6 minute read

Cover story Project highlights industry potential

Project highlights industry potential

A corporate dried fruit producer says there’s huge potential in the dried grape industry and has joined a Dried Fruits Australia project to demonstrate its possibilities.

Duxton Dried Fruits’ Liparoo property has joined DFA’s 10 Tonne Project, and is among three other properties at Red Cliffs and Merbein all aiming to achieve high production and improve land and water efficiency.

The sites will be used to demonstrate how to consistently achieve 10 tonnes per hectare, compared to the industry average of five tonnes per hectare.

The 10 Tonne Project is a three-year project funded by the Australian Government through the Murray Darling Basin Economic Development Program.

The project includes grower technology training sessions to demonstrate the use of pest and disease modelling, NDVI (normalised difference vegetation index) imaging, and soil moisture monitoring.

Monitoring to achieve high yields

Duxton Dried Fruits chief viticulturist Sam Bowman said the company was keen to be involved in the 10 Tonne Project to show what a property could produce at scale.

“A lot of the smaller growers have dropped out of the industry and larger corporates are taking more of a dominant role in the industry, so for us it’s about showing – on a commercial scale as well as on small blocks – that you can achieve those yield targets,” Sam said.

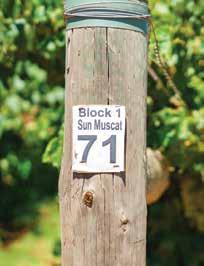

The Liparoo block involved in the 10 Tonne Project is a patch of Sunmuscat, while the remainder of the dried fruit on the property is a mix of sultana, Sunmuscat and Sunglo.

Sam said the 10 Tonne Project complemented Duxton’s approach to horticulture production across the company, including closely monitoring soil moisture and nutrients.

“Water management is the most crucial thing for us because it’s a hot, arid climate,” he said.

“Nutrient management is a big key, too, as is getting that microclimate management right.

“Achieving those high yields for us is about making sure we’ve got the right nutrition, right water and right balance for the soil.”

Sam said monitoring through the 10 Tonne Project would teach the company and its farm managers – as well as the broader industry – more about effective and efficient farm management.

“Using aerial imaging and having monitors within the canopies is going to teach us about how we’re going, what we’re doing and how we can start using that information as a resource across the other farms, too,” he said.

Sam said while it would likely be a full 12 months of monitoring to capture a complete picture of how the farm was operating, he could already see the benefits of being part of the project and how it would contribute to overall industry knowledge.

Investing in potential

Duxton Dried Fruits’ 200ha Liparoo property was acquired in 201516, while another larger 600ha development at Euston has been underway since 2017.

Sam said the investment was driven by the potential Duxton saw in the dried grape industry.

“We see heaps of opportunity in dried fruit – we wouldn’t be investing in it as heavily if we didn’t see the opportunity with it,” he said.

“The industry is undersupplied and we’re importing fruit into Australia that we could be growing ourselves and supplying from Australian growers, so it makes sense for us to try to fill that gap.

“We think it’s pretty exciting and it’s a great place for growing dried fruit as well.”

Sam explained Duxton Dried Fruits was heavily involved with offtake partner Australian Premium Dried Fruits, who had given the company confidence in pursuing large planting developments. at other potential development sites in the next couple of years, too,” he said.

“In the past couple of years we’ve seen Australian Premium Dried Fruits with their own farms, and Murray River Organics and larger corporates moving into the space, so for us there’s a fair bit of pressure to make sure we perform.”

Planning for success at scale

Duxton’s Liparoo site is 50-50 dried grapes and wine grapes, while the Euston property will be solely dried fruit.

The Euston site will produce a variety of dried grapes to ensure production is efficient and timely and to mitigate risks.

“If you’ve got 600ha of one variety that’s all ready at the same time, the logistics management is pretty tricky to get it all harvested in time, so we’re staggering that with some of the other varieties, like Selma Pete and currants, just to make sure our operation flows as efficiently as possible,” Sam said.

“It’s also mitigating that seasonal risk, because often around April you get that late rain and that’s horrible for dried fruit. If 50 per cent of the farm is early and mid-varieties and 50 per cent is late, it spreads that risk across the season.”

Sam said the information and methods involved in the 10 Tonne Project would guide and inform future developments.

Adapting to an ever-changing landscape

Sam said growing strategies and ideas continue to change as the climate changes and as more research becomes available.

He said the 10 Tonne Project monitoring would provide a clear

picture of how improvements could be made.

“We’re a pretty arid climate here, with low organic matter,” he explained.

“We’ve got the land, but we really need to work it.

“We try to focus on increasing the microbiology in the soil because that helps for our nutrients that are bound up in the soil and adding back organic matter to the soil as well.

“The tricky thing with having low organic matter is that the water holding capacity of the soil is a lot lower, so you’re putting water in and a lot of it is just evaporating or draining away.

“The more we can build on increasing the organics on the vine and basically the whole area we’re farming, water use efficiency will get better over time.”

Bird’s-eye view adds value

One of the key components of the 10 Tonne Project is aerial imaging to gain a full picture of how a farm is performing.

Agtech company Ceres Imaging is contracted to perform eight plane flights over each property throughout the season to capture a range of imagining.

Ceres Imaging customer success manager for Australia Scott Gillett, based in Loxton, said the company provided a range of imagery, including water stress, thermal and NDVI, to give growers a clearer picture of how their crops are performing.

“This means we can identify growth areas and growers can decide to fix problem areas as they arise,” Scott said.

Scott said the Ceres Imaging team was able to work alongside growers to teach them how to read the data and patterns captured through the flights, which gave them a chance to make truly informed decisions about their farm management.

“They’re really interested to see differences, and in some cases have made changes,” he said.

“It provides a snapshot in time, so growers can see how their property changes.”

He explained growers could improve their water efficiency and yield quality with the help of Ceres Imaging’s analytics products that make it easy to identify and prioritise issues in their high-resolution imagery.

“For example, growers are alerted to high water stress issues by email before they are visually noticeable to the naked eye, so managers can be more proactive with remedial actions instead of waiting,” Scott said.

“It’s a really good way to improve production and, as a grower, there’s potential to compare in terms of where you’re sitting in the industry and to see where properties vary.

“Being able to compare could definitely add value.” v

Pictured: Duxton Dried Fruits Liparoo farm manager Mark Luehman and Duxton Dried Fruits chief viticulturist manager Sam Bowman.