PORTFOLIO

VESELA TABAKOVA M.SC.

SELECTED WORKS

3 VESELA TABAKOVA

Experience

09.2021 – 10.2023

Research Assistant

Atelier for Ceramics, RWTH Aachen Rresearch projects and teaching courses focusing on digital fabrication and additive manufacturing with fluid clay and 3-axis robots.

10.2022 – 05.2023

Junior Architect

Mescherowsky Architekten GmbH, Aachen Projects in existing and new buildings. Main tasks in execution planning and tendering.

04.2020 – 07.2021

Working student

Glashaus Architekten, Aachen

Projects in existing and new buildings. Main tasks in execution planning, tendering.

10.2018 – 07.2019

Internship

pmp Projekt GmbH, Hamburg

Projects in existing and new buildings. Experience in inventory, design and execution planning.

Architectural Designer with focus on addtive construction

Education

09.2023 – 03.2024

3D printing Architecture, Postgrad. IAAC, Spain

Prototype 3D printed earthen building for mediteranian climates.

09.2019 – 05.2022

Architecture, M.Sc, RWTH Aachen

Thesis: Exploring the effects of form-generating parameters on Liquid Deposition Modelling of ceramic components.

10.2015 – 10.2018

Architecture, B.Sc, RWTH Aachen

Thesis: E-Car Recharging Station

Software Skills

Digital Modelling

Grasshoper & Rhino, Revit, AutoCAD, ArchiCAD

Digital Fabrication

Grasshoper, Rhino CAM, Cura

Project Management ORCA, Microsoft Exel

Visualisation

Adobe Family

General Microsoft Office

Language Skills

Bulgarian Native language

English Level C2 (CPE)

German Level C1 (DSD)

Machines & Materials

WASP Crane Earthen Mixtures

WASP 40100, KUKA, ABB Clay, Concrete

Desktop 3D Printer PLA, TPU, clay, metalic composites

CNC

Timber & Wood derivatives

Laser Cutter Diverse Plastics

Publications

Dynamic Extrusion Control in Spot Deposition Modeling for Porous 3D Clay Structures. Tabakova, V.; Klug, C.; Schmitz, T.H.

MDPI Ceramics 2023, 6

3D printed earthen porous wall

IAAC, Barcelona| Edouard Cabay|Alexandre Dubor Postgraduate in 3D printing Architecture 23/24 https://blog.iaac.net/teixit/

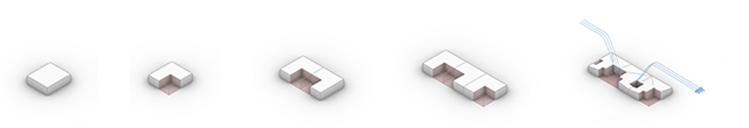

Situated in Valldaura Labs, Caserolla Park, Barcelona, Teixit is a conceptual step towards a 3D printed living complex for the Mediterranean climate. It expands the existing TOVA bedroom pavilion by incorporating a kitchen and a living room. This space, serving as an open-air fabrication lab until the completion of the complex, is dedicated to future student generations. The open-air pavilion and the resulting outdoor spaces create a holistic ensemble with the existing context furthering the purpose of study, experimentation, and fabrication at Valldaura Labs.

The in-situ walls were strategically placed to complement the surroundings, framing work areas and outdoor spaces. Positioned between existing and new structures, a tranquil patio, a peaceful space in front of a prominent tree, and an expansive open space enhance the complex. Wall alignment and segmentation were guided by practical considerations, including the WASP Crane printer’s reach and maneuverability, cost-effective use of existing foundations, and structural and time constraints, influencing segment length and buttress addition.

Fig. previous page left |

Fig. previous page right|

Fig. this page |

Teixit, Author: Daniela Claros

Close-up of Kibaha wall prototype during printing, Author: Daniela Claros

Teixit Masterplan, 3DPA 23/24, Author: Vesela Tabakova

Fig. | Teixit, Author: Daniela Claros

Pattern modification

The diamond space frame developed during Techne and Research, was modified to match the spatial and structural functions arising from the orientation and anchoring. The different strata of the wall were treated differently according to the functions they were subjected to. Starting with outermost strata, the pattern profiles were modified with a gradient that allowed the transition from completely closed to a perforated surface, that also translated to a transition from a private to a more public space.

