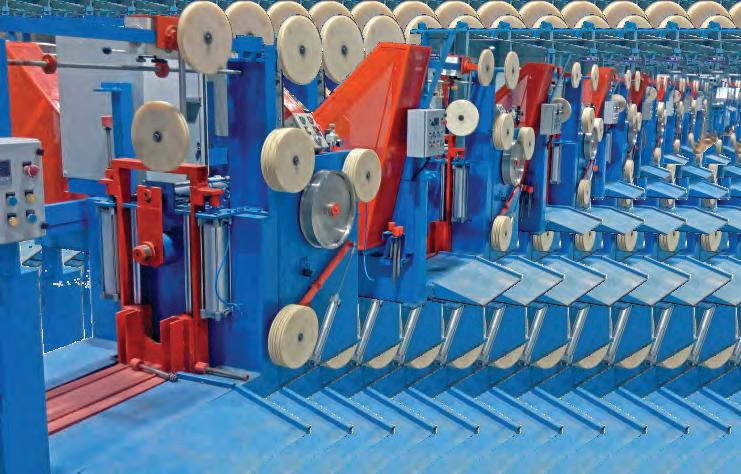

Taping Machines and Equipment

(An ISO 9001 : 2015 Company)

Office & Works-1: Plot No.744, Sector-69, IMT, Faridabad (NCR), Distt.: Faridabad, PIN-121004, State: Haryana (India) Landline: 0129-2977999, Mobile: +91- 9811010197, +91-8586969099, +91-8586969100

E-mail: info@cabletechindia.com, cabletechmachines@gmail.com, ctm97@rediffmail.com, Works-2: Plot No.143 & 150, NangIa - Gajipur Road, Gajipur, PO: Pali, Distt.: Faridabad, PIN-121004, State: Haryana (India) Phone: +91- 9811010197, +91-8586969099 www.cabletechindia.com

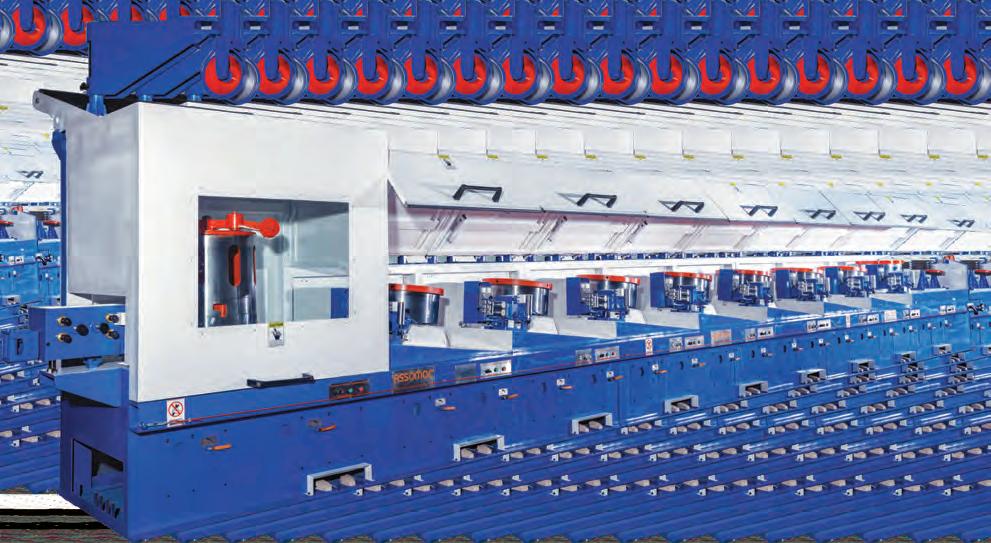

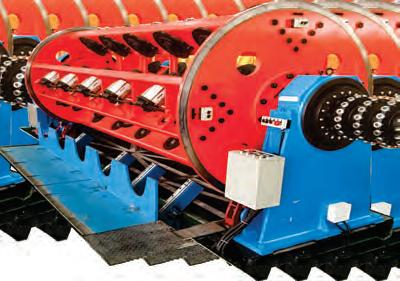

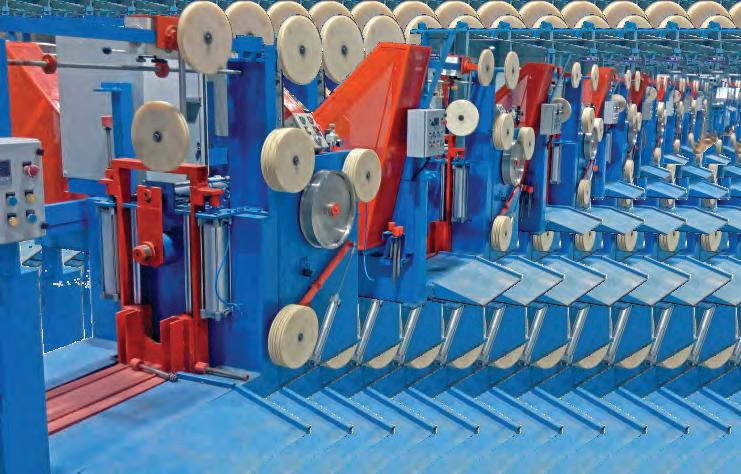

Rigid Stranding Machines

Heavy Duty Take up & Pay off stands

Rigid Armouring Machines

Rigid Armouring Machines

Rigid Armouring Machines

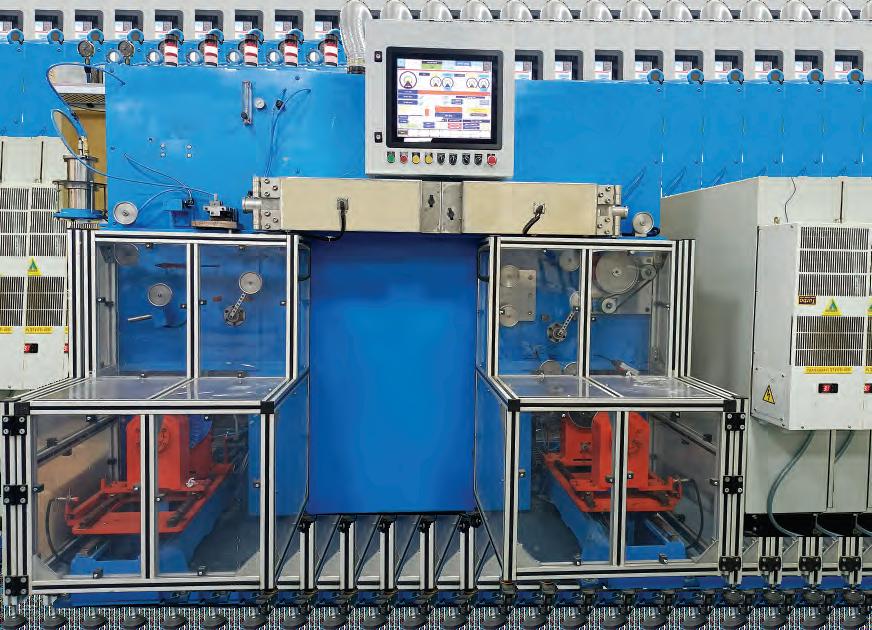

Drum Twister Machines

High Speed Semi Automatic Core Rewinding Line

Rigid Stranding Machines

Rigid Stranding Machines

Heavy Duty Take up & Pay off stands

Rigid Armouring Machines

Rigid Armouring Machines

Rigid Armouring Machines

Drum Twister Machines

High Speed Semi Automatic Core Rewinding Line

Rigid Stranding Machines

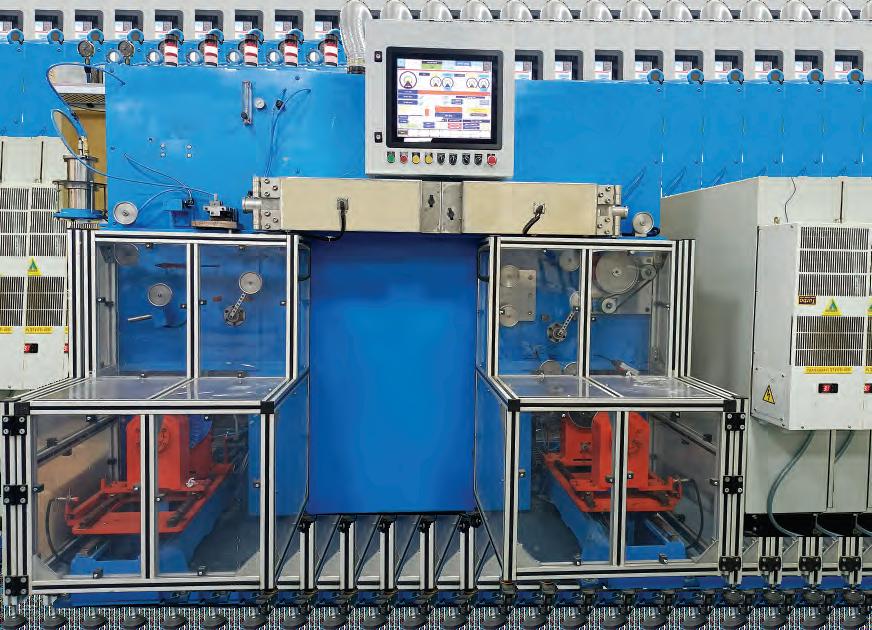

Your Partner in Extrusion Technology

technological leader in manufacturing of Extrusion machines since 1974. It supplies the high productivity extrusion line for Solar cables. The extrusion line can be used in tandem or Co extrusion process.It can easily handle variety of compounds related to solar cable manufacturing .

For other wire and cable extrusion machinery related information, visit Supermac Website.

Phone : +91-11-45574317

E-mail : office@supermacindia.com

Phone : +91-124-4690500

E-mail : office1@supermacindia.com

A-28,

Naraina Industrial Area, Phase-I, New Delhi 110029, INDIA

Plot no.2, Sector-6, IMT Manesar, Distt.Gurgaon, Haryana 122050, INDIA

Plot No.72, Sector-8, Industrial Estate Dharuhera, Distt.Rewari 123110, Haryana, INDIA

