DECARBONISATION STRATEGY

A LEGACY WORTH LEAVING

Acknowledgement and Recognition of Country

Kestrel Coal Resources acknowledges and pays respect to the Western Kangoulu people, the registered native title claimants for the land on which we operate. We pay our respects to Elders past, present and emerging. We proudly work in collaboration with the Western Kangoulu people under a voluntary Cultural Heritage Investigations and Management Agreement to achieve effective management that actively maintains, protects, and preserves heritage. Working together, our shared goal is to create meaningful, sustainable opportunities for Indigenous peoples through employment and business development.

IMPORTANT NOTICES AND DISCLAIMER

This document has been prepared by Kestrel Coal Resources (ABN 98 624 245 325) (Kestrel) for informational purposes only. Kestrel has prepared this document based on information available to it at the time of preparation. The information contained in this document is general in nature & does not purport to be complete. The document does not contain an offer, solicitation, invitation to apply, recommendation or advice to buy, sell or hold any securities of Kestrel. This report has been prepared in accordance with the International Council on Mining and Metals (ICMM) Mining Principles. Metrics describing health, safety, environment, people and community related performance in a joint venture operation, from 1 January 2023 – 31 December 2023. This document may contain forward looking statements, including statements about plans, strategies and objectives of management; and anticipated productive lives of projects, mines and facilities; and climate change, other environmental and energy transition scenarios (which are potential scenarios and not forecasts). These forward

of future performance.

or

CEO's Message

Shane Hansen CEO Kestrel Coal Resources

Supplying metallurgical coal to the steelmaking industry around the world, Kestrel Coal Resources recognises the urgency and importance of collective climate change action. This decarbonisation strategy documents our intent, ambition and progress in contributing to emissions reductions. It is a complement to, and extension of our climate change action plan embedded within our broader ESG Strategy.

With the legislation of Australia’s Climate Change Targets in the Climate Change Act 2022 and the tightening of the Safeguard

Mechanism through the Safeguard Mechanism (Crediting) Amendment Act 2023, Kestrel finds itself uniquely exposed to the cap and trade carbon pricing regime now in place. The agglomeration of open cut and underground mines into the same category under the Safeguard Mechanism as legislated, fundamentally disadvantages the productive and environmentally responsible footprint that Kestrel maintains.

This has focussed our resourcing on targeting substantive and innovative emissions reduction projects. We will need to invest in first of its kind and scale technology in Australia to deliver the emissions reductions required to meet the declining emissions baselines. This will require collaboration with Government Regulators, our staff and technology providers to deliver reductions on the methane in our ventilation air and to reduce the emissions from coal mine waste gas drainage. The overlapping ambition between safety initiatives and environmental improvement is a challenge to be worked through carefully and deliberately.

I am confident that Kestrel will rise to this challenge as we continue to sustainably supply the steelmaking industry.

At the very heart of Kestrel is the aim to create a Legacy Worth Leaving. This Decarbonisation Strategy is how we ensure we continue to deliver on this.

Climate Change Position

Kestrel recognises the challenges that climate change presents to human and natural systems.

Our approach to Climate Change is informed by and is consistent with Australia’s Climate Change Act 2022, the targets set by the Paris Agreement and the ICMM Climate Change Position Statement.

1.0 Kestrel Coal Resources

1.1. Who is Kestrel?

Kestrel Coal Resources (Kestrel Coal or Kestrel) operates in Queensland’s Bowen Basin region and is located 40km north of the vibrant town of Emerald. The majority of our workforce live in Emerald and surrounding areas, with a small team working from Brisbane for finance, sales and marketing, planning and corporate leadership.

Kestrel extracts metallurgical coal from the German Creek coking coal seam, using the underground longwall mining method. The mining process delivers Run-of-Mine (ROM) coal onto a 7km overland conveyor to the Coal Handling and Preparation Plant (CHPP) for washing, and then to our dedicated train loadout for delivery to our international customers via Gladstone Port. We produce 8-10MT/year of ROM coal with typical yields of 70-80%. The metallurgical coal produced at Kestrel is of high quality and is valued for its properties in steel production.

1.2. Sustainably Supplying the Steelmaking Industry

There are two main types of coal; thermal coal which is used in power generation; and metallurgical coal used as a reductant in the integrated steel making process.

