GENERAL

INTRODUCTION

This section has a description and the service procedures for the brake system. The brake system includes the following parts: master cylinder, master cylinder with brake booster [only available lift truck models H2.00–3.00XL (H40–60XL)], brake shoes, wheel cylinders, a single inching/brake pedal and

linkage, and the parking brake system.

Two sizes of service brakes are used on the H3.00XL (H60XL) lift trucks: a 260 mm (10.25 in) or a 310 mm (12.20 in). New drive wheels and tires are required for the larger diameter service brake. Both sizes of service brakes are described in this section. A troubleshooting section is included at the end of this section.

SERVICE BRAKES AND PARKING BRAKE

DESCRIPTION AND OPERATION

Service Brakes

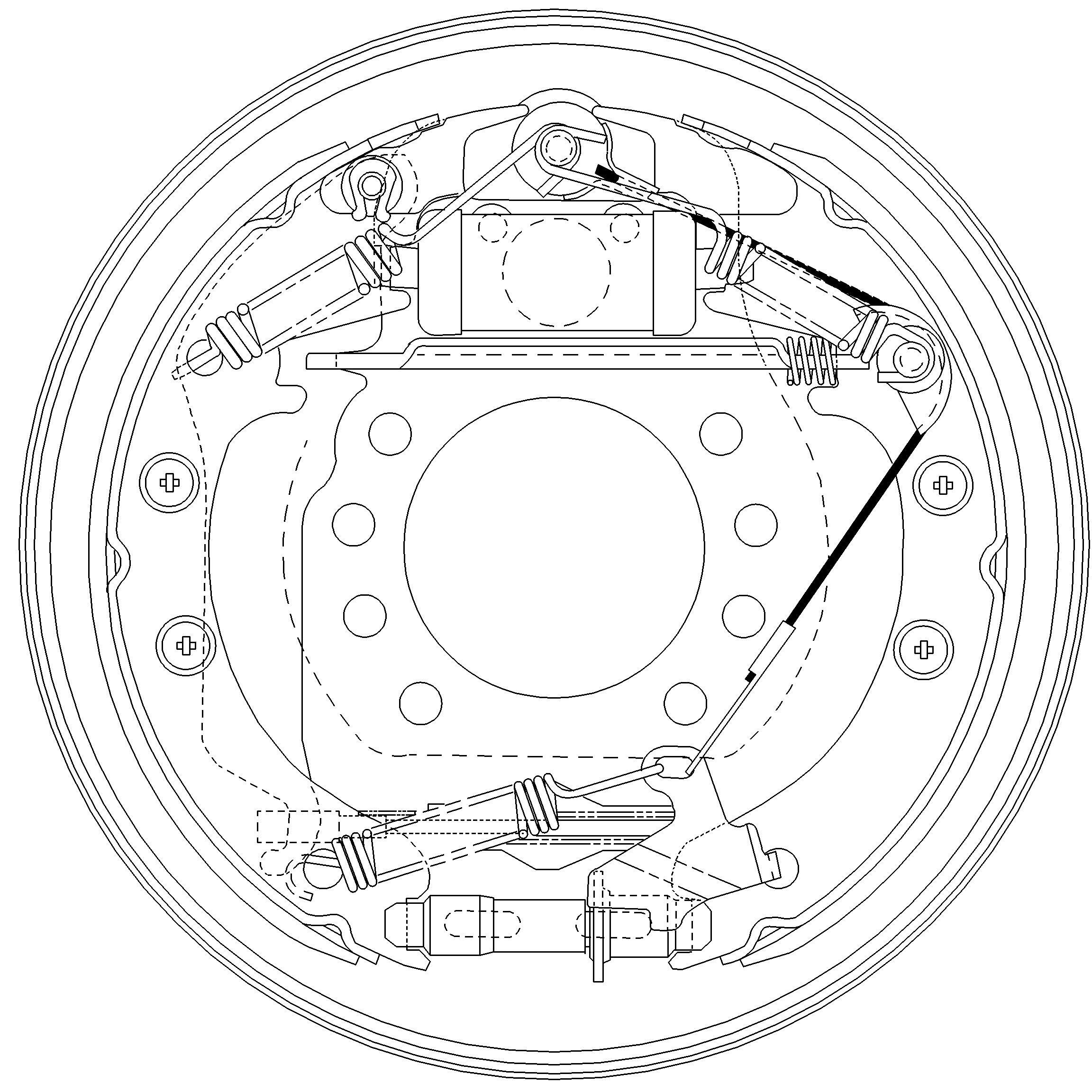

A service brake assembly is installed on the brackets at each end of the drive axle. The parts of the service brake assembly for the 260 mm (10.25 in) brake are shown in FIGURE 2. The parts of the service brake assembly for the 310 mm (12.20 in) brake are shown in FIGURE 13. When the brake pedal is pushed, fluid pressure from the master cylinder causes the pistons in the wheel cylinder to extend. The pistons expand the brake shoes against the drum.

The clearance between the brake shoes and the brake drum is adjusted automatically. An adjuster linkage turns the adjuster wheel to adjust the clearance. When the lift truck moves in the REVERSE direction and the brakes are applied, the rear brake shoe and the adjuster links move with the drum. This linkage moves the adjuster lever to rotate the adjuster wheel. The adjuster wheel can turn only when there is clearance between the lining of the brake shoe and the brake drum. The adjuster wheel can also be turned with a tool. A hole in the drum is used for access to the adjuster wheel in the 260 mm (10.25 in) brake. A slot in the back plate gives access to the adjuster wheel in the 310 mm (12.20 in) brake.

1.LEVER, PARKING BRAKE

2.PEDAL, SERVICE BRAKE

