CULTUREservicetechnicians,instrictaccordancewiththeinstructionsgivenandusinganyspecifictoolsnecessary. Anyoneperformingtheoperationsdescribedhereinwithoutstrictlyfollowingtheinstructionsispersonallyresponsible

SafetyrulesSAFETYREGULATIONS

TOPREVENTACCIDENTS

Accidentsmayoccurwithalltypesofvehicle,regardlessofhowwellitwasdesignedandbuilt.

GENERAL

•

• Itisadvisedtowearapprovedsafetyclothing,e.g:non--slipfootwear,gloves,safetygoggles,helmets,etc.

• Donotcarryoutrepairoperationswithsomeonesittinginthedriver’sseat,unlessthepersonisatrainedtechnician

• Operatethevehicleandusetheimplementsexclusivelyfromthedriver’sseat.

•

•

•

• Servicestepsandplatformsusedinaworkshoporinthefieldshouldbebuiltincompliancewiththesafetyrulesin

• Disconnectthebatteriesandlabelallcontrolstoindicatethatthevehicleisbeingserviced.Blockthemachineand

• Donotcheckorfillfueltanks,accumulatorbatteries,norusestartingliquidwhensmokingornearnakedflames,

•

• arecompletedinordertoavoidpossiblesparkscausedbytheaccumulationofstaticelectricity.

• aresecuredinpositionbeforeapplyingtraction.

• Transportvehiclesthatcannotbedrivenusingatraileroralow--loadingplatformtrolley,ifavailable.

• position.

• efficientgroundinsulationtoavoidelectricalshockhazards.

•

•

•

• Neverusegasoline,dieseloilorotherinflammableliquidsascleaningagents.Usenon-flammablenon-toxicpro-

•

• Limittheairpressuretoamaximumof ( 8456801422/03/2013

• • •

• Allmovementsmustbecarriedoutcarefullywhenworkingunder,onornearthevehicleandwearprotectiveequip-

• Whencarryingoutcheckswiththeenginerunning,requesttheassistanceofanoperatorinthedriver’sseat.The operatormustmaintainvisualcontactwiththeservicetechnicianatalltimes.

• lockthevehicleinpositionandmovetoaflatareaassoonasissafelypossible.

•

•

WELDINGOPERATIONS

•

•

Beforestartingthevehicleorimplements,makesurethatthedriver’sseatislockedinpositionandalwayscheck

•

• Removetheelectroniccontrolunitslocatedonthetractorifweldingistobecarriedoutnearthesecontrolunits.

• inprogress.

•

STARTUP

ENGINE

• offuelspillage

• Nevercheckoradjustfanbelttensionwhentheengineisrunning.

GENERALSPECIFICATIONS

4Cylinders

Timing overheadvalvesoperatedbytappets,rodsandrockerarms viathecamshaftlocatedintheengineblock;thecamshaftis

Engine-Remove (1) asindicatedin Hood-Remove (90.100)

WLAPL4S10C101A 1 assembly (1) fromthesupport.

WLAPL4S10C103A 2

andremovethefront wheelmudguards (2) (ifapplicable)Dothisonboth

WLAPL4S10C104A 3

anddetachtheengine

.Carryoutthesameoperationfortheright−handsidepaneltoo.Removethe WLAPL4S10C105A 4

8456801422/03/2013 10.1[10.001]/5

WLAPL4S10C114AA

(1) thepropellershaftandremovetheshafttogetherwith shimontheback.

WLAPL4S10C115AA returnpipe,drainandcollecttheenginecoolant.

