quicker to install than similar tiles and has never been made at high production speeds before.

Read more on page 18 - 19.

Enquiry - 11

TSP Media Ltd, Grosvenor House, Central Park, Telford, TF2 9TW

T: 01952 234000

E: info@tspmedia.co.uk www.tspmedia.co.uk

Glenigan, one of the construction industry’s leading insight and intelligence experts, released the December 2024 edition of its Construction Review.

This Review focuses on the three months to the end of November 2024, covering all major (>£100m) and underlying (<100m) projects, with all underlying figures seasonally adjusted.

It’s a report which provides a detailed and comprehensive analysis of yearon-year construction data, giving built environment professionals a unique insight into sector performance over the last 12 months.

The latest data paints a generally positive picture. Project-starts and main contract awards showed promising year-

on-year growth, highlighting returning socioeconomic stability after an extended period of market uncertainty. However, tempering these activity boosts, detailed planning approvals suffered a significant decline, indicating that persistent cost pressures and dented industry confidence continue to hinder sector-wide revival.

Commenting on the December Review, Allan Wilen, Economic Director at Glenigan, says: “There’s definitely work to be done and the latest figures show glimmers of recovery, with modest growth in project-starts and contract awards offering a degree of optimism.

“The Autumn Statement and some of the immediate actions taken by the Government to kickstart building in some verticals, particularly housebuilding will

Foster + Partners has revealed designs for Regent Residences Dubai, Sankari Place, which comprises two striking residential towers (180 metres) in Dubai’s Marasi Marina, Business Bay.

Inspired by cascading water, the adjacent towers make a unique contribution to the city’s skyline and waterfront, with sixty interlocking apartments and staggered terraces. The project is a collaboration between Sankari and IHG Hotels & Resorts.

Gerard Evenden, Head of Studio, Foster + Partners, said: “Regent Residences Dubai, Sankari Place’s dynamic twisting form and articulated façade will make it a distinctive

new addition to Business Bay and the wider city. Our design harnesses connections to nature, with generous shaded terraces and optimised views of the waterfront.”

The architectural form is divided into two towers, which share the same design language. This creates space for one generous apartment per floor, thereby increasing natural ventilation and light. Every apartment is orientated to offer panoramic views of the Burj Khalifa, while capturing the city’s spectacular sunrises and sunsets. Designed to enhance wellbeing, the apartments all have expansive terraces that allow residents to enjoy outdoor living and a healthy lifestyle.

have helped. However, the sharp decline in detailed planning approvals highlights investors will be keeping their powder dry until more stability returns to the market, inspiring the confidence needed to turn on the development pipeline tap.

"In line with our Forecast predictions, H.1 2025 will unlikely see significant growth, however, H.2 will likely see a sudden spurt, following the Government’s Spring Spending Review and sector-specific strategic announcements.

“A sustained focus on public infrastructure, health, and housing projects will be critical to driving recovery in 2025 and beyond. The industry will be watching closely to see how these fiscal policies and investment commitments translate into on-the-ground activity."

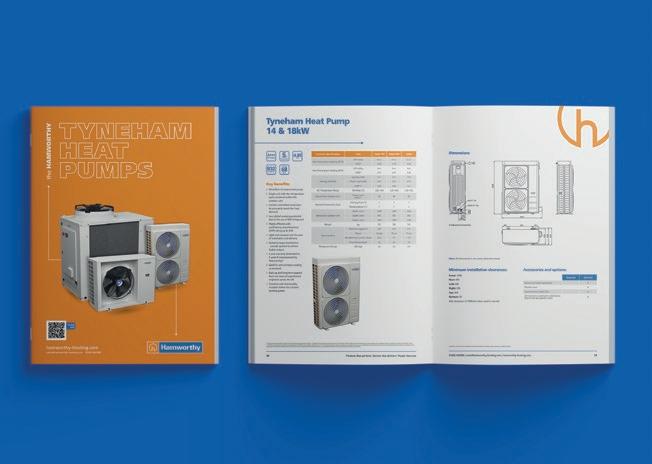

Mitsubishi Electric, the UK’s largest heat pump manufacturer, is proud to announce that its Training Centre in Hatfield has been approved as a LCL Level 3 training centre for air source heat pumps.

This prestigious accreditation is a testament to the company’s commitment to providing top-tier education and training for installers in the renewable heating sector.

Installers who register for the LCL Level 3 training at the Hatfield Training Centre, and who meet the grant eligibility criteria*, can benefit from a £500 grant to cover most of the training cost.

On completion of the three-day course, installers will receive an LCL Awards Level 3 Certificate, which is recognised by the Microgeneration Certification Scheme (MCS). In addition to this, Mitsubishi Electric is offering a two-day training course in low temperature and hot water at its Hatfield centre.

Introducing the brand new FP McCann range of high quality, machine produced Concrete Roof Tiles. Now available in a variety of profiles and colour options. FP McCann also boast an extensive range of roofing accessories, each specifically chosen and designed to work in cohesion with all aspects of the FP McCann Full Roof offering and are completely compliant with BS 5534 and NHBC guidelines.

CONTACT: JONATHAN PRATT FP MCCANN NATIONAL ROOF TILE MANAGER 07740433860 | JPRATT@FPMCCANN.CO.UK

A new study from the Building Services Research and Information Association (BSRIA) has found that retrofit training gaps are stalling Net-Zero progress in UK construction.

The research surveyed 500 construction professionals and revealed that there is a low sector-wide understanding of retrofit technologies and approaches, creating a potential bottleneck in the UK’s plans to decarbonise.

Four in ten professionals stated that the level of training available to them was insufficient and that industry knowledge and understanding of retrofit techniques are currently ‘lacking’.

However, many professionals see retrofitting existing buildings as a more effective path to reducing carbon emissions compared to constructing new. Nearly two in three (62%) believe retrofit projects provide greater benefits for achieving net zero than newbuild homes.

QUALICOAT UK & Ireland has welcomed Origin, which has recently been awarded their QUALICOAT licence.

Origin joins a growing number of powder coaters across the UK & Ireland who are taking advantage of the QUALICOAT Specification to elevate their commitment to coating quality. Origin is now able to use the QUALICOAT label of conformity on all their paperwork and market communications.

The label, which can only be used by licensed members of the QUALICOAT Association, is registered worldwide. Members of the Association include powder manufacturers, pretreatment systems suppliers and powder coating applicators.

These three main membership groups form the vertical integration required to precisely specify both product and processes that offer the best quality coating for architectural aluminium products used in either commercial or residential applications.

Another area of the study examined how professionals measure the impact of applied retrofit measures.

Just two in five professionals (43%) measure building performance after envelope changes, highlighting a concerning 'do-it-and-dash' trend that skips energy, carbon, and comfort evaluation. An approach that can lead to suboptimal results.

The study also flagged an interesting area of debate – what constitutes ‘comfort’ within Net-Zero spaces. Professionals remain divided - two in five identified it as air quality and ventilation, while just over half (52%) said thermal comfort was the most important factor. Natural lighting closely followed (50%) and then acoustic comfort (40%).

In context, these stats show variations in which retrofit measures take precedence. It also highlights a growing need in the

industry to define a standardised approach to retrofit assessments, such as the new BS 40104 standard.

Tom Garrigan, Technical Director at BSRIA said: “The results of this study show a snapshot of the industry’s approach to retrofitting. There’s a clear need for detailed pre- and post-retrofit assessments. Understanding a building's condition, possible defects, and energy performance is an essential step but one that appears to be lacking. Without high-quality testing, building owners will never know the true value of retrofit investments.”

Lisa Ashworth, CEO at BSRIA said: "Retrofitting 29 million homes by 2050 is an ambitious goal for the UK. To achieve it, we must upskill the construction workforce on the value of retrofitting and the need for a meticulous approach to every property. As the saying goes, ‘you can’t test what you don’t measure’—a mindset the entire industry must embrace."

CIBSE unveils its modern new head office

CIBSE has opened its new head office at 91-94 Saffron Hill, EC1N 8QP, in the vibrant Farringdon area of central London.

This relocation marks a monumental milestone in CIBSE’s history, following 44 years at its previous home in Balham.

Situated in one of London’s most dynamic and accessible locations, the new head office embodies CIBSE’s vision for the future - offering an innovative,

inclusive and collaborative environment that reflects the Institution’s global reach, growth and ambition. This new space underscores CIBSE’s commitment to its members, the wider industry and its international footprint, enabling even greater engagement and collaboration.

The new CIBSE head office is a significant upgrade in size, design and functionality compared to the previous Balham location.

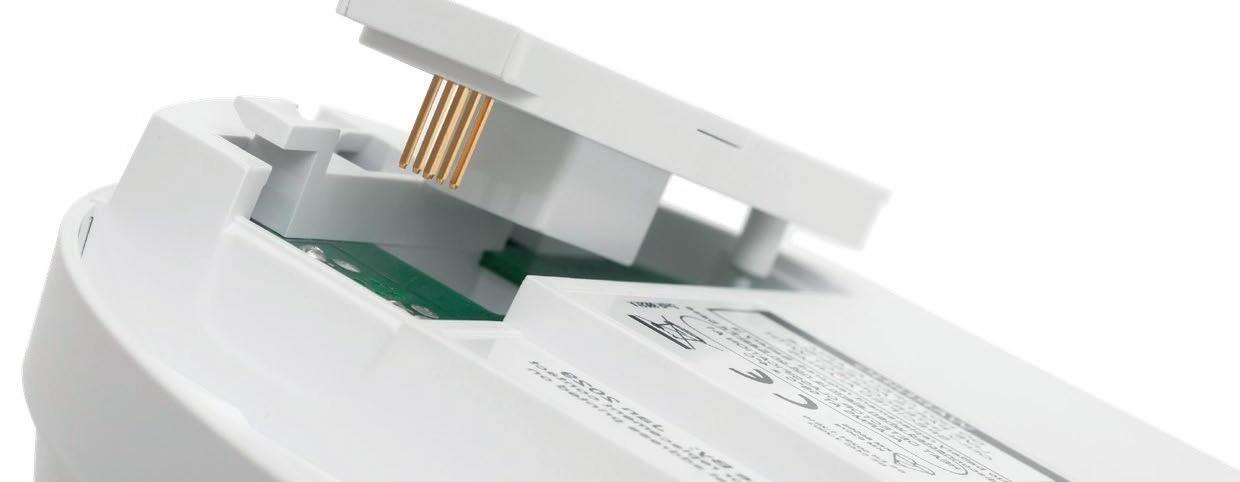

The latest addition to the technologically advanced 30 0 0 Series, the Ei3030 combines individual Optical, Heat and CO sensors for the ultimate fire and CO response, while maintaining the simplicity that Installers love.

