Link Product / Engine

Front loader bucket hydraulic system

Front loader hydraulic system control T

quick coupler hydraulic system

Foreword - Important notice regarding equipment servicing

L213

L216

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution including - without limitationlocal reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer any warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The information this manual - - date the date the the policy the manufacturer for continuous Some information could not updated due modifications a technical commercial changes the laws and regulations dif ferent

case refer your NEW HOLLAND CONSTRUCTION Sales and Service

Safety rules

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury .

Throughout this manual you will find the signal words DANGER, W ARNING, and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the machine.

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation that, not avoided, could result minor moderate injury .

F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation not could result machine property

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a other information the The word Note not intended address personal safety property

L213

L216

Safety rules - Personal safety

Carefully study these precautions, and those included the external attachment operators manual, and insist that they followed those working with and for you.

Thoroughly read and understand this manual and the attachment Operator ’ s Manual before operating this any other

Be sure all people and pets are clear the machine before Sound the three times before starting

Only the operator should the machine when Never allow anyone climb the machine while the machine equipped with Instructors this must only used for training Passengers must not allowed use the Instructors

Keep all shields

Never work around the machine any the attachments while wearing loose clothing that might catch moving

Observe the following precautions whenever lubricating the machine making

• Disengage all clutching levers

• Lower the the ground raise the attachment completely and engage the cylinder safety Completing these actions will prevent the attachment from lowering unexpectedly

• Engage the parking

• Shut f the engine and remove the key

• W ait for all machine movement stop before leaving the operators

Always keep the machine gear while travelling

The machine should always equipped with suf ficient front rear axle weight for safe operation.

Under some field more weight may required the front rear axle for adequate stability This especially important when operating hilly conditions / when using heavy attachments.

Always lower the shut f the set the parking engage the transmission remove the key and wait for all machine movement stop before leaving the operators

the attachment machine should become obstructed plugged; set the parking shut f the engine and remove the key , engage the transmission wait for all machine attachment motion come a before leaving the operators platform removing the obstruction plug. 1 Never disconnect make any adjustments the hydraulic system unless the machine and / the attachment lowered the ground the safety lock(s) the engaged position.

Use the flashing lights highly recommended when operating a public

When transporting a road highway , use accessory lights and devices for adequate warning the tors other this check local government V arious safety lights and devices are available from your NEW HOLLAND CONSTRUCTION dealer

Practice safety 365 days a year

Keep all your equipment safe operating

16. Keep all guards and safety devices place.

Always set the parking shut f the engine and remove the key , engage the transmission wait for all machine attachment motion come a stop, before leaving the operators platform service the machine and

Remember: A careful operator the best insurance against

Extreme care should taken keeping hands and clothing away from moving

Engine - Remove W ARNING

A void injury! Always the following before servicing the Disengage all drives.

Engage parking brake.

Lower all attachments the raise and engage all safety

Shut off engine.

Remove key from key

Switch off battery key , installed.

W ait for all machine movement stop.

Failure comply could result death serious injury

W ARNING

Fire hazard!

When handling diesel observe the following precautions: not smoke.

Never fill the tank when the engine running.

W ipe spilled fuel immediately .

Failure comply could result death serious injury .

W ARNING

Escaping fluid!

W0047A

W0099A

Hydraulic fluid diesel fuel leaking under pressure can penetrate the skin and cause infection other injury T o prevent personal injury: Relieve all pressure before disconnecting fluid lines performing work the hydraulic system. Before applying pressure, make sure all connections are tight and all components are good condition. Never use your hand check for suspected leaks under Use a piece cardboard wood for this injured leaking see your doctor immediately .

Failure comply could result death serious injury

W ARNING

Heavy objects!

W0178A

Lift and handle all heavy components using lifting equipment with adequate capacity . Always support units parts with suitable slings Make sure the work area clear all

Failure comply could result death serious injury .

Prior operation:

Disconnect the negative battery cable from the battery .

Prior operation: Remove the engine

Remove the rear access door See Engine inspection door - Remove

Drain the engine

Remove the radiator . See Radiator - Remove

Remove the oil cooler See Oil cooler / Heat exchanger - Remove (35.300)

W0398A

Loosen the hose clamps the intake tube both remove the intake tube (8) , cover turbocharger inlet avoid entry debris.

