Know your numbers, rural contractors told

Rural contractors really need to know the numbers that drive their business and share them with their farmer clients.

That was the advice from NZX Head of Insights Julia Jones at a Rural Contractors NZ roadshow held in Palmerston North, Whangarei and Hamilton in August. NZX is being contracted to deliver a cost reference point to RCNZ and Federated Farmers.

“It will be available to RCNZ members via the organisation’s website allowing them to track two of their biggest costs – fuel and fertiliser – and help them with their planning.

“Other cost reference points may be added in time if we can get meaningful independent data,” said RCNZ CEO Andrew Olsen.

Julia Jones told the contractors who attended the meetings that they needed to know the margin they were making.

“What revenue do you get from a job? No one wins if you are not making money.’’

Waikato Federated Farmers vice-chair Keith Holmes, who was part of initial meetings earlier this year on cost issues, told the Hamilton meeting he fully endorsed the accord being developed.

“Farmers and rural contractors need each other,” he said.

As a lifestyle block owner in Waikato, Julia Jones said she is a user of the services provided by the $2b rural contracting industry.

“I tell my rural contractor to charge me more,” she said, impressed by the machinery used and the speed at which jobs like baling silage could completed.

A show of hands at the Palmerston North meeting indicated few contractors had increased their prices by 20% or more in the past four years

when the cost of two of their biggest inputs – diesel and urea fertiliser – had doubled. That wasn’t the case when other areas were provided with a show of hands.

“I expect we’ll see contractors having these conversations with farmers and growers more consistently – they need to,” said Andrew Olsen.

Julia Jones said rural contractors needed to develop an ethos about charging appropriately. “You don’t have to do business with everyone.”

World food prices were going through the roof and no matter how global tensions played out, people would always need to eat. Rural contractors were key to that happening.

“Your role isn’t going to go away but you do need to evolve and stay relevant.” She said rural contractors were an essential, if largely unrecognised, contributor to New Zealand’s role as a food producer and exporters. The ÿ rst priority for a rural contractor was to look after their well-being and then to be on top of their costs.

Andrew Olsen added his organisation has been working constructively with Federated Farmers over recent months to develop an accord on cost volatility that works for both contractors and farmers.

“These roadshows are conÿ rming costs are the big issue for rural contractors and we need contracts that re° ect scalability in how costs are being treated by contractors and farmers.

That’s our focus in the next weeks and months –Federated Farmers and RCNZ wrapping education around this issue.”

A draft contract was currently with Federated Farmers for use by rural contractors and farmers.

www.age.co.nz Thursday, October 6, 2022 FEATURE SUPPLEMENT 25

61 Georges Rd, RD3, Martinborough P: 06 306 9168 or M: Rob Gawith 027 454 6982 | Rob Carter 027 449 8023 E: rob.coltbros@gmail.com WE SEE YOU THROUGH FROM START TO FINISH • Direct Drilling • Minimum To Full Tillage Cultivation • Maize Planting & Side Dressing • Pasture & Crop Spraying • Silage Grass, Cereal & Maize • Baleage & Hay • Grain & Seed Harvesting • Grain Drying & Handling • Cartage • Supplementary Feed Trading AGRICULTURAL CONTRACTOR For a professional result, call the experienced team at Colton Bros. Ltd

The art of making good grass silage

What is pasture silage?

Silage is pickled pasture. When pasture is ensiled, its sugars are converted into lactic acid by bacteria. It is the lactic acid which pickles the pasture, allowing it to be preserved for a lot longer than it would have been if left in the open air.

With well-preserved silage, losses in feeding value during fermentation will be small, and the ÿ nal silage will be only slightly lower in feeding value than the original pasture.

Good quality pasture needed

It is impossible to produce high quality silage from low quality pasture, no matter how good the fermentation is. Both the quality of the ensiled pasture and the quality of the fermentation must be considered.

Good quality pasture silage is a good source of energy and protein for a milking cow and can be used as a ÿ bre source when feeding high sugar or starch feeds.

However, a poor quality pasture silage (made from low quality pasture, or ensiled with low

quality fermentation, or both) will not support high milk yield and will only be suitable for dry cows, or as a ÿ bre source to reduce risk of acidosis.