Add the Ei3000MRF for wireless interconnection and data extraction via the Ei1000G Gateway

Smart, connected and future-proof.

Scan here to learn more about the Ei3030

For the B uilding S afety- R egulator, the B uilding S afety A ct ( BSA 2022) has been about turning plans into action.

The Grenfell Tower Public Inquiry’s Phase 2 report remains a stark reminder of why this work matters. It challenges the industry to learn from past mistakes and ensure residents’ safety and well-being are at the heart of every decision.

That is the message of Philip White, HSE Chief Inspector of Buildings, in a review of 2024. He says 2024 was a transformative year for building safety in England. It marked the shift from groundwork to meaningful action.

“Think of it like moving into a new home – exploring the space, tackling immediate priorities, and laying the groundwork for improvements, he said.

“Since our May conference, which marked a new era for building safety, BSR has become fully operational. This isn’t business as usual – it’s a generational shift in how the construction industry operates. BSA2022 introduced new frameworks and principles that require fresh thinking and collaboration.

“The post-conference survey reinforced this commitment: 71% of the 1,300 delegates reported a good or full understanding of their responsibilities, and nearly half (47%) said they intended to make significant changes to their practices this year.

“Throughout 2024, we’ve worked to embed these principles. By setting consistent building control standards and holding those managing higher-risk buildings accountable, we’ve laid strong foundations for lasting change.

“July brought one of our biggest challenges when an unexpected surge in applications,

In 2025, the BSR will continue strengthening the regulatory framework, improving competence across the sector, and amplifying residents’ voices. The mission goes beyond compliance -it’s about rebuilding trust and creating a safer future.

“Next year, we’ll work with government, industry regulators, fire authorities, Mayors, and local leaders to accelerate remediation for higher-risk buildings still affected by unsafe cladding,” he said. “Collaboration will be key to driving this critical work forward.

driven by external industry issues, caused delays in processing building control applications.

“We acted quickly to keep things on track, putting contingency measures in place, such as recruiting additional staff and securing industry support. These steps are already having a positive impact, helping us manage the increased demand.

“We’re committed to overseeing the safety and compliance of higher-risk buildings, while supporting industry to deliver safe and successful projects. The new gateway processes, introduced in response to the Grenfell tragedy, are central to raising safety standards.

“We know that adapting to a new system takes time. That’s why we’re working closely with industry leaders – listening to feedback, strengthening our advice, and providing clearer guidance to help applicants navigate this process with confidence.”

He said building safety is more than meeting regulations – it’s about transforming how we work and think. At the heart of this shift is competence.

“Another priority will be modernising the Approved Documents framework in particular consulting on a revised Approved Document B, which covers fire safety. By simplifying and clarifying these rules – especially for smaller builders – we aim to make compliance more accessible and straightforward. A public consultation is expected by early autumn. The progress we’ve made proves what can be achieved when we work together. But there’s still more to do. Professionals, policymakers, and residents all have a role to play in shaping a safer built environment.”

It’s not a box to tick but an ongoing responsibility. Professionals must ask themselves:

• Do my teams have the skills and attitudes needed to deliver safe outcomes?

• Am I staying within my expertise and improving my knowledge?

• What more can I do to embed safety into everything we do?

“Building safety isn’t just about technical standards – it’s about people and their homes,” he added. “At BSR, we’re committed to putting residents’ safety at the heart of everything we do. It’s not enough for people to be safe; they also need to feel safe. That means knowing their homes are secure, their concerns are heard, and their voices matter.

“Change isn’t easy, but it’s essential. This year’s challenges have only strengthened our resolve. One clear message has emerged: those who create risks must be held accountable for managing them.

“As Gateway 3 progresses, we’re focusing on verifying compliance during the final stages of construction. Managing design changes to maintain safety standards will be a critical priority.”

The Verta range provides a versatile solution for concealing interior & exterior concrete columns, and structural steelwork, with durable and decorative column casings.

With six separate products within the range, Verta casings can be specified in a choice of materials, standard dimensions & shapes, while fully bespoke manufactured solutions are key features in the range, alongside a wide palette of decorative finishes.

This enables us to offer column casing solutions that can meet the broadest scope of specifications, installations and project needs. We also provide a dedicated professional installation service, allowing us to maintain complete control over any Verta column casing project.

Whatever your casing requirement - we’ve got it covered.

The Royal Institute of British Architects ( RIBA ) named six columns by 31/44 architects as the winner of RIBA House of the Year 2024, the annual award for the UK’s best new home.

Designed by Will Burges, Director of 31/44 Architects, as a family home for himself, his wife and two children, Six Columns cleverly occupies a tight urban plot in the leafy suburbs of Crystal Palace, South London. As the family occupy the building, they will continue to tinker with it, inside and out, allowing it to evolve to their changing needs over time.

Named after the six columns that form the main structure of the building, the two-storey, four-bedroom house echoes the proportions and materials of neighboring terrace houses, while retaining its own individual character that references the designer’s broad architectural influences, such as the Barcelona Pavilion by Mies van der Rohe or the Case Study houses in California.

The house is discrete and considerate to its neighbours but there are design flourishes that allow the project to carefully balance both conventional and contemporary features. For instance, its brick façade and terracotta tile roof align with the rest of the street, while concrete beams and a statement veined marble panel by the front door add a touch of bespoke grandeur.

Inside, the layout makes the most of the wedge-shaped site, creating a functional family home that can be easily adapted for future requirements.

The entrance hall serves as the central hub, connecting the home’s various zones.

To the left, a light and airy kitchen diner blends modern finishes – such as full height sliding windows and sleek white granite countertops –with a distinct raw aesthetic, exemplified by oiled, unpainted pine cupboards and drawers.

To the right of the entrance, the layout swaps open-plan design for modular living, with smaller rooms that prioritise storage and privacy. The living room is characterized by thick exposed pine walls that double as shelving units and serve as a Wunderkammer (or cabinet of curiosities) to showcase the family’s collections and memories. While designed to feel snug

in winter, the room can be opened up via a sliding door to the kitchen during the summer months.

In addition to the self-contained bedroom suite on the ground floor, two further bedrooms can be found on the second floor, and a fourth within the attic, nestled within a raised roof box. >>