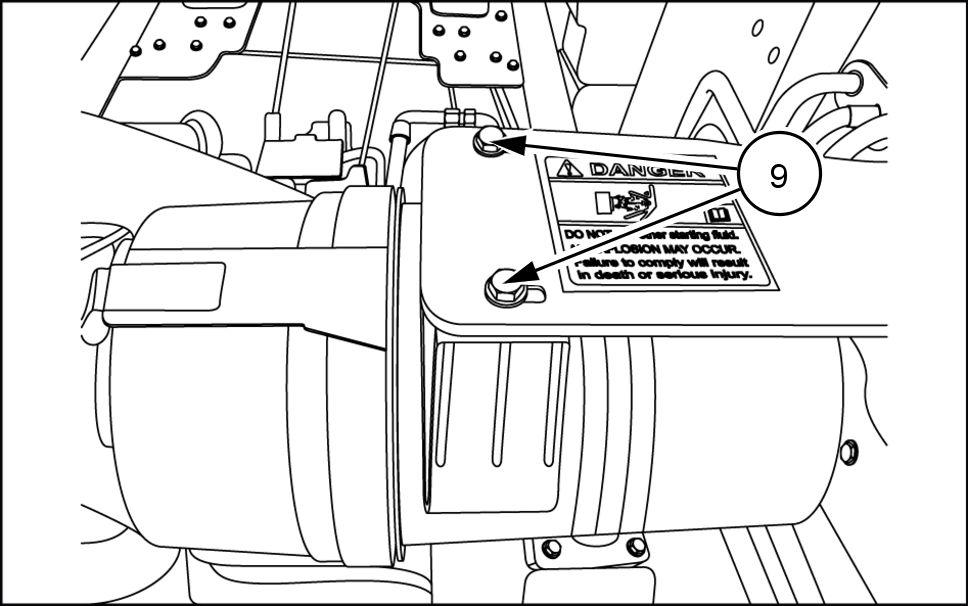

10. Remove air cleaner housing (9) .

1 Loosen hose clamp and remove upper radiator hose (10) from

17. Disconnect throttle cable removing the nut (A) and bolt (B) from the throttle body Remove cable support clamp (C) loosening the two hex head bolts (D)

931002039

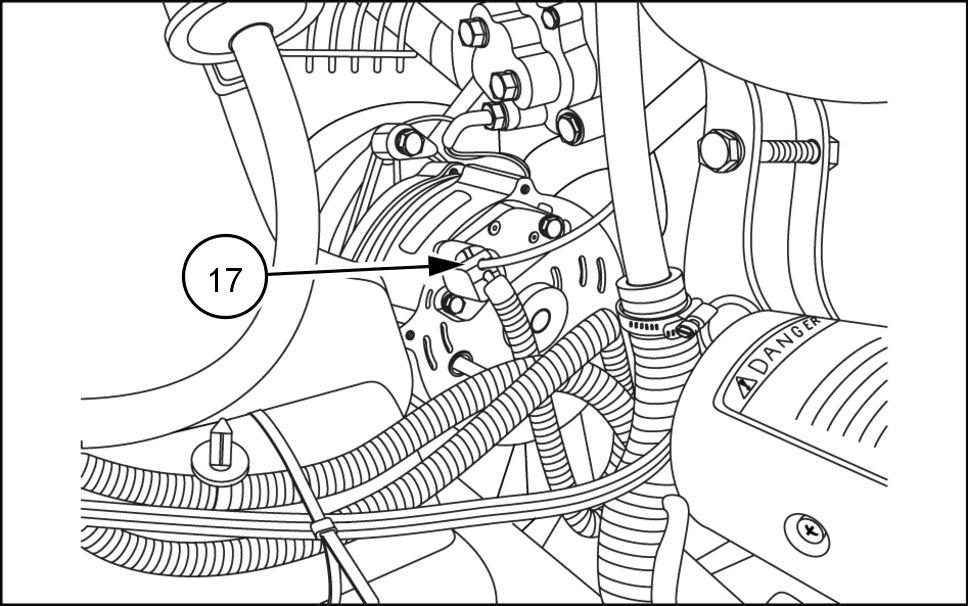

18. Disconnect wire harness (18) and clamps (19) from the top the flywheel

931002040

W ARNING

Fire hazard!

When handling diesel observe the ing precautions: not smoke.

Never fill the tank when the engine running.

W ipe spilled fuel immediately

Failure comply could result death serious injury .

W0099A

W ARNING

Escaping fluid!

Hydraulic fluid diesel fuel leaking under pressure can penetrate the skin and cause infection other injury . T o prevent personal injury: Relieve all pressure before necting fluid lines performing work the hydraulic system. Before applying pressure, make sure all connections are tight and all components are good condition. Never use your hand check for suspected leaks under Use a piece cardboard wood for this purpose. injured leaking fluid, see your doctor immediately . Failure comply could result death serious injury .

W0178A

Place a suitable container under lines prevent spillage and remove the fuel supply line (20) .

931002042

20. Remove the fuel return line (21) . 931002041

21. Disconnect the spade connector (E) from the back side the fuel shut f 931002043

Place a suitable container under the remote engine oil filter Label and disconnect oil filter lines (22)

NOTE: Cap the ends avoid entry 931002044

Disconnect the ground from the engine (23) the tery quick 931002045

Engine - Engine and crankcase

Place a suitable support beam across the skid steer T a suitable strap around the pump and cure the support beam, shown. 931002051

DANGER

Heavy parts!

Support designated component(s) with adequate lifting

Failure comply will result death serious injury . D0018A

Attach proper lifting straps the eye hooks (28) vided the engine. 931002052

Use a suitable hoist carefully lift the engine slightly rearward separate from the hydraulic Once lift the engine and remove from the rear chassis. 931002053

Engine - Engine and crankcase

Engine - Install DANGER

Heavy objects!

