2023-24 ANNUAL REVIEW

2023-24 ANNUAL REVIEW

TeamMADE, a home design and construction crew with student members from UCI and Orange Coast College, placed second overall with their luminOCity home in the Orange County Sustainability Decathlon, which was held last fall in Costa Mesa, California.

TeamMADE (Modular Affordable Dwellings for the Environment) was one of 14 teams competing. Many participants were California-based, but other teams included members from China and the United Kingdom. The group had its name show up in several of the award categories, including first place in engineering & construction; first place in market potential; second place in sustainability & resilience; third place in architecture & interior design; third place in communications & marketing; and third place in innovation.

For TeamMADE’s first-place showing in engineering & construction, the O.C. Sustainability Decathlon jury recognized the 750 square-foot, two-bedroom, two-bathroom home’s modular design as one eligible to be built as an accessory dwelling unit throughout California.

LuminOCity was donated to Homeless Intervention Services of Orange County, which has been helping at-risk youth between 18 to 24 years old rebuild their lives. The ADU enables the center to raise their capacity from nine to 17 beds.

Good engineering is almost by definition creative. We pursue and envision solutions to some of the most complex and urgent problems we are facing around sustainability, health and societal impacts of technology. But how does this somewhat illusive concept of “creativity” get infused into the engineering curriculum? This past year, I have spent time thinking about this very question.

Don’t get me wrong. I don’t need our students to become great artists. But I do want them to have the creative confidence of standing in front of a blank canvas and imagining something new and bold – and to will new solutions and designs into existence. To that end, we have rolled out a few experiments in the Samueli School of Engineering, trying to capture this notion of “creative confidence.” One inspirational and fun example of this is the E-SONIC competition that we held jointly with the UCI Claire Trevor School of the Arts and the Pacific Symphony during the 23-24 academic year. E-SONIC stands for Engineering-Symphonic Orchestra New Instrument Competition, and the original idea was to have student teams design and showcase never-beforeseen instruments. We had really no idea what to expect from this program, but I am happy to report that the result exceeded all expectations.

But creative confidence can mean so much more than forays into the arts. It can mean the ability to envision commercial opportunities for our research inventions. Or, it can mean daring to take the leap, as a faculty member, from the familiar settings of an academic lab into the unstructured and unchartered startup

world. We are seeing an increasing number of faculty, researchers, and students take this leap, and the theme behind this Annual Review is “Lab to Market.”

The ability to go from lab to market in a major and structurally well-defined way was identified as one of the key goals in our recent strategic plan. The reason why this played such a prominent role in the plan is that we want to make sure that what happens in our labs and our classrooms is relevant and has impact. This means that our innovations cannot stay hidden and bottled up, but are given opportunities to transition from campus and out into the world. And only through a strong, vibrant and structurally robust lab to market culture can we make that transition happen at scale. This Annual Review is in part a report of the strides we have made in this regard, and in part a celebration of the creative confidence that is required to take this leap.

UCI Samueli School’s Chem-E-Car team placed first at the 2024 Western Regional Competition, beating all other university teams across California and Arizona. The student-designed cars are powered by a chemical energy source and the competition required the cars to run a specific distance that was announced only an hour before the contest. The champion UCI car is named Acid Ron and is powered by a lead acid battery the students created. The contest required the cars to stop at the 22.86 meter mark. Acid Ron stopped the closest at 21.95 meters.

“The car was able to stop so precisely by employing a reaction between sodium thiosulfate and hydrochloric acid,” said Chem-E-Car Lab Lead Lorena Martinez. “We calculated the necessary concentrations of the chemicals to run for the required length and stop at the desired distance.”

Co-Project Manager Zaid Alsharif said four teams of engineering students spent a year of endless hours in the lab to build Acid Ron. They did hundreds of tests throughout the year and were working until 2 a.m. the two nights before the competition. Everything about the car is built from scratch, including the chemical reaction and power source.

The annual American Institute of Chemical Engineers’ Chem-E-Car competition has the potential to contribute new ideas for sustainable technologies and gain sponsorship from companies to help fund the teams.

The UCI engineering team will compete in the international competition in October in San Diego.

The UCI Samueli School’s CanSat team won second place in the United States and fourth place worldwide in the 2024 CanSat Student Competition in June in Staunton, Virginia.

The annual competition, hosted by the American Astronautical Society in conjunction with the U.S. Naval Research Laboratory, is a unique opportunity for university students to develop, build and launch a soda can-sized satellite designed to meet specific mission objectives.

impressed with our design because everything was integrated into one mechanic.”

They also borrowed an idea from SpaceX and used pink grid fins around the base to prevent wobbling on the descent. “This helped us achieve rotational control and allowed a more steady descent,” said Liu. “We’re judged not on the ascent, but on going down. Once the CanSat ejects from the rocket, it goes through the whole activation sequence as it descends. That’s when it collects information.”

(below) The Anteater engineering CanSat team took fourth place worldwide and second in the U.S. at the international student competition.

This year’s challenge required the students to design and integrate electrical, mechanical and software components to simulate the landing sequence of a planetary probe. The CanSats were launched to an altitude of approximately one kilometer, where they needed to collect data, send radio-frequency telemetry, and activate heat shields and parachutes to ensure a controlled descent and intact landing. Out of the 140 competing teams, only 32 were invited to the launch event.

Ten members of the team traveled to Virginia for the competition. Team lead Ryan Liu, a fifth-year electrical engineering major, said they had a novel design. “One of the cool things about our CanSat was that the mechanical team developed the actual nose cone of the rocket to act as an aero-braking heat shield. The other teams were

Kaylee Kim, a second-year mechanical engineering major who served as a software engineer, will lead the team next year. She said they learned a lot from this competition and she gained some important takeaways. “Everything was working independently before we left and got on the plane to Virginia. So, we were very chill thinking that everything would be fine.”

However, the day before the competition, when they put it all together and conducted final testing, it did not work. There were problems with the flight software and flow – certain triggers were not activating the sequence of mechanisms. “Because we had been testing each subsystem independently, we kind of assumed it would work altogether, but it turned out it was too much for our power supply,” Kim explained.

They ended up pulling an all-nighter the day before launch and had to make some hard decisions. “One of the big issues with the power supply was the camera, so we decided to get rid of it, as it was only a small percentage of the scoring,” said Liu.

This proved to be the right decision as the UCI CanSat performed so well on launch day, even though the team was operating on just a few hours of sleep.

“As a multidisciplinary effort, it takes a dedicated group of students to successfully design and integrate the mechanical, electrical and software components of the project in only nine months,” said Roger Rangel, professor emeritus and the team’s faculty adviser. He noted that this is the highest rank the UCI team has achieved in seven years of participating in the international contest. “This is a greatly deserved accomplishment as this year’s team was made up of students deeply committed to success.”

Growing up in Torrance, Calif., Christopher Arauzo spent his childhood surrounded by immigrant families like his own, where he learned the value of hard work.

Arauzo decided to pursue mechanical engineering at UCI after a high school internship at Marathon Petroleum Corp. As he watched his mentor try to repair a heat exchanger, he realized that almost all major systems require some form of thermal management.

“Pairing that with my love for math

and problem-solving, I was led to mechanical engineering,” Arauzo says. “With every experience I’ve gained, my interest has become more concentrated in thermal and fluid systems.”

Arauzo has been given the prestigious Matthew Isakowitz Fellowship for 2024. Only 31 university students were chosen in the nation for this program, which seeks to inspire the next generation of commercial spaceflight leaders. As part of the fellowship, Arauzo will receive a paid aerothermal engineering internship with ABL Space Systems, a one-onone mentorship with a space industry leader and the opportunity to attend a summit with top industry leaders.

At the Samueli School, he was the team lead for Spacecraft Thermal Management Systems, a studentled undergraduate research project. He also became the chief mechanical and aerospace engineer for STMS. The endeavor allowed Arauzo to learn and grow exponentially, and it also helped him secure a position at Boeing as an extreme environment materials intern.

In addition, he belongs to the UCI chapter of MAES: Latinos in Science and Engineering, where he has mentored underclassmen and written

fundraising proposals for the Office of Outreach, Access and Inclusion and other campus entities.

He plans to pursue his master’s degree in mechanical engineering at UCI, after which he hopes to work in the commercial space industry where he looks forward to solving thermal challenges. “There are so many technological challenges to explore when designing spacecraft,” he said. “Whether it’s rockets or satellites, they won’t function properly without the right materials or thermal management systems!”

What was your favorite class at UCI?

My favorite class was Fluid Dynamics II. Xian Shi [assistant professor of mechanical and aerospace engineering] did an excellent job structuring the course, during which I decided I wanted to work in fluids in addition to thermal.

What advice would you give to a student starting their journey at UCI?

