7 minute read

Schimpff’s Confectionery

By Kandy Derden

Managing Editor

What is the sweetest job in the entire world?

Having spent time working in an ice cream shop and a bakery, I can tell you neither is it. They both have their merits, but hands down, the winner is working in a candy store.

Stepping through the front door of Schimpff’s Confectionery in Jeffersonville, Indiana is all it takes to transport customers back in time. Sadly, children of today aren’t given the opportunity to create memories of a trip to the candy store. Rather than selecting from brightly colored wrappers on the shelves in the grocery store, Schimpff’s offers a myriad of colorful candies. Nostalgia aside, the options are greater here with multiple flavors in numerous varieties.

Schimpff’s Confectionery has been in business for 133 years. That fact alone should be enough to convince anyone they must be doing something right!

Warren and Jill Schimpff are 4th generation owners and operators with their nephew, Steve Shepherd, a 5th generation OIT (Owner-In-Training). There are other closer relatives, but Steve has a passion for the candy making business. His daughters, the 6th generation, have already begun learning various jobs from candy making, to packaging, to selling at the counter. Only time will tell if one of them will continue the family business.

Five times a day, demonstrations are given so the public may watch the process of creating Schimpff’s famous hard candies. Part of their charm is in continuing to use antique equipment and copper pots. Why copper? Copper is known for providing an even heat, with no hot spots. It is also lighter in weight than other metals and doesn’t stick as bad as other metals. “It is also prettier,” explained Jill Schimpff, who narrates the candy making process.

A mixture of cane sugar, corn syrup, water, food coloring and oil-based flavoring for stronger taste is used. Including lemon and cinnamon, 20 different flavors are available. It takes roughly one hour of cook time to reach the correct temperature. The original owner did not own a thermometer, so he had to check the temperature the old-fashioned way. This involved adding a small amount of the hot cooking syrup to a cup of water and listen for the ‘hard crack’. Using a thermometer is much easier and consistent.