Kestrel is a leading global supplier of high-quality metallurgical coal to the steel industry.

Our product is highly sought after for its low impurity levels and unique coking properties. At present, metallurgical coal is the primary and most cost effective means to create steel for our global economies. Steel is an important commodity for the green energy transition, with approximately 250 tonnes of metallurgical coal required to build a single offshore wind turbine (generator, blades, tower and foundation). Our continuing focus is to provide this critical product to the steel industry in the most sustainable manner possible.

2.0 Our Emissions Profile

2.1. Scope 1 and 2 Emissions

We measure our Scope 1 and 2 emissions consistent with the requirements of the National Greenhouse and Energy Reporting Act 2007 (NGERs). To verify the emissions reductions projects are achieved, Kestrel has focussed on the accurate measurement, calculation and reporting of greenhouse gas emissions in the first half of 2024. This has included reviewing all emissions reporting methodologies, integrating data collection into a data lake and developing material emissions source reporting dashboards.

In doing so, we implemented a change to the calculation methodology for the emissions from Coal Mine Waste Gas (CMWG) pre and post drainage emissions which has resulted in our re-statement of these emissions in our FY22/23 NGER report to the Clean Energy Regulator (CER). The figure below has been updated to reflect the resubmitted NGERs report for FY22/23.

2.2. Scope 3 Emissions

Scope 3 emissions are defined consistently with the Corporate Value Chain (Scope 3) Accounting and Reporting Standard as, “All indirect emissions (not included in scope 2) that occur in the value chain of the reporting company, including both upstream and downstream emissions.”

Kestrel has prepared its first Scope 3 emissions inventory for the FY22/23 year, setting out in the basis of preparation the data collection processes, emissions factor source and identified areas for improvement in future inventories. It is Kestrel’s intention to make the calculation of Scope 3 emissions publicly available on our website annually. We will incorporate considerations of Scope 3 emissions into this decarbonisation strategy commencing next reporting period.

2.3. Period Considered

This Decarbonisation Strategy focuses on Kestrel’s material sources of Scope 1 and 2 emissions, that is:

ventilation air emissions;

pre and post mining gas drainage emissions;

electricity consumption; and

post mining emissions.

Kestrel moved into an area of the mine known as the 500 series in 2024. This area of the mine is significantly higher

in methane than the previous worked areas. In preparation for this, Kestrel commenced CMWG drainage activities in 2018 to reduce the residual gas in these areas to ensure both the safety of our workers and the responsible management of the contained gas. We will be mining in this higher gas area for the next five to seven years and will see increased emissions in our mine ventilation and the gas drainage activities without additional emissions abatement measures as a result of this.

Kestrel’s internal planning horizons are used for the periods considered in this decarbonisation strategy. That is, “Short Term” for the next year, “Medium Term” for the next two to five years and “Long Term” as greater than five years. As the annual NGER report is prepared on a financial year basis, financial years are referenced in this strategy.

3.0 Climate Risk Assessment and Management

The Australian Climate Service is currently preparing Australia’s First National Climate Risk Assessment (Australian Government, Australian Climate Service, 2023). Kestrel intends to incorporate the results of this, when available, into the established Risk Management Framework within the business.

In the interim, Kestrel has undertaken to review the existing internal Risk Management process for climate related risk considerations.

4.0 Climate Scenario Analysis and Strategic Planning

4.1. Climate Scenarios Analysed

Whilst the work of the Climate Projections Roadmap for Australia progresses, Kestrel has relied upon the Queensland Government’s Queensland Future Climate Dashboard to determine the scenarios for which climate change impacts are considered. This modelling relied on the Couple Model Intercomparison Project Phase 5 model, organised under the World Climate Research Program (Queensland Government, 2024). It was then downscaled to a spatial resolution of ~10km using Conformal-Cubic Atmospheric Model (CCAM) developed by the CSIRO to present regional climate models (Queensland Government, 2024).

As there are two emissions scenarios currently available in this model, Kestrel has considered the effects of these scenarios as presented. The scenarios considered are based on “Representative

Concentration Pathways” (RCP) as used in the IPCC Fifth Assessment report (Australian Government Department of the Environment and Energy, n.d.). The numerical value assigned to each scenario is the radiative forcing value, with the associated temperature rise with each scenario set out in Figure 2.

