Jan-Feb, 2023 Vol. 12 No. 02 1000/RR Kabel Envisions a Bright Future for Indian Wire & Cable Manufacturers Polycab: Organized Market and Product Awareness Necessary for Industrial Demand and Growth

Expanding Capacity, Product Portfolio & Markets The 5th International Exhibition & Conference for Wire & Cable Industry Oct., 2023 6 7 8 FRI SAT SUN Pragati Maidan New Delhi www.cablewirefair.com

Constantly Supporting the Indian Steel Wire Industry...44 12 20 16

HFCL:

SWMAI:

MANUFACTURING PROGRAMME

n Straight Line Wire Drawing Machines

n OTO Type Wire Drawing Machines

n Inverted Drawing Blocks (IVD)

n Vertical and Horizontal Bull Blocks

n Rod Break Down Machines

n Wet Wire Drawing Machines

n Furnace-Wire Annealing, Patenting, Stress Reliving

n Tubular / Skip Stranding Machine

n Vertical Drop Coilers (VDC)

n Dead Block Coilers (DBC)

n Wire Spooling Lines - Multi / Single Wires

n Wire Flattening Mills / Shaped Wire Mills

n TIG Wire Straightening Cutting Machines

n Welded Wire Mesh Lines

TURNKEY PROJECTS

n Plants For Galvanized Wires – Hot Dipped and Electro coated (High Speed Galvanizing Line with Nitrogen / Pad Wiping)

n Plants For M.S., H.B. & Binding Wires

n Plants For High Carbon And Alloy Steel Wires (40mm to 0.20mm)

n Plants For Stainless Steel Wires

n Plants For Cold Ribbed Wires/Deformed Bars

n Plants For Tire Bead Wire (Bronzing Lines)

n Plants For Copper Coating and CO2 MIG / TIG / Saw Welding Wire

with

Embossing

Panels Corporate Office & Works : 546, Bisrakh Road, Chappraula, Dist. Gautam Budh Nagar - 201 009 (INDIA) Cell: 0091-9810075965 Website: www.assomacmachines.com Correspondence Address : 26/2 South of G.T. Road Site No. 1, B.S. Road Indl. Area, Ghaziabad - 201 001 (INDIA) Ph.: +91 120 2866505, 506, 507 Fax: +91 120 2866508 E-mail: info@assomac.in Website: www.assomac.in Design by: info@tulip3pmedia.in

For Mesh Rolls Or Mesh

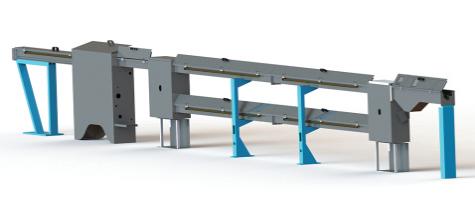

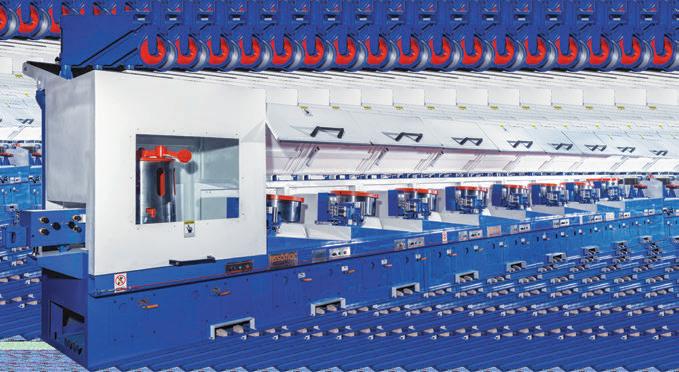

Intermediate Straight Line Wire Drawing Machine

Inverted Vertical Drawing Block

Taping Machines and Equipment

(An ISO 9001 : 2015 Company)

Office & Works-1: Plot No.744, Sector-69, IMT, Faridabad (NCR), Distt.: Faridabad, PIN-121004, State: Haryana (India) Landline: 0129-2977999, Mobile: +91- 9811010197, +91-8586969099, +91-8586969100

E-mail: info@cabletechindia.com, cabletechmachines@gmail.com, ctm97@rediffmail.com, Works-2: Plot No.143 & 150, NangIa - Gajipur Road, Gajipur, PO: Pali, Distt.: Faridabad, PIN-121004, State: Haryana (India) Phone: +91- 9811010197, +91-8586969099 www.cabletechindia.com

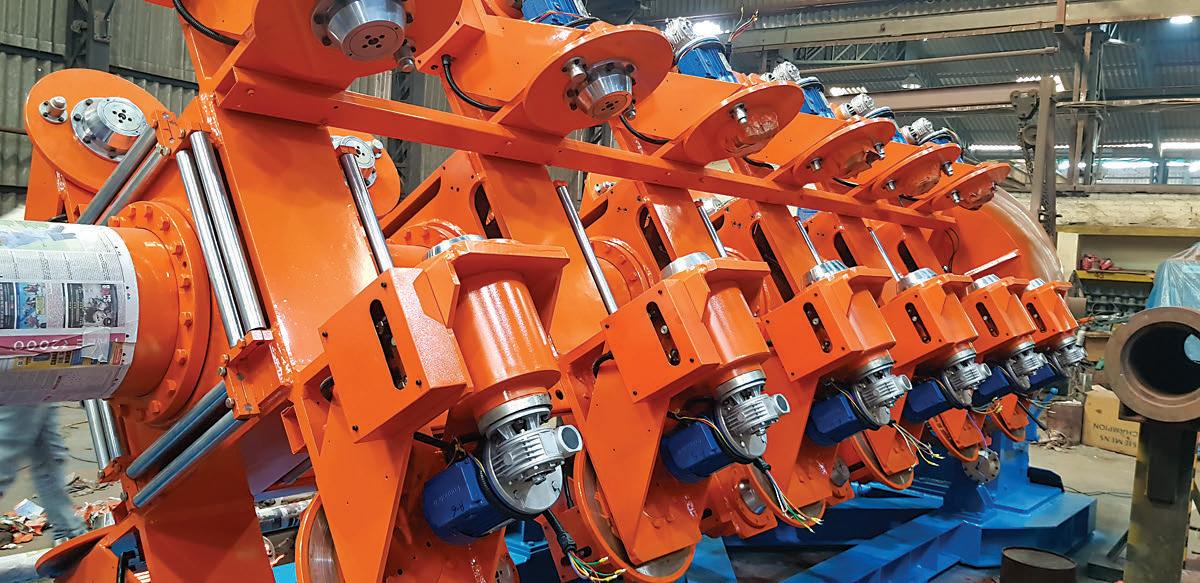

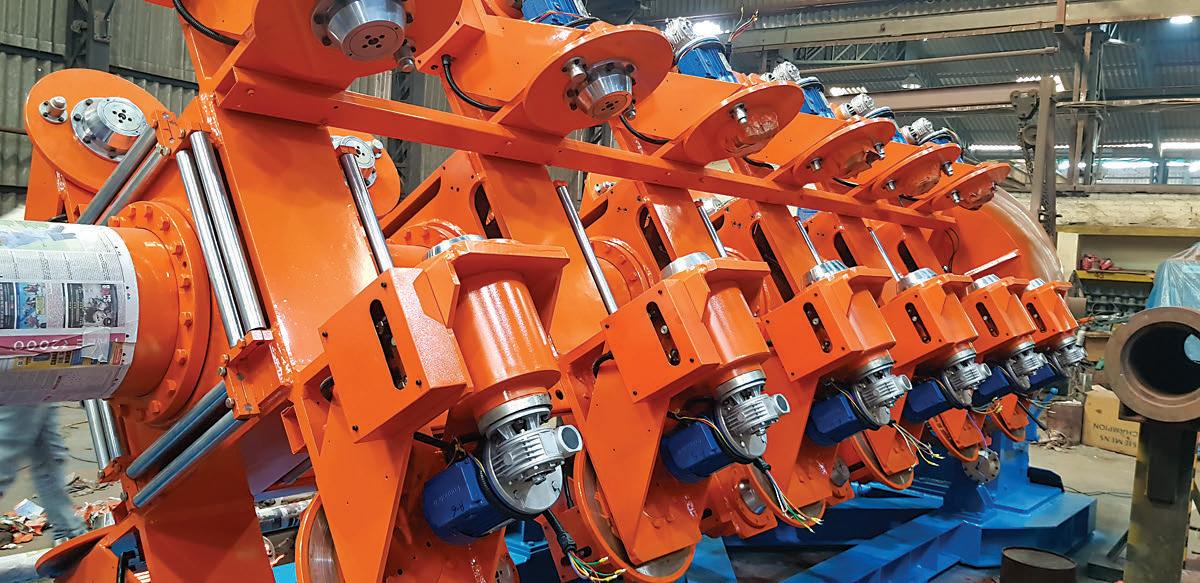

Rigid Stranding Machines

Heavy Duty Take up & Pay off stands

Rigid Armouring Machines

Rigid Armouring Machines

Rigid Armouring Machines

Drum Twister Machines

High Speed Semi Automatic Core Rewinding Line

Rigid Stranding Machines

Rigid Stranding Machines

Heavy Duty Take up & Pay off stands

Rigid Armouring Machines

Rigid Armouring Machines

Rigid Armouring Machines

Drum Twister Machines

High Speed Semi Automatic Core Rewinding Line

Rigid Stranding Machines

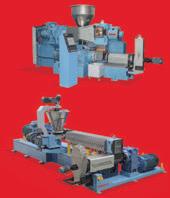

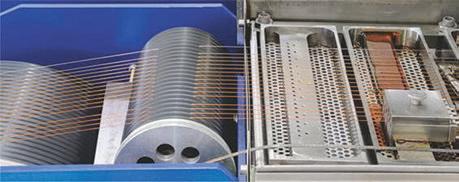

WORLD CLASS EXTRUSION SYSTEMS

Supermac – Global Solution Provider in Extrusion

and

Process Technology along with IIOT Applications

Supermac Industries established in the year 1974 is a leader in manufacturing of high end systems and process technology for the wire & cable in Power and telecom sector and related Industries. The ISO 9001 and CE certified company specializes in offering customized and tailor made solutions to fulfil specific needs of the variety of customers all across the globe. With a highly skilled design team, with the best of manufacturing and highly talented commissioning team, trained experts in cable processes and technology , we offer design to process expertise to bring in the best product for you. Supermac has expertise providing on line commissioning from remote. Post commissioning customer service support is provided from both on site as well as from remote. In our endeavor to conform to industry 4.0 norms, Supermac has taken strong strides forward in implementing several digital initiatives and can provide IIOT enabled extrusion lines supported by Siemens Mind sphere software. The company has three established and running units near New Delhi and we are adding another unit under our expansion program.

