#1, 2024 Water Alliance magazine NEW LIFE FOR FATHER’S INVENTION DRINKING WATER FOR EVERYONE IN SEARCH OF THE HOLY GRAIL

WaterProof is the magazine of the Water Alliance, a partnership between government, research institutions and industry in the field of innovative and sustainable water technology. From its base, the WaterCampus in Leeuwarden, the Water Alliance builds on the ‘water technology innovation chain’; a process whereby new ideas from universities, laboratories and test sites are converted into worldwide marketable products. WaterProof provides regional, national and global information on developments, results and background in the field of water technology.

Editor

Menno

Narvic Media

Translation

Presence

Graphic

janrobert@minkgraphics.nl

Photography

Lucas Kemper and many others

Text

Henk Dilling and many others

Printer

Drukkerij Van der Eems

waterproofmagazine 2 con tents colophon and...

3 Column by Hein Molenkamp 4 Short Cuts 16 The Water Technology Innovation Chain 17 What’s on WaterProof TV? 20 Opening doors with EEN 26 Water Alliance Members WaterProof magazine #01, 2024

Photo Silas

| Unsplash

Cover

Baisch

Kramer

Editor Nynke

Journal Management

in Chief/

Bakker

|

narvic.nl

Translate

& Interact

Design

08 JANTIENNE VAN DER MEIJ DIRECTOR OF WATER TECHNOLOGY GROWTH PLAN 14 NEWDEALSEALS INTERVIEW WITH DIRECTOR ED DE GRAAF 12 WIS AWARD KICKSTART FOR GROWTH 22 18 IN SEARCH OF THE HOLY GRAIL OF BIOBASED PLASTIC JOIN THE PIPE ‘DRINKING WATER FOR EVERYONE’ 06 SENSIBLUE NEW LIFE FOR FATHER’S INVENTION

Pioneering is best done together

Many of you are likely aware that our LinkedIn account is the place to be for the most up-to-date posts about everything Water Alliance does. We post almost daily about new developments; about our over 200 members and their often groundbreaking innovations; about the great strides that the Triple Helix of Education, Government and Entrepreneurs in the Netherlands is making when it comes to being smarter about water, its social importance; and, last but not least, about the international ambitions of entrepreneurs in our water technology sector.

Nevertheless, the world of social media moves fast. For that reason alone, we think it is also good to regularly pick out a few pearls from all these developments, which we exhibit in this magazine and on our YouTube channel, WaterProof TV. We aim to maintain a down-to-earth, journalistic attitude. Still, I must admit that reading through an issue of WaterProof also fills me with pride, because I remember what this sector looked like twenty years ago. I can see with great clarity the huge strides we have taken, and I hope you do, too. Reading this issue alone, it becomes evident that the Dutch government has embraced the water tech sector as one of the most promising showpieces of the Dutch economy (more on this in the Water Technology Growth Plan article). At the same time, you will be able to conclude that new and eager frontrunners keep emerging and winning national and international awards. While reading, you may also come to the conclusion that self-awareness is growing rapidly in this traditionally modest sector. Now more than ever, we are aware of the urgency of water challenges around the world, and that the Dutch watertech sector offers solutions. The world needs to know that.

Conquering new international markets requires great pioneering efforts, and pioneering is best done together. We do so by working intensively with dozens of partners in the Netherlands and far beyond. I take my hat off to any entrepreneur also working to get ahead by collaborating with others. I hope that this magazine may offer a brief moment of inspiration.

Hein Molenkamp Managing Director, Water Alliance

by Hein Molenkamp waterproofmagazine 3

column

Photo: Marcel J. de Jong

SHORT CUTS

NEWS FROM AROUND THE WORLD OF WATER TECHNOLOGY

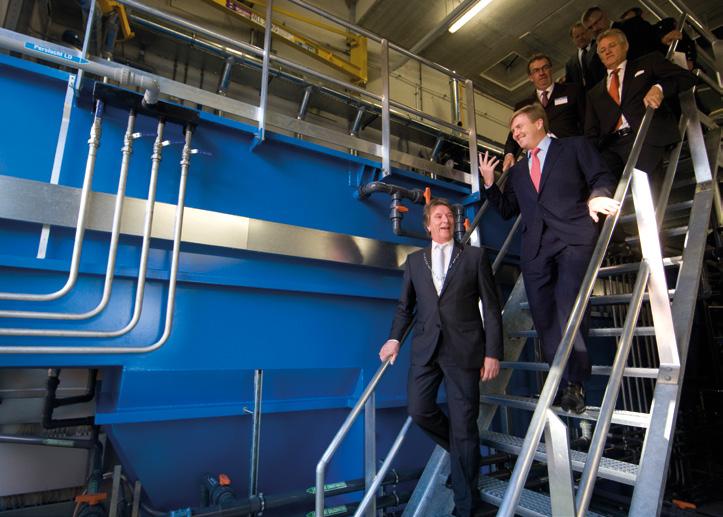

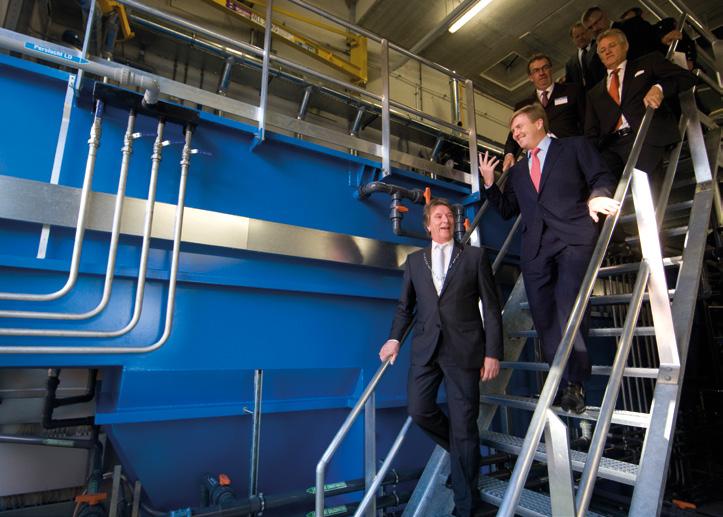

WAFILIN SYSTEMS CELEBRATES OPENING OF NEW FACILITY IN LEEUWARDEN

Wafilin Systems, member of the Water Alliance, marked an exceptional milestone with the opening of their new facility in Leeuwarden, in November 2023. This move is a direct effect of the significant growth the company has experienced over the last few years. Sybrand Buma, Mayor of the city of Leeuwarden, initiated the official opening.