My advice to any new student would be to get involved with research or projects as soon as you can. Join an organization you care about to grow your support system and give back to your community. I would also add that you should not be afraid to be ambitious. Practice overcoming your anxiety about speaking to new people and speak up for yourself. You are capable! Also, make sure you say yes to things that will bring you one step closer to your goals.

“Chris is an outstanding critical thinker who can synthesize complex information and communicate it effectively to others. He is also empathetic, courteous and works well with his colleagues. One could not ask for a better student! I have no doubt as to his continued growth and success in his field and positive impact on his community,” said Stephen Bach, engineering lecturer.

When Adam Wu arrived at UCI as a first-year computer engineering major, he knew how to write computer code but didn’t have any experience with hardware. He wanted to gain hands-on project skills, so he turned to one of the Samueli School’s many student organizations for opportunities.

He discovered UCI’s student chapter of the Institute of Electrical and Electronics Engineers (IEEE), which offers members the chance to participate in guided projects. Wu was one of more than 200 students who applied to the Open Project Space, a studentled embedded electronics course for beginners.

The yearlong program accepted 100 students and is led by OPS

alumni who are now upper division students. Rachel Villamor, a senior in computer engineering, participated in the program during the pandemic.

“As someone who didn’t have a lot of personal project experience, I got a lot out of it,” she said. “It built the foundation and confidence for me to apply to internships.”

Benjamen Bielecki, a computer science and engineering senior and lead instructor, said a big appeal of the program for students is access to equipment they wouldn’t have otherwise.

“We accept first- and second-year students and transfer students, those who haven’t had the time or opportunities to develop some of these hard skills, like soldering and PCB design and building hands-on projects,” said Bielecki. “These aren’t things that are covered until upper division courses. The challenge is that at that point, you want to have acquired an internship of some kind and companies are looking for those skills.”

Third-year UCI mechanical engineering student Ozzy Sanchez-Aldana dreams of working in NASA’s space exploration division. A proud Mexican American, the 21-yearold is the first in his family to pursue a bachelor’s degree.

Sanchez-Aldana developed an interest in robotics while watching “Star Wars” as a child. Curious about the character C-3PO, he made it a point to see more movies with humanoid machines and animatronics. Immersing himself in the world of robotics, he devoured behind-the-scenes documentaries about such films, learning about the technical workarounds of the ’80s and ’90s.

“It was just awe-inspiring to me,” he said, “to see engineers use inanimate parts to create a living, albeit mechanical, being.”

In 2017, as a sophomore in high school, Sanchez-Aldana got his first taste of STEM research interning at Portland State University. While he had wanted to gain experience in the field of engineering, Sanchez-Aldana was placed in PSU’s computer science program, where he learned programming languages like Python/C. It confirmed his passion for engineering; he wanted to do something hands-on rather than just sort out raw data.

“What makes engineering enticing to me,” explained SanchezAldana, “is the ability to appreciate my work and creativity in the palm of my hand. It’s a little hard to do that when I’m kind of just sitting at a desk and programming.”

The 2023-24 recipient of a scholarship from the Eric Clayton Pedersen Endowed Memorial Fund, Sanchez-Aldana says that the award helps him to focus on his studies, save for the future and prepare for his transition from student to working professional.

Sanchez-Aldana intends to pursue a career with NASA’s space colonization projects and Artemis missions to design autonomous devices that collect samples and explore dangerous terrain.

"Engineers are hope-givers,” said Joyce Chen, the engineering school’s 2024 student commencement speaker. “We have to believe what we can make tomorrow is better than what exists today.”

The biomedical engineering senior comes from a family of engineers and Anteaters. She’s been zotting at UCI ball games since she was 8 years old. Her parents, brother and sister-in-law are all Anteaters and the men in her family – grandpa, father, uncles and brother – have the spectrum of engineering covered.

“I used to think engineering was for boys,” she said. She had no interest until her dad started working on medical devices. That’s when she saw the inspiring connection between innovation and helping people.

While airshows hooked her father and brother to become engineers, for Joyce, it was trips to the orthodontist. She was fascinated with braces and asked the dentist endless questions on how they worked. That’s when she set her sights on biomedical engineering, and UCI’s program impressed her.

“My favorite part of engineering is making things,” she said. As a girl, she loved making fun items like bracelets and jewelry boxes. Now at UCI, she’s creating a medical device that could revolutionize an area of women’s health care: the pelvic exam. At the startup company Feminora, she helped design the award-winning OneSpec, a new take on the vaginal speculum – which hasn’t been reinvented in over a century.

“Not only did she take on a design that still required significant engineering and innovation to make it work,” said her adviser Christine King, biomedical engineering associate professor of teaching, “she was able to build it physically through computer-aided design as we grew our team.”

Their speculum promises to be easier for doctors to use and more comfortable for the patient, which means women will be more willing to get preventative care. Joyce said Feminora is the coolest thing she’s been a part of at UCI and women love the concept. “Every single woman that I’ve told we’re reinventing the speculum says, ‘Oh, thank goodness! It’s about time!’”

When she’s not designing medical devices, Joyce likes to lose herself in a world she’s invented in her mind. “I love writing because it’s an escape from reality where your imagination is really the limit,” she said. Joyce has been writing stories and poetry since fifth grade.

This past Valentine’s Day, Barnes & Noble published her first romance mystery "Champagne Problems." Inspired by a Taylor Swift song title, the novel is a wholesome love story between a boy and girl from rival towns whose residents are forbidden to interact with each other. She describes it as “a Hallmark movie in a book.”

As for biomedical engineering, she loves the challenge and potential benefits to humanity that creating medical devices brings. She says the impression that engineering is hard is true. “That’s because you’re solving problems that have never been solved before,” Joyce said. “We have to believe that we can make the impossible possible.”

(top) Student Commencement speaker Joyce Chen enjoys UCI’s Aldrich Park.

(bottom) The Chen family zots in front of Engineering Hall (from left): Lisa, Joseph, Joyce, Diane and Harvey.

The Creophone, Wube Tubes and Saxatars sound like fictional things in a Dr. Seuss book, but actually they were some of the cool creations by engineering students who had to meet a challenge: invent a new musical instrument for a UCI contest. Their inspirations included harnessing brainwaves, capturing the wind and upcycling instrument parts. That was the ingenious imaginative spirit on display at the first EngineeringSymphonic Orchestra New Instrument Competition (E-SONIC) in May.

“This new instrument competition is all about having the courage to go after new and wild ideas,” said Samueli School of Engineering Dean Magnus Egerstedt who together with Pacific Symphony President John Forsythe conceived of the contest over lunch. “I want our students to have creative confidence –the confidence to embrace a new problem or stand in front of an empty scoresheet and imagine something that didn’t exist before.”

The Pacific Symphony welcomes these inventions as there hasn’t been a new instrument added to the orchestra in a century. “The idea that there could be a new color or texture introduced to orchestral

music through an invented instrument would be an amazing addition to our ability to create beautiful art,” said Forsythe. Winners not only received a cash prize ($1,000 and $500) but will also have the chance to work with the Pacific Symphony to compose and perform a piece around their instrument.

Six teams of engineering students spent months designing and creating their musical inventions. The rules were simple. The instruments had to meet three criteria: it had to be new, playable with notes and have some physical manifestation.

The six entries included three synthesizers. The Creophone, worn over the head, is an EEG-controlled synthesizer that detects specific brainwave thresholds to evoke enchanting chords. Pulstar is an electronic synthesizer, while the May Organ is an amplified electromechanical instrument that fuses concepts from the Hammon organ and digital wavetable synthesizers.

The Wube Tubes is a fusion of recycled wind and string instruments that’s played by blowing into the tubes while plucking the strings. The Saxatar, the winner of the People’s Choice Award, harnesses the wind through the science of fluids and vibrations.

Taesung Hwang, a senior who majors in both computer engineering and music, created the jury’s top choice - the Inductus - which he affectionately calls a “cool big stick.” The

three-foot long rod exudes an extraordinary array of ethereal sounds as a magnet slides inside, passing through coils of wire that send electronic impulses to a microcontroller that transforms the signals into music.

“There’s definitely a deep connection between the arts and STEM fields,” Hwang said. “We can use computer algorithms to generate melodies, harmonies and rhythms. It’s fun putting the two together.”

In addition to the debut of these novel instruments, the evening was graced with performances from a band comprised of Dean Egerstedt and four engineering faculty musicians: Herdaline Ardoña, Pim Oomen, Maxim Shcherbakov and Ali Moraz, who were also advisers to the student teams. They all rotated instruments as they sung engineeringthemed tunes like “Rocket Man” and “The Scientist.”

E-SONIC will be an annual contest and project that UCI students can participate in for academic credit. “This is only the beginning,” said Egerstedt. “Next year will be bigger, shinier, with even more instruments.”