3.BRAKE ROD

4.BRAKE BOOSTER *

5.MASTER CYLINDER

6.BRAKE LINE, RH

7.BRAKE LINE, LH

8.CABLE, LH

9.CABLE, RH

10.BRAKE ASSEMBLY

11.DRIVE WHEEL

*AVAILABLE ONLY ON MODELS H2.00–3.00XL (H40–60XL)

Parking Brake

The parking brake system uses the service brake shoes. Additional linkage activates the parking brake system. When the lever is moved to apply the parking brake, the cables and linkage expand the brake shoes against the drum. The design of the parking brake linkage adjusts each cable so that the tension is the same when the lever is moved to apply parking brake.

REMOVAL AND DISASSEMBLY OF THE 260 mm (10.25 in) SERVICE BRAKES

WARNING

Brake linings can contain dangerous fibers. Breathing the dust from these brake linings is a cancer or lung disease hazard. Do not create dust! Do not clean brake parts with compressed air or by brushing. Use vacuum equipment approved for asbestos dust or follow the cleaning procedure in this section. When the brake drums are removed, do not create dust.

Do not sand, grind, chisel, hammer or change linings in any way that will create dust. Any changes to brake linings must be done in a restricted area with special ventilation. Protective clothing and a respirator must be used.

1. See the procedure “HOW TO PUT A LIFT TRUCK ON BLOCKS” in the MAINTENANCE section or the OPERATING MANUAL. Start the engine and tilt the mast fully backward. Put blocks under the mast. Tilt the mast forward until the wheels just touch the floor. Stop the engine. Put blocks under the frame of the lift truck.

2. Remove the capscrews that hold the axle shaft to the hub. Remove the axle shaft.

3. Bend the lock plate and remove the nut that holds the axle bearing. Remove the washer and the bearing cone.

4. Put grease on the floor so that the wheel assembly will slide easily from the axle tube. Pull the wheel assembly from the lift truck.

WARNING

When the brake shoes are removed do not create dust in the air. See the cleaning procedure in this section.