Wafilin Systems specialises in designing, developing, and delivering innovative membrane filtration systems for the dairy and food industry. The company had been located at the WaterCampus in Leeuwarden for years, but due to the significant growth it has experienced, it was forced to look for a new premises. This is especially due to the rapid developments in the food and dairy industries in both the Netherlands and the UK.

“With our state-of-the-art offices, an in-house membrane application centre

and warehouse, we are able to organise our work processes more efficiently and to serve our clients more efficiently and with even greater speed,” remarked CEO Henk Schonewille. “By investing in our own dedicated office space, we have created an ideal work environment which will provide an inspiring workplace, contribute towards the personal growth of the team and in turn the continued growth our company.”

Jos van Dalfsen, Business Development Director, underscored the importance of having their own facility: “By investing in our own dedicated office space, we have created an ideal work environment which will provide an inspiring workplace, contribute towards the personal growth of the team, and in turn the continued growth of our company. Our collaboration with Jaap Hoekstra Vastgoed has been crucial in bringing this vision to life.”

UK AND NL WATER TECHNOLOGY COLLABORATION

Like many other countries, The UK faces major and pressing water issues arising from population growth, aging infrastructure, and climate change. The Dutch Embassy, Netherlands Enterprise Agency (RVO) and Water Alliance have been working together under the public-private partnership programme ‘UK Water Technology’ to bring Dutch and British water technology sectors closer since October 2023. In February this year, this programme was officially signed by Dimitri Vogelaar, Head of the Economic Department of the Embassy, and Hein Molenkamp, Director of Water Alliance.

The programme includes various activities such as knowledge exchange, missions, trade fairs and matchmaking. One of the most recent activities organized by the partnership was a business mission to the World Water-Tech Innovation Summit 2024, in London. Representatives from the Dutch companies CirTec, FibreSecurity, Hydraloop, LG Sonic, NX Filtration, Royal HaskoningDHV, Samotics and Technimex International were present at the exhibition area with a joint booth and participated in the conference and company visits. Amongst other activities planned for 2024, a British delegation will attend the European Water Technology Week which will be held in Leeuwarden, the Netherlands, from 23 to 26 September.

The source for this post was an article previously published on:

waterproofmagazine 4

Dimitri Vogelaar and Hein Molenkamp signing the programme.

Photo: from left to right: Henk Schonewille, Sybrand Buma, the Mayor of the city of Leeuwarden, Abel Reitsma, alderman of the city of Leeuwarden and Jos van Dalfsen.

SHORT CUTS

NEWS FROM AROUND THE WORLD OF WATER TECHNOLOGY

HOLLAND WATER ACQUIRES ULFIMA

Extraordinary news from Water Alliance member Holland Water. They reported the acquisition of industry peer Ulfima in February of this year. Holland Water is an expert in technology-driven legionella management, and Ulfima develops, supplies and manages physical management systems based on ultrafiltration technology. The strategic acquisition is the fourth since Holland Water formed a partnership with investment company OxGreenfield in late 2020.

Rogier van den Brink, CEO of Holland Water, explains the acquisition: “Holland Water stands for modern drinking water management, in which the building owner can count on a well-considered balance between water safety, sustainability, and cost efficiency, in addition to compliance with current laws and regulations”, says

Rogier van den Brink, CEO of Holland Water. “Finding and maintaining that balance is a delicate process that requires seamless coordination between legionella control activities, which is why we are consolidating all management services and techniques. Ultrafiltration is an excellent prevention technology and an essential addition to our portfolio.”

“Our water solutions match the specific building situation”, adds Jeroen Roosien, COO of Holland Water. “Sometimes the most appropriate technology is copper and silver ionisation, sometimes it is a gatekeeper based on ultraviolet light, and other times still, it is ultrafiltration. The acquisition of Ulfima and the addition of ultrafiltration to our portfolio gives us everything we need to compile the optimal management solution for each customer.”

FERR-TECH: NO. 1 IN THE DUTCH INNOVATION TOP 100

They keep winning awards. Ferr-Tech, the world leader in Ferrate(VI) applications for industrial wastewater treatment, has been named the most innovative company in the Netherlands, winning first place in the 18th KVK Innovation Top 100 for their innovation FerSol. The KVK stands for the Dutch Chambers of Commerce. The official announcement was made during a special event at DeFabrique Evenementenlocatie in Utrecht on November 30.

The KVK Innovation Top 100 recognises and celebrates the most innovative companies in the Netherlands. Out of the 300 applicants, Ferr-Tech, member of Water Alliance, has become the undisputed winner and has thus secured the top position in a field of more than 100 remarkable innovations.

Judith le Fèvre, Co-owner of FerrTech, remarked, “Securing top spot in the KVK Innovation Top 100 is a testament to the dedication and ingenuity of our team. It’s not just a win for Ferr-Tech; it’s a win for innovation in wastewater treatment and a recognition of the transformative power of FerSol.”

Ferr-Tech’s groundbreaking innovation, FerSol, a stable Ferrate(VI) solution, has revolutionised wastewater treatment, surpassing chlorine by 63% and enabling water reuse. The patented production process (a global first) extends its application to diverse sectors, from cleaning food and beverage crates to purifying plastic flakes in polymer recycling plants.

The company won the WIS award in 2022 with this innovation.

waterproofmagazine 5

Pictured from left to right: Rogier van den Brink, Emile Bruschinski (former co-owner and outgoing director of Ulfima) and Jeroen Roosien.