The Queensland Future Climate Dashboard has modelled two specific scenarios, which will also be adopted by Kestrel for the purposes of climate scenario analysis:

1. Moderate emissions scenario (RCP 4.5), temperature expected to rise to 1.8°C and medium efforts to curb emissions.

2. High emissions scenario (RCP 8.5), temperature expected to rise to 3.7°C and low effort to curb emissions.

Scenario RCP 4.5 will achieve one of the proposed objectives of the Paris Agreement, to limit Global Warming to between 1.5 and 2 degrees above pre-industrial levels. Scenario RCP 8.5 models emissions rise throughout the 21st century. The results are available at twenty-year intervals from 2030. For Kestrel’s planned operations, the projections at 2030 and 2050 were considered.

Kestrel will review the scenarios considered and the best available data for the Kestrel mine as and when it becomes available. Kestrel intends to rely on the climate scenario analysis and data published by the Queensland Government, to ensure that the best available data at our regional level is used to strategically plan for the effects of climate change.

Figure 2: Explanation of the relative impacts of Representative Concentration Pathways (Australian Government Department of the Environment and Energy, n.d.)

4.2. Impacts of Climate Scenarios on the Kestrel Mine

Kestrel’s key operational asset, the Kestrel Mine is located, 40 km north of Emerald, within the Central Highlands Regional Council (CHRC) Area. With the intention to extend the mining operations into the future through the Kestrel West extension, the climate scenario analysis focuses on this single site.

All modelled impacts are summarised in Appendix One, with the key metrics set out below.

Figure 3: Mean annual temperature change for CHRC 2030 of 0.98°C (left) and 2050 of 1.5°C (right) under RCP 4.5 (right) under RCP 8.5

Figure 4: Mean annual temperature change for CHRC 2030 of 1.0°C (left) and 2050 of 1.9°C (right) under RCP 8.5

The most significant predicted climate change impact for Kestrel Mine are increases in the temperature (mean, minimum, maximum), an increase in the heatwave peak temperature and extreme temperature indices. These will impact surface operations including: gas drainage activities, mining rehabilitation, coal handling, and processing. The underground mining operation will also be affected by the impacts of the changing climate, where it is expected to require additional cooling to account for the higher surface temperatures.

5.0 Decarbonisation Pathway

For each material emissions source for Kestrel Mine the feasible options for emissions reduction are set out below, with carbon offsets considered as part of our wholistic carbon management approach.

5.1. Reducing Emissions from our Material Sources

5.1.1. Ventilation Air Emissions

The material source of ventilation air emissions represents a significant challenge for the underground coal mining industry worldwide. Emissions in this category are generated from the very low concentrations of methane and carbon dioxide which are contained in the high volume flowrates of ventilation air, circulated throughout the underground workings to ensure the safe operation of the mine. With concentrations of methane ranging from ~0.2% to 0.6% the ventilation air is well under both the lower explosive limit of methane and the concentration at which the gas would ignite to combust the methane to carbon dioxide.

Kestrel’s priority is to minimise methane available to the ventilation air flow through a targeted and comprehensive gas drainage program.

As part of this comprehensive drainage program, Kestrel pre-drains not only the extracted coal seam (German Creek Seam), but also the overlying Corvus coal seam. Drainage of this overlying

seam prior to mining minimises the gas available to migrate post mining through the goaf to the ventilation system.

Kestrel is also undertaking enhanced post mining gas drainage activities including both goaf and post seal drainage following mining of an area.

Even with this extensive drainage program, our Ventilation Air Methane

(VAM) is the single largest emissions contributor and Kestrel engaged external expertise in the search of options to further reduce this emission source. Kestrel commissioned internationally recognised decarbonisation experts, Stantec, to consider all technology options for the abatement of ventilation air emissions. The technologies considered are summarised in the table below.

This analysis clearly indicates that Regenerative Thermal Oxidation (RTO) technology is the best available technology in the short term for reducing ventilation air methane. Accordingly, Stantec then considered the current technology provider options in Table 4.