Losses when making pasture silage

Losses occur as sugars and protein in the grass is broken down by enzymes, and bacteria.

This process starts as soon as the grass is cut. Losses decrease quality as well as quantity, because it is the highly digestible components which are most rapidly broken down.

Losses during harvesting

Losses depend on the dry matter (DM) of the pasture.

The optimum DM for silage is 25-30% because total DM loss is minimised.

Cut in the morning of a sunny day, for rapid wilting. Cutting after 1-2 days’ sunny weather will result in good sugar levels in the pasture, even when cut in the morning.

Avoid wilting for any more than 24 hours. Compact the silage well. In a stack or pit, use

the heaviest wheeled vehicle available.

Tractor wheels should not sink into the pile of pasture any further than the depth of rubber. For baled silage make sure that a high density baler is used.

Seal the stack completely with a weighted, airtight cover. Wash old polythene before use to avoid contamination with the wrong bacteria.

Don’t reopen a covered stack to add more pasture on another day.

Losses while grass is in the stack, pit or bale

Once the silage is sealed, nothing can be done to change the fermentation process. Poor fermentation (eg air in the stack) leads to major losses of protein quality.

In poorly preserved silage protein is broken down into ammonia, which decreases the feeding value of the silage.

Getting things right while the grass is being harvested will maximise the chance of having a

good fermentation:

A fast wilt to 25-30% DM will leave good sugar concentrations in the pasture.

Quick compaction and e° ective sealing will keep out oxygen, making conditions more suitable for bacteria to convert sugars into lactic acid.

Fast production of lactic acid will quickly reduce the pH, to prevent protein losses.

Feeding out losses

Silage begins to break down once exposed to air, and will begin to heat up as microorganisms turn the remaining sugars and protein into heat and energy. When feeding out, aim for as little time as possible between exposing the silage to air, and the cow eating it.

There are several ways to limit losses from silage while feeding out:

Remove at least 20cm o° the whole stack face each day, so silage at the face is not exposed to air for a more than one day.

Cut silage o° the face, rather than pulling it o° This keeps a smooth surface at the stack face, which reduces air penetration into the stack.

Leave the stack face open on dry days to avoid heat build-up under the polythene.

Do not feed out more than one day in advance, especially in summer.

Cows will be able to eat more of the silage they are o° ered if it is fed out on dry paddocks or feed out areas, along fence lines, or in feed bins or troughs.

Do not allow cows access to spoiled silage.

Source: DairyNZ www.dairynz.co.nz

Higher temperatures and normal rainfalls predicted

Above average temperatures are expected from now till November, according to NIWA in its Seasonal Climate Outlook for September to November 2022.

“Temperatures are very likely to be above average (65% chance). More northeasterly winds may lead to higher humidity levels, more cloud cover, and warmer overnight temperatures.

“Rainfall totals are most likely to be near normal (45% chance). The potential for more frequent onshore winds during spring could lead to more wet days.

“Sub-tropical lows may occasionally track toward the region, increasing the risk for heavy rain, particularly in the northern part of the East Coast region, such as northern Hawke’s Bay and Gisborne.

“Soil moisture levels and river ˜ ows are most likely to be near normal (45% chance).”

More cloud cover and humidity is expected.

www.age.co.nz Thursday, October 6, 2022 FEATURE SUPPLEMENT 2726 FEATURE SUPPLEMENT Thursday, October 6, 2022 Wairarapa Times-Age

Both the quality of the ensiled pasture and the quality of the fermentation must be considered.

James Schofield Sales 027 205 6732 Zac Chandler Sales 027 421 4585 Graeme Garrity Construction Sales 027 208 2664 P: 06 370 8240 307 High St, Masterton Prices valid till 30 October 2022 We can help with: • Batteries • Bearings • Belts • Nuts & Bolts • Grease, Oils & Lubricants • PTO shafts & Gearboxes • Hydraulic Hoses & Fittings • Pins & Bushes Repaired & serviced your gear yet? Book it in now. BE HARVEST READY! Belvedere Road, Carterton Ph 06 379 8044 sales@massons.co.nz • Plowing • Cultivation Work • Direct Drilling HOME 06 379 5953 • WAYNE 027 4979 837 • WATERSONS LINE, CARTERTON WAYNE & ANDREA PRICE CONTRACTING

Keeping safe on farm during summer

Summer means heavy workloads on farms, from weaning lambs and calves to hay and silage making.