Our Services IIOT

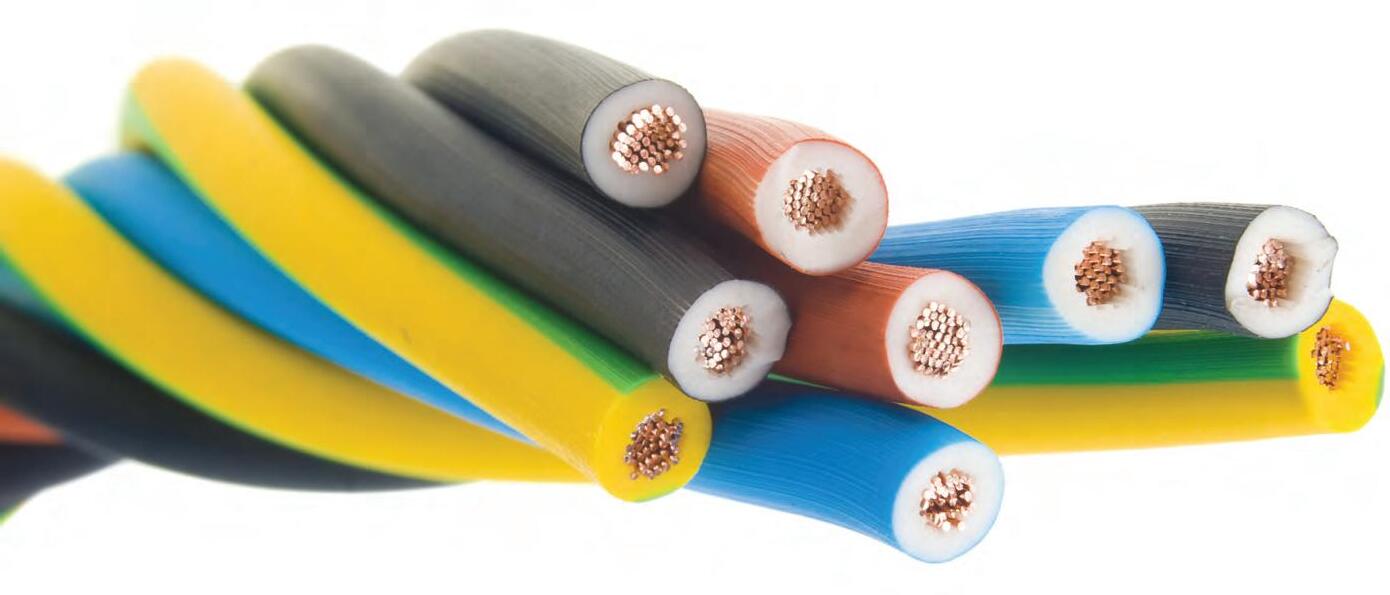

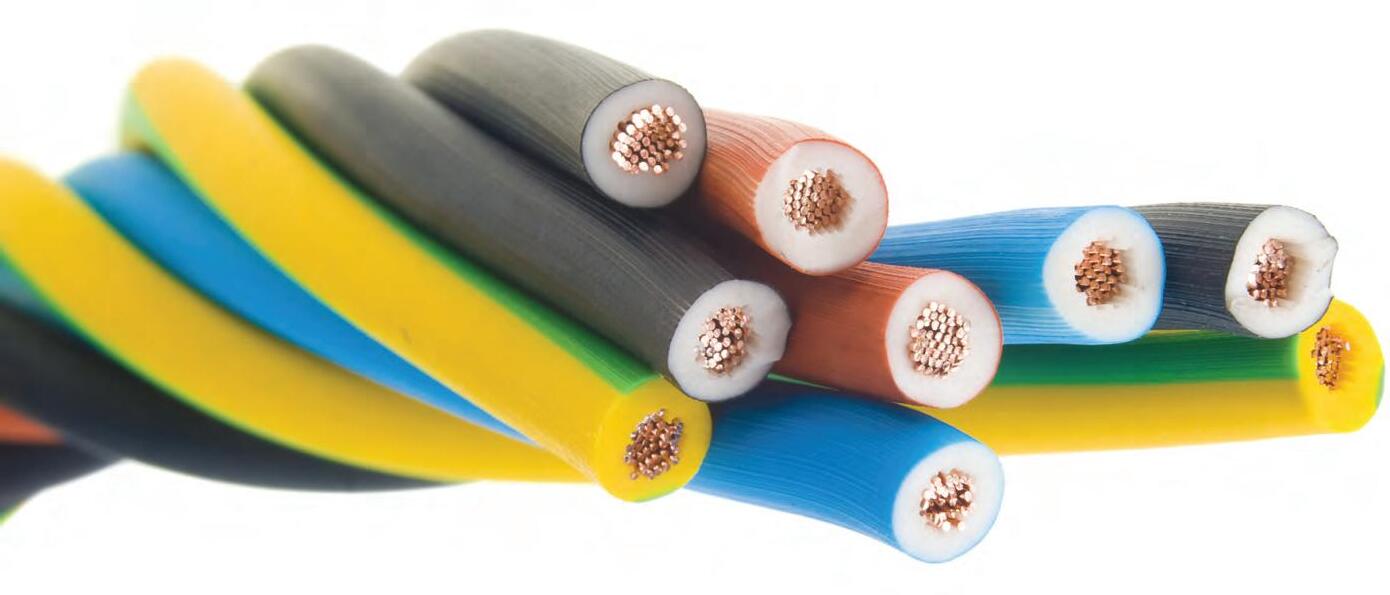

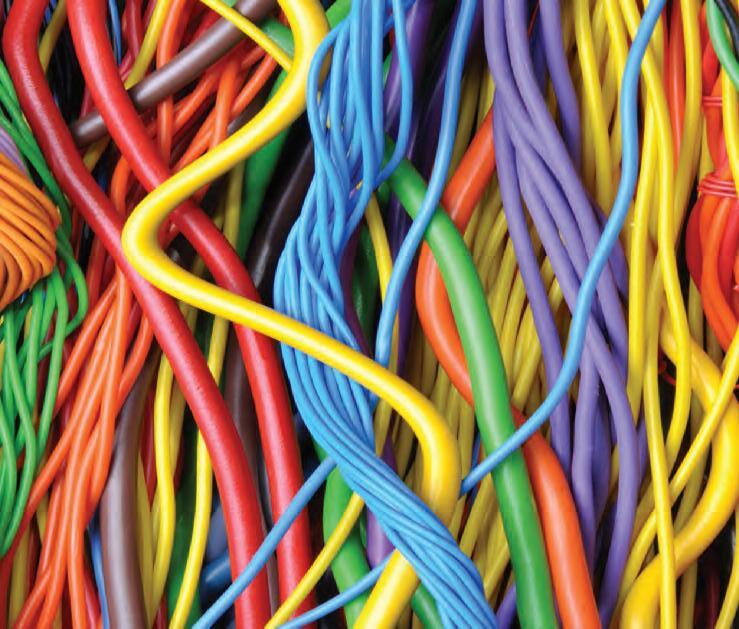

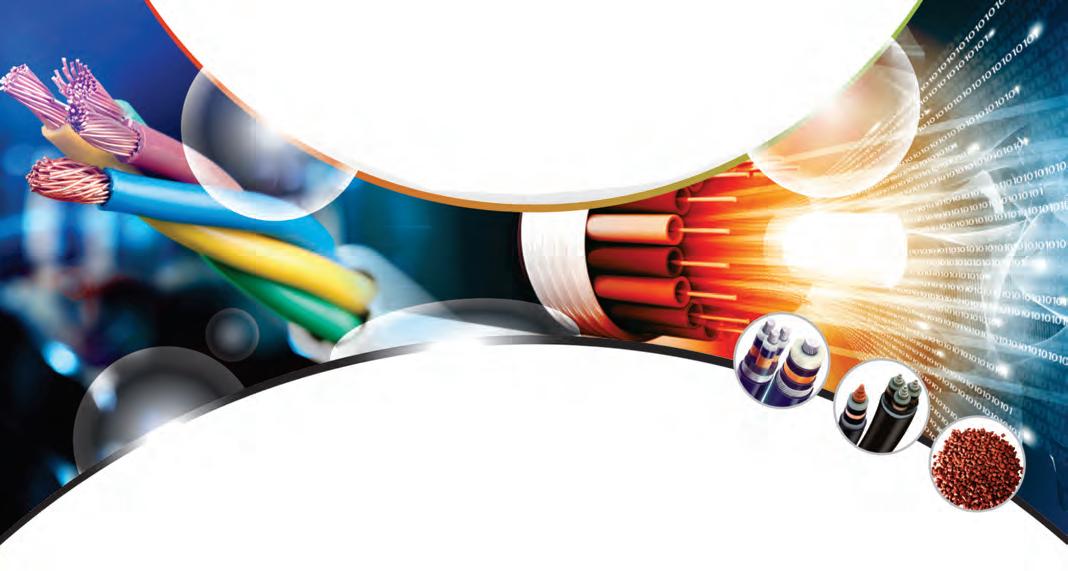

OPTIMIZE YOUR ENERGY CONSUMPTION WITH OUR HIGH-QUALITY WIRES & CABLES RESIDENCIAL WIRES & COMMERCIAL CABLES COMMUNICATION CABLEARMOURED CABLES AGRI & SOLAR CABLES

WIRES

Home First Fire Insurance Follow us

ORBIT

INDIA (PVT) LTD

Speakin

Spearing the Mammoth Demand

In the last few years, clean energy is being used increasingly to replace fossil-based energy solutions. In fact, geopolitical and environmental events have pushed the envelope in favor of clean energy solutions and applications; Electrical Vehicles (EVs) being one of them. It has been a certain time since the discovery of the technology and its application is gaining momentum worldwide.

At home, the market size of EVs is growing rapidly, especially backed by government subsidies and initiatives like Faster Adoption and Manufacturing of Electric Vehicles (FAME). At the beginning of 2023, Economic Survey released a report that placed India as the third-largest automobile market in the world, following Japan and Germany. The same report projected a YoY CAGR of 49 percent for the EV market in India during FY 22-30. The Indian market is expected to record a conservative sale of 1 crore units per annum by 2030.

India aims to electrify its vehicular structure by up to 30 percent by 2030. It translates to 8 crore EVs in the country by 2030. Presently, the EVs market is concentrated in Tier 1 cities, while bleeding sporadically into Tier 2 cities. Hence, the majority of the country is still comparatively untouched by technology. One of the major factors contributing to this imbalance is the lack of ancillary infrastructure.

The vision for this note was clear; I wanted to talk oneon-one with the readers about all that Wire & Cable India has to offer. I wanted to share our efforts in bringing forward this edition, the concurrent events of the industry, and a small, profound piece of personal opinion. There are various ways to achieve our targets, and mine was to ensure a connection with my readers.

Shri R K Singh, Union Minister of Power, shared in Lok Sabha, that as of January 23, 2023, India had 5,254 public EV charging stations and 20.65 lakh EVs. Hence, the ratio of EV stations to the number of EVs was 1:393. Alvarez and Marsal, a US professional services firm, released a white paper in 2022, stating that globally the EV station and EVs ratio ranged between 1:6 (China) to 1:19 (Netherlands). India is likely to have nearly 10,000 public charging stations by the end of 2025, however, to achieve its electrification targets the country may require nearly 20.5 lakh charging stations by 2030.

The figures send a clear message, India needs to push its EV ancillary infrastructure at an advanced rate to meet its self-allotted targets. Hybrid EVs are powered by an internal combustion engine and one or more electric motors and could be used to support the gradual shift of the Indian public to clean energy solutions. Hybrid EVs do not need a charging station, their electric motor is charged by the regenerative braking and internal combustion engine.

The situation presents an opportunity as well as a challenge for the industry. While the scope of development is huge enough for vast capacity expansion and addition, the requirements need expedition in efforts and investments. The country requires the government and the industry to create an ecosystem by not only supplying the infrastructure but planning the development and integration of the same in a way that the current sporadic and concentrated pattern could be diffused across the nation. This will help the targets to be achieved comparatively faster and easily, as new stakeholders joining in would push the demand get diffused regionally. Furthermore, the subsequent vehicular structure electrification post-2030 could also be easily planned and implemented by building on a strong foundation of the base period.

The wires and cables industry needs to buckle up itself for a huge demand needs to be catered, from supplying the construction of EVs infrastructure to its integration within the National Grid of India.