6 waterproofmagazine

report

SENSIBLUE’S NATIONAL AND INTERNATIONAL AMBITIONS

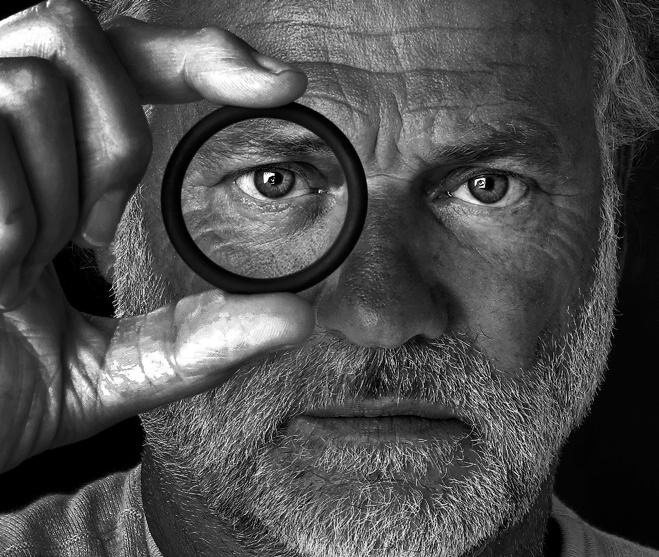

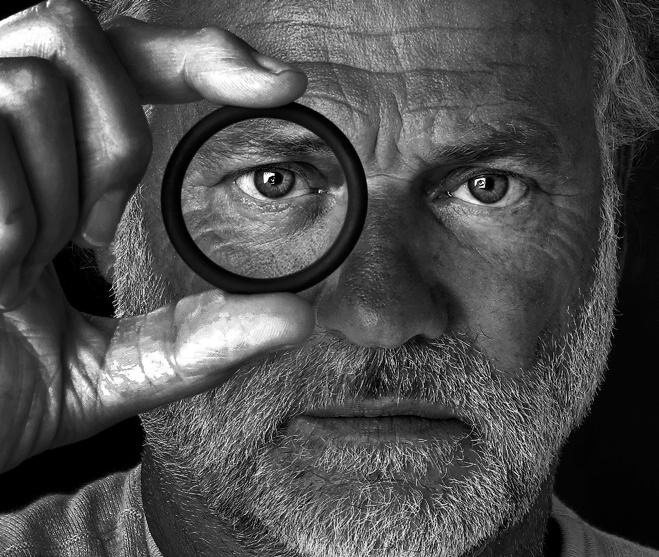

WIRIJN THOLEN BREATHES

NEW LIFE INTO FATHER’S INVENTION

The Sensiblue is a device capable of safely disinfecting drinking water. What makes it unique is that it kills viruses and bacteria without using electricity. After a redevelopment period, Sensiblue is ready to enter the scale-up phase. Owner Wirijn Tholen is ready to conquer the world with a product invented by his father, Jan Tholen, in 2001.

Heycop B.V., based in Houten, pulled their investment in the Sensiblue in 2020. Wirijn Tholen did not want the product developed by his father to be discontinued and took over. “I was working as a manager in logistics and purchasing at the time, and I lacked experience in the water industry, but watching everything go up in smoke was not an option. It took three years of hard work to redevelop the unit. The product is now finished, and we found VDH Watertechnology as a strategic partner through a funding round. With ProMinent GmbH as their parent company, we can sell and provide the desired service globally.”

UNIVERSALLY APPLICABLE

With the joint venture, including a product and a newly granted patent, Tholen is on the eve of rolling out Sensiblue in the Netherlands and far beyond. The proposition is twofold, he explains. “Unsafe drinking water is a problem all over the world. The Sensiblue can be connected anywhere drinking water and rainwater are stored, and water systems are unreliable. The system disinfects the water using a safe amount of active chlorine from salt electrolysis. This is a natural method that doesn’t require electricity, which makes the product unique”, Tholen says.

ENERGY TRANSITION

Sensiblue also plays into the energy transition in the Netherlands, as an alternative disinfection method for shower water. “The Netherlands is trying to get rid of gas, which means we have to switch to heat pumps and heat grids. Shower water is currently

heated to sixty degrees, but our device would allow that temperature to be lowered significantly. By disinfecting close to the tapping point, the water only needs to be heated to forty-five degrees. This greatly reduces power consumption, which is reflected in your energy bill. You will recoup the cost of the device within two to five years. The goal in the Netherlands is simple: all eight million households will have a Sensiblue within the next five years.”

‘ALL EIGHT MILLION HOUSEHOLDS WILL HAVE

A SENSIBLUE

WITHIN THE NEXT FIVE YEARS.’

OFFICE IN THE HAGUE

Sensiblue currently consists of three people; in addition to Tholen, the company employs a designer and a financial officer. “We will be moving to The Hague soon, where we will have an office and a production area”, Tholen continues. We want to grow into a company of about twenty-five people within two years. The focus in the Netherlands is primarily on achieving savings in heating shower water. Our technology can serve 2.5 billion households globally, so we will be looking for distributors and working hard to build our brand internationally in the next few years.”

TECHNOLOGY

SENSIBLUE SAFELY DISINFECTS WATER USING JUST ONE KILO OF SALT FOR EVERY 60,000 LITRES AND WITHOUT USING ENERGY. THIS SAVES 350 TO 1,000 KWH OF ELECTRICITY PER YEAR COMPARED TO ALTERNATIVE TECHNIQUES, THE COMPANY SAYS. THE DEVICE IS INSTALLED IN-LINE (E.G., IN THE METER CUPBOARD) IN THE WATER SUPPLY, AND THE DEVICE ITSELF GENERATES THE ENERGY REQUIRED FOR THE PROCESS. THIS CONNECTION ALLOWS PRECISE AND INHERENTLY SAFE OPERATION. THE SENSIBLUE WORKS WITH AS LITTLE AS THREE METRES OF WATER PRESSURE, ALLOWING SAFE WATER DISINFECTION AT ALL TIMES.