The event included performances from a band comprised of Dean Egerstedt (on drums) and four engineering faculty musicians, from left: Maxim Shcherbakov, Herdaline Ardoña, Pim Oomen and Ali Moraz.

(top) “This new instrument competition is all about having the courage to go after new and wild ideas,” said Dean Egerstedt.

(middle left) Leo Harjanto and Naya Sterritt perform with their musical invention named Wube Tubes, a fusion of recycled wind and string instruments.

(middle right) Taesung Hwang wins the E-SONIC competition with his performance of the Inductus, which he affectionately calls a “cool big stick.”

(bottom) Praneet Iddamsetty performing with the Creophone, an EEG-controlled synthesizer that detects specific brainwave thresholds to evoke enchanting chords.

Universities, government labs and private companies invest billions of dollars in the research and development of breakthrough innovations that have the potential to transform industries and lives — but very few of these discoveries ever leave the lab.

Engineers however, as natural problem solvers, make great entrepreneurs. They’re used to taking complex technical challenges, breaking them down and building robust solutions from scratch. Some of the most notable modernday entrepreneurs started out as engineers, people like Bill Gates, Lisa Su and Jeff Bezos. There are many other examples of successful engineers who became founders and CEOs. A recent study by Crunchbase found that three out of 10 of today‘s most valuable U.S. tech companies were started by people with engineering degrees.

At UCI, a strong entrepreneurial ecosystem helps engineering researchers successfully navigate the path to commercialization. After protecting their intellectual property through a patent process, innovators can choose multiple ways to commercialize their technology, including translational funding for further development, finding industry partners to license technology, or establishing a startup company.

The speed of the lab-to-market process of an invention depends on multiple factors, including regulatory requirements and market demand. Some research discoveries have immediate potential for reaching the market, while others could take years.

Samueli School engineers, with their strengths in math, science and technology, are designing, building, creating and improving products and solving challenging technical problems.

The following pages give just a few examples of Anteater engineers taking innovation from lab to market.

The U.S. has the highest number of startups by almost three times the amount of the global leaders combined. In 2021, the U.S. was home to ~63,703 startups. Second was India with over 8,300, and then U.K. with roughly 5,400.

Money is a top concern for those considering a startup. About 33% of small businesses get started with less than $5,000. The majority, 58%, launched with less than $25,000

Approximately 30% of new small businesses fail by the end of year two, while half will fail before year five.

Women and minorities are more likely to own very small businesses in California than larger companies. Women own 22% of very small businesses; Asian Americans own 23%; Latino Americans own 11%

With a mission to help UCI students explore the process of entrepreneurship, the ANTrepreneur Center serves as a hub to help them develop skills necessary to start a business.

(top) Diced silicon chip with a side length of 2mm on a U.S. quarter. The chip contains a blown glass sphere with a diameter of less than 1 mm.

(middle) A fused quartz dual-shell prototype. The two-layer shell structure was co-fabricated using micro-glassblowing.

(bottom) A glass blown microsphere (1 mm in diameter) surrounded by eight satellite micro-domes can enable new classes of highperformance chipscale systems for communication, photonics and navigation applications.

During a stroll down a street in Barcelona’s Poble Espanyol, Andrei Shkel saw a man inflating molten glass with a blowpipe and shaping it into a perfect sphere. As a professor of mechanical and aerospace engineering, Shkel imagined an ingenious application for the ancient art: glassblowing could enable the world to make tiny “wine glasses” for small gyroscopes.

That epiphany skyrocketed his career, bringing him to the U.S. Department of Defense to head the mission to miniaturize gyroscopes – the key devices that measure rotation for navigation, positioning and stabilization. From 2009 to 2013 at the Defense Advanced Research Projects Agency (DARPA), he oversaw $200 million and 300 researchers from 20 companies, 16 universities, six national labs and seven government organizations as they forged ahead to make microchipscale gyroscopes. For his extraordinary contribution to defense technology, Shkel was awarded the Office of the Secretary of Defense Medal for Exceptional Public Service in 2013.

What was so revolutionary about Shkel’s idea? Picture this: It takes about three months of manufacturing, polishing and manual assembly of 96 parts to create a single high-precision gyroscope – a process that costs a staggering one million dollars for a single extreme-quality device. The engineering craft is one that only a few companies in the world are skilled to do.

His lab invented glassblowing technology that can create thousands of “small wine glasses” simultaneously by simply putting a specially prepared stack of wafers in a furnace at 1,500 to 1,700 C. “It’s like making muffins,” Shkel says, “we have specialized ovens, and wine glasses pop up like muffins with very little human involvement.”

It is extremely efficient because thousands of wineglass structures can be made instantly as they form and organize themselves organically and symmetrically. The researchers create air cavities inside wafers and the air trapped between wafers expands as the glass starts softening, becoming almost like liquid at such high temperatures. The combination of glass softening and a pressure increase inside the cavity does the magic of forming three dimensional micro-structures. When the shaped glass is pulled out from the furnace and cooled, the lab releases, metalizes and interfaces them with electrodes to complete the product.

The wine glass-like structure, made of fused quartz, is the heart of hemispherical resonance gyroscopes that have applications for defense, medicine, consumer electronics, transportation vehicles and much more. Over a dozen of Shkel’s inventions have

been licensed by industry and are used for advanced braking systems in SUVs, autonomous driving, navigation of UAVs, gaming, stabilizing images on camera phones and more.

Shkel’s groundbreaking work has given him 43 issued U.S. patents, making his MicroSystems Lab a global leader in chip-scale gyroscopes and inertial measurement units (IMU). The processes he invented have achieved a mechanical quality factor in the millions. This means that once stimulated, the resonator will oscillate on its own back-and-forth well over a million times before it loses its energy, which is a record for microscale devices. This quality factor is a key characteristic for precision measurement of rotations and reduction of drift in rotation measurements.

The Korean conglomerate Hanwha recently invested $3 million in MicroSystems Lab’s research to construct a prototype that would cut the cost to produce a high-precision hemispherical resonance gyroscope to just a few hundred dollars. “If we succeed, this would give the sensor in our cell phones the navigation capability of those on Boeing 747s,” Shkel says. Hanwha wants to use the technology for highly autonomous vehicles of the future.

“The Hanwha investment is the largest single industry award UCI has received to advance a faculty invention,” says David Gibbons, director of UCI’s Industry Sponsored Research division. “Given Professor Shkel’s five issued patents, this is an outstanding outcome and opportunity to see his work reach the market.”

Industry-sponsored research generally aims to advance research projects to product development and commercialization and, by doing so, can help move a researcher’s innovation out of the lab and into the market to benefit society.

“This is particularly exciting as I want to see increased industrial engagement more broadly and this is a perfect example of that,” Dean Egerstedt wrote in a congratulatory email to Shkel, pointing out the Hanwha contract demonstrates the tremendous value Shkel’s research brings to the market.

In a project called NEVERLOST, Shkel is working on putting mini gyroscopes and accelerometers in the soles of shoes worn by first responders so their whereabouts can be known at all times. It will go where current

GPS technology cannot – indoors and in covered outdoor environments. His lab is also developing a location-based service that provides path guidance for emergency responders to help them arrive at a goal destination, such as an emergency exit from a building. This project was awarded nearly $1.4 million from the National Institute of Standard and Technology Public Safety Communication Research division.

Shkel’s biggest dream is to make microchips that can restore the inner ear’s vestibular system, which provides a person’s sense of balance and spatial orientation. Currently, there’s no known cure for those who lose their sense of balance and it’s the main reason the elderly fall and hurt themselves. Future microchips could potentially be implanted to prevent those injuries.

Other biomedical applications include developing lower limb prosthetics that are a more natural fit to the patient. AI can collect motion data and make personal adjustments to the device via these miniinertial sensors.

The applications are endless as the lab works to perfect its mini gyroscope technology. “Every time I see a glass shop, I start thinking, ‘What can I do next?” says Shkel, the man who revolutionized gyroscopes with a glance at a glass blower.

