Distributed every two months to sports turf professionals, independent schools, universities, local authorities and buyers of turfcare machinery and products.

The last two months have been a nightmare for many people in certain parts of the country and my heart goes out to everyone dealing with the aftermath of unprecedented flooding and devastating erosion.

The best case scenario for many is months of temporary living. For others, lives will never return to what they were.

While the fate of sports grounds and golf clubs might seem inconsequential in the face of such hardship, we at Turf Matters have a particular empathy with everyone who has seen years of agronomic husbandry literally washed away in the space of a few weeks.

Well, I think we can honestly say that the sporting year is in full swing. We’ve had the Six Nations, and well done to Ireland on being unbeatable! So too, to Jon Rahm, who managed to get his nose in front of LIV man Brooks Koepka at The Masters and so prevent a ginormous PR coup for Greg Norman. The football season is coming to its elongated conclusion thanks to the World Cup and cricket is getting set for an Ashes summer, the Solheim and Ryder Cups, then the Rugby World Cup. This issue includes an article with Jordan Fairweather, who has progressed through the greenkeeping ranks from the role of fairway divotter, to being in charge of over 100 staff on three courses in Dubai.

It must be hoped that banks – the financial institutions, not the things which edge overflown rivers – take an understanding approach to sporting facilities which have been unable to service loans as a result of them being unplayable and so unable to bring in revenue.

The point of the feature is that he was told in school that to enroll in greenkeeping college would be a waste of time. Indeed, hoping that a career in greenkeeping would offer any fulfilment or job satisfaction was a “silly” notion.

As we have seen with the recent Winter Olympics, sport has such a galvanising effect on society and can be the catalyst for so much good, that it is imperative sporting facilities are not forgotten when the promised assistance is being allocated.

Jordan has since travelled the world and achieved much more than your average careers advisor. It says so much for Jordan that he expresses no desire to track the person down, with the sole intention of laughing in their face.

On the issue of improving sporting facilities, we have been invited by Briggs & Stratton to become involved in its Pitch to Win competition, which provides a £3,000 makeover for what is judged to be the Under 18s football pitch in most need – find out more on pages 16-17. I am on the judging panel and visits will be made to a shortlist of deserving pitches soon. We will be looking not so much at the DESSO but the desperate!

I’m sure Jordan’s experience is not unique and it demonstrates just how lowly a career in turf management features on a careers advisor’s hit list. We all know that it’s a fabulous industry for so many young men and women but that they are often steered away in favour of other careers that might not hit so many of their buttons.

On a final note, I am thrilled by the reception that the first issue of Turf Matters received. Many people have taken time to say how much they liked the look of the magazine and how they enjoyed the articles. We’re all pleased you found it to your liking and we will work hard to maintain the high standards. Thank you all very much.

Scott MacCallum, Editor Scott MacCallum, EditorEditor: Scott MacCallum scott@turfmatters.co.uk

Design/Production Editor: Tim Moat tim@turfmatters.co.uk

Distributed every two months to sports turf professionals, local authorities and buyers of turfcare machinery and products.

Sales Executive: Marie Anderson marie@turfmatters.co.uk

Editor: Scott MacCallum scott@turfmatters.co.uk

Design and Production Editor: Tim Moat tim@turfmatters.co.uk

Sales Manager: Pauline Thompson

Contributor: Summer Rogers

To advertise in Turf Matters, call Pauline on 07720 055676 or email pauline@turfmatters.co.uk

To advertise in Turf Matters, email marie@turfmatters.co.uk

To subscribe, go to www.turfmatters.co.uk

Turf Matters is published by Straight Down the Middle Communications Ltd.

All material © Turf Matters magazine 2023.

Turf Matters is published by Straight Down the Middle Communications Ltd.

Awarded Best Writing and Best Design in the Turf & Ornamental Communicators Association (TOCA) Awards 2019-2022 inclusive

All material © Turf Matters magazine 2014. No part of this publication may be reproduced in any form whatsoever, either for sale or not, without the written permission of the publisher. Information contained in Turf Matters is published in good faith and every effort has been made to ensure its accuracy. Turf Matters can accept no responsibility for any error or misrepresentation. All liability for loss, disappointment, negligence or other damage caused by reliance on information contained in Turf Matters or in the event of any bankruptcy or liquidation or cessation of trade of any company, individual or firm mentioned is hereby excluded.

Follow us on Twitter @TurfMatters

No part of this publication may be reproduced in any form whatsoever, either for sale or not, without the written permission of the publisher. Information contained in Turf Matters is published in good faith and every effort has been made to ensure its accuracy. Turf Matters can accept no responsibility for any error or misrepresentation. All liability for loss, disappointment, negligence or other damage caused by reliance on information contained in Turf Matters or in the event of any bankruptcy or liquidation or cessation of trade of any company, individual or firm mentioned is hereby excluded. Printed by Warners Midlands PLC.

Printed by Warners Midlands PLC.

SAGE 2023 will be held at the Three Counties Showground, Malvern on 19 and 20 July, and the recent announcement of it playing host to the UK Loggers National Championships adds to the long list of reasons to enjoy a day or two in the Worcestershire countryside.

Visitors can now pick up tickets for the show by visiting sportsandgrounds.events.

Filled with live outdoor demos of the latest machinery, leading industry exhibitors, expert-led summits, live music, entertainment, food stalls, and the ever-popular sponsored bar, SAGE should be top of your list of expos to exhibit at and visit this summer!

Here’s what to expect:

This test of precision and skill will determine an overall precision chainsaw champion – with the best among the competitors going on to represent their country at the World Logging Championship next year. Consisting of five disciplines, the championship tests every facet of logging – from cross cutting, to felling, limbing, a chain change and a relay race. n sportsandgrounds. events/

Graham Instone of Dunnington Bowls Club, York, has been crowned as the Bowls England Greenkeeper of the Year. In the hotly-contested category – sponsored by Dennis and SISIS –Graham took the honours, largely for his innovative roadshows, sharing his knowledge with local clubs. He has been a member of his beloved Dunnington for over 40 years and has been looking after the green for the past 15 years. Graham, 80, and his right-hand man ‘Big’ Jim, 88, have a consistently busy schedule of fixtures and work hard throughout the year to keep the green in a superb condition. In fact, the impressive green has become the talk of the Yorkshire bowls community and it is for this reason that Graham decided to undertake a series of roadshows. Graham visited various bowls clubs throughout Yorkshire to help other volunteer greenkeepers raise the standards of their greens. Following the roadshows, Graham

continues to offer advice to most of the bowls clubs he visited.

The Greenkeeper of the Year Award received over 120 entries and Graham was one of five shortlisted finalists. Joined by family and friends, including ‘Big’ Jim, at the award ceremony, it was a moment that Graham will never forget.

“My name was called out and I was shell shocked. I can’t really put into words how I feel. I normally get very emotional, so everyone was worried that I would get on stage to collect the award and cry. Fortunately, I kept it together!”

“It is the achievement of a

lifetime, but this award just isn’t for me as an individual. It is for my team, for the club, and for my family.”

Award sponsors Dennis and SISIS have long supported the sport of bowls and are committed to educating greenkeepers and raising the standards of bowling greens. For over 20 years, they have been organising and hosting educational maintenance seminars throughout the country which are designed to ultimately help club greenkeepers and volunteers maintain their bowling greens.

n www.dennisuk.com

n www.sisis.com

Unique in the world, the airter loosens the turf layers homogeneously from 8 cm to a depth of more than 24 cm - with adjustable compressed air and in one continuous operation.

A total of 14 specially developed injection lances with different types of nozzles inject up to one million litres of air per working process into the ground of a football pitch. With regard to water infiltration, an improvement can be measured immediately

on the treated surfaces.

Even football pitches that tend to become waterlogged due to an unfavourable structural quality

in terms of material selection and grain size distribution. Indeed, unwanted and harmful grubs such as May and June beetles as well as Tipula larvae (leatherjackets) can be effectively and biologically controlled with the airter using compressed air at 100% and guaranteed.

These are the facts:

Proven soil loosening of the turf base layer of at least 30%, the soil loosening lasts up to 4 weeks

At the same time a 23% increase in lawn clippings was measured As well as up to 48% better water drainage in the soil

Also the unwanted grubs (May and June beetles) and the Tipula larvae can be controlled

• Effectively - with the airter and biologically with compressed air to 100%.