7 waterproofmagazine

JANTIENNE VAN DER MEIJ

DIRECTOR OF WATER TECHNOLOGY GROWTH PLAN

8 waterproofmagazine

inter view

‘YOU WON’T FIND THIS LEVEL OF INTEGRATION AT THIS SCALE ANYWHERE’

The words ‘Bring in the Dutch’ have been spoken frequently at international trade fairs and conferences over the past few decades in the context of water technology challenges. That may be a somewhat one-sided approach to things, but the fact is that the Dutch have a reputation to maintain when it comes to delta works or smarter use of water as a step toward a circular economy. Those developments recently received another big boost. A Dutch consortium comprised of no less than 600 companies and organizations has developed the Water Technology Growth Plan in collaboration. Through this plan, Dutch companies, research institutions and organizations, co-financed by the Dutch government, will invest 342 million euros in smart water solutions over the next ten years. There is a dual objective: ensuring the sustainable availability of water in the Netherlands and increasing the earning capacity of the Dutch water technology sector, e.g. by promoting exports. WaterProof spoke with director Jantienne van der Meij about the significance of the Growth Plan for the Dutch economy and, more importantly, in solving global water issues.

Jantienne, by way of introduction, can you tell us a little about yourself and your experience in the international water sector?

To go back quite a while: I studied at the University of Amsterdam, starting with a Master’s degree in Medical Biology; study of the human biochemical and molecular biological systems and later a Master’s degree focused on water management and nature conservation. If you were to delve a little deeper into my resume, you would see that I have actually been doing things related to water, circularity and renewable energy since 2008. I served at the Dutch Embassy in Washington, DC, from 2011 to 2016 and worked on those issues there as well. Water has increasingly become a key focus in my career in the last eight years.

What is the Water Technology Growth Plan, in a nutshell?

The growth plan is a collaboration between all actors in the Dutch water technology world. In short, the goal is to ensure sufficient clean water in the Netherlands by enabling an acceleration of the development and introduction of innovative techniques. At the same time, we must also ensure that these new techniques are properly tested, find a place with participating

‘launching customers’ and can then be launched in international markets. There are four programmes [see info box, ed.] which are supported by a cross-cutting work package. This support is primarily aimed at increasing the pace and maximizing results. Our focus areas will be water treatment, alternative sources, circularity, decentralization and digitalization.

How unique is this on a global level? There are people in other places in the world working on the same challenges, but I think it is unique that we can take up these challenges seriously with universities, universities of applied sciences, research institutes, water boards, government authorities, businesses and industry associations. You won’t find this level of integration at this scale anywhere.

Everyone talks about the great international urgency to sustainably make more water available to everyone, yet the consequences of overpopulation and, in particular, climate change seem to be growing faster than the number of global solutions. Where do you find optimism in your responsibility? Yes, the world is facing a daunting task. On the topic of clean water, did you know that more people die each year

from lack of clean water than from wars? Fortunately, that realization is becoming more and more prevalent. For example, the World Economic Forum has named water scarcity one of the five greatest threats to global prosperity for eight consecutive years. Some say, ‘It’s too late; there’s no fixing this’, but doing nothing is guaranteed to end in disaster. I am practical about it. I get my optimism from the fact that science is also gaining new knowledge every day. Capitalizing on that knowledge much faster is an inspiring task for all of us.

WaterProof has many international readers. Suppose I am a politician, an administrator or an entrepreneur abroad, and I want to get in touch as soon as possible with solutions that are ready or almost ready for the market. Who should I contact?

I would say: do it! Contact me or Ronald Wielinga at the Water Alliance. The details can be found in the info box on the folllowing page (10) of this article.

9 waterproofmagazine

THE WATER TECHNOLOGY GROWTH PLAN

The Water Technology Growth Plan brings around 600 Dutch entities together, including water technology companies, water boards, drinking water companies, consulting firms, research institutions and government bodies. The plan is an initiative by Samenwerkende waterschappen Oost-Nederland, together with Wetsus, KWR, STOWA (water board research foundation), Water Alliance and TKI Watertechnologie. Knowledge and research institutions and companies can develop, test and demonstrate their innovative solutions to partners from all over the world. The Water Technology Growth Plan is aimed at improving the sustainable security of water availability and quality, even in times of increasing drought. At the same time, it is also intended to help Dutch companies export their expertise to other countries.

Four programmes

The Growth Plan consists of four programmes.

1) Wetsus [the “European centre of excellence for sustainable water technology”, ed.] coordinates Programme 1: ‘Enabling Watertech’, in which companies, public and private stakeholders and knowledge institutions work on knowledge and technology development in theme teams. The ultimate goal is to achieve technological innovations that foster earning power, sustainability and the availability of sufficient clean water.

2) Stowa [the knowledge centre for water boards, ed.] and KWR coordinate with UDAC [the Directorate of Implementation and Decentralised Advice and Control of the Dutch Ministry of Infrastructure and Water Management, ed.] to execute Programme 2: ‘Pilots & Testing’, where consortia test, scale up and validate innovative water technologies through pilots and test projects. The goal is to enable development toward further demonstration.

3) The eastern water boards play a central role in Programme 3: ‘Full-scale Demonstration’. This involves demonstrations of innovative water technology in practical applications. These demonstrations take place in the Eastern Netherlands through innovative collaborations between end users, water boards, water technology companies and knowledge institutions.

4) Programme 4 is called ‘To the Marketplace’ and is driven primarily by Water Alliance. The programme valorises knowledge and development, promotes entrepreneurship and facilitates internationalization with a particular focus on strengthening exports.

These four programmes are supported by the ‘Accelerate and Maximise’ work package, which focuses on three areas:

• Change Management and Transition Processes

• Administrative and Legal Conditions

• Learning and Development (Human Capital)

An ‘innovation squad’ will also be established for each focus area and led by someone from the business community. Innovation squads are tasked with accelerating the time-to-market of new technologies and maximizing economic and societal value. They do this by exchanging knowledge across the breadth of the relevant focus area, raising issues and pooling resources to reach the market.

Participation

Participation in the programmes will be arranged through public procurement procedures. For more information, keep an eye on the following websites: tkiwatertechnologie.nl/ groeiplanwatertechnologie/ and wateralliance.nl

Alternatively, you can contact the organizations directly.

For programmes 1, 2 and 3: Jantienne van der Meij j.vandermeij@ watercampus.nl

For programme 4: Ronald Wielinga r.wielinga@watercampus.nl

INFO

10 waterproofmagazine inter view

‘COMPANIES CAN DEVELOP, TEST AND DEMONSTRATE THEIR INNOVATIVE SOLUTIONS TO PARTNERS FROM ALL OVER THE WORLD’

JANTIENNE VAN DER MEIJKRANENDONK IS DIRECTOR OF THE WATER TECHNOLOGY GROWTH FUND. SHE IS ALSO DEPUTY DIRECTOR OF THE TOP CONSORTIUM FOR KNOWLEDGE AND INNOVATION (TKI) IN WATER TECHNOLOGY.