WLAPL4S10C116A

(1) box--transmissioncasing. WLAPL4S10C117A

18.Loosenthedevicejoiningtheoutletonthefilter DPF , freetheoutlettubefromanybracketsfasteningitto

WLAPL4S10C118A

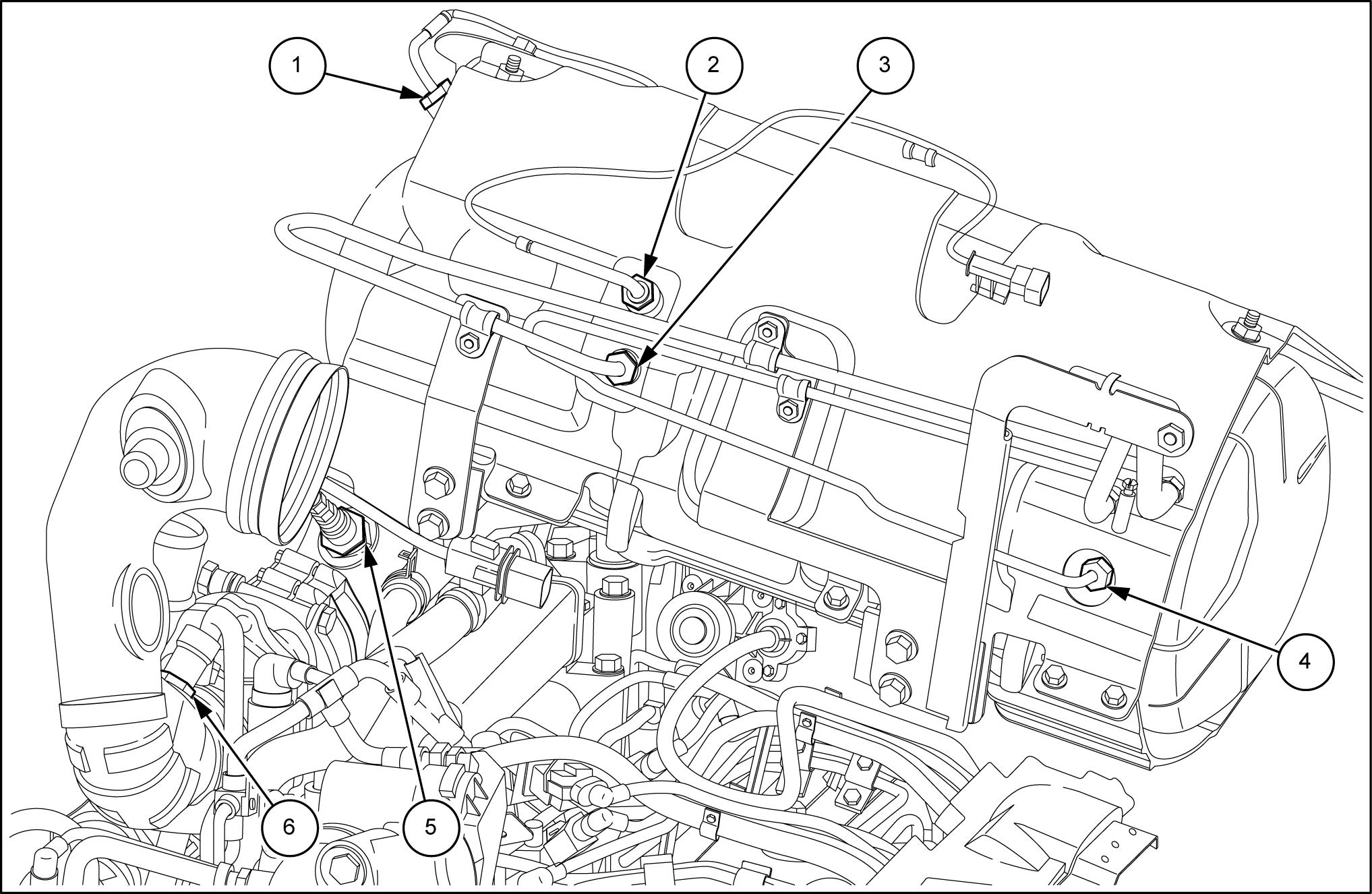

(1) andextractthepipe fromtheturbinetotheradiator intercooler(2) outthesameoperationforthepipefromtheradiator intercooler totheengine (3) .

