Sustainable solutions for innovation and global development demand cooperative, multidisciplinary problem solving. NIER’s strategic partnerships and engagement platforms enable the merging of practical experience with theoretical and technological innovation to create a responsive environment essential for solving complex problems and driving meaningful progress.

Alignment with strategies and endeavours of the University and our partners is paramount to our success. Shared vision, quality engagement and sound partnerships enable valuable collaboration opportunities, and access to:

Our industry networks provide access to programs that promote collaboration, drive innovation and boost competitiveness and growth through information sharing. The networks allow us to harness connections to develop a thorough knowledge of industry needs, challenges and sector trends, both existing and emerging, leading to more relevant sector solutions.

Knowledge of regions forms the bedrock of our strategic research approach and supports the transfer of new skills, technologies and markets - driving the next wave of innovation and jobs, while strengthening regional resilience.

By harnessing collective expertise and unique capabilities, we are able to deliver outcomes that support regional strategies and frameworks. Initiatives have a measurable and beneficial economic, environmental, and social impact as a result of leveraging local and acquired knowledge to drive innovation and technology outcomes.

Alignment with local, state and federal government on the vision of creating more resilient communities allows us to clearly define our strategy, priority and direction in order to stay relevant to local, national and global priorities.

The input of diverse perspectives, local understanding, global insights and multidisciplinary expertise has enabled us to establish a trusted cadre of research excellence in energy, resources, food and water.

Through partnership programs such as the Doctoral Training Centres, we provide comprehensive and hands-on learning experiences to equip students with the skills and knowledge needed to be the industry leaders of tomorrow.

With sustainability at the forefront of everything we do, NIER proudly continues to attract interest from local, national and international industry and government representatives, demonstrating our relevance in the research landscape.

In a testament to the research and innovation advancements underway at the University of Newcastle, and to our shared objectives, NIER has hosted an impressive array of guests over the past year, including the European Commissioner for Energy, the Governor of Tokyo, delegations from the Republic of Indonesia, the Government of Samoa and the UK Universities Alliance, as well as federal and state Members of Parliament.

NIER remains focused on building collective capacity to create more resilient regions, recognising that we are stronger together, in partnership. Our research impact reflects the priorities of our partners and our regions, and our joint ambition to address some of modern society’s most rapidly advancing global challenges.

We are proud of the networks we engage with, and of building meaningful and wide-reaching strategic alliances. In the Partnerships and Engagement Platforms feature on the inside cover of this report, we have illustrated the breadth of our strategic collaborations, initiatives and partnership network - all contributing to the innovations and technological advancements needed to develop a more sustainable future.

Our research focus is driving beneficial outcomes in the critical areas of energy, resources, food and water. With the goal of sustainable solutions, we are working with our partners and aligning to the University’s broader strategy and our priorities to boost industrial innovation, productivity and efficiency, technology and utilisation, and sustainability and security.

Our partnerships and our commitment to building engagement, delivering transformative industry research and innovation, and providing quality research education is, and will always be, of greatest importance to our success.

We thank you for your ongoing support that has helped us achieve practical outcomes for our partners, the University and our overarching objective of providing sustainable solutions for global challenges.

PROFESSOR ALAN BROADFOOT Executive Director, NIER

PROFESSOR ZEE UPTON Deputy Vice-Chancellor, Research & Innovation

Weleveragenetworkstopropelresearchthat respondstolocal,nationalandglobalneeds, connectingideastopeopleandplaces.

NIER’s management, strategic direction and initiatives are steered by a dedicated governance framework representing the research centres and groups that collectively create the NIER model, as well as the industry and regions we support.

During 2023, we welcomed Mr Pierre Gouhier to the newly created role of NIER Deputy Director, to support increased activity, assist the navigation of more complex commercial partnerships, and drive strategy and engagement to help achieve the best possible industry solutions. With a background spanning research, engineering, management, governance and business development, and motivated by innovation, Mr Gouhier has hit the ground running, taking on the management of the University’s Trailblazer for Recycling and Clean Energy program, in collaboration with our counterparts at UNSW.

The Advisory Board comprises members with diverse knowledge and experience across the sectors of energy, resources, food and water, as well as the tertiary education, research and innovation spheres. The Board contributes to strategic NIER activities and initiatives by identifying opportunity pathways for building capacity, focusing priorities to support our regional industries and communities, while ensuring alignment with the overarching Research and Innovation Division and University Strategic Plans and Engagement Priorities.

At the end of 2023, NIER said farewell to a much respected Board member, Mr Kim Hockings following his retirement from his role as Principal Technical Marketing, BHP Coal Strategy and Planning. A member since 2017, Mr Hockings has been a steadfast supporter of research advancement and industry engagement at NIER, championing many of the programs delivered as part of our longstanding partnership with BHP through the Centre for Ironmaking Materials Research, now known as the BHP Centre for Sustainable Steelmaking Research. Included was the Diverse Talent Program for Inspiring Women in Research, which addressed gender related challenges while helping talented female researchers progress their careers. We thank Mr Hockings for his valuable and trusted contributions over many years and wish him well in his retirement.

To fill this vacancy, the Advisory Board recently welcomed Ms Liz Watts, Vice President, NSW Energy Coal, BHP. Ms Watts has over 24 years’ experience in various technical, frontline and corporate roles within the mining industry and is also a University of Newcastle student, undertaking a Doctorate in Sociology and Anthropology focused on sustainable outcomes for mine closures. With these studies, alongside her expertise in the resources sector and current role transitioning Mt Arthur Coal to closure in 2030, Ms Watts is well positioned to provide valuable insight to the Board.

The Management Committee is responsible for oversight of high level infrastructure and utilisation issues, including space allocation, safety and environmental management, large-scale demonstration plant and infrastructure risk management, and other strategic and operational risks specific to precinct activities. In May 2024, the University appointed Mr Kevin McCarthy to the role of Director of Infrastructure and Facilities Services (IFS). As the lead for IFS, Mr McCarthy has responsibility for the planning, development and operation of the University’s physical infrastructure, estate and campus services to support strategic objectives and meet the needs of students, staff and other stakeholders. As a member of the Management Committee, Mr McCarthy’s extensive experience provides significant insight into operations, governance, project delivery and strategy as it relates to activity impacting the NIER Precinct’s 3.8-hectare site and integrated campus planning.

The Management Committee also recently welcomed Professor Brett Nixon, Deputy Head of College, as the ongoing delegate for the Pro Vice-Chancellor of the College of Engineering, Science and Environment. Many research groups located at NIER are also part of this College, and broad engagement through NIER’s governance framework enables members to more actively represent the interests of these groups while demonstrating our ongoing commitment to working collegially across campus to ensure optimal research outcomes.

and Water CSIRO

JULY 2023 - JUNE 2024

35% Repeat clients

145 Engaged University researchers

16 Research centres & groups

24 International partners

214 Active industry partners Industrial workshops Glasshouses

2 Global & regional nodes

217 PhD students supported by NIER centres

360+ Precinct occupants

5

3 &

3.8 HA Precinct Size

NIER’s research is helping find solutions to global challenges in the energy, resources, food and water sectors. NIER facilitates activity that enables the University to drive impact and deliver next generation resources to support resilient regions, with research expertise across four key capability areas:

Unlocking sector potential with a generation of new materials, processes, technology and services.

Solutions to reduce waste and optimise the use of the world’s resources.

Transferring the latest technology into sectors of significance for sustainability and competitive advantage.