The oxygen from the aeration provides stronger roots and vital plant growth

• No more black layer!

After Poa annua was disrupting play on the greens at Bothwell Castle Golf Club, the Head Greenkeeper found a solution in BASF’s Attraxor®, which was recommended and supplied by Agrovista Amenity.

Alan Boyd, pictured above, is the Head Greenkeeper at Bothwell Castle Golf Club in Lanarkshire - a flat 18-hole parkland course located in the woodland area surrounding the 13th century Bothwell Castle.

Alan explained how he first started using Attraxor. “Our greens are predominantly a Poa – bent mix. When the Poa is coming into bloom it starts causing issues with the ball swaying and the greens don’t run true. Ramsay MacGregor (Amenity Specialist for Agrovista Amenity) told me that Attraxor reduces seedhead production in Poa and I was keen to give it a try.”

Attraxor is a plant growth regulator

containing the active substance, prohexadione calcium and can be used to regulate growth of all managed amenity turf. This active substance inhibits the gibberellic acid pathway, which results in a reduction of turf height and turf biomass. Root growth is promoted while turf colour and quality are maintained. Furthermore, the product provides almost instant results, as it is activated once diluted in water. Contrary to other plant growth regulators that need to be activated by the plant enzymes, Attraxor can be used earlier or later in the season during cooler weather.

Alan initially applied Attraxor at a rate of 375 g/ha before increasing it to 800 g/ha and hasn’t looked back.

“You can build it up to that rate or bring it back down – whatever you think is needed,” he said.

“The results speak for themselves. Finer grasses have started coming through because the Poa is not overtaking. It is easy to use, easy to measure out and the granules easily disperse in the water. As a greenkeeper, our priority is to keep golfers happy and since using Attraxor®, the feedback on the surfaces over the past three seasons

has been exceptional. They now have a consistent ball speed, and the ball isn’t swerving all over the Poa.”

In addition to supressing the Poa annua seed heads, Alan has reported some other positive findings.

“We spoke with some people from BASF and they shared with us the results from a golf club in another part of Europe with similar weather to us. They sprayed Attraxor consistently throughout the year and noticed a reduction of disease. I was really interested in this because we do get hit with disease, but it has been getting better since we have been applying Attraxor. BASF explained that as the regular use of Attraxor causes the thickening of plant cell walls and epidermis, it can lead to a reduced susceptibility to diseases such as Microdochium patch by mechanical means rather than by directly affecting the pathogen itself.

“If I carry on seeing a reduction in disease it will be a game changer,” continued Alan. “We know the bad press fungicides are getting and you are saving money by not using them, so the money you are saving on the fungicide can be put into something else.”

n www.agrovista.co.uk/amenity

“THE RESULTS SPEAK FOR THEMSELVES. FINER GRASSES HAVE STARTED COMING THROUGH”

Over 100 exhibitors have booked to attend GroundsFest 2023 with more confirming their presence each week.

The event, which is the talk of the industry, will be held at Stoneleigh Park, Warwickshire on 20 & 21 September 2023.

Over 9,000 square metres of space has already been taken by a wide range of exhibitors with over 75% of allocated space accounted for as the event continues to grow.

These impressive figures are testament to just how well the show has been received by the industry. Close to 5,000 visitors, which includes grounds staff, greenkeepers, landscapers, local authorities, estate managers and contractors, have already signalled their intention to attend by registering for the GroundsFest visitor newsletter.

Attendees can expect to see hundreds of brands at the event. Some of the latest

names to confirm their presence at GroundsFest include Honda, STIHL, AMS Robotics, The Pitchmark Group, KAR UK, Wicksteed Leisure, ICL, Dennis & SISIS, Shelton Sportsturf Drainage, Origin Amenity, Kress UK, EGO, Makita, Greenbest, Soil Scout, Karcher UK, Foley Grinders, RT Machinery and Etesia UK.

“I believe GroundsFest could be exactly what the groundscare industry needs in terms of trade shows. We have all been attending the same existing

shows which have not changed for several years. Therefore, I think we should all be looking forward to something different,” said Etesia Managing Director Les Malin, on their decision to exhibit.

“There is no such thing as too many shows in my opinion; it is more about having events that work for individual companies. We are all different, but we all want to give our customers the chance to experience something new and exciting. GroundsFest

will offer exactly this.”

The indoor halls and outside areas of GroundsFest will not only feature hundreds of exhibitors and products in action, but it will also include a free-to-attend LANTRA accredited education programme, free practical training sessions, the largest retail area ever to be seen at a groundscare event, a dedicated landscaping zone, a music festival and much more.

Commenting on the event’s promising start, GroundsFest’s Event Director Christopher Bassett, said that GroundsFest continued to grow, and that the sales team were receiving new enquiries every week.

“We have also been upbeat about how much interest we are receiving from visitors.

“There promises to be a diverse visitor profile at GroundsFest this year and we can’t wait to see the magic unfold in September.”

n www.groundsfest.com

The central risk with lithiumion batteries is fire. They might be unlikely to catch fire – but they can, through faults inside the battery, or from external damage.

With this in mind Pellenc, distributed in the UK by Etesia UK, has launched the Securion storage option. When they do catch fire, the consequences can be serious. The batteries are most at risk when being stored and charged, and therefore extra thought on safety features should be explored.

Lithium-ion batteries have raised increasing interest due to their high potential for providing efficient energy storage and environmental sustainability. It is no wonder that the batteries are now used in a wide range of groundscare tools and machinery. Naturally, increasing attention is being paid to the safety performance of the batteries which has been intensified due to several reported fires. It appears that the majority of problems arise when the batteries are

being charged and stored overnight. In fact, even the best batteries can suffer from knocks and drops resulting in potential damage to cells. This damage rarely comes to light until they are charged.

Securion from Pellenc is one solution which is already proving to be an extremely popular choice with councils, large contractors, schools, colleges, universities, golf clubs, and several other sports clubs.

Securion has been designed to protect employees,

buildings and equipment from fire, heat and toxic fumes and smoke gases.

In the event of a fire, the doors inside or outside the Securion cabinet close automatically.

In an emergency, those affected have enough time to get to safety and to alert rescue services. Fire, vapours, and fumes remain mostly inside the cabinet Depending on which Securion model you choose, the cabinets can hold up to 40 lithium-ion batteries.