Priyank Jain, CEO Tulip 3P Media Private Limited

www.wirecable.in

OUTLOOK

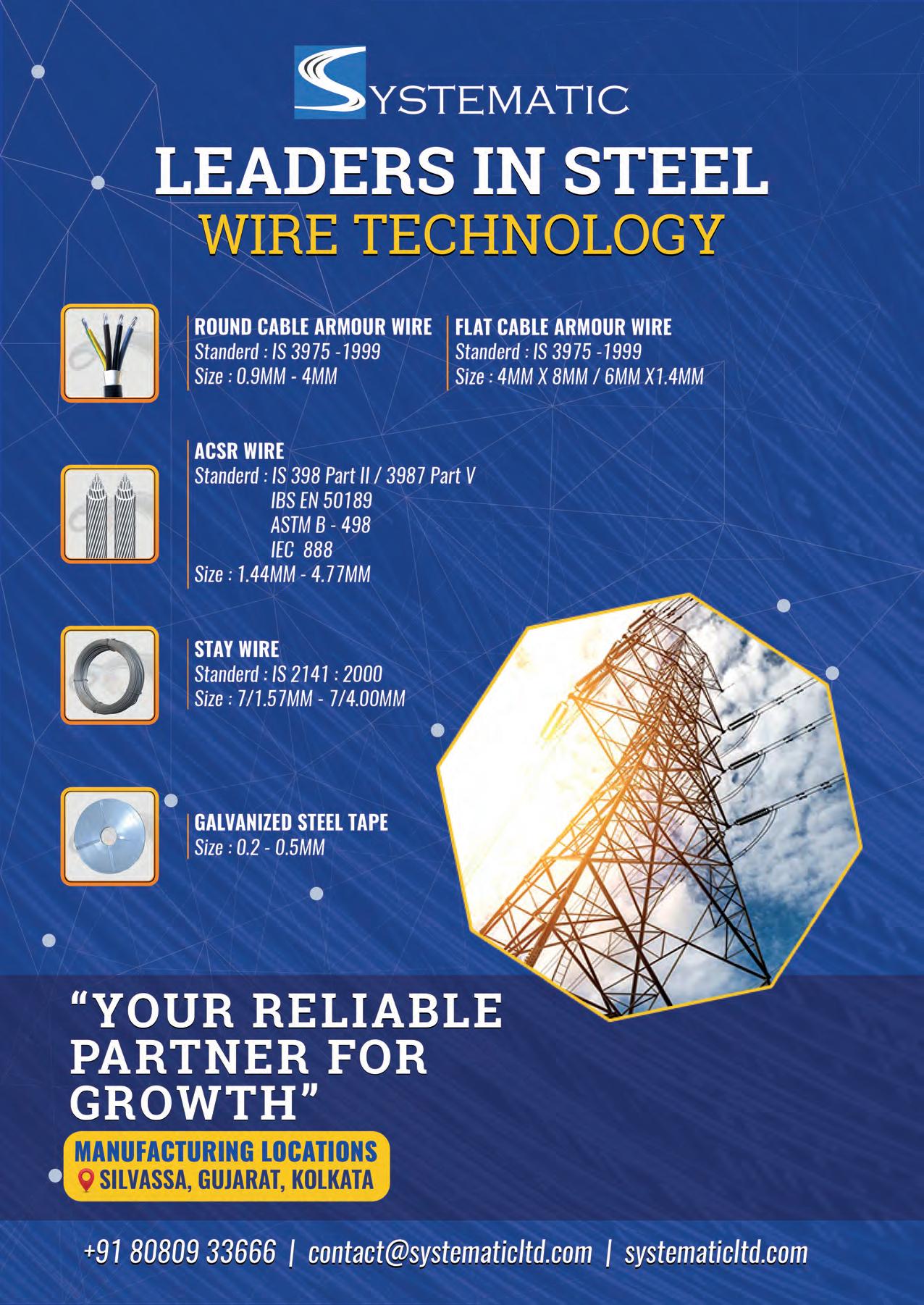

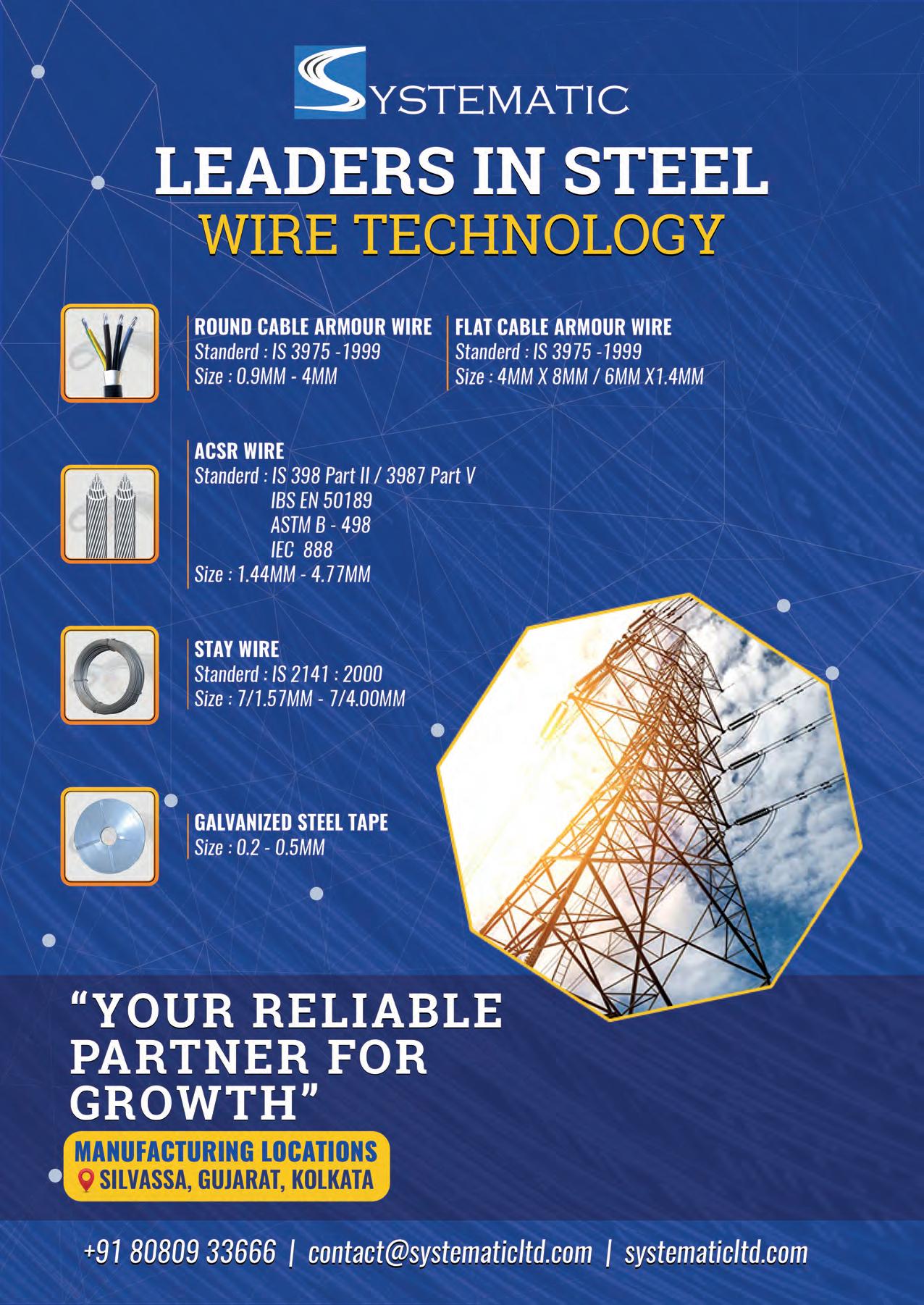

Steel Wire Industry to Ride on Economic Growth

Resurgent Demand in the Indian Steel Wire Industry

The global steel wire industry is witnessing a stage

of speedy recovery and development after the COVID-19 pandemic, as the demand for steel wire has graphed upwards, propelled by multiple factors of rapid urbanization, growth in the infrastructure, industrialization, augment in construction activities, transportation & mobility, automotive, aerospace, energy sectors, as well as technological advancements. The global steel wire industry is expected to showcase a growth opportunity of approximately USD 100 billion at a CAGR 4.7% from 2022-2030, expected to reach USD 180 billion in 2030 from USD 103 billion in 2021, as per reports by Astute Analytica & Grand View Research.

The Indian steel industry has entered into a new development stage, post de-regulation, riding high on the resurgent economy and rising demand for steel. Rapid rise in production has resulted in India becoming the 2nd largest producer of crude steel during the last four years (2018-2021), from its 3rd largest status in 2017.

India is one of the key players and leading producers in the steel wire market, owing to a strong domestic market. The growth of the Indian steel wire industry is being driven by multiple factors like rapid urbanization, infrastructure development, industrialization, construction

May-Jun, 2023 www.wirecable.in FEATURE 12

activities, transportation and mobility, need for lightweight materials across automotive and aerospace segments,and growing demand from the energy sector. The construction industry is a major consumer of steel wire products. The increasing demand for infrastructure development in India is driving the growth of the construction industry, in turn driving the demand for steel wire products. Steel wire is also increasingly being used in automotive applications, as automotive manufacturers are increasingly using steel wires in automotive structures and parts owing to their easy processing and characteristics of ductility, high tensile strength, and corrosion resistance. The growing demand for fuel-efficient and lightweight vehicles is driving the use of steel wire in automotive applications. The energy sector has also become one of the thriving sectors in the last few decades, with steel wires being predominantly used in manufacturing transmission lines, steel core wires, overhead power lines, and ground wires for wind power. Growing demand from the energy sector is one of the factors driving the steel wire segment's market growth.

Additionally, as the steel wire industry continues to evolve constantly, new technologies are being developed to improve the performance and quality of steel wire products. There's a huge push towards value addition and enhanced quality which matches internationally acceptable quality standards. This enables the manufacture of international quality steel wire and wire products which throws open a wide market nationally and internationally for us. The technological advancements are helping to meet the growing demand for steel wire products in a variety of applications. Thus, demand from these sectors are pushing the growth of the Indian steel wire industry.

Government Initiatives Fostering the Industry

The Indian government has been providing support and nurturing the growth of the steel wire industry through a number of policies. In 2017, the Indian government introduced the National Steel Policy (NSP) aiming to take India's steel production capacity to 300 million metric tons by 2030, as well as enhancing India's domestic consumption, producing high-quality steel and making India's steel sector globally competitive. The NSP 2017 Policy was aimed to boost economic growth through measures such as meeting steel demand domestically through availability of raw materials and capacity additions and in a costeffective manner.

The Indian government launched another major policy in 2019, called the Steel Scrap Recycling Policy, which provided a framework to facilitate and promote establishment of metal scrapping centers in India for scientific processing and recycling of ferrous scrap generated from various sources. Through this policy the government helped create a conducive ecosystem for the entrepreneurs and investors to establish scrapping centers in the country. This is to recycle and reuse scrap to produce high quality steel. This will ensure more steel production and, thus, reduce dependency on imports.

Under the recent Production Linked Incentive (PLI) scheme for Specialty Steel, launched in 2021, the government aims to promote specialty steel manufacturing in India, through attracting capital investment, generating employment as well as promoting technology up-gradation in the steel sector. With a major fiveyear financial outlay of INR 6322 crore, the scheme has taken up 67 applications from 30 companies in December 2022. This will attract a committed investment of INR 42,500 crore. The government's support for

the steel wire sector will help the industry to grow and meet the growing demand for steel wire products in India and around the world.

The government has also taken steps to promote ease of doing business, attract foreign investment, establishment of Steel Zones and Clusters, promotion of greenfield investments, and encourage research and development in the steel sector for better quality and cleaner steel production, and trade agreements. The government has also announced a policy for providing preference to domestically manufactured iron and steel products in government procurement. The government is providing incentives to put up steel wire plants in rural and semi-rural areas, providing export incentives for export of high carbon, alloy steel and spring steel wires, as well as reducing power tariffs for industries to make them a viable unit.

Additionally, the government has undertaken infrastructure projects that boost demand for steel wire, such as the development of smart cities, metro rail systems, and rural electrification. These initiatives create a favorable environment for the growth of the steel wire industry and provide opportunities for domestic manufacturers to meet the increasing demand. In addition to this, the government's emphasis on Make in India and selfreliance has further bolstered the steel wire industry by promoting domestic manufacturing. This has led to a more robust and competitive domestic steel wire market.

Challenges and Redressal

There are several challenges hindering the operational efficiency, innovation, and growth of the Indian steel wire industry today. Major challenges are the lack of technical know-how, lack of modern steel wire plants with latest technology, lack of research and development activities, non availability of skilled manpower and non

May-Jun, 2023 www.wirecable.in 13

FEATURE

abidance to the best global practices. The industry also lacks the technical infrastructure that is required for improving quality and productivity, thereby affecting the overall cost effectiveness of the production process.

Other major challenges is the competition from companies from Turkey, Vietnam and South Korea; cheap import of wires from China, Vietnam, Indonesia, Turkey etc., interrupted power supply for steel wire production, dependence on costly coal imports resulting in higher steel prices, frequent change in raw material prices, and logistics and transportation problems.

The industry will have to prepare to provide the best quality products at competitive prices. The price of the steel wires largely gets influenced by the cost of the raw material which are mainly imported. Hence, in order to effectively compete with manufacturing hubs like China and other global players, the Indian steel wire industry may need to procure raw materials at a competitive price.

While the industry has grown at a

robust pace over the last three years, it is witnessing a relative slowdown, due to surplus production capacities across the sector. After a period of over three years, the demand for steel wires seems to finally be lower than the available manufacturing capacities and this is resulting in a pressure on the operating margins in the shortterm.

These challenges are crucial in nature and need to be addressed to ensure the industry's competitiveness and sustainable development. With the growth of the Indian economy and the increased focus on manufacturing, India is soon going to be the manufacturing hub of the world and the steel wire industry cannot stay far behind during this phase of growth. To address the surplus capacities manufactured, we will have to find ways to improve our export share in this market. It is crucial for the steel industry to focus on optimizing costs throughout the value chain, including raw material procurement, production processes, and supply chain management. This may involve exploring alternative sourcing options, negotiating favorable pricing

contracts, improving operational efficiencies, and adopting costeffective technologies. Lastly, it becomes important for the government to create a conducive business environment.

Path to Growth

India's steel industry is currently in a new stage of development, where the market is enjoying rising steel demand from multiple growing industries. As the steel consumption increases following the increase in infrastructure, automobile, energy and technology sectors, the Indian steel wire industry shows major scope for growth. The steel wire industry is an essential cog in the system of the working of a developing nation, and with the support of the various initiatives and policies by the Indian government, the multifold development of the industry will further foster India's steel industry.

In the longer term, the industry outlook continues to be quite strong and the Indian steel sector should continue at a much faster pace compared to the global steel sector. To stay ahead of the curve, industry stakeholders need to deliver ESG performances at par with global counterparts. Due to the energy intensive nature of the processes, we need to start making a concerted effort towards adopting clean technologies and reducing emission. Observing the ever-increasing importance of the steel wire industry, Wire & Cable India conducted interviews with major companies, where they shared their contributions to the steel wire industry through their manufacturing operations and product lines as well as their expert insights on the current scenario of the global and Indian steel wire industry, the Indian government's initiatives for the steel-wire industry's growth, the challenges faced and how they can be solved.