5. If the wheel assembly cannot be removed easily, remove the wheel from the hub. Align the hole in the brake drum with the adjuster wheel. Pull the adjuster actuator away from the adjuster wheel. Use an adjuster tool or a screwdriver to turn the adjuster wheel to loosen the brake shoes. Remove the hub and drum assembly. Do not damage the seal when removing the hub.

6. See FIGURE 2. Remove the return springs (2) (15) with spring pliers.

NOTE: The return springs (2) (15) are not the same part number. Make sure the springs are installed in the same positions from which they were removed.

7. Remove the retainers, springs and retainer pins that hold the brake shoes to the back plate. See FIGURE 4. Remove the brake shoes and adjuster assembly.

NOTE: The adjuster wheel for the left brake is not the same as the adjuster wheel for the right brake. The adjuster wheel for the right brake has left–hand threads.

8. The back plate must be removed from the axle housing for access to the capscrews for the wheel cylinder. Remove the brake line from the wheel cylinder. Remove the capscrews that hold the back plate to the axle housing.

9. Remove the dust covers, pistons, cups and springs from the wheel cylinder. See FIGURE 3.

10. Remove the snap rings from the brake levers. Remove the parking brake levers from the back plate.

1.PORT FOR SPECIAL FITTING

2.INLET PORT

3.BRAKE SHOE

4.DUST COVER

5.WHEEL CYLINDER

6.SPRING

7.CUP

8.PISTON ASSEMBLY

1.WHEEL CYLINDER

2.RETURN SPRING, LEFT

3.PIVOT PLATE

4.LINK

5.RETAINER PIN

6.ACTUATOR FOR ADJUSTER WHEEL

7.ADJUSTER WHEEL

8.ADJUSTER NUT

9.CABLE

10.SPRING RETAINER (SPRING NOT SHOWN)

11.LEVERS FOR PARKING BRAKE

12.LINING FOR BRAKE SHOE

13.BRAKE SHOE

14.ANCHOR

15.RETURN SPRING, RIGHT

16.BACK PLATE

1.SNAP RING

2.ANCHOR PIN

3.BACK PLATE

4.CABLE 5.CABLE GUIDE

6.SPECIAL CAPSCREW 7.CAPSCREWS

8.PARKING BRAKE LEVER 9.WHEEL CYLINDER 10.PIVOT PIN 11.BRAKE SHOE 12.PIVOT PLATE

Parking Brake

13.RETURN SPRING (GRAY)

14.RETURN SPRING

15.SPECIAL CAPSCREW (SPRING ANCHOR) AND WASHER

16.LINK 17.LINK

18.RETAINER SPRING ASSEMBLY

19.BRAKE SHOE

20.SPRING

If the lever assembly for the parking brake must be removed from the cowl, use the following procedure (see FIGURE 11.):

a.Use blocks next to the wheels to make sure the lift truck can not move. Release the parking brake lever.

24

21.ADJUSTER NUT

22.ADJUSTER WHEEL

23.ACTUATOR, ADJUSTER WHEEL

24.CRANK, PARKING BRAKE

b.Remove the four capscrews that fasten the bracket for the parking brake lever to the cowl. Remove the bracket and lever assembly.

c.Loosen the jam nuts that fasten the threaded ends of the parking brake cables to the bracket assembly.

d.Turn the adjuster knob counterclockwise until the brake cables are loosened. Disconnect the parking brake cables from the link.

CLEANING

WARNING

DO NOT use an oil solvent to clean the master cylinder, wheel cylinder, or the brake linings. Use a solvent approved for cleaning of brake parts. Do not permit oil or grease in the brake fluid or on the brake linings. Oil and grease will cause damage and leaks in the seals of a brake system. The brakes will not operate correctly if oil, grease, or brake fluid is on the brake linings.

WARNING

Cleaning solvents can be flammable and toxic, and can cause skin irritation. When using cleaning solvents, always follow the safety instructions of the solvent manufacturer.