Further, the middle strata of the wall was assigned a purely structural function housing the roof anchoring profiles. The pattern profiles, where the diagonal cables would be driven through, were stretched along the wall axis to create tolerance for discrepancies caused by the shrinkage of the walls or movement of the roof structure. The profiles of the inner-facing strata of the wall, where a kitchen space was planned, were flattened to allow for the easy installation of furniture. Finally, vertical segments were introduced on the buttress facing the fig tree to allow for direct peaceful view towards the existing vegetation on site.

Axonometry of the different stratas of the wall, Author: Vesela Tabakova Fig. |

The connection between the wall and the truss carrying the roof is realised through multiple interconnected elements. The transition from 3D printed earth to wooden framework executed through a diagonal grid that sits between the diamond profiles of the wall. The grid is secured via a distribution plate which allows for the positioning of the T-beam spanning the two walls. The cables are secured on top of this beam and the main truss is mounted on top it. The separation of the T-beam from the maint truss allows for the equalisation of height differences between the two walls.

Roof Truss

In earthen architecture is of great importance ,ensuring protection against rain and in our topic specific design, the Mediterranean summer direct sun . Therefore, the project’s double-sloped roof consists of a main and a secondary truss. The main truss was designed considering the wall’s structural grid.The elements consisting the main truss adapted to allow manual access to cable tensioning devices until the wall dries. It also supports the secondary truss and roof surfaces, distributing their loads evenly. The secondary truss extends forming cantilevers on both sides to cover the wall adequately. Regarding space design, the main axis forms an acute angle to blend with the surrounding nature, prevent excessive space expansion, and define the living area. This angle also dictates column placement.

Sitcks: Due to the complex design itself, some places will print in the air. To solve this problem, we chose to put some sticks manually based on where the next layer will be printed in the air to create a support.

Mesh: In addition to sticks a mesh is insterted at diffrent levels throughout the print to provide support to parts of the print where the overhang angle is greater than 25 degrees.

Partial Collapse

Due to an accumulation of diffrent negative infuelnces during the prinitig a collapse occurred at the weakest area of the wall, namely at a corrner with poor ventilation and weak straight geometry without infill support.

To fix the wall after the collapse the affeced area were removed and reprinted using a nozzle extension.

Fig. | Teixit, Author: Daniela Claros

CASA FAMI

ICON - Initative 99

1st Prize Winner in Student Category Team: Joseph Naguib, Justin Hanlon, Vesela Tabakova https://blog.iaac.net/casa-fami/

Set in Austin’s dynamic climate, Casa Fami is a 3D-printed house uniquely tailored to single-parent families as studies show that single parent families resembles 32 % of families in Austin. Embracing the challenges of long, hot summers and chilly winters, the house uses passive techniques to reduce as much possible the need for energy-intensive heating and cooling.

The design optimize 3D-printed walls for passive temperature control and privacy. This same sophistication allows light into the interior while limiting the sun’s intense rays.

Courtyards and a strategic layout foster community connections and child-friendly environments. It is a home where layout, walls, and roof collaborate together to create a comfortable and efficient space.

PERFORMANCE TECTONICS

Computational design shapes the walls. Selectively porous, they serve multiple purposes: allowing light, ensuring privacy, and channeling airflow. Their unique composition and structure enable them to cool humid air and maintain a comfortable indoor climate.

3D printed walls allow for an array of wall typologies that respond to the different climatic, visual, and practical requirements of the floorplan. The walls can be porous in certain areas to conduct airflow, while being closed and insulated in others to retain heat. For light permeability, openings in the walls can be precisely oriented; direct views, selective glimpses, diffuse light that tempers the sun’s harshest rays are all possible. Surfaces can vary from flat to richly textured within the same wall, allowing for the placement of furniture or wall hangings as desired. These parameters can be functional, but also provide a sense of organic sophistication to the space.