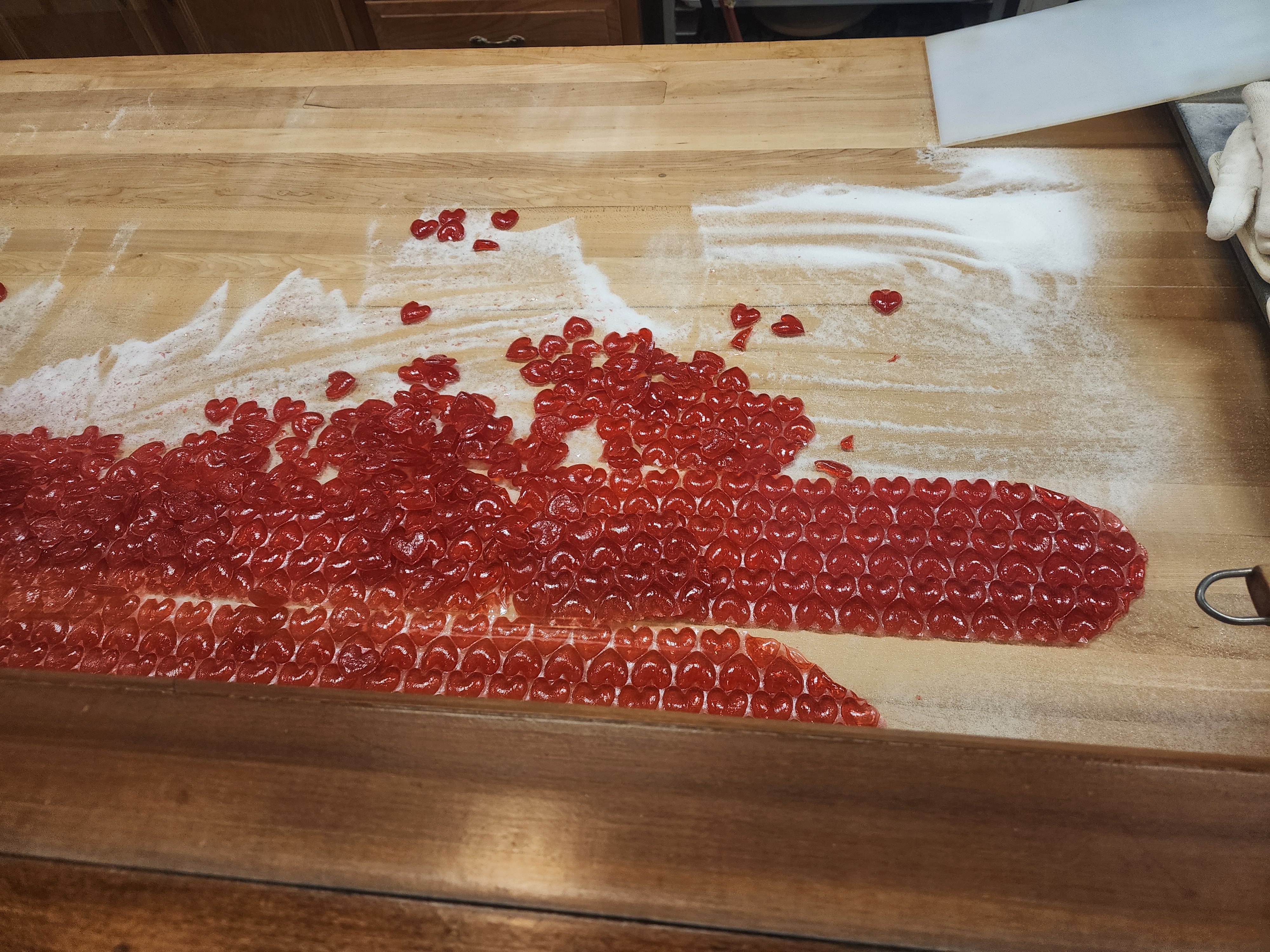

Once the correct temperature is reached, the candy is poured onto a cooling table where it is pulled and stretched until it is ready for shaping. Small portions of the candy are processed through a rolling machine which flattens it and molds it. Shapes include squares, hearts, rounds, leaves, flowers, and fish. Why fish? This shape is a tradition because of being close by the river.

There is a large collection of candy molds on display. Not all were used in the shop, but most were collected by Warren and Jill for their museum located in the rear portion of their store. When you visit, allow time for browsing through several decades of candy-making history.

After cooling, the slabs of candy are easy to convert into individual pieces. The only thing which is necessary is to pick it up a few inches above the cooling table and drop it. The pieces break apart easily and are ready for packaging, minus the odd scraps around the edge and broken pieces. These are gathered and melted into the next batch. Generally, there are 100 pieces of hard candy per pound.

The goodies don’t stop there. Chocolates are hand dipped on the premises also. The varieties are abundant so call (812) 283-8367 for more specific information. As an aside, I thoroughly enjoyed and highly recommend the caramel collection.

Christmas is Coming

Plans are being made for candy cane production. I didn’t get to see this in progress, but I have no doubt it is interesting. Like the hard candy demonstrations, candy cane and ribbon candy demonstrations are available. However, the only two days when Schimpff’s can promise this is Friday and Saturday after

Thanksgiving. Any other day, demos are limited to whatever item they happen to be producing.

In addition to all this, I found it quite interesting that Schimpff’s Confectionery has been making cough drops since 1891. My imagination ran wild with all sorts of questions about this and any medical requirements.

However, the answers were surprisingly simple. According to Steve, “We call them horehound cough drops because that’s the name of the herb. The herb is a natural remedy for coughs and colds. It is an old-fashioned remedy that grandmother would’ve had in her cabinet.”

There is no medical license required to manufacture this product. Steve continued, “The recipe is our simple hard candy made with sugar, corn syrup and horehound. This is the only flavor we offer, and they only come in the square shape. We sell them in the store and online.”

Anytime you are in the area, make plans to stop by Schimpff’s Confectionery, a Historic Store, Candy Museum and Candy Kitchen located at 347 Spring Street in Jeffersonville, Indiana. Just be sure to allow plenty of time because there is a lot to see, taste and enjoy!

A Sweet Step Back in Time:

In another room at the back of the store, Schimpff’s Candy Museum is a treasure trove of confectionery history. It showcases an impressive collection of artifacts that tell the story of candy-making through the decades.

Established in 1891, it is safe to say Schimpff’s Confectionary is one of the oldest continuously operated family-owned candy businesses in the United States. Its museum complements this legacy, offering visitors a peek into the evolution of sweets.

Exhibits feature antique candy molds, vintage packaging, and machinery once used to churn out treats for generations past. Among the highlights is a display of early 20th-century advertisements, which reveal the creativity and charm of candy marketing in bygone eras.

A focal point of the museum is its tribute to iconic candies like Red Hots and Lemon Drops—classics still handmade in the adjoining shop. Guests can marvel at the tools and techniques that shaped these nostalgic favorites while reflecting on how candy has brought joy to countless lives.

Whether you’re a history buff or a lover of all things sweet, Schimpff’s Candy Museum offers a delightful experience that pairs perfectly with watching candy-making in action next door.

This recipe below is a personal favorite shared by the Schimpff family.

Benedictine Cheese

Ingredients:

24 oz. cream cheese

1 c. mayonnaise

1 large cucumber

1 small onion

3 drops green food coloring

Directions: Peel cucumber and cut into 4 pieces. Peel onion and cut into 4 pieces.

Food process the cucumber and onion until they have a creamy texture. Put the slurry in a fine mesh strainer and drain off any liquid. In mixer, beat cream cheese until smooth in texture.

Add all ingredients to cream cheese in same mixer and mix.

Refrigerate; good for 7 days.

This is a very refreshing dip, suitable for use with chips or crackers. The green color looks festive at any Christmas gathering, especially those where finger-foods are being served.

Submitted by Warren and Jill Schimpff http://www.schimpffs.com/