There’s close work with animals, many large vehicles coming and going, contractors on farm and heavy use of tractors and machinery.

At the same time, you may also have summer visitors, and children wanting to be out playing or helping out.

“All these factors carry health and safety risks,” says Mark Harris, lead extension manager at Beef + Lamb New Zealand.

“Vehicles and machinery feature in almost 90 per cent of fatal workplace accidents on farms and accidents requiring more than a week o˜ work.

“Recognise vehicles as a critical risk on farm and establish good ongoing practice around using them. Always select the right vehicle and Personal Protective Equipment (PPE) for the job.

“A quad bike might be ideal for nipping round but not for towing a heavy load, take those few minutes to get the tractor.”

One of the main causes of deaths involving tractors are where it hits the operator or another person because it hasn’t been properly braked, or through the tractor rolling, with

the driver not wearing a seatbelt.

Most fatal tractor rollover accidents in recent years would have been prevented by the driver wearing a seatbelt on a Roll Over Protection (ROP) ÿ tted tractor.

Contractors

‘It’s a good idea to consult with your contractors ahead of any work, to establish clear roles, responsibilities and actions and discuss risks - it’s as simple as a phone or email conversation.”

Children on the farm

“Naturally, farmers want their children, grandchildren and other young visitors to enjoy the farm with them, it’s the Kiwi way – but vehicles also pose a major risk for children,” says Mark.

“Don’t let children ride on tractors, quad bikes or on the back of utes. Children should be in car seats or seat belts when in cars, utes or trucks, including on private roads.

“Always walk around a vehicle to check children are a safe distance away before starting the engine – and never leave vehicles unattended with the engine running or the key in the ignition.”

Children lack the judgement,

body weight and strength to handle full-sized farm vehicles, like quad and other farm bikes.

According to ACC ÿ gures, more than 100 children hurt themselves on these vehicles annually. About 28 are hospitalised and tragically from three to six are killed.

“When walking around the farm with children, identify risks together,” says Mark.

“Make sure children wear high visibility clothing and teach them to wash and dry their hands after touching animals.

Water, be it rivers, creeks, troughs, dips, tanks, dams or ponds, all pose risks.

“Where reasonably practicable, set up safety barriers around play areas, animal pens, work areas and water spots.

“Cover tanks and wells with child restraint covers or ÿ ll in disused ones. Lock doors and ensure agri-chemicals are stored safely out of children’s reach. Small hands may also be able to reach through machinery guards.”

Tie spare tractor wheels to walls or lie them ˛ at. Ensure bikes children ride are appropriate for their age and height.

“Above all, ensure children are well supervised,” says Mark. Even the most sensible child can do

Make sure children are well supervised on the farm

something impetuous.

“It’s important safety conversations are part and parcel of everyday life on farm.

“If someone is getting out of the tractor, check they’ve put the brakes on. If they’re hopping into or getting out of machinery remind them to always use three points of contact and buckle up.

“If you lead by example, like wearing an approved helmet (PPE) on a quad bike and wearing your seatbelt in vehicles where provided, your team and your kids will learn that’s the way to do things – and you will be setting them up for lifelong good safety habits.”

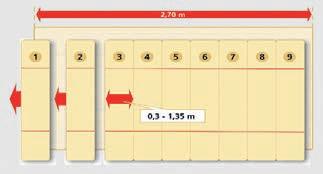

Safe stacking of hay

It is important to stack bales correctly to avoid creating hazards to yourself and other people.

Build stacks on ÿ rm, level ground away from ÿ re hazards, sources of ignition, overhead power lines, dwellings, boundary fences and footpaths. Ensure stacks are safe at all times.

Take precautions to prevent mechanical damage, for example by transport, rodents and undermining by cattle.

Never stack higher than the lifting capabilities of the handling equipment used for stacking and destacking.

This is particularly important if you employ contractors to do the job. Make sure stack and load heights do not exceed the lifting capabilities of your own handling equipment.