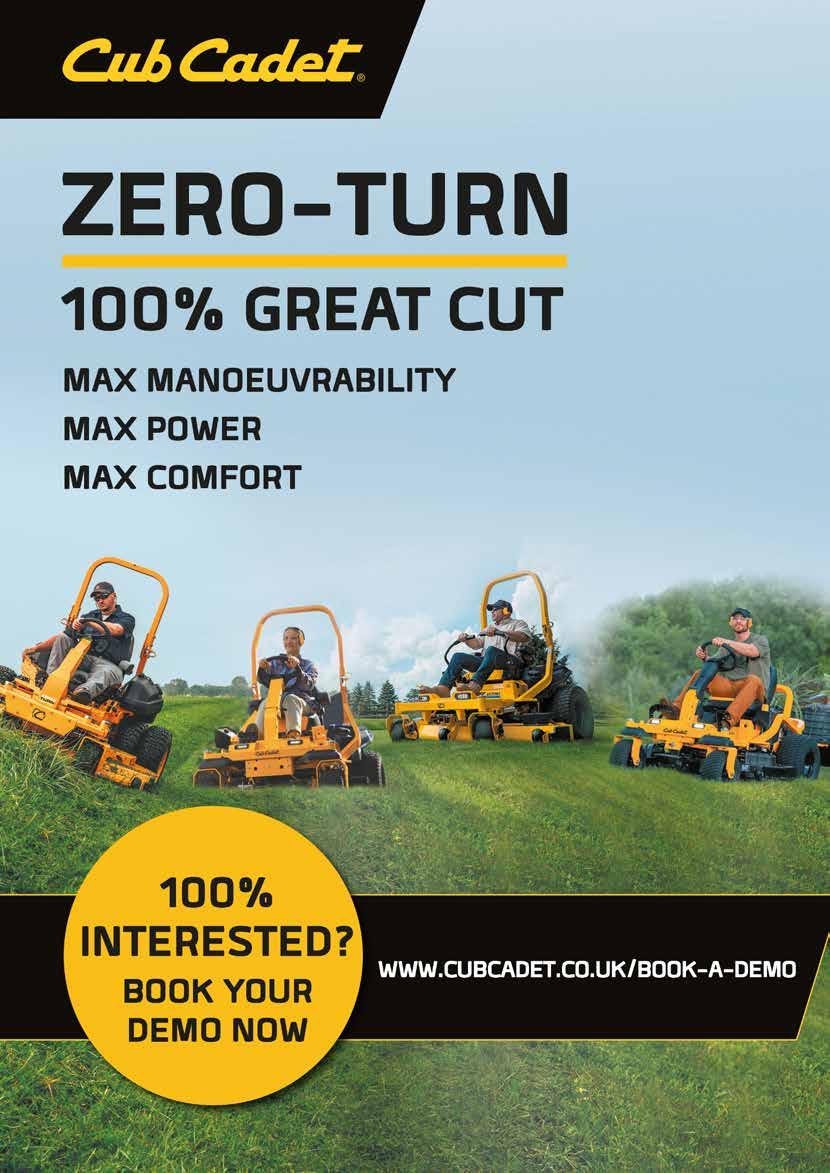

Our large range means that both professionals and business owner alike can find their ideal zero-turn machine; whether they are looking for a serious bit of kit to mow steep slopes or to mow their customers large lawns… Cub Cadet have got you covered this year and every year going forward.

Once tried. Never forgotten.

The Z9 183id zero-turn, will fulfil all commercial requirements.

With extremely wide double wheels, the Z9 has been developed to tackle effortlessly even the steepest slopes up to 25°/ 46%.

The ability to control all four wheels with a steering wheel and steerable front wheels, an exclusive offering by Cub Cadet in the commercial sector, minimises the turf being churned up by the wheels or crabbing on banks. The patented Synchro Steer technology means that even the less experienced operators can benefit from the ease of use and amazing manoeuvrability of this machine.

The Z9 provides greater hillside stability and enhanced traction on uneven terrain as well as mowing in straighter lines.

It powers through the thickest grass in one pass at maximum speeds of up to 12mph meaning that the job can be accomplished quicker. The high lift Marbain blades with a blade tip speed up to

18,500 fpm and the 3” total blade overlap will ensure that you always get a tight consistent cut. The frame and axle on the Z9 floats as the machine moves, allowing the multi-reinforced steel deck to follow the shape of the terrain and avoid scalping. The cutting deck can be adjusted at the touch of a button.

The Kawasaki EFI engine provides the consistent power you need to get the job done and maximise your workday – reducing the downtime which could cost you both time and money. The petrol engine benefits from having reduced fuel usage, while the 2 x 34 litre tanks gives you the ability to operate all day.

Comfort is at the forefront of the machine’s design. Your operators can experience a smooth ride all day long thanks to the exclusive air-ride seat and isolated dampening system on the Z9 – meaning they are working in vibrationcontrolled comfort, lessening downtime for your business. Angled back adjustments, padded armrest and lumbar support give added protection.

The Z9 has everything and more you would expect from a quality professional machine - ultimate performance, comfort and durability that delivers a fast, premium cut time and time again.

You can book a demo of our machines at www.cubcadet. co.uk/book-a-demo

Flora, fauna and lesser plantain are flourishing in Aberdovey Golf Club’s wetland habitats following meticulous drainage works from Duncan Ross.

Aberdovey had suffered from increasing course closures since 2005 due to many drainage and water management related issues. However, the approach taken by the golf club and the work completed by Duncan Ross was awarded the STRI Outstanding Environmental Project of the Year in 2021, with benefits still being seen today.

David Tomkinson, Greens Chairman at Aberdovey Golf Club, explained that Duncan Ross had carried out a major clearance of the ditches on the Golf Course in 2018/19, a programme of work consented to by Natural Resources Wales, as the course lies within the Dyfi SSSI.

“The water table was lowered to improve the playability of the course, while barriers were put into the ditches to maintain a water level in dry spells to maintain the wet conditions required by a rare plant, lesser water plantain. Banks of a number of ditches were widened to allow more light to reach the ditch bases, which, together with

the reed clearance, led to more favourable growing conditions for the plantain,” said David.

“As a result of the work carried out and the use of specialist equipment to follow the requirements of NRW, the Golf Club was nominated as one of the four finalists in the STRI Environment awards 2020.

“The drainage carried out at that time led to significantly fewer days when the course was closed after heavy rain. The way in which the work has been carried out has, we believe, led to constructive discussion with NRW on other aspects of conservation in the area of land owned by the Club,” he added.

“Subsequently, Duncan has been employed on an annual basis to clear reeds and other vegetation from the ditches which impede the flow of water off the course and to carry out a phased replacement of blocked or collapsed field drains under the fairways. There has not been any further requirement to excavate spoil from the base of ditches, leaving the roots of the plantain intact and not disturbing the pupae of insects such as dragonflies and damselflies.

“Aberdovey GC has been very impressed with the work carried out by Duncan and his team and looks forward to employing him again.”

The course, which is flanked by Cardigan Bay and a long sandy foreshore incorporating a semimobile dune system, is highly valued as a rich source of ecology and biodiversity and is classed as a site of special scientific interest and also serves as a special area

of conservation. As such, the club works with the STRI, Natural Resources Wales (NRW), Gwynedd County Council, Snowdonia National Park Authority and the Amphibian and Reptile Conservation Trust.

The ditch system in the centre and northern end of the course supports a population of lesser water plantain, which used to be scattered throughout the country but is now mainly found in coastal regions and the East Anglian fens.

To achieve the water run off objectives while maintaining conservation, the base of the main ditch was increased in depth across half its width, with levelling techniques maintaining a steady fall of 750mm over a 3km length.

Disruption to the fairway was reduced by leaving the old clay pies in place, and putting new pipes in parallel at the new, lower water level. A sluice was installed near the main outfall to hold back at least 50mm of water in the ditch system while allowing the run-off of stormwater.

A requirement from NRW was the excavation of wetland scrapes in low lying areas near the 11th green, which were constructed and provide an additional area for the plantain to colonise.

Aberdovey continues to focus on environmental projects. They include monitoring coastal erosion, protecting wetland areas from seawater ingress, creating further wetland and sand scrape areas, monitoring population of sand lizards, management of rank grass areas to for sheep and management of areas of degenerate gorse.

A SLUICE WAS INSTALLED NEAR THE MAIN OUTFALL TO HOLD BACK AT LEAST 50MM OF WATER IN THE DITCH SYSTEM

Gareth Fowler-Simons is the director of Lakeside Grounds Maintenance, a second-generation family operated firm based in Coventry.

Covering the Midlands and beyond, Lakeside Grounds Maintenance is a long-standing customer of Origin Amenity Solutions and was actually the first in the UK to own a TinyLineMarker GPSguided robotic line-marker. They are a well-respected independent contract specialist in the grounds maintenance industry.

“We always brought grass seed, fertilisers and chemicals from Rigby Taylor and also had a traditional line marking machine, the IGO Premier, but when we decided to move to a robotic line marker back in 2018, we trusted Rigby’s, and after doing our research, we choose their TinyLineMarker Pro which turned out to be the best decision,” explained Gareth.

TinyMobileRobots is marketed and distributed exclusively in the UK by Origin Amenity Solutions which comprises four leading industry names - Headland Amenity, Rigby Taylor, Symbio and TurfKeeper.

“We are a team of around 15 specialising in sports turf and grounds maintenance. We primarily undertake work for councils, schools, sports clubs, and professional sporting clubs. We use our TinyLineMarker Pro for initial marking, overmarking at multiple sites within our contracting businesses, as well as alteration of pitches,” said Gareth.

Origin Amenity Solutions has recently delivered their latest GPS guided robotic line marking machine, the TinyLineMarker Pro X to Gareth. He purchased this in a part-exchange deal and traded in his old Tiny Pro robot.

“Our original robot was coming up to five years old and our policy is to keep the frontline specialist

equipment as fresh as possible to minimise drama and cost. We looked at a competitors machine, but I thought the new TinyLineMarker Pro X Robot had the biggest and the best jump in technology to enhance our marking operation,” he said.

“It was smaller and lighter than the competitors and is an enhanced version of what we currently have – the Pro, which we know from experienced is good, but the additional features on the new Pro X are fantastic. We have already seen good saving in labour for initial marking, especially as operatives can complete other tasks while the robot is in use.”