The state-of-the art facilities are equipped with international and indigenous machinery to carry out the process of manufacturing as per the customer's requirements.

Supermac has strategic partnership with German Company – M/S Scholz to cover CCV Lines, and Simpack USA for Coiling machines and Solutions.

Supermac specialises in following areas:

Ÿ State of the art CCV Line with Scholz Vulcanization system for Power Cables up to 132 KV XLPE and 33 KV for Rubber.

Ÿ Specialized Medical Tubing extrusion lines

Ÿ Proven Triple Extrusion Line for SIOPLAS (XLPE) Cables

Ÿ High speed Insulation Line and Sheathing Line for House Wiring & Control Cables and medical equipment sector.

Ÿ High output and best in class Insulation Line and Sheathing Line for Power Cables and Optical Fiber Cables..

Ÿ HCV Insulation and Sheathing Line

Ÿ Hybrid and Composite CCV Lines for both XLPE and Rubber.

Ÿ Rubber Extruders for Insulation and sheathing Materials.

Ÿ Silicone Extrusion Lines with Infrared Vulcanization System.

Ÿ Cat 5.6 and 7 Lines

Ÿ FTTH drop cable lines

Ÿ Fluoropolymer – FEP, PTFE/ETFE Lines

Ÿ Loose tube/Secondary coating lines for fiber optics

Ÿ Extruders for variety of applications – up to 175 mm

Ÿ Cross-Head Single/Dual/Triple

Ÿ Haul-Off Caterpillar

Ÿ Capstan

Ÿ Take-up and pay-off of all types and sizes and as per requirement above 4.5 meters and 40 MT.

OFFICE : A-28 & 29, NARAINA Industrial Area, Phase-1, New Delhi-110028, INDIA

Ph.: +91-11-45574317

E-mail: office@supermacindia.com

UNIT-I : Plot No–2, Sector-6, IMT Manesar, Gurgaon Haryana, INDIA

Ph.: +91-0124-4690500 | Fax: +91-0124-4690501

E-mail: jasvinder@supermacindia.com, vkohli@supermacindia.com

UNIT-II : Plot No. 18-19, Sector-2A, IMT Manesar, Gurgaon, Haryana, INDIA

www.supermacindia.com

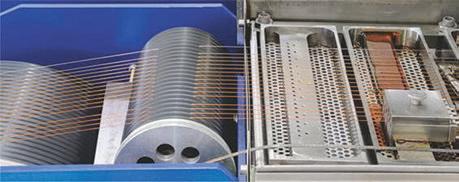

Supermac CCV Line

High speed building wire line

IIOT Screen

The vision for this note was clear; I wanted to talk one-onone with the readers about all that Wire & Cable India has to offer. I wanted to share our efforts in bringing forward this edition, the concurrent events of the industry, and a small, profound piece of personal opinion. There are various ways to achieve our targets, and mine was to ensure a connection with my readers.

TheSpinning !GoldCoin

Wire & Cable India's Jan-Feb 2023 edition brings forth a spinning gold coin; the gold coin being the wires and cables industry, and the spinning motion as the hopeful and bright future, which is constantly fueled by the plethora of opportunities.

Envisioning the Indian wires and cables industry in both global and domestic contexts presents a wide scope of exploration, advancement, and growth. In fact, globalization makes it easier for the industry to gain a powerful presence, especially as it coincides with our domestic demand growth. The Indian government's efforts in empowering the industry were recently re-confirmed at the Elecrama 2023 platform. The five-day exhibition, held in Greater Noida, served as the Mecca of the global electrical and power industry; hence, serving as a relevant platform to advent the future of the Indian electrical and power industry.

But, what exactly does the Indian electrical and power industry's future look like?

In light of the Indian government's humongous targets for the industry, like power capacity expansion of 400 GW by 2030 (which is to be doubled to 800 GW by 2047), 500 GW of renewable capacity, integration of IoT and AI to establish a nationwide unified Smart Grid, the future can only be described as vast and bright. Power once generated has to be transmitted and distributed till the end user, which is generating huge demand for wires & cables. It is the impact of these Government targets that the majority of companies in India are planning huge capacity expansion projects over their existing operations. These inferences find affirmation in the statements of the industry's top leaders of major companies, which have been covered in this edition. However every coin has two sides, hence challenges are inevitable. Despite various challenges, India's profitable placement proposes wider opportunities for the domestic industry. India is the most preferred region for the application of the China Plus One strategy in post Covid-19 period, which has opened up newer avenues and enhanced export channels for Indian companies. Moreover, Russia-Ukraine war has led India to gain a strong diplomatic and economic position. Closer home, nearly 50 percent of wires and cables market is unorganized, allowing the qualitative expansion scope for the industry and elimenating price-based competition.

Hence, this edition compiles all the surrounding events concurrently through opinion articles, interviews of top leaders, events coverage, and news covering various capacity expansion plans, new projects, sales and acquisitions, etc.

Penning the final lines of this note, I wish to urge the readers to take some action –Actions that ensure that challenges and opportunities are addressed with effective and lasting solutions, like quality products, consumer awareness, healthy competition, and take initiative for Make in India for the world. In this manner WCI can achieve what it set out to do, support the industry to accomplish the best of its potential.

And finally, I leave you to explore in depth the fruits of the WCI team's efforts.

Priyank Jain, CEO Tulip 3P Media Private Limited

SPEAKin

OUTLOOK

RR Kabel: Envisions a Bright Future for Indian Wire & Cable Manufacturers

Polycab: Organized Market and Product Awareness Necessary for Industrial Demand and Growth

HFCL: Expanding Capacity, Product Portfolio & Markets

Diamond Cables: Has Restarted Operations in Vadodara, Gujarat Unit, Phase 1 Targets the Northern and Western Region

Thermo

Pioneering Speciality Cables, Competing with Global Leaders

SWMAI: Constantly Supporting the Indian Steel Wire Industry

CONTENTS Jan- Feb, 2023, Wire Cable India 12 20 26 32 38

Cables:

16

44

Laser Power and Infra Aims for 100 Percent Capacity Expansion

00 GK Winding Aims to Localize Rectangular Wires Manufacturing for Indian EV Market 48 JSK Industries: Ventures into Cyber Security & IT Segments through Technological Collaborations 56 Special Cables: Targets Growth with Product Diversification and Market Expansion 64 West Coast Optilinks to Setup Optical Fibre and Optical Fibre Cable Plant in Hyderabad 60 Pinank Wires: Future Ready Winding Solutions 68 Zenium Cables: To Develop Kynar Insulated and Higher Voltage Cables 76 KENTER's Success Formula Sustainable and Quality Products at Economical Prices 72 Vidya Wires: One-Stop Shop for Copper Conductors Aims 25,000 TPA Production by 2025 52 • Wire & Cable • Telecom & OFC • Transmission & Distribution 90 101 105

RR Kabel Envisions a Bright Future for Indian Wire & Cable Manufacturers

RR Kabel, part of RR Global, a USD 1.25 billion

conglomerate, is a wire manufacturing company spread across multiple business verticals. The company offers the widest range of premium wires and cables for various residential, commercial, industrial and infrastructural purposes.One of the leading companies in the electrical and copper industry, RR Kabel believes that the future of the industry lies in innovation and effective R&D. In a recent conversation with Wire & Cable India, Mr. Shreegopal Kabra, Managing Director and Group President, RR Group shared his views on fire safety and need for various legislations with regard to selection of right wires & cables. He also highlighted the government initiatives uplifting the electrical sector along with challenges and changes required for the industry's growth.

Wire & Cable India: Could you tell us how the electrical industry is growing and how government initiatives are uplifting the industry?