Balancing environmental, social and economic activity for regional resilience.

The Research Leadership Committee meets regularly to support the delivery of research and innovation through the NIER model. This is an important function to ensure research excellence by helping to identify relevant research and collaboration opportunities, consider strategies for attracting research funding and recommending methods for building NIER’s profile and reputation among industry and other stakeholders.

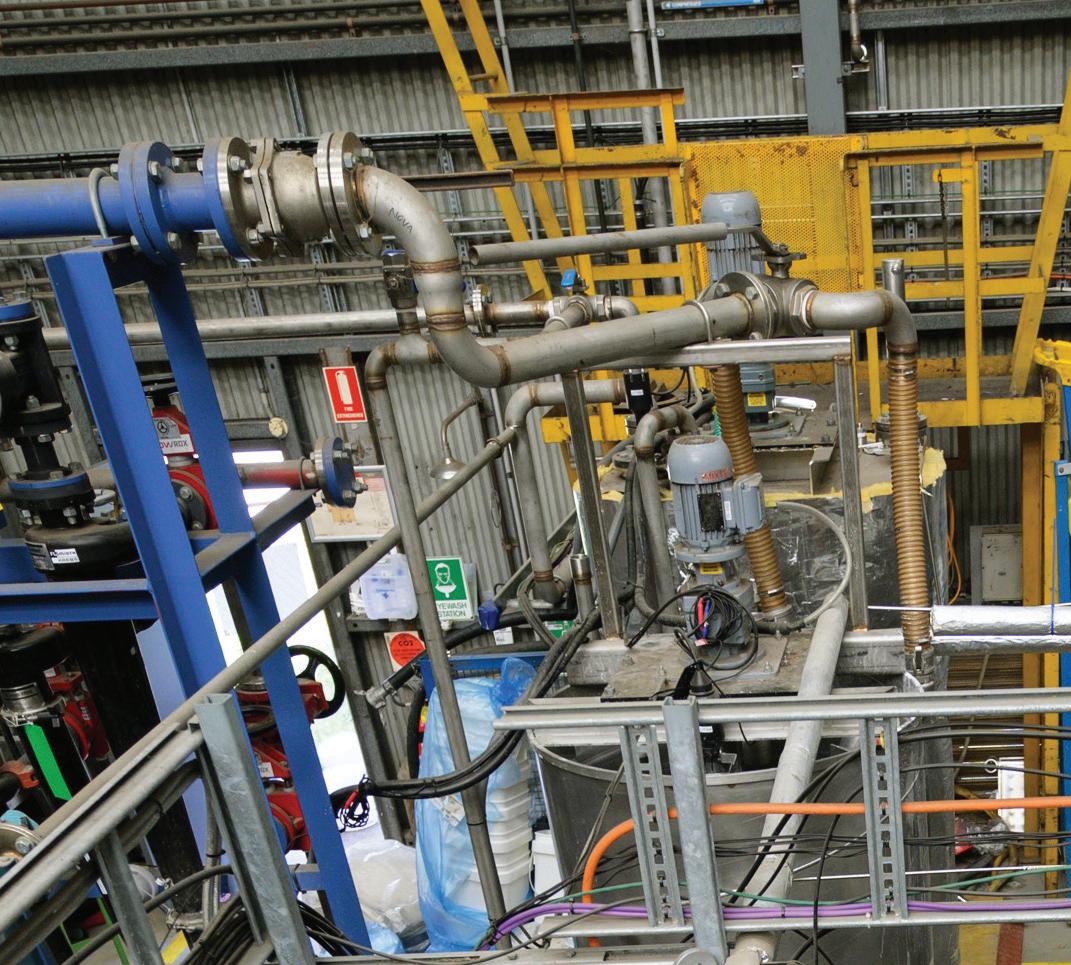

The NIER Precinct stands at the historical site of BHP’s former Newcastle Technology Centre, one of the first industrial facilities in Australia for international research in chemistry, chemical engineering, coal and ore beneficiation, and metallurgy.

The Precinct provides large-scale industrial research workshops, glasshouses, laboratories and office space, and is designed to support the growing number of groups engaged in collaborative research partnerships with industry, as they work to advance market-ready technologies.

Activity and research capacity at the precinct is diverse and evolving. With the oversight of the Management Committee, NIER provides dedicated precinct coordination ensuring safe and effective outcomes for various requirements including:

• Accommodating shifts in research scale and changing workplace or research configurations

• Aligning infrastructure allocations with research collaborations, commercial contracts and outcomes

• Strategic site service provisioning to accommodate and futureproof large-scale industrial research

• Ensuring compliance with co-location, dangerous goods and bulk storage

• Managing demobilisation of research plant, equipment and materials

Due to the complex nature of the research activity that is undertaken onsite at NIER, a comprehensive Health, Safety & Environment (HSE) Management System, aligned with the University’s broader frameworks and supported by a dedicated HSE committee ensures the safety of all occupants, tenants, guests and visitors.

NIER’s collaborative partnerships help address the unique challenges of regions, contributing to improved sustainability, diversified economic growth and a resilient future.

The Central-West Orana district of NSW covers a significant portion of the state’s total size, encompassing 23 local government areas including regional centres such as Dubbo, Mudgee, Parkes, Bathurst and Orange. It is a region of booming business and potential, particularly with the development of the state’s first Renewable Energy Zone (REZ), and in the sectors of critical minerals and agribusiness.

This region was allocated as a REZ by the Minister for Energy and Environment in 2021 due to its rich natural assets for strong renewable energy resource potential and proximity to the existing electricity network and transport infrastructure. The subsequent burst of investment and activity in the region has included several renewable energy projects and major investments in the Central-West Orana REZ transmission project, Inland Rail and Parkes Special Activation Precinct. The REZ is expected to bring up to $20 billion in private investment to the region by 2030 (EnergyCo).

With these many opportunities come challenges for affected towns and communities, and in response, NIER has prepared a Central-West Orana Plan which sets out how our research capability and strengths align with the region’s energy, environment, resource sustainability, and health and wellbeing goals.

Core functions of NIER aligning to Central-West Orana regional priorities include:

• Water security and climate adaptation

• Social impact and mental health resilience

• Food innovation

• Resources health and safety

• Clean energy and decarbonisation

• Next generation mining solutions

• Training for the skills of tomorrow

Based on our Central-West Orana Plan, our strategic engagement has the purpose of generating opportunities for collaboration to contribute research solutions as the region grows and diversifies.

In delivering opportunities for growth, the plan is closely aligned to local, state and federal government policy and programs to ensure our activities support industry and sector needs. To achieve this we work with state and federal government departments including Regional Development Australia, the NSW Department of Primary Industries and Regional Development and the Department of Climate Change, Energy, the Environment and Water, in support of the implementation of the 2023-2026 Orana Strategic Regional Plan and the Central-West Orana Regional Plan 2041.

“RenewableEnergyZones(REZ)willgroupnewwindandsolarpowergeneration intolocationswhereitcanbeefficientlystoredandtransmittedacrossNSW.Five zones have so far been identified.” - NSW Government, EnergyCo

NIER’s engagement in the region is to better understand local drivers and challenges, and to build collective research capacity through new partnerships and collaborations. The NSW Decarbonisation Innovation Hub - with its key focus areas in Electrification & Energy Systems, Land & Primary Industries, and Power Fuels including Hydrogen - recognises significant opportunities to contribute to carbon reduction in the region. The Trailblazer for Recycling & Clean Energy (TRaCE) program is also well-aligned to support renewable energy developments in the region, with focus areas including Next Generation Solar Photovoltaics, Electrification, Energy Systems and Storage, Sustainable Fuels and Chemicals, Recycling and MICROfactories.