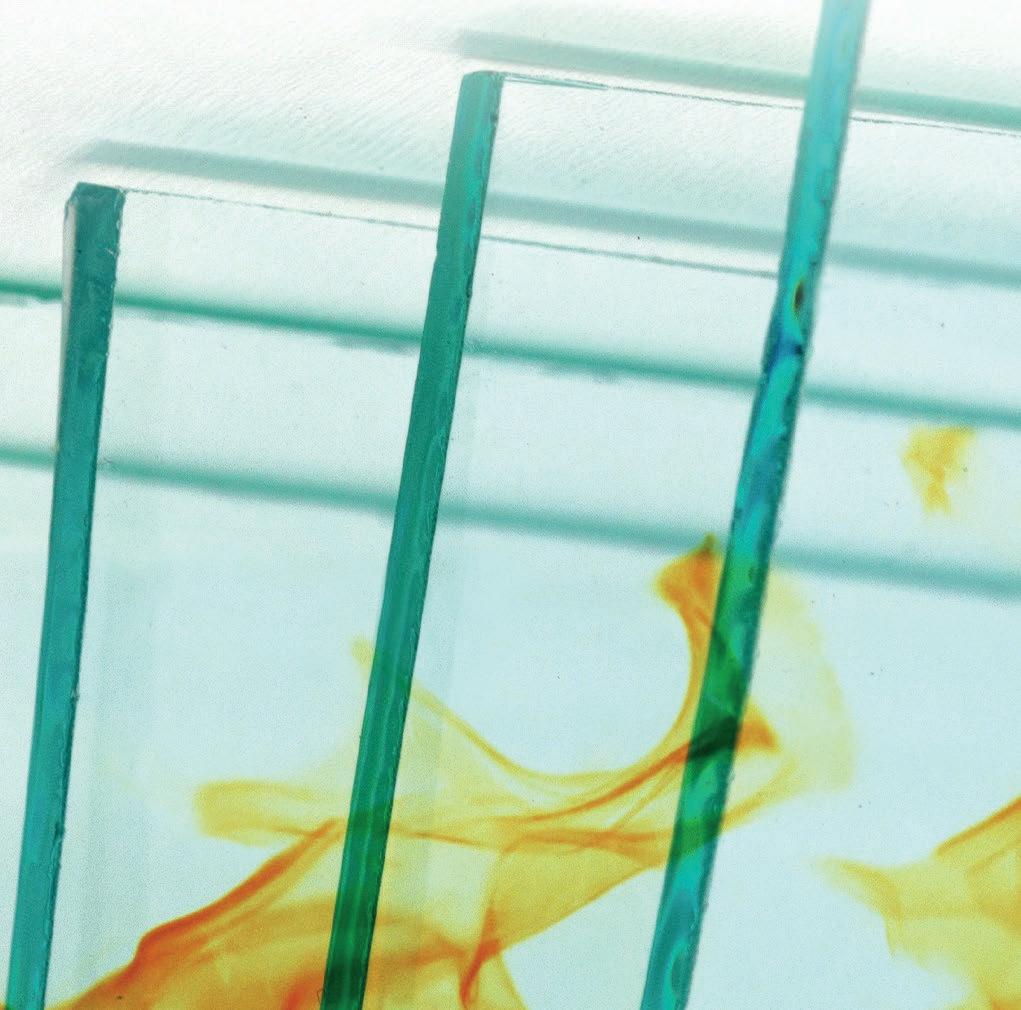

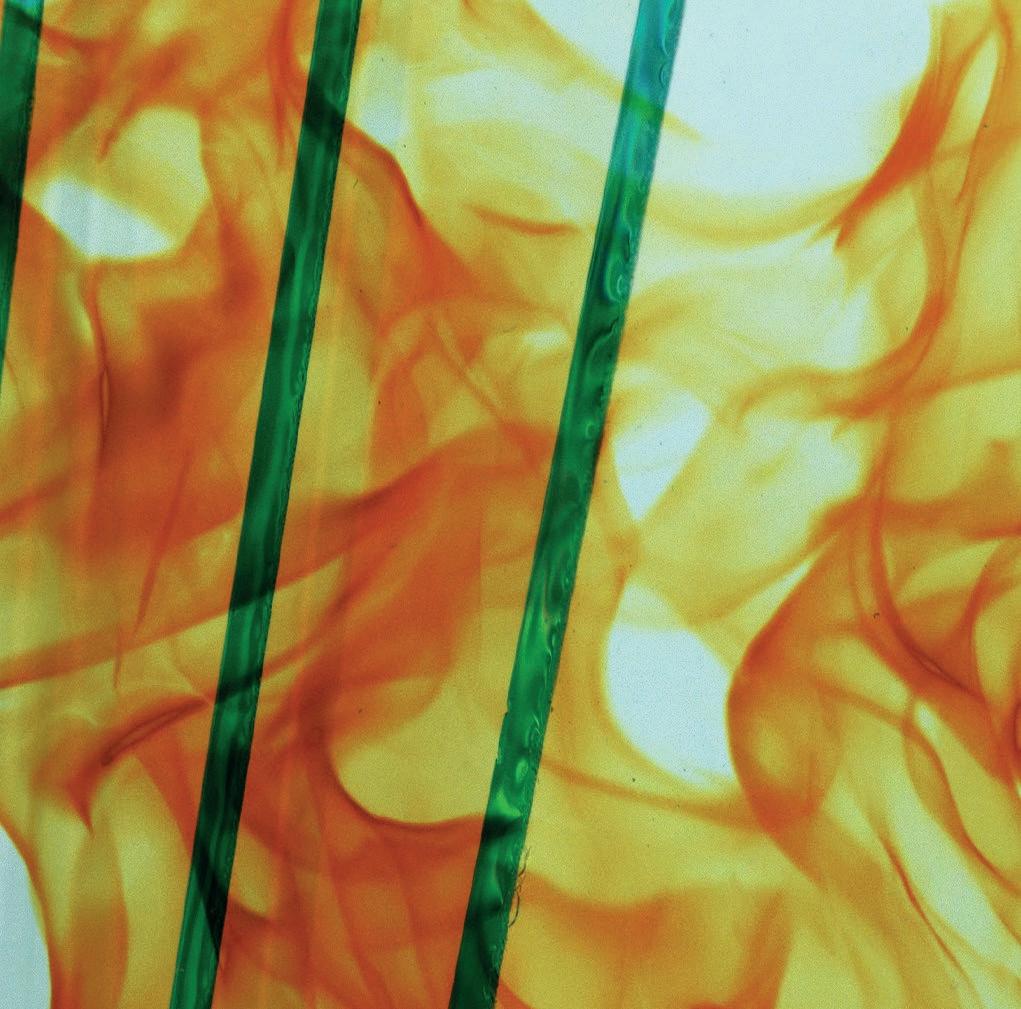

For fire resistance and protection of people and property

Multifunctionality in fire protection

PYRAN® S is a pre-stressed, monolithic borosilicate single pane safety glass in accordance with EN 13024-1.

As a component in fire-resistant glazing that meets the requirements of resistance classes E 30, E 60, E 90 and E 120, it has proven its outstanding optical and mechanical characteristics over the years in a wide variety of buildings.

Areas of application

PYRAN® has been internationally approved and ideally suited for:

• Facades

• Partition walls

• Skylights and rooflights

• Doors

• Roofs

• Smoke screens

• lift door glazing

• lift shaft glazing

Facts

• Higher ability to withstand temperature differentials: In comparison to soda-lime glass, tempered borosilicate glass can better withstand temperature differentials and can therefore be glazed with normal edge covers (20±2 mm).

• Higher softening temperature: Because the glass is selfsupporting for more than 30 minutes, large panes and simple frame constructions are now possible.

• Higher viscosity: The glass flow rate is low due to the high viscosity and durability of borosilicate glass, so with more edge cover, greater fire resistance times in excess of 90 minutes can be achieved.

• NiS crystals do not form: Due to the chemical composition of borosilicate glass, nickel sulphide crystals cannot form. Spontaneous glass fracture due to embedded NiS crystals cannot happen with PYRAN®.

Further information is available from our sales and technical offices or visit www.firmanglass.com

Tel: 01708 374534 Email: Pyran@firmanglass.com

Firman Glass, 19 Bates Road, Harold Wood, Romford, Essex RM3 0JH Enquiry 7

>> The use of self-finished materials throughout intentionally challenges the layering and ‘covering-up’ of contemporary construction. Exposed painted brickwork and readily-available spruce pine panels for fittings and joinery not only offer a natural warmth, but can be adjusted with ease in the future.

Outside, the house boasts three separate garden spaces, including a low-maintenance, west-facing rainwater garden that channels water from all the roofs that tumble out of a huge spout and into a steel tank to prevent overflow and promote reuse.

RIBA President Muyiwa Oki, said: “Six Columns is a beautifully crafted family home that cleverly incorporates Brutalist references and creative flourishes while retaining a strong sense of suburban belonging.

“It shows what can be achieved when working with even the tightest of suburban sites, and its flexible, unfinished aesthetic offers a solution to futureproofed design: this is a home that can evolve with its occupants’ changing needs overtime.

“The generosity of space belies the limitations of this small garden plot.

As we look for creative and practical solutions to the housing crisis, Six Columns offers a blueprint for bespoke urban infill development.”

The 2024 RIBA House of the Year Award Chair, Je Ahn, said: “What makes a great home? Building your own home is a hugely intensive endeavour; if you are lucky enough to do it at all, you will probably only ever do it once in your life. One-off houses are as unique and varied as we are as individuals, so often producing them needs a closer understanding between the client and architect.

“This philosophy of the home as a lifelong process might be a tricky concept in this fast-paced contractual world, however, Six Columns demonstrates an important message that we should all remember; your home is not a static slice of time, but continuously evolves with you.”

A spokesperson for 31/44 Architects described Six Columns as “discrete and considerate of the setting but not meek in character or detail”.

From a distance it sits comfortably alongside its neighbours, as you approach its personality is revealed. The resulting home is rich in architectural character; stepping brickwork wall, ‘rustication’ and ‘pilasters’ and a green marble panel capture memories of buildings visited but also contribute positively to the street; adding detail and a sense of civic luxury to the entrance area.

“Houses should be a positive contribution to the character

of the neighbourhood and the city beyond,” they said.

“The house prioritises shared spaces to gather across its three floors and minimises individual sleeping spaces. There are very few corridors and a deliberate strategy to make contained rooms complemented by more open areas. Part farmhouse and part Californian Case Study House.

“The brief was for an interior that could adjust with future requirements and tastes – in some senses it is ‘unfinished’. This strategy, facilitated by a Brutalist application of materials allowed careful control of the budget. Simply-finished bespoke joinery allows easy adaptation over time avoiding precise paint finishes and employing oiled pine with details inspired by Enzo Mari’s self-design furniture project, Autoprogettazione, and early modern joinery by Le Corbusier.”

With Promat SYSTEMGLAS®, you don’t have to choose between fire protection and sustainability in your glazing specification – you can achieve both in one system.

The fully tested fire resistant glazing system is ideal for energy-efficient, naturally lit buildings, offering a durable, long-term solution with between EI30 and EI120 protection. Manufactured in highly resource-efficient facilities using environmentally responsible processes, the system is optimised for sustainability too.

Promat UK Ltd 0800 588 4444 promatglass@etexgroup.com

Enquiry 8

As an acknowledged specialist in restoration, asws is regularly called upon to carry out surveys for client’s consultant teams in advance of major projects beginning.

Copthall House in the City of London being one instance where its involvement in preparing a scope document led to the company being awarded a contract to carry out the demanding work.

The property on the edge of the City of London dating from the late 19th Century –originally built as described in ‘The Buildings of England’ (Pesvner guides) as ‘Mathiesons the Printers’ – has been redeveloped into four high specification serviced offices by L.M. Stern. The cost consultant for the scheme was Gardiner & Theobald, with whom ASWS has a long association and which led to the fenestration specialist’s early involvement, surveying the historic four-storey frontage and advising on the most economic intervention for the aging aluminium fenestration.

The Contracts Director for ASWS, Kris Bennell explains, “We were approached during the tender process by three contractors as we were the recommended specialist for the glazing restoration/work; having made the recommendation in our original scope document that the windows

could be refurbished instead of being replaced. Culena London was successful in being appointed as main contractor, and we were awarded our contact in December 2022, two years after conducting the survey.”

“When work began the programme was very tight with the scaffold due to be struck in April 2023 while, with the aluminium frames being 30 years old, there were a number of split edges to the casements which required repairing, but the bulk of the work involved servicing the vents, replacing the factory fitted draught strips, as well as cutting out the perished rubber glazing gaskets and replacing them with manually applied silicone top caps, internally and externally.”