Shreegopal Kabra: There are many market segments which have started growing in India, one of these being the real estate market. The real estate market continues to grow and as a result electrical consumption is everincreasing. In the electrical market, product quality is extremely important. Even the Indian government is contributing a lot to the real estate market, with their “Housing for all” scheme. Moreover, there is a general environment in the country where people wish to own houses, and in order to facilitate this the government has also created the “Power for all” programme. India has around 7 lakh villages and even today 30 percent of our population lives in places where they cannot get proper food, clothing and housing. Gradually, electricity will reach these people and even people with lower pay grades

Jan-Feb, 2023 www.wirecable.in INTERVIEW 12

Mr. Shreegopal Kabra, Managing Director and Group President, RR Group

will start saving up and bring electrical appliances into their houses. Through an ongoing government scheme, the government provides 90 percent cost subsidy for solar submersible pumps for farmers. Through these pumps, the farmer gets a supply of both electricity and water. This is a great initiative which will help farming to grow in the future and help our country in retaining the title of an agricultural country. Furthermore, there is a lot of ongoing and upcoming growth in our country. The government is building medical colleges in every district, the Ayushman Bharat Yojana, providing people with homes, building 3 crore toilets all over India, and a general development in the country which has helped in the growth of the Indian economy. And any kind of growth in the country means growth for the electrical sector and major consumption of the electrical sector is for wires and cables.

WCI: What are the major challenges being faced by the Indian electrical industry?

SK: We believe that India's goal for a USD 3 trillion economy will be achieved before estimated time seeing our current economic and political conditions. However, along with growth we must simultaneously focus on quality and safety in the electrical sector. The quality of electrical products is decreasing day by day, whether it be due to preference given to L1 suppliers or just a general lack of knowledge of the industry. Firstly, there are multiple high rise buildings being built in India, but our fire brigades have no infrastructure in place to extinguish fires above the 20th floor.This is a big concern, especially in cities like Mumbai with buildings having over 70-80 floors. PVC and LS0H wires are easily flammable, smoke producing wires. Still such wires are being used in prestigious projects in India like Central Vista. The class 2 conductor flexible wire in itself is a technically wrong product. Initially, these house wires were reserved for small-scale industries but later these wires were turned into flexible wires and manufactured in 90m packaging, and that trend is still being followed in the industry. These multi strand wires are not used as house wires in any country except India. FRLS wire, which is manufactured in India, is another similar exception. Moreover, most electricians lack the proper knowledge, tools and skill required for efficient functioning of wiring. Today, the main concern in most of the house fires is the presence of flexible wires and class 5 conductors. The available product LS0H wires have a heat resistance capacity of 90 degrees, but they are also sold with capacities of 70 degrees, which we call “Halogen free duplicate”. Another challenge is regarding fire survival cables. The National Building Code has mandated use of

fire survival cable in common facilities. However, BIS has given aluminum wires the hallmark for fire survival cables. When there's a fire, the ambient temperature goes around 850 to 950 degrees, while aluminum melts at 650 degrees, making the cable useless at times of emergency. Furthermore, there is a large possibility that if all power cables in India are checked by the government, at least 70 percent of power cables will be found below the BIS standard.

WCI: What immediate changes should be made to facilitate growth in the electrical sector?

SK: Firstly, fire survival cables should be used in common facilities, made with good insulation. It is important that FRLS cable and class 5 conductor wires should be banned immediately. Class 2 wires should be removed in a phased manner; they should be used till the 7-strand wire which is actually safe is approved by BIS, and then banned. We request consultants to not focus on reducing costs but help people in learning about the industry and making the right choices, as well as request contractors to act responsibly. We also request the government to increase RERA's current 5 years guarantee for electrical, plumbing and firefighting to 10 years. This is because if plumbing is not proper then the building life is reduced, if electrical fittings are bad it can cause fires, and bad firefighting can cause issues. Government should evolve the testing facility in India by giving more powers to BIS, even if it increases the manufacturing cost. The government has also been working a lot on green energy. However, all solar cables being used in projects should be checked. The cables being used in solar projects have a life of 25-30 years. Currently they might be functioning, but if they are not working in 5 years it will give reduced output.

If all these issues gradually get solved, the electrical sector can become a big growth sector for India. There is consistent growth in export of the wire and cable sector in India. Indian manufacturers in the electrical industry have the capability to become global suppliers in the electrical sector, especially in wires and cables.

WCI: Please tell us about your participation in Elecrama 2023.

SK: We participate in Elecrama because we get to meet many new people from the electrical industry, as well as get an opportunity to meet with old acquaintances which helps in relationship building in the industry. Elecrama is the only platform where we showcase our products and future launches. We feel that Elecrama has great scope for growth and hope that in the future IEEMA broadens its focus towards new and growing markets, along with the electrical board.

Jan-Feb, 2023 www.wirecable.in INTERVIEW 14

ABROL ENGINEERING COMPANY PVT. LTD. EST. 1958 Copper Conductors ISO : 9001:2015 | 14001 : 2015 ROHS & REACH COMPLIANT Bare & Tinned for all Cable Manufacturers Specialising in Electroplated Tinned Unilay & Concentric Bunched, Parallel & Single Wires State-of-the-art Plant In KAPURTHALA, PUNJAB, INDIA More than 6000 MT per annum capacity for Bare Copper More than 3000 MT per annum capacity for Electroplated Tinned Copper Supplying to Automotive, Solar, Defence, Railway, Special & Signalling Cable Manufacturers Mobile: +91 9888555846 | +91 9779090919 | Email: abelabrol@aecoindia.com | sales@aecoindia.com Website: www.aecoindia.com/copper-conductor ROD BREAK DOWN LINE 16 MULTI WIRE DRAWING LINE ELECTROPLATING TINNING LINE DOUBLE TWIST BUNCHERS D630 & D800

Polycab: Organized Market and Product Awareness Necessary for Industrial Demand and Growth

olycab India Limited holds a 22-24 percent share of P India's organized electrical market. The company's observation reflects market conditions, its solutions represent market needs, and its vision is in line with the industry's future. As Mr. Bhushan Sawhney, Executive President & Chief Business Officer (Cables) of Polycab India Limited, expresses his views to Wire & Cable India about the present and future of the industry, it is important to reflect on his words, especially as he mentions fire safety and having an organized market structure as the biggest concerns of the current times. He puts it aptly; the industry needs to improvise its products and educate its customers if it wants to fruitfully tap the growth potential and opportunities of the industry.

Wire & Cable India: Please elaborate on your views on Elecrama 2023. What is your theme of participation this year?

Bhushan Sawhney: As India's largest manufacturer of wires and cables, our advanced and innovative product portfolio is ever-expanding and Elecrama gives us the right platform to showcase this to our current and potential customers. Therefore, it was a great platform for us to establish new business prospects and relationships.

This time, we demonstrated our products from an industry viewpoint, and we've chosen eight distinct industries to do so. In addition to this, our entire range of smart automation solutions (Hohm), fans, lights and luminaries, switches, switchgears, pumps, and solar products was showcased during the event.

Polycab has been consistently participating in Elecrama and each time it has provided us with a unique experience.

WCI: How is fire safety a concerning issue for the wires and cables industry?

Jan-Feb, 2023 www.wirecable.in INTERVIEW 16

Mr. Bhushan Sawhney, Executive President & Chief Business Officer (Cables) of Polycab India Limited

BS: Fire safety is a huge concern for the wires and cables industry, there is an average of 30 deaths per day according to the National Crime Records Bureau Report 2019. Fire accidents are the second most common cause of human casualties after road accidents. However, the important thing is the underlying fact that it is not the fire but the harmful fumes that kill people.

Smoke density poses a significant threat to individuals trapped in a burning building, as it can cause sightlessness and choking, preventing escape. Poor-quality electrical components, such as impure copper, and inferior PVC, can produce toxic smoke during a fire, exacerbating low visibility and increasing the risk of injury.

Unfortunately, many people remain unaware of the critical role that electrical products play in fire safety. While the general public tends to prioritize high-end finishes like branded tiles and marble flooring, they often neglect to consider the quality and features of electrical wiring and other components.

WCI: What are the other challenges that the wires and cables industry faces today?

BS: The biggest challenge for the industry is to convert the unorganized market to an organized one. Approximately 60 percent of the market is unorganized and unbranded products are being sold, which are made

of impure copper and inferior quality PVC. Wires and cables are like veins in our bodies, that is one might do all kinds of physical grooming but if their nervous system is not well catered to then their immunity and overall health suffer.

For instance, in Europe, anything below FRLS wires is not used in buildings, while people in India are not aware of what is FR, FRLS, ZHFR, etc. Wires are the backbone of the entire electrical system of any house, however, for consumers, it is a low involvement category. Hence, educating consumers is a priority.

WCI: How do you propose to resolve the industrial challenges and what is Polycab's contribution in this area?

BS: General awareness and quality products are the only solutions as we move forward and Polycab is dedicated to both. There is a general shift in the overall mentality of people across the nation.

As a manufacturer, we are dedicated to providing quality products and our R&D team is continuously working towards innovation. We are also dedicated to educating our customers. We engage in both above-the-line (ATL) and below-the-line (BTL) campaigns to achieve the same. We do everything that helps us stay true to our mission of electrifying India with safety.

WCI:Couldyouelaborateonyourrecentdevelopments?

BS: The wires and cables industry is continuously working towards improving the safety and reliability of power transmission and distribution. Some recent innovations include high-temperature cables, smart cables with built-in sensors and communication capabilities, low-smoke zero halogens (LSZH) cables, fiber-optic cables, and crosslinked polyethylene (XLPE) cables. These advancements are designed to enhance the durability and performance of cables, reduce the risk of fire, and increase the efficiency of the power grid. These innovations help ensure a safe and reliable power supply to consumers.

WCI: Could you elaborate on the current trends of the Indian wires and cables industry and how you see it progressing in the coming years?