Strategic knowledge-exchange networks and events o ered by the NSW Energy and Resources Knowledge Hub provide targeted opportunities for end user problem solving and connections.

NIER has also been active in demonstrating our research and technology capabilities to industry representatives from Central-West Orana. Late last year, NIER welcomed a group of 28 delegates from several Central-West mining companies with an interest in the sustainable innovations and processes in development at the University. Delegates were presented with a showcase of current and emerging technologies at the NIER Precinct, and enjoyed a robust forum, supported by Austmine, and attended by SMEs and Hunter-based companies, to discuss current and future priorities, operational needs and how new solutions and technologies have the potential to unlock future growth for mining companies.

NIER has been exploring opportunities with RDA Orana around renewable energy activity including the activation of an industry innovation hub with support from the NSW Department of Primary Industries and Regional Development. NIER will return to Dubbo to participate in the 2024 Resources, Energy and Industry Innovation Forum, and continue discussions with Dubbo Regional Council on capabilities of the University around wastewater treatment and associated opportunities.

The Mid-Western Regional Council is one of the local government areas (LGA) in the Central-West Orana REZ. While mining remains the dominant industry for this LGA, increased investment towards renewable energy generation and storage capacity is changing the economic landscape.

NIER was part of the Mid-Western Regional Council’s 2024 Economic Think Tank, an event which attracted business leaders from key local industries of mining, renewable energy, agriculture, tourism, health, education and government. Discussions focused on the local economy, major projects and economic development initiatives in the region, as well as local challenges and opportunities.

In better understanding the specific challenges of the area, NIER was able to make connections and demonstrate how University research capabilities can provide a competitive advantage for industry in the region.

A key theme locally is the social impact of the expanding energy and resources industries, consistent with challenges communities in the Hunter region are facing as industry shifts from a mining base to a more diversified energy economy. NIER was able to showcase evidencebased research activity aimed at supporting the mental health and wellbeing of impacted communities during transition.

Communities in the Hunter region are not alone in the challenges they face in moving away from traditional sources of fuel and energy production. Closures of power plants and mines are increasing both domestically and abroad as pathways towards renewable energy production gather pace. Mine closure and new energy projects pose distinct questions about the future. Within traditional coal based communities, the challenge of addressing climate change and achieving global and national climate targets translates into local tensions and uncertainty, as well as opportunities.

Associate Professor Hedda Haugen Askland is a social anthropologist with almost a decade of experience working with industry and communities in transition in the Hunter region.

In partnership with BHP, Professor Askland is leading a project which aims to establish a community-engaged dialogue and collaborative partnership with the Muswellbrook community to develop a draft roadmap for the successful closure of the Mt Arthur coal mine. This roadmap will engage with key stakeholders and utilise a place-based design to identify and address key challenges and opportunities with communityled solutions. This research will offer a concept for future place-based and community-owned projects that will serve as a foundation for wellbeing and connection, not only for Muswellbrook but for other communities experiencing similar transitions.

Air quality concerns are significant for Upper Hunter residents near operational mines. Dust from mine sites can affect health, the environment, and the reputation of mining operations. Dust monitoring relies on costly sensors at site boundaries, far from dust generating activities, and mitigation mainly depends on operator judgement on when to suppress dust with water.

Advances have introduced lower-cost solutions and different technologies that can enhance monitoring and visualisation of dust sources.

Since 2018, researchers Dr Dusan Ilic and Dr Aleksej Lavrinec from the Centre for Bulk Solids and Particulate Technologies, collaborating with Associate Professor John Holdsworth from the School of Environmental and Life Sciences, and PhD candidate Liam Sutton have worked to innovate dust monitoring and dust emissions management. With projects supported by MACH Energy Mount Pleasant, the team has integrated a 3D LiDAR system and a real-time, low-cost sensor network that can be used for both environmental and occupational hazard assessment.

These innovations enable data-based decision making, improved identification of dust sources, emissions control and reduced water consumption, leading to more sustainable engineering practices.

The new energy sector is growing significantly in both importance and relevance. New energy developments in the Hunter region are accelerating and far reaching in scope across segments of energy generation, storage, transmission, equipment and services.

Rapid skills development is required for new energy industries to flourish. Skills development is a key tool of economic participation in clean energy sectors, and will continue to be crucial to meeting the demands of a complex and changing energy landscape.

Funding from the Australian Government's Priority Community Infrastructure Program has been awarded to develop the New Energy Skills Hub (The Skills Hub) to provide a unique, flexible environment for education providers and industry to co-develop and deliver courses of study that include and combine university education and competencybased training.

The Hunter region has a robust asset base, established supply chains, skilled workforce, and a rich energy research and innovation ecosystem. The Skills Hub will serve to deliver workforce development needs and address emerging new energy standards. Servicing a region built on industrial innovation, the University will work cooperatively with TAFE, education partners, industry and regulatory bodies to act as a key enabler of the future energy economy and to ensure skill development and education keeps pace with industry development.

Supporting the University’s commitment to the Pacific Islands region, senior University representatives participated in the Secretariat of the Pacific Regional Environment Programme’s (SPREP) 31st Meeting of Officials. As part of the visit, a new round of PhD scholarships, Masters research and coursework pathways were announced, and a Memorandum of Understanding was signed with the Scientific Research Organisation of Samoa (SROS), aimed at nurturing the region’s talent and equipping scientists with the tools needed to address local challenges.

These collaborative initiatives contribute to the strengthening of our global ties with our Pacific neighbours, enabling the exchange of scientific information, research methodologies, and educational materials to spark innovation and drive progress. Together with several other University student mobility and capacity building activities in the region, activities will help to position the University to collectively contribute to tackling complex issues such as climate change, food insecurity and sustainable development, with the ultimate goal of supporting regional resilience.

The University recently welcomed a delegation from Samoa to explore additional collaborative opportunities for energy and environmental research and amplify local ingenuity in the Pacific to address global challenges.

The delegation included Toiata Apelu-Uili, Assistant Chief Executive Officer for the Renewable Energy Division of the Ministry for Natural Resources and Environment, and Faafetai ‘Tai’ Kolose, Principal Research Scientist in Renewable Energy at the Environment and Renewable Energy Division of the Scientific Research Organisation of Samoa.

During their week-long visit, they met with University leaders, researchers and PhD candidates, and several partners in the region including CSIRO’s Newcastle Energy Centre and Lake Macquarie City Council’s sustainability team. They also joined the University’s Resources and Energy Doctoral Training Centre students for a tour of AGL’s Bayswater Power Station and the Ethtec Pilot Biorefinery in the Upper Hunter.

The visit forms part of NIER’s continued commitment to supporting the advancement of the Pacific region, knowledge exchange and collaborative research through the Pacific Node initiative.

The University of Newcastle has signed a research agreement with the National Environment Service (NES) of the Cook Islands to prevent habitat degradation and conserve the rich biodiversity in the Cook Islands region.

Project activities are focused on evaluating and improving the sustainability of four vital catchments on Rarotonga – Avana, Takuvaine, Turangi and Avatiu – and strengthening the capacity of government and citizen scientists to undertake catchment audits, environmental monitoring and ecosystem assessments. Rarotonga relies on these catchments for social, cultural, economic and ecosystem services. In the face of negative effects on biodiversity, this project brings together NES and local communities to provide research and training, and assist in the implementation of sustainable practices.