May-Jun, 2023 www.wirecable.in FEATURE 14

Global Wires India-Tata Steel Aims to Double Capacity to 1 Million Tons by 2030

Global Wires India (GWI), a division of Tata Steel

Limited, is a preferred supplier of steel wires across diverse industry segments ranging from construction, automotive and power to general engineering and retail. The company, with a combined annual manufacturing capacity of 670,000 MT, manufactures a wide range of value added product offerings like motor tyre bead (MTB), low relaxation pre-stressed concrete (LRPC), induction hardened and tempered (IHT), knotted fence, and 3D weld mesh. GWI's future plan is to double its capacity to 1 million tons by 2030. In a recent conversation with Wire & Cable India, Mr. Anurag Pandey, Executive-in-Charge, Global Wires India-Tata Steel shared about the company's journey, specialized products and their USP, along with his thoughts on the current scene of the steel wire industry and how the company is working to overcome the challenges.

Wire & Cable India: Could you please take us through the business journey, milestones, and achievements of your company?

Anurag Pandey: Global Wires India's (GWI) strong presence for 7 decades has helped grow and achieve many milestones. From being incorporated in 1958 as Special Steels Private Limited to becoming a subsidiary of Tata Steel in 1979 and subsequently, to becoming a division of Tata Steel in 2002, GWI has come

a long way. GWI is planning to double its capacity to 1 million tons by 2030 by ensuring that changing expectations and requirements of customers are being met.

Keeping pace with the mega trends that are shifting the global world through urbanization, changing economic power, and technology, Tata Wiron is set to take full advantage of the boosted infrastructure, automotive, and energy sectors. Our product offerings have all set industry

May-Jun, 2023 www.wirecable.in 16

FEATURE

Mr. Anurag Pandey, Executive-in-Charge, Global Wires India-Tata Steel

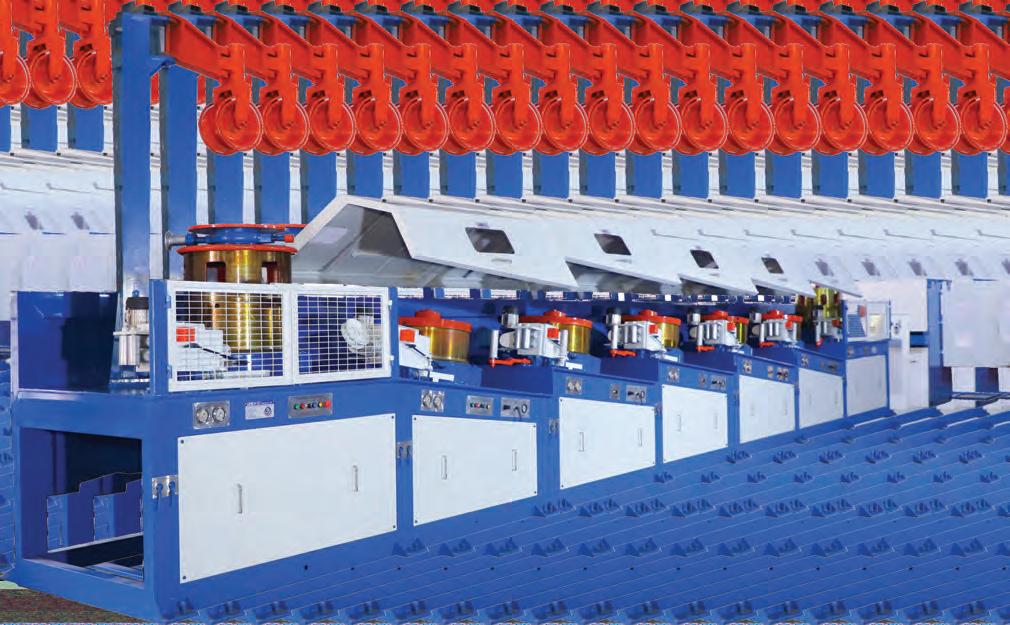

Ÿ Straight Line Wire Drawing Machine Ÿ Inline Wire Rod Preparation System Ÿ CO2 Wire Production Line Ÿ Pay-off & Take-up Systems for Galvanizing Line Ÿ Pay-off & Take-up Systems for Patenting / Annealing Line Ÿ Inverted Drawing Machines (IVD) Ÿ Wet Wire Drawing Machines Ÿ Vertical / Horizontal Spoolers Ÿ Dead Block Coilers Ÿ Pay-offs for Wire Drawing Machine Ÿ Rewinder Machines Our Product Range SWARAJ TECHNOCRAFTS PVT. LTD. Plot-40, Sector-II, Pithampur, Dist. Dhar (M.P.), India-454775 Ph.: +91 7292 407213, 407304, Email: Info@swarajtechnocrafts.com, Website: www.swarajtechnocrafts.com Mob.: +91-97522 65813 Built like a tank…. Runs like a Race car Leading manufacturer of wire drawing machine and auxiliary equipments for steel wire industry

benchmarks in terms of quality and to deliver application support expertise.

Growing in volumes in value added product offerings like Motor Tyre Bead (MTB), Low Relaxation Pre-Stressed Concrete (LRPC), Induction Hardened and Tempered (IHT), knotted fence, and 3D weld mesh, GWI seeks to successfully leave its mark. We have been touching lives of millions of customers every day and we take pride in saying that one in every 3 tyres in India runs on the tyre bead made by GWI, 2 out of every 3 flyovers in India stand tall on our LRPC strands, 1 in every 2 eggs In India are laid in a cage made from Tata Wiron, and 1 out of every 2 two-wheelers manufactured in India uses Tata Steel suspension wire. Tata Wiron is poised to grow through entry in the higher technology arena while also focussing on scaling up downstream play.

WCI: Brief us about your specializedproductsalongwiththeirUSPs.

AP: In the auto segment, Tata Wiron has helped the import substitution for spring manufacturers by bringing indigenous IHT (Induction Hardened Tempered) wire which otherwise was imported. We enjoy a healthy 80% market share in IHT 2W/3W suspension segment, enabling 90% localization of the category. In the fencing segment, we have added two new products offering - knotted fence and 3D weld mesh, which have proved to be a game changer in the fencing segment. Knotted fence is a uniquely designed and technically superior fencing solution, designed to offer maximum protection through a unique cross lock knot, which has improved the overall strength of the fence by 3 times more than a conventional fence. Owing to variable spacing, the product is 25% cheaper than the chain link solution. Through 3D weld mesh, we have offered aesthetically superior and robust one stop fencing solution which is 25% cheaper than traditional brick wall.

Superior quality, high durability, easy installation, and complete impenetrability offered by this solution provides convenience and peace of mind to consumers. At Tata Wiron, we work tirelessly to serve our purpose to attain excellence through purposeful innovations and responsiveness while enabling improvement in quality of life.

WCI: Please share your views on the Indian vis a vis the global steel wire industry. What is the role of the Indian government in the growth of this sector?

AP: The global steel wire industry is expected to grow at a CAGR of 5-6% by 2030 with the Asia Pacific region accounting for over 40% of consumption as well as production of steel wires. The main drivers of this growth would be improved construction activities in India and China, as well as the replacement market in developed markets such as Europe and US.

The global steel wire industry is highly fragmented with the top 5 producers accounting for only 32% of global production. This trend is expected to continue with more new entrants coming from both developed and emerging markets. The Indian steel wire industry has come a long way since its establishment in the 1920s. If we look at the wire demand, nearly 88% of wires are in carbon steel grades against the global average of 56%. Low per capita steel consumption in India against the world average and various government schemes will drive the steel wire growth in India. For example, the government has approved the Production Linked Incentive (PLI) Scheme for Speciality Steel, with budgetary outlay of USD 6.32 billion over five years. Current PLI Scheme covers 5 categories of steel wire and with phase 2 of PLI in motion further scope of products are expected to be widened. The Indian government has also launched various schemes to

support greener products and processes which have helped the steel as well as steel wire industry players to move towards net zero carbon emissions by 2045-2050.

WCI: What are the major ongoing challenges in the Indian steel wire industry?

AP: Like any other industry, the steel wire industry is also affected by cost and availability of raw material, technological advancements, price fluctuations, government policies and regulations, competition from imports and other supply and demand side factors. Needless to say, the companies have to continuously invest and adopt advanced technologies to remain competitive in the domestic as well as global market. Indian steel wire manufacturers face strong competition from imported products, particularly from China, which puts pressure on local manufacturers to improve their cost competitiveness. Fluctuations in global demand for steel wire products and price volatility impacts the profitability. The industry and the government need to monitor and adapt to changing market dynamics to maintain steady growth. Responsible supply chain should be a major focus given the industry is growing steadily and the companies have to adapt necessary changes in their processes to adhere to environmental obligations.

WCI: How can these challenges of the industry be addressed? How is your company contributing towards this transition?

AP: The upstream value chain needs to grow in tandem with the increasing steel wire demand. Along these lines, Tata Steel long products are expected to grow to 13 million tons by 2030 a/a the current level of 5 million tons. Moving towards technologically advanced and value-added products is necessary to stay away from commoditization and be ahead of the market. To address this, we have

May-Jun, 2023 www.wirecable.in 18 FEATURE

introduced IHT (Induction Hardened Tempered) wire, Aayush coating, knotted fence, 3D weld mesh, etc. As a player, one needs to diversify their product offering or the target market

to remain immune to cyclicity in the business. We are constantly reviewing our product offerings and target market to adapt to the changing market dynamics. We at Tata Wiron,

believe in growing responsibly and we are focusing consistently in adapting greener processes and products to achieve zero liquid discharge and reduction of carbon emissions.

May-Jun, 2023 www.wirecable.in 19

FEATURE

Tata Wiron awarded “Brand of The Year Award” in Auto and Infrastructure Category by Marksmen Daily in association with India Today (Print Partner - Hindustan Times)

Viraj Profiles Aiming USD 3 Billion Turnover in Next 4 Years

Established in 1992, Viraj Profiles Private Limited has emerged as the leading manufac-

turer of stainless-steel long products globally with its integrated manufacturing facilities and premium quality for three decades. With a production capacity of 528,000 tons per annum, Viraj manufactures stainless steel products like wire rods, wires, fasteners, bright bars, profiles and flanges in various grades and sizes. Moving forward, the company aims to increase its turnover from USD 1.2 billion to USD 3 billion within the next 4 years.

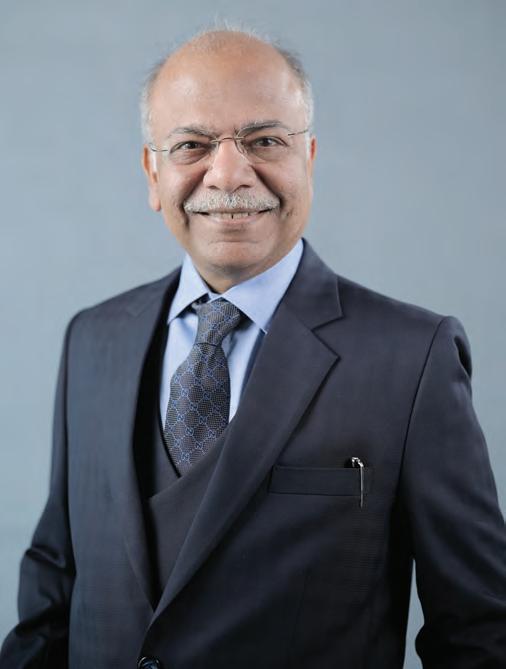

In a recent interview with Wire & Cable India, Mr. Rakesh Chauhan, CEO, Viraj Profiles Private Limited, shared insights about the company's journey, manufacturing capabilities, product portfolio, market footprint, USPs, CSR initiatives and future plans.

May-Jun, 2023 www.wirecable.in 20

FEATURE

Mr. Rakesh Chauhan, CEO, Viraj Profiles Private Limited

Wire & Cable India: Could you give us a brief overview of the business journey of your company.

Rakesh Chauhan: Viraj is a 30-yearold company that started with a melting shop in 1992. Within 3 years, stainless-steel production commenced. Equipped with integrated manufacturing facilities and trust in delivering premium quality, Viraj Profiles has emerged as the leading manufacturer of stainless-steel long products globally. We have been serving the industry for 3 decades and have excelled with the support of our customers. They are the most important pivot for us, and all our efforts are only to sustain and build relations with them. Viraj Profiles' traditions, business principles and ethical practices have propelled it to the forefront of the industry.

WCI: Kindly tell us about your company's manufacturing capabilities, infrastructural setup and product portfolio.