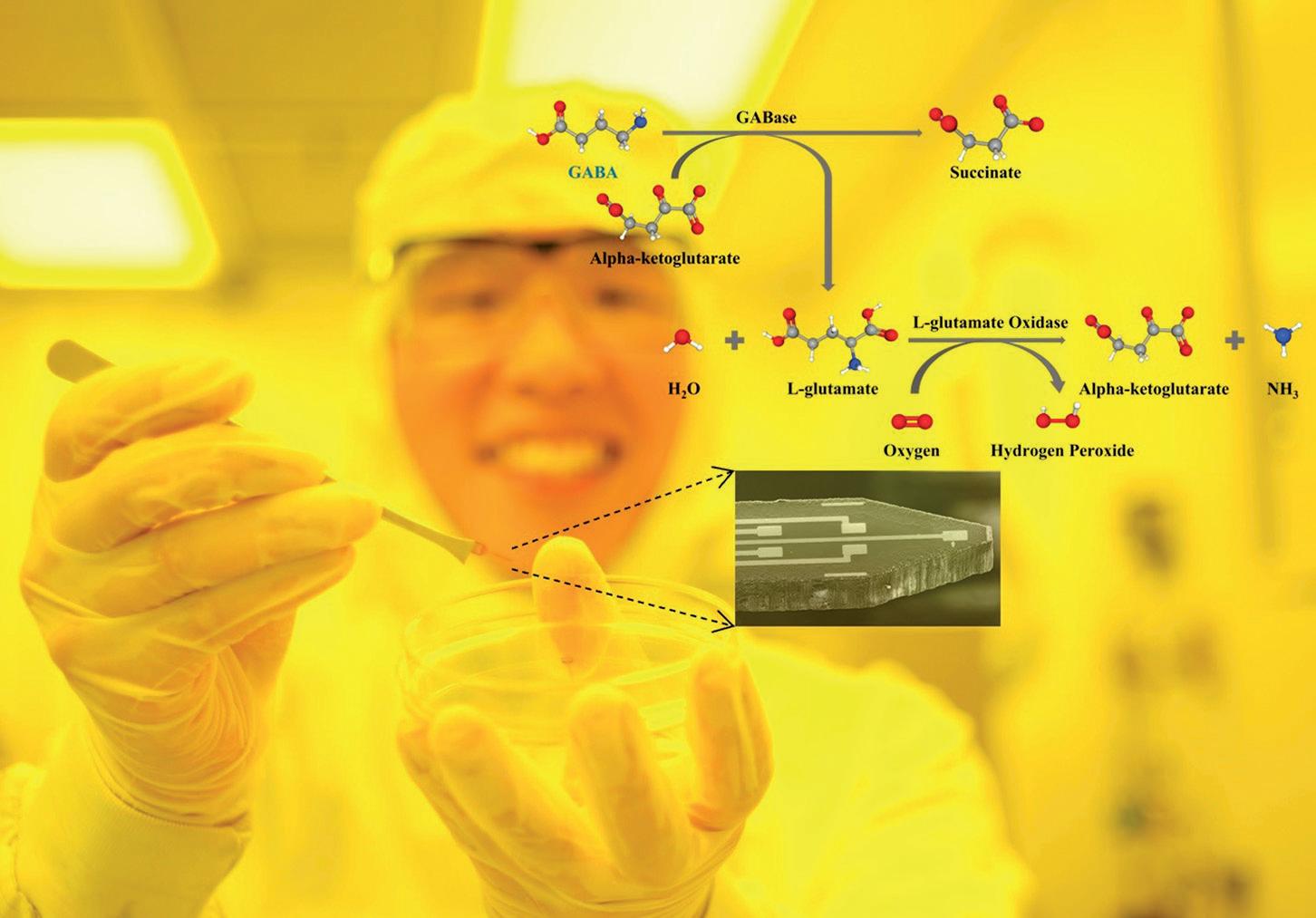

Han Li has developed tools that can control biochemical reactions in living cells. Called artificial cofactors, these tools are able to turn cells into tiny biofactories in which researchers can make a wide variety of useful chemicals. Her discovery could reimagine biomanufacturing and lead to more efficient, sustainable production of useful molecules for food, medicines, energy and materials.

Li’s invention was just a fun scientific exercise at first. She wondered, can we introduce artificial small molecules that bind to synthetic enzymes and reduce or accept electrons to cause a reaction within a cell? And can we do it without interfering in the cell’s natural processes?

“We’ve demonstrated that fundamentally we can do this, so now the question is what cool things can we do with this new tool?” says Li, an associate professor of chemical and biomolecular engineering.

Li says it works like a switch. “These artificial cofactors are really a way to direct electron flow inside the cells,” she explains. This engineered process causes a parallel biosynthesis within a cell to make a chemical while the cell continues to conduct its own functions as an organism working to survive. She then developed several distinct applications to make chemicals that are useful for society such as flavor and fragrance, food additives, plastics, renewable fuels and pharmaceuticals.

Li’s research team used the artificial cofactors to make a valuable medicine building block called a chiral compound. “It’s difficult to produce with chemical synthesis, so if we can make it biologically in a cell and then hand it over to the pharmaceutical or chemical companies, they can incorporate it into medicines or pesticides in a more cost-effect and sustainable process,” she explains.

She also used it to make citronellal, a compound used to give candles, soaps and lotions a citrus scent. Currently the compound is produced from orange peels. Using engineered cells to make citronellal would mean no more wasted oranges.

Li has been advancing this research since she joined the UCI faculty in 2016. She won a National Science Foundation CAREER Award ($500,000), NIH New Innovator Award ($2.2 million) and Sloan Early Career Award ($75,000) – all to support this work. But she didn’t consider its market potential until an attendee at a scientific conference mentioned the idea to her after watching her presentation. He referred her to the U.S. Department of Energy’s high-risk, high-impact Advanced Research Projects Agency (ARPA-E), which funds the development of energy technologies.

The ARPA-E grant proposal required a technical-economic analysis, forcing Li to consider the scalability and costs of commercializing her research as well as the potential customers, manufacturing bottlenecks and profit margins – all foreign concepts to her as an academic.

“I knew my tool was powerful and could do impressive things, but only in the lab,” she says. “I didn’t have a concrete idea of how to use it.”

“ARPA-E’s funding is a cooperative agreement – meaning, the agency works alongside Han Li with the resources and goal to push her transformative research into a technology to reimagine U.S. biomanufacturing,” says Kirk Liu, the technology-to-market program adviser at ARPA-E who worked with Li on the project. “This model has launched over 150 companies, of which six were listed in TIME’s Best Inventions of 2023.”

The agency granted Li $1.8 million to further her progress. She was also selected as one of 35 researchers in the nation to participate in an NSF IDEAS lab, a fiveday interactive workshop of experts and stakeholders interested in collaboratively developing solutions to a specific problem or grand challenge. Li was matched with an industry member who ran the numbers on scaling up her tool and using it in the bio-renewable chemical manufacturing industry. After their pitch, the team was invited to submit a proposal.

Li also received a Proof of Product grant from UCI Beall Applied Innovation, a resource hub for faculty innovators, entrepreneurs, investors and industry. She’s accessed many of its services related to intellectual property strategy, conflicts of interest, legalities of technology transfer, peer mentoring and entrepreneur workshops. Li now has three U.S. patents and is on the verge of starting a business.

“When you first talk to industry people, you quickly realize they speak a different language,” says Li. “When I say I have this cool idea, the next thing they do is open a spreadsheet, plug in numbers and spit out a cost analysis. At the IDEAS lab, my teammate performed this analysis and got super excited.”

Her teammate’s company has been making a renewable substitute product for a commodity chemical, which has a big carbon footprint and is not very degradable. This company has customers lined up to buy renewable bio-based alternatives. They know the molecule they want to make but haven’t identified an efficient process. That’s where Li’s innovation comes in.

Li never thought of herself as a business person. She studied biology as an undergrad, then switched to chemical engineering in graduate school and ended up in metabolic engineering. “I found the science of biology fascinating but I struggled with the question of what would I do with my knowledge. With engineering, there is always a purpose in mind, and the thing about biomanufacturing is it’s very versatile. It can make anything.”

Matt Lee ’12 invented a game-changing carbon capture solvent that catches one thousand more times carbon than a forest for less than $100 a ton – a goal set by the U.S. Department of Energy. Current costs range between $250 to $600 today, according to the World Resources Institute.

With his revolutionary technology, Lee and prominent entrepreneur Charles Cadieu founded the new company Spiritus and are now on the cutting-edge of reducing carbon for the U.S. and major companies around the world.

While competing technologies use giant fans to suck up air, Lee’s solvent is brilliantly modeled after alveoli - the air sacs in the lungs where carbon dioxide and oxygen are exchanged when we breathe. The solvent is shaped like round balls that will be laid out like fruit in a carbon-capture orchard. They’ll then passively absorb carbon from the air in just a few hours without making a sound.

The sorbents are then taken back into a capsule, what Spiritus calls a “tree,” to remove the CO2 so it can be transported and injected underground. The whole desorption process is powered by clean energy and the sorbents are reusable.

“We have multiple innovations that reduce energy costs,” Lee says. “We utilize passive air contacting that doesn’t use fans, and we have a novel desorption process that releases the CO2 from the sorbent with reduced energy needs.” This technology makes Spiritus, which means “breath” in Latin, a remarkable innovator in the carbon capture industry.