BS: The recent Union Budget of India has measures to support the growth of the transmission and distribution (T&D) sector, including the wires and cable industry. The budget has increased allocation for power and renewable energy, emphasized rural electrification, provided tax incentives for MSMEs, and emphasized infrastructure development. These measures are expected to drive demand for wires and cables and support the growth and development of the industry. Various projects are launched to support and make the most of this consumption, such as 5G, solar plants, renewable capacities, marine, and defense, etc.

Jan-Feb, 2023 www.wirecable.in INTERVIEW 18

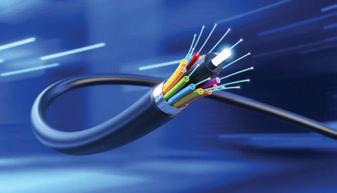

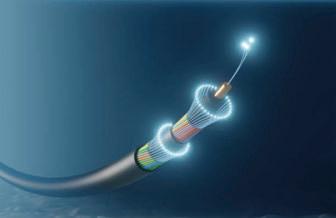

HFCL: Expanding Capacity, Product Portfolio & Markets

Telecom industry is one of

the direct beneficiaries of the ongoing era of technological advancement. Mr. Harsh Pagay, Executive President of Optical Fiber & Optical Fiber Cable, HFCL Limited, shares with Wire & Cable India the current state of Indian and global telecom industry, demand trends, and upcoming opportunities. He also divulged information about HFCL's capex investments for increasing manufacturing capacity of OFC and fiber cables, to 35.08 mn fkm and 22 mn fkm per annum respectively. The company is also targeting to double its exports to INR 750 crore by FY23.

Wire & Cable India (WCI): Please take us through the new/innovative product launches at your company.

Harsh Pagay (HP): HFCL has emerged as a technology-driven enterprise that has placed a significant emphasis on developing innovative and futuristic technology products. As a market leader in Optical Fiber Cables (OFC) manufacturing in India, we are developing various types of next-generation OFC for different applications and installations like

underground cables, aerial cables, micro cables, mini cables, high fiber count ribbon cables, FTTH cables, micro module cables, blown fibers, etc. We offer multiple variants of lowdiameter micro cables with higher fiber densities, in optimum size, and customized according to the consumer's needs.

With the advent of 5G, there is an uptick in demand for greater bandwidth, lower latency, and the quantum of data generation and transmis-

20 Jan-Feb, 2023 www.wirecable.in INTERVIEW

Mr. Harsh Pagay, Executive President of Optical Fiber & Optical Fiber Cable, HFCL Limited

Biggest cable compound expert in Asia. Cable compound Capacity of 600,000MT per year

4 Plants all over China

Headquarter Plant (Hangzhou City)

Huzhou Plant (East China)

Sichua Plant (West China)

Qingyuan Plant (South China) COMPANY

Our Products

LSZH (Green Low Smoke Halogen Free Compounds Applied for Solar, EV, Nuclear, LV, HV cable)

XLPE

FR-XLPE

Semi-con

PVC CMR / CMP

TPE/TPU/TPV

ADDRESS: Plot A-14, 7th Floor Eco Towers, Sector 125, Noida, UP, 201301, INDIA

ADDRESS: 276, Nilgiri Apartment, Alaknanda, New Delhi - 110019, INDIA

REGISTERED

Goyal

CONTACT PERSON: Naval Singhal (navalsinghal@gmail.com) Mobile: +31-619253386 Abhinav

(abhinav@navank.onmicrosoft.com) Mobile: +91-8860364748

Pioneer in Bringing to Cable Industry... Add: No.555 Heting Street, Lin’an Economic Developing Zone, Hangzhou, Zhejiang, China (311305) Franks Shaw (franks@wanmaco.com) | Mobile: +86 13819125233 | Website: www.wanma-mm.com/en

Indian Partner: Green Technology

sion, resulting in an unprecedented rise of data centers in India and abroad, and hence contributing in the rise of data center cables. To meet the growing demand, HFCL offers compact design high-fiber-count cable products that are easy for installations/terminations and consume less duct space. The currently available optic fiber counts in the industry are as high as 6,912, and we are now trying to develop an entire range of these products with unique propositions for packaging them with our connectivity solutions. Our new cable designs are a technological breakthrough that allows packing more fiber into a cable and lowering the diameter of cables without compromising the performance of cables in the field. Many of our microcable designs are unique and the first of their kind in terms of cable dimensions and bending performance, and they are duly tested and qualified for the cable blowing test by international agencies.

India is ahead of the US and Europe in the rollout of 5G infrastructure. In fact, leading Indian telecom operators like Jio and Bharti Airtel have been able to roll out their 5G services in 225 and 65 cities, respectively, by the end of January 2023. As the market for products that support 5G networks is growing rapidly, we took this opportune time and introduced various next-generation products and solutions, including the world's First Open Source Wi-Fi 7 access points, 5G 8T8R macro radio units, our 5G labas-a-service, and 5G outdoor small cell product development. We are confident that our world-class innovations will further aid and accelerate 5G adoption and network upgrades, both in India and globally.

WCI: Has there been any recent development in terms of capacity expansion, product development, or technological innovations?

HP: There has been multi-fold growth in the demand for fiberization in India, led by the launch of 5G,

penetration of FTTH in the country, and the ongoing BharatNet and NHAI initiatives launched by the government. As per a report by CRISIL, 5G technology dictates fiberization levels of over 70 percent, versus 25–30 percent levels at present. CRISIL estimates that if each player were to reach this level individually, Indian telcos may need investments of up to INR 1,00,000 crore only in laying fiber networks over the next 2-3 years. Further, according to Fortune Business Insights, the global fiber optics market size is expected to reach USD 9.73 billion by 2027, exhibiting a CAGR of 10.3 percent during the forecast period.

As one of the largest suppliers of OFC in India, we are expanding our consolidated OFC manufacturing capacities, our existing capacity is 25.08 mn fkm and its going to increase further by 10mn fkm and we are expanding our fiber manufacturing capacities from 10 mn fkm to 22 mn fkm per annum. This huge capex investment will be focused on nextgeneration products, and this expansion will help us further develop innovative network solutions. As mentioned earlier, we are also manufacturing new-age high-fiber count cables to meet the growing demand from data centers. Highfiber-count cables allow extremely high fiber counts in small cable sizes, thus making them extremely suitable for dense applications in data centers and metro areas. HFCL has further optimized its costs by investing in backward integration, which has led to our customers seeing us as their high-end partners.

Further, HFCL, via its subsidiary, HTL Limited, is also developing state-ofthe-art futuristic optical fiber cables. Our Optical Fiber Capacity Expansion, coupled with the vast opportunity landscape, will enable us to strengthen the supply chain, improve our profit margins, and further help us to tap more customers in the domestic and global markets.

WCI: How do you foster innovation and R&D at your company?

HP: Strong investment in R&D and developing robust innovative products has always been the core value of our company. To meet the accelerated rate of fiberization and growing demand for 5G products and innovations, we have heavily invested in the production of next-gen equipment, backward integration, and capacity expansion in the optical fiber cable business. This will enable us to tap into the growing opportunity spectrum across technology, including 5G and OFC. We have a dedicated team of highly qualified engineers with rich experience in developing next generation telecommunication equipment and optical fiber cable. This team works in close coordination with our customers to understand their needs and develop new, innovative products for them. We have cable designers and material experts on our team who work continuously to develop a better offering for our customers.

As a technology-driven company, HFCL owns in-house R&D centers in Bengaluru and Gurgaon. Further, we have also engaged a R&D team in partnership with leading engineering companies like Wipro, Capgemini, Qualcomm, Metanoia, NXP, BigCat Wireless, VVDN and others. These partnerships will help us develop the latest generation yet indigenous telecom products and multicore cables under our intellectual property rights (IPR). We are also designing and developing multiple ranges of optic fiber and optic fiber cable to meet the networking needs of our

22 Jan-Feb, 2023 www.wirecable.in INTERVIEW

“

”

Indian telcos may need investments of up to ~Rs 1 lakh crore only in laying fiber networks over the next 2-3 years.

Connecting Users in a New Era FRP ROD (Composite): Thermal Resin for FRP Rod Glass Rovings Glass Capillaries UV Technology: UV Curing systems (Arc and Microwave ) Spares for all kind UV Curing Systems UV Radiometer Optical Fiber and Cable Division: Optical Fiber and Cable manufacturing Machines Single Mode and Multimode Fiber Speciality Fiber Optical Fiber Primary & Secondary Coating, UV Coloring ink and Ribbon Matrix ECCS tape PBT Compound Cross heads FRP Rod Arunav Technology & Systems Pvt. Ltd. S-16, Malik Plaza, IInd Floor, Plot-5, Sec-4, Dwarka, New Delhi-110078 Cell: +91-9818061025 | Phone: +91-11-28080670 | Fax: +91-11-43019966 Email: navin@arunavindia.in | Mr.Navin Agarwal Dive into Arunav Now: www.arunavindia.in

customers. Our in-house R&D capabilities have further enabled us to offer field-proven optic fiber cables and telecom equipment and solutions at competitive price points to our customers both in India and globally.

WCI: Please outline your goal for 2023 as regards increasing your reach in the domestic and global markets.