RESPONSIVE WALLS

Casa Fami is introverted in nature, providing internal views through courtyards such that every home is a person- al oasis, even in a busy, built up environment. Sheltered and comforted, yet not closed off from the outer world. Different regions of the home have varying degrees of openness to the external environment, leaving the choice of interaction open to the inhabitants.

Inner patterns within the wall can be adjusted to various purposes. Precise openings permit selective ventilation. Closed cavities can be used for insulation, and utilities can be routed through as needed. Using a parametric pat- tern, mass can be increased to provide load bearing performance or to provide sound insulation between spaces.

BUILDING STRUCTURE

The roof is kept to a simple timber beam structure to reduce costs while using sustainable materials. The load from the roof is transferred evenly from the beams through horizontal caps on an outer ring of load bearing walls. Inexpensive, recyclable, commonly available metal sheeting shields the roof from the deterioration and rain water. The roof is designed in specific inclination to avoid rain water accumulation while its overhang protect the walls from rain fall and provide need shade in extreme summer days.

PRIVACY AND SAFETY

The house is designed so that views of the courtyards are available from any part of the home. This serves two purposes. First, it facilitates the supervision of children playing in the sheltered spaces. Second, serene glimpses of natural space are always in view, while the house is flooded with natural light. Wall-to-ceiling courtyard windows frame peaceful views for quotidian enjoyment. Designed with families in mind, particularly single parents, the house boasts large courtyards for safe, supervised play, and communal spaces that foster neighborly support and interaction.

Openings in the walls can be oriented in such a manner as to provide line of sight only in selected areas. In this way they can dictate which areas are sheltered and private from the outside world, and which are open to interaction with neighbors and the community. For instance, the openings in the garden walls are shaped in such a way to protect the bedrooms from outside view, while still permit ting someone sitting in the courtyard to see out through the walls.

SUSTAINABLE HOOCGCRUTS

Master Project & Summer School

RWTH Aachen| Theory of Architecture| Summer Semester 2020 Group Members:

Gereon Berz, Vesela Tabakova, Jan Vagaday, Mascha Creutz and Belit Keles

The former monastery of Hoogcruts, near the Dutch town of Gulpen ,went through a turbulent history and is now being restored. More accurately it is being preserved as it suffered a fire and years of degradation. The building, as well as the garden, is filled with layers of historical development and the restoration itself is becoming part of it. The crucial question is how do we use such a space nowadays and because no one has a clear answer the program stays rather undefined.

The garden is for now left alone. Only gloriette in the corner is maintained. But there is plentiful material and space, which provides perfect circumstances for experimenting with hand-craft. Our proposal is dealing with space these inhabit and is an experiment on its own - assembled with mostly natural and found materials allowing reversibility in construction.

Our intervention is not terminated. We are only setting in motion a process that will develop on its own. The primary idea is to invite and collaborate with other courses and schools and this can be achieved within the frame of the building process itself. The outcome is a bricolage of various experiments - gravel foundation, rammed earth wall, the roof of recycled wood... etc. The form stays open.

The advantage of such an approach is that the form continually evolves and optimizes itself to its purpose - now it is a workshop, later it can serve other function or it can be dismantled and disappear completely. Following this line, we can use all the materials located within the monastery garden and start development of a truly sustainable Hoogcruts.

https://theorie.arch.rwth-aachen.de/research_module_sommerschool/

From 10th to 20th of August, 2020, the Department of Architectural Theory and Research at RWTH Aachen University, under the direction of Prof. Axel Sowa, organized a Summer School on sustainable building with clay and earth at the Hoogcruts Monastery not far from the Dutch municipality of Gulpen. The goal of the workshop was to experiment with rammed earth techniques and consequently built the load-bearing walls of a future garden pavilion. The material and energy balance of construction will be of particular importance. The teaching and research area of architectural theory is in close exchange with the Sitchting het Limburgs Landschap. The Dutch foundation intends to transform the monastery complex into a workshop for the future, in which the building and living of tomorrow will be considered.