Associate Professor Troy Gaston, Professor Bill Leggat, and Dr Sascha Fuller from the School of Environmental and Life Sciences will be leading this project for the University of Newcastle. Outcomes will benefit both local communities and international initiatives promoting sustainable natural resource management.

The project’s environmental research and conservation activities build on the partnership between the University and NES, formalised in 2022, which enables us to collaborate on initiatives that will have lasting beneficial impacts for communities and organisations in the Cook Islands.

As a global impact leader, deliver research and education excellence with Pacific partners that drives sustainable solutions and enhances capacity across the Pacific Islands region. Our activities will be considered an exemplar for training and mentoring future Pacific Islands leaders and will expand career pathways for Pacific and Australian students.

• Uphold Pacific Peoples’ custodianship of land, sea and sky

• Include Pacific Peoples’ histories, perspectives and priorities

• Inform and engage Pacific Peoples’ in planning processes and outcomes

• Integrate Pacific Peoples’ knowledge into practices

• Develop mutually beneficial relationships of value

Hosted by NIER, delivered by UNSW Sydney and the University of Newcastle, and supported by the Australian Government Department of Education, the Trailblazer for Recycling and Clean Energy (TRaCE) is moving research out of the lab and into market.

TRaCE de-risks the research and development of emerging energy technologies by enabling industry to tap into the world-class research teams, facilities, specialist equipment, and knowledge within these universities. By creating a new and lasting ecosystem of support, TRaCE will help develop and scale commercially viable products, ensure we have the critical skills to manufacture them in Australia, and reduce carbon emissions.

The TRaCE program is supporting research projects in the following four key areas, handpicked for their potential to decarbonise industry.

TRaCE recently launched two fellowship programs that will allow researchers to grow their careers by collaborating with industry partners to solve recycling and clean energy challenges.

Three fellows, awarded the TRaCE Enterprise Academic Fellowships in late June 2024, will pursue a new project with industry for up to three years that focuses on accelerating commercialisation outcomes.

TRaCE Mobility Fellowships will enable researchers to add value to an existing real-world research problem for up to a year, enabling two-way mobility between the researcher and the industry partner.

Applications for the Mobility Fellowship Program are open until the completion of the TRaCE program in 2027. RECYCLING

Since its o cial launch in April 2024, the TRaCE R&D Voucher program has supported SMEs, startups and scaleups to grow their sustainability solutions.

By embarking on a research project with university researchers, these businesses can get their ideas o the ground and scale to commercial success with tailored expertise, equipment and co-funding.

The TRaCE program at the University of Newcastle has commenced four R&D Voucher projects:

• EM Energy is testing their Organic Hydrogen Electrolyser Cell (OHEC), which can produce hydrogen from almost any organic material on-site and on-demand.

• ARC Ento Tech LTD is investigating if their SynCoal™ product, made from plastic and inedible organics like paper, textiles and wood, could partially substitute metallurgical coal in blast furnace ironmaking.

• Ellipsis IP is upscaling their electrolytic iron ore reduction method to test whether it can power the ironmaking process with renewable energy instead of fossil fuels.

• HydGene Renewables is testing if they can combine their hydrogen production technology with the University’s ammonia capabilities to help farmers create eco-friendly fertilisers.

“Startupshavetotestfasttoshowgrowthto ourinvestors,soagreementsneedtobein placequickly.Withintwomonthsofmeeting theTRaCEteamattheUniversityofNewcastle, wehadcreatedaresearchprojectandsigned anagreement.It’spracticallyunheardofto enteraresearchagreementthatquicklywitha university.Ifanything,weweretheonestoslow downtheprocess!”

- Dr Louise Brown, CEO and Founder HydGene Renewables.

These academics will all gain hands-on experience in an industry setting to grow their networks and foster collaborative relationships that align with their career goals.

The International Air Transport Association has projected that sustainable aviation fuels could contribute around 65 per cent of the reduction in emissions needed by the aviation industry to reach net zero CO₂ emissions by 2050.

Laureate Professor Behdad Moghtaderi, and his team at the University of Newcastle’s Centre for Innovative Energy Technologies, with the support of TRaCE, is leading three projects that, together with his carbon capture capabilities, provide the core ingredients for producing sustainable aviation fuels.

The team is working with AMMONIAC on the production of green ammonia, LAVO on the storage of hydrogen in a solid state, and Elmntre on the conversion of municipal solid waste into hydrogen.

Scan code to find out more www.trace.org.au

Opening doors between academia and industry, NIER facilitates partnerships and collective expertise to drive collaborative innovation.

Laureate Professor Behdad Moghtaderi and his team at the Centre for Innovative Energy Technologies are gaining recognition as world leaders in hydrogen and ammonia safety. They are collaborating with Singapore’s Agency for Science, Technology and Research (A*STAR) on a project to quantify and mitigate risk associated with large-scale storage of ammonia as a hydrogen carrier. This initiative is part of Singapore’s LowCarbon Energy Research Programme, funded by the National Research Foundation and hosted by A*STAR. The goal is to enhance capabilities across the hydrogen supply chain, enabling safe and cost-effective hydrogen importation and utilisation during Singapore’s energy transition.

Professor Moghtaderi’s team will construct and develop a pilotscale detonation tube to assess the explosion characteristics of ammonia. This research will help mitigate risks associated with large-scale storage and inform safety protocols for new ammonia facilities in Singapore. The detonation tube facilities were originally designed and developed by Professor Moghtaderi at the NIER Precinct.

Co-founders of EM Energy, Ms Isabel Toasa and Mr Chris Wilson had an idea to take waste and turn it into green hydrogen. It evolved following Ms Toasa's experience in her home country, Ecuador, where she experienced waterways being polluted with batteries, and children suffering from illness as a consequence.

Ms Toasawanted to pursue her mission to give remote communities a better life, so came up with an idea for an organic, renewable battery.

As a result, EM Energy began the journey to commercialise a non-polluting battery. As research progressed, the team discovered the reaction of the organic materials in their battery also created hydrogen gas. This discovery evolved into the Organic Hydrogen Electrolyser Cell which can produce hydrogen from almost any organic material to provide a green power solution.

A considerable barrier for EM Energy was not having access to facilities or equipment to safely test their technology; a dilemma that was solved following a fortuitous meeting with Dr Peter Richardson from the School of Engineering during a Hydrogen Showcase at NIER.

EM Energy became the first recipient of TRaCE’s R&D Voucher Program, and have since received additional grants through the Powerfuels Including Hydrogen Network of the NSW Decarbonisation Innovation Hub and the NSW Government’s Minimum Viable Product (MVP) Ventures Program. These grants will enable the team to target the characterisation, testing and validation of various aspects of the technology, and support them as they seek an international patent.

Solar power shows incredible promise in the global transition to renewable energy. Already, rooftop solar panels are installed in more than 3 million Australian homes. The energy that solar can produce is practically limitless so long as the sun keeps shining. But unfortunately, one increasingly glaring issue with solar is the life of panels is not limitless, and there are a lack of recycling options.

A 2016 study concluded end-of-life solar waste will cumulate to an estimated 80 million tonnes by 2050. The critical materials such as silver and silicon in the solar panels are particularly challenging to extract without contaminating them with other materials.