The TinyLineMarker Pro X is packed with a range of brand-new innovative features and hardware upgrades; deigned to make line marking projects as streamlined and effortless as possible.

“The new multi-select tool is saving us time. We can now queue up multiple pitches to be marked out in whatever order we want. We don’t need to recalibrate the robot

each time and it displays the route it will take to mark out all queued pitches, so we can ensure there are no obstructions in the way. The robot also gives us an estimated time of completion as well as the distance to drive so we can plan other jobs in.”

The Tiny Pro X appeals to a wide audience; it is designed for fast and accurate initial and overmarking of a huge variety of sports ranging from mainstream athletics, football, and rugby to the more obscure such as Quadball. Customers save money and time as operators can carry out other essential tasks such as mowing, aeration, spraying and spreading while the robot does the marking.

‘’After looking at other machines on the market and having discussions with our sales adviser, Glen, I felt this would be a significant improvement to the way we operate our line marking. I am proud to be the first contractor in the UK to take the jump into a sector of the business that needed help from the traditional ways of carrying out these works.’’

Turfco built the world’s first mechanised topdresser in 1961 and now, over 60 years later, manufactures a range of broadcast topdressers, drop spreaders, blowers, overseeders and edgers.

“Our philosophy is to design and build equipment that increases productivity, saving work hours while reducing fuel costs when operating on fine turf surfaces,” say John Moore, Turfco’s European Sales Manager.

“Our WideSpin topdressers reduce the number of passes and compaction to complete the job, while ensuring an even distribution of material in all conditions.

Turfco’s WideSpin 1550 topdressers are available in truck-mounted and tow-

behind models with engine or hydraulic power options. They are available with standard electronic control or a patented digital Smart Controller. Standard electronic control models are easy to use and offer good value for the money. Smart Controller models offer rate calculation and programmable pre-sets for greater productivity and labour savings.

The result is that when using the WideSpin 1550 calculating and retaining application rates is easier. Adjusting settings is easier and saving preferred settings is easier. Loading is easier. Topdressing greens, approaches and tees at the same time is easier. And getting the exact spread required, every time, is easier.

n jmoore@turfco.comThe last 25 years since the management buyout from the original owners, Collier Turf Care has been an extremely exciting journey. Every year we have grown and invested back into the business with our number one focus always being around delivering great customer service and every member of the team in all areas of the business are fully trained to meet the highest standards.

Over the years the company has grown considerably; supplying grass seed, fertiliser, pesticides and sports equipment throughout the UK. Customers receive sales and technical support from officebased staff and a sales team that complete on-site visits, as well as via the website which is fully e-commerce and supports integrated client trade accounts.

Our sales and technical support team are backed up at our modern head office facility with an excellent support team, along with over 30,000 sq. ft of warehousing which includes a large

BASIS registered chemical store.

As our industry evolves and for the business to remain sustainable, it will increase investment into training, technical advances, technology, its website and customer service.

Think of a town centre high street: 30 years ago you had Woolworths, which was the place to go for Pick ‘n’ Mix as well as your records. A lack of investment and modernisation into their business led to the failure and collapse of the chain.

Now look at Next, the clothes retailer who invested into the out-of-town shopping outlet experience along with a website and great delivery service, creating a sustainable modernised experience.

All industries must evolve, and our industry sector is no different. Collier Turf Care have positioned themselves to be the “Next” of our industry.

Key points to consider when purchasing products within our industry:

• That technical staff available are BASIS and FACTS registered.

• You are buying pesticides from a BASIS registered company that comply with current legislation for delivering pesticides.

• Your supplier carries the stock to deliver your whole order on one delivery.

• Your order is packaged well with no split bags and arrives on time.

• You can buy flexibly via online, phone or a sales representative.

• You receive an excellent standard of customer service.

Collier Turf Care Ltd work with industry leading brands such as Aquatrols, Barclay Chemicals, Barenbrug, Harrod Sport, ICL, Prestige, CMW, Syngenta, KAR and Vitax, and have recently started a new key relationship with Olmix importing from Europe the Marathon range of fertilisers.

Collier Turf Care has many clients throughout the UK, our customer retention is extremely high and with new accounts opening daily it is an exciting time for the company. n www.collier-turf-care.co.uk

BIGGA has appointed an experienced project manager to oversee the implementation of their First Green initiative and to create an online resource centre that will showcase careers in greenkeeping to a wide audience.

Jennifer Bledge, pictured, is a qualified teacher and also has experience of developing relationships with various stakeholders across education, which will prove vital as BIGGA seeks to engage with other

organisations to implement its outreach programme.

At BTME 2023, BIGGA announced it would be adopting the GCSAA’s successful First Green initiative to transform golf courses into STEM classrooms. Jennifer will oversee the development of a UK-specific toolkit as part of the roll out of this scheme.

She will also lead in the development of a digital careers in greenkeeping resource centre that is aimed at school leavers, graduates,

second careers and golfers. Supporting this, she will liaise with ex-military and public services careers services, the National Careers Service, various charities and universities with related degree courses.

Jennifer has an existing understanding of the greenkeeping industry as her husband James Bledge is Royal Liverpool Golf Club’s Course Manager and is preparing to host The Open in July this year.

“The appointment is one of

the most important strategic decisions the association has made in some time.” said BIGGA CEO Jim Croxton.

“Jennifer was the outstanding candidate for this role and given her experience working within education, I am thrilled she has joined the team. I look forward to sharing updates about the various projects she will be working on in the coming years.

“There is a long way to go, but I am confident we have taken a vital first step.”

Wholesale native wildflower seed supplier, Bradford Green has welcomed English Heritage’s plans to establish 100 wildflower meadows at historic sites to celebrate the King’s coronation.

The start-up business is based at Bradford Estates on the Shropshire/ Staffordshire border. Here they produce high-quality sustainable wildflower seed to be used by private, public and charitable organisations, as well the general public for a range of biodiversity projects and wildflower plantings.

Bradford Green Director, Bethan Pugh, recognises the value of initiatives such as English Heritage’s dedicated King’s Coronation Meadows and calls for further restoration of the country’s lost flower-rich grasslands.

“Our ancient meadows drastically declined after WWII. We’ve lost 97% over 70 years which has had a hugely detrimental impact

on the wildlife these habitats sustain,” says Ms Pugh.

“Thankfully, there is growing recognition of wildflowers’ multiple benefits. Reinstating meadows is a great way to create a lasting and positive legacy for future generations.

“However, it’s important to remember, no matter how much space you have, you can make a difference. Anyone can help prioritise the natural world by establishing flower-rich spaces. The key is to source native wildflower seed which has been produced

as sustainably as possible, right here in the UK.,” she adds.

From farmland to urban spaces, wildflowers not only enhance biodiversity, but they also improve soil health, as well as delivering aesthetic and wellbeing value for local communities.

As the Government’s land management, farming and environmental policies continue to promote more naturefriendly approaches, the introduction of native species is being actively encouraged.

Creating flourishing natural spaces that support pollinators and other wildlife depends on having the highest concentration of native wildflower species to attract bees and other insects.

“I hope English Heritage’s visitors will be inspired and make their own contribution to reversing biodiversity loss in the UK as a result,” says Ms Pugh.

compaction through to the free draining soil. But unfortunately, because our golf courses were built with bulldozers, there is no free draining soil anywhere.

“If you make a hole with an aerator, you don’t get below the compacted level, and all you do then is fill the holes with water in the winter, and it just stays wet.

“We had lateral drainage put in those fairways when the golf course was built, and basically, I wanted to find a way of moving the water sideways rather than down the way until it found a drain which is where the ShockWave came in.

Keeping three courses open all year round is no easy task, but when you’re reaching to achieve the standards expected at Celtic Manor Resort, it gets that little bit harder.

The Welsh resort is famed for producing the Twenty Ten course, the first ever European course purpose-built for a Ryder Cup. Hosting one of golf’s largest spectacles brings enduring expectations from visitors. Whether it’s summer or winter, the Roman Road or Montgomerie courses, play needs to be on at Celtic Manor.

Since 1993 the man making that happen is Director of Golf Courses and Estates Management Jim McKenzie MBE. Over almost 30-years, he has overseen the transformation of the Wentwood Hills course into the Twenty Ten and countless other developments. However, the one constant is keeping

play on and joining that process are the ShockWave and Rotoknife from Campey Turf Care Systems.