HP: FY 2024 will see us continue our strategy of reaching New Products, New Geographies, and New Customers. As part of this, we are focused on the development and production of newage products and solutions and expanding our global footprint. The governments of leading economies, including the US, UK, and Europe, are investing heavily in building robust fiber connectivity for the deployment of 5G networks and fiber-to-the-home networks. Currently, we have a strong

footprint in 30+ countries, serving more than 80 clients globally with optical fiber cables and telecom products. While we already have employees in different countries to look after various overseas markets, we are further appointing distributors and agents to deepen our customer reach. We have also been able to maintain a strong order book of over INR 7,000 crores as of Q3 FY23, and our exports grew nearly 140 percent YoY during Q3. We have also bagged various significant orders from domestic and overseas industry players for the supply of optical fiber cables. Further, HFCL is also one of the providers of Wi-Fi 6 APs in the WiFi4EU project in the city of Dublin, which will help offer free wireless internet access.

On the back of these tremendous global opportunities, we are positive about growing at a rate of 15-20 percent every year. We are also optimistic about doubling our exports to INR 750 crore by the end of FY23. We aim to increase our revenue share from our optical fiber cable business in the upcoming years, given the opportune landscape. Leading global economies, including the US, UK, Europe, Germany, and France, are

some of the key focus markets for us this year. With our focus on developing and designing a wide range of indigenous futuristic products and solutions, we plan to bridge the existing digital divide and expand the reach of high-quality networks across rural, suburban, and dense urban areas.

WCI: What, according to you, are the key trends driving the growth and demand in the year ahead?

HP: The pandemic has sharply accelerated the rate of digitalization across the world. As digital adoption has now become a necessity, we will continue to witness a huge demand for innovative products and highfiber-count cable. This demand is further fueled by key factors like network expansion, a boom in demand for data centers, the 5G rollout in India, and the upcoming 6G transformation. In 2023, this will positively impact demand for (OFC) both in India and in key markets like the US, Europe, and the UK.

2023 will witness organizations embarking on their Industry 4.0 journey. There will be a further acceleration in digital transformation across industries spanning manufacturing, retail, utilities, smart cities, gaming, augmented reality and virtual reality (AR/VR), robotics, education, and healthcare, amongst others. However, as a result of this massive demand for OFC, there's a worldwide shortage of cables. It has further resulted in driving prices higher and lengthening order delivery times. To combat the supply gap, HFCL is increasing its capacity and developing new cables to meet this demand.

24 Jan-Feb, 2023 www.wirecable.in INTERVIEW

“

”

“We are expanding our consolidated OFC manufacturing capacities, our existing capacity is 25.08 mn fkm and its going to increase further by 10mn fkm and we are expanding our fiber manufacturing capacities from 10 mn fkm to 22 mn fkm p.a.”

DICABS® Has Restarted Operations in Vadodara,

Gujarat Unit, Phase 1

Targets the Northern and Western Region

Diamond Power Infrastructure Limited (DICABS®)

has been among the major players in the industry for a long time and it is re-starting operations while retaining the brand identity. As the company has refinanced and re-structured itself to reenter the market, Mr. O.P. Tiwari, Executive Director, & Mr. Pragnesh Modi, President National Sales, sat with Wire & Cable India to share the company's ongoing processes, market strategy, and future plans. During the conversation, they also discussed the direction where the Indian power sector was headed and DICABS®' determination to contribute towards it. DICABS®' Gujarat manufacturing unit is now operational, and its market strategy finds reflection in a Jewish proverb, “I ask not for a lighter burden, but for broader shoulders.”

Wire & Cable India: DICABS® is in the process of restarting its manufacturing operations. Can you please walk us through the process?

Pragnesh Modi: DICABS® used to be an established brand in the Northern and Western regions of India, however, we had to discontinue our operations for a certain period of time due to unavoidable circumstances. Fortunately, our difficult times are past us and we are all set to re-enter the market. There are a lot of aspects to re-establishing any setup, such as land clearance, equipment finalizing and testing, additional integration, test operations, etc. Re-establishment requires recruiting all the major key resources again, that is manpower, material, money, and machine. DICABS® is also going through the same process. Fortunately, we have completed a major portion of the re-establishment process, for instance, we have strong investors who are helping us with working capital. We completed the land acquisition in Gujarat a long time ago and a part of our factory setup is already revamped

Jan-Feb, 2023 www.wirecable.in INTERVIEW 26

Mr. O.P. Tiwari, Executive Director, & Mr. Pragnesh Modi, President National Sales

ISO 9001-2015 Co.

With its presence for over 40 years in supply of machinery to the wire and cable sector the India-based Sarvasv Group has primarily been known to infuse its machinery with innovations so as to take care of a client's minutest needs.

SARVASV with time has earned the reputation of being the most reliable supplier and partner for supply of machinery for Wire and Cable Manufacturing. It has manufacturing units that are equipped with the most sophisticated and modern machinery and equipments, which is complemented by highly qualified team of professionals who are always striving hard to improve on the already attained success. It has also been exporting its machines to various countries across the globe like Middle East, UAE, Bangladesh, Nepal, Iran, Africa, Europe andAustralia.

Our Product Range & Services

• High Speed Skip Stranders (AI, Cu, Steel and Insulated Cores)

• Skip Laying Machine for AB Cables

• Rigid Stranding Machine. (Steel, AI and Cu)

• Rigid Stranding Machines With Batch Loading (Steel, AI and Cu)

• Armouring Machine.

• Core laying Up Machine.

• Armouring Cum Laying Machine. (Multi Purpose)

• Special Planetary Stranders I Anti Torsion Machines

• Double Twist Bunching Machines

• Drum Twister for LT /HT Power Cables

• Extrusion and Sheathing Lines. (PVC and XLPE)

• Dual Automatic Spoolerfor Rod Break Down Machine (AI and Cu)

• Rewinding Lines, Take Up Units, Payoff Units and Catterpillar Units

• Taping Solution for PVC, Copper & Steel

• High Speed Tubular Stranding Machine Upto 36 Wires (AI, Cu and Steel Ropes)

Sarvasv Machinery and Equipments Pvt. Ltd.

Regd. & Corp. Office: B-200, Okhla Industrial Area, Phase-1, New Delhi-110020, INDIA

Factory: B-194B/195, RIICO Industrial Area, Kahrani, Bhiwadi Ext, Rajasthan-301019, INDIA

Phone: + 91-11-66401582 / 83 Mobile: + 91 9871163831

Email: info@sarvasv.com • varun@sarvasv.com

Website: www.sarvasv.com

Rigid Stranding Machine

Armouring Machine

Double Twist Buncher

Skip Stranding Machine

Drum Twister

Auto Loading Machine

and operational, while the other portion is also under the process of setting up. We are currently shipping material for production and have planned phases to reach our fulloperational capacity, out of which our first phase is already complete. We shall become fully operational in about 6-8 months.

Additionally, for the last six months, we are in the process of finalizing our key personnel team. All our senior professionals are people with industrial experience spanning 25-30 years and are experts in their fields and functions.

WCI: What are your plans to re-establish DICABS® as a leading brand in the industry?

PM: DICABS® is a familiar name in the industry owing to our past legacy, and we plan to gain energy from this. We are not only focussing on continuing the qualitative attributes that helped us the first time, but we are also looking to reconnect with our past partners and customers. DICABS® has been fortunate to have strong connections with major industrial players because of our qualitative products and services, which also matched their quantitative requirements. We plan to rehash these so that we will have a reliable market once we enter the competitive landscape.

Geographically, our factory is located in Gujarat, which is the largest industrially growing state and our niche market. Moreover, it is surrounded by other strong markets, such as Maharashtra and Rajasthan. While Maharashtra is the largest industrially driven state, Rajasthan has immense scope and opportunities in solar and wind power, that is renewable sources of energy. Additionally, before pausing our operations Western and Northern regions used to be our major markets, and the Gujarat location gives us easy access to both these directions.

WCI: Please elaborate on your product profile and USP after restarting your operations.

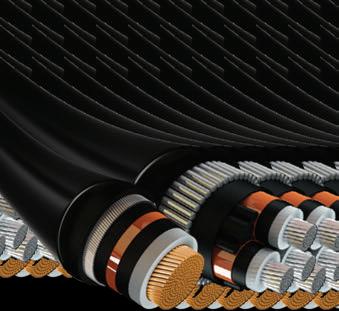

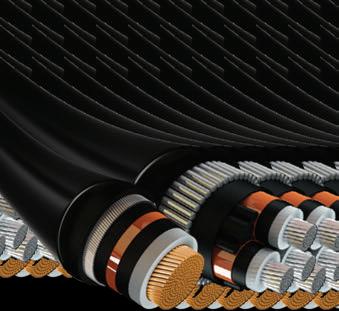

PM: Power Infrastructure is our main forte and we undertake two different functions of transmission and distribution within this sector. Our product profile consists of

anything and everything that has an application in the transmission and distribution of power from its source. Our products can be used for all types of sources, thermal, hydro, solar, kinetic, nuclear, etc. We manufacture everything from LT wires & cables to HT wires & cables to conductors. We have a full-fledged capacity to manufacture different types of overhead conductors in addition to underground HV and EHV cables up to 550 kV.

Our product supremacy is evident by the profile of our customers, such as POWERGRID, which is a union government-supported establishment for setting up and updating the nationwide power supply grid, and our focus on the quality of our products.

WCI: Please comment on the current and upcoming trends of the Indian wire and cable industry.