With these critical materials becoming harder and harder to obtain in raw form, it’s becoming more important to find a way to extract them from old panels using an energy efficient, lowcost method that won’t compromise purity. NIER researchers are joining the effort to tackle this issue from different directions.

In partnership with CSIRO and PV Industries, CSIRO Industry PhD candidate Jackson Lee, under the supervision of Dr Jessica Allen, is analysing solar panel recovery methods and proposing a model for recycling silicon.

Jackson's latest review has found that electrochemical approaches show promise in extracting these precious materials but has identified key areas that need to be further investigated to make the process more feasible and costeffective. By the end of his PhD, Jackson aims to develop a silicon electrorefining process to produce upgraded silicon from a recycled silicon feedstock derived from end-of-life modules.

The Centre for Organic Electronics together with industry partner, Kardinia Energy, specialise in printed solar, a technology that has been designed to be fully recyclable from the start. Printed solar uses carbon-based semi-conducting polymers printed on recyclable PET plastic using reel-to-reel printing techniques.

Testing is focused on investigating the performance of a wide range of organic feedstocks, such as coal waste or agricultural waste that would otherwise go to landfill or be burned, increasing greenhouse gas emissions. If successful, this technology would produce a truly sustainable source of green hydrogen, contributing to a circular economy.

Once they’ve stopped producing energy effectively, the solar PV ink can be removed, leaving the plastic sheets ready to be put through the printing process again.

On top of the sustainability benefits, the materials for the technology are highly abundant and do not require energyintensive manufacturing, pricing them at a much lower cost than traditional silicon solar panels.

Safety berms are an essential safety feature in surface mining, quarry and construction sites. Usually made from waste rock material available from the site at the time, they are strategically placed barriers used to prevent heavy mining equipment from falling off an edge or colliding with other obstacles.

Despite being the go-to safety barrier for the industry for more than half a century, there have been many unknowns about the proper design of safety berms, their stability in collision scenarios, and what limitations exist.

As the use of ultra-class haul trucks in mining and articulated haul trucks in quarrying and construction become more prevalent, there is a growing need for rigorous design guidelines specific to safety berms.

Research conducted by the University of Newcastle’s Professor Anna Giacomini and Associate Professor Klaus Thoeni funded by the Australian Coal Association Research Program (ACARP) and the New Zealand quarry industry has provided a scientific tool to efficiently design safety berms. The research team applied advanced numerical modelling techniques combined with full-scale experimental testing to provide guidelines on how to design safety berms for heavy machinery.

Research findings have provided advanced knowledge of haul truck interactions, and failure modes in waste rock barriers, providing guidelines with wide-reaching impact across the resources sector. Regulators and operators in New Zealand and Australia have implemented findings to optimise safety berms, improve mine safety operations and increase cost efficiencies.

Steel production from iron ore is a major contributor to greenhouse gas (GHG) emissions, accounting for over seven per cent of global annual GHG emissions. In Australia, where half of the world's iron ore originates, finding innovative ways to reduce emissions in the steel industry is important for both the economy and the environment. Traditional steel production relies on blast furnaces, and is a process that emits considerable amounts of GHGs. To address this challenge, researchers are exploring alternative ironmaking methods that can significantly reduce emissions.

Co-Director of the BHP Centre for Sustainable Steelmaking Research at the University of Newcastle, Professor Tom Honeyands, is leading a collaborative project to develop a lower emission alternative ironmaking process. The goal is to create steel using hydrogen and electricity, with a focus on Australia’s hematite-goethite iron ore resources. The project involves partnerships with BHP and RWTH Aachen University in Germany, and this year received more than $2.9 million in funding from the Australian Renewable Energy Agency (ARENA).

The team is investigating a two-step process where they produce hydrogen direct reduced iron from iron ore before using an electric smelting furnace to remove impurities. Electric smelting furnaces offer several advantages over traditional methods, including the potential to replace coal with electricity as an energy source. When powered by renewables, this approach substantially reduces GHG emissions.

The demand for low GHG emission steel is expected to grow exponentially over the next decade. The BHP Centre for Sustainable Steelmaking Research is at the forefront of innovation in lower GHG emission intensity steel production

and low-carbon steel research. This project also aligns with NIER's strategic goals to pursue international collaborations that advance high impact solutions for energy and resources sectors, while showcasing our research capabilities and boosting our global profile, paving the way for more collaborative connections.

This innovative system extracts water from wet coarse tailings and product streams originating from below water mining operations or after wet beneficiation processes. This water reclamation process promises to lower transportation costs for trains, trucks, and shipping, while also decreasing tailings volume.

The ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals has been instrumental in advancing this technology. Centre members are focused on enhancing dewatering capabilities through ongoing testing, analysis, and improvement initiatives.

Professor Ken Williams, the technology’s inventor, says the goal is to maximise water removal efficiency to facilitate reuse, thereby reducing overall water consumption in mining and mineral processing. With international patents secured, the next step involves bridging the gap to commercialisation through partnership with industry leaders.

Oleskii Merkulov, visiting from the Iron and Steel Institute of the Ukraine National Academy of Sciences, came to Australia in late 2023 for ten weeks of research with Professor Tom Honeyands from the BHP Centre for Sustainable Steelmaking Research

Made possible by the Ukrainian-Australia Research Fund of the Australian Academy of Science and the University of Newcastle, Oleksii joined the Centre to advance research on high-temperature properties of iron ore materials used in blast furnace smelting, with a particular focus on the use of hydrogen as an alternative fuel source. The results will contribute to learnings about how to use hydrogen in the smelting process without affecting total fuel consumption and the durability of the blast furnace.

HydGene Renewables, a startup specialising in hydrogen production from waste, has partnered with Laureate Professor Behdad Moghtaderi from the Centre for Innovative Energy Technologies, to see if farmers could produce eco-friendly fertilisers from farm waste on home soil.

The team at HydGene Renewables has engineered biocatalysts that enable them to convert agricultural waste, food waste, paper waste, brewery waste and even sewage waste into green hydrogen on-site and on-demand, showing enormous potential to decarbonise hard-to-abate sectors.

In the agriculture industry, the building block of all mineral fertilisers is ammonia, traditionally made with hydrogen from fossil fuels contributing to global greenhouse gas emissions. By bringing in Professor Moghtaderi’s ammonia expertise, they can explore its use as the primary ingredient in ammonia production for sustainable fertilisers.

Dr Louise Brown, CEO and Founder of HydGene Renewables said a benefit is the solution would give control back to the farmers, enabling them to make fertilisers on-site for their crops using their farming residues such as straw stubble.

The project, anticipated to finish in August 2024, will provide the information needed to determine if Professor Moghtaderi’s technology is the right fit for a pilot plant on a farm, the next step in making on-site production of green fertilisers a reality.

Professor Moghtaderi says HydGene Renewables’ solution has the potential to de-centralise the process, which would significantly reduce costs associated with storage and transportation, making products such as fertilisers less expensive.

One third of the world’s food is lost or wasted, not only costing the global economy but also affecting the environment. This expansive issue has financial, socio-economic, and environmental impacts for sectors including agricultural and food manufacturing, as well as for consumers.

The demand for plant-based milk has increased significantly in recent years, leading to large quantities of food waste associated with its production. For example, oat pulp, a major by-product of oat milk production, accounts for 20-45 per cent of the product’s volume, resulting in approximately 228 kilotonnes of oat pulp annually. Oat pulp is rich in protein, dietary fibre, beta-glucan, lipids, and bioactive compounds. However, only a small portion is used for animal feed or bioenergy, and a large quantity is discarded to landfills, contributing to increasing levels of environmental waste.