“Then because the original manufacturer of the window system could not be identified, we also faced a significant task of sourcing new ironmongery; eventually going to Steel Window Fittings, a fellow member of the

Steel Window Association.” Derek Finnegan, the Project Manager for Culena London, confirmed, “This was the first time we have worked with ASWS, but they did a good job keeping to what was a tight timetable and sourcing all the replacement ironmongery required. Overall, the project went well.

“The letting agents for the development describe the way various interventions at Copthall House have blended, saying, “The sensitively refurbished exterior stone elevation to Copthall House gives way to an immaculately presented reception and other interior spaces within the building, resplendent with period features such as glazed brick bays and decorative cast iron columns, which have been retained and restored in respect of the historic building, and combined with luxurious modern finishes.”

Our fire and safety glass products are ideal for fire doors, screens, and glass partitioning systems.

We offer in-house CNC work and oversized IGUs to meet your bespoke project needs.

Technical advice and support is provided, and we stock all major brands of fire-rated glass, as well as acoustic, laminated, toughened, and mirrored glass products, available with short lead times. Supply only or supply and fit, to ensure your project is completed efficiently and to the highest standards.

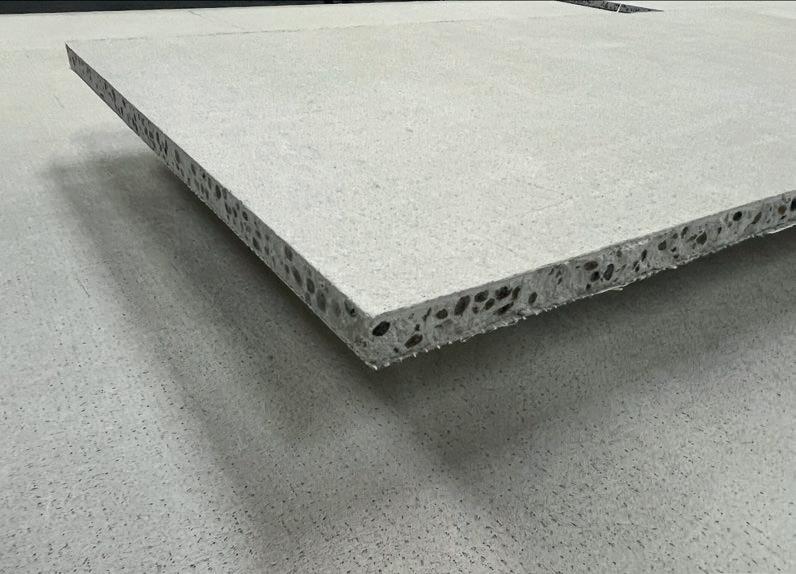

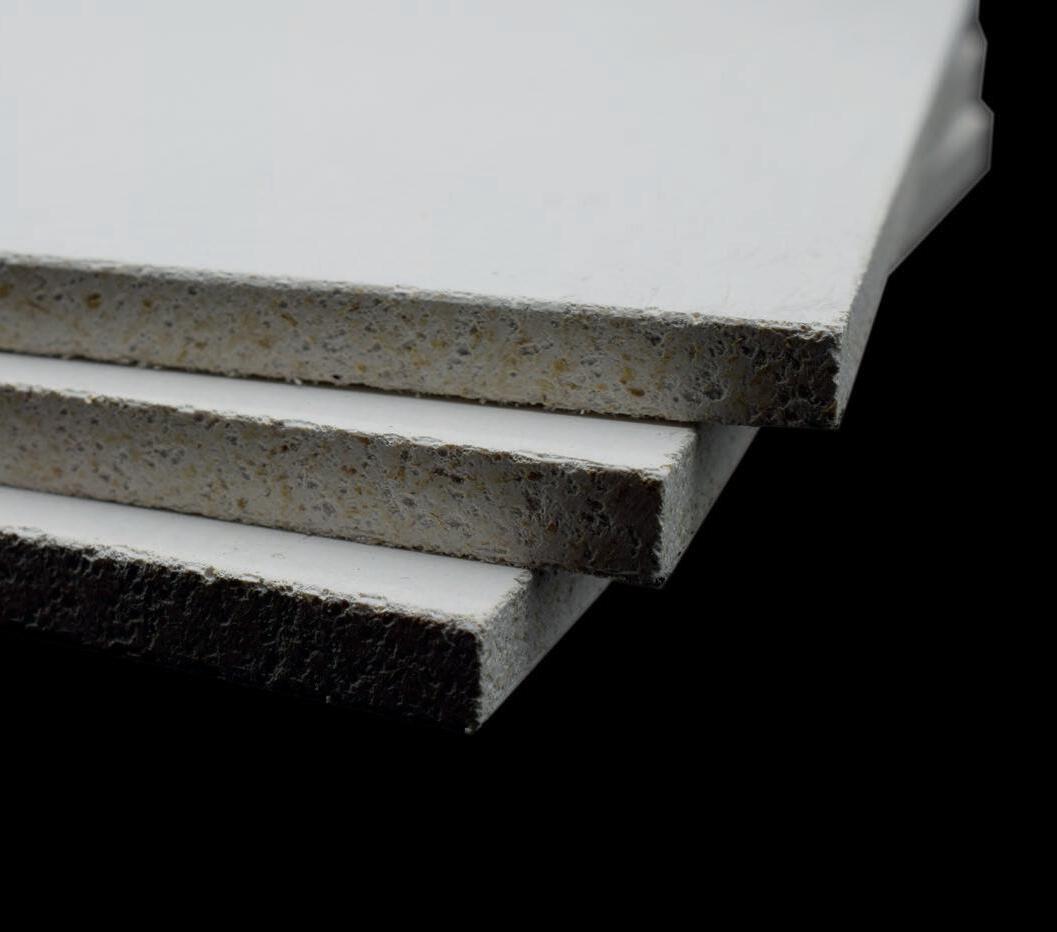

After five years of investment in design and development and using six decades of experience, leading manufacturer Russell Roof Tiles has created a revolutionary new concrete roof tile suitable for a wide variety of applications.

Russell Roof Tiles is an independent tile manufacturer supplying products for housebuilders, high-profile social housing and commercial projects.

The revolutionary new concrete roof tile, called Bute3® is 33 per cent quicker to install than similar tiles and has never been made at high production speeds before, anywhere.

Concrete tiles are often favoured because they are easier to manage and install. Compared to their ‘natural’ counterparts, concrete tiles can be less costly to fit than slate tiles for example, with fewer tiles per square metre. They are also less prone to breakages, resulting in less waste. In addition to being easy to handle (when installed correctly), concrete options will withstand the harshest of weather. With their durability and resistance to fading and deterioration, concrete roof tiles also require minimal maintenance throughout their lifespan.

The first of its kind in the UK, Bute3® is a truly innovative design, a triple interlocking multipurpose concrete roof tile. The design and colour options of the thinner leading

edge Bute3® provide a real alternative to small-format concrete, natural clay, and slate roof coverings.

Russell Roof Tiles has invested more than £2million in its design, pushing the boundaries of manufacturing. The new roof tile is being produced at the firm’s brand new £18.5million fully automated production line in Burton on Trent, designed specifically for this product.

Mark Parsons, Technical Director at Russell Roof Tiles led the design and development team of the new triple tile, using his four decades of technical expertise. Mark runs through the development process: The idea for Bute3® was first conceived following the launch of our Galloway flat interlocking roof tile when we could see that the process and technology capable of manufacturing this new format of tile was feasible.

Who was involved?

The development was a collaborative effort involving multiple teams. Internally, we had our whole technical department

involved, working in sync with our production manufacturing team as well as with specialist design experts and material scientists to bring our vision to life.

Aggregate, cement, and admixture suppliers were also involved at key stages of the project. From the beginning, we engaged with them to assist in sourcing the highestquality materials that would allow us to achieve the thin, yet strong robust structure of Bute3®

The initial idea for Bute3® and all its accessories underwent numerous iterations throughout its development stages. Our philosophy looks at both the customer's and installers' needs to ensure ease of use and seamless integration with fixings and accessories. This enables us to provide a quality roof covering with energy efficiency and durability at its core. The design for Bute3® started out focusing primarily on aesthetics and technical goals and quickly expanded to include advanced functional features.

Dedicated research and development and customer feedback allowed us to continue to consider the requirements of our users throughout the whole design process of Bute3 ®

All aspects, from local planning authorities right through to the contractor's work practices, usability, and site safety influenced the design. Early prototypes were adjusted to enhance the durability and ease of installation, ultimately leading to a product that met both design and performance goals.

One of the major initial design choices was the decision to create a wider tile with the appearance of Three Plain Tiles to make the speed of installation faster and easier.

Early prototypes were modelled in both 2D and 3D, with testing phases involving our technical, production, and quality control teams. We utilised external testing facilities such as the BRE (Building Research Establishment), with rigorous testing including wind-driven rain performance.

Robust testing and analysis has ensured that Bute3® meets the requirements set out by key industry standards BS EN 490:2011 and BS EN 491:2011.

A key challenge during the development process of Bute3 ® was striking a balance between aesthetic and technical functionality. Enabling the tile to boast the thinnest leading edge on the market whilst ensuring structural integrity was no mean feat.

From vision to reality, we pushed the boundaries of material technology to get the desired, and preferred look required by planners, without compromising on durability.

Designing a production line for a tile that had never been made this way proved a tough ask. Also the new line wasn’t just for the creation of Bute3®, we faced the challenge of creating a solution that would enable us to produce different-width products on the same line.

With innovative thinking from the entire internal project team we were able to collaborate and find a resolution. We also utilised various production methods, such as a new state-of-theart curing system, which integrates technologies developed to achieve the optimal balance between the tiles desired look and function.

Curing is an essential part of the successful manufacture of concrete roof tiles and the more aesthetically demanding the concrete, the greater the importance of consistency of curing.