Never stack more bales on handling equipment, to a height higher than the equipment is designed to handle.

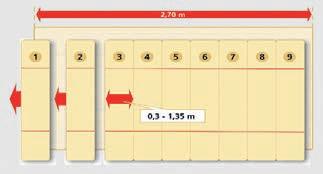

Wherever possible, stack big bales (rectangular,

square or high-density) by overlapping to form a stable stack. Big square bales are normally stacked to a maximum of four layers high. High-density bales can be stacked ˛ at up to six layers high.

Big round bales may be stacked either on their ends, if covered, or on their sides in a pyramid. End stacking: Use bales of the same diameter. Pyramid stacking: Don’t stack more than four layers high. Each bale on the bottom layer may be chocked to enable safe and convenient destacking. Fit stakes or supports to either side of the stack.

Never build a conventional stack of bales higher than the limits of safe access to and from the stack. Height will also be limited by the means used for getting bales from the loads on to the stack.

Stacks will be more stable if their height does not exceed 1.5 times the shortest base dimension.

Where stacks are likely

to be dismantled over a period of time, build them under cover so the stack can be taken down without exposing each layer to the weather.

Where regular access past stacks is unavoidable, either by employees or other people, or where excessive wind loading is likely, do not stack to these maximum heights.

Large hay bales often weigh about 500kg and a stack collapsing inside a building could cause damage to its structure, which in turn may injure people.

Some structures may not be strong enough to support large hay bales stacked against them. For these reasons, structures for storing large hay bales should be designed, manufactured and built by suitably qualiÿ ed people who have taken these factors into account.

Source: Guidelines for the SAFE HANDLING, TRANSPORTATION and STACKING of LARGE HAY BALES. The full guidelines can be found at worksafe.govt.nz

www.age.co.nz Thursday, October 6, 2022 FEATURE SUPPLEMENT 2928 FEATURE SUPPLEMENT Thursday, October 6, 2022 Wairarapa Times-Age

Buy online at www.biostart.co.nz or phone Rex Turnbull 027 575 2696 The new BioGro Certiÿ ed Forage Preservation range from BioStart Enquire now for all your mowing requirements. MASSEY FERGUSON DM 306P DISC MOWER Massey Ferguson DM Series Disc Mowers offer uncompromising quality and finish. Designed for smaller operations through to professional contractors. MF mowers feature innovations that drive high performance, increase productivity and lower operational costs. BE QUICK, ONLY 2 STOCK UNITS AVAILABLE AT THIS PRICE HOT PRICE $18,495 + GST! (RETAIL PRICE $24,000 + GST)

Designing silage and feed storage areas

Well placed supplementary feed storage areas can save money through reduced spoilage, fuel use and travelling time. Ideally, you want to store feed as close to where you will be using it as possible. A good design will help to reduce spoilage from rodents, surface or rainwater, and prevent water pollution by capturing toxic leachate and run-o˜ Placement should also take the food safety minimum distances into account.

Site selection

Silage storage facilities should be sited on land that is: easily accessible (e.g. close to the feed pad if you have one) and relatively ° at at least 45 metres from any farm dairy at least 50 metres from waterways, open drains or dams, and the catchment areas of bores; further away if the land is steep, soils are coarse textured, or ground water may enter sensitive waterways well away from gullies or other places where run-o˜ catchment water can ° ow into the storage area

not prone to ° ooding or that has a high water table

away from any subsurface drains.

Silage leachate should never enter waterways as it is highly toxic to aquatic life.

Construction

The walls and oor of a silage bunker must be capable of withstanding the hard knocks of tractors and other machinery as well as resisting corrosion from leachate. Concrete with a water/ cement ratio less than 0.4:1 should be used. A concrete ° oor should be 125mm thick and reinforced to support 20 MPa if vehicles are used on it.

The silage bunker ° oor should be watertight and extend out beyond the bunker walls.

Construct a nib wall along the sides. This will keep freshwater out and leachate in. Slope the ° oor 1m:50m towards a drainage channel laid across the front of the bunker.

For bunkers cut into the side of a hill, an impermeable surface is still essential. Concrete is best, but compacted clay may be suitable. Check with your local council for any requirements they may have.