The results of the SummerSchool are the four rammed earth walls that now stand in the garden of the monastery. Special formworks were used that enabled the controlled ramming of wall sections. The sections were shifted with each layer so that the vertical edges wouldn’t align and cause weaker points in the walls. The main mixture used for the wall consisted of earth, clay, sand, gravel and recycled bricks. A second mixture containing lime and without large particles was used at the corners of the walls. The design of the formwork can still be clearly read through the different layers and holes in the wall.

Fig. top left| Manual ramming of the earth

Fig. top centre| Removing the formwork

Fig. top right| A completed section

Fig. bottom | Isometry of formwork disassembly

walls Fig.

Detail of the wall with formwork holes and reinforced edges

Fig. left| The four rammed-earth

right|

RECHARGING STATION

Bachelor Thesis Project

RWTH Aachen| Department for Building Design and Realisation & Department of Visual Arts| Summer Semester 2018

With the adoption of electric cars as an individual means of transportation, there is a demand for recharging stations. Nowadays it takes about 60 minutes to fully charge a battery, so it is necessary to rethink the type of charging station.

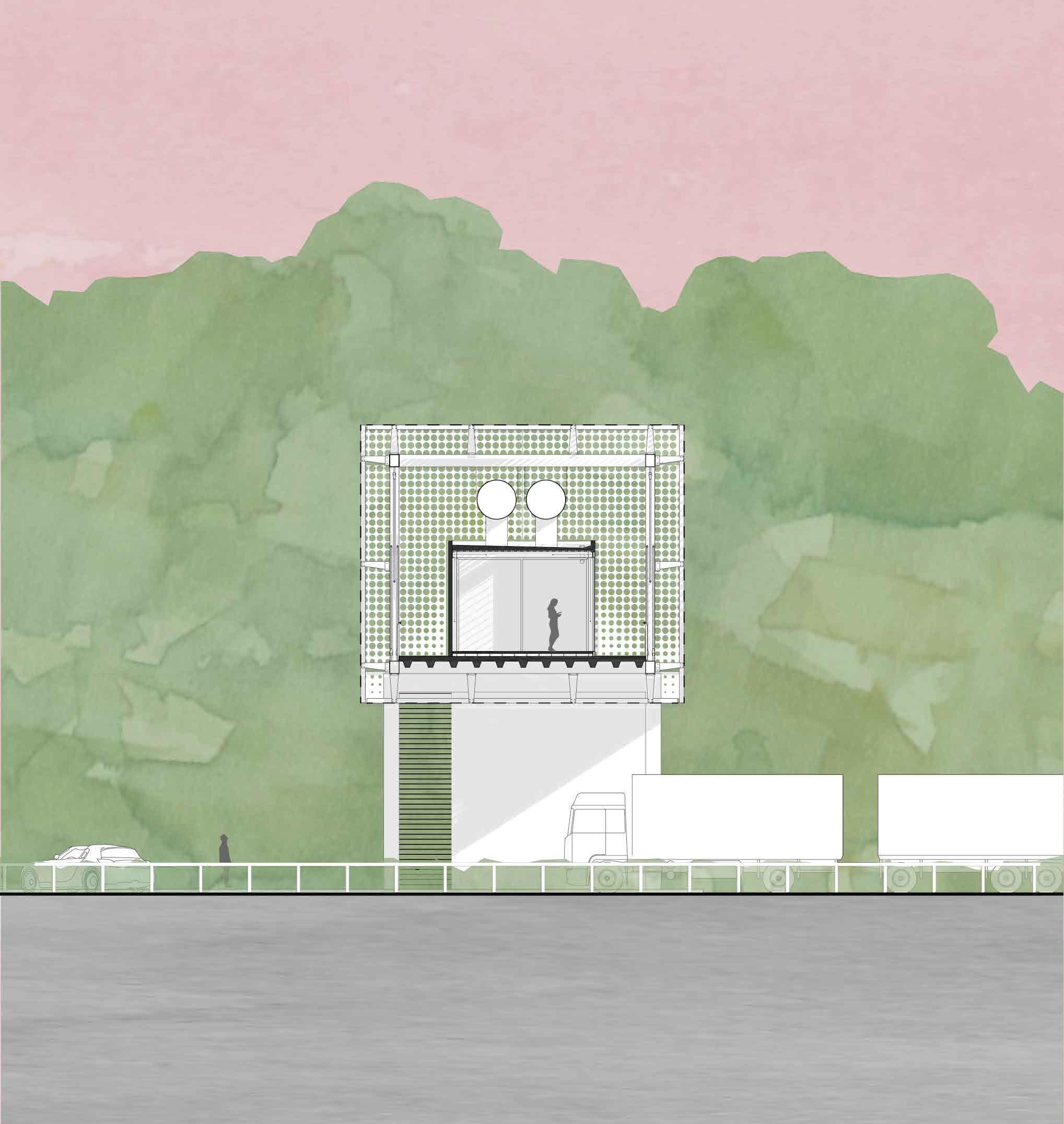

By studying today’s petrol stations and freeway service areas, it has become clear that they are optimized for car traffic but neglect pedestrians. The elevated position of the Frechen rest station provides an exciting view of the Cologne skyline. The positioning of a rest station above the highway provides a direct view of Cologne and creates a level for pedestrians. The rest area will be based on the typology of bridge restaurants, but it will have to be interpreted differently. The bridge rest area marks a borderline situation - that between a geographically unclear position on the highway and the geographically concrete city. For this reason, this situation must be staged elegantly but at the same time memorably, which is achieved through the interpretation of a floating cloud above the highway. The perforated façade and the truss girders suggest the lightness and translucency of a light cloud hovering over the highway.

At the same time, the façade design offers an unusual lighting situation and a surrealistic atmosphere that provides drivers and passengers with a break from the monotony of the highway and the hectic pace of everyday life. They can then enjoy their 30 to 60 minutes of free time, where they have the opportunity to concentrate on the moment through various activities, such as watching the process of preparing their own food or drinks, or simply by observing the skyline of Cologne.