The new triple tile has the strength and characteristics of a regular large format tile. Bute3® is being launched in six colour options, including credible alternatives to clay interlocking and plain tile products and features an innovative doublecambered shape.

Ensuring that the tile also met not just our own future carbon reduction goals but helped our customers manage their output too was a key consideration during its development stages. The production methods that were established for Bute3® mean that the whole process is up to 20 percent more efficient.

Due to the tile's larger size, emulating 3 Plain Tiles in one, only 10.9 tiles are required per m2 compared to other small format derivatives which in turn means up to 40 per cent fewer deliveries are required to site – reducing the carbon output created during construction projects.

The journey to bring Bute3® to life presented challenges, but the result is a truly collaborative effort pushing the boundaries of design, manufacturing, and technology.

For more information visit www.russellrooftiles.com or follow us on social media @russellrooftile.

Russell Roof Tiles – Enquiry 11

Durable class D Redwood Thermowood Cladding from international timber has been used for the construction of government and local council-funded additional needs school in Newtown, Wales, led by the award-winning Wynne construction.

Ysgol Cedewain is a purpose-built school located on the outskirts of Newtown Wales, neighbouring with the picturesque Welsh landscape. Redwood Thermowood timber cladding, supplied by International Timber, features on the exterior of the school alongside traditional brickwork and contemporary glass.

International Timber is proud to have contributed to the construction of this new Additional Learning Needs school. The school will offer state-of-the-art facilities with additional features such as a hydrotherapy pool, sensory and physiotherapy rooms.

With a £22 million pound investment into the development of the school, Wynne Construction required materials that would stand the test of time and worked alongside Jewson to source products that would do just that. The Thermowood cladding supplied by International Timber ensures that the investment will last for up to 30 years due to the wood’s resistance to weathering and fungi, increasing its durability. Wynne Construction specified the volume and

lengths of timber necessary for the build and International Timber sourced directly from Scandinavia prior to the project start date to ensure production was not held up.

Class D Thermowood Redwood timber which undergoes heat treatment, was the ideal choice for Wynne’s cladding as this process modifies and enhances the properties of the timber. Thermowood is lightweight, durable, and less prone to warping compared to natural timber, ensuring long-lasting performance and minimal maintenance.

Thermowood can be also used in conjunction with metal. The low moisture content means when metal comes into contact with thermally modified wood, it does not corrode as much, another added benefit of Redwood Thermowood.

James Sadler, Sales Executive at Jewson, said: “After collaborating with International Timber for many years, they constantly provide expert guidance for all timber challenges, offering effective solutions.”

Rob Trill, Senior Sales Executive at International Timber, added: “We are thrilled to be chosen as a supplier for this incredible build. Timber cladding is often specified in large builds with high volumes of traffic, wear and tear due to its durable and environmentally friendly qualities.

“Redwood Thermowood is a great eco-friendly and stable timber, which played a huge part as to why it was chosen for this particular project. It also has many other benefits, including the fact it is resistant to rot giving it a 30-year service life if maintained correctly, increased stability due to thermal modification and is a low-maintenance material choice for external facades.” >>

Enquiry 12

Reliable insulated render systems, bringing unrivalled versatility and a professional finish to commercial and residential projects.

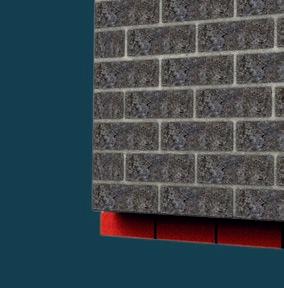

Fassatherm insulated render systems for steel frame, certified by Kiwa BDA

TO FIND OUT MORE about Fassa Bortolo and its range of render systems and building products. Visit www.fassabortolo.co.uk or call 01684 218 305

>> Major step forward

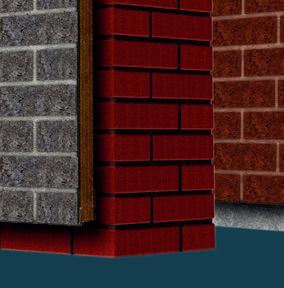

ACS Stainless Steel Fixings Limited has formed a dynamic industry partnership with global construction leader, The Hilti Group – a collaboration that aims to advance industry standards, focusing on improving building safety and promoting best practice.

At the core of the partnership is ACS’s award-winning Certus modular brick façade system and Hilti’s advanced modular framing system. Together, they offer the construction industry a fully integrated, seamless solution that enhances efficiency, safety, and sustainability. Certus is the first

A1 non-combustible product with a 60year design life and it boasts vast versatility – being suitable for both full facades and as a hybrid solution in tandem with traditional brickwork.

The partnership will give architects, contractors, and developers access to a comprehensive package under one roof, from framing to façade, simplifying the construction process and ensuring compliance with the stringent requirements of the Building Safety Act.

Matt Freeman, Engineering Director at ACS, said: "We are thrilled to announce this partnership with Hilti – a collaboration that represents a major step forward for the construction industry.

“By combining our innovative Certus system with Hilti’s world-class modular framing, we are delivering a fully integrated solution that simplifies construction, enhances safety, and supports sustainability. It’s a collaboration built on shared values, and we’re excited to lead the way in offering customers a seamless, cutting-edge

approach to building for the future."

Hilti’s Lead Engineer, Enis Brkic, added: “By partnering with ACS, we’re offering a complete solution to our customers. This partnership combines Hilti’s innovation and productivity standards with ACS’s unique product development approach. We share the same values – safety, sustainability, and excellence – and together, we’re leading the way for positive change in the industry.”

Hilti’s Key Accounts Manager, Joanna Judges, emphasised the importance of the partnership in light of the industry’s evolving regulatory landscape adding:

“Since the Grenfell Tower tragedy, the construction industry has faced new and complex challenges. Our collaboration with ACS bridges that gap, providing a unified solution that simplifies compliance, reduces costs, and offers peace of mind. The Certus system, paired with Hilti’s framing, allows for flexible design and all-weather installation –a revolutionary step forward.”

The ACS Certus system has undergone rigorous testing to ensure flawless integration with Hilti’s framing, it offers the A1 non-combustible rating, plus its industryfirst 60-year design life - providing architects with greater design freedom while enabling contractors to meet the highest durability and safety standards.

Both ACS and Hilti are committed to driving innovation, sustainability, and excellence in the construction sector. This partnership reflects a shared mission to offer cutting-edge solutions and reshape the future of the industry.

We are proud to announce that Fassa UK has achieved an Environmental Product Declaration (EPD) for our versatile A96 Fibre Reinforced Skin Coat, available in grey and white. A96 is a cornerstone of our Fassatherm External Thermal Insulation Composite Systems (ETICS) and is already certified by both the BBA (British Board of Agrement) and Kiwa BDA. This new EPD further solidifies its reliability and sustainability credentials.

What is an EPD, and Why Does it Matter?

An EPD is an independently verified document that provides transparent and comparable information about the environmental impact of a product throughout its lifecycle.

It’s a vital tool for construction professionals looking to make informed decisions that align with sustainability goals.

By achieving this certification, Fassa is demonstrating our commitment to reducing environmental impact and supporting greener building practices.

Sustainable Solutions with Fassa Gaining the EPD for A96 reflects our dedication to developing environmentally conscious solutions that meet the demands of modern construction.

By choosing A96, you are not only selecting a reliable, high-performance product but also contributing to a more sustainable future.

A96 is an essential building product in external thermal insulation systems, offering a range of applications:

• Bonding and smoothing: Ideal for moulded or block-cut EPS panels and mineral wool panels.

• Embedding reinforcing mesh: Ensures durability and performance within Fassatherm systems.

• Superior performance: Its fibrereinforced formula enhances strength and longevity in thermal insulation projects.

Certified, Reliable, and Sustainable Already certified by leading bodies like the BBA and Kiwa BDA, A96 is a trusted choice for insulation systems. Now, with the addition of an EPD, it’s clear that this product not only meets industry standards for quality but also addresses growing demands for sustainability.

Fassa UK remains dedicated to innovation, reliability, and environmental responsibility. With A96 and our full range of Fassatherm solutions, we are building a better, greener future – one project at a time.

Fassa UK - Enquiry 14

Housebuilders can introduce retaining walls that combine reduced noise levels with attractive vertical landscapes, offering a real variety of planting options as an alternative to what would be otherwise dull and un-inspiring structures.

Wakefield based Grass Concrete has a line-up of vertical landscaping products, the Betoconcept range. The proven range brings different shapes and styles to accommodate planting on high or low walls.

Retaining walls on road highways or the simplest garden or boundary walls now feature: planting, colour, shape or textured finish. The Betoconcept range brings different shapes and styles to accommodate planting on high or low walls with; Betoatlas, Betoflor, Betotitan, Leromur, Betojar, Betoplus and Betonap products

Where garden space might be at a minimum a vertical landscape offers an attractive alternative.

Betoconcept blocks provide adequate soil pockets for all types of plants, shrubs and climbers. Good drainage and water capture with the stepped bank also helps keep landscape maintenance to a minimum. Using the depth for landscaping means significant growth can benefit both sound suppression and help get quick landscaping results across a wide walled area

The Betoconcept range has interlocking blocks made from high strength machine pressed concrete, offering dry build solutions and noise absorption, excellent for external wall solutions in urban and rural areas.

Dry built blocks interlock to form the required face angle and can be easily planted.

Easy and quick to construct with a choice of plantable or stonefaced finishes. The contemporary colours include: natural, buff and red will fit in with a variety of environments and tone with natural landscapes.

With individual interlocking blocks and dry-build interconnectivity the range offers the ability to free-form wall layouts in single or terraced wall format. These interlocking units enable a quick and easy construction process and can cope with complex curves, ground embankments and weight surcharges with various wall heights right up to 22m with different types to suit all kinds of housebuilding plots and surrounding hard landscaping.

Grass Concrete’s retaining wall range bringing together both structural integrity and a variety of landscape design options.