1. Do not release brake lining dust from the brake linings into the air when the brake drum is removed.

2. Use a solvent approved for cleaning of brake parts to wet the brake lining dust. Follow the instructions and cautions of the manufacturer for the use of the solvent. If a solvent spray is used, do not create brake lining dust with the spray.

3. When the brake lining dust is wet, clean the parts. Put any cloth or towels in a plastic bag or an airtight container while they are still wet. Put an “ASBESTOS” warning label on the plastic bag or airtight container.

4. Any cleaning cloths that will be washed must be cleaned so that fibers are not released into the air.

CAUTION

Do not permit oil or grease on the brake linings because the brakes will not operate correctly. Use a brake cleaning fluid as necessary to clean brake linings that will be installed again.

INSPECTION

1. Inspect the bore of the wheel cylinder for holes or scratches. Replace the wheel cylinder assembly if there is any damage.

2. Inspect the return springs for defects. Inspect the back plate for wear where the brake shoes touch the back plate. remove any grooves worn into the back plate.

3. Inspect the brake shoes for cracks or damage. If the linings or shoes are worn or damaged, replace the brake shoes. Maximum wear is to within 1 mm (0.039 in) of contact with the rivets, or the metal shoe on bonded linings. Brake shoes must be replaced in complete sets. Inspect the brake drums for cracks or damage. Replace any damaged parts.

WARNING

The brake shoes on both wheels must be replaced if any shoe is damaged. The brake performance on both ends of an axle must be equal or the lift truck can be difficult to steer when the brakes are applied.

4. Inspect the brake drum for deep grooves or other damage.

NOTE: If grooves must be removed from the brake drums, do not grind more than 1.5 mm (0.060 in) from the internal diameter of the brake drum. The maximum limit of the internal diameter of the brake drum is 262.7 mm (10.35 in). If the internal diameter is larger than the limit, replace the brake drum.

5. The teeth of the adjuster wheel must not be worn. The adjuster wheel must turn freely. Check the adjuster links for damage.

6. Make sure the parking brake levers and crank move freely.

7. Check the grease seals and the surfaces for the seals for wear or damage.

ASSEMBLY AND INSTALLATION OF THE 260 mm (10.25 in) SERVICE BRAKES

1. Assemble the wheel cylinder. See FIGURE 3. Use only HYSTER APPROVED parts.

2. Install the wheel cylinder on the back plate. Make sure the special fitting for removing the air is in the top hole. Put LoctiteR 271 on the threads of the capscrews. Tighten the two capscrews that are near the top of the wheel cylinder to 78 to 85 N.m (58 to 66 lbf ft). Tighten the two larger capscrews to 80 to 102 N.m (67 to 75 lbf ft).

3. See FIGURE 5. Put the retainer pins that hold the brake shoes through the back plate. Install the shield and back plate on the axle housing.

in the pivot plate. Install the pivot plate (12), links and cotter pin.

NOTE: The upper link for the left brake assembly is not the same as the upper link for the right brake assembly. Install the pivot plate (12) so that the letter “L” is seen on the left brake assembly. Install the pivot plate (12) on the right brake assembly so that the letter “R” is seen.

4. See FIGURE 4. and FIGURE 6. Tighten the two special capscrews (6) for the parking brake levers (8) to 244 N.m (180 lbf ft). Tighten the capscrews that hold the back plate to the axle housing to 245 N.m (180 lbf ft). Install the washer and the special capscrew (15) that is the anchor for the return springs. This capscrew (15) must be tightened to 125 N.m (92 lbf ft). Make sure the washer is installed so that the capscrew (15) does not loosen during operation.

7. Lubricate the back plate with a small amount of grease where the shoes touch. Install the brake shoes. Install the retainer spring assembly. See FIGURE 7. Put a spring seat, spring and retainer on the pin. Push the retainer on to the pin and rotate the retainer 90 degrees to lock the pin into the retainer. Install the other spring assembly.