Lee invented the technology and is chief technology officer and co-founder of Spiritus. He began working on synthesizing porous materials at UCI, where he received a master’s degree and a doctorate in chemical engineering.

“Matt was truly a superstar,” says Ali Mohraz, professor of chemical and biomolecular engineering, who mentored him. “He had a keen eye to unveil exciting and unexpected science in our journey, a high standard of scientific excellence and an uncanny drive to reach it.”

While at UCI, Lee developed a new method of making porous materials with unique pore connectivity and internal surface geometry, using bijels as templates, an expertise the research group is still known for today.

“My experience at UCI was inspirational in that the faculty, staff and my fellow students always encouraged collaboration and the value of new perspectives that come from working alongside experts in technical areas different from my own,” Lee says. “The carbon capture problem can only be addressed with a multidisciplinary approach.”

Lee began his venture with Cadieu in December 2021, after working for 10 years as a specialist in colloid science at Los Alamos National Lab. Cadieu also founded IQ Engines and Caption Health. IQ Engines was acquired by Yahoo!/Flickr while Caption Health developed new medical technology that was named a 100 Best Invention by TIME Magazine in 2021. Spiritus raised $11 million in funding through an effort led by prominent venture capital firm Khosla Ventures. The startup is one of 12 companies that Stripe, Shopify and H&M Group have selected for carbon captures. “We’ve partnered with some incredible companies who are serious about advancing their net zero goals,” says Lee.

Lee is also working with the world’s largest oil company Aramco, which is set to make a major investment in Spiritus. The Saudi Arabian company signed a memorandum of understanding with Spiritus as it aims to transition to low-carbon technology.

Central Wyoming will also host one of the world’s largest carbon capture facilities built by Spiritus. “Our first facility, which we’re calling Orchard One, is coming along well and on track to begin carbon removal operations in 2026,” says Lee. “That’s a major milestone we’re all looking forward to.”

Orchard One will be able to capture megatons of carbon from the atmosphere and send 2 million tons of CO2 underground every year. That’s the equivalent of removing emissions from 340,000 pickup trucks annually. Spiritus will be able to receive tax credits to the tune of $180 for every ton of CO2 captured and stored in the ground.

“Our vision is a future world where carbon removal becomes a pillar of civilizational infrastructure, similar to waste disposal and wastewater treatment,” Lee says.

“If we can establish carbon removal as such a pillar, then the reversal of global warming truly becomes viable for future generations.”

The carbon capture solvent is modeled after air sacs, or alveoli, in the lungs.

“Our vision is a future world where carbon removal becomes a pillar of civilizational infrastructure, similar to waste disposal and wastewater treatment. If we can establish carbon removal as such a pillar, then the reversal of global warming truly becomes viable for future generations.”

Nizan Friedman ‘12 and Danny Zondervan ‘14 were graduate students in 2010 when they developed a novel medical device to help people recover from stroke. The two are musicians as well as biomedical engineers and their invention, the MusicGlove, uses technology and music to gamify the physical rehabilitation process and motivate people to exercise. It is used at home or in clinics to help stroke patients with hand paralysis regain function, augmenting traditional physical therapy.

And it works. They’ve sold over 10,000 MusicGloves over the past 10 years and have developed additional products based on its essence – the connection between music, the brain and the addictive qualities of game playing.

The alums started their company Flint Rehabilitation Devices in 2011 with UCI engineering faculty members David Reinkensmeyer and Mark Bachman. They received their first National Institutes of Health phase one grant ($150,000) in 2012 to help them commercialize the MusicGlove. The NIH small business innovation research and small business technology transfer grants program supports early stage businesses like FlintRehab in taking an innovation from the lab to the marketplace.

In 2017, the company launched their second device, FitMi, a full-body hometherapy tool to help patients retrain their brains and improve movement through repetitive exercises set to music. It includes two wireless pucks and a therapy software app, which guides patients through workouts to improve strength and

dexterity for various parts of the body. It offers 40 different exercises, such as arm raises, toe taps and torso twists, designed by rehabilitation therapists for people with a neurologic injury. The pucks contain multiple sensors and algorithms, and movements are tailored to a patient’s stage of recovery. As patients improve, the FitMi exercise difficulty levels increase to enhance recovery.

FitMi has sold three times as well as the MusicGlove and the founders are developing additional iterations for patients with other conditions like Alzheimer’s and Parkinson’s Diseases.

They hired fellow biomedical engineering alum Justin Rowe ‘15 as lead engineer to develop new devices. Flint makes custom hardware, firmware and software for its products and maintains active Facebook support groups and a popular blog for customers. “We are always listening to our customers as to which additional devices they are looking for,” says Friedman.

After years of being in business, they’ve learned that the technology is only a part of the story. A large missing element in athome neurorehabilitation programs is the interaction and expertise of a clinician. They are now repositioning FlintRehab as a remote therapeutic monitoring company in which their devices will be used in conjunction with a therapist to offer personalized rehab at home. In 2021, Friedman and Zondervan started another company that automates the transfer of patient physiological data from a patient’s home to a clinician.

They created a cellular modem called the Tenovi Gateway that connects to a growing ecosystem of medical devices. Data from each medical device is transmitted seamlessly to clinicians using Tenovi’s HIPAA compliant software.

The concept of remote therapeutic monitoring, or “tele-rehab,” has been around for decades. However, in 2022, federal health insurance enabled therapists to bill Medicare for musculoskeletal or respiratory remote therapeutic monitoring.

“Many stroke survivors will not purchase devices that are not reimbursed by insurance,” says Friedman. “Finding reimbursement pathways to rehabilitation at home naturally leads to the largest impact.”

Tenovi connects to over 30 medical devices including those for patients with hypertension, diabetes, congestive heart failure, chronic obstructive pulmonary disease and those that require medical adherence. Tenovi has sold more than 150,000 Tenovi Gateways and devices.

Friedman and Zondervan are not only nimble businessmen but successful at garnering funds. They’ve received 25 grants, totaling $15.5 million, from four different NIH agencies since 2012. FlintRehab has grown to 10 employees and Tenovi employs 30 people. They have six U.S. patents and are still developing new devices. The companies have made $40 million in revenue.

“As a small business you are competing against large companies that have an order of magnitude larger budget and human resources,” says Friedman. “The only way to win is to work both smarter and harder.”

data to their clinician who can remotely monitor their progress.

“By far the most important lesson I’ve learned is the importance of surrounding yourself with a good team,” says Zondervan. “Our success has only been possible because of the contributions of the people who we’ve hired.”

Their engineering education also inspired them. “My experience at UCI was instrumental in shaping my entrepreneurial aspirations,” says Friedman, “and I was fortunate to be co-advised by professors Bachman and Reinkensmeyer, both of whom had extensive experience in translating academic research into commercial products.”

FlintRehab still maintains ties with the Samueli School of Engineering and is releasing a new product called Boost in conjunction with Reinkensmeyer, professor of mechanical and aerospace engineering and anatomy and neurobiology and a National Academy of

Inventors fellow. Boost is a novel wheelchair armrest that helps stroke survivors safely perform arm exercises right from their wheelchair, in the earliest stages after injury when the brain has the most plasticity.

“It’s been wonderful to see Nizan and Danny take ideas from the lab environment and make them useful for people in the real world. They have worked hard to develop the diverse skills needed to achieve this translational impact.” says Reinkensmeyer.

“There’s a deep sense of happiness and satisfaction in seeing the positive impact our products have had on the lives of stroke survivors,” says Friedman. “Knowing that our work has made a difference in helping individuals on their rehabilitation journey makes it all worthwhile.”

Every year, 39 million babies are born with outer ear deformities that predispose them to teasing, bullying, anxiety and depression during childhood. These conditions disproportionately affect Hispanic, Native American and Asian-Pacific Islander communities that are often underserved. Nonsurgical options for correction must take place within two to six weeks of birth, making access to treatment difficult for many families, particularly those in low income and remote communities.

