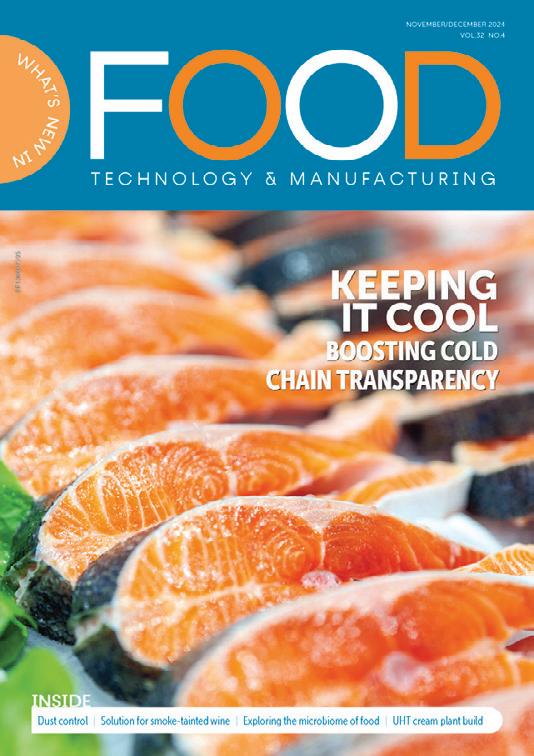

TECHNOLOGY & MANUFACTURING

Texture science for plantbased meats

Maple syrup explored as a potential sugar substitute

Kokumi sensation in wines

Cheese chemistry: fullbodied cheese flavourprediction using analysis method

Lab-cultured plant yoghurt that rivals dairy creaminess?

Who will pay for lower emissions in Australia’s drinking milk market?

Lactose-free market growth: solutions to meet consumer demands in Australia and

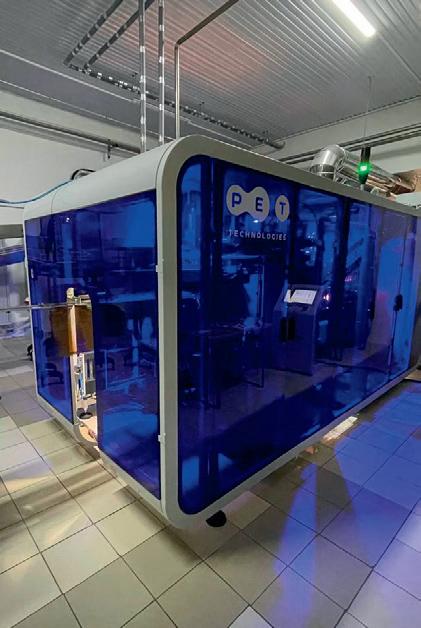

Bolstering brewing with new blow moulding machinery

What’s on trend with flavour and colour?

Making scents of aromas

Egg yolk power for colour stability 50 What's new: six on the shelf

CAROLYN JACKSON EDITOR

For many large food manufacturers, 2025 marks the beginning of mandatory Scope 3 greenhouse gas (GHG) emissions disclosure. As these indirect emissions represent a large portion of a manufacturer’s overall footprint, it is hoped that the new targeted reporting requirements will lead to further mitigation strategies being implemented across upstream and downstream value chains.

Many in the industry are also working towards achieving net-zero emissions by 2050. We take a look at Mars Incorporated, which is implementing a large-scale steam-based manufacturing site in Australia to deploy a 100% renewable energy solution for its pet food processing facility within the next two years.

Buying food and drink is also set to become easier than ever in 2025 with automation rising to new levels — for example, automated trolleys on trial at Coles, facial recognition for purchases at the Australia Open tennis event, and the list goes on.

These new levels of efficiency are also being seen across the food processing industry. For example, Coca-Cola Europacific Partners (CCEP) Australia has opened an upgraded can line at its production site in Queensland, which has the capacity to make up to 2000 cans per minute in a variety of formats. The new can line is projected to conserve more than three Olympic-sized swimming pools of water annually compared to other existing can lines.

With a focus on dairy in this issue, we take a look at how Australia's dairy industry is grappling with how to best transition to lower-emissions production, and how the cost will be borne.

I hope you enjoy the read.

We welcome submissions from the food industry across Australia and New Zealand that will be considered for possible inclusion in the bi-monthly print publication and our daily web page. If you have a story you think would be of interest, please send an email to wnift@wfmedia.com.au.

Westwick-Farrow Media is committed to using environmentally responsible print services to produce our publications. This edition is printed on a paper made with a mixture of materials from PEFC-certified forests and recycled materials and made from elemental chlorine free bleached pulp with is PEFC certified from sustainably managed sources. It is delivered in a totally degradable plastic wrapper.