RC: Our integrated manufacturing process starts from scrap processing within our own scrap yard. We sort scrap in our Zurik sorting plant based on the requirement of the melting shop. This is the first step in the value chain. Next, we have the melt shop which has “Computerized Intelligent Refining System”, induction furnaces, AOD's and continuous billet casters. Our rolling mills include a wire rod mill, section rolling mill and round rolling mills. Both our wire rod and section rolling mills have level 3 automation. These mills work depending on the product size and form. These rolling mills feed our wire, bright bar, profiles and fastener mills. Additionally, we have a forging shop which feeds our flange and forge bar mills. Also, we are set to start production of seamless pipes by the middle of next year.

WCI: Please shed some light on Viraj's clientele and market footprint.

RC: Our presence is all around the world. We export our products to over 1300 customers based in 96 countries across 6 continents. We have over 90 certifications and approvals for our products, which are used in a rich and diverse list of industries such as oil & gas, petrochemicals, food & beverages, construction, shipbuilding, pharmaceuticals, aerospace, defense, and marine industries.

WCI: What according to you are the USPs of your company, setting it apart from the competition in the market?�

RC: Our USP is our relationship with our customers, which is never just a buyer-seller relationship. Though business is done on the basis of proper fundamentals, we have a familial connection with all our customers. We have built detailed systems to ensure quality, delivery, and after-sales services so that customers are completely assured and satisfied. Another big USP we have is our team of extremely talented and dedicated professionals backed by a corporate culture of openness and collaboration. We focus on automation, with all our machinery being equipped with level 2 or level 3 automation. We also have regular reviews to ensure that we keep up with the demands and requirements of our customers.

WCI: What are the ongoing or upcoming developments at Viraj?

RC: In the recent past, instead of making heavy investments in our capacity, we have been investing in removing bottlenecks in the value

chain. For example, earlier we had a mismatch in the capacities of our rolling mills vis-à-vis melting capacity and then a mismatch between our finishing capacity and rolling capacity. This was worked upon, and today we carry out full-capacity melting and finish it completely. Moving forward, our next step is to diversify into new products and increase our capacity in our existing product range.

WCI: Moving forward, what are the future plans for growth at your company?

RC: We have multiple projects in the pipeline. For this year, green manufacturing and green steel are our key focus areas. A major project we have undertaken is getting our facilities audited. The Europe branch has scope 1, scope 2 and scope 3 regulations and we are currently required to report and cover scope 1 and scope 2. Our carbon footprint is around 0.7, which is much better than any global player. Moreover, we have started the process of auditing scope 3, which is expected to be done by the end of this year and will come into force within the next 2 years.

We're aiming for green steel certifications and have also invested in a 100megawatt solar power project, which covers almost 40% of our electricity requirements. Following this huge step towards carbon footprint reduction, we are now working on our next project to utilize another 100 megawatts of solar power. So, almost 80% of our energy needs would be fulfilled via greener alternatives. Our current turnover is around USD 1.2 billion, and our vision is to make it a USD 3 billion turnover

“

”

Viraj focuses on automation, with all its machinery being equipped with level 2 or level 3 automation.

“

” May-Jun, 2023 www.wirecable.in 21 FEATURE

Our integrated manufacturing facilities, based in India, have a production capacity of 528,000 tons per annum.

company within the next 4 years. That's a big target and we are confident that we will achieve this.

WCI: How does Viraj invest towards CSR initiatives?

RC: We have a lot of CSR initiatives running near our manufacturing facilities in Tarapur. To help schools impart education, we have taken the responsibility to provide hardware and books for underprivileged children. We also run a school called Viraj Shri Ram Centennial School, which is one of the best schools in the Palghar region. It admits students from places as far away

Our presence is all around the world, we export our products to more than 1300 customers based across 96 countries spread across 6 continents.

as Vapi and Gujarat and imparts quality education to them. In addition to this, we have vocational training centers where women from nearby villages get trained in various skills like candle making, stitching, etc. We also provide medical help for many villages around our factories.

Additionally, we offer CSR support on a global scale. For instance, a few months back, when Turkey experienced a significant earthquake, we contacted the Turkish embassy and requested for a list of urgent supplies they needed for aid and provided the same to them.

Sterlite Power Commences Aerial Operations for Flagship Mumbai Urja Marg Power Transmission Project

Sterlite Power has deployed state-of-the-art lightweight helicopters to overcome the challenges of terrain and speed up material transfer to fasttrack the construction process of the Mumbai Urja Marg project (MUML). The MUML project is a vital cog in the Centre's plan to fulfill the escalating electricity demands of Mumbai.

May 31, 2023

Sterlite Power has announced the commencement of

aerial operations to expedite the construction of its flagship Mumbai Urja Marg Project (MUML), the 400kV transmission corridor connecting Padgha to Khargar, which links Mumbai to the national grid. To fast-track this project, Sterlite Power has deployed state-of-the-art lightweight helicopters to overcome the challenges of terrain and speed up material transfer. The aerial operations will involve the movement of around 3000 metric tonnes of material over a period of 2 months.

The lightweight helicopter AS 350 B3 with a load-carrying capacity of up to 1000 kgs per sortie will be pressed into service to transport heavy equipment and material across several locations in and around the Mumbai region. To carry out this herculean task, a 13-acre helicopter yard has been constructed to house and load the machine for sorties. Sterlite Power's Mumbai Urja Marg project is a vital cog in the Centre's plan to fulfill the escalating electricity demands of Mumbai. As a project of national significance, MUML is being closely monitored by the

Prime Minister's Office via the PRAGATI Portal. Once operational, the project will have the potential to carry more than ~2000 MW of additional power to Mumbai and Navi Mumbai.

May-Jun, 2023 www.wirecable.in FEATURE 22

“

”

NEWS

Synergy Steels: Expanding ValueAdded Products Range to Cater to Evolving Market Demands

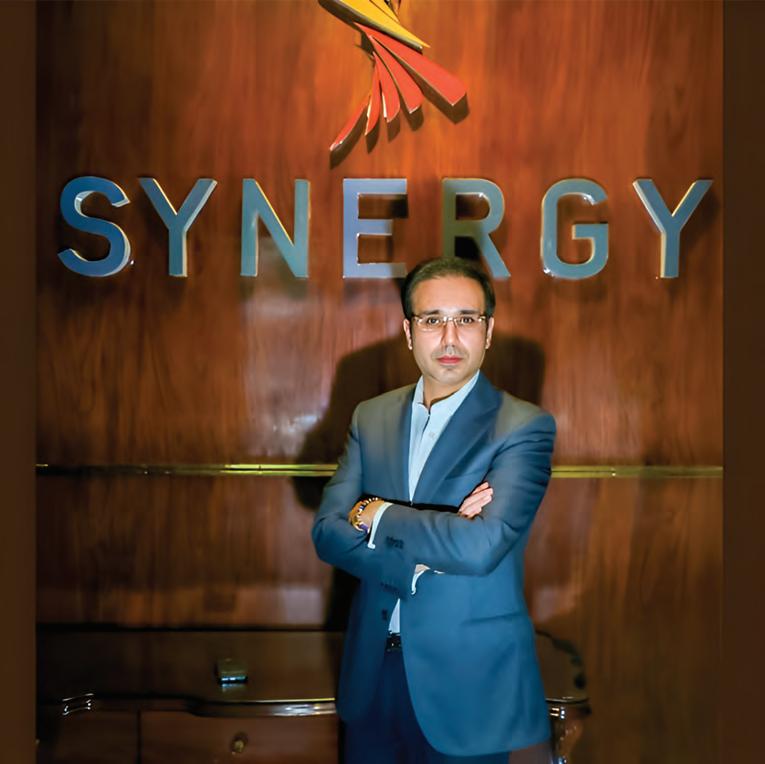

Synergy Steels Limited is

one of the leading and most trusted stainless steel companies in the country. The company offers a range of high-quality value-added stainless steel long products, catering to various industries and applications. Their latest product, the stainless steel rebar, is an ideal choice for infrastructure and construction projects as it is corrosionresistant and durable. The company witnessed a 10x growth in revenue, with an increase from USD 30 million in 2012 to USD 315 million in 2019. In a recent interaction with Wire & Cable India, Mr. Anubhav Kathuria, Director, Synergy Steels Limited talked about his company's journey and growth, recent developments, product portfolio along with his inputs on the challenges in the Indian and global steel wire industry, and how to overcome them.

May-Jun, 2023 www.wirecable.in FEATURE 24

Mr. Anubhav Kathuria, Director, Synergy Steels Limited

Wire & Cable India: Could you please take us through the business journey, milestones and achievements of your company?

Anubhav Kathuria: Established in 2012 in Alwar, Synergy Steels is one of the fastest growing stainless steel manufacturing companies in the country. Throughout our existence, we have remained committed to continuous improvement, focusing on innovation and adopting new technologies to enhance our products and services. We have experienced significant growth in revenue, with an increase from USD 30 million in 2012 to USD 315 million in 2019, representing a substantial growth of 10x. This achievement corresponds to a CAGR of 42%. Additionally, our operations consistently generate positive EBITDA within the industry, contributing to month-on-month stability. Our overall business strategy is aligned to ensure consistent year-on-year growth.

Currently, our strategic focus lies in expanding our operations to include value-added products such as wire, bright bars, and fasteners. To support this expansion, we have been steadily increasing our melting capacity and diversifying our product portfolio. One of our significant achievements is our dedication to sustainability. We have forged alliances with solar companies to ensure that 50% of our energy requirements come from renewable sources. This commitment to clean energy not only contributes to our environmental stewardship but also aligns with our efforts to reduce our carbon footprint and create a more sustainable future. Furthermore, we prioritize ESG performance and continually strive to improve in these areas year after year. Our focus on sustainable practices, technological advancements, and diversified product offerings positions us as a dynamic and responsible player in the stainless steel industry. As we continue our business journey, we remain dedicated to delivering high-

The government has implemented reforms and programs such as the Production-Linked Incentive (PLI) Scheme for specialty steel, foreign direct investment (FDI), establishment of Steel Zones and Clusters, promotion of greenfield investments, research and development for better quality and cleaner steel production, and trade agreements.

quality products, embracing innovation, and adhering to sustainable practices, all while striving for excellence in every aspect of our operations.

WCI: Brief us about your specialized products along with their USPs?

AK: We offer a range of high-quality value-added stainless steel long products that cater to various industries and applications. Our most recent launch, the stainless steel rebars are corrosion-resistant and durable, making them ideal for infrastructure and construction projects. These rebars provide enhanced structural integrity, longevity, and design flexibility while minimizing maintenance needs. Our stainless steel wire rods serve as a vital raw material for the production of wires and bright bars. These wire rods are widely used in the construction and infrastructure sectors. With their mechanical properties and dimensional accuracy, our stainless steel wire rods enable the production of valueadded products that find applications in sectors like construction, engineering, and electrical industries. In order to further expand our product range, we have recently introduced 5mm stainless steel wire rod across various grades. Known for their aesthetic appeal, our stainless steel bright bars are also extensively used across various industries, including kitchens, home appliances, and consumer durables. Bright bars are processed to manufac-

ture handles, shafts etc, enhancing the visual appeal and functionality of a wide range of products. Our extensive range of stainless steel fasteners encompasses 26-27 different types, making them versatile and suitable for a wide range of industries. These fasteners are known for their strength, durability, and corrosion resistance. They provide reliable and secure connections in industries such as construction and infrastructure development, ensuring the longevity and safety of assemblies. Synergy Steels has been the pioneer in stainless steel flats, and we have been instrumental in delivering and catalyzing the growth of the utensil market in India. With our focus on quality, innovation, and customer satisfaction, we strive to deliver exceptional products that meet the unique requirements of our clients.

WCI: What have been the recent developments at your organization and what are your future growth plans?

AK: At Synergy Steels, we are committed to continuous growth and innovation. In line with our mission to maintain a high quality and diverse product line, we have recently launched production of stainless steel reinforcement bars (rebars). These rebars are designed to offer exceptional corrosion resistance and fire resistance, making them an ideal choice for construction projects. By introducing these rebars, we aim to provide our customers with efficient,

May-Jun, 2023 www.wirecable.in 25

FEATURE

“

”

reliable, and durable solutions that enhance the durability and strength of concrete structures, especially in coastal areas. Further, we have also expanded our product range to include 5mm stainless steel wire rod across various grades. As we look ahead, diversifying our product portfolio remains a key focus area for us. We aim to expand our range of value-added products to cater to evolving market demands and customer requirements. We will also continue to invest in research and development to stay at the forefront of technological advancements, ensuring that our products meet the highest quality standards and offer innovative solutions to our customers.

WCI: Could you tell us about your major projects and clientele you are catering to?