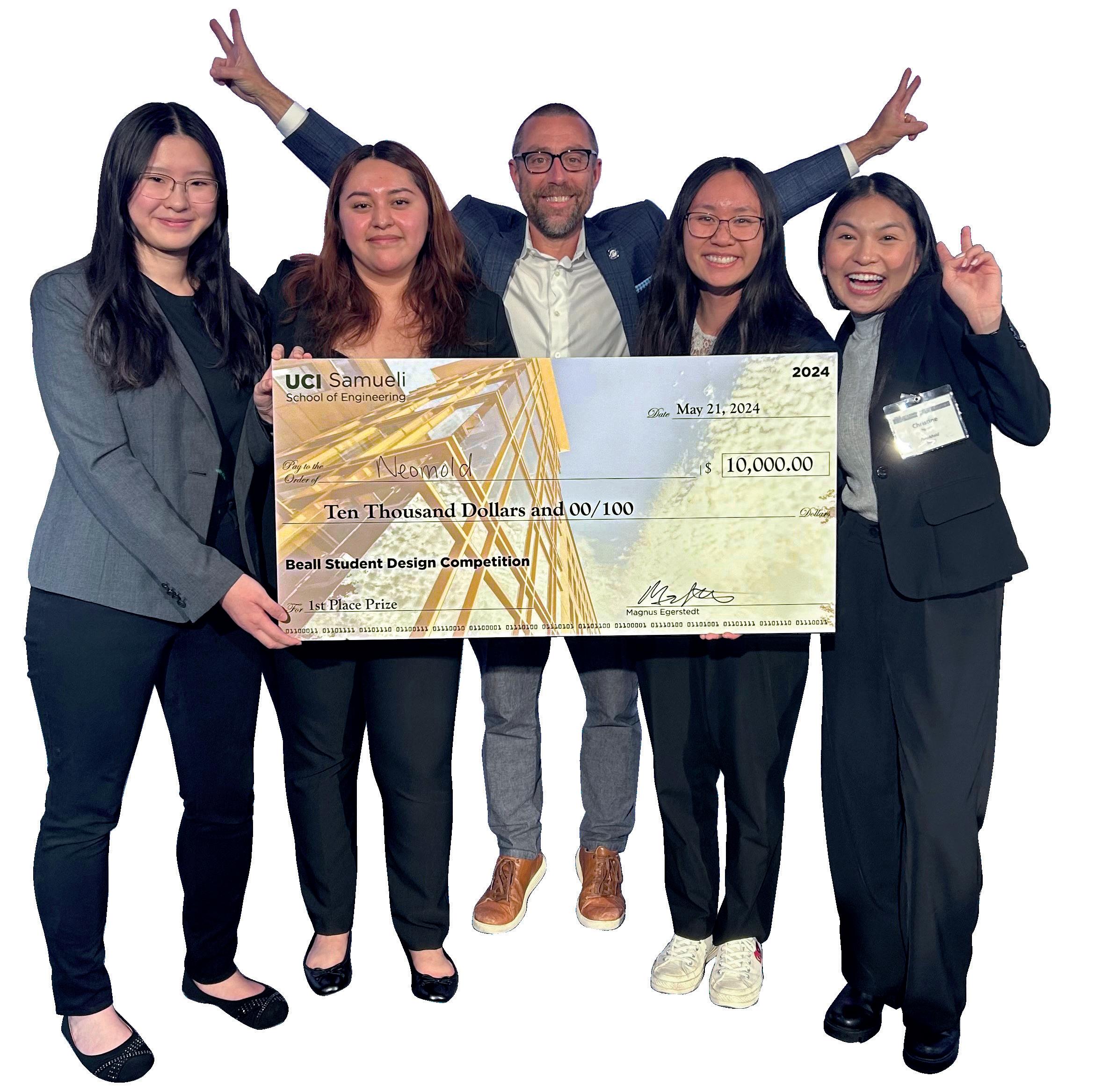

Dr. Miles Pfaff, a pediatric and craniofacial plastic surgeon at Children’s Hospital of Orange County (CHOC) and assistant professor of health sciences at UCI, had an idea for a noninvasive, affordable solution, and he turned to a group of UCI senior biomedical engineering students for help with designing and developing a prototype. The undergraduates – Christine Ly (team lead), Christine Nguyen, Kathy Duong and Frida Sandoval – produced a customizable, neonatal ear mold called NeoMold.

“NeoMold originated as an idea. By creating a simple, custom and inexpensive way to mold an ear and putting it in the hands of caregivers, when successful, we could avoid a surgery in the future,” says Pfaff, who provided the basic design idea of the mold to the team.

The team’s prototype is 3D-printed and made of a flexible

filament. NeoMold’s minimized design sets it apart from existing bulky and often uncomfortable newborn ear molds and avoids common problems of other devices such as skin irritation and dislodgement. Unlike currently available designs, NeoMold is customizable to each patient’s ear. Each mold is based on a 3D scan of a patient’s unique anatomy and is designed to correct conditions such as prominent ear, Stahl’s ear and lidding.

“We decided to pursue this project because of the potential impact it could have to improve quality of life, and in general, the standard of care for patients with these conditions,” says Ly.

If left uncorrected, infants with these deformities tend to encounter bullying, causing psychological and social stress during their childhoods. Furthermore, NeoMold’s 3D-printed base lowers cost and shortens manufacturing time, aiming to improve accessibility for a wide geographic range and various income levels so treatment can take place quickly after birth.

The team garnered support for the project through UCI’s many resources and opportunities for entrepreneurial students. Christine King, an associate professor of teaching and director of the BioENGINE program, supports biomedical engineering student design projects. She

advised the NeoMold team and allowed them to use her lab and equipment for developing the prototype.

Pfaff said he sought out the engineering students because he wanted to contribute to the momentum that UCI has built around education, innovation and collaboration between different disciplines. “King’s BioENGINE program was the perfect venue for this,” he says.

“There are a lot of aspects students need to consider in design: safety, efficacy, marketability and regulatory affairs,” says King. “We collaborate with industry, startups and physicians to help provide students with the translation of ideas into real-world devices that can be eventually used in health care.”

In the spring, NeoMold placed first at the Beall Student Design Competition, a UCI entrepreneurship event that focuses on product design and technology development. The team attended six months of coaching sessions to prepare their pitch before exhibiting their work at a demo day, and they received $10,000 as first-place winners to continue improving their prototype.

They took second place overall at the Stella Zhang New Venture Competition, hosted by the UCI Paul Merage School of Business. After passing a concept-paper round, the team prepared for the final, which is modeled after the Shark Tank television show. Finalists gave a threeminute pitch followed by a five-minute question-and-answer session with a panel of esteemed entrepreneurs, and NeoMold received a $5,000 prize.

NeoMold also won the Dean’s Choice Award at the Samueli School’s Annual Winter Design Review, the Chancellor’s Award for Excellence in Undergraduate Research, the Best Oral Presentation Award from the Undergraduate Research Opportunities Program and the Nguyen Tarbet IP Law Entrepreneurial Award at the BioENGINE Annual Device Design Symposium. Through

participation in all of these competitions, NeoMold has gained publicity within the UCI community and earned a total of $30,000.

The team has submitted their record of invention for review to Beall Applied Innovation, UCI’s center for entrepreneurship education, to determine the patentability of the product. They hope to license the technology and sell it to industry for manufacture.

“We started everything from scratch so seeing the project go from sketches on my iPad to something that judges were physically holding in front of us at competitions has been very rewarding,” says Ly. “If we didn’t have the kind of support we received, the project would not have come so far in such little time.”

For engineers who want to be entrepreneurs, the gold standard is Distinguished Professor Diran Apelian, who co-founded Ascend Elements, a company that invented ways to recycle EV batteries and is valued at over $1 billion. TIME magazine named it one of America’s Top Ten Green Tech Companies of 2024.

Did you always imagine you’d be an entrepreneur?

No, however I always imagined I’d be in charge of my destiny and that I would work on problems that are important and impactful. In academia, I saw the opportunity to work on problems I cared about and that mattered and I felt an ownership toward them.

What was the key factor to the success of Ascend Elements?

The stars were aligned. EVs were just coming in and people were making fun of Tesla. The masses didn’t think EVs would someday replace internal combustion engine cars but we knew there was going to be a future in lithium-ion batteries. Lithium is not abundant and the elements that go into making the cathode in those batteries are near

critical and precious such as Co and Ni. One needs to recover and reuse the spent batteries at the end of life. Three of us –Yan Wang, Eric Gratz and I – decided to form a company with no money. We had no revenues and started with a federal contract. It required grit, persistence and more grit.

How were you able to raise money?

As chairman of the board, I recruited my cool friends and formed an advisory board. It became evident that we needed a professional team to take us to the next level so I recruited a CEO, CFO and COO who we couldn’t pay so we gave them equity. With the right team, it just took off. The key is putting the right team together and creating the right culture where people are helping each other with no ego trips. We were all aligned with one goal. Leadership influences the environment and the environment influences people’s behavior. So, the human assets are the most important asset, more than financial and capital assets.

Were you surprised at its success?

I’m surprised at how fast it happened. I knew it was going to happen but not in six to seven years. Yes, the success is a sweet surprise and the credit goes to the team.

Tell us about your other company Solvus Global.

At Solvus Global, we harness the power of a creative and multidisciplinary team to solve difficult problems through development and commercialization of next generation technologies. We take ideas, derisk them, and create a product and market for them and spin out companies. We have the best talent to start companies – two of my former Ph.D. students – Sean Kelly and Aaron Birt who are COO and CEO. Solvus Global provides the infrastructure – everything you need to start a company. It functions like a studio model you find at venture firms. I would say think of Solvus Global as a technology incubator.