WLAPL4S10C119A

(2) fasteningtheairintakepipe totheturbine,thenfreetheaircleaner (4) together withthesupportbracket (3) Disconnecttheoilvaporpipe (1) oftheengineatthelevelofthefuelpump;removeit

WLAPL4S10C120A

(1) from

WLAPL4S10C121A

ATTENTION: Thefilteroutletunion DPF(1) atitsterminal (2)

(4)

Asmallmisalignmentoftheaxisofthedecouplerwithrespecttotheaxisoftheturbineoutlet (3) wouldproduce

22.Disconnectallthefiltersensors,loosentheclamp

lambda probeand heatguardsbyundoingthefourscrews (5) fixingit

WLAPL4S10C122A

ATTENTION: neaththe DPF

Thetoppart (1) (2)

screws (3) totherightoftheengine(thesescrewsworkon averticalslotthatallowsthesupport (2) totakeonvarious positionsinheight).Beforedisassembly,takesomereferencesonthepositionoftheunitontheengine,sothat duringreassemblyitispossibletorestoreittotheexact

WLAPL4S10C123A

screwsfasteningthesupport (4) support (1) (5) unscrewthetwoupper screwsforthecenteringbushingsandthatsecure theleftbrackettothesupport (1) Asregardsremovingthesupport (1) and (2) there arenospecialinstructionstofollow.

WLAPL4S10C124A (1) and (2) andthe pipedeliveringoiltothespoolvalve (3) Removethefastenersofthebracket (4) gine

WLAPL4S10C125A

thegearboxspoolvalve (2)

thegearboxspoolvalvesupplypipe (1) .

port (3)

WLAPL4S10C126A

mission (2)

(1) onthe

attheheightofthecabsupport.

Disconnectthedeliverylinetothelift (3) againatthe heightofthepipe (2)

Detachthedeliverypipes (5) totheliftandtothe powersteeringanti-cavitationtank (6) (4) (6) ,

WLAPL4S10C127A (1) (3) and,ifapplicable,frontbrakingassembly (4) .

dothesamethingalsoforthepipesdirectedtothe steeringsystemcylinder (2)

WLAPL4S10C128A

(1)

(3)

(4) andupper rubbersleevesjoiningradiator-engine.

WLAPL4S10C134A

(1) onthe startermotor (2) batterycut-offswitch,thecablejoiningittothealterthevariousclamps.

(3) thenremovetheground

WLAPL4S10C135A

(1) ofthe FTP detachalltheconnections (2) then,aftercuttingtheclamps,collectthecableonthe frontnearthecontrolunit (5)

(3) disconnecttheconnec(4) themaxifuseboxandfromthevariousswitchesand fromtheclamps,moveitontothebackattheheight

WLAPL4S10C137A 36.Ontheleft-handsidedisconnecttheconnectorofthe powercableofthecab (1) ,freeitfromtheclamps

(2) (3) thatjoinsthelattertothemechanicalprimingpump

WLAPL4S10C139A

afixedstand (2) undertheclutchhousing (1) near

WLAPL4S10C129A

39.Positionthemovabletoolfordismantlingtractors 380000569(2) withthebracketandadapterplate undertheengineandplaceawoodenblock (1) betweenthepointsofcontactbetweenthetooland

Wedgetheaxletopreventswinging.

WLAPL4S10C140A (1) betweentheengine

WLAPL4S10C130A (1) fromthetransmissionwith thetool 380000569(2) .

WLAPL4S10C131AA (1) undertheballastsupport andsecurethefrontwheelswithwoodenblocks (2)

WLAPL4S10C132AA

8456801422/03/2013

10.1[10.001]/13

followingthisprocedure:

(1)

andtherelatedcompressor

2 polyv(2) beltisperfectlyhoused

(2)

keepingthetool 380200011 ontotheclutchofthecompressorattheinnermost

andtightenthethreescrewstakingcaretospreada filmofthreadlockontheendssotheydonotcome

8.-Applytherequiredtorquesettings(seeenginesection) theplatformsupport. incorrectoperationswiththehoistsoasnottolet ingboltsandthenecessaryadjusterspacersforthe monobloc/sumpsupport.