To find out more about vertical landscaping options, call us on 01924 379 443, visit our website at www.grasscrete.com or email us at info@grasscrete.com

Grass Concrete – Enquiry 16

Betoatlas for complex curved retaining walls

Using Betoatlas gave the flexibility of a complex curve and natural tone to fit the local environment

With a 250mm long gauge to the blocks the wall could easily cope with the hillside profile of this residential setting with the edge of the wall stepping down

with each course, so minimising the visual impact of the structure. From this concave section the wall continues around the rear of the building with a series of dramatic reflex curves that show to good effect the ability to mirror rolling natural profiles. The 5-metre height of the structure has in this case been softened by the introduction of a wood decked patio area.

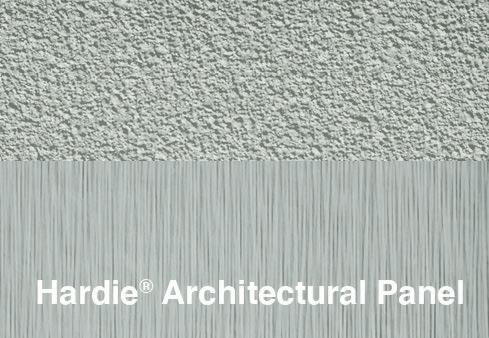

Hardie® Architectural Panel is versatile and high-performance cladding solution, ideal for both contemporary and traditional architectural designs. These fibre cement panels offer a wide range of textures and colours, enabling specifiers to create visually striking facades that can be seamlessly integrated with other materials like stone and brick.

Their design flexibility allows for innovative and aesthetically pleasing building exteriors that meet modern architectural standards.

In terms of fire safety, Hardie® Architectural Panel achieves an A2-s1, d0 fire rating. This high fire rating provides an added layer of safety for building occupants. Compliance with UK building regulations is another key advantage of Hardie® Architectural Panel.

The product meets the requirements of The Building Safety Act and Approved Document B, which mandates the use of materials that enhance fire safety in building exteriors.

This compliance ensures that Hardie® Architectural Panel is not only safe but also

reliable and durable, making them a preferred choice for architects and builders aiming to meet regulatory standards while achieving design excellence.

Overall, Hardie ® Architectural Panel offers a blend of aesthetic appeal, fire safety, and regulatory compliance, making them an excellent choice for modern construction projects.

Brett Martin’s Marlon Clickfix polycarbonate panel glazing system has provided a key architectural feature for Farnborough Airport’s new state of the art hanger – Domus III.

Incorporated as part of the hanger’s extensive door system, the Clickfix panels allow daylight to flood the hanger and reduce the need for artificial lighting in the highly sustainable facility.

With some of the most ambitious environmental targets in the sector and a commitment to identifying and minimising

the effects of aviation on the environment, Farnborough Airport was keen to set a new benchmark in terms of aviation design with the hanger and ensure sustainability was at its heart.

As such, aviation specialist architectural practice Gebler Tooth designed the facility – known as Domus III - to incorporate the

latest state of the art technology and drive environmental performance. This included the use of translucent automated doors along the entire length of the building, to optimise the level of natural light inside. Alongside an intelligent artificial lighting system that dims when the daylight is sufficient, this would ensure that the facility is highly energy efficient. The doors would also ease aircraft manoeuvrability and help to mitigate unnecessary emissions from aircraft handling.

Jewers Doors was awarded the contract to supply and install the doors by main contractor McLaughlin & Harvey. Jewers Doors specified its Esavian Type 126 power operated steel frames, powder coated RAL 9007 with Brett Martin’s Marlon Clickfix VF90 clear glass polycarbonate cladding panels to create the doors. Each door measures approximately 7.3m wide by 10.6m high and has four equal-width leaves that run on four independent tracks.

Brett Martin – Enquiry 19

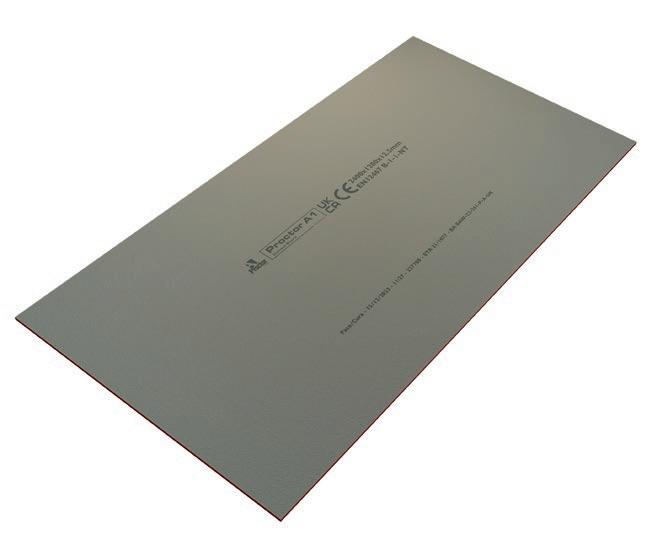

The A. Proctor Group is introducing a score and snap sheathing board to its range of facade solutions.

Used in conjunction with the highly regarded and wellestablished Wraptite® external air barrier, the Proctor A 1 Cement Board can help specifiers and contractors move more towards a system solution.

While suitable for all buildings, the throughwall fire testing carried out featuring Proctor A 1 Cement Board means it can be used with Wraptite to support compliance with fire safety requirements for relevant buildings.

“As a cementitious product, Proctor A 1 Cement Board is automatically classified as non-combustible,” said Will Jones, Head of Business Development at the A. Proctor Group. “Through-wall testing has confirmed the sheathing board’s compatibility with our Wraptite membrane, delivering a result of 120 minutes without integrity failure. Customers can therefore feel assured when choosing a fully-adhered external air barrier and vapour permeable membrane.”

There are further benefits from the compatibility with Wraptite. As the membrane offers a W 1 classification for water hold out, there is no need to use tapes and sealants on the Proctor A 1 Cement Board to provide airtightness and temporary weather protection.

Key to the development of Proctor A 1 Cement Board was the desire to offer the best possible all-round solution. As a result, it combines the benefits of traditional fibre cement boards with

desirable qualities of newer gypsum sheathing boards that have gained acceptance in the marketplace.

As with all products offered by the A. Proctor Group, Proctor A1 Cement Board is backed up by comprehensive technical support, plus onsite support including all complementary fixings and accessories.

Freefoam Building Products, a leading manufacturer of PVC building products, is proud to announce the launch of its latest product – the Agate Grey Single Shiplap PVC Cladding.

his new addition to Freefoam’s existing Single Shiplap cladding range offers architects, developers, PVC suppliers, installers and homeowners a contemporary yet timeless design solution.

Agate Grey has become a popular shade for window, door and roofline replacements. A delicate blend of light green and soft grey that can give a home a fresh and light appearance. Freefoam have introduced this new option in response to the growing trend for muted, subtle exterior colours and to provide a stylish alternative to traditional darker wood colour cladding options.

Agate Grey is already an established foiled finish option in Freefoam’s fascia and soffit range. The introduction of the same shade in the cladding range offers the perfect solution to any home refurbishment project allowing homeowners to create a truly coordinated make over, matching cladding to windows, doors, fascia and soffit.

Agate Grey cladding is suitable on a wide variety of house styles, whether enhancing the charm of a rustic country property or adding a modern edge to an urban home. A good choice for properties built from light sandstone brick, but also works well with many other types of materials.

The Single Shiplap profile provides a clean, sleek finish, while the durable PVC material ensures longevity, low maintenance, and weather resistance.

The 150mm board is particularly suitable for smaller external

areas such as dormer extensions and panels between ground and first floor.

21

Vertik-Al’s annual colour audit has shown that 2024 was dominated by neutrals and various shades of grey, especially warm greys.

Khaki Grey, Moss Grey, Silk Grey and Pebble Grey all rank in the company’s top 20 most used powder colours 2024. Unlike the perennially popular Anthracite Grey, Basalt Grey, Slate Grey and Black Grey, these greys are much softer. Warm and calming, they work particularly well in spaces

with good natural light and are enriched by sunlight. Their increased use suggests the cool grey trend may be in decline!

Speaking about the move to warmer shades of grey, John Park-Davies, group managing director for Vertik-Al said: “Those who follow

our journey will know that Anthracite Grey in a matt finish has been a firm favourite for several years now. However, while there was no change in 2024 and it remained our most popular powder colour, we also saw a distinct shift towards more delicate greys for the first time.”

The popularity of warm greys is complemented by a rise in the use of black and white coloured powders. “These neutral tones have slowly been regaining ground over the past couple of years,” continues, John, “…and they now account for 11 of our top 20 most applied powders.”

Jet Black, HIPCA White, Signal White, Pure White, Signal Black and Traffic White all feature. HIPCA White is also the only top 20 powder to feature in both matt and gloss finishes.

Vertik-Al is the UK’s largest independent powder coater and applies thousands of different colours, textures and finishes each year.

Vertik-Al – Enquiry 22

The revival in hotel & leisure-related construction work seen over the past year is set to continue into 2025 and beyond as developers respond to the growth in tourism and improving consumer spending.

Following a 19% increase in the value of underlying hotel & leisure starts this year, the new Glenigan Construction Industry Forecast 2025-26 predicts a 6% rise in starts in the sector next year and a further 9% growth in 2026.

The upturn reflects an improving work pipeline in the sector with detailed planning approvals for hotel & leisure projects rising by 4% in the third quarter of this year to stand 35% higher than a year earlier.

Construction work on hotels & guest houses is one of the most promising areas for new work as accommodation is expanded and modernised to cater for growing visitor numbers.

According to figures from the tourism agency Visit Britain, room occupancy in England has been higher in every month this year compared to 2023, with a peak occupancy of 85% seen in July. Overall, in the year to date to October, room occupancy stood at 78% across England up from 76% in the same period last year.