Jantienne is also a part-time manager of Government Affairs for WaterCampus Leeuwarden (Wetsus, Water Alliance and Centre of Expertise Water Technology).

Previously, Jantienne served as an advisor for innovation, technology, and science (TWA/Innovation Attaché) at the Embassy of the Kingdom of the Netherlands in Washington, DC, where she promoted technological cooperation by building and maintaining a science and technology network in the Netherlands, the U.S. and Canada in the water technology, circular economy, and renewable energy sector.

11 waterproofmagazine

EXPLORING POTENTIAL WITH THE WIS AWARD

‘THIS AWARD KICKSTARTS GROWTH’

The Water Alliance Innovation Stimulation Award (WIS Award) holds a special place among the many awards for innovation and entrepreneurship in the Netherlands and abroad. In first place, because the award focuses specifically on water technology, but also because the award increasingly seems to be emerging as a portal for explosive growth, especially in recent years. We asked Agnes Dirksen and Harro Brons of the Water Alliance and the latest winner, Judith le Fèvre of Ferr-Tech, to explain what exactly the WIS Award stands for and why it could be very lucrative for many companies to participate.

12

waterproofmagazine

TO SIGN UP FOR THE WIS AWARD, SCAN THIS QR-CODE: THE WIS AWARD IS THE WATER ALLIANCE’S BIENNIAL INNOVATION AWARD. SEE A RECENT VIDEO HERE: THE FINAL WILL BE HELD DURING THE EUROPEAN WATER TECHNOLOGY WEEK (EWTW) IN LEEUWARDEN ON 25 SEPTEMBER 2024:

“The WIS Award is given to the most innovative company in Dutch water technology once every two years”, says Agnes Dirksen, Marketing & Communications Manager at Water Alliance. “Participants submit an innovation which is critically monitored for some time and ultimately judged by an expert jury chaired by Cees Buisman [director of Wetsus, ed.]. Participation is open to anyone under a few conditions. For example, your innovation must be less than two years old, but it must also be ready for the market.”

SELF-REFLECTION

Harro Brons, International Business Development Manager at Water Alliance: “The main prize is no joke: the winner receives 10,000 euros in marketing support. However, there is much more on offer for participants. We guide the candidates during their path to the finals. We provide extensive publicity and serve as a sounding board on numerous issues, which is always hugely appreciated by the companies. People work hard every day to develop their incredible innovation that they believe has was it takes, but it’s also good to take time for self-reflection and think about important questions: How do I pitch my story? What segments will I target, and with what proposition? We aid that process with our knowledge and international network. Companies get a much clearer picture of their story, which enables them to present it better. There is always something to be gained.”

There are no guarantees that a WIS winner will break through internationally, but Dirksen says it is notable that the winners in recent years have scored big far beyond our borders. “Wafilin Systems, Hydraloop, Samotics and more recently Ferr-Tech, all winners of the WIS Award, have not only developed a unique innovation but also have the right mindset. They are all enthusiastic entrepreneurs who take a very proactive approach to the market and maintain a strong focus on marketing and communication. Those types of companies often go on to win other awards as well.”

PROUD

One such winner is Ferr-Tech from Meppel. Entrepreneur Judith le Fèvre won the award in 2022 with the product FerSol (Ferrate(VI)), and it has proven invaluable. “The ten thousand euro cash prize is great, obviously, but the impact of the PR is much more valuable in the long run”, says Le Fèvre. “An expert jury judged Ferr-Tech on innovation, impact, sustainability and resilience, among other things. These are all important criteria, and we are proud to have come out on top. We got a lot of media attention, and the market started looking at us differently after that.”

The entrepreneur is happy to explain the technical story to anyone unaware. “Ferr-Tech produces FerSol”, Le Fèvre said. “That is Ferrate(VI) in liquid form. Ferrate(VI) has been known worldwide for decades as the strongest oxidant for treating industrial wastewater. It is green, environmentally friendly and leaves no harmful residue in the water. Until recently, it was impossible to produce shelf-stable Ferrate(VI), but Ferr-Tech developed a process that stabilises Ferrate(VI) for industrial use. Ferrate(VI) makes industrial processes more sustainable, energy-efficient and circular.”

The company’s growth has continued well after winning the WIS Award. “Definitely”, says Le Fèvre. “Since its inception, Ferr-Tech has consistently shown triple-digit growth every year.

The team has been expanded, and we are now shipping to multiple countries in Europe and are working on a largescale demonstration project in the US.”

KICK-START

Brons and Dirksen believe that many Dutch water technology companies should put more effort into marketing. Dirksen: “I understand it; it’s easy to shout from the sidelines. Many entrepreneurs have their feet on the ground and are heavily involved with day-to-day operations. However, sometimes it also seems that entrepreneurs are too easily satisfied with stable revenue in their own region despite potentially having struck a goldmine, which could help them achieve tremendous national and international growth.”

‘PARTICIPATION IN THE WIS AWARD IS BASICALLY A KICK-START FOR GROWTH, A GREAT FIRST STEP TO START EXPLORING YOUR POTENTIAL FURTHER’

13 waterproofmagazine

DIRECTOR ED DE GRAAF OF NEWDEALSEALS:

‘WITH PROPER SEALING, ORGANISATIONS CAN AVOID COSTS AND HEADACHES’

NewDealSeals develops and supplies sealing solutions for a range of industries. With a staff of thirty people, the Dutch company’s focus areas range from food processing to transportation and from aviation to maritime. The company is the world’s largest supplier of seals for marine engines on passenger and container ships. In the water technology sector, they developed seals for water treatment plants for the soft drink industry, among other things. “Success for us is when changing a sealing concept results in cost savings and environmental gains”, says director Ed de Graaf.