8. Put an anti–seize compound on the threads of the adjuster wheel. Install the adjuster wheel assembly between the two brake shoes. Make sure the adjuster wheel is toward the rear of the lift truck.

WARNING

5. Install the parking brake levers (8) and cable (4). Install the snap rings. Install the cable guide (5) and snap ring on the crank (24) for the parking brake.

6. Install the pivot pin (10) through the brake shoe that is toward the rear of the lift truck. Install the links (16) (17)

The threads of the adjuster wheel are not the same for each brake assembly. If the adjuster wheel assemblies are installed on the wrong brake, the brake shoe clearance will increase each time the brakes are applied. The adjuster wheel for the right brake has left–hand threads. The adjuster wheel for the left brake has right–hand threads.

Turn the adjuster wheel into the adjuster nut so that the adjuster assembly is in its shortest position. This action permits the brake drum to be easily installed over the brake shoes.

9. Install the link in the adjuster wheel actuator. Put the adjuster wheel actuator in the hole in the brake shoe. Fasten the spring to the adjuster wheel actuator and the brake shoe. The spring must be installed in the position shown in FIGURE 8. Install the return springs for the brake shoes. Make sure the return springs are installed in

1.SPRING FOR (LEFT) SHOE

2.SPRING FOR (RIGHT) SHOE (GRAY)

3.ADJUSTER LINK, UPPER

4.ADJUSTER LINK, LOWER

the correct positions. See FIGURE 8. A gray spring is always installed on the right brake shoe.

10. Make sure the bottom edge of the adjuster wheel actuator is just above the center of the teeth of the adjuster wheel. Bend the lower link to align the adjuster wheel actuator.

Thank you very much foryourreading.Please Click Here Then Get MoreInformation.

NOTE: If there is no response to click on the link above, please download the PDF document first and then clickonit.

11. Clean the hub bearings and lubricate them with wheel bearing grease. Install the hub bearings and seals in the hub. Install the brake drum and hub on the axle housing. See FIGURE 9. and FIGURE 10.

the hub so that the clearance of the brake shoes can be adjusted.

12. Adjust the hub bearings by tightening the nut to 205 N.m (150 lbf ft) while rotating the hub. Loosen the nut until the hub turns freely. The torque must be less than 27 N.m (20 lbf ft). Tighten the nut to 34 N.m (25 lbf ft) or until the first alignment position after 34 N.m (25 lbf ft). Bend the lock plate over the nut.

13. Adjust the clearance of the brake shoes. Put a brake adjustment tool or a screwdriver through the hole in the drum. Turn the adjuster wheel so that the teeth of the adjuster wheel nearest the back plate move upward. Turn the adjuster wheel until the hub will not turn. Pull the actuator away from the adjuster wheel and turn the adjuster wheel approximately 15 teeth in the opposite direction. The brakes will adjust to the correct clearance when they are applied while the lift truck is traveling in the REVERSE direction.

NOTE: If the brake shoes were not replaced, loosen the adjuster wheel approximately 25 teeth.

CAUTION

If there is too much clearance, the automatic adjusters will not operate. If the clearance is too small, the automatic adjuster cannot turn the adjuster wheel to increase the clearance and the adjuster wheel will not turn until the brake shoes wear. If the adjuster wheel does not move for a long operating period, the adjuster link can wear a spot on the adjuster wheel so that it will not turn correctly.

14. Put sealant on the flange of the axle shaft. Install the axle shaft and capscrews. Tighten the capscrews to 98 N.m (72 lbf ft).

Adjustments

1. Remove the air from the brake hydraulic system. See the procedure “Remove The Air From The Brake System”, under CHECKS AND ADJUSTMENTS.