PM: Post-Covid-19 demand for wires and cables has gone up and the government has launched various programmes and schemes to support electrical infrastructure. It is easier for industrial players to get subsidies, subject to targets and conditions. New initiatives like green energy have gained momentum and large investments, including international ones, are being made. The Indian government's 2049 vision of a unified nationwide smart grid, one that connects power generated from various resources and transmits it across the nation through an interconnected grid, is already in place.

Mr. O.P. Tiwari: The market is growing and cake is getting bigger and bigger. Moreover, various government laws, like The Goods and Services Tax Act, 2017, have helped to convert a major portion of the unorganized market into an organized one. The overall power cables market value is INR 100,000 crores, out of which 60 percent is organized. In this INR 60,000 crore market, there is a huge scope of opportunities as it is controlled by a handful of players. Earlier the approximate market share of organized to unorganized markets used to be 40 percent to 60 percent, which has been reversed now. Today, close to 60 percent of the wires and cables market is organized.

Jan-Feb, 2023 www.wirecable.in INTERVIEW 28

3R POLYMERS PVT

OUR OFFERINGS

ü PVC Compound for Wire & Cables Segment as per IS / BS / IEC / UL Standard

- Insulation & Sheathing Compound

- FRLSH (Fire Retardant Low Smoke) Insulation & Sheathing Compound

- HR (Heat Resistant) Compound up to 125 °C)

- Low Temperature Insulation & Sheathing (up to - 55 °C)

- UV Resistant & Oil Resistant Compound

- Rigid & Soft Molding Compound Plug Molding, Injection Molding application

- Transparent PVC Compound

- Elastomeric Compound

- Customised Compound like High Abrasion Compound for Elevator Cable

ü TPE Compound for Wire & Cable Segment

Zero Halogen Flame Retardant (ZHFR / HFFR / ZHLS) Insulation & ü

Sheathing Compound

PVC & PE Based Smart Batch ü

Universal Smart Batch ü

ü

PVC & PE Based Anti – Rodent & Anti Termite Smart Batches

HDPE Compounds for Data Cables ü NEW

Registered Office: info@3rpolymers.in, sales@3rpolymers.in +91 9711006346, +91 9999653077 www.3rpolymers.in E - 7A Phase I, RIICO Industrial Area, Bhiwadi - 301019, Rajasthan, India 2011/65/EU 2

WCI: Can you elaborate on the advantages and challenges that the industry shall be witnessing in the upcoming years?

OPT: The opportunities and challenges in the upcoming Indian scenario stem from a single fact, India is looking forward to increasing its power generation capacity and application.

Currently, only urban Tier 1 cities and partially Tier 2 cities are continually connected by power. This is on the government's radar, and they plan to bring Tier 2 and Tier 3 urban areas, and subsequently rural areas as well under the power grid transmission and distribution system. Our current power generation capacity needs to be doubled in the next nine years, from 410 GW to 800 GW, so that the growing power consumption could be matched. Additionally, the

Indian government is also looking to build an immense storage capacity, which shall be fuelled by various sources, namely thermal, hydro, solar, kinetic, and nuclear, and the government aims to increase the renewable sources contribution tosupport the Indianeconomy'sclimate, environmental, and other CSR responsibilities. Hence, asmartgrid is planned. This plan is a clear message to the market, that they need to double their capacities, which requires renovation of complete cycles of business and operations, such as conductors, towers, LT & HT cables, EHV, etc. Moreover, safety is another issue, as the lives of India's 141 crores population cannot be mishandled, so the scope of the organized market also needs to be increased. Currently, the organized market is controlled by three to four major players, who cannot possibly cater to the whole nation singlehandedly. Hence, there is a vacuum in the market as well, for a community effort is required.

Conclusively, thechallenges lie in theupcoming opportunities, which are interlinked with humongous targets and vision.

WCI: How do you see DICABS® contributing to the Indian industry?

OPT: DICABS® was a major player in the power industry for the last 15 years, and we havespecialistsand considerablepast experience toourcredit. The market isdefinitelygrowing and getting competitive and many players are there, but we have ourownedge, products, capabilities, and skilled manpower.

Our USP is our quality, which is paramount for any business's success in the current scenario and in step with the infrastructural development the country is going through. We shall reactivate our connections and network and use our quality to add new customers to it. In Phase 1 we will focus on our niche markets of Northern and Western India, and in Phase 2 of our operations, we will expand into Southern and Eastern regions of India.

PM: We accept that today we are only starting, but we also wish to contribute in our own humble way to the growing Indian economy. Our specialty is that we have all the required facilities in one place. We have power and control cables, substation-to-substation connectivity through overhead transmission, etc. We are confident that this will help us win the customers again and win the market share for what we are planning to be.

Jan-Feb, 2023 www.wirecable.in INTERVIEW 30 “

”

The overall power cables market value is INR 100,000 crores, out of which 60 percent is organized. In this INR 60,000 crore market, there is a huge scope of opportunities as it is controlled by a handful of players.

HI-TECH EXTRUSION LINE FOR WIRE & CABLE INDUSTRY

Building Wire (House Wire)

Optical Fibre Cable

Submersible Cable

Flexible / Industrial Cable

Cat-6 / LAN Cable

Control Cable

Power Cable

H.T Cable

Rubber Cable

Solar Cable

We Specialise in :

Wire & Cable Extrusion Lines

Optical Fibre Extrusion Lines

Rubber Extrusion Lines

Profiles Extrusion Lines

Medical Tubing Industry Extrusion Lines

Extrusion Components :

Extruders : 30MM to 175MM

Fixed Center Cross Heads : Upto 120MM

ManualCenterCrossHeads:Upto200MM

Take Up & Pay Off : Upto Din 5250MM

Screw & Barrel : 25MM to 175MM

Caterpillar & Capstan, Cooling Trough

Screw & Barrel : 25MM to 175MM

Tips & Dies : 0.40MM to 200MM

Toolings & Spare Parts, etc.

Plot No.- E - 7 & 8, FIT, Sector - 57, Faridabad - 121004, Haryana, India. info@durgaengineering.in, csdagar@yahoo.com www.protomac.in, www.durgaengineering.in +91- 9999489412, 9999599412

Laser Power and Infra Aims at 100 Percent Capacity Expansion

Indian power transmission and distribution sector is looking forward to a period

of capacity expansion and enhancing presence from urban to the most remote areas. There is enough scope for an existing and new organization to grow and make profits, however, to unlock these attributes, strategy, and innovation would be required. Laser Power and Infra have these already in place, owing to its market experience, and the vision of its leaders, Mr. Devesh Goel & Mr. Akshat Goel, Directors of Laser Power & Infra Private Limited (LPIPL). The company is a well-known name in the country, especially in the Eastern region, undertaking EPC projects as well as supplying products for their application. Its R&D team is working to consolidate all the internal data on its own interface. This conscious coupling of information technology will surely help the company achieve its 100 percent capacity expansion target.

Jan-Feb, 2023 www.wirecable.in INTERVIEW 32

Wire & Cable India: Please share with us Laser Power's journey and crucial milestones achieved along the way.

Mr. Devesh Goel (DG): Great things have small beginnings. The journey of LPIPL started from a small shop in Ezra Street, with an electrical cables trading business. My grandfather made a modest beginning, but we were very focused and seized every opportunity that came our way. My father, Shri Deepak Goel, joined the business in the late 80s and with his vision, approach, and hard work, the company grew exponentially. With his vision, the company has done both backwards and forward integration through acquisitions and mergers. His vision is to make Laser Power as one of the leading power infrastructure company in the world through technological upgrading, 100 percent automation, and by expanding new geography and foray into new markets.

Liberalization of the economy in the early 90's, along with power sector reforms gave us the platform to expand our business & explore new territories. The company made a major foray in expanding manufacturing capacities & started its EPC business division.

Over the years, the power sector has grown exponentially both in capacity addition in power generation & in transmission & distribution sector.

Power sector reforms continue to be the main focus area. With the growth of the power sector, the company also continued to grow, being one of the key players in the power sector.

WCI: Please tell us about your manufacturing setup, product portfolio, and EPC division's projects.

DG: We have three manufacturing plants, all in West Bengal, at Dhulargarh, Howrah, Kharagpur, and Kalyani. All of them are involved in the manufacturing of different products. In Dhulargarh and Kharagpur, we are engaged in manufacturing of conductors upto 765

KV and power and control cables upto 33 KV. Our product range comprises ACSR, AAC, and AAAC conductors, MV overhead covered conductors, and AL-59 conductors, PVC insulated power and control cables, MV and LV aerial bunched cables, LV PVC control cables, LV PVC power cables, LV XLPE control cables, LV XLPE power cables, MV power cables, underground jelly filled quad cables, railway power cables, and railway signaling cables. We also manufacture aluminum rods and aluminum alloy rods in our properzi unit. We are also manufacturing PVC compounds in-house, required for our cable units.