“Because we’re not a golf club, we rely very much on visitors for income 12 months of the year, including the winter,” explained Jim.

“We really do need to stay open during the winter and we’ve been putting in extra drainage, and we’ve been doing extra topdressing on the fairway and the Rotoknife and ShockWave are a part of that process.

“Our golf courses are modern designs, so they were built within the last 30 years. With traditional golf courses, no bulldozers were involved in the shaping, so many of the original golf courses are quite free draining because the soil was never compacted.

“A lot of golf courses aerate in the winter just to get through that top couple of inches of

“We’ve probably had it for around a year on-site. By the time it arrived last winter, it was quite wet, and we didn’t want to use it in wet conditions.

“We’ve done all of the fairways and all of the approaches on the Twenty Ten course, and it’s been really good so far. Whilst we haven’t had enough rain to test it out, it has allowed us to utilise it, knowing that we’re not going to get these thirty-degree temperatures again, and we will get rain at some point.

“So, the fact that we’ve been able to actually use it in dry weather whilst we wait for the rain has been really good.”

With the fairways covered by the ShockWave, the fine turf areas are left to the Rotoknife. For Jim, it’s doing the same job on the tees and approaches with a less prominent slit, but the level of compaction is the main determining factor as to what machine is used.

Syngenta has further added to its Turf & Landscape team in the UK, with the appointment of Sarah Hughes (pictured) as a dedicated Business Manager to strengthen support for its broadening product range.

Joining from the company’s Seeds division, Sarah is an experienced agronomist with a background in plant science and genetics. She has a wealth of knowledge in bringing products from

the Syngenta R&D pipeline into the commercial market for customers.

“It is an incredibly exciting time in the turf and landscape business, with the introduction of new chemistry to add to the existing Syngenta portfolio, alongside pioneering biological and biopesticide innovations.

“Working with Syngenta’s R&D scientists, technical support and commercial partners, there’s now the

opportunity to develop more effective and consistent integrated turf management solutions to benefit our customers and achieve better results,” she said.

Allied to further developing initiatives including Syngenta’s Operation Pollinator, new digital decision support resources and enhancing accurate application technology, Sarah reinforced the company’s commitment to delivering sustainable solutions.

Following BCP Council’s declaration of a climate and ecology emergency in 2019, the decision was made to review the management of some green spaces across the Bournemouth, Christchurch and Poole areas.

With a subsequent reduction in the cutting of some verges and open land, a Trilo S20 with its large 20m 3 hopper capacity was brought in to increase productivity as the cut and collect operation expanded – taking not just large quantities of meadow grass in its stride but also assisting with leaf clearance during the winter months.

The Trilo S20 was purchased in May 2022 by Simon Woodall, Team Operations Manager for BCP Council who spearheads a 30-strong

team responsible for looking after all aspects of maintenance and landscape construction.

“Our ecology programme included creating more grass meadows by leaving areas uncut to improve carbon sequestration and increase our biodiversity to support pollinators. We also reduced cutting on other green spaces such as verges to give plants a chance to flower, providing a valuable source of nectar and adding interest and colour to amenity areas” he explained.

“With this change to our cutting operation, we needed a machine that could handle large-scale cut and collect and found the Trilo was a perfect addition to our existing fleet of mountable cut and collect machines.” The S20 is the largest

capacity model in Trilo’s multipurpose S-Line range which, when fitted with a flail shaft, offers a cutting width of 2.1m and powerful vacuum collection of the clippings to leave a clean finish after every pass.

Following the delivery by Hunt Forest Group, the S20 was put straight into operation between August and October. “The size of this unit has transformed the task of maintaining our meadow areas” Simon explains. “Not only does it cut and collect in its own right, but we can use it to support the smaller machines which can cut in tighter areas then tip their arisings on the ground to be sucked up by the hose on the S20 – all done using the intuitive control box from the comfort of the cab.”

A successful tour of both Northern Ireland and the Republic of Ireland saw Toro and Cyril Johnston host Dealers at three venues over a week. Showcasing the Consumer, Landscape Contractor, Siteworks and Construction products, Dealers were updated on the product ranges and Toro’s plans for the future. They also had the opportunity to get hands on with the product range itself.

Dealers were able to test out for themselves some of the innovative Toro features such as the MyRIDE suspension system on the ZeroTurn range, which reduces impacts, bumps and vibrations reaching the operator, resulting in a superior ride.

Dealers also got hands on with the Toro Landscape Contractor and Construction ranges, testing the

Dingo® TX700, Compact Utility Loader.

“We are proud to have Cyril Johnston as our exclusive Toro Distributor for both Northern Ireland and the Republic of Ireland and we are pleased to support them and their Dealers,” said Craig Hoare, Toro Sales & Marketing Manager.

Tom Black, Managing Director of Cyril Johnston, praised Toro U.K. Limited on their support adding that he was really looking forward to building on this initial visit.

“The product range is vast and allows us to offer Dealers unrivalled opportunities to grow.”

n contactcentre@ cyriljohnston.com

A brand-new ISEKI tractor has not only saved Osterley Cricket Club a significant amount of time and money, but it has also helped its ground rating climb into the top three rankings.

Established in 1940, Osterley Cricket Club, in Southall, specialises in cricket, football and social gatherings. Somewhat of a hub for the local community it boasts 2.2 hectares of grounds. This consists of two cricket pitches which convert to seven football pitches during the winter.

Nadeem Chowdhry, Chairman of Osterley Cricket Club, explained why the Club was in the market for a new tractor.

“We started looking for a new tractor because we were using an old ride-on mower and a 1960’s

cylinder mower which had all kinds of hydraulic issues,” he said.

“It was an important decision and so we did a lot of research.

“We selected ISEKI because of the brand’s renowned build quality and ease of use. After deciding on the brand, we then spoke to several dealers and the one that stood out was RT Machinery. They understood our challenges, they pin-pointed the ISEKI tractor for us, and the presale and after sale service was phenomenal.”

Based on RT Machinery’s recommendation, Nadeem decided that the ISEKI TLE3400 was the perfect fit. The TLE3400 is ISEKI’s premium economy tractor. This 38 horse-power tractor has a threespeed hydrostatic transmission and a lift capacity of 1000 kg. It is supplied with agricultural

or turf tyres as standard.

An optional front loader is also available. Ideal on the farm, an estate, or sports pitches, it is an all-round tractor for all those tasks that just need doing – from muck scraper to harrow or mower to loader, it’s capable of doing it all.

According to Nadeem, Osterley Cricket Club has not looked back since purchasing this unique tractor.

“It used to take our groundsman two whole days, to cut, stripe and tidy up – but since purchasing the ISEKI tractor this has been reduced to just two hours,” he said.

“The cost of running it, on fuel alone, is six times cheaper as well.

“This tractor is fantastic to store because it is compact, and it is so versatile. We use it with lots of different attachments

such as a grass cutting deck, a verticutting unit, a scarifier and all sorts of other attachments.

“Everyone at the club suddenly wants to help and have go on it because it is so easy and so comfortable to use – it is hard getting people off it!

“In fact, a lot of other nearby clubs have seen our ground rating go from near the bottom of the table to the third best and have been asking how we have managed to do it. We tell them that is down to the ISEKI tractor.

“Ultimately, it has made a huge difference to our club, because everyone really enjoys playing on this gorgeous, lush outfield, and it is all because of this tractor. I would tell any sports club that has grass to look at ISEKI – they will never look back.”

2023 is a special year for Deighan’s Caravan Park, as the family-run business celebrate 30 years since the doors first opened on the 5-star resort close to Benone, Northern Ireland. Their first mower – installed by local dealers D.A.Forgie – was a Kubota and three decades on, it remains Kubota at the heart of site maintenance, with a fleet of Kubota F-Series mowers ensuring a picturepostcard start to every holiday.

Open every year from April to October, Deighan’s consists of static and touring caravan facilities managed and maintained by Thomas Deighan Jnr alongside a team of four.

“From March, I will have two people on full-time grass cutting and strimming duties

and when I say full-time, they’ll start at one end of the park at 9am on a Monday and will only just get to the other end of the site come 5pm on a Friday… then it’s time to start again!” explained Thomas.

“We take massive pride in our grass areas. Keeping this well maintained gives the great first impression we’re looking for.”