2. Install the wheel on the hub. Tighten the wheel nuts 610 to 650 N.m (450 to 477 lbf ft).

NOTE: To prevent damage to the inner oil seal when installing the hub, the hub and drum assembly can be temporarily fastened to the wheel. Align the height of the axle housing with hub bearings. Put grease under the wheel and slide the wheel toward the axle housing. Install the outer bearing and nut. Remove the wheel from

3. Start the engine and tilt the mast backward to remove the blocks. Push on the brake pedal. The pedal must not touch the floor plate. Move the lift truck in REVERSE and push on the brake pedal to permit the adjuster mechanism to operate.

4. The service brakes must be adjusted before the parking brake can be adjusted. See FIGURE 12. and the fol-

lowing paragraphs in this section for the correct adjustment of the parking brake.

Parking Brake Installation (See FIGURE 11.)

If the lever assembly for the parking brake was removed from the cowl, use the following procedure for installation:

a.Make sure the parking brake lever is in the released position.

b.Adjust the cable assemblies so that the threads of the cable ends extend above their support to the dimension indicated at dimension “S” or “H” in FIGURE 12.

c.Turn the adjustment knob until the link (4) is adjusted to the bottom of the adjustment slot (13).

d. Install the round ends of the two brake cables (5 and 6) into the link (4) inside of the lever assembly. Tighten the jam nuts (14) on the threaded ends of the brake cables as shown in FIGURE 11.

e.Use the four capscrews, washers and nuts (12) and fasten the lever assembly to the inside of the cowl (17).

d.Before the cable assemblies are connected to the crank on the back plate of the service brake, pull on the crank to remove any clearance from the internal cable and cable guide inside of the brake.

Models S2.00–3.00 (S40–60XL). Check that the crank (8) is between 40 and 60 from vertical toward the rear of the lift truck.

Models H2.00–3.00 (H40–60XL). Check that the crank (8) is between vertical and 20 from vertical toward the rear of the lift truck.

If the crank is not in this position, remove the crank from the shaft, move it to the correct position on the shaft.

e.Connect the cable assemblies to the crank. Adjust the cables at the clevis to remove the looseness from the cables when the parking brake is released.

Adjust The Parking Brake For Lift Trucks

With 260 mm (10.25 in) Service Brakes

(See FIGURE 12.)

Make sure that the service brakes are adjusted and the operation of the automatic adjuster mechanism is correct. Test the operation of the parking brake. The lift truck with a capacity load must not move when the parking brake is applied on a 15% grade, [a slope that increases 1.5 metres in 10 metres (1.5 ft in 10 ft)].

1. Make sure the parking brake lever is in the released position.

2. Adjust the cable assemblies so that the threads of the cable ends have the dimension indicated at dimension “S” or “H” in FIGURE 12.

3. Turn the adjustment knob (3) until the link is adjusted to the bottom of the adjustment slot.

4. Before the cable assemblies are connected to the lever on the back plate of the service brake, operate the crank with your hand to remove any clearance in the internal cable and cable guide inside the brake.

Models S2.00–3.00 (S40–60XL). Check that the crank (7) is between 40 and 60 degrees from vertical toward the rear of the lift truck.

Models H2.00–3.00 (H40–60XL). Check that the crank (7) is between vertical and 20 degrees from vertical toward the rear of the lift truck.

If the crank is not in this position, remove the crank from the shaft, move it to the correct position on the shaft.

5. Connect the cable assemblies to the crank. Adjust the cables at the clevis (9) to remove the looseness from the cables when the parking brake is released.

6. Turn the adjustment knob (3) to raise the link and tighten the parking brake cables. Turn the adjustment knob until the parking brakes are fully applied when the lever (1) is used to apply the parking brake.

21 mm (0.80 in)

13 mm (0.51 in)

REMOVAL AND DISASSEMBLY OF THE 310 mm (12.20 in) SERVICE BRAKES

WARNING

Brake linings can contain dangerous fibers. Breathing the dust from these brake linings is a cancer or lung disease hazard. Do not create dust! Do not clean brake parts with compressed air or by brushing. Use vacuum equipment approved for brake dust or follow the cleaning procedure in this section. When the brake drums are removed, do not create dust.