AK: As an ISO 9001:2015 certified company, we have a state-of-the-art industrial set-up with customized plants equipped with the latest technology-driven machinery. With our commitment to delivering excellent quality, exceptional service, and timely delivery, we have established ourselves as a leading manufacturer of top-quality stainless steel flats, billets, and wire rods. With a capacity to produce 2,50,000 tonnes of stainless steel, a turnover of more than USD 315 million, and a continuous expansion into value-added products, we have emerged as a key

player in the stainless steel long products market. Our major stainless steel and rolling mills are based out of the Matsya Industrial Area in Alwar, Rajasthan, which is at a 140 km distance from Delhi. Over the past two decades, we have built a vast clientele across India, Europe, the Middle East, South America, Southeast Asia, and North America, solidifying our position as a trusted name in the industry. All major fastener and wire producers around the world remain our customers.

WCI: Describe your infrastructure and manufacturing setup for the steel wire sector along with their manufacturing capabilities.

AK: We operate three state-of-the-art manufacturing setups, including a steel melting shop, wire rod mill, and Alwar rolling mill. Our facilities are equipped with advanced testing infrastructure and automated machinery, ensuring high-quality production. We also have a corporate office based out of New Delhi, India. We have a wire drawing facility, precision heat treatment, SMS with AOD, and continuous caster located in the Matsya Industrial Area in Alwar, Rajasthan. The integrated stainless steel melt shop in Alwar has integrated raw material handling yard, test furnaces, quality control labs for metallurgical research, induction furnaces, AOD, billet caster with a melting capacity of 250,000 MT per annum. The integrated wire rod mill is fully automated with a reheating furnace, precision heat treatment and annealing facilities, pickling facility and garret coiler to produce wire rods between 5-34mm. We have a super specialized downstream value additive product portfolio with advanced testing infrastructure that includes wire drawing lines to produce fine wires, stainless steel flats, bright bars, fasteners and stainless steel rebars. We have recently introduced stainless steel rebars to our product lineup, in addition to the introduction of 5mm stainless steel wire rods in various grades. With these new additions, we

reaffirm our commitment to innovation. We constantly strive to deliver high-quality value-added stainless steel long products and enhance our product offerings.

WCI: Please share your views on the Indian vis-a-vis the global stainless steel wire industry. What is the role of the Indian government in the growth of this sector?

AK: The stainless steel wire industry plays a crucial role in the global economy, with applications in construction, automotive, and transportation. The industry has witnessed significant growth due to the increasing demand for stainless steel wire products worldwide. The global stainless steel market had a value of USD 112 billion in 2022. It is projected to reach USD 223.89 billion by 2032, with a CAGR of 8-9% during the forecast period, driven by investments in the construction industry, which are anticipated to augment market growth during the forecast period. India is a key player in the global steel wire business, benefiting from a substantial domestic market. The Indian government has been actively supporting the steel and stainless steel industry through various initiatives, including the National Steel Policy 2017, which aims to increase the country's steel production capacity to 300 million metric tons by 2030. Additionally, the government has implemented reforms and programs such as the Production-Linked Incentive (PLI) Scheme for specialty steel, foreign direct investment (FDI), establishment of Steel Zones and Clusters, promotion of greenfield investments, research and development for better quality and cleaner steel production, and trade agreements. With growing demand across industries, the stainless steel wire industry is expected to expand globally. By embracing sustainable practices considerations, the industry can

May-Jun, 2023 www.wirecable.in FEATURE 26

“

”

Incentivizing the adoption of environmentally friendly technologies and cleaner production processes will help the industry reduce its environmental impact and ensure compliance with regulations.

successfully meet market demands, while also contributing to a greener and more sustainable future.

WCI: What are the major ongoing challenges in the Indian stainless steel wire industry?

AK: There are several challenges that face the Indian stainless steel wire industry today. These challenges are crucial in nature and need to be addressed to ensure the industry's competitiveness and sustainable development. The industry is facing a shortage of skilled labour, including technicians, engineers and operators, hindering operational efficiency, innovation, and growth. The industry also lacks the technical infrastructure that is required for improving quality and productivity, thereby affecting the overall cost effectiveness of the production process. Many manufacturers, especially the MSMEs are facing challenges in accessing the

necessary funds and expertise to upgrade their production processes.

WCI: How can these challenges of the industry be addressed? How is your company contributing towards this transition?

AK: To address these challenges, it is important to focus on bridging the skill gap through training programs and providing opportunities for workforce development. Investing in research and development will enable

the adoption of advanced manufacturing technologies, leading to increased innovation and productivity. Additionally, incentivizing the adoption of environmentally friendly technologies and cleaner production processes will help the industry reduce its environmental impact and ensure compliance with regulations. These measures will contribute to the growth and sustainability of the Indian stainless steel wire industry.

May-Jun, 2023 www.wirecable.in 27

FEATURE

Nirmal Wires' R&D and Product Portfolio Expansion to Enhance Efficiency and Capacity

Originating in the year 1981, Nirmal

Wires (P) Ltd. is one of well-renowned names in the industry which is fulfilling the requirements of high-quality industrial products. Nirmal Wires' product range consists of GI wires, welding electrodes, aluminum conductors, galvanized stranded wires, galvanized steel wires, high carbon steel wire, deformed steel bars, and others. By exceeding customers' expectations with their products and services, Nirmal Wires has maintained healthy relations with its wide range of customers. In a recent conversation with Mr. Nirmal Saraf, Managing Director, Nirmal Wires Private Limited, spoke about the company's history and journey, specialized product portfolio, recent developments, views on the Indian and global stainless steel wire industry, ongoing challenges in the Indian stainless steel wire industry and solutions to the challenges.

Wire & Cable India: Could you please take us through the business journey, milestones and achievements of your company?

Nirmal Saraf: Our journey began in 1971 with Shri Ramautar Saraf at the helm. Fueled by the spark to create the best quality steel products in West Bengal he established a small wire drawing unit under the corporate entity Central Store Supplies (P)

Limited incorporated in 1942. After many years of hard labor and facing multifarious challenges, he kept the flame alive, and in 1985 put up a steel wire galvanizing plant under the corporate entity Nirmal Wires Private Limited incorporated in 1981. He handed over the torch, kindled by him, to his sons Mr. Nirmal Saraf, Mr. Raman Saraf and Mr. Piyush Saraf. In a few years, we had established a

May-Jun, 2023 www.wirecable.in FEATURE 28

Mr. Nirmal Saraf, Managing Director, Nirmal Wires Private Limited

C-164, Site-1, BSR Industrial Area, Ghaziabad-201 001.

Email: info@zenithmachines.com | zenithmach@gmail.com

Website: www.zenithmachines.com

Weldaids Ltd.

PRODUCTION PROGRAMME

Ÿ Straight Line Wire Drawing Machine (SLM)

Ÿ Inverted Vertical Drawing Machine (IVD)

Ÿ Rod Preparation Systems

Ÿ Wet Drawing Machines

Ÿ Rod Break Down Machines

Ÿ Stress Relieving & Strand Annealing Furnace

Ÿ Stranding Machines

Ÿ Vertical Drop Coilers

Ÿ Spool And Coil Take Ups.

TURN KEY PROJECTS

Ÿ Plant For Stainless Steel Wire

Ÿ Plant For P.C Wire

Ÿ Plant For Galvanised Wire

Ÿ Plant For ACSR Conductors

Ÿ Plant For Ribbed Wire

Ÿ Plant For Bead Wire

Ÿ Plant For Spring Steel Wire

Ÿ Plant For MIG Wire

Ÿ Plant For Brass Wire

flourishing business in the steel products industry mainly steel wires and rolled products. The torch burning brighter than ever before was handed over to the third generation of leaders: Mr. Varun Saraf, Mr. Prateek Saraf, Mr. Vidyut Saraf and Mr. Parag Saraf. They have carried the torch far and wide and are now meeting customer needs in over 40 countries around the globe.

Moving from one milestone to another, we have now expanded our product range to over 100 SKUs of different products including galvanized and black steel wires, aluminum conductors, ribbed wires, welding electrodes and hot rolled steel products. Some of our wires and their vast applications include- wires for producing umbrella ribs, various types of springs, wires for earthing, wires of staying, armoring of cables, and concrete re-enforcement wires. These wires are used in transmission, distribution and generation of power, security and protection, fencing, general engineering, automotive, amongst others.

WCI: Brief us about your specialized products along with their USPs.

NS: We have an expansive product range of over 100 SKUs of different products including galvanized and black steel wires, ribbed steel wires, welding electrodes, aluminum conductors and hot rolled steel products. Some of our wires and their vast applications include- wires for producing umbrella ribs, various types of springs, wires for earthing, staying, armoring of cables, and concrete reenforcement.

One of our newest products is Niznal™, a zinc aluminium alloy coated wire, that redefines strength, durability, and reliability. Niznal™ is a high-performance wire made from a special alloy of zinc and aluminum, which gives it superior corrosion resistance and durability compared to

With the growth of the steel industry, there's a huge push towards value addition and enhanced quality which matches internationally acceptable quality standards. This enables the manufacture of international quality steel wire and wire products which throws open a wide market nationally and internationally for us.

a traditional galvanized wire. It provides up to 6 times longer life (as compared to a standard GI wire) and therefore lower product lifecycle cost.

We have also launched ASTM class B and class C zinc coated wires. These provide a heavy coating of 850 gms, with maximum durability and enhanced corrosion protection. These heavy coated wires are designed for use in harsh and corrosive environmental conditions (eg: salty and moist atmosphere near seashores.) We stand out in the wire and cable industry as a holistic solutions provider. We don't just guarantee product quality; we guarantee extensive after-sales service, and a robust customer feedback collection system to further our customer-first commitment.

WCI: What have been the recent developments at your organization and what are your future growth plans?

NS: Some of our recent developments have been the production line that was designed, installed, and commissioned in house for our newest product NiznalTM. We are immensely proud of all the work put in by our technical team to successfully launch this product. Along with this we have also developed ASTM class B and class C zinc coated wires as well as highspeed wire drawing processes. Future product offerings include zinc wires, zinc aluminum wires, low relaxation prestressed concrete wires and patented steel wires. Along with this

we are constantly working in R&D on ways to make our production process more sustainable, galvanizing without the use of acids and flux, and ways to increase efficiency and thus capacity.

WCI: Please share your views on the Indian vis-a-vis the global stainless steel wire industry. What is the role of the Indian government in the growth of this sector?

NS: With the growth of the steel industry, there's a huge push towards value addition and enhanced quality which matches internationally acceptable quality standards. This enables the manufacture of international quality steel wire and wire products which throws open a wide market nationally and internationally for us. Such opportunities were so far not accessible to the steel wire and wire products industry due to paucity of raw materials of proper quality. Consequently, the growth in the steel wire and wire products industry will be greater than the growth in the steel industry itself. However, the downstream industry will have to meet the challenge of producing world class products and more importantly providing world class services along with them. The Indian government needs to encourage the production of value-added products by various measures. Primarily, the availability of world class raw materials at international FOB prices so that the downstream industry can compete in global markets.

May-Jun, 2023 www.wirecable.in 30

“

FEATURE

”

WCI: What are the major ongoing challenges in the Indian stainless steel wire industry?

NS: Some of the major ongoing challenges in the Indian steel wire industry are unsteady availability of steel wire rods of proper quality, less to no awareness of potential products and its potential uses in different infrastructure projects and agriculture, housing, horticulture, non-availability of state-of-the-art process technology to ensure quality of finished products and cost economics, as well as the fragmented nature of the industry, with a major chunk of the players are small and

scattered, making it difficult to come together.

WCI: How can these challenges of the industry be addressed? How is your company contributing towards this transition?

NS: The biggest challenge faced by the steel wire industry at large is the availability of steel wire rods, and for this to change primary producers need to increase production, moderate prices, and focus on quality production. Along with this the steel wire industry needs to modernize process technology and work on gathering the best skilled labor and machinery to

produce top quality products. This supplemented by ample marketing and awareness of products can help push the industry to greater heights. We, as a company, are working towards accessing raw material from the best in the country and we have made ourselves present on all public forums to make sure we are accessing the best quality of raw material. We also prioritize accessing top technology from the best in the world supplemented with in-house development. Building a strong technical team with the best training and knowledge has been crucial for enhancing capacity for us.