Rubber and seals; Director Ed de Graaf has a lot to say on these topics. “Rubber is a fascinating material with an amazing history,” he says. He treats us to a compact lecture on the history, explaining that the time-honoured eraser in 1770 was the first industrial application of rubber, which can be attributed to English chemist and inventor Joseph Priestley. He discovered a material that could erase pencil marks. He called it rubber, after the English verb, to rub. Another meaningful invention followed around seventy years later when an American chemist, Charles Goodyear, mixed rubber with sulfur, improving the material and inventing the process of vulcanisation. De Graaf: “He heated a mixture of rubber and sulfur under high pressure, creating a strong and elastic material that was resistant to both heat and cold. Something plastic became elastic. No other material in the world will return to its original shape after being stretched. We have been working with those incredible properties for more than a quarter of a century now.”

Sustainability requirements and standards

Rubber lends itself to a variety of applications, including sealing liquids, gases and solids in pipes, valves, pumps and cylinders; protecting electrical

waterproofmagazine 14 CEO talk

TEXT: HENK DILLING

and electronic components from moisture, dust, dirt and corrosion; and insulating from heat, cold and electricity. “With proper sealing, organisations can avoid costs and headaches” A seal that is improperly designed, used or maintained can damage machinery, the environment and more. For example, a leak could release oil or other fluids into the environment. This can lead to pollution, loss of biodiversity, health risks and economic damage. Seals must be environmentally friendly and meet sustainability requirements and standards.” In addition to being manufacturers of sealing solutions, De Graaf and his team consider themselves designers and engineers for the future. “We strive to develop sustainable solutions and create a better future for everyone”, he explains. “We want to reduce, recycle, replace and reuse where and when possible.”

O-RINGS AND SEALS

De Graaf explains that an O-ring is a toroidal seal placed between two parts to prevent the passage of liquids and gases. “It is an efficient sealing element for both static and dynamic applications. O-rings are the most widely used seals in the world for industrial applications because they are effective, economical and easy to use.”

Although the O-ring is a simple seal, there are many factors to consider when selecting the right O-ring for a specific application. “We have put together a technical handbook which explains those factors”, says De Graaf. “We supply O-rings in any size and tolerance required, and they can be produced in compliance with various standards and approvals.”

Water technology applications primarily use EPDM O-rings and seals. “Ethylene-propylene is a copolymer of ethylene and propylene (EPM), or— in some cases—a terpolymer by the addition of a diene monomer (EPDM). These rings have extreme weather resistance. The material also exhibits exceptional resistance to certain brake and hydraulic fluids. EPDM O-rings and seals are also highly resistant to steam.”

waterproofmagazine 15

< Test equipment: NewDealSeals’ machines and software are capable of testing components for chemical resistance, thermal degradation, mechanical properties and dynamic sealing

Ed de Graaf

The Water InnovationTechnology Chain

The WaterCampus brings together a complete chain of innovation for water technology, from first idea, research, specialized laboratories, various demo sites, launching customers to commercial international applications by commercial companies. Indeed from knowledge to business. It is driven by the idea that technological development and innovation is needed to develop new markets and create new business opportunities.

waterproofmagazine 16

Some updatesinteresting on WPTV

THE WATERCAMPUS INNOVATION CHAIN

On the left page you can see an organisational chart of The WaterCampus Innovation Chain.

It forms an innovation eco-system that is widely praised around the world.

Scan the QR code and see all about this ecosystem.

ENTERPRISE EUROPE NETWORK

This film is borrowed from the website of our partners at Enterprise Europe Network (EEN). EEN is the largest support network for organisations with international ambitions. It helps entrepreneurs, research institutes, universities and technology centers find partners worldwide for free. Enterprise Europe Network Netherlands supports organisations with practical information and advice about innovation and internationalisation.

Elsewhere in this edition: Brigitte Duffhues from Water Alliance about the EEN network.

COMING UP: WIS AWARD

Elsewhere in this WaterProof: Agnes Dirksen, Harro Brons and Cees Buisman about the WIS award.

Also watch the film versions of their message on WaterProof TV.

magazine 17

2024

try me!

18 waterproofmagazine ‘ELON MUSK IS WELCOME TO CALL ME AT ANY TIME’

CEO talk

Geraldo Vallen

JOIN THE PIPE WANTS TO DISTRIBUTE DRINKING WATER FAIRLY WORLDWIDE

Drinking water for everyone is one of Join The Pipe’s key focus points. Entrepreneur Geraldo Vallen is the man behind the initiative. As the owner of a club in Amsterdam and a beach club in the Dutch seaside resort of Bloemendaal, he was looking for additional entertainment venues in Spain early this century. Instead of a new club, however, Vallen ended up with a lasting ambition.

The idea to filter tap water was born during a visit to his business partner in Spain. Vallen: “Coming from the advertising world, I started a club and a beach club. I was looking to expand and visited an associate in Barcelona. He told me about filters he had installed in the water pipes of his house so he could drink from the tap. We then thought about rolling this out as an alternative to mineral water in plastic bottles in schools and supermarkets in Barcelona. That sowed the seed for Join The Pipe CityWater.”

Bottles and taps

Today, the concept has been launched globally with multiple products that contribute to Vallen’s dream of fairly distributing our planet’s drinking water. In addition to selling refillable water bottles made from sugarcane (the city water concept), the organization collaborates with Culligan and Holland Water to install and maintain water taps. “There are now more than five thousand taps all over the world”, Vallen continues.

“Africa has been our largest market in recent years. For example, we install a refilling station in every school in The Gambia, and all schoolchildren receive their own bottle.”

Coronavirus

Vallen is aware that travelers are an important target group and essential to Join The Pipe’s existence. In that context, he looks back on the struggle through the COVID years. “We sell our bottles in supermarkets and airports, but Join The Pipe is now a preferred supplier for most international hotel chains. No travellers meant no revenue.” Sales plummeted by seventy per cent but have since recovered to pre-pandemic levels. “The larger hotel chains want to stop using mineral water, and we offer a sustainable solution. Those chains operate in every city in the world, which benefits the sales of our city water concept”, Vallen says.