Do not sand, grind, chisel, hammer or change linings in any way that will create dust. Any changes to brake linings must be done in a restricted area with special ventilation. Protective clothing and a respirator must be used.

1. Remove the capscrews that hold the axle shaft to the hub. Remove the axle shaft.

2. See the procedure “HOW TO PUT A LIFT TRUCK ON BLOCKS” in the MAINTENANCE section or the OPERATING MANUAL. Start the engine and tilt the mast fully backward. Put blocks under the mast. Tilt the

mast forward until the wheels just touch the floor. Stop the engine. Put blocks under the frame of the lift truck.

3. Bend the lock plate and remove the nut that holds the axle bearing. Remove the washer and the bearing cone.

4. Put grease on the floor so that the wheel assembly will slide easily from the axle tube. Pull the wheel assembly from the lift truck.

WARNING

When the brake shoes are removed do not create dust in the air. See the cleaning procedure in this section.

5. If the wheel assembly cannot be removed easily, use a small screwdriver to lift the adjuster actuator away from the adjuster wheel. Use a brake adjustment tool or a screwdriver to turn the adjuster wheel to loosen the brake shoes. Remove the hub and drum assembly. Do not damage the grease seal when removing the hub.

6. Make a note of the arrangement of the parts. See FIGURE 13. and FIGURE 14. Remove the return springs (2) (3) with spring pliers.

8.RETAINER

9.PIVOT

10.LINK

11.ACTUATOR,

12.ADJUSTER

13.PARKING

14.SPRING,

15.BRAKE

18.PARKING

19.PIVOT

7. Remove the retainers, springs and anchor pins that hold the brake shoes to the back plate.

8. Disengage the link (10) from the adjuster wheel actuator (11). Remove the link (10), washer (20), and the pivot plate (9). Remove the anchor guide (5).

9. Move the brake shoes away from each other to disengage the brake shoes from the wheel cylinder. Disconnect the parking brake lever (18) from the parking brake cable (13) as the brake assembly is removed from the back plate. The parking brake lever has a hook that engages the parking brake cable.

10. Make a note of the arrangement of parts and disassemble the brake assembly. Remove the parking brake link (16) and spring (17) if they are still engaged with brake shoes. The parking brake link and spring will often fall from the brake assembly when the brake assembly is removed from the back plate. The adjuster wheel (12) will also disengage from the brake shoes after the brake assembly is removed.

NOTE: The adjuster wheel for the left brake is not the same as the adjuster wheel for the right brake. The adjuster wheel for the right brake has left–hand threads.

11. Remove the spring (14) for the actuator, adjuster wheel (11). Remove the actuator, adjuster wheel (11) from the brake shoe. Loosen the nut and remove the anchor (22) and spacer (23) from the brake shoe.

12. Use a screwdriver or small prybar to move apart the ends of the retainer (19). Remove the spring washer (19) and pivot pin (19) to remove the parking brake lever (18) from the brake shoe (15).

13. Disconnect the brake line from the wheel cylinder (1). Remove the capscrews that hold the wheel cylinder to the back plate and remove the wheel cylinder.

15. See FIGURE 15. Remove the push rods, dust covers, pistons, cups, and spring from the wheel cylinder.

NOTE: The back plate is not normally removed from the axle housing for brake repairs. Eight special capscrews are used to fasten the back plate to the axle housing and the locking function of the capscrews is reduced if they are removed. These capscrews are tightened to 255 N.m (188 lbf ft).