380000569

undertheengineandplaceawooden blockinbetweenthepointofcontactbetweenthe

8456801422/03/2013 10.1[10.001]/17

Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL.NOWAITING

NOTE:

If there is no response to click on the link above, please download the PDF document first and then clickonit.

16.-Apply L OCTITE

13.-Removethefixedstandpreviouslypositionedunder thesupportofthegrooveofthedriveofthefrontaxle

gineandclutchcasingmatingsurfaces.

presenceoftwoorthreeworkerstousethemovable toolfordismantlingtractors 380000569 tomovethe engine/frontaxleassemblyclosetothegearbox.

calconnectionstopreventcrushingbetweenthetwo bodies.Duringthisphase,itismoreovernecessary ingfantohelpthecouplingbetweenthesleeveand 20.-Securebothassembliesbytighteningallthebolts lockingtheenginetothegearbox.

viouslyfittedundertheclutchcasingandrecoverthe movabletoolfordismantlingtractors 380000569 . imentfilter.

23.-Ontheleft-handside,connectthecabpowercable connector,takeitontothemaxifuseboxandlockit

24.-Returnthemainenginecablebackintoposition, connecttheconnectorstothesensorsandswitches 25.-Layoutthe

26.-Fitthestartermotorbackon,thenconnectthetwo groundwiresontheengineandbatterysystem.

cut-offswitchandalternator.Fittheguardbackonto 28.-Refitthetwodeliveryandreturnlinestothecab heaterandthepipeinsertedonthelowersleeve steeringoildrainpipeandthesupplypipetothe onthetransmissionoilfilterassemblyandfixthe

twosuctionlinesfromthefiltertothepump.

ceedasfollows:

DPF

(1) ontherightone (2)

(5) securingittotheengine (1) and (2) totheenginewiththefourscrewsinposition (3) spectingthereferencemarksmadewhendisman-

(5) tothesupport (1) withthe

(4) totheenginewiththetwo

port (5) andwiththetwoupperscrewstothesupport (1)

DPF

Observation:

Ifafterrefittingthe DPF

entireunitintopositionandfasteningthefourfixing screwsoftheassemblytothecradle.

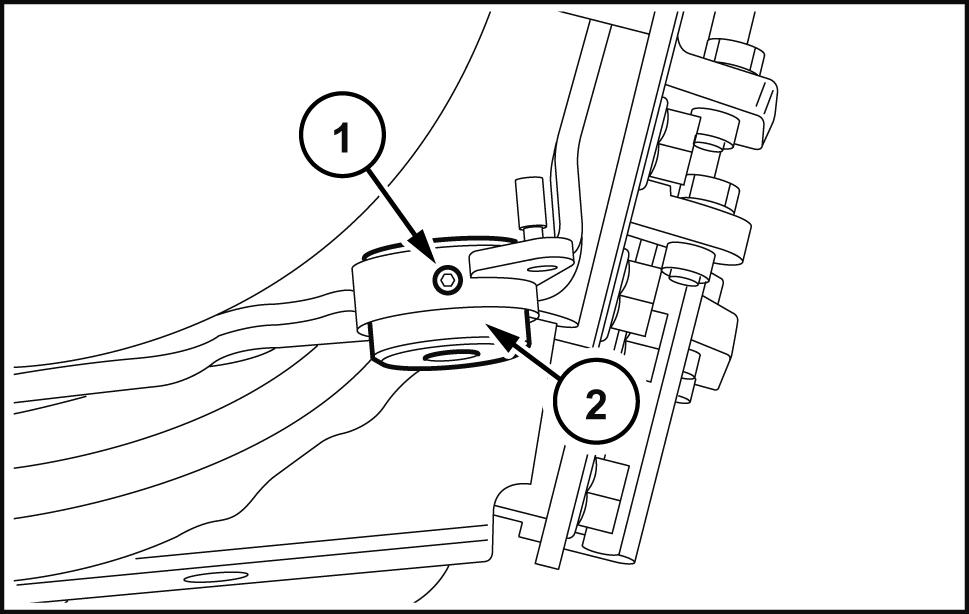

tertothecradletherearetwothreadedbushings (2) heldinpositionbyagrubscrew (1)