Thomas currently has four mowers, including an F3890 and F391 from Kubota’s F-Series. The F3890 sets the benchmark for the out-front mower market, featuring a 38hp 4-cylinder engine that delivers unbeatable productivity and impeccable cut quality. The F391 further enhances the F Series’ position as the professional’s choice for parks, open spaces and local authorities with a high output, maximum comfort philosophy.

The newer, stage-V compliant model also offers power steering and an adjustable out-front deck making the F391 highly manoeuvrable – a feature praised by Thomas.

“We can cut between the caravans and around the bollards at the back of the caravans with ease, leaving a finish

that we can’t fault. Kubota is the only brand that has ever cut our grass and we would never use anything else.”

Together with an RTV-X1110 used to transport the team around the site, the latest delivery was a Kubota M4063 tractor, fitted with turf tyres, installed in December 2021.

“We decided to purchase a second tractor to complement our multi-use M5112 and already the M4063 has proven to be a great addition.

“With caravans getting longer, we were having to use rubber matting to protect our turfed areas when we moved them around. With the turf tyres, we were able to use the M4063 to move a 41ft caravan a few weeks ago without the need for any protective matting – saving a significant amount of labour and time.

“Our relationship with the Kubota brand is longstanding, delivering reliable, well-built machinery backed up with brilliant service and support every time from D.A.Forgie. We look forward to continuing this partnership through our celebratory year and long into the future.”

Outside the electrification, how does a modern day ride-on differ from one of 20 years ago?

The biggest difference is the technology. From the engine to the ease of maintenance to the electronics and the computers to the ergonomics, almost every element of a ride-on mower benefits from the last 20 years of research and product innovation. And as a result, these machines are so much more intuitive, accurate, consistent and controlled.

Do battery operated ride-ons now have the equivalent performance levels of a petrol or diesel version?

Without a doubt, they do. Toro was first to market with its lithium-ion battery powered greensmower and that easily manages 18 greens or a full-day mowing on a single charge. And it won’t be long before battery powered ride-on mowers are available for other areas of the golf course and for grounds applications. The technology and run time from the bat-tery packs is constantly improving.

We are hearing a lot about multi-purpose “Swiss Army Knife” machines. What’s the case for a ride-one mower these days?

Multi-purpose mowers have their place and are very

good tools for specialised jobs, like cutting banks for example, but they are very much a jack of all trades. Because of the na-ture of the machine they’re not built for a specific job and lack the features and productivty frontline dedicated machines have. Although with certain attachments they may be able to be used for the same task they can’t produce the level of consistency and quality that comes from a dedicated mower built for that purpose. Many top clubs are using ride-ons for cutting greens - even at The Open - because of the consistency of speed and pressure to the cutting units. Is that something you are aware of too?

Yes, absolutely. Clubs will want to hand cut if there’s the workforce to do it and they are trained and have experience of using the machines, but ride-ons provide a comparable con-sistent and reliable quality of cut as pedestrian mowers. On top of the time savings gained from using a ride-on mower, they can also be kinder on the turf spreading its weight across the machine and applying less ground pressure than a pedestrian mower and its operator walking across the green. A ride-on has the benefit of removing all operator variables.

n Jon Cole is Divisional Business Manager – Turfcare at Reesink Turfcare.

Burnham Beeches Golf Club, in the Thames Valley in south Buckinghamshire, 25 miles west of London, is one of the latest clubs to take a package of Ventrac equipment.

Delivered by local dealer, RT Machinery Ltd, the package includes a Ventrac 4520 all-terrain compact tractor unit together with a three different cutting decks and a trencher attachment.

Now in his 24th year at the club, Lee Bishop is the Course Manager, where he leads a team of seven greenkeeping staff. Later this year the team will be expanding with the addition of a further experienced greenkeeper, an apprentice and two summer staff. He began his career at the nearby Harry Colt-designed Stoke Park Golf Club in 1992, before

moving to Burnham Beeches as an assistant greenkeeper back in 1999. He became Couse Manager in 2006

“We are an established parkland course, now over 130-years old, and situated mainly on clay,” he said.

“Therefore, we have a requirement to manage the trees and woodland margins that line the fairways and frame the greens. We can be wet after heavy rainfall.

“I first saw the Ventrac on social media and then I was invited by a very good friend of mine, Stuart Langhorn, the Course Director at Beaconsfield Golf Club to see the machine that he had bought. I was extremely impressed and contacted our local dealer, RT Machinery to arrange a demonstration. The management team were so impressed and we purchased the package within a couple of weeks of the demonstration!

“The Ventrac is so versatile that

we purchased three different cutting attachments in the package; the Tough Cut deck is superb for managing our woodland margins; it takes down brambles and young saplings with ease and this helps to keep up the pace of play, making it easier for our golfers to find their balls after a wayward shot.

“The Contour deck is articulated at both ends and that makes it ideal for bunker surrounds and tee banks, but it has been a godsend during the winter months as we have been using it on our fairways when it is too wet to cut with our fairway mowers.

“We can get out when it’s wet and put some definition down; the members have noticed and we’ve had many favourable comments. The Triple Cylinder unit will be used for the perimeter fairway cut and this has enabled us to remove a dedicated machine from our fleet.

“The Trencher has been outstanding this winter. As I said earlier we can be wet after heavy rain, but the trencher enables us to get out and drain the wetter areas when we want. We are not reliant on contractors, we can do it in-house and in a timely fashion. I would recommend not severing power cables, though; National Grid are not too happy when that happens!

“Finally, a shout-out for Price Turfcare, RT Machinery and Tom Stidder. Price Turfcare, the importer, have been so reactive and professional to work with; RT Machinery are renowned for the way they treat customers and we can certainly support that and Tom Stidder, who did the installation training was extremely thorough and knowledgeable.

“That’s formidable support, all round.”

n www.priceturfcare.com

“THE TOUGH CUT DECK IS SUPERB FOR MANAGING OUR WOODLAND MARGINS”

With many years’ experience in producing agricultural and horticultural equipment, South Korean manufacturer KIOTI have expanded their product offering with the addition of ZX Zero-turn ride-on mowers.

Offering a cutting width of either 122cm or 137cm, the ZX mower is available in two versions, the 24hp ZXR for domestic use and the 25hp ZXC for commercial use. Both are powered by a Briggs and Stratton petrol engine with

keyless numeric start, keeping the mower safe but removing the hassle of handing over keys.

The ZXR has a maximum forward speed of 12.9 km/h with a fuel tank capacity of 28.4l, sufficient for domestic applications. In contrast the ZXC has a maximum forward speed of 16.1km/h and a fuel tank capacity of 47.3l, allowing operators to cover more ground quickly. To support this higher use, the ZXC is also equipped with a premium suspended seat with a higher back

rest and an uprated drive system. The comfortable seating position combines well with the front castering wheels and zeroturn steering to make the mower highly manoeuvrable, especially in tight spaces. The cutting height can be adjusted on the move by a conveniently located dial, with numerical indication, from 38 to 127mm and the side discharge deck can be fitted with an optional mulch kit.

n Call 01480 401512

Etesia UK has launched the new Hydro 100 MK124 ride-on mower. The new mower boasts all the features of the popular Hydro 100 but has a larger 124cm cutting deck.

It boasts a modern hydrostatic drive transmission with differential lock for better driveability and greater safety. Its 18 HP twincylinder Kawasaki engine and its larger 16-litre tank give it more power and range. The cutting deck with rear central ejection combined with two counter-rotating blades, the high clearance bridge and the large box make it an undisputed standard-setter for mowing and collection in all weathers.

Furthermore, it has a large 500-litre grassbox that can be emptied in seconds thanks

to its hydraulic pump.

Its ergonomic design, low noise emission and supple new drive give the user the best working conditions for professional applications. All the controls are accessible without leaving the driving seat.

The hydrostatic drive makes gradual movement extremely smooth, and the absence of a turbine considerably reduces the noise emission, for greater user comfort. Also, it is designed to offer maximum safety.

The 18 HP Kawasaki engine offers unparalleled power and optimum work efficiency. The chassis is fully treated for corrosion protection and can withstand the effects of the weather in harsh working conditions. The cutting deck is cast in a single

piece of one-centimeter-thick aluminium, for extreme strength. The Hydro 124 has a wide range of accessories for winter work and for cutting long grass. n www.etesia.co.uk

Next to traditional lawn tractors, Zero Turns have become more and more popular in Europe. The name already includes the most important feature: the possibility to turn on the spot, allowing one to mow quite narrowly around obstacles and in corners.