Site plan with context and topography lines

Schwarzplan 1:2000

Grundriss 2. Obergeschoss 1:200

Schnitt 1:200

Floor Plan, Bridge Level

Bridge Cross Section

BRIDGE CONSTRUCTION

Fassadenschnitt, Ansicht Tag/ Nacht 1:25

Detailed Bridge Cross Section

Functions, Gradient & Facade Porosity

Daytime perspective

Westfassade

Terrasse Warteraum Terrasse Restaurant Küche Büro Café

Treppe Terrasse

Terrasse Warteraum Terrasse Restaurant

Küche

Büro Café

Treppe Terrasse Restaurant

Treppe Terrasse

Terrasse Café Küche Umkleide

Terrasse Warteraum

Dachfassade

PRACTICE & TEACHING PROJECTS

FAMILY STAIRCASE

Apartment extension, 2019

Hamburg, Germany

pmp Architekten, Hamburg

Planning: Elinor Schües, Vesela Tabakova

Extension from fist floor apartment to a store space in the street level floor, which accommodates a living room in the back and a work space in the front. The stair case should provide direct connection between the bedrooms and the living room, also being a visual separation between the living room and the work space. A spatial challenge presented due to the height of the street level floor and its total width as it allowed only for a steep stair case to be constructed, which is not optimal for a family with children. The half turn of the stair case enabled a tolerable stair rise of 21 cm to stair width of 25 cm.

Wood was chosen for the staircase construction to as it better transfers with the warmth of the family apartment to the street level space. A challenging, but visually pleasing technical detail that testifies to the carpenters abilities is the piece that allows the 90° turn on the inner stair string

30 CODE FOR PRODUCTION

Elective Module

RWTH Aachen |Vesela Tabakova M.Sc|Prof. Thomas Schmitz

Selected works from Winter and Summer Semester 22-23

Within the seminar we dedicate ourselves to the ornament and deepen the topics geometry, pattern, joining and materialization. Parametrically developed forms become 3-dimensional structures through programmed arrangements. Complex modules are created which can be converted into 2-dimensional objects using operators within the programming environment. The seminar is structured in such a way that the basics of the programming environment (Grasshopper) are taught by means of various predefined exercise packages - and then own designs are tested with the help of the developed instructions. In teamwork, the own design is then prepared as a CNC laser/cutter file. The subsequent production takes place in the ManuLab of the Faculty of Architecture.