Silage stacks on the ground also require a sealed surface with leachate directed to a collection point and properly contained.

A shallow cut-o˜ trench around the stack will help prevent water run-o˜ from the paddock entering the stack.

All other stored feed is best contained in a concrete bunker.

At the very least, it needs a sealed surface plus proper sides and a cover to keep rain and wind out and control leachate production.

Minimising leachate

Silage leachate is surplus water from silage, which carries soluble sugars, proteins and nutrients with it as it seeps out of the stack. This leachate is extremely acidic and polluting to waterways. It is approximately 40 times stronger than farm dairy e˛ uent and 200 times stronger than raw domestic sewage. It is also extremely corrosive and can damage concrete and steel. Leachate entering freshwater is likely to result in regional council enforcement action.

Leachate production is initially determined by the moisture content of the cut pasture (or other feed) when it is placed in the bunker. Maize silage produces very little leachate.

Wilting is the key to minimising silage leachate. If grass is cut and ensiled without wilting, over 500 litres of leachate per tonne of grass would be produced; if the

grass is wilted to 25% dry matter (DM), less than 30 litres per tonne is produced.

Properly covering stacks to keep the oxygen out and prevent rainwater entering is crucial to reduce the volume of leachate.

For bunkers with sides, the cover should extend and be secured over the sides. Stack the grass higher in the middle to allow water to run o˜ the cover.

For free-standing stacks, timber or concrete posts and soil should be used to hold the cover in place.

Silage and feed bunker leachate collection

If the silage stack or bunker is close to the farm dairy, the easiest option may be to channel leachate into the farm

dairy e˛ uent system (unless it is an oxidation pond treatment system as this will overload the system).

If the silage stack or bunker is away from the dairy, leachate should be directed into a watertight storage sump. The sump should be resistant to corrosion with at least 3m3 storage per 100 tonnes of grass ensiled. It is recommended that it is diluted (1:1) and applied to land at regular intervals, or it can be added to farm dairy e˛ uent. Applying 25m3/ha will supply approximately 25-75kg/ha of nitrogen, 25 kg/ha of phosphate and 100kg/ha of potassium.

To ensure continued e˝ cient leachate collection, clean and inspect the walls, ° oors and drainage channels when bunkers are empty and mend any cracks, corrosion or other faults before reÿ lling.

Source Dairy NZ

Important to analyse pasture silage

Why analyse pasture silage?

To assist your management. An analysis will tell you the quality of the silage so you can decide whether to feed milking or dry cows, and allows you to value silage based on its Metabolisable Energy (ME) content.

How to sample silage

Take at least ÿ ve handfuls of silage from di˜ erent places and mix them together. Send a subsample of one litre (half a bread bag) for analysis. The sub-sample should be representative of all the silage in the stack or bale.

You can take silage sampled from unopened stack or bales to tell the quality of the feed before it is fed out. It will also not have been spoiled through exposure to air) or sample silage as it is being fed out.

Assessing silage quality by sight and smell

If you don’t have a feed analysis for your silage, you can estimate quality from its appearance.

Well-preserved silages are green, yellow, or pale brown. Dark brown silage is generally poorly preserved

Feed quality: High quality silage has lots of leaf, and very little stem in it. The more stem in silage, the poorer its quality.

Colour: Well-preserved silages are green, yellow, or pale brown. Dark brown silage is generally poorly preserved.

Smell: Well preserved silage has a sweet, tobacco smell. Foul, rancid smells indicate the presence of butyric acid from poor preservation.

Moulds: Moulds grow where silage has been exposed to air. Some fungi can produce toxins.