What advice do you have for engineers who are aspiring entrepreneurs?

What we often find is that an aspiring entrepreneur has an idea – a cool idea –one they are passionate about. But that’s not enough. The question that needs to be answered is: Whose problem is being solved and are they willing to pay for it?

What’s the key to successful innovation?

Anticipate needs that people don’t even know they need, envision the future, also verify and validate and be willing to drop ideas and move on to the next one. Ultimately, one needs to create value for others, and not for themselves. If one succeeds in creating value for others, they will end up creating value for themselves. The focus should be on others.

How do you know if something has market potential?

Some of it is a gut feeling, some of it is your right brain, some of it’s intuition and some of it is timing, and we can’t forget good luck.

How do you develop the marketplace?

Developing a market is a long process; it requires an acumen for listening, forming relationships, earning trust and delivering on the promise.

Where should people get money for investment?

Simply stated, whoever gives it to you; well almost, as one needs to be concerned about the strings attached with the money that is coming your way. The key is to make the case for why anyone should invest in your startup. The value proposition needs to be made clearly and credibly. I have found that people listen to you if they like you, but they need to trust you if they want to do business with you. So much of it is not about the money, but rather earning the trust and developing the relationship. One’s sincerity, authenticity and humanity, if you will, plays a big role.

Why did you start the Essential Skills class?

In French, the root of engineer is genius. Where I grew up in Europe, engineers are leaders. When I joined the materials science and engineering faculty at UCI, I had the privilege to examine the curriculum and suggest courses. To be successful, engineering students should understand the human dimension.

The answer was to develop a course that awakens in our students the essential skills they need to develop for success in professional life. This course is all about the things I wish someone had told me when I was 20 years old. This is my way of giving back, and the success of the course has been most gratifying. What type of personality is suited to be an entrepreneur?

Not everyone can be one, probably only about 10% are suited. However everyone, with no exception, can develop an entrepreneurial mindset. By this I mean having an understanding of why one is doing what they are doing. Who is the customer? Who benefits from this? Whose problem are we solving?

Being an entrepreneur is not easy. You’re living in a world of uncertainty. You have to be comfortable being uncomfortable. You are afraid to fail, but you also have that resilience that if you fail, you have to get back up on your feet quickly and keep going. It’s chaotic. You have to be willing to do many chores from accounting to janitorial work to making a pitch to investors. It’s not for everyone.

What’s your motto?

“Create value for other people and you end up creating value for yourself.”

Nothing is easy. Doing things for the wrong reasons – just to make money – is not a good reason to start a company. If your reasons are genuine or right – you’re serving a need and creating value – you will succeed and it is sustainable.

The Institute for Rapid Antibody Engineering and Evolution with Chang Liu as director is the inaugural Engineering+ Health Institute. Samueli School Dean Magnus Egerstedt announced the selection this past winter. This is the first of three interdisciplinary institutes outlined in the Samueli School’s 2030 strategic plan – Engineering+ Health, Engineering+ Environment and Engineering+ Society. The institutes are funded by a $50 million gift from Susan and Henry Samueli.

Egerstedt explains that E+ is an inclusive concept. “It acknowledges that although engineering is at the center of the big, impactful research questions we are currently facing, we must go beyond historical, disciplinary boundaries and adopt a deeply collaborative approach to be able to address them.”

With $2.5 million over five years, the Institute for Rapid Antibody Engineering and Evolution will mature and scale up a new synthetic antibody discovery, generation and evolution technology called AHEAD. This revolutionary technology essentially boots up an immune system in a test tube using only yeast cells. Originally developed in 2020 by Liu’s group, in collaboration with researchers from Harvard Medical School, AHEAD uses the research team’s rapidly evolving genetic systems to potentially make disease-fighting drugs faster, cheaper, more effective and accessible, which would transform health care around the world.

“Antibodies are the ‘magic bullets’ of biology, acting as drugs, molecular sensors for disease diagnosis, frontline therapeutics for outbreaks and fundamental research tools for biomedical discovery,” says Liu, professor of biomedical engineering. “Yet the generation of specific antibodies that hit desired molecular targets has historically been a challenging bioengineering problem. With this funding and the collaborative research between antibody evolution, design and application testbeds it will catalyze, the problem of antibody generation should become solved within a few years leading to a new era of medicine and life science research.”

The new institute will have three thrusts. First, it will further develop and disseminate the AHEAD technology, making it as effective and easy to use as possible. Second, it aims to serve a critical function in pandemic prevention by generating therapeutics targeting anticipated pathogens and creating a reservoir for rapid outbreak surveillance and response. Third, the institute will embed rapid antibody engineering technologies into the core capabilities of UCI research groups working on a diversity of diseases, thus demonstrating the general power of this approach in biomedicine and giving UCI an advantage in drug development as an important epicenter for rapid antibody engineering.

Members of this institute span the fields of biomolecular engineering, protein engineering and design, immunology, ophthalmology and infectious disease. In addition to Liu, participants include UCI researchers Han Li, Phil Felgner, Krzysztof Palczewski, Wendy Liu, Ryan Hayes and Greg Weiss, along with collaborators outside of UCI such as Andrew Kruse and Debora Marks from Harvard Medical School.

18 1 16 1

53 9 5 12 28 6 2

National Academy of Engineering Members

National Academy of Medicine Member

National Academy of Inventors

American Academy of Arts and Sciences

Member

NSF CAREER Awardees

NIH New Innovators

DOE Early Career Awardees Endowed Chairs and Professorships

Distinguished Professors Chancellor’s Professors Chancellor’s Fellows

Newsweek - April 11, 2024

Neuroscientists have discovered a surprising new source of deepsleep brain waves, shaking up our understanding of the architecture of sleep and how we treat sleep disorders. “These findings have significant implications for sleep research, potentially paving the way for new approaches to treating sleep-related disorders,” co-author Gregory Brewer, adjunct professor of biomedical engineering at UC Irvine, said in a statement.

Los Angeles Times - August 16, 2023

“We’re not ready to live without cars at this point in most parts of California,” said Jean-Daniel Saphores, professor [and chair] of the department of civil and environmental engineering at UC Irvine. Saphores, who studied the carless population, said such people generally fall into two categories. There are people … who choose not to have a car for a variety of reasons, whether it’s health, convenience, the environment, or something else entirely. … The other group is made up of people who can’t afford cars, Saphores said.

Bloomberg - June 18, 2024

“The common denominator here is rising temperatures,” says Amir AghaKouchak, a professor at University of California, Irvine who has studied the future risk of compound events.

“Temperature has increased significantly, and it’s contributing to all of [the disasters] and it’s intensifying maybe the relationship between different hazards.”

ABC News - November 30, 2023

Researchers at the University of California, Irvine who study the behavior of fire embers have determined the majority of fire damage in major wildfires comes from embers that have the ability to move far away from the actual burn site. They also have studied how strong wind gusts can send even large embers flying long distances where they can land and create new spot fires. “We are trying to understand under what conditions the embers are lofted away from the fire,” Tirtha Banerjee, associate professor of civil and environmental engineering at UC Irvine, told ABC News. “So, how fast do they emerge? How many of these embers can emerge and how far they can really land?”

Phys.org - November 28, 2023

Using new super-resolution microscopes, researchers at the University of California, Irvine and the University of Pennsylvania have for the first time observed electrical charge and discharge functions inside mitochondria isolated from cells. “When we first started studying isolated mitochondria, we knew they behaved like a battery,” said co-author Peter Burke, UCI professor of electrical engineering and computer science. “Now we can control each individual electrical component and cause it to charge and discharge.”

The Wall Street Journal - February 10, 2024

“The infrastructure is optimized to move water quickly to the ocean, and it did its job,” said Brett Sanders, a professor of civil and environmental engineering at the University of California, Irvine. “But had we had another storm right after that, we might have gotten close to the limits of that system.” A 2022 report from UC Irvine determined that a 100-year flood event in Los Angeles would expose more than 400,000 people to danger, with property damage of more than $50 billion, comparable to that of a major hurricane.

The New York Times MagazineNovember 12, 2023

“The bladder may reach maximum capacity before an urge is felt, at which point urination may happen suddenly and spontaneously,” according to “A Review of Challenges & Opportunities: Variable and Partial Gravity for Human Habitats in L.E.O.,” or low Earth orbit. This is a report that came out last year from the authors Ronke Olabisi, an associate professor of biomedical engineering at the University of California, Irvine, and Mae Jemison, a retired NASA astronaut.