Often overlooked, soil health plays a crucial role in sustainable agriculture and a resilient ecosystem. Globally, soil health is declining due to factors like intensive agricultural practices, environmental pollution, and climate change. This degradation has far-reaching consequences, from reduced crop yields to increased greenhouse gas (GHG) emissions, exacerbating global challenges related to food and water security.

At the Global Centre for Environmental Remediation (GCER), soil health is viewed as an integrative property that reflects the soil’s capacity to respond to agricultural interventions and environmental impacts. The Integrated Soil Health Technology project, led by Professor Megh Mallavarapu and Dr Abinandan Sudharsanam, aims to revolutionise soil health through innovative approaches.

This project investigates the diversification of organic nutrient sources, focusing on novel products from Biocarbon and PyroAg, alongside demonstrated TRL >5 developed algae technology. The goal is to shift reliance away from synthetic fertilizers, enhancing soil health, reducing GHG emissions, and improving soil carbon storage.

The project will identify suitable algae strains for biofertilizer production and test these in a series of trials using NIER’s specialised temperature-controlled glasshouse facilities. The development of this integrated soil technology will include rigorous testing and feasibility studies, utilising advanced technology for monitoring GHG emissions and conducting comprehensive cost-benefit analyses to scale these technologies to a commercial level.

By pioneering these advancements, the project contributes significantly to sustainable agriculture and addresses global challenges related to climate change and human impacts on the environment. Additionally, this initiative aligns with United Nations Sustainable Development Goal 15, which emphasises the importance of sustainably managing forests, combating desertification, halting and reversing land degradation, and biodiversity loss. Through this work, GCER is helping to create a healthier planet and more secure future for all.

Biosolids produced from wastewater treatment are a significant source of microplastics, which are contaminants of concern for agriculture, food security and ecosystems.

A study by Professor Megh Mallavarapu and Associate Professor Geoff MacFarlane will provide the first major investigation into the fate of microplastics in biosolids and biosolid-amended soils in Australia. The knowledge gained will inform future protocols for Australian soil and water quality monitoring programs to support agriculture sustainability, human health and the quality of our food supply chains.

In partnership with the Agency for Science, Technology and Research (A*STAR) in Singapore, Minh Son Le, a PhD candidate of the Doctoral Training Centre for Food and Agribusiness, supervised by Associate Professor Quan Vuong, is undertaking a research project that seeks to provide costeffective solutions for valorisation of oat pulp by applying advanced technologies to convert the pulp into quality flours with high levels of dietary fibre, protein, antioxidants and functional peptides. Further potential applications of these flours are being investigated for use in food, cosmetic and pharmaceutical products, with tackling waste, adding value to the industry, and contributing to Australia’s circular economy expected outcomes of this project.

In May 2024, a research team from the University’s Centre for Innovative Energy Technologies (CINET) officially unveiled technology capable of harvesting up to 1000 litres of drinkable water per day – from air.

The Hydro Harvester absorbs water from the atmosphere. Solar energy or waste heat is used to produce hot, humid air – the hotter the air, the more water it holds. This hot air is then cooled using ambient air as a heat sink to extract water for drinking or irrigation.

This project received funding from the Australian Government’s Future Drought Fund, enabling Laureate Professor Behdad Moghtaderi and his team to scale up the Hydro Harvester from pilot form generating 20 litres of drinkable water per day to the modular 1000 litres per day system it is today.

Nearing market readiness, this model Hydro Harvester has the capacity to produce enough drinking water to sustain a small rural community or up to 400 people – a potentially lifesaving tool during drought or emergencies.

Unlike commercially available atmospheric water generators (AWGs), the Hydro Harvester works by heating air instead of cooling it. By using solar thermal energy, or waste heat, the Hydro Harvester has a lower electrical demand and lower average cost of water per litre than commercial AWGs.

Additionally, the technology is designed to operate independently of the ambient temperature and humidity, so it’s suitable in for use in virtually any environmental condition.

Official observed weather records in Australia are typically available from the early 1900s, but what do we know about the time before observed records were available? Recent research examining ice cores from Antarctica has provided an understanding of Australian weather patterns tracing back thousands of years.

When eastern Australia experiences hot, dry weather conditions, there is less wind around Antarctica, which means less sea-salt spray is laid down at the ice core site. Particles of sea-salt spray trapped inside the Antarctic ice cores have revealed at least seven occasions over the last 2000 years when Australian bushfire (and drought) weather was as bad or worse than what we experienced during the devastating Black Summer bushfires of 2019/2020.

This extended knowledge of Australia’s natural climate variations is valuable information for natural disaster and climate resilience planning.

Associate Professor Anthony Kiem from the University of Newcastle’s Centre for Water, Climate and Land worked on this collaborative project alongside the Institute for Marine and Antarctic Studies and the Australian Antarctic Program Partnership at the University of Tasmania, the ARC Centre of Excellence for Climate Extremes and the Australian Centre for Excellence in Antarctic Science.

Warmer than usual temperatures are threatening coral and marine ecosystems in reef locations across the Pacific Ocean. University of Newcastle coral scientist Professor Bill Leggat from the Coastal and Marine Science Research Group has coordinated long-term monitoring of heat stress and related coral bleaching events at reefs surrounding world heritagelisted Lord Howe Island.

An increase in frequency and intensity of climate-related coastal hazards has triggered a rise in demand for coastal resilience expertise. In response, research at the University of Newcastle has broadened to help overcome challenges in coastal management, improve engineering techniques, and deliver predictive capabilities to effectively model, plan, mitigate, and prepare for coastal hazards including storm tide inundation, flooding, freshwater contamination, coastal erosion, harmful algal blooms, tsunamis and rising sea levels.

The mounting burdens of coastal hazards on our marine, estuarine, and catchment waterways impact the 87 per cent of Australia’s population that lives within 50 kilometres of the coast, with similar impacts on our Pacific Island neighbours.

The spectrum of expertise in coastal resilience research means we can address mitigation and future adaptation with coordinated and flexible multidisciplinary approaches.

Microplastics, defined as plastic particles smaller than 5mm, have become significant environmental pollutants in wastewater due to their widespread presence in everyday products like microbeads in exfoliants and toothpaste, microfibres from washing clothes, and plastic waste. These particles pose substantial ecological risks, as they can be ingested by aquatic organisms, leading to physical and chemical harm. Current conventional wastewater treatment facilities lack dedicated processes to separate these tiny particles, resulting in their uncontrolled discharge into natural water bodies.

Dr Subhasish Mitra from the ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals has partnered with Hunter Water on a project funded by a College of Engineering, Science and Environment fellowship accelerator scheme to tackle this challenge using micro-nanobubbles technology. Dr Mitra has developed a proof-of-concept flotation system utilising a polydispersed bubble system involving milli-, micro-, and nano-sized bubbles to separate microplastics from wastewater. This process has successfully separated microplastics of various sizes and shapes (1D, 2D, and 3D) and is simple enough to be integrated into existing wastewater treatment systems as a polishing unit.

NIER’s research education initiatives provide industry embedded, targeted training and skills development for postgraduate students, to address the workforce needs of future industries.

Doctoral Training Centres (DTC) offer PhD candidates the opportunity to enhance their learning through industry-engaged experiences, crucial for developing advanced skillsets, increasing industry exposure, and boosting employability. Experiences such as industry site tours immerse candidates in real-world operations, providing first-hand insights and fostering valuable industry connections.