Scalability (Near Term)

per unit

Modular Design Modular Design Modular Design (can be designed for smaller units) Modular Design

Safety Isolating Damper Isolating Damper Isolating Damper Isolating Damper

Table 4: RTO Technology Providers Comparison

Kestrel are working with technology providers to progress the options for the safe destruction of the methane in the ventilation air emissions. This technology is untested in Queensland and Kestrel are committed to working with the relevant Regulators to ensure that progress is achieved only to the strictest of safety standards and controls.

SHORT TERM

MEDIUM TERM

RTO FEASIBILITY

Obtain all relevant Regulatory approvals

Kestrel's Final Investment Decision

RTO CONSTRUCTION

With all relevant approvals, construction and commissioning of the VAM RTO

LONG TERM

RTO OPERATION

Destruction of methane emissions from the Ventilation Air

5.1.2. Pre and Post Mining Drainage Emissions

Drainage of CMWG occurs both in advance of, and post mining, to ensure the safe working conditions for coal mine workers. The type and extent of the gas drainage is coal seam dependent. At present Kestrel is pre and post draining via the following methods:

Surface-in-Seam

Underground-in-Seam

Goaf Drainage

Post Seal Drainage

Whilst the methane and carbon dioxide concentration of each gas reservoir does change both over time and per well, generally this gas contains concentrations of methane above 65%, meaning it can be safely and easily combusted.

The global warming potential on methane is 28 times that of carbon dioxide, that is, one tonne of methane released to the atmosphere is as impactful on global warming as 28 tonnes of carbon dioxide. Combusting methane through flares, materially reduces the emissions from this gas source, an activity which Kestrel has been undertaking since 2018.

In the short term, ensuring that all collected pre and post drainage gas is flared, either through the newly commissioned blower plant and/or through movable well skids is the aim for Kestrel.

In the medium to long term, Kestrel is proposing to collect pre and post

drainage gas and install up to 30 MW of power generation capacity to achieve beneficial use. In offsetting grid purchased power, the power station will also achieve the following key benefits:

Reduction in Scope 2 emissions

Reduced reliance and capacity demand on the electricity grid

Excess power delivered to the electricity grid

The Power Station project is currently working through Kestrel’s internal approval process.

SHORT TERM

CMWG FLARED

Obtain all relevant Regulatory approvals

Signifantly reduce the CMWG Vented

MEDIUM TERM LONG TERM

POWER STATION CONSTRUCTION

With all relevant approvals construction and commissioning of power station

5.1.3. Post Mining Emissions

POWER STATION OPERATION

Power generation and CMWG Destruction

As Kestrel is defined under the National Greenhouse and Energy Reporting (NGER) as a gassy underground mine, we are required to report fugitive emissions associated with the post mining emissions for the Run-of-Mine (ROM) coal. As there is only a single method to calculate this emissions source under the NGERs which applies a factor to the ROM coal, there is no opportunity for Kestrel to reduce the reported emissions from this source without a direct impact on ROM production.

5.1.4. Electricity Consumption

Scope 2 emissions are calculated by multiplying the consumed electricity by a Queensland State based factor. The options to reduce the total Scope 2 Emissions include: reducing the electricity consumed and/or sourcing emissions from a lower emissions intensity generation source.

As outlined in the pre and post mining drainage emissions section, Kestrel is progressing plans to produce power from our generated CMWG, and as such reduce the emissions intensity of the generation source. This leaves reducing the total electricity consumption onsite as the final emissions reduction activity for

this source. Kestrel will internally review options to increase electrical efficiency across our operations and proceed with projects that demonstrate cost and emissions savings as per the Kestrel internal approval metrics.

POWER STATION FEASIBILITY

Obtain all Regulatory approvals required

POWER STATION

CONSTRUCTION

With all relevant Regulatory approvals, construction and commissioning of power station

5.1.5. All other Emissions Sources

POWER STATION OPERATING

Power generation and CMWG destruction

Comprising approximately 1% of total Scope 1 emissions, all other emissions sources comprise the following:

the use of hydrocarbons for stationary energy purposes;

the use of hydrocarbon for transportation purposes;

the use of petroleum based oils and greases;

switchgear installed onsite; and

the emissions from the decommissioned Kestrel North Mine.

Of these, the largest single emissions source relates to the onsite diesel use. Accordingly, Kestrel will investigate options to reduce the onsite diesel use in the short, medium and longer term.