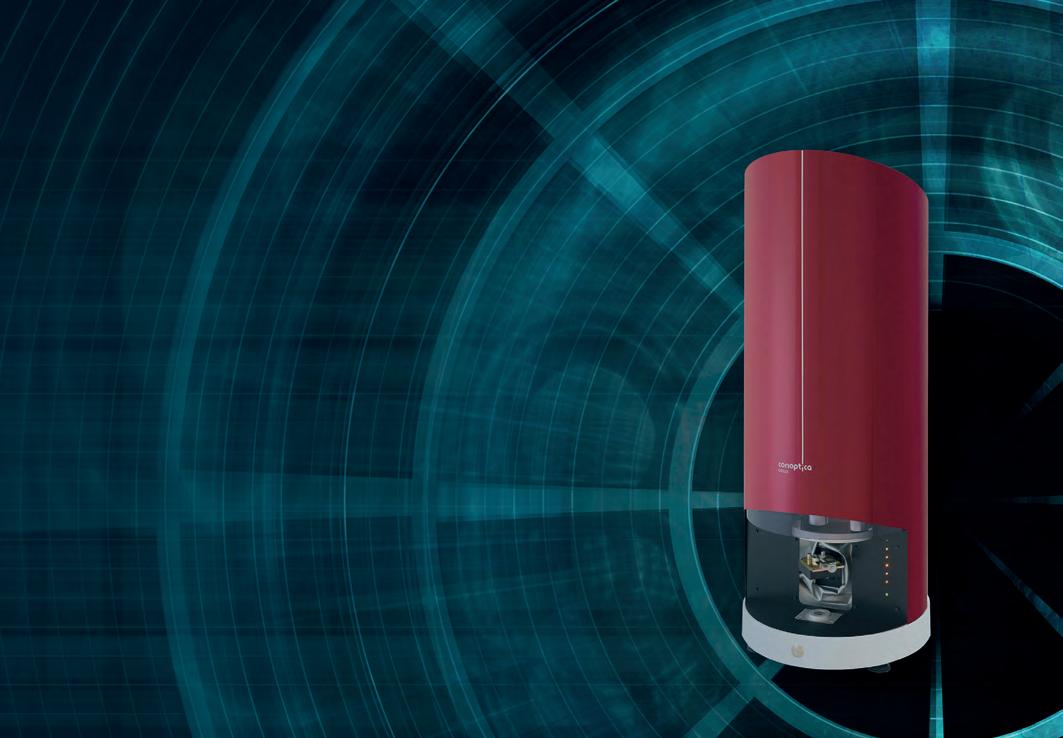

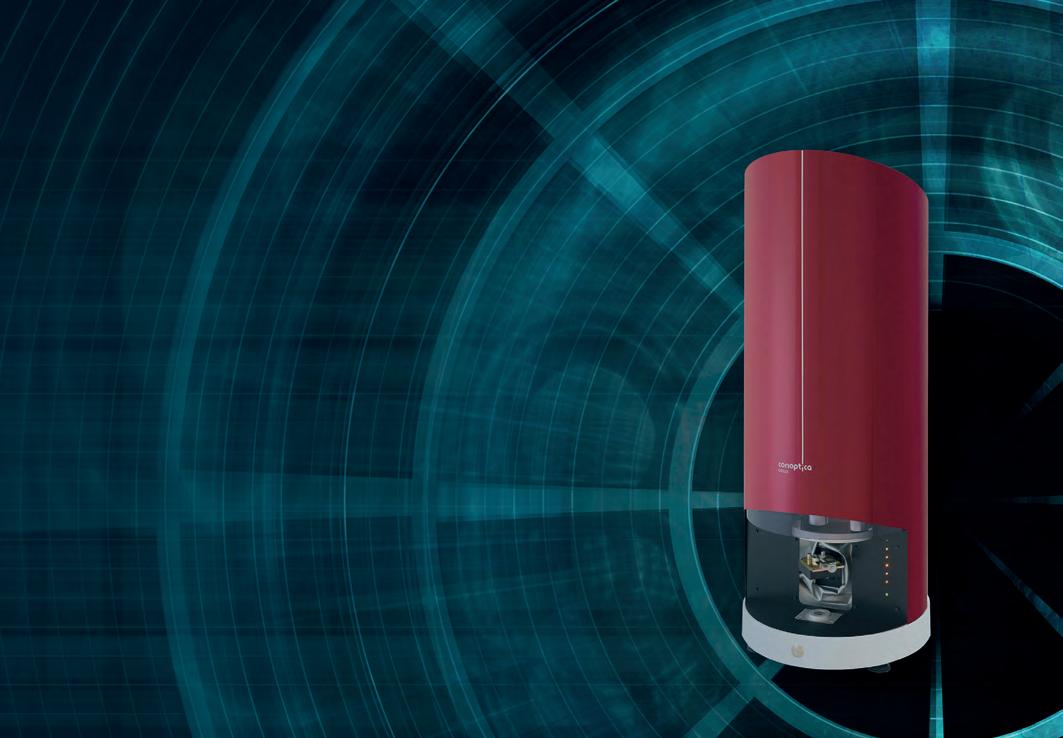

Sikora's LASER Series 2000/6000 Feature New Swiveling Measuring Head Concept

Sikora's Laser 2000 and 6000 series introduce next level precision with their various laser-based gauge heads providing highest reliability in production and quality end products. Their special feature is the swiveling measuring head concept, allowing the measuring head to be easily moved out of the working area.

May 10, 2023

easuring technology specialist Sikora's LASER MSeries 2000 and 6000 provide unparalleled precision, high availability and production-proven design. Both the series include various laser-based gauge heads that continuously measure contactless diameter and ovality of cables during extrusion. Users benefit from the highest reliability in production and quality end products. The compact and slim measuring heads of the LASER Series 2000/6000 are designed such that the optical components are located in protected areas so that process-related dust and dirt particles do not affect the measurement. In addition, the diffraction analysis detects unavoidable, gradually emerging contamination and reports it long before the measured values are affected by it. The smaller gauge heads of the LASER Series 2000 are equipped with a proven multi-slot protection. The larger gauge heads, which cover a product diameter

from 30 mm (1.2”), as well as all 3-axis gauge heads are designed open at the bottom so that neither water nor dirt can enter the gauge head.

A special feature is the swiveling measuring head concept, which allows the measuring head to be easily moved out of the working area. The measuring heads are free of wear parts, retain their precision throughout the entire operating life and require no calibration or maintenance.

May-Jun, 2023 www.wirecable.in FEATURE 32

NEWS

ABROL ENGINEERING COMPANY PVT. LTD. EST. 1958 Copper Conductors ISO : 9001:2015 | 14001 : 2015 ROHS & REACH COMPLIANT Bare & Tinned for all Cable Manufacturers Specialising in Electroplated Tinned Unilay & Concentric Bunched, Parallel & Single Wires State-of-the-art Plant In KAPURTHALA, PUNJAB, INDIA More than 6000 MT per annum capacity for Bare Copper More than 3000 MT per annum capacity for Electroplated Tinned Copper Supplying to Automotive, Solar, Defence, Railway, Special & Signalling Cable Manufacturers Mobile: +91 9888555846 | +91 9779090919 | Email: abelabrol@aecoindia.com | sales@aecoindia.com Website: www.aecoindia.com/copper-conductor ROD BREAK DOWN LINE 16 MULTI WIRE DRAWING LINE ELECTROPLATING TINNING LINE DOUBLE TWIST BUNCHERS D630 & D800

Mukand Improves Steel Products' Quality Through Silicon Metal Usage in EOF Tapping

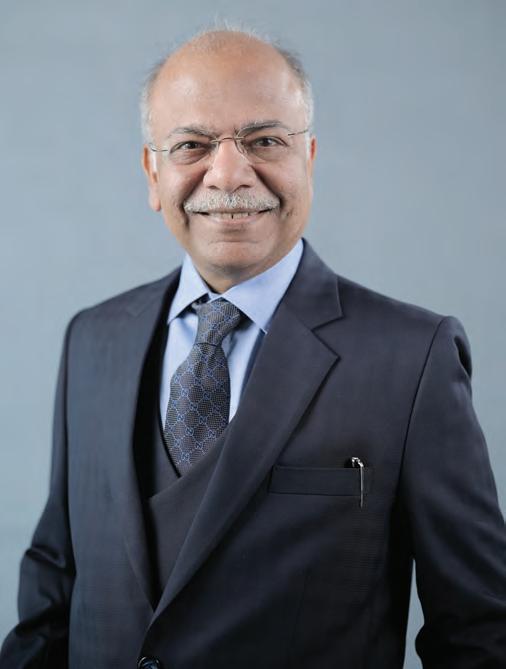

Registered in 1937, Mukand Limited started

operations as a 're-rolling mill' and a foundry. Today, the company is one of the leading manufacturers of steel and stainless steel long products and heavy engineering equipment. Mukand has manufacturing capabilities to produce more than 400 grades. Mukand recently used silicon metal during the tapping in EOF, which resulted in minimizing the levels of aluminum and titanium in the final steel product, and improvement in the quality of the company's steel products. In a recent conversation with Wire & Cable India, Mr. Shashibhushan Upadhyay, President, Mukand Limited, spoke on various topics like the company's journey, recent developments, the current scenario of the global steel wire industry, the challenges faced by the Indian steel wire industry and how to overcome them.

Wire & Cable India: Could you please take us through the business journey, milestones and achievements of your company?

Shashibhushan Upadhyay: Mukand Limited, a Bajaj group company, is a leading manufacturer of specialty steel long products and heavy machinery in India. Incorporated in the year 1937, the company produces alloy steel from its facility in Hospet, Karnataka and stainless steel from its facility in Thane, Maharashtra. The company is

also in the business of design, manufacture and commissioning of heavy machinery to a cross section of industries. It was in the year 1939, at the behest of Mahatma Gandhi, Shri Jamanalal Bajaj and Jeewanlal Motichand Shah took over the company from Shri Lala Mukund Lal who wanted to devote all his time to the freedom struggle. Coming to 2023, today Mukand is established as one of the leading manufacturers of steel and stainless steel long products and heavy engineering equip-

May-Jun, 2023 www.wirecable.in FEATURE 34

Mr. Shashibhushan Upadhyay, President, Mukand Limited

ment. Our steel and stainless steel products are used across various industries including automobile, the industrial machinery division, designs, manufactures, assembles and commissions heavy-duty cranes, bulk material handling equipment, process plant machinery and turnkey projects. These heavy cranes are primarily used in power industry, metals production, steel industry, automobile sector etc.

WCI: Brief us about your specialized products along with their USPs.

SU: Mukand Limited has manufacturing capabilities to produce more than 400 grades. The wires manufactured by us vary in the size range of 5mm to 30mm and can be supplied as cold finished, soft annealed and spheroidized annealed, pickled and hardened condition. Our modern and technologically upgraded wire rod mill is equipped with a walking hearth furnace and on-line measurement and automatic coil handling system. We have also deployed online automatic inspection for size and surface defects to ensure that nothing but the best is delivered to our customers. The state of the art manufacturing facility also boasts of loop control cooling for wire rods ensuring optimal properties suiting customers' processes.

WCI: What have been the recent developments at your organization and what are your future growth plans?

SU: Mukand Limited shall continue to focus on increasing efficiency, improving quality, and increasing its output in the year ahead. The company has invested in cutting-edge technology and modernized its production processes to ensure that its products are of the highest quality and are produced with minimal waste. In the last year, we developed several new grades in our steel business for various applications like prestressed wire, fastener Industry, seamless tube

This demand is driven by the growing need for lightweight materials across various sectors, including automotive and aerospace. Manufacturers are actively responding to this trend by investing in innovative approaches to produce steel wire products that offer exceptional strength, resilience, and corrosion resistance.

application, oil and gas industry, automotive crankshaft, railways and others.

All these new grades are specifically developed for demanding applications, in consultation with its customers. The company's team of experts worked closely with its customers to understand their needs and requirements, and the company is proud to have developed a material that offers a unique combination of strength and corrosion resistance and can withstand extreme pressure and extreme temperature conditions. Mukand has also implemented the usage of silicon metal during tapping in EOF. This innovation has resulted in minimizing the levels of aluminum and titanium in the final steel product, particularly for spring application grades. This has led to a significant improvement in the quality of our company's steel products, making them more suitable for various industrial applications.

WCI: Please share your views on the Indian vis a vis the global steel wire industry. What is the role of the Indian government in the growth of this sector?

SU: As a steel manufacturing company, we believe that the Indian steel wire industry holds significant potential in the global market. India has witnessed steady growth in this sector, driven by factors such as increasing infrastructure development, construction activity, transpor-

tation and mobility and industrialization. India has witnessed substantial growth in its steel wire production capacity in recent years. With the establishment of new manufacturing facilities and technological advancements, India has the ability to produce a wide range of steel wire products to meet domestic as well as international demand.