COMPANY LANDMARKS & MILESTONES

1988 Setup Conductor Unit in 20,000 sq. ft. shed area

1998 Setup Cable Unit and shifted to 90,000 sq. ft. shed area

2004 Setup Properzi Aluminium Wire Rod Plant

2007 Started Rural Electrification EPC Projects

2008 Shifted Manufacturing Unit to 185,000 sq. ft. shed area

2009 Got Power Grid & RDSO approvals

2012 Entered into Export Market

2016 Acquired further 600,000 sq. ft. space area in Manufacturing Unit

2017 Entered into Rooftop Solar Projects

2018 Started producing HT Cables upto 33 KV with a state-of-the-art CCV Line

2021 Entered into Water Projects

2022 Entered into Gas Distribution Projects

Turnover First 500 Crores G. happened in 2018 & 1000 Crores G. in 2020

Jan-Feb, 2023 www.wirecable.in INTERVIEW

“

” 33

As of now, we have more than INR 5,000 crore invested in EPC projects, and our cables order book accounts for INR 1,000 crore. We have also recently acquired UIC Udyog Limited, which is a galvanized steel manufacturing company

Mr. Devesh Goel, Director of Laser Power & Infra Private Limited (LPIPL)

In Kalyani, we manufacturer entire range of steel wires comprising HT steel indented & plain wire, used for PSC pole industries; ACSR core wire & strand – size 1.57mm to 4.77mm and cable armouring wire; GS earth wire; G.I. stay wire, G.I. wires of all sizes & grades; barbed wires and earthing coil; M.S. & G.I wires of all sizes.

Our EPC Division started in 2007 and has really done very well in terms of volumes and timely executions of projects. The company has completed many prestigious projects for central utilities like NTPC, Power Grid, BHEL, NHPC, ONGC & DVC etc. to name a few. The company has also executed many projects for various state government utilities in West Bengal, Bihar, Odisha, Assam, and Jharkhand. Repeated jobs from these utilities are a testimony of the quality of performance of the company, The company has already electrified around 13k villages, and has given more than 15 lakhs house-hold connections. The company has erected and commissioned more than 60k ckm of HT & LT overhead lines, 109 ckm of HT 33/11 KV underground cabling, and more than 150 33/11 KV sub-stations (new/augmentation).

WCI: Could you elaborate on your market footprint and clientele?

DG: We have a very strong domestic market presence, looking into a vast clientele base. We are amongst one of the major players in the country in our field. We are serving both government utilities (center and state) and private sector companies. Our clientele includes Indian Railways, Powergrid, NTPC, BHEL, NHPC, ONGC MRPL, WBSEDCL, APDCL, DHBVN, Madhya Pradesh Power Transmission Company Limited, SAIL, etc., and our private sector clients include L&T, Tata Steel, Godrej, Jindal Steel & Power, Tata Power, Adani, Sterling & Wilson, Bajaj Electricals Limited, KEC, JSW, Shapoorji Pallonji, Aditya Birla Group, and Kalpataru Power Transmission Limited among many others.

We are also very active in international markets and regularly supply to various power utilities in South Africa, Africa, Nepal, Bhutan, Maurois, Dubai, Sri Lanka, Bangladesh, etc.

WCI: How does Laser Power use R&D to fuel its growth?

Mr. Akshat Goel (AG): R&D is the integral part of any successful enterprise. We have also invested very heavily on R&D not only to upgrade the existing products and manufacturing facilities but also by introducing new products and manufacturing processes in our system. This is very essential to cater to the ever growing demand of the customers. Today our product line is fully integrated through scada systems.

Further, data and information are the lifelines of the 21st century and we are trying to integrate technological advancement into our company. Our vision is that all our products, services, customers, vendors, and any possible determinant could be integrated within a single interface. This will allow Laser Power to access our internal information and data within seconds, and cut down our servicing and lead time by a significant margin. Presently we are using an integrated interface to sign contracts, issue orders, internal processes, etc., but our R&D team is still working on improving it to next-level technology.

WCI: Do you believe exhibitions contribute towards the growth and development of any industry?

AG: Yes, I do believe that exhibitions drive the industry to make a community effort toward growth and development. Our targets are not ordinary and to achieve them we need not only participation but a substantial contribution from every unit of industry. We take support of exhibitions to drive a community effort as they are huge drivers of international and domestic business, the domino effect of which continues over the years. It is hence a great opportunity for us to attend industrial exhibitions and fairs. In fact, we will be participating in Cable & Wire Fair, a global B2B exhibition for the wires and cables industry, in October and look forward to unlocking immense business opportunities there as well.

WCI: How do green energy and sustainable growth fit into the Indian scenario?

AG: India's power sector is undergoing significant transformation, with the country working to increase generation capacity, expand the transmission and distribution network, and improve access to electricity. The government has set ambitious targets for increasing the share of renewable in the energy mix, and there are several initiatives underway to promote the adoption of

INTERVIEW Jan-Feb, 2023 www.wirecable.in 34

Mr. Akshat Goel, Director of Laser Power & Infra Private Limited (LPIPL)

Ÿ Straight Line Wire Drawing Machine Ÿ Inline Wire Rod Preparation System Ÿ CO2 Wire Production Line Ÿ Pay-off & Take-up Systems for Galvanizing Line Ÿ Pay-off & Take-up Systems for Patenting / Annealing Line Ÿ Inverted Drawing Machines (IVD) Ÿ Wet Wire Drawing Machines Ÿ Vertical / Horizontal Spoolers Ÿ Dead Block Coilers Ÿ Pay-offs for Wire Drawing Machine Ÿ Rewinder Machines Our Product Range SWARAJ TECHNOCRAFTS PVT. LTD. Plot-40, Sector-II, Pithampur, Dist. Dhar (M.P.), India-454775 Ph.: +91 7292 407213, 407304, Email: Info@swarajtechnocrafts.com, Website: www.swarajtechnocrafts.com Mob.: +91-97522 65813 Built like a tank…. Runs like a Race car Leading manufacturer of wire drawing machine and auxiliary equipments for steel wire industry

clean energy technologies. Green energy is the next big thing and sustainable growth is the need of the hour, especially for India. India is growing on various levels, and as urbanization reaches our most remote areas, an immediate inference is a reflection of urban culture in all parts of the country. Today when we enter any enclosed space we can spot and name at least 10 electrical or powerconsuming appliances. With growth, this scale of consumption will also increase, and we need to ensure that the development we are driving doesn't deny our future generations a chance to enjoy the same. This means that while we expand our power generation we need to shift in favor of renewable energy sources or green energy. Subsequently, our power distribution sector also needs to grow and be more organized so that we do not exploit our resources towards waste and the same level of luxury and comfort can be ensured for our future generations. The Indian government is taking various steps to cut down the losses of public distribution companies as people opt for trickery and theft to access power sources like LPG and electricity. These fallacies are in fact a by-product of substandard manufacturing practices and need to be curtailed in favor of qualitative and price-competitive growth.

The transition to green energy is India's chance to improve the situation and deservingly earn its title

of being a superpower and hub of innovation and growth.

WCI: CSR is one of the great initiatives to contribute to society in return for its resources. Can you elaborate on how Laser Power uses this opportunity?

DG: We undertake activities that are in accordance with our CSR responsibilities and also with our culture and ethos. Our CSR activities stem from our legal responsibilities and familial roots, for instance, we have a dairy farm in which we take care of about 1200 cows who have got injured, been abandoned due to old age, are malnourished, or are suffering from any disability.

We have made donations for ventilators installation, which were a huge necessity during the pandemic, in hospitals and deployed various health, like masks and sanitizers, and basic necessity resources, such as food, and temporary tents for migrators and the unprivileged, to tackle the unprecedented health and humanitarian crisis arising from the COVID-19 pandemic outbreak. We have also contributed to various awareness training projects on health and education in rural areas of Bihar and West Bengal headed by the central or state governments. We provide for all educational and living needs, including books, stationery, fees, food, clothing, etc., for a class of students at a West Bengal school for underprivileged students.

WCI: What are your plans for Laser Power's future?

AG: Indian economy is in the process of growth and development, and this phase is going to last at least 10-20 years. The government already has Vision 2047 in place and various schemes and projects have already been launched to drive ground-level action. The infrastructural growth is being focused primarily and huge capex investments have been announced for the same. In such a scenario every Indian organization is looking forward to investing and generating exponential growth and profits.

At Laser Power as well, we are aiming for a 100 percent capacity expansion. Power consumption is increasing and we need better practices and systems in place, as I mentioned earlier, so we are looking forward to using our market presence for these purposes.

Urbanization and infrastructural growth have other collateral applications as well, such as water supply, fuel applications, etc, and we are looking forward to tapping new markets. We are venturing into water distribution and LPG gas distribution sectors as well. We recently acquired G M Dalui Valve Private Limited, a valve manufacturing company, and have bagged INR 300 crore water distribution project in Kuchinda, Orissa. We also have undertaken an LPG gas distribution project in West Bengal.

Jan-Feb, 2023 www.wirecable.in INTERVIEW 36

STE is one of the biggest FRHC copper rods manufacturers in India with over 4 decades of scrap handling experience.

We have the technology of continuous copper rods which is supported by oxy fuel from Linde. We use this technology to process the raw materials and produce copper wire rods utilizing technologically efficient and environmentally friendly processes.

ABOUT US OUR AIM

We aim to provide flexible solutions to our partners in terms of products, delivery and all the parameters associated with the business to create a symbiotic and win-win situation for the client as well as for STE.

VISIT US: E-1226, RIICO Industrial area, Bhiwadi, Alwar, Rajasthan, 301019

productivity.

AT WE BUILD STE TRUST, WE ALSO SELL COPPER RODS

Every coil manufactured undergoes rigorous testing at our in-house testing laboratory. These technology and production facilities allow us to create high-quality, competitive products. While creating the products that are superior in quality, we also ensure to give our topmost priority to the environment in order to create a sustainable ecological system.