Zero turns are especially useful for mowing large areas but also come in handy for broad mowing in narrow spaces or parks and areas with many trees, bushes, and flower beds. The driver sticks allow easy steering, handling, and turning.

Zero Turns are known for a quite compact product design, allowing the user to sit on top of the machine in an ergonomic sitting position and easily ascend and descend. Mowing with Zero turns is significantly faster than with traditional tractors with exceptional manoeuvrability

and visibility of the working area - and without having to compromise on the quality of mowing. Evenly cut green grass in faster, more ergonomic, and easier work.

Most Zero Turns and most lawn tractors in the market are petrol driven. With Cramer’s Zero Turn 82ZT132 you get introduced to the innovation of a batterydriven mower that is equivalent to an 800cc petrol-driven Zero Turn – with lower running and ownership costs. The 82ZT132 with an integrated 82V 16kWh battery enables landscapers to mow a 40.000 m 2 area / 5 hours on a single charge.

With a forward speed of 16 km/h and perfect turning around obstacles, you receive a highly productive mowing experience. The fabricated 132cm cutting deck, with 3 efficient brushless 1.5 kW motors, is wider than most common cutting decks and will cut grass reliably, fast, and evenly without having to use

petrol you also work with lower vibrations, lower noise and zero emissions or harmful fumes – large scale mowing has never been this green, user-friendly, and efficient.

In addition, the suspended seat provides extra driving comfort. The Zero Turn also provides extra safety: with the integrated 4G SIM card you will always stay connected to your device.

The Cramer Connect App allows you to set schedules, get notifications, and reports from driving and have total security over your device’s location at any time. Extra protection against theft offers the GSM Geofence. It makes sure the Zero Turn is not used outside its home territory.

The 82ZT132 is the right choice for landscapers and landowners who expect the ultimate in performance and durability. Discover the Cramer Zero Turn now – find your retailer: www. cramertools.com/gb/en/dealers.

Scott MacCallum speaks with Ian Smith, Sports Turf Consultant for St Alban’s School, about climate change, sustainability – and the days when meeting Elton John was a regular occurrence

Think back to last summer and the scorching temperatures. We hadn’t seen anything like it. For many of us we could get by with desk fans and cold showers but for those working outside, and I’m thinking about those in the sports and amenity turf industry, they not only had to cope with the blazing sun, they also had to keep their surfaces alive. Not easy with water restrictions in place.

One man in the middle of it all was Ian Smith, Sports Turf Consultant for St Alban’s School, who, at the time, was also planning the programme for the annual Dennis SISIS Seminar which had been postponed from the previous two years.

“I was going to go down the environmental route with the programme anyway, but then we had

the drought last year which made it even more relevant,” explained Ian.

“I had seen (Met Office Meteorologist) Aidan McGivern’s presentation on the 2050 weather forecast and when I was able to get Aidan to appear at the seminar it tied everything in.”

What made Aidan’s presentation all the more impactful was that the “shock factor” of the 2050 forecast was 40-degree temperatures in the UK and what would be the consequences of such heat. Those temperatures were reached in southern England last year – 28 years ahead of Aidan’s schedule.

“That really brought it to a head,” admitted Ian.

That led him to look to shape the day’s programme, which he widened to water resourcing, water

capture and recycling, as well as how we should build pitches in the future to retain moisture rather than drain it away and what diseases might become more prevalent in a hotter, drier climate.

The Seminar, which attracted well over 200 turf professionals from around the country, was a huge success but left delegates with a genuine sense of foreboding about what the future will have in store if nothing is done imminently to change from the current course.

But Ian works at a school which has already shown its desire to do the right things when it comes to a sustainable model.

“It is something that the school governors are embracing. When we first set up the new site here at the school in 2000 I wanted to

install irrigation with recycled water, but at the time mains water wasn’t that expensive and it was felt that with the hassle of cleaning and filtering etc, mains water was the way to go. Obviously in the 20 years since, things have changed.”

Now the school has plans for maximising the water at its disposal including capturing and harvesting rainwater which is something all facilities are going to have to investigate given that the Environment Agency is going to be clamping down on extraction licences for bore holes in legislation which is earmarked for 2028.

“We are looking to capture water from the pavilion roof which should help to reduce what we are drawing off the mains. ln future we are looking at the water which

LEGISLATION EARMARKED FOR 2028.

currently disappears in to a soak away on our artificial pitch.

“If we can store that water and re-use it on the sports field or in the pavilion it would be a good way of maximising our water usage,” explained Ian, who added that in an ideal world they would tap into grey water from water treatment plants, but sadly the school is too far away from the nearest one.

Much of the school’s drive towards a more sustainable future is led by the pupils, who have their own Green Council.

“We have meat-free Mondays and they have ensured all our lightbulbs are eco-friendly. From our perspective all our hand tools are now battery powered and when the bigger pieces of kit come up for renewal, we have been told to look

at the battery option if we can.”

There are 23 hectares (73 acres) of pitches at Woollams to be maintained by Ian and Head Groundsman Steve Ascott, Mark, Jason, Riz and Richard. “We are in the same position as most in that we struggle to find staff. Our last two members of staff employed have not been experienced groundsmen and are of a more mature age, one laid tarmac and the other was a firefighter who had retired at 60 but wanted to keep working. They have both been brilliant.”

It is not just the pupils of the school that use the pitches. The Old Albanians, the school’s old boys’ club, have 30 of the 73 acres some of which they sub-let to Saracens Rugby, with the professional club spending quite a bit of money }

NOW THE SCHOOL HAS PLANS FOR MAXIMISING THE WATER AT ITS DISPOSAL INCLUDING CAPTURING AND HARVESTING RAINWATER WHICH IS SOMETHING ALL FACILITIES ARE GOING TO HAVE TO INVESTIGATE GIVEN THAT THE ENVIRONMENT AGENCY IS GOING TO BE CLAMPING DOWN ON EXTRACTION LICENCES FOR BORE HOLES IN

ensuring their two pitches were well-watered during the drought.

Ian’s own path to a top grounds management job started in familiar fashion, and familiar surroundings – an unhappy school classroom. So many successful turf professionals struggle academically until a light goes on in their heads when they discover a subject which really makes them click.

“It was classic really. I was no good at school. Both my kids are dyslexic and I think I was too. But I

was just told I was stupid as pupils were told bluntly then. I was the invisible kid in the classroom who spent his time looking out of the window, because I’d far rather have been outside,” he recalled.

“I’d have loved to have been a professional sportsman, but I never made the grade. However, Watford FC was my big passion and in the school holidays they used to take kids on to do jobs, like painting the crash barriers. Some of the jobs were just horrible but rather

than get £2 a week doing a paper round, I was getting £25 a week.”

There is one particular job which remains stuck in Ian’s memory –and not for any good reasons!

“There was an old wooden stand, and this was just before the fire which burned down the wooden stand at Bradford and people had been dropping rubbish through the gaps in the floorboards. The Fire Officer said that it was a real fire risk and that we had to clear it out.

“So I spent six weeks, the whole of

THERE CAN’T BE MANY WHO GET A REFERENCE FROM AN ENGLAND FOOTBALL MANAGER, BUT IAN DID – FROM GRAHAM TAYLOR, WHILE HE WAS ALSO ON-HAND TO SEE THAT FAMOUS FOOTBALL CLUB OWNER ELTON JOHN AT FIRST HAND.

the school holidays, being lowered down between some floorboards that had been removed and picked up rubbish. The pile was taller than I was. I had to pick it up, put it in a bin and then pass it back up through the floorboards. I looked like a panda when I got out.”

He loved all the work maintaining the stadium, but particularly when he got out onto the pitch. When he got to 16 and everyone else returned to school or went into sixth form he just turned up again at Vicarage Road

“They asked why I wasn’t going back to school and I just said I didn’t fancy it. So they said that they might as well keep me on then. I signed a contract and that was that.”

Ian was at Vicarage Road for two and a half years before moving on to North London Polytechnic which was the Watford Training Ground where he worked for a further six years.

There can’t be many who get a reference from an England football manager, but Ian did – from Graham Taylor, while he was also on-hand to see that famous football club owner Elton John at first hand.