Source: DairyNZ/www.dairynz.co.nz

www.age.co.nz Thursday, October 6, 2022 FEATURE SUPPLEMENT 3130 FEATURE SUPPLEMENT Thursday, October 6, 2022 Wairarapa Times-Age

Silage storage should be located where it is easily accessible

CALL ARRON Operations Manager 027 498 7104 tullochcontracting@xtra.co.nz www.tullochcontracting.co.nz Cultivation | Direct Drilling | Baling/Balage Silage | Harvesting | Supplements SHED YOUR HAY FROM YOUR TRACTOR SEAT, NO SWEAT! Conventional sized sub bales in an easy-to-handle big square bale • cut the cost of bale handling without touching a bale • mechanical handling reduces the weather risk • safe and stable to cart and store WE MAKE HAY THAT’S CHEAP TO MAKE AND EASY TO FEED *Bale length 1.8m–2.7m KRONE BiG PACK 870 MULTI BALE YOUR LIFESTYLE BLOCK AGRICULTURAL SPECIALISTS We also sell high quality feed products - Call to discuss your requirements, or visit our Facebook Shop where you can purchase Conventional bales Mini bales Large rounds Medium rounds Round balage WOODLEA CONTRACTING 027 284 7543 | woodleacontracting@hotmail.com Lucerne, Meadow & Clover available while stocks last Woodlea Contracting o er a wide range of lifestyle block and small farm services to the highest standard Hay and balage cutting Fencing Yard construction Digger work

Good management vital for maize silage

What is maize silage?

Maize silage is a maize crop cut and ensiled in a stack or bunker. It is commonly used as a supplement to pasture in situations where cows would otherwise be underfed.

Maize silage is a high quality forage supplement. However, it is particularly low in sodium (Na), calcium (Ca) and phosphorus (P), and can be used as an e˜ ective carrier to supplement cows with magnesium (Mg).

Maize silage is a useful supplement for ÿ lling genuine feed deÿ cits, but needs to be well managed to reduce costs and wastage.

New Zealand trials have found production responses to maize silage range from 32g MS/kg DM to 178g MS/kg DM.

The highest response came from more days in milk created by feeding maize silage in a year a˜ ected by a dry summer.

Analysis of more than 600 NZ dairy farms found on average, that supplements fed added only 50g MS/kgDM to annual milksolids/ cow and 96g MS/kgDM to annual milksolids/ha.

With such variation in response possible, attention to detail is required to turn additional fed into additional proÿ t.

Why is maize ensiled?

Maize silage is full of soluble carbohydrates which while being a great food for cows, is also loved by spoilage bugs, such as yeasts and mould.

The aim of the ensiling process is to get air out of the stack and keep it out until maize silage is ready to be fed.

Bunkers

Storing maize silage to minimise losses

Consider stack location and prepare site in advance of harvest. Consider environmental implications, eg risk of runo˜ , distance to waterways, drains and other sensitive areas.

Consider whether to use a bun (stack) or a bunker. Buns can be located around the farm and therefore are more ˛ exible, whereas bunkers are initially more expensive but have higher compaction rate and therefore less wastage.

Stack dimensions, the aim is to build a stack so that when being fed out, as little maize as possible is exposed to air. Consider quantity of maize, how many animals you are feeding and what inoculant you are using.

Ideally it should take no more than three days to feed across the stack face, taking about half a metre each feed. Cover immediately after contractor has ÿ nished rolling the maize. Seal around the base of the stack with soil, sand or lime and place tyres to completely cover stack.

Feeding out maize silage

When you start feeding maize open the stack at the opposite end of the prevailing wind to prevent air getting pushed under the cover. Use a front end loader to create a face. Once the face has been created, chip away from the top to the bottom of the stack, rather than lifting from the bottom of the stack face.

Don’t ram bucket or silage forks into the face of the stack as this creates shatter and may allow air to penetrate the maize stack.

Source: DairyNZ www.dairynz.co.nz

32 FEATURE SUPPLEMENT Thursday, October 6, 2022 Wairarapa Times-Age

are initially more expensive but have a higher compaction rate and therefore less wastage. (06) 323 0309 4 Turners Road, Feilding TRC Tractors your local Stewart Trailer Dealer www.trctractors.co.nz tractors@trctractors.co.nz STOCK AVAILABLE NOW! MAKE WILLIAMS TRUCKING YOUR FIRST CHOICE Servicing Masterton and surrounding areas. Regular runs to Tinui, Castlepoint, Whareama & Riversdale 027 243 3666 • robert@williamstrucking.co.nz Call Robert today 20+ Years industry knowledge and experience www.williamstrucking.co.nz FOR ALL YOUR HAY, BALEAGE AND GENERAL FREIGHT CARTAGE Now able to cart from 1-28 Tonnes