Major events

In addition to wonderful projects in numerous developing countries,

Join The Pipe is closely involved in large events. For example, during the Summer Olympics in Paris, the company will sell its tap-filled bottles at all airports around the capital, featuring an image of Paris and the Games on the bottle. “That was at the top of my list. Being able to compete with Coca-Cola and McDonald’s is a breakthrough. We previously supplied bottles featuring the Rotterdam skyline during the Eurovision Song Contest, and we have now been chosen to supply refill stations during the European Football Championship in Germany.”

A smile appears on Vallen’s face when we ask about his ultimate ambition. “We produce bottles with city and island skylines and company logos; we were recently commissioned to produce bottles with the skyline of the moon. I admire the disruptor Elon Musk and like to think ahead. Elon is welcome to call me at any time about setting up the first tap on the planet Mars”, says Vallen in closing.

JOIN THE PIPE’S SUSTAINABLE, BPA-FREE BOTTLES ARE MADE FROM THE WASTE OF THE SUGARCANE PLANT, ALSO KNOWN AS GREEN POLYETHYLENE (PE), FOR WHICH IT COLLABORATES WITH CHEMICAL COMPANY BRASKEM. VEOLIA MANUFACTURES THE BOTTLES IN DRONTEN. THE COMPANY INSTALLS TAPS ALL OVER THE WORLD, BOTH FOR INDOOR USE (E.G., HOSPITALS, AIRPORTS AND BUSINESSES) AND OUTDOOR USE (E.G., PLAZAS, PUBLIC SPACES AND SPORTS CLUBS). THE TAPS COME IN A RANGE OF SHAPES AND SIZES AND HAVE BEEN DEVELOPED IN COOPERATION WITH DUTCH WATER COMPANIES. THE FILLING LINES IN THE TAPS HAVE THREE FILTERS TO CLEAN THE WATER. A COARSE FILTER (FROM BWT) REMOVES SOLIDS AND ODOURS. THE HW ULFIMA SYSTEM (ULTRAFILTRATION) FILTERS BACTERIA AND VIRUSES. A MEMBRANE IS USED TO BLOCK VARIOUS SUSPENDED PARTICLES. THE THIRD FILTER IS THE HW UVIDIS SYSTEM, WHICH USES POWERFUL ULTRAVIOLET LIGHT (UV-C) TO REMOVE BIOORGANISMS FROM THE WATER. THE PROCEEDS FROM BOTTLE AND TAP SALES ARE USED TO FUND PROJECTS IN DEVELOPING COUNTRIES.

waterproofmagazine 19

20 waterproofmagazine

Brigitte Duffhues

NETWORK FOR ORGANISATIONS WITH INTERNATIONAL AMBITION

OPENING DOORS WITH EEN

One of the strengths of an organisation like Water Alliance is that it is an alliance between government agencies, the knowledge sector and entrepreneurs. Water Alliance is directly or indirectly involved in all important and promising water technology projects in the Netherlands and Europe. This enables Water Alliance to put the more than 220 companies that are now members in pole position when it comes to participating in international projects. Those projects open doors. One example is the project ‘EEN’. International Project Manager Brigitte Duffhues explains.

Brigitte, what exactly is EEN?

The acronym stands for Enterprise Europe Network. EEN is the largest support network for organisations with international ambitions.

The project helps entrepreneurs, research institutes, universities, and technology centres find partners worldwide at no cost. It is a powerful network; to date [April 2024, ed.], it consists of about 600 organisations spread across 56 countries.

What kind of activities can you help with?

There are really too many to mention, but it primarily concerns support in internationalisation, financing, innovation, EU legislation and digitalisation. Anyone interested in the full scope of our activities should visit our website [see info box, ed.]. We also regularly host events that companies can participate in. They will also be published on our website.

You have been active for a while now; are there any clear results you can tell us about?

We started in 2022 and have now helped more than 100 companies make contacts. Our network is also linked to other networks. It may seem complex, but it is actually very positive. Through EEN, for example, companies have often become involved in other projects. One such example is CircInWater, a European-funded project in which five water and cleantech clusters from five countries collaborate to support European SMEs, particularly financially. Another example is the Dutch institute Vertify, which conducts application-oriented research in greenhouse horticulture, arable farming, flower bulbs and fruit. EEN helped them get in touch with a Spanish partner. Together, they secured 200,000 euros in EU funding for research through the Horizon 2020 project.

We understand that relationship-building and matchmaking is an essential part of the EEN project. How does that work, and what does it yield in concrete terms? Having a network and being able to find partners is indeed essential for success. Water Alliance can help with that, but entrepreneurs also need to have a proactive attitude. A great example is the pilot conducted by Water Alliance member Ferr-Tech [WIS Award winner in 2020, ed.] in France. It happened as follows: we organised a matchmaking event at Pollutec [leading trade fair for environmental solutions for industry, cities regions, ed.] in Lyon. We knew that our member Ferr-Tech was looking for a launching customer in the polymer recycling industry. They needed a company where they could demonstrate the capabilities of their product, FerSol. We came into contact with Granuplast in Lyon through one of our EEN partners in the Rhône-Alpes region. They recycle plastic and showed an interest in the innovation. They started by validating the technology on a lab scale and then conducted a pilot. That was recently completed, and the results were positive, according to CEO Judith Le Fèvre. Using FerSol in the plant’s washing procedure improved water quality at this launching customer, resulting in a better end product. The parties have since discussed the results and are awaiting the follow-up

WATER ALLIANCE IS A PARTNER IN THE EEN NL CONSORTIUM, AN EU PROJECT THAT WILL RUN UNTIL JUNE 2025. FOR MORE INFORMATION, VISIT:

21 waterproofmagazine

MORE

CONTACT

R.SINNEMA@WATERALLIANCE.NL

INFORMATION?

RIXT SINNEMA:

IN SEARCH F THE H LY GRAIL F

BI BASED PLASTIC

22 waterproofmagazine

A NEW RAW

PRODUCTION IN THE

THE SOURCE FOR THIS ARTICLE WAS AN EARLIER STORY ON TKIWATERTECHNOLOGIE.NL biology

MATERIAL

MAKING

The exponential increase in plastic production in the world not only causes CO2 emissions, but also serious pollution of land and oceans. A transition to a circular world with biodegradable products and raw materials that can be reused is therefore a necessity. The good news is that it should be possible to produce a sustainable alternative to plastic entirely from wastewater flows. But the question is: how do you ensure that the necessary bacteria can give maximum performance in relatively unusual circumstances? And how do you bring it to the market? Some of the people involved tell their story.