Focusing on clean and renewable energy, this year candidates from the Resources and Energy DTCs toured Bayswater Power Station and the Hunter Pilot Biorefinery Site. These tours offered an in-depth look at the operations and future plans for largescale renewable energy initiatives. At the Hunter Pilot Biorefinery Site, candidates learned about innovative, environmentally sustainable processes for producing biofuels and renewable chemicals from crops and forestry waste, in partnership with University of Newcastle researchers.

Candidates also visited Tomago Aluminium, Australia’s largest aluminium smelter. Here, they experienced the scale and complexity of large-scale industrial operations, gaining invaluable technical insights from on-site engineers about the smelter’s continuous 24-hour operations.

These industry engaged learning experiences are essential in advancing students’ understanding of their field. They bridge the gap between academic theory and practical application, equipping students with the knowledge and connections needed to enter industry roles with confidence and expertise.

“Beingachemicalengineer,Ivaluedthis opportunitytoseetheAluminiumproduction operationsandtechnologyworkingtogetherin real time.”

The Food and Agribusiness DTC farewelled Academic Convenor, Associate Professor Tamara Bucher in 2023 as she commenced a new role overseas. Associate Professor Bucher was instrumental in establishing the DTC, bringing her wealth of knowledge and local industry partners to contribute to a diverse and dynamic doctoral program.

The DTC welcomed Dr Taiwo Akanbi as the new Academic Convenor and Associate Professor Quan Vuong as Deputy Convenor to continue to support the established focus areas; product science, climate resilience and sustainability, advanced technology and market access.

The Centre for Bulk Solids and Particulate Technology (CBSPT) is actively involved in both fundamental and applied research on a range of problems associated with bulk solids and particulate technology. In addition to research activities, the CBSPT conducts specialised education strands in this focus area for undergraduate engineering degrees, short intensive professional development programs and supervision for Higher Degree by Research candidates.

Through its partnerships with international research groups and universities, CBSPT continues to strive for excellence in knowledge translation. One of the most recent collaborative engagements has been with Istanbul Technical University and the Technical Institute Georg Simon Ohm in Nuremberg where students Nidanur Sevinç, Nisa Coşkun, Elif Karaboğa, Rabia Gülhan Koç, and Florian Schropp, visited NIER to undertake an internship under the supervision of Professor Ken Williams, Dr Elif Ergun Donohoe and Dr Lauren Bradney.

The interns from CBSPT, consisting of undergraduate and postgraduate students in the field of mineral processing engineering, were given the opportunity to work on a number of projects relating to their program through valuable handson experience and research in the laboratory as well as networking experience.

“Thisprocesshasprovidedmewiththe opportunitytodiscoverAustralia,myfieldof expertise,mypassions,andmyself.”

- Nidanur Sevinç, graduated from the Department of Mineral Processing Engineering at Istanbul Technical University (Türkiye)

“Throughmyinternshipexperience,Ihave learnedmanythingsintheresearchfield,andI nowknowhowIwanttoprogressinmycareer path”

- Nisa Coşkun, undergraduate at the Department of Mineral Processing Engineering at Istanbul Technical University (Türkiye)

“AsaninternfromTürkiye,thenetworkIhave gainedherewillalsoaddvaluetomewhen Ireturntomycountry.Ihopetherewillbe moreopportunitieslikethisforinternational students in the future”

- Elif Karaboğa, graduated from the Department of Mineral Processing Engineering at Istanbul Technical University (Türkiye)

Two researchers from the BHP Centre for Sustainable Steelmaking Research completed a development program in late 2023, initiated by BHP, designed to assist in breaking down barriers that often prevent women in the engineering and mining sectors from entering leadership roles.

NIER partnered with BHP to develop the Diverse Talent Program for Inspiring Women in Research with an aim to support talented researchers to progress their careers.

“Thisprogramexposesresearcherstothe real-worldchallengesandproblemsthat industriesface,enablingustoworkonmore targetedsolutions.”

- Dr Simin Moradmand

Laureate Professor Kevin Galvin from COEMinerals showing some of his concepts to the Hon. Courtney Houssos, NSW Minister for Natural Resources, Minister for Domestic Manufacturing and Government Procurement, and Minister for Finance.

NIER’s collaborative model accelerates opportunities for the deployment of technologies and services to deliver sustainable solutions for the vital sectors of energy, resources, food and water.

Developed jointly by FLSmidth and the ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals (COEMinerals), The REFLUX™ Flotation Cell (RFC) has undergone full-scale trials in Australia and Europe. The technology was recently launched as a commercial product, attracting a 2023 Mining Magazine Technology and Innovation Award recognising breakthrough innovation in flotation technology offering superior performance and efficiency.

Initial work by Laureate Professor Kevin Galvin and his team took the RFC from concept to pilot scale, and FLSmidth’s support enabled the technology to be scaled-up for production, with large-scale designs completed for onsite trials. One such trial is currently underway at a copper concentrator, where an 850mm diameter RFC850 is treating 60m³/h of scavenger feed material which is about three times the throughput rate of an equivalently sized conventional flotation machine. Testing is being performed in a self-contained system that was designed and built by FLSmidth. It comprises feed and overflow tanks with associated feed, concentrate, and tailings pumps.

Commercially available industrial samplers are employed to sample the streams entering and leaving the RFC. Results have already demonstrated that the kinetics of the industrial system are better than the pilot-scale system at equivalent or better grades and recoveries.

The project supports the transition to more sustainable mineral processing operations consistent with COEMinerals' mission to establish new, transformational technologies in minerals beneficiation to help achieve the goal of significantly reducing energy and water use during mineral processing by 2030, while also maintaining the drive towards the ‘zeroemission’ mine.

The REFLUX™ Concentrating Classifier (RCC), which is derived from the Reflux Classifier technology, is expected to undergo a trial as part of the upscaling of a COEMinerals study on cassiterite recovery from a tailings dam in NSW. This technology attracted the 2023 Mining Technology Excellence Award for the best new product launch. A new provisional patent (lodged in 2023) will feature in a further advancement of this work.

Developed by FLSmidth in collaboration with Laureate Professor Kevin Galvin and his COEMinerals team, its unique design demonstrates several hydrodynamic advantages, with the ability to recover a wide size distribution of minerals at a rate of up to 7-10 times faster than traditional methods.

The RCC utilises gravity-based separation techniques to tackle the recovery challenges associated with low-grade minerals. This results in vast recovery improvements for low-grade mineral ores and tailings. Highly effective in upgrading the concentration of valuable minerals in low-grade feed samples, the modifications allow heavy minerals to settle in a lower gangue ratio region induced by split fluidisation flow.

Compared to traditional minerals recovery methods, the RCC offers a smaller footprint requiring no expensive foundations or tall structures to accommodate multiple stages - a more efficient and cost-effective solution. Improved recovery of valuable minerals in feeds of 3 per cent or less make it a crucial tool for improved sustainability in the mining industry.

ARC Ento Tech Ltd is a biotech company that is exploring an innovative new solution to help address the landfill crisis by transforming waste into valuable products.

They’ve partnered with Dr Arash Tahmasebi from the BHP Centre for Sustainable Steelmaking Research to investigate if their SynCoal™ product, made from plastic and inorganic waste like paper, textiles and wood, could partially substitute metallurgical coal in the cokemaking process for blast furnace ironmaking.