Lift and handle all heavy components using lifting equipment with adequate capacity . Always support units parts with suitable slings hooks. Make sure the work area clear all bystanders. Failure comply will result death serious injury

Attach proper lifting straps the eye hooks (1) vided the front right and rear left the engine.

Using a suitable hoist carefully lower engine into engine compartment the skid steer .

Slowly orient the hydraulic pump coupler the adapter the engine ensuring the attachment engine plate flywheel

Apply L OCTITE ® 243 the threads the bolts (2) . tach engine hydraulic pump mounting plate using the twelve mounting bolts (2) T ighten the mounting bolts (2) a torque - N·m ( - )

Engine - Engine and crankcase

10.

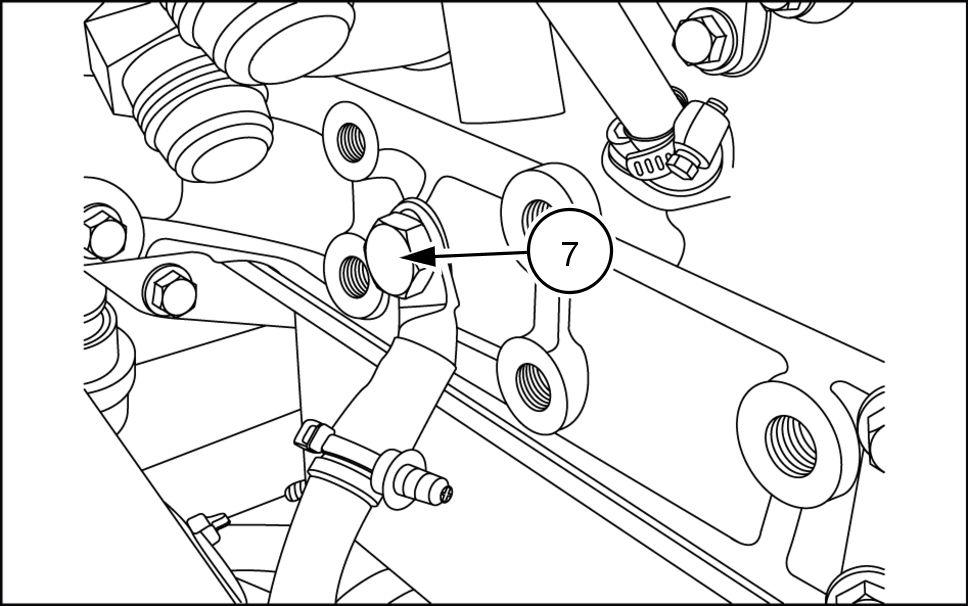

Connect ground from the quick battery disconnect the engine (7)

remote engine oil filter lines (8) .

13. Connect the fuel supply line .

14. Connect the wire harness (12) and clamps (13) the top the flywheel

Connect throttle cable installing the nut (A) and bolt (B) the throttle body Install cable support clamp (C) and tighten the two hex head bolts (D)

Connect oil pressure sender wire (14) and support (15)

Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL.NOWAITING

NOTE:

If there is no response to click on the link above, please download the PDF document first and then clickonit.

Engine - Engine and crankcase

25. Install muf fler inlet pipe mounting flange bocharger and secure with the five mounting bolts (25) T ighten mounting bolts (25) a torqueN·m ( - )

931002028

26. Install the two retaining bolts (26) the muf fler

931002029

Place fan hub and secure with the four ing bolts (A) T ighten the four retaining bolts (A) a torque - ( - )

931002027

Install oil cooler See Oil cooler / Heat exchangerInstall (35.300)

Install radiator See Radiator - Install

Add engine

Fill hydraulic oil reservoir See Oil reservoir - Filling (35.300)

Fill See Radiator - Filling

Install Install rear access door See

Throttle linkage - Adjust

L213 TIER 3 [NEM4591 - ]

W ARNING

A void injury!

Always engage the parking brake and switch off the engine before working the machine. Failure comply could result death serious injury .

Before adjust the please inspect all linkage components for wear and Replace components essary

Start the Press and hold the auxiliary ride button (1) for two Release the then press the auxiliary override button (1) toggle next display Continue press and release the auxiliary override button (1) until RPM

Adjust the clevis (1) the end the foot that within the first five degrees handle the pedal starts move. the pedal does not move with the throttle turn the clevis shorten the

Loosen the jam nut (1) , and turn the stop bolt (2) several turns

NOTE: Make sure the plunger through the L - bracket when the jam nut The plunger must move freely through the L - not pinch the L - bracket between the plunger and the washer

Place the engine throttle low idle position and record the Stop the For specifications gine RPM, please see Engine - General specification

T urn the plunger thumb screw (1)

Start the engine and check the Repeat steps 4 and 5 until achieved the desired RPM.

Start the engine and move the hand throttle (1) the full idle position and record the Stop the For specifications engine please see Engine - General specification

Adjust the plunger thumb screw necessary

Start the engine and check the Repeat steps 7 and 8 until achieved the desired

T urn the stop bolt (1) out until contacts the T ighten the jam nut (2)