A growing number of overseas tourists has helped hoteliers keep their rooms full. Last year, 38 million international visitors came to the UK, up from 31.2 million in 2022. Yet this was still below the pre-pandemic level of

Glenigan data highlights the wide range of hotel & accommodation projects where construction work is due to get underway.

One flagship project in London where work is set to start next spring is a £192.7 million, 31-bed hotel for Grosvenor Group which forms phase 3 of its South Molton Triangle development in Westminster. Detailed plans have been granted on the project which is at the pre-tender stage but where BDP has recently been appointed as the landscape consultant (Project ID: 23120621). Elsewhere in the capital, tenders have been returned and work is also due to start next spring on

a £19.4 million hotel project at 9 Bridewell Place in the City involving a change of use from office to hotel use across a floor area of over 1,500 sq m (Project ID: 22457276).

Hotel refurbishment projects are generating work in various tourism hotspots. In Bath, detailed plans have been granted for a £13 million scheme of alterations at the Francis Hotel in Queen Square with work set to start next April (Project ID: 24145930).

Meanwhile, at Linton Lodge Hotel in Oxford, work is due to start in the spring on a £16.2 million reconfiguration of the facility to provide 42 bedrooms, a function space and landscape improvements.

Detailed plans have been granted on the scheme which is at the pre-tender stage (Project ID: 11370817).

Smaller hotel & leisure schemes catering for tourists are also in the pipeline. Planning conditions are currently being resolved on a £6.5 million hotel/leisure project at The Old Ship Hotel in Brighton where work on a remodelling and extension scheme is pencilled in to start in the new year (Project ID: 07556721).

Meanwhile, work on some major flagship projects around the country is also set to buoy up activity in the wider hotel & leisure sector next year.

Lendlease is due to start construction work on The Sage International Conference Centre in Gateshead early in the new year. The £150 million project involves a hotel and arena facilities across more than 61,000 sq m of space and has benefitted from £20 million of Levelling Up funding (Project ID: 06021815).

Meanwhile, detailed plans have been submitted for a new hotel and stand as part of the £20 million Edgbaston Stadium Redevelopment which will create a mixed-

use destination around the Birmingham cricketing landmark. Work on the project is due to start next year and run for 19 months (Project ID 24328718).

Stroud District Council has approved the external appearance of the new Forest Green Rovers 5,000 capacity stadium.

The decision marks a significant step in the development of the world’s greenest sports complex.

Chairman of Forest Green Rovers, Dale Vince OBE said: “This ground-breaking stadium will provide a new home for FGR. The 5,000-capacity stadium will be the first stadium to be made almost entirely from wood which is beautiful, natural, durable and sustainable.

“We’ve taken a step closer towards the world’s greenest sports complex and a fabulous facility for the local community.”

The concept began in 2015 with a global design competition, culminating in Zaha Hadid Architects winning the bid in 2016. Following years of rigorous planning outline

approval was secured in August 2020. Now, after more than a decade of dedication, the layout, scale and external appearance of the stadium has been approved by the council.

The 5,000 capacity, state-of-the-art stadium for Forest Green Rovers, will be made almost entirely from wood – nature’s original renewable building material – and will offer every fan an unrivalled view of the action.

The Point is a collection of self-catering holiday homes in the heart of picturesque Cornwall.

The family-run business includes The Point at Polzeath, where several timber-built cabins have been created which required green roofs to be installed to comply with planning regulations.

Wheelbarrow Landscapes provides professional landscaping and garden maintenance services throughout Cornwall. A long-term customer of Green-tech, they turned to their sales advisor George Barton for advice and expertise in supplying green roof materials.

Wheelbarrow Landscapes opted for Greentech's proven roof garden solutions, which included Gt RoofDrain for drainage. This lightweight drainage layer enables the collection and storage of water whilst providing a continuous drainage layer across the roof structure. The core acts as a water reservoir for plant roots to access in dry periods.

Green-tree roof garden substrate was chosen for the planting scheme. It is a blend of lightweight aggregate and awardwinning Green-tree topsoil, which is ideal for green roof construction projects, due to its weight, excellent water-holding capacity, optimum drainage properties and good levels of aeration.

TORMAX was recently contracted to install two sets of bi-parting sliding doors at a new Botham’s of Whitby bakery shop and tearoom in North Yorkshire.

The first door is a main entrance into the shop, and the second leads from the Tea Rooms to a patio area with outdoor seating.

Both entrances are powered by TORMAX 2201 sliding door drives, each of which are housed in a compact casing that requires an installation height of just 100mm, delivering unobtrusive yet highly functional automation.

With the capacity to handle high levels of footfall, the entrance doors are robust enough to meet the demands of Botham’s daily customer traffic while maintaining low maintenance costs and superior reliability.

Botham’s of Whitby is a fifth generation, family-run business that was established over 150 years ago. Using many traditional methods of baking, a daily array of breads and baked goods, including the infamous Whitby lemon bun, is produced.

A simple programmable control allows bakery staff to change the opening and closing speeds, hold-open times and opening widths to match foot traffic and weather conditions, minimising heat loss whilst ensuring a smooth through-flow of customers.

Tormax – Enquiry 23

Hotel specifies Dorma Huppe moveable walls

Jestico & Whiles and contractors, BAM Construction, to deliver flexibility to the main function space in Edinburgh’s prestigious new W Hotel.

Allowing the hospitality area to be sub-divided into either three small rooms, or one large and one small room, Style installed three Dorma Huppe Variflex moveable walls, each with semiautomatic operation. With an impressive 55dB acoustic rating, the moveable walls create a superb acoustic barrier, allowing multiple events to be held concurrently, without disturbance.

A bespoke Autex cube panel finish further enhances the acoustic performance of the rooms, as well as adding an interesting aesthetic to the eclectic interior of the hotel.

When larger events are scheduled, the moveable walls are neatly stacked to one side, quickly creating an impressive, open-plan function room.

W Edinburgh is a luxury, landmark hotel that forms the centrepiece of Edinburgh’s newest neighbourhood, St James Quarter. A destination for performance, music and fashion, the hotel boasts unique rooms and suites that are anything but expected. Breath-taking dining and specialty bars, a signature restaurant and intimate cocktail bar, the W Lounge and a unique rooftop deck with the finest 360-degree views of Edinburgh and beyond.

Gilberts helps spa hotel expansion

The Crow Wood Hotel & Spa Resort - winner of the Best UK Hotel spa award 2024 - is taking its visitor experiences to the next level, with contribution from Gilberts Blackpool.

The globally renowned venue has invested £16m in a new thermal experience- the Woodland Spa- set within the facility’s 100acre grounds in the heart of Lancashire.

To confidently create the perfect atmosphere in each area, addressing the specific ambient conditions required, building services consultants Petit Singleton Associates utilised the expertise of Gilberts Blackpool to supply the air movement supply and extract.

For ventilation within the internal spaces, Gilberts worked closely with PSA to develop a scheme that predominantly uses a combination of Gilberts’ contemporarystyled louvre faced ceiling diffusers (DGA, four-way blow configuration), linear slot diffusers (GSLS) and high-capacity slot diffusers (HSLS), with separate units for supply and extract. To compliment the clean, modern décor, all were finished in either pure white with a 20% gloss finish or matt traffic white.

And to ensure the air handling equipment with heat recovery connected to air source heat pumps all functions at optimum efficiency, constantly, Gilberts’ plant ventilation louvres in anthracite grey have been incorporated into the first- and second-floor facades.

Blackpool – Enquiry 25

A major canal-side development, at Hackney Wick, on the edge of London’s Olympic Park, is being delivered by CJ O’Shea.

Known as Wickside, it will provide 475 homes across a seven-acre area, along with an art gallery, shops, restaurants, creative studios and even a brewery. Buildings in Phase 1 have an under-croft walkway with a row of exposed concrete columns that required a recently introduced solution from Schöck – the Sconnex range.

Schöck has transferred its Isokorb expertise from balconies, to walls and columns, offering a high-quality solution that’s easy to use and contributes to a sustainable building concept. This is a unique solution in meeting the building physics calculation that estimates around 40% of all structural thermal bridges in buildings are caused by walls and columns; and these can be responsible for at least 10% of the heating energy loss.

The exposed concrete columns in question at Wickside support residential apartments, which sit above the commercial space below. When the commercial space is not in use there are effectively cold spaces below, with heated apartment space above. To avoid having to insulate the column heads, Schöck incorporated two of its Sconnex products, which allow walls and columns to be directly and permanently insulated. This solution allows for exposed concrete finishes below the slab soffit, resulting in both an aesthetic finish and excellent thermal performance.

There are three Sconnex product variations, the type W, type P and type M. At Wickside

it is the Sconnex type W and type P that are incorporated. The type W thermal insulation element for reinforced concrete walls transmits very high compressive, tensile and shear forces in the walls’ longitudinal and transverse directions. In addition to its already high compressive and flexural strength, the addition of steel fibres also results in excellent post-cracking behaviour.

Eliminates the need for flanking insulation

The Sconnex type P consists of a thermal and a reinforcement element, both of which are required to withstand the bearing load. The thermal insulation element has a pressure-resistant support structure, made of lightweight concrete and polypropylene fibres. Its performance significantly reduces heat flow, but importantly, also eliminates the need the for the traditional solution of using cumbersome flanking insulation.

The Building Safety Act prioritises stringent safety and performance standards for high-rise and multi-occupancy buildings. The inclusion of the Schöck Sconnex products demonstrates a proactive commitment to safety and energy efficiency. The Act emphasises the importance of robust construction methods and materials that mitigate risks, particularly in structurally sensitive areas like the exposed concrete columns used at Wickside. The Sconnex products address both safety and sustainability by reducing structural thermal bridging—a critical area of focus in ensuring the longevity and integrity of modern building designs.