“Elton had a football pitch in his back garden which we used to look after. He was always around the club, popping into the tearoom. He liked it because we all treated him like a normal person and took the mickey. He loved that we treated him like one of the lads.”

Ian used to cycle the 18 miles each way from Luton to Watford to work and it was this journey which was to open the door to his links with St Alban’s School.

“I used to cycle past this beautiful little sports ground which belonged to St Alban’s School and I always looked at it with envy. Then I heard on the grapevine that the school wanted a bigger site – this one was

just 16 acres – and being the cocky, confident person, I was I went to the school and said that I gathered that they wanted to build a new sports ground. I was the man to do it for them. I was 23 or 24 at the time.”

The bravado paid off as, armed with his Graham Taylor reference, the school bursar was impressed and said that there was a deputy groundsman job available and that the Head Groundsman, had two years until he retired.

“That would give me two years to prove that I could do what I said I could do.”

All went to plan up until the part about moving to the new site when three public inquiries stood in the way of a swift build. It wasn’t for a further nine years that it was finally finished.

“I was involved right from the start, working with the STRI and the Head of Sport

}

to decide the requirements of the new facility and where everything should go,” said Ian. He was also to sit in on all three inquiries alongside the school’s barrister so, if required, they could counter the arguments put forward by the local council.

“It was a fascinating few years,” he said with genuine understatement. Such heavy involvement did mean that when construction finally got underway, he was front and centre when it came to pitch construction so what he was left to maintain was exactly what he had specified.

Construction started in 2000 and finished in 2002.

“The pitches are still performing 21 years on. We did think that they would start to give us problems by now but we have installed secondary drainage and Sand master a couple of pitches each year. In many ways its strength is also its weakness because it drains so well all the time, drains are at four metre centres and we ameliorated lot of sand and then top dress every year. So we do get the situation we found last year with the drought. But you very rarely call a match off because it’s too dry.”

Ah yes, that drought. With Saracens using two of the pitches, the grounds team were using mobile sprinklers for two pitches on the old Albanian side and two on the school side, every school match was played on those two rather than the usual six they

would have at their disposal.

“They had to amend match timings and they were played one after another starting at 9am and going on well into the afternoon.”

So, what happened to that original playing field which caught young Master Smith’s imagination and caused him to move away from his beloved Watford?

“That’s sad. I worked on it for 13 years before we moved to the new site and I put my heart and soul into it. It’s covered in houses now. The day the diggers came in, as a joke, I lay across the square with banners saying, ‘Save My Square’,” he laughed.

But for now, Ian is planning how to save his newer responsibility from the ravages of climate change and the rapidly increasing temperatures.

Worksop College offers a wide range of academic and sporting programmes to its students.

Like many schools and universities, maintaining well-marked sports pitches is an important part of ensuring that their athletes can compete at their best. However, manually line marking these large outdoor surfaces can be timeconsuming and labour-intensive, presenting a significant challenge for the college’s groundskeeping staff.

In order to improve their operations and provide their athletes with top-quality playing fields, Worksop College recently invested in a Turf Tank line marking robot. This cutting-edge technology allows the college to quickly and accurately mark their pitches, saving time and effort while maintaining the high standards that their athletes and coaches’ demand.

In addition to serving the needs of the college’s own athletic programmes, Worksop College also rents out its sports pitches to outside organisations, which became an important source of revenue. Chris explained that without the Turf Tank line marking robot, it would be difficult for the college to accommodate these external bookings, as the time and effort required to manually mark the pitches would be prohibitive.

“If we just did it with string lines and a roller, you know, it’s probably two to three hours. With the robot - it’s 20 minutes. It’s done. It’s always programmed in.

“So now when they tell us that they’re coming up this weekend, we just send the robot down and get him to mark that pitch whenever it is needed. No problem.”

“If we get requested on a Monday morning at nine o’clock we’ll have a pitch there for Monday morning at 11 o’clock,” said Matthew Binns, Grounds Foreman.

Apart from making the line

marking process hassle-free and allowing the college to fulfill these requests, the robot also has another great advantage over its manual counterpart - the accuracy.

“Turf Tank works everything out perfectly for us. Everything’s symmetrical, every time. Before, obviously, if you’re doing freehand you’re never ever going to get it as perfect as you are, with the Turf Tank. It’s all GPS. It’s all perfect every time,” said Matthew.

The staff at the college is thrilled that they can provide even more than perfect pitches.

They can use it to mark letters and special messages in the grass, that can help to create a more professional and impressive appearance for the pitches , making them stand out and providing a memorable experience for the teams and spectators.

“We also do little messages around the school every now and again, Chris explains.

“We did some prize giving, we put that on a piece of grass. We put welcome back messages on the front of the lawns and things like that.”

“Like the guys for Joe Root. We didn’t tell them we were doing it. And we just did it. And they spent most of their time photographing their logo and tweeting about it. So it just gives them a little bit more ownership.”

By offering its sports pitches in a timely manner, at a high level of quality, and with the added value of special messages in the grass, Worksop College is able to provide an

exceptional experience for the teams that rent their facilities. As a result, these teams and organisations are likely to return in the future, and to spread the word about the college’s outstanding services to other organisations.

The Turf Tank line marking robot proved to be essential for Worksop College’s operations, not only improving the efficiency of their line marking process, but also helping to build a thriving business that benefits the college, its students, other teams, and the wider community.

Scott MacCallum caught up with Jordan Fairweather and learned just how far greenkeeping has taken him.

‘You want to work in greenkeeping? That’s an absolutely silly idea. It will never give you a career, never give you enough money and you’ll be spending the rest of your life cutting grass.’

Jordan Fairweather had been joined by his parents for a meeting with the school’s careers’ advisor. Always keen to keep busy, he had been splitting his time between two holiday jobs, one at his father’s car dealership and the other divotting fairways at Letham Grange Golf Club, near Arbroath.

When it came to the inevitable question of “What do you want to do?”, it was as much a surprise to his mum and dad as it was to the careers’ advisor when he replied, “I’d like to go to Elmwood College and give greenkeeping a go”.

It was perhaps the fact that his parents were so dumbstruck by the answer that it was neither of them who spoke next.

“’That’s an absolutely silly idea. It will never give you a career, never give you enough money and you’ll be spending the rest of your

life cutting grass, You should go into the family business’,” was the response from the person whose sole role was advising young people on the path to career fulfilment.

That was back in the mid ‘90s and Jordan was recounting the story from Dubai, where he is in charge of operations at three prestigious golf clubs. He had just spent his weekend with his wife and two young children around the private pool in his housing complex. He has responsibility for around 115 staff and regularly meets with the clubs’ boards and stakeholders to discuss the current performance of the business along with further development opportunities.

Thinking back to that careers’ advisor, there is no feeling of having proved her wrong, just a degree of frustration that an excellent career option could so easily be ridiculed.

“I remember thinking I wonder what she would have said if I’d told her that I wanted to be a Formula One driver or a fighter pilot. She’d probably have said it was a good ambition to have. But what are the chances of making a life at that? Very slim!”

Being brought up on the east coast of Scotland – not far from Carnoustie – Jordan was very much in a golfing/ greenkeeping heartland, particularly with that other huge employer of greenkeepers, St Andrews Links, not too far away either. However, Jordan had a thirst for knowledge and to make the most of his career, and without a genuine affinity for links golf, he felt the urge to move away.

“I could see that I wasn’t going to learn any more where I was and so I took a long shot and gave up my full-time position and took a seasonal job at Loch Lomond }

Golf Club, working for Ken Siems and David Cole. I stayed there for seven and a half years.”

After just one year Ken, known for his ability to identify talent, was giving Jordan special projects to handle, including installing the SubAir system, one of the first at any UK golf club, irrigation-related projects and installing drainage

pumps on what was and is regarded as a particularly wet site.

“What he saw in me? I’ve no idea. You’d have to ask him. Maybe it was a willingness to learn and try anything new. That was what I saw in Ken. He’d take a risk on anything. The view was if you don’t try you are never going to improve. The funny thing is we still call each other now

bouncing ideas of each other.

“Loch Lomond was certainly a stepping stone to learning and creativity, the management team were always trying to see how to take something to the next level.”

Certainly Loch Lomond was a great place to develop and Jordan was there when it was a regular host of the Barclay’s Scottish Open. He also

grabbed the opportunity to study at Rutgers University in New Jersey.