U.S. News & World Report - April 11, 2024

Kyriacos Athanasiou, a biomedical engineering professor at the University of California, Irvine, said it was because TMJ disorders are more prevalent among women that they were historically dismissed as neither serious nor complex, slowing research into the cause and treatment. The resulting dearth of knowledge, which is glaring when compared with other joints, has been “a huge disservice” to patients, Athanasiou said. In a 2021 study he co-authored, researchers found that the knee, despite being a much simpler joint, was the subject of about six times as many research papers and grants in a single year than the jaw joint.

Futurity - January 4, 2024

Senior coauthor Alon Gorodetsky, professor of chemical and biomolecular engineering at the University of California, Irvine, [said], “For this project, we worked to mimic the octopus’ natural abilities with devices from unique materials we synthesized in our laboratory, and the result is an octopus-inspired deception and signaling system that is straightforward to fabricate, functions for a long time when operated continuously, and can even repair itself when damaged.”

The New York Times - January 17, 2024

The challenge for electric vehicles is the two sides of the battery — the anode and the cathode — have chemical reactions that are slowed during extremely cold temperatures. That affects both the charging and the discharging of the battery, said Jack Brouwer, director of the Clean Energy Institute and a professor of mechanical and aerospace engineering at the University of California, Irvine. “It ends up being very difficult to make battery electric vehicles work in very cold conditions,” Mr. Brouwer said. “You cannot charge a battery as fast or discharge a battery as fast if it’s cold. There’s no physical way of getting around.”

UCI engineering researchers have designed a new biointerface technology for organizing engineered cardiac tissues that could pave the way for future light-triggered, life-saving cardiac devices such as pacemakers.

Herdeline Ann Ardoña, assistant professor of chemical and biomolecular engineering, said that light-based stimulations are better because it could mean that nextgeneration cardiac devices could be light-sensitive and minimize the need for invasive, wired instrumentation.

“The convention in the field is to use metal-based electrodes to electrically stimulate cardiac tissues,” said Ardoña. “Here, we built current-generating interfaces with organic-based soft material components that are light-responsive, and with well-defined surfaces as an interface for cardiac muscle cells.”

The cardiac cell-compatible technology generates electrical currents in response to pulsed light stimulation. It is the first example of a cardiac photoconductive biointerface that is powered by soft material components (peptides and polymers) and is also capable of controlling biomolecular assembly and the organization of cardiac cells cultured atop devices. The findings are featured in Advanced Materials’ Rising Stars special collection

The technology also holds promise for higher spatial resolution stimulation when working with lab-based models. Lab-grown tissue models are beneficial for studying mechanisms of diseases and natural biological processes, or for performing high-throughput drug screening or toxicology studies.

The lead author of the paper is Ze-Fan Yao, a postdoctoral researcher from Ardoña’s group. According to Yao and Ardoña, “In addition to achieving a photoresponsive biointerface, our study with these nanoscale-featured surfaces that drive the assembly of semiconducting peptides also revealed insights on the sensitivity of cardiac tissues to the molecular composition and order of the biomolecules that comprise its microenvironment.”

The paper also features UCI graduate students in chemical and biomolecular engineering, and biomedical engineering: Yuyao Kuang, Emil Lundqvist and Natalie Celt, along with UCI materials science and engineering alumnus Xin Fu ’23, Ph.D., from Professor Emeritus Albert Yee’s group. The work was funded by the National Heart, Lung, and Blood Institute and supported by a seed grant from UCI’s Center for Complex and Active Materials.

“We

built currentgenerating interfaces with organic-based soft material components that are light-responsive, and with well-defined surfaces as an interface for cardiac muscle cells.”

Haithem Taha, an associate professor of mechanical and aerospace engineering, and his group developed a new theory of lift to solve a century-old technical challenge in aerodynamics. Based on the principle of least curvature, the new theory fundamentally changes how researchers understand flight. In their recent research, published in the December 2023 issue of Physics of Fluids, they extend this work and propose a new approach for solving fluid mechanics problems based on a principle of minimization. The researchers applied the new theory of lift to the flow over a rotating cylinder, such as the one used on a rotor ship, and managed to find simple analytical solutions without the need to solve the complicated nonlinear partial differential equation of Navier-Stokes. “We named it the Principle of Minimum Pressure Gradient (PMPG). So, this technique turns fluid mechanics problems into an optimization problem,” said Taha.

A UCI team of researchers is making exciting advances in DNA nanotechnologies. The group, led by Stacy Copp, assistant professor of materials science and engineering, recently reported a new approach to enhance the stability and functionality of DNA nanostructures while still retaining their remarkable bio-enabled properties. The research is published in the American Chemical Society journal ACS Nano. The researchers address the major, long-term issue of thermal and chemical fragility of DNA nanomaterials by creating DNA duplexes that are paired together with silver ions. These silver-mediated DNA duplexes are far more stable than nature’s DNA duplex and can persist up to nearly the temperature of boiling water. They also discovered that under certain conditions, the silver-paired DNA duplexes appeared to assemble into larger nanostructures, which could have novel applications for DNA-based nanoelectronics.

Penghui Cao, assistant professor of mechanical and aerospace engineering, led an effort to develop a neural network to search and identify materials with optimal compositions to improve the performance of energy systems. The newly introduced neuron map presents an effective process for exploring the vast compositional space of multicomponent alloys and lays the groundwork for discovering ultrastrong and creep-resistant alloys for application in severe environments. The researchers' work appears in the May 2024 Nature Communications. “We reveal the diffusion-induced chemical and structural evolution in complex, concentrated chemical environments and find the critical temperature at which the chemical order reaches a maximum,” said Cao.

A team led by Dr. Arash Kheradvar, professor of biomedical engineering and medicine, received funding from the National Institutes of Health to develop a new method for grading mitral valve backflow. Researchers want to determine the efficacy of a noninvasive technique for evaluating the severity of mitral valve regurgitation in which blood flows backwards from the left ventricle into the left atrium of the heart. On average, the disease affects more than 2% of the population with a prevalence that increases with age. The condition can be debilitating and lead to severe heart failure and death. Kheradvar stressed that although detection of mitral valve regurgitation with standard imaging methods such as echocardiography is straightforward, grading its severity is challenging and requires considerable experience. He proposes using a novel technology called “volumetric echocardiographic particle image velocimetry,” which was developed in his UCI lab. V-Echo-PIV will derive three-dimensional information of blood flow in the left side of the heart to accurately measure how much is regurgitating near the mitral valve. Kheradvar said a procedure employing V-Echo-PIV can provide determinative data in as few as four heartbeats.

California is set to build the nation’s largest clean hydrogen ecosystem after the White House announced it will award $1.2 billion toward the plan. That figure is only part of a $12 billion hydrogen hub led by the Alliance for Renewable Clean Hydrogen Energy Systems (ARCHES), a public-private partnership, which includes the University of California. As an intellectual leader in the hydrogen economy, UCI engineers initiated the move to unite the University of California in this unprecedented effort. Professors Plamen Atanassov and Jack Brouwer are interim directors for business development on the ARCHES leadership team. The ARCHES plan will build infrastructure that can transport, store and dispense hydrogen throughout California. A key focus of the plan are ports that will transition to using hydrogen-fueled trucks and cargo handling equipment. At least 40% of the benefits of the hydrogen hub will flow to disadvantaged communities, who have been engaged in the proposal development process.

Assistant Professor Maxim Shcherbakov is developing a new method of shaping materials that could reduce the cost of fabricating microelectronics, such as those used in cellphones. “We use specially designed microparticles that can funnel light into much smaller spots, modifying materials such as silicon at a scale of down to almost one-hundredth of a wavelength,” said Shcherbakov. He published the new technique, called femtosecond laser-assisted nanostructuring of engineered microstructures (FLANEM), in Nature Communications. FLANEM expands the nanofabrication toolbox and offers exciting opportunities for high-throughput optical methods of nanoscale structuring of solid materials, such as silicon and other semiconductors. This finding is timely as the nation gears up its efforts to increase microelectronics and semiconductor manufacturing as part of the CHIPS and Science Act.

The diabolical ironclad beetle, a native to desert habitats in the southwest United States and Mexico, and the Japanese rhinoceros beetle are the subjects of a new Air Force Office of Scientific Research-funded project led by David Kisailus, professor of materials science and engineering. The researchers will study structures in the beetles’ exoskeletons that make them so well-adapted to harsh environments and use those blueprints to create new multifunctional synthetic materials useful in national defense, aerospace and other applications.

In a paper published in Nature in 2020, Kisailus directed a team that revealed some of the secrets behind the otherworldly toughness of the flightless insect. In this newly funded AFOSR research, principal investigator Kisailus, with colleague Pablo Zavattieri, professor of civil engineering at Purdue University, will further examine the elytra, or protective forewings, of the ironclad and an airborne relative, the Japanese rhinoceros beetle.