Parking Brake

If the lever assembly for the parking brake must be removed from the cowl, use the following procedure (see FIGURE 19.):

a.Use blocks next to the wheels to make sure the lift truck can not move. Release the parking brake lever.

b.Remove the four capscrews that fasten the bracket for the parking brake to the cowl. Remove the bracket and brake lever assembly.

c.Loosen the jam nuts that fasten the threaded ends of the brake cables to the brake lever assembly.

d.Turn the adjuster knob counterclockwise until the brake cables are loosened. Disconnect the cables from the link.

e.The service brake assembly must be removed before the parking brake cable can be removed from the back plate of the service brake. A snap ring holds the sheath of the parking brake cable in the back plate of the service brake. Remove the snap ring and remove the parking brake cable from the back plate.

CLEANING

WARNING

DO NOT use an oil solvent to clean the master cylinder, wheel cylinder, or the brake linings. Use a solvent approved for cleaning of brake parts. Do not permit oil or grease in the brake fluid or on the brake linings. Oil and grease will cause damage and leaks in the seals of a brake system. The brakes will not operate correctly if oil, grease, or brake fluid is on the brake linings.

WARNING

Cleaning solvents can be flammable and toxic, and can cause skin irritation. When using cleaning solvents, always follow the safety instructions of the solvent manufacturer.

1. Do not release brake lining dust from the brake linings into the air when the brake drum is removed.

2. Use a solvent approved for cleaning of brake parts to wet the brake lining dust. Follow the instructions and cautions of the manufacturer for the use of the solvent. If a solvent spray is used, do not create brake lining dust with the spray.

3. When the brake lining dust is wet, clean the parts. Put any cloth or towels in a plastic bag or an airtight container while they are still wet. Put an “DANGEROUS FIBERS” warning label on the plastic bag or airtight container.

4. Any cleaning cloths that will be washed must be cleaned so that fibers are not released into the air.

CAUTION

Do not permit oil or grease on the brake linings. Use a brake cleaning fluid as necessary to clean linings that will not be replaced.

INSPECTION

1. Inspect the bore of the wheel cylinder for holes or scratches. Replace the wheel cylinder assembly if there is any damage.

2. Inspect the return springs for defects. Inspect the back plate for wear where the brake shoes touch the back plate. Remove any grooves or replace a worn or damaged back plate.

3. Inspect the brake shoes for cracks or damage. If the linings or shoes are worn or damaged, replace the brake shoes. Maximum wear is to within 1 mm (0.025 in) of contact with the rivets, or the metal shoe on bonded linings. Brake shoes must be replaced in complete sets. Inspect the brake drums for cracks or damage. Replace any damaged parts.

WARNING

The brake shoes on both wheels must be replaced if any shoe is damaged. The brake performance on both ends of an axle must be equal or the lift truck can be difficult to steer when the brakes are applied.

4. Inspect the brake drum for deep grooves or other damage.

NOTE: If grooves must be removed from the brake drums, do not grind more than 1.5 mm (0.060 in) from the internal diameter of the brake drum. The maximum limit of the internal diameter of the brake drum is 311.7 mm (12.27 in). If the internal diameter is larger than the limit, replace the brake drum.

5. The teeth of the adjuster wheel must not be worn. The adjuster wheel must turn freely. Check the adjuster links for damage.

6. Make sure the parking brake cables are in good condition.

7. Check the grease seals and the surfaces for the seals for wear or damage.

ASSEMBLY AND INSTALLATION OF THE 310 mm (12.20 in) SERVICE BRAKES

1. If the wheel cylinder was disassembled for repair, assemble the wheel cylinder. See FIGURE 15. Use only HYSTER APPROVED parts.

2. Install the wheel cylinder on the back plate and tighten the two capscrews. Connect the brake line to the wheel cylinder.

3. See FIGURE 14. Install the parking brake lever (18). Use the pivot pin, spring washer, and retainer (19) to fasten the parking brake lever to the brake shoe (15). Close the ends of the retainer to fasten the pivot pin in position.

4. Install the anchor (22) and the spacer (23) in the brake shoe (7). Install the actuator, adjuster wheel (11) in the brake shoe (7).