Plastics used in this particular waste to resources process are required to be clean and free from organic matter, and the ARC Ento Tech group have found an original solution to this problem in the form of the larvae of the black soldier fly. By enlisting the black soldier fly larvae to eat the organic waste and clean food scraps off inorganic waste, they are doing the job of preparing the material for the next phase where it can be recycled into valuable products.

In the next phase the waste is turned into SynCoal™ and mixed with natural coal to make a hybrid coke. Working together the team is researching how SynCoal™ can be used effectively in cokemaking applications, and identifying the upper limit of blending ratios between SynCoal™ and metallurgical coking coal.

Through pyrolysis, the waste is thermally decomposed into hydrogen and hydrocarbon. Industrial ovens collect the gas

that’s generated in the coke oven and generate electricity from it in a boiler, or inject it directly into the blast furnace to further reduce the fossil carbon input.

Every tonne of bulk material (iron ore, coal, copper) exported from Australia, is at some stage transported by belt conveyors.

A $1.13m ARC Mid-Career Industry Fellowship has been awarded to Professor Craig Wheeler, of the University’s School of Engineering, to improve efficiencies in this process.

This project will deliver a step change improvement to conveying technology and halve the energy used to handle and transport Australia’s most valuable export commodities. The system, developed by researchers in the Centre for Bulk Solids and Particulate Technologies and TUNRA Bulk Solids along with industry partner FLSmidth, replaces conventional conveyor belt-idler support sets with support carriages on steel to steel contact, this system drastically improves efficiency and reduces operating costs by up to 60 per cent.

The new technology merges the benefits of both the belt conveying technology and rail to produce a continuous low rolling resistance bulk material transportation system. Advanced models and novel experimental equipment will be developed to model this new innovative system to ensure safe, efficient and reliable design.

Some of the first sophisticated building supplies humans ever made were bricks and mortar. While they still play a fundamental role in construction today, there's been a growing demand to make these products more sustainable. Current manufacturing processes contribute significant CO₂ emissions, and after demolition, bricks are often thrown to landfill because the mortar is too difficult and expensive to remove.

Dr Josephine Vaughan from the Centre for Innovative Energy Technologies has partnered with Brickworks and the Royal Melbourne Institute of Technology to develop a removable mortar so once buildings are set to be demolished, the bricks can be reused at their full value. Through an Enterprise Academic Fellowship project with the Trailblazer for Recycling and Clean Energy, Dr Vaughan aims to expand on this work by creating a complementary mortar from construction, industrial and agricultural waste.

NIER is committed to the delivery of multidisciplinary education and training. We work closely with our industry partners to deliver a training experience to equip the next generation of graduates with the most up-to-date knowledge, technical abilities, and a skillset to solve problems that haven’t emerged yet. Here we meet three candidates at di erent milestones on their Higher Degree by Research pathways.

Dr Caroline Gomes De Oliveira, who was in the first cohort of students to go through the Resources Doctoral Training Centre (DTC), completed her PhD in 2023 with a portfolio of industry experience and knowledge which helped her move into a technical role with Elastotec.

Reminiscing on her experience at the University, she credits the DTC’s model for industry collaboration and training with

giving her specialised insights into her industry, including safety considerations and communication skills. Without this, she says the change and the challenge of moving into industry would have seemed much bigger.

While at NIER, Caroline worked closely with industry partners at Metso Outotec under the supervision of Professor Ken Williams from the Centre for Bulk Solids and Particulate Technologies (CBSPT) to develop an erosion model for the materials handling industry which is used to help determine the lifespan of liner materials in transfer chutes of mining machinery.

“I never wanted to write a thesis that would collectdust.ByworkingwithdatafromMetso Outotec,IknewIwaswritingsomethingthat wouldhelpsolvearealchallenge.”

- Dr Caroline Gomes De Oliveira

Following her graduation, Caroline moved into a role as a Research Associate with CBSPT for six months before joining Elastotec, a company that specialises in pulley lagging and wear panel solutions.

As Key Account Manager, Caroline maintains client relationships and is able to engage with the company's partners in all steps of pulley lagging design, manufacturing, and application.

Caroline is learning a lot in the new role, and enjoys being able to utilise her technical knowledge. "Right now I’m writing a white paper for a conference. My technical background is still very valuable and applied here,” she said.

Kellie Ashton commenced her PhD at the University of Newcastle in August 2023, working with biofuel experts at Ethanol Technologies (Ethtec) to investigate a way to turn agricultural waste into bioethanol more efficiently and at a lower cost. Bioethanol is a renewable and low-carbon fuel, seeking to make the transportation industry more sustainable.

The traditional method for making bioethanol relies on food crops, requiring a massive amount of arable land and valuable resources that might otherwise be used to nourish people and animals. With the support of the Trailblazer for Recycling and Clean Energy (TRaCE), Ethtec are investigating an alternative process called ‘second-generation bioethanol production’, which creates bioethanol from inedible agricultural waste like woodchips and rice husks.

Supervised by Associate Professor Ian Grainge, Kellie is working with Ethtec to engineer a yeast strain that will make the fermentation process of bioethanol production faster and more resource efficient. In addition to bioethanol, the yeast can be engineered to produce other high value chemicals. For example, it can currently produce an alternative sweetener as a by-product of the fermentation process, not unlike what you’d find on supermarket shelves.

The team aims to take the fermentation process from the lab to Ethtec’s Hunter Pilot Biorefinery in Muswellbrook, NSW, where they will refine the technology with an aim to streamline it for full commercial deployment.

“ThesupportfromProfessorGraingeand EthtecasIbeginmyPhDprojecthasbeen invaluable.I’mlookingforwardtothehands-on industryexperienceI’llgettestingtheproduct atalargerscaleintheBiorefinery,”

- Kellie Ashton

Edward Bissaker is a PhD Candidate within the BHP Centre for Sustainable Steelmaking Research and is part of the Energy Doctoral Training Centre. Supervised by Associate Professor Bishnu Lamichhane, his thesis ‘Improved Coal Blending Models through Optimisation of Coke Microstructure’ uses advanced mathematics and computational tools to classify metallurgical coke microstructure formations and develop models to optimise the mechanical properties of coke.

Edward is seeking to identify what coke attributes are desirable for high strength; a fundamental property of coke for current and future high-efficiency ironmaking. The aim is to gain an improved understanding of which cokes may be important for future decarbonised ironmaking techniques.

Edward’s research is supported by BHP who has provided opportunities for hands-on experience with numerous in-person meetings with company mentors, site visits and presentations at large industrial conferences. This support has provided Edward an understanding of the complex, largescale industrial applications of his research.

“BeingpartoftheDTChasbeenapositivepart ofmyPhDexperience.Ithashelpedmebuild myrelationshipwithBHP,gainfriendshipswith fellowcandidates,developindustryknowledge andessentialskillsincommunicating, presenting,networking.”

- Edward Bissaker

• ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals

• Australian National Fabrication Facility Newcastle Hub

• Centre for Critical Minerals and Urban Mining

• Centre for Innovative Energy Technologies

• Centre for Organic Electronics

• Global Centre for Environmental Remediation

• Global Innovative Centre for Advanced Nanomaterials

• International Collaborative Centre for Carbon Futures

• Centre for Advanced Energy Integration

• Centre for Bulk Solids & Particulate Technologies

• BHP Centre for Sustainable Steelmaking Research

• Centre for Resources Health & Safety

• Centre for Water, Climate & Land

• Applied Electrochemistry Group

• Coastal & Marine Science Research Group

• Food Science Research Group