More solutions than any other manufacturer in Europe

The Sconnex type W and the Sconnex type P installed at Wickside are fully certified by the Passive House Institute in Germany. With the Sconnex type P being the only column connection certified by the Institute.

For full details of the Sconnex range contact Schöck on 01865 290 890; or go to: www.schoeck.com/en-gb/sconnex

Schöck – Enquiry 26

The UK’s leading manufacturer of adhesives for floorcoverings and subfloor preparation products, F. Ball and Co. Ltd., has unveiled the latest print edition of its industry-leading Recommended Adhesives Guide (RAG®), which lists the compatibility of the company’s adhesives with practically every commercially available floorcovering.

The 2025 RAG® enables contractors and specifiers to quickly check the compatibility of F. Ball adhesives and chosen floorcoverings, including new adhesive recommendations for floorcoverings launched by manufacturers over the past 12 months. Featuring recommendations for over 6,000 branded floorcoverings from over 200 leading international manufacturers, it is the most comprehensive publication of its kind.

In addition to the annually updated A5 printed book, a continuously updated version of the guide is available on the F. Ball website, and as a mobile app, which is free to download from the Apple App store or Google Play. The app has emerged as the most popular way to access the guide, with over 1,000 downloads last year.

Gerflor and Gradus deliver world class flooring and interiors

International Plywood has recently gone through a much-needed refurbishment of their main office complex, with the specification and install of flooring and finishing solutions from Gerflor, an international flooring specialist, and Gradus, a UK manufacturer of a comprehensive range of contract interior solutions.

The vast array of products installed were selected for their outstanding striking aesthetics and high standards of safety and durability which both Gerflor and Gradus products are world-renowned for. Solutions included world class Creation LVT, Gradus Lunar Carpets, Mipolam Planet, Gradus XT and BasicZ stair edgings, Gradus SureProtect Pure Wall protection and Gradus Mat-in-a-Box.

Gerflor – Enquiry 28

F. Ball’s Technical Service Manager, Steve Boulton, said: “It is always advisable to check the compatibility of adhesives and chosen floorcoverings to ensure against floor failure. The RAG® is designed to make this effortless, with recommendations for any of the listed floorcoverings available in an instant, via the smartphone app.”

Recommendations are only included in the guide after the completion of a rigorous 56-day testing programme at F. Ball’s state-of-the-art testing facilities and require a positive endorsement by the relevant floorcovering manufacturer.

Flowcrete takes on Hygiene at Foodex 2025

Furthermore, every recommendation listed guarantees the resulting bond performance for the entire lifetime of the flooring installation.

F.Ball – Enquiry 27

Maintaining hygiene throughout the entire food and beverage production process, from processing to packaging, is crucial for minimising contamination risks. Flowfresh, an antibacterial flooring solution from Flowcrete is made with the food and beverage industry in mind. This flooring solution can kill up to 99.9% of bacteria through silver ions that attack bacteria and viruses on the floor’s surface.

Flowcrete, a brand of Tremco CPG UK and leading manufacturer of seamless resin floor coatings will be participating at Foodex 2025, the premier event for the food and drink processing, packaging, and logistics industries from 7-9 April 2025, at the NEC Birmingham.

Flowcrete – Enquiry 29

Beauflor gives Blacktex a boost

Beauflor has updated its Blacktex cushion vinyl flooring range with new designs that reflect the latest in interior style.

Blacktex cushion vinyl from Beauflor brings private and social housing a fast and easy flooring option and with brand-new designs for 2025, one that now reflects the latest in home interior style. The popular collection comes in a range of 56 wood and stone looks, including 24 new for this year. Introduced designs include the classic style of Oakland and Gambel Oak wood planks, the limestone of Pamplona and the elegant, polished concrete of Beton Cire.

Beauflor – Enquiry 30

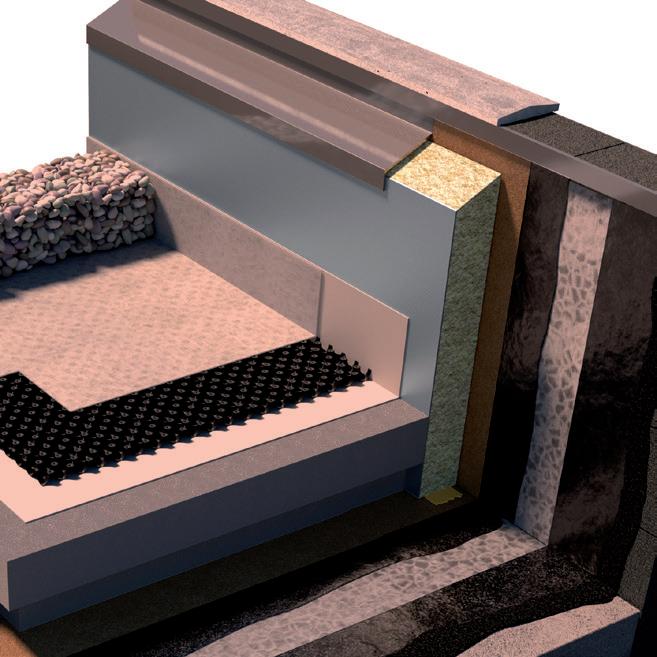

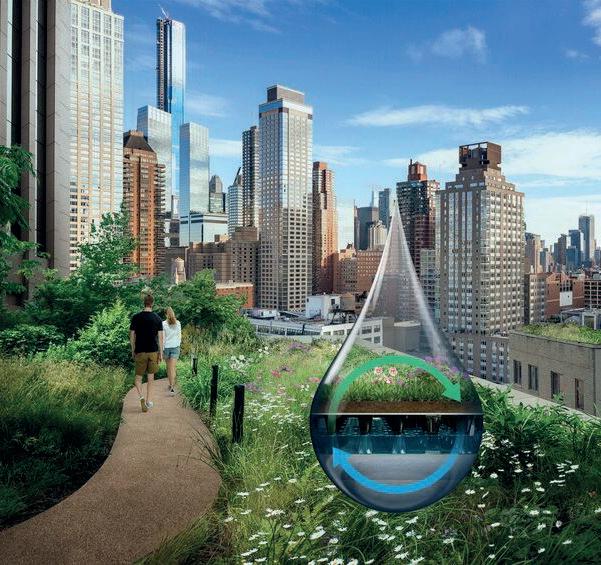

Smart technology, such as sensors used in smart blue-green roofs, are emerging as essential tools to increase water circularity. This allows more control of water levels and release rates on site creating environmental resilience on urban developments.

Water circularity minimises water waste by capturing, treating, and reusing water within urban environments. Therefore, reducing reliance on external water supplies, mitigating flooding, and promoting sustainability.

It also addresses the growing challenges posed by urbanisation, where impermeable surfaces like concrete increase surface runoff, overwhelm drainage systems, and reduce groundwater replenishment.

To achieve water circularity, cities must adopt integrated systems that manage water at every stage, from capture to reuse. By doing so, they can reduce the risk of water scarcity, enhance urban biodiversity, and contribute to climate resilience.

Smart blue-green roofs represent an innovative solution that integrates green

Water circularity is the concept of ensuring water is reused and managed efficiently within a closed loop system. As climate change accelerates, rainfall patterns are becoming more erratic, with intense storms and prolonged droughts threatening water security meaning water circularity is becoming a critical focus in urban planning.

vegetation (green roofs) with water retention and reuse systems (blue roofs). These roofs collect and store rainwater, enabling gradual release or reuse.

Their multifunctionality makes them an excellent addition to traditional water attenuation methods, such as underground attenuation tanks and infiltration systems.

Key benefits of blue-green roofs include:

1. Rainwater Management: They retain rainwater during heavy downpours, reducing runoff and easing pressure on drainage infrastructure.

2. Thermal Regulation: By lowering rooftop temperatures and improving building insulation, blue-green roofs enhance energy efficiency.

3. Urban Biodiversity: These roofs create habitats for plants, insects, and birds, enhancing the ecological value of urban areas.

4. Water Reuse: Stored rainwater can be repurposed for irrigation or cooling, contributing to water circularity.

While blue-green roofs provide many benefits, they work best when integrated with traditional water management solutions.

Developments can use these roofs alongside attenuation tanks, permeable paving, and rain gardens to create a holistic system that manages water effectively across a site.

Smart technology further enhances their efficiency. Sensors embedded in blue-green roofs can monitor water levels, enabling precise control over storage and release.

This ensures the system adapts dynamically to changing rainfall patterns, providing optimal performance.

As a leading manufacturer of water management solutions, Wavin offers tailored solutions to meet the unique requirements of any development. From designing blue-green roofs to integrating them with traditional systems, Wavin works closely with developers to value-engineer the most effective and sustainable solutions.

By partnering with Wavin, developers can benefit from advanced technologies, expert guidance, and high-quality products. Whether it’s a residential, commercial, or industrial project, Wavin ensures water management solutions align with regulatory standards and sustainability goals, all while delivering longterm cost efficiency.

Find out more about how Wavin can help you create the best solution for your development by visiting: solutions.wavin.com/en-gb/ urban-climate-resilience

Wavin – Enquiry 32

By supporting ‘green by default’ best practice and complementing it with engineered grey infrastructure, we are helping to pioneer eff ective hybrid water management solutions that can:

• reduce the urban heat island eff ect

• boost biodiversity

• increase water circularity

• create amenity value

We work closely with our partners to create smart solutions including tree tanks, blue-green roofs, irrigation, rainwater attenuation and infi ltration tanks.

See how we could help develop your hybrid water management solutions for a more climate-resilient future.

Scan to learn more

An insurance expert is calling on construction companies to assess the risks associated with living walls, which may not be fully covered by standard insurance policies.

Lee Musgrove of specialist insurance broker Lycetts has issued the warning as the demand for sustainable ‘vertical gardens’ grows.

“With the increasing integration of green roofs and living walls in modern architectural designs, there is a pressing need to address the fire risks linked to the materials used in these on-trend systems,” Musgrove said.