The global steel wire industry, on the other hand, has a diverse production capacity spread across various countries, with established players in developed and emerging economies. One of the significant trends influencing the global steel wire industry is the increasing demand for superiorquality and high-performance steel wire products. This demand is driven by the growing need for lightweight materials across various sectors, including automotive and aerospace. Manufacturers are actively responding to this trend by investing in innovative approaches to produce steel wire products that offer exceptional strength, resilience, and corrosion resistance. These advancements enable them to meet the rising demand for cutting-edge solutions that align with the evolving requirements of industries seeking lightweight yet durable materials.

The Indian government plays a crucial role in fostering the growth of the steel wire industry. Various initiatives and policies implemented by the government of India like the National Steel Policy, which seeks to boost the

May-Jun, 2023 www.wirecable.in 36

“

FEATURE

”

nation's steel production capacity to 300 million metric tons by 2030 and enhance the competitiveness of the industry. The government has also taken steps to promote ease of doing business, attract foreign investment, and encourage research and development in the steel sector.

Additionally, the government has undertaken infrastructure projects that boost demand for steel wire, such as the development of smart cities, metro rail systems, and rural electrification. These initiatives create a favorable environment for the growth of the steel wire industry and provide opportunities for domestic manufacturers to meet the increasing demand. In addition to this, the government's emphasis on Make in India and selfreliance has further bolstered the steel wire industry by promoting domestic manufacturing. This has led to a more robust and competitive domestic steel wire market.

In a nutshell, the steel wire industry is projected to grow, owing to its increased demand from various

industries from across the globe. There has been a significant rise in global buyers expressing interest in establishing enduring partnerships with Indian companies, which is an extremely positive development. However, it becomes imperative for the Indian steel wire industry to shift its focus towards a more qualitycentric approach in order to bring India to the forefront of the industry.

WCI: What are the major ongoing challenges in the Indian steel wire industry?

SU: With the growth of the economy and the increased focus on manufacturing, India is soon going to be the manufacturing hub of the world and the wire industry can not stay far behind when this growth happens. As a country, we might not be able to utilize the full capacity of wire manufacturing so we will have to find ways to improve our export share in this market. However, the road to this may not be as easy as it sounds. The industry will have to prepare to provide the best quality products at

competitive prices. The price of the steel wires largely gets influenced by the cost of the raw material which are mainly imported. Hence, in order to effectively compete with manufacturing hubs like China and other global players, the Indian steel wire industry may need to procure raw materials at a competitive price.

Also, it becomes crucial for the steel industry to focus on optimizing costs throughout the value chain, including raw material procurement, production processes, and supply chain management. This may involve exploring alternative sourcing options, negotiating favorable pricing contracts, improving operational efficiencies, and adopting costeffective technologies. Lastly, it becomes important for the government to create a conducive business environment. This can include measures such as reducing import duties on raw materials, streamlining regulatory processes, and providing incentives to promote cost competitiveness.

WCI: How can these challenges of the industry be addressed?

SU: Addressing these challenges requires collaborative efforts from industry stakeholders, government support, and a proactive approach to innovation, infrastructure development, skill enhancement, and market adaptation. By addressing the pricing challenges and improving cost efficiencies, the Indian steel wire industry can enhance its competitiveness on the global stage and effectively compete with manufacturing hubs while meeting the demands of international buyers. By continuously optimizing processes, by adopting advanced manufacturing technologies, and promoting innovation we can establish a competitive edge in the market.

May-Jun, 2023 www.wirecable.in FEATURE 38

ISO 9001-2015 Co.

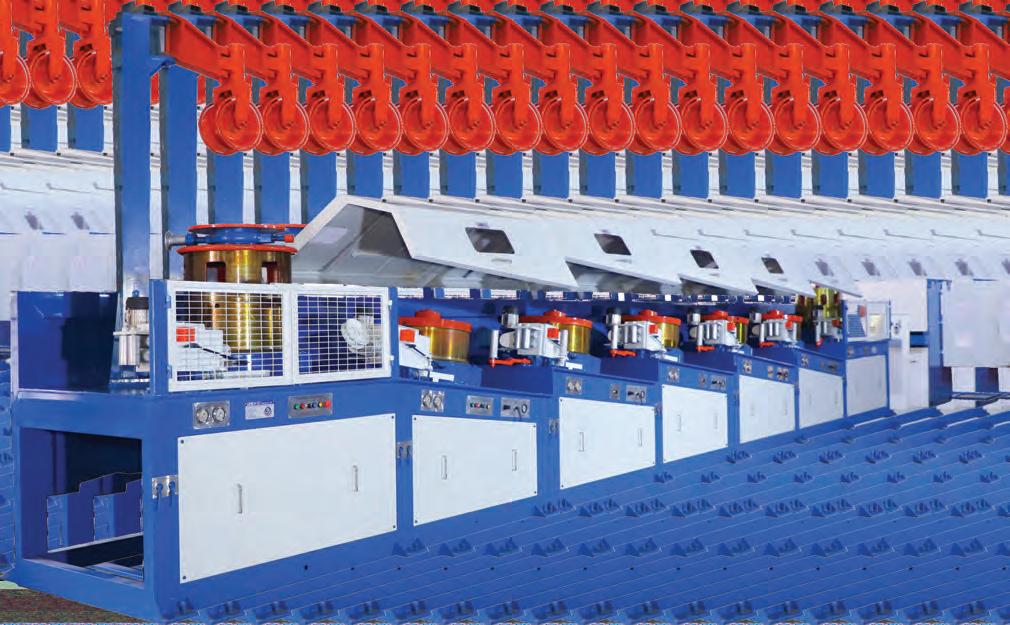

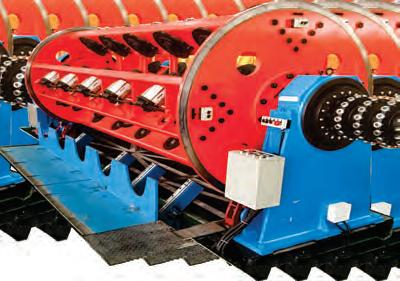

With its presence for over 40 years in supply of machinery to the wire and cable sector the India-based Sarvasv Group has primarily been known to infuse its machinery with innovations so as to take care of a client's minutest needs.

SARVASV with time has earned the reputation of being the most reliable supplier and partner for supply of machinery for Wire and Cable Manufacturing. It has manufacturing units that are equipped with the most sophisticated and modern machinery and equipments, which is complemented by highly qualified team of professionals who are always striving hard to improve on the already attained success. It has also been exporting its machines to various countries across the globe like Middle East, UAE, Bangladesh, Nepal, Iran, Africa, Europe andAustralia.

Our Product Range & Services

• High Speed Skip Stranders (AI, Cu, Steel and Insulated Cores)

• Skip Laying Machine for AB Cables

• Rigid Stranding Machine. (Steel, AI and Cu)

• Rigid Stranding Machines With Batch Loading (Steel, AI and Cu)

• Armouring Machine.

• Core laying Up Machine.

• Armouring Cum Laying Machine. (Multi Purpose)

• Special Planetary Stranders I Anti Torsion Machines

• Double Twist Bunching Machines

• Drum Twister for LT /HT Power Cables

• Extrusion and Sheathing Lines. (PVC and XLPE)

• Dual Automatic Spoolerfor Rod Break Down Machine (AI and Cu)

• Rewinding Lines, Take Up Units, Payoff Units and Catterpillar Units

• Taping Solution for PVC, Copper & Steel

• High Speed Tubular Stranding Machine Upto 36 Wires (AI, Cu and Steel Ropes)

Sarvasv Machinery and Equipments Pvt. Ltd.

Regd. & Corp. Office: B-200, Okhla Industrial Area, Phase-1, New Delhi-110020, INDIA

Factory: B-194B/195, RIICO Industrial Area, Kahrani, Bhiwadi Ext, Rajasthan-301019, INDIA

Phone: + 91-11-66401582 / 83 Mobile: + 91 9871163831

Email: info@sarvasv.com • varun@sarvasv.com

Website: www.sarvasv.com

Rigid Stranding Machine

Armouring Machine

Double Twist Buncher

Skip Stranding Machine

Drum Twister

Auto Loading Machine

Rigid Stranding Machine

Armouring Machine

Double Twist Buncher

Skip Stranding Machine

Drum Twister

Auto Loading Machine

Miki Wire Works Introduces “Green Route” for High Carbon Wire, Now an Industry Practice

Miki Wire Works Private Limited is a trusted

name in the steel wire industry, with a vision to adapt their processed product line to keep pace with new concepts and products. The company's manufacturing units are present in four locations, with their mother plant in Ranchi, Jharkhand, and the rest in Visakhapatnam, Bangalore and Nagpur, respectively. The plant has a current capacity of 1 lakh tonnes per year, out of which they utilize 85 percent. In a recent conversation with Wire & Cable India, Mr. Mahesh Poddar, who also happens to be former member of Parliament & SWMAI past president Chairman, Miki Wire Works Private Limited, shared the company's overview, manufacturing plants, sectors catered, the organization's recent developments, his views on the current state of the steel wire industry, the Indian government's support, challenges faced and how to overcome them.

Wire & Cable India: Could you please take us through the business journey, milestones and achievements of your company?

Mahesh Poddar: Miki Wire Works Private Limited, Ranchi has emerged as a multifaceted, well- diversified and a professionally managed company. In a span of over 40 years, the Miki Wire Group has grown many folds; our wings have now spread to all corners of India. With four manufacturing units spread across India, Miki Wire is a trusted name in the steel wire industry, owing to its superior quality and supply chain management. We now cater to the 20% of the railway concrete sleeper wire

requirement of the Indian Railways. Our continued investments in superior technology consistently push products to the highest quality standard. We have consistently been learning and reinvesting back into the company. We make sure to focus on relevant products, demanded byourconsumers.

WCI: Describe your infrastructure and manufacturing setup for the steel wire sector along with their manufacturing capabilities and total production capacity.

MP: Our production facilities are present in four locations, namely, Ranchi, Visakhapatnam, Bangalore

May-Jun, 2023 www.wirecable.in FEATURE 40

Mr. Mahesh Poddar, Former Member of Parliament; Past President of SWMAI and Chairman of Miki Wire Works Private Limited

and Nagpur. Most of these plants cater to their nearby areas, but our Ranchi plant, which is our mother plant, caters to consumers from Agarthala to Jammu. We are mainly catering to two sectors, one is concrete sleeper reinforcement for the Railways and the second is PCC reinforcement. We have recently started making automotive spring wire and LRPC strands. In terms of capacity, we currently have a capacity of 1 lakh tonnes per year, out of which we are achieving about 85 percent of the capacity. Our other wires are for rolling shutters springs, umbrella ribs, fibre wire, etc.

WCI: What have been the recent developments at your organization and what are your future growth plans?

MP: It was my personal ambition to produce steel wire through a green route. Recently, we have also started to produce wires with the dia of 12mm or 14mm, high carbon grades; drawing through the mechanical decaling route. We also introduced green induction heating for stress relieving of the wire, eliminating lead and Furnace oil as heat transfer medium to ensure consistent quality. Additionally, we are constantly looking out and experimenting with the products, which reduce power requirements and create high quality products. Fortunately, we have access to wire rods from most of the steel

producers in the country, allowing us to continue with our innovative ideas. We are planning to produce more spring wires and specialty wires. We have also decided to improve the efficiency of our existing facility, through cutting down the cost and modernizing the machines, so that we remain efficient and our profitability is protected though it is a “decades“ old MSME unit.

WCI: Please share your views on the Indian vis-a-vis the global steel wire industry. What is the role of the Indian government in the growth of this sector?

MP: Globally, the steel industry's growth naturally propels the growth of the steel wire industry. This refers to the fact that if the steel industry grows manifold, the steel wire industry will also be growing. India has a stable and ambitious government, with clear goals. The Indian government has set various targets following strict timelines, and one of the major targets set by the government is that India will become a developed nation by the time India completes 100 years of independence. In order to achieve this feat, every industry has to take major leaps, in terms of both volume and technically niche products. Talking specifically about the steel industry, globally economic development is also matched with the per capita demand

of steel of a particular country or economy. Today we can see that China is producing nearly half of the world's steel, whereas India's production is lagging behind. However, the government has now set a steel production goal for 300 million tons by 2030, which further involves subtargets like 55 million tons of special steel. In addition to this, the way our industry's growth is mostly driven by domestic demand, this seems like an achievable goal, despite global slowdowns. In order to achieve this goal, the government is providing major support through PLI schemes, promotional or supportive activities, opening up of mining activities, major amounts being spent on infrastructure, power sector reform and growth particularly through solar power availability in an ever-growing quantum. These are a few things which emphasize the seriousness of the growth of the steel industry. We have witnessed how China has taken a big leap in terms of production, from 2004 to 2014. I can visualize similar growth in India in the next few years.

WCI: What are the major ongoing challenges in the Indian steel wire industry?