MAIL US: info@stecopper.com

CALL US: 9899521581, 9999020699, 9899038002, 9999721516

A guarantee to exceed expectations in the entirety of our tasks by showing cooperation, trust and

Thermo Cables: Pioneering Speciality Cables, Competing with Global Leaders

Established in 1990 in

Hyderabad, Thermo Cables is a leading manufacturer of various types of specialty cables. An ISO 9001-2015, ISO 14001-2015 & ISO 45001 certified company, Thermo Cables is an accepted brand across sectors including Indian Railways, Navy, defense, renewable energy (wind and solar), nuclear power, process industries and underwater applications. The in-house testing laboratory is NABL-accredited which makes the test results unanimously accepted. In a recent conversation with Wire & Cable India, Mr. Srinivasa Rao Nagula, President-Marketing, Thermo Cables Limited, shared the company's recent ventures, expansion in infrastructure and manufacturing capacity, the segments they serve and their future plans.

Wire & Cable India: Please tell us about the recent developments at your company.

Srinivasa Rao Nagula: Thermo Cables has consistently been a strong

38 Jan-Feb, 2023 www.wirecable.in INTERVIEW

Mr. Srinivasa Rao Nagula, President-Marketing, Thermo Cables Limited

ResistanceAnnealingMachine

CAB DEVICE INDUSTRIES

A63,StreetNo.4,KarkhanaBagh,16/5, MathuraRoad,Faridabad-121002

ContactNo.:+911294041641

Email:info@cabledevice.com,cabdevice@yahoo.com

Mob.No.:+91-9910360641,+91-8826059696

Website:www.cabledevice.com

Runningin: JMW,SvarnGroup, AdvanceCable,LaserCable, GlosterCable,SpecialCable, GemscabInd.,NeelkanthCables,RPGCable, andmanymore..

formoreinformation

ScanQRCode

Runningin: UKBElectronics, CordsCable,TamraDhattu, KMGWires,ZenithWires andmanymore..

OffLineMultiWireAnnealingMachine

Runningin: AparIndustries,Polycab, RRKabel,AdvanceCable, LAPPIndiaand manymore..

CABLE

TinElectroplatingOnCopperWire

Tin/NiElectroplatingMachineOnCopperWire

InductionPre-Heater

player in the specialty cables industry and around three to four years ago we ventured into the cable harnessing industry. In this industry, we have already started doing business with the railways, navy and wind energy sectors, where we are supplying cables along with connectors, and have already become established players. We have undergone large scale capacity expansion for cable manufacturing and harnessing processes, as there is a huge demand from many consumers. Furthermore, we have ventured into developmental activities for the Indian Navy and Indian Railways, for which we have set up multiple specialty machines as well as testing equipment. Our company is also one of the chosen partners for the development of the indigenous cables for the Indian Navy. We have manufactured about 35-40 indigenous products which they have been importing. We have also been manufacturing and delivering fire survival cables for Indian Railways.

WCI: How have the infrastructure and manufacturing capacity grown in line with the developments?

SRN: We have expanded a lot in terms of manufacturing and infrastructure as cable harnessing is a complex industry which requires a good level of technical know-how. For example, there are some typical connectors which require hot pot moulding, even for that process the right polymer must be found to be compatible with the molding activities. To take care of this we have a professional polymer engineer present at our facility, who works on developing and manufacturing of good quality polymers. All of our manufacturing is done in-house, from copper rod drawing to various polymers. We have also added some high end machines to our facility for processes like insulation and sheathing. We have added an 8 wire

drawing machine, which has great speed and maintains the uniformity of the wire, and some bunching and wire drawing machines from Niehoff, Germany, for fluoro-polymer high temperature cables from Rosendahl, Austria. In addition to this, we have our R&D team, called the New Product Development or NPD team, which is consistently working on new development activities. The professionals in our NPD team and maintenance team have the technical expertise to build certain machines at our in-house R&D laboratory, which has been NABL accredited for 5 years.

WCI: Please shed some light on the industries that your company caters to.

SRN: Our company mainly caters to 5

verticals. The first one is the domestic market, where we sell the general type of cables. The second sector is railways and third is the navy, where we have been working for 6 years and have established a strong presence. The fourth sector is wind energy, where we are associated with all big companies who are doing lots of wind energy projects in India like Enercon, GE, Siemens and other European brands. The fifth sector is exports. We have multiple export approvals in the Middle East as they have a huge market for oil and gas, which is another industry we are present in. Although we get many orders from India for oil and gas, even outside of India we are competing with companies like Prysmian, Nexans and Draka and other Turkey manufacturers, we win many orders against them. Our

40

Jan-Feb, 2023 www.wirecable.in INTERVIEW “

”

We are competing with companies like Prysmian, Nexans and Draka and other Turkey manufacturers, we win many orders against them. Our export turnover has been contributing about 50 percent of our revenue for the past 2-3 years.

export turnover has been contributing about 50 percent of our revenue for the past 2-3 years.

We also have our representatives working in many countries across Europe and especially in the Middle East because it is important to have a local presence. We have also established ourselves in the South American and Russian markets.

WCI: What are your future plans for expansion and how do you plan to achieve them?

SRN: Currently we have a turnover of

almost INR 600 crore and we aim to achieve a turnover of approximately INR 1,000 crore in the next 2 years. We are foreseeing the requirements for more machines at the facility in order to reach our turnover target.

Therefore, we plan to keep expanding our existing facilities by adding newer machines and increasing developmental activities as we have to be ready for consumer and market demands.

“

” 42 Jan-Feb, 2023 www.wirecable.in INTERVIEW

Currently we have a turnover of almost INR 600 crore and we aim to increase it by another INR 1,000 crore in the next few years.

SWMAI: Constantly Supporting the Indian Steel Wire Industry

To comply with today's changing business scenario and the result-

ing changes in the activities of any industry, it is much necessary to have an association of that industry, giving out information to all concerned members. Established in 1968, Steel Wire Manufacturers Association of India (SWMAI) is the apex national body of steel wire and wire rope manufacturers in India. The association assists the Indian steel wire industry to take the full advantage of production capacity, cost effectiveness, international standard of quality, knowledge base and above all, march together for a better tomorrow. SWMAI is a tool for growth of everybody related with the steel wire industry such as respective customers, raw material suppliers, equipment manufacturers etc. Wire & Cable India would like to congratulate Mr. Siddharth Agrawal, Managing Director, Systematic Group, for being elected as the youngest Chairman of SWMAI, and would like to gather his valuable insights about the steel wire industry and its challenges, and the initiatives taken up by the association on behalf of the industry.

44 Jan-Feb, 2023 www.wirecable.in INTERVIEW

Wire & Cable India (WCI): Please give us a brief background of the association, how it was formed, and its journey so far.

Mr. Siddharth Agrawal (SA): Steel Wire Manufacturers Association of India (SWMAI) is the apex national body of steel wire and wire rope manufacturers in India. Established in 1968 and registered under the Companies Act in 1970, the association has in its membership steel wire drawing units and wire rope manufacturing units, producing bulk quantity of steel wires and wire ropes in India. SWMAI is recognized by Government of India and steel producers as the representative body of steel wire and wire rope manufacturers and is consulted by them on issues pertaining to this industry. SWMAI has an expanding nationwide membership of enterprises, drawn from organized and small-scale sectors, representing the steel wire & wire rope industry. With the continuous patronage of SWMAI, Indian steel wire industry has progressed remarkably over the years on every count, like increase in volume, cutting down costs, quality at par with International Standards (ASTM, DIN, JIS, BSS etc.), in achieving wide range of products of various types.

Versatility has been achieved by the industry for meeting the requirements of numerous consuming sectors in India and abroad. To keep up this sophistication, SWMAI continuously emphasizes on the R&D activities. With members' active participation, SWMAI, in collaboration with other national and international organizations, is carrying on the well-planned R&D activities.

SWMAI is a platform for continuous Government-Industry communications on various policy and problem related issues of the industry. Adequate supply of wire rods, adjustable prices of wire rods with international prices and suitable Government policy would ensure the growth of the steel wire

industry, making it to be sustainable and globally competitive. With this view, SWMAI is continuously working to protect the interest of the industry. We frequently send representations at the ministerial levels of the Govt. of India and to the steel producers so that the supply of raw materials does not become a constraint. We also consult with the Govt. of India directly relating to their industrial/ financial/ exportimport policies concerning to the industry.

Presently, SWMAI has, in its membership, 83 ordinary members and the figure is increasing in every year. In addition to this, some machinery manufacturers are associate members of the SWMAI.

WCI: Please share the initiatives taken up by the association on behalf of the industry.

45

Jan-Feb, 2023 www.wirecable.in INTERVIEW

SA: In the coming 2 years, our goal will be to make this association moreeffective, collaborativeand run inan energeticway. Being elected as one of the youngest Chairman, pressurises me to perform more efficiently and I would like to seek support and advice especially from all the senior members.

We have identified 4 major challenges in running our industry and we have respective leaders to overcome the challenges as mentioned below:

1) Increasing the market size: Mr. Pranay Surana, Surana Wires

To explore both domestic and global market & increase the market / application of quality steel wire in India.

2) Technology: Ms. Namrata Salunke, Bekaert

To get better technology / technical tie up / share good business practices across the world. Explore the possibility for research centre for steel wires.

3) Skill Development: Mr. Yashovardhan Chordia, Rajratan Global; Mr. Mayank Mittal, Bharat Wire Ropes

We are always short of good efficient manpower. It's a major pain point for all of us. Hence, we need to create tie up with engineering colleges to make them aware about our industry needs. Develop content related to wire industry in their curriculum and also provide proper induction.