Westwick-Farrow Media A.B.N. 22 152 305 336 www.wfmedia.com.au

Head Office Unit 5, 6-8 Byfield Street, North Ryde Locked Bag 2226, North Ryde BC NSW 1670 Ph: +61 2 9168 2500

Editor: Carolyn Jackson wnift@wfmedia.com.au

Publishing Director/MD: Janice Williams

Art Director/Production Manager: Linda Klobusiak

Art/Production: Marija Tutkovska

Circulation: Alex Dalland circulation@wfmedia.com.au

Copy Control: Ashna Mehta copy@wfmedia.com.au

Advertising Sales Manager: Kerrie Robinson Ph: 0400 886 311 krobinson@wfmedia.com.au

If you have any queries regarding our privacy policy please email privacy@wfmedia.com.au

Printed by Ive Group

Print Post Approved PP100007395 ISSN No. 1039-8414

NOTICE:

All material published in this magazine is published in good faith and every care is taken to accurately relay information provided to us. Readers are advised by the publishers to ensure that all necessary safety devices and precautions are installed and safe working procedures adopted before the use of any equipment found or purchased through the information we provide. Further, all performance criteria was provided by the representative company concerned and any dispute should be referred to them. Information indicating that products are made in Australia or New Zealand is supplied by the source company. Westwick-Farrow Pty Ltd does not quantify the amount of local content or the accuracy of the statement made by the source.

Australian smallgoods producer D’Orsogna has received a $1 million WA Government Value Added Investment Grant to help with an expansion and upgrade of its salami and fresh meat production facilities in Palmyra in WA.

D’Orsogna Managing Director Jason Craig said the grant will be co-invested in establishing automated manufacturing technologies to increase capacity and efficiencies in the production of cooked sausages, including cabanossi, tasty sticks and fermented salami products.

In addition, the boning room will be upgraded with layout changes to increase meat volume throughput and a packing area transformed with new equipment for more efficient transfer of fresh meat into retail-ready packaging.

“The Palmyra plant has been D’Orsogna headquarters since 1973 and the family continues its 75-year investment in WA with the assistance of this Value Added Investment Grant. We thank the WA Government and DPIRD for their continued support of food manufacturing,” said board member Eugene D’Orsogna.

Dairy consulting company Pure Dairy has appointed Andrew Wellington as its Chief Commercial Officer (CCO).

With over 20 years’ experience in the dairy and food processing industries, Wellington brings a wealth of expertise in operational leadership, market expansion and supply chain optimisation for the business at a pivotal time.

In April next year, Pure Dairy will be opening its own production facility in Dandenong South, which will feature state-of-the-art manufacturing equipment, an R&D kitchen, logistics operations and the company’s corporate offices. The facility is designed to strengthen Pure Dairy’s ability to deliver innovative solutions for dairy and plantbased products.

The company’s new CCO has been immersed in the dairy industry ever since his early childhood. Having grown up on a dairy farm in northern Victoria, he started his career driving milk tankers and then completed a cadetship with Murray Goulburn and studied food technology at The University of Melbourne.

Over the following years, he held leadership positions across the dairy sector in both Australia and New Zealand. Most recently, Wellington was Chief Operating Officer at Union Dairy Company, where he managed large-scale operations with a focus on driving efficiency and innovation.

Hygiena, a global food safety and environmental diagnostics business, has completed the acquisition of Nexcor Food Safety Technologies. Nexcor is the creator of KLEANZ and CAMSPM, two software solutions for managing sanitation and equipment maintenance in food and beverage manufacturing facilities.

“Effective cleaning and monitoring of facilities with food safety diagnostic testing are essential for quality control and risk mitigation across all food processing environments. With our acquisition of Nexcor software solutions, we plan to integrate our SureTrend analytics platform with KLEANZ’s sanitation software, delivering powerful tools to drive quality improvement, prevent food safety issues and enhance operational efficiencies,” said Steven Nason, CEO of Hygiena.

SureTrend currently enables users to plan, schedule, test, capture, store, protect, analyse, audit and report on their testing data. Integrating Nexcor’s data will allow it to use machine learning AI for predictive insights, with the aim of enhancing the safety and operational efficiency of food and beverage facilities.

Robert Burgh, President of Nexcor Food Safety Technologies, said, “This collaboration with Hygiena allows Nexcor to create greater customer value by streamlining two critical, interconnected functions within food companies worldwide.”

Kilcoy Global Foods has officially taken ownership of burger patty business Tyson Foods Australia’s Coominya Operation, just an hour’s drive from its Kilcoy facility.

The Coominya Operation is principal supplier of beef patties to McDonald’s Australia, and exports to markets in Asia. It produces up to 3 million patties per day, often taking up to four loads of chilled and frozen beef from the Kilcoy facility daily.

“The potential business synergies are exceptional,” said Kilcoy Global Foods Australia President Jiah Falcke.

“We’ve been supplying to Coominya for more than 20 years,” Falcke said. “The Coominya team has the same high standards that we do and for us, the fit made perfect business sense.”

Kilcoy Global Foods intends to invest in the Coominya facility (now known as Kilcoy Global Foods Coominya), readying it for the next wave of growth.

The Coominya Operation officially joined the Kilcoy Global Foods Australia Division on Monday, 28 October 2024.

The Arnott’s Group has expanded its ‘better-for-you’ snacking portfolio with the acquisition of Mother Earth, Flemings and VP brands from New Zealand-based food manufacturer Prolife Foods.