thebushinginoroutbytheamountnecessaryto

ontheinletpipeontheradiator.Refitthesleeves intercooler and

38.-Fittheexhaustpipebackonandtightentherelevant retainingclamps. adjusttheshaftendfloat.

tankinpositionandsecureittighteningtherelevant returnthewheelintopositionandmountthefixing

45.-Reconnecttheair-conditioningpipesandthesen-

47.-Rechargetheair-conditioningsystemwithrefrigerantusingthespecificcontrolunit 380000315 .

49.-Refitthefrontwheelmudguards,ifapplicable,and pin. Hood-Install (90.100) 8456801422/03/2013 10.1[10.001]/20

andthatofthealternatorpivot (1)

(2) thenloosen

sioner (4)

WLAPL4S55C301A 1

(1) , (2) and (3) , 1

Thedrivebeltistensionedasfollows:

(5) , 1

Componentsoffigure 2 :

.Alternatorpulley.

308.6mm ( 12.1496in 1.5mm ( 0.0591in fixingholes (10) andtheonewiththeadjustablefixingholes (11)

46mm ( 1.8110in 1mm ( 0.0394in

134mm ( 5.2756in 1mm ( 0.0394in

)Distancebetweenthecentreoftheturbineorthecentreoftheunionof thedecoupler/turbineandtheadjustablefilterfixingbushings (12)

)Distancebetweenthecentreoftheturbineorthecentreoftheunion/ turbineandthebandsupportingsurface (4) withsetfixingholesonthefiltersupport.

5.InitialpartoftheDPFfilter,connectedwiththesleeve. (15) totheturbine. (14)

(6) \endpart (7) (6) \initialpart (5) (3)

keeponetohandandtoreassembleitbeforestartingtodisassemblethefiltersothatthedecouplerundergoes

21.Exhaustgastemperaturesensortotheintakeofthemiddlepartofthefilter.

DieselParticulateFilters(DPF)-Dynamicdescriptionmanual regenerationofthedieselparticulatefilter(DPF)

Adieselparticulatefilter (DPF) isadevicedesignedtoremovepollutingdieselengineparticulatefromexhaustgas;

Theregenerationprocessissignaledtotheoperatoronthecentralmonitorofthedashboardandwithanacoustic signal.Theindicationisnecessaryforthepurposesofsafetytowarntheoperatoraboutthehighexhausttemperature

Theautomaticregenerationshallnotaffectengineperformance.Duringtheprocedure,theoperatorcancontinue

Undercertainoperatingconditionsautomaticregenerationmightnotbecompleted(enginecontinuouslystoppingand dashboardandthesamesymbolappearsevery5minutesonthecentralmonitorwiththeword “ON” combinedwithasinglebeep.Onconcludingtheoperationthesymbolappearswiththeword “OFF” . regeneration.

NOTICE: Ifthefilterisnotregeneratedwhenrequired,whethermanuallyorbyforcing,thefunctionalityofthefilteris

DPFtoberegenerated

Whenthefollowingwarningsappearonthedashboarditisnecessarytoproceedasfollows:

Startofautomaticregenerationor,withthecontrol,start offorcedregeneration

Imagelegend:

WLAPL4S55C111A 1

DPFtoberegenerated Lowseverity

Automaticregenerationinhibited,onlystartofforcedregenerationwithcontrol

DCAPLT5NE058S3A 2