Fig. previous page left |

Fig. previous page right |

Fig. top left |

Fig. bottom left |

Fig. top right |

Möbius strip as a trigonometric mesh, Project by Mihaela Georgieva & Valentina Edreva

Flexible diagonal mesh with droplets of varying sized, Project by Max Blake

Curved surface generated out of a main parametric clover module and connecting elements, Project by Joel Manolias & Sophia Hehnen

Digitally modular curved wall out interconnected modules, Project by Leon Pihan & Alina Veverita

Light regulating porous wall, Project by Sophie Drescher & Thadshajini Gegatheesmaran

BEYOND THE PRINTING PATH

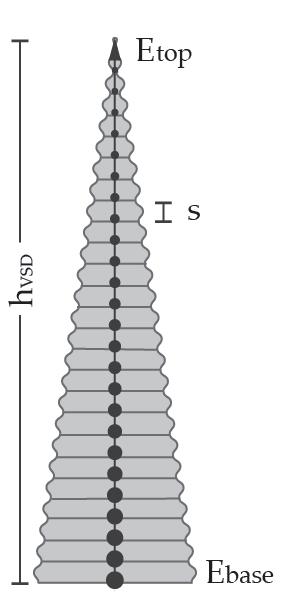

Dynamic Extrusion Control in Spot Deposition Modelling for Porous 3D Clay Structures

Article in the scientific journal MDPI Ceramics

Vesela Tabakova M.Sc | Christina Klug M.Sc | Prof. Thomas Schmitz https://doi.org/10.3390/ceramics6040124

The dynamic state of the viscous clay in Liquid Deposition Modelling (LDM) often leads to discrepancies between the digital model and the resulting physical object. This emergent behaviour can be harnessed to produce complex physical structures that would not be possible with other methods. This study takes advantage of the viscous state and tensile strength of the extruded clay strand to explore the impact of dynamic extrusion and deformations through travel paths in LDM to manufacture complex porous physical structures. The effects of these parameters are discussed in two case studies: (1) regular and semi-random Spot Deposition surfaces with either open or thickened regions, and (2) porous 3D lattice structures created through the controlled bending of vertical extrusions. The achieved higher geometrical complexity of objects through the algorithmically programmed alternations in the sequence and rate of material deposition allows for a wide range of build-up approaches that expand the production spectrum of sustainable small- and large-scale elements.

DYNAMIC EXTRUSION

In conventional FDM and LDM, the G-code is generated with any generic slicer software that slices a digital volume model into horizontal layers, divides it into points and assigns extrusion values that are executed from point to point. The distance between the points defines the resolution of the print, where a good resolution can be achieved when the distance between the points is equal to the nozzle diameter. These instructions are loaded into the 3D printer and executed by the axis and extrusion motors. The extrusion path is the most tangible and easily modifiable aspect of actuator material deposition AM, such as FDM or LDM. However, the control over the extrusion value in the G-code provides digital control over the flow of clay paste by allowing different values for different segments of the model. It enables travel paths where no material is extruded.

SPOT DEPOSITION MODELLING

Spot Deposition (SD) in AM relates to the act of material deposition, where the actuator first travels to the desired position and then deposits a discrete amount of material. In this paper, the basis of the two presented AM strategies is SD. It can be used to create geometries layer by layer, but it also allows for layer-free deposition such as vertical or random deposition. SD is modelled by creating geometrical target points and a separate extrusion value for each target. This is achieved in G-code by separating movement and extrusion in two lines of code. For example, for two SDs at a 5 mm distance in X direction from each other:

G01 F1000 X0 Y0 Z0 E0

G00 E5

G01 F1000 X5 Y0 Z0 E0

G00 E5

Targeted deflecting of the vertical strands leads to linear instead of point supports that reduce the axial instability and whirling of the following vSDs. Stacking and deflecting the vertical strands in alternating directions achieved a stable build-up process. Considering this, an arc-like geometry with semi-constant width could be produced by bending two tapered vSDs towards each other. This arc system is then utilized to create simple 3D lattice structures with larger openings compared to the porous surfaces produced through extrusion control.

THANK YOU FOR YOUR TIME!