IDENTIFY

Identify opportunities for reduction in diesel consumed

IMPLEMENT

Undertake Diesel consumption reduction activities

REVIEW

Review for opportunity to extend/enhance diesel consumption reduction program

5.1.6. Forecast Emissions

Considering the individual decarbonisation projects nominated for Kestrel’s material sources, the impact on the Scope 1 and 2 emissions for Kestrel are set out in the figures below.

These forecasts are based on the Life-of-Mine plan developed in early 2024, with emissions reductions consistent with Version 2 of the Kestrel greenhouse gas model.

5: Kestrel Mine Forecast Year on Year Emissions –No Additional Abatement Measures

6: Kestrel Mine Forecast Year on Year EmissionsWith VAM Abatement and CMWG Projects

Figure

Figure

5.2. Carbon Offset Project Opportunity

As a large landholder in the region, Kestrel are actively considering the Australian Carbon Credit Unit (ACCU) Scheme project opportunities available within our landholdings.

IDENTIFY

Identify and register any approved opportunities under the ACCU Scheme IMPLEMENT

ACCU Scheme Projects IMPLEMENT

Evaluate opportunities to expand ACCU Scheme Projects

5.3. Carbon Offset Strategy

With the amendments made to the Safeguard Mechanism through the Safeguard Mechanism (Crediting) Amendment Act 2023, Kestrel expects to have a safeguard liability in the short term whilst working through project definition and approvals for each of the ventilation air methane abatement projects and the coal mine waste gas power station. Kestrel will manage this liability consistent with the requirements of the National Greenhouse and Energy Reporting Act 2007, ensuring that it does not have excess emissions through the use of available carbon offset units by 1 April each year.

IDENTIFY

Implement Carbon Offset Strategy as required to meet Safeguard Mechanism Liabilities

IMPLEMENT

Implement Carbon Offset Strategy as required to meet Safeguard Mechanism Liabilities

Implement Carbon Offset Strategy as required to meet Safeguard Mechanism Liabilities

6.0 Summary of all Decarbonisation Initiatives

ALL TARGETS

Obtain all relevant Regulatory approvals for each of the VAM RTO and CMWG Power Station Projects

Significantly reduce the CMWG vented

Identify opportunities for reduction in diesel consumed

Identify and register any approved opportunities under the ACCU Scheme

Implement Carbon Offset Strategy as required to meet Safeguard Mechanism Liabilities

ALL TARGETS

With all relevant approvals, construction and commissioning of the VAM RTO

With all relevant Regulatory approvals, construction and commissioning of Power Station

Undertake diesel consumption reduction activities

Undertake any approved ACCU Scheme Projects

Implement Carbon Offset Strategy as required to meet Safeguard Mechanism Liabilities

ALL TARGETS

Destruction of methane emissions from Ventilation Air

Power Generation and CMWG destruction

Review for opportunity to extend/enhance diesel consumption reduction program

Evaluate opportunities to expand ACCU Scheme Projects

Implement Carbon Offset Strategy as required to meet Safeguard Mechanism Liabilities

7.0 Reporting and Strategy Update

Kestrel’s focus on emissions reporting in 2024 is designed to provide monthly updates on emissions measurement so that the progress of the planned decarbonisation projects can be accurately tracked. Kestrel intends to update this Decarbonisation Strategy annually.

Appendix One: All Climate Scenario Modelled Variables

1. PRECIPITATION

7: Mean Annual Precipitation Change (mm/day) for CHRC 2030 of -0.08mm/day (left) and 2050 of -0.08mm/day (right) under RCP 4.5

8: Mean Annual Precipitation Change (mm/day) for CHRC 2030 of -0.06mm/day (left) and 2050 of -0.04mm/day (right) under RCP 8.5

Figure

Figure

2. PAN EVAPORATION

Figure 9: Pan Evaporation (mm/day) for CHRC 2030 of 0.45 mm/day (left) and 2050 of 0.65 mm/day (right) under RCP 4.5

Figure 10: Pan Evaporation (mm/day) for CHRC 2030 of 0.42 mm/day (left) and 2050 of 0.82 mm/day (right) under RCP 8.5