[PHA]

(polyhydroxyalkanoate) seems to be a promising substance, due to its natural production method and easy degradation in nature. And it is an attractive material because it can be produced and extracted from municipal sludge, a residual resource rich by-product that flows from wastewater treatment plants. “PHA is actually a kind of bacterial fat –a biodegradable polyester,” explains Alan Werker, who is the theme leader for the ‘Biopolymers from water’ project at Wetsus, European centre of excellence for sustainable water technology. “Good bacteria, that are naturally produced during wastewater treatment as a waste by-product, will store PHA to excess levels within their cells under certain circumstances. These PHAs are long chain polymers that nature can provide us, and that can be processed into reusable, but still biodegradable and compostable, (bio) plastics .”

So, a possible golden solution to the global plastic problem could be found in our wastewater. But turning wastewater treatment plants into production locations requires a paradigm shift for society. After all, the infrastructure and conditions between water treatment plants can differ considerably from location to location.

So it takes pioneering of principles with engineering to get to the Holy Grail where all wastewater treatment plants could be renewable resource production factories.

René Rozendal, managing director at Paques Biomaterials, still remembers how that process started, some year ago. “The Dutch Water Boards and TU Delft were already working on research on how to produce PHA and Paques Biomaterials also became involved early in the process. Ultimately, it even led to the construction of a joint demonstration factory in Dordrecht together with establishment of a new research theme at Wetsus (city of Leeuwarden, ed.).”

That theme was called ‘Biopolymers from water’. Researcher Ángel Estévez Alonso (now promoted to doctor and affiliated with Gent University, ed.) started working at Wetsus with the question of how one could improve PHA production in such a way that you could make more material and improve its properties on a larger scale. Experiments were carried out on the biological process to produce PHAs, but completely by chance the (then) PhD candidate Estevéz Alonso came across his very own eureka moment. He says: “When I was going to show a student in the lab how we worked, one of the substances we used in the process was simply missing. I didn’t push it too hard and decided to use a salt of calcium instead of the

usual one with potassium that had run out of stock. Just another salt. And to everyone’s surprise, the bacteria suddenly produced three times as much PHA as usual!”

Rozendal: “Of course, that was very good news. At Paques Biomaterials we have the mission to make biobased products, with which we can make the urgent transition to a circular economy worldwide. With our product Caleyda we are well on our way to providing a solution to the many problems of traditional chemical plastic. However, this requires years of research and investment. Ángel’s work was therefore important to us. We gained a lot of new knowledge.”

23 waterproofmagazine

IN SEARCH F THE H LY GRAIL

F BI BASED PLASTIC

‘We are working hard to scale up our technology’

The research and development presses on in the Wetsus Biopolymers from water theme. It supports its theme members (Paques Biomaterials, Unilever, STOWA and N.V. Slibverwerking Noord-Brabant) with steps forward to support this Holy Grail, and spinoff knowledge with insights to the members along the way. In 2020, for example, the construction of a test scale-up installation at Wetterskip Fryslân in the city of Leeuwarden followed as part of this close cooperation and knowledge transfer. This gave the research team and its members a critical experience in applicability of ideas of process challenged by an increase in scale. Alan Werker’s team champions details in the ways to make PHA production applicable to almost any wastewater treatment plant, to maximize the quantity of the PHA produced from every batch, and to engineer the quality and quality control of the PHAs recovered. For example, a current PhD candidate (Yizhou Xing) extends outcomes of Ángel’s eureka with know-how in the microbiology that extend beyond the previously observed effects of calcium – this opens a door to use any municipal sludge to produce a lot of polymer. In other R&D, a postdoctoral fellow (Sanjay Pal) and a

PhD candidate (Liang-Shin Wang) explore on innovative ways to not only purify the polymers but also to control its properties, and to process recovered PHA directly towards valued applications. In the EU project Agro2Circular (agro2circular.eu), Zarja Medved together with Raquel Barbosa and Sanjay Pal adapt processes in PHA recovery for its purification from a completely different kind of bioprocess using agricultural waste by-products as a renewable resource. Zarja Medved now joins Paques Biomaterials, and this is a natural way for effective knowledge transfer and growing together.

Managing director René Rozendal is convinced that Paques Biomaterials’ efforts will pay off in the coming years. “We are working hard to scale up our technology. We recently raised 14 million euros in an investment round (investors include Invest-NL and the NOM, ed.). This allows us to scale up by building a Caleyda Extraction Facility in Emmen, where raw PHA is extracted into a highquality biopolymer. In the meantime, we are exploring with the Korean Kolon Industries and Kolon Global in South Korea how we can export the technology to the Korean market. But that is still in the early stages.

24 waterproofmagazine

MORE ON THIS TOPIC CAN BE SEEN ON YOUTUBE, WATCH: ‘WETSUS BIOPLASTICS IN A CIRCULAR SOCIETY’. biology

Poly Hydroxy Alkanoate (PHA)

[advertisement] Get a preview of what’s to come: Save the Date for EUROPEAN WATER TECH WEEK LEEUWARDEN 2024 Connecting Global Water Tech Networks PREPARE TO BE INSPIRED! SPEAKERS | PRESENTATIONS WORKSHOPS | DISCUSSIONS MATCHMAKING | INDUSTRY EXPERTS 23-26 SEPTEMBER CITY THEATRE DE HARMONIE LEEUWARDEN INCLUDING: WETSUS CONGRESS AND AWARD!WIS

Water Alliance members waterproofmagazine 26 Circular Rain D2D WATER SOLUTIONS SYSTEMS FOR WATER PURIFICATION DRYING & FILTRATION T CHNOLOGY techniek

waterproofmagazine 27 Water Alliance members water onderzoek advies

Agora 4 8934 CJ Leeuwarden The Netherlands

E info@wateralliance.nl

T +31 58 284 90 44

Follow us! @WaterAllianceNL water-alliance WaterAllianceNL wateralliance.nl

watercampus.nl Science Applied research Business Education