Appendix One: All Climate Scenario modelled variables

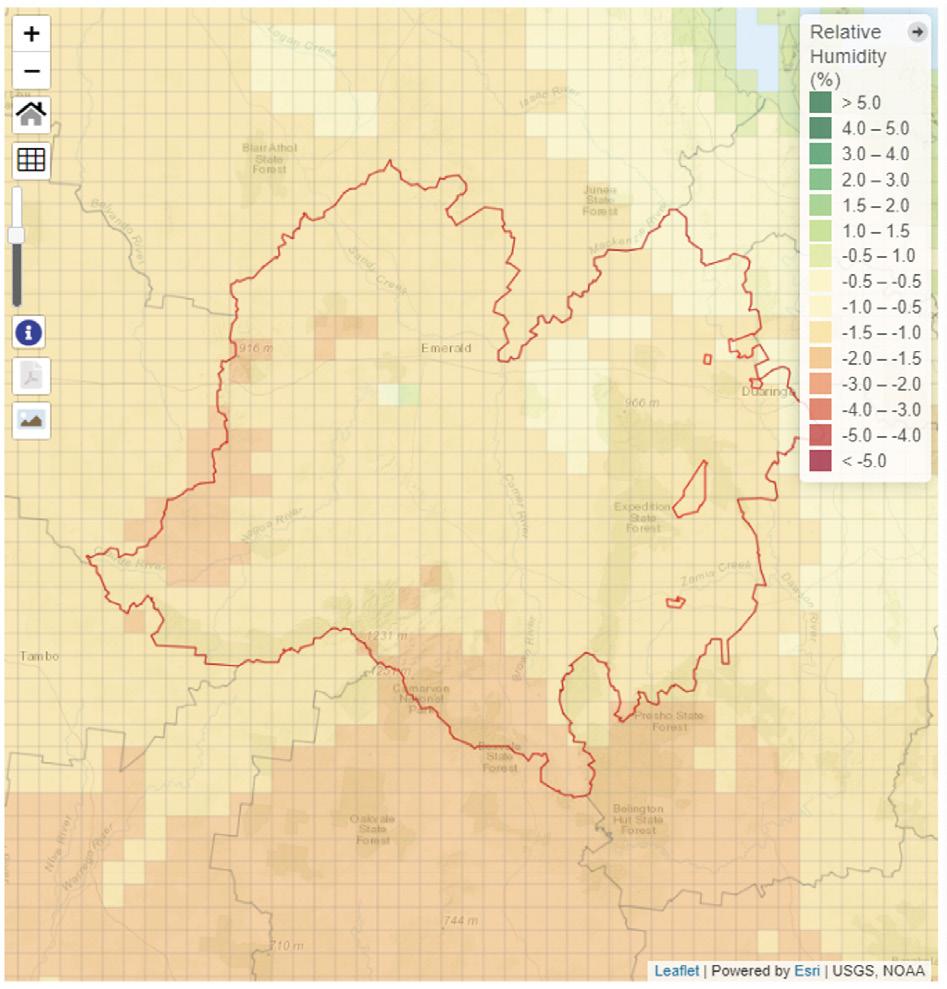

3. RELATIVE HUMIDITY

11: Relative Humidity (%) for CHRC 2030 -0.95% (left) and 2050 of -1.2% mm/day (right) under RCP 4.5

12: Relative Humidity (%) for CHRC 2030 -0.6% (left) and 2050 of -1.3% mm/day (right) under RCP 8.5

Figure

Figure

CENTRAL HIGHLANDS REGION– CHANGES IN MEAN CLIMATE

Precipitation (mm/day)

Bibliography

Australian Government Department of the Environment and Energy. (n.d.). What are the RCPs Infographic. Retrieved from https://coastadapt.com.au/sites/ default/files/infographics/15-117NCCARFINFOGRAPHICS-01-UPLOADEDWEB%2827Feb%29.pdf

Australian Government, Australian Climate Service. (2023). https://www. acs.gov.au/pages/national-climate-riskassessment. Retrieved from https://www. acs.gov.au/pages/national-climate-riskassessment

Queensland Government. (2024, 2 7). Queensland Future Climate: Understanding the data. Retrieved from https://longpaddock.qld.gov.au/qldfuture-climate/understand-data/