Mother Earth is an established muesli bar and baked-slice brand in New Zealand with a growing presence in Australia. Flemings and VP are also recognised brands in the New Zealand nutritional snacking market, with product offerings spanning bars, nuts and snack mixes.

This acquisition forms part of the Group’s broader strategy to build a branded better-for-you business, unlock new manufacturing capabilities, and enter new category segments.

Arnott’s Group CEO George Zoghbi said the announcement signals the business’s commitment to increasing its presence in better-for-you snacking category.

“We recognise the growing demand for nutritious snacks and plan to leverage the Mother Earth, Flemings and VP brands to support our ambition of becoming a leader in this space.”

“The brands will provide us with new platforms for innovation and growth, harnessing our near 160 years of manufacturing and logistics expertise to expand their ranges and distribution.”

“We remain committed to expanding our snacking portfolio beyond biscuits and to investing in manufacturing both in Australia and New Zealand,” Zoghbi said.

The acquired brands will join The Arnott’s Group’s growing portfolio of betterfor-you cereals and snacks, which includes brands like Freedom, Messy Monkey and Sunsol.

Coles is claimed to be the first retailer in Australia to trial an all-in-one AI-powered Smart Trolley. Developed in partnership with grocery technology company, Instacart, the Coles Smart Trolley is designed to allow users to track their spending in real time, pack as they shop and skip the checkout line.

The technology will be trialled at Coles Richmond Traders in Melbourne from January 2025.

The smart trolleys use AI technology, sensors and an in-built scale to scan groceries directly into shopping bags, including fresh produce, and streamline the checkout process by paying on the trolley.

Featuring a digital screen which displays current in-store specials and product aisle locations, the trolley is designed to make it easier to locate items and features a running total to help users manage their budget.

Coles Chief Digital Officer, Ben Hassing, said, “We’re excited to offer our customers a convenient and engaging way to shop in-store, helping them save time, manage their budget and checkout faster — or at their own pace.”

Instacart Chief Connected Stores Officer, David McIntosh, said the partnership with Coles represented an exciting entry into the APAC market.

The ACCC will not oppose Australian Health & Nutrition Association Limited’s (Sanitarium) proposed acquisition of the brand and intellectual property assets necessary for the supply of Vita Brits from Société des Produits Nestlé S.A. and Nestlé Australia Ltd (together, Nestlé).

Claimed as the leading wheat biscuit brand in Australia, Weet-Bix is made by Sanitarium using 97% wholegrain wheat. Vita Brits is part of Nestlé’s Uncle Tobys brand and is physically similar to Weet-Bix, made from 99% wholegrain wheat. Sanitarium is also currently manufacturing Vita Brits for Nestlé.

The proposed acquisition involves Vita Brits branding, intellectual property and goodwill. It does not include the Uncle Tobys branding or any manufacturing assets.

The ACCC’s review focused on how closely Weet-Bix and Vita Brits compete in the wholesale supply of wheat biscuit cereal and the future of the Vita Brits product should it not be acquired by Sanitarium.

The ACCC’s analysis of data to assess whether consumers would switch between WeetBix and Vita Brits products in response to price changes indicated that, although the products are similar in nature, Vita Brits is unlikely to be a strong competitive constraint on Weet-Bix in the absence of the proposed acquisition.

“We tested the closeness of competition between the WeetBix and Vita Brits products and found that consumers do not typically switch between the two. This finding was consistent with the feedback we received from market inquiries. We found that the proposed acquisition would not be likely to substantially lessen competition,” ACCC Commissioner Dr Philip Williams said.

The ACCC also closely considered the viability of the Vita Brits product without the acquisition, following Nestlé’s loss of Vita Brits manufacturing capability.

A new white-flesh fish variety could soon work its way onto Australian plates, following successful breeding trials by Australia’s national science agency, CSIRO.

Suntory Oceania has announced that Darren Fullerton, CEO of Suntory Beverage & Food Oceania, will retire in 2025.

Fullerton joined Suntory in 2020 following CEO roles at PepsiCo and Winc, and has been instrumental to the growth of the business across Australia and New Zealand.

Most notably, he has played a critical role in building Suntory Oceania, a $3bn multi-beverage group which brings together the end-to-end manufacturing, sales and distribution of Suntory’s licensed and non-alcohol portfolios.

In strong partnership with Mark Hill, Managing Director of Suntory Global Spirits Oceania, the team has created Suntory Oceania beverage group, which is set to launch in mid-2025.

With over 12 years of experience as a CEO, Fullerton said that now is the right time to embark on his next chapter.

Fullerton will lead the final stages of the creation of Suntory Oceania to the end of March and then continue as an advisor. A successor will be announced in due course.

The Pompano (Trachinotus anak) has been identified as the suitable white-flesh fish for developing in northern Australia’s tropical climate.

“The Pompano is a robust, sociable fish endemic to northern Australia that grows really quickly and tastes great, making it an ideal candidate for adapting to our aquaculture environments,” said Lead Scientist Dr Polly Hilder.

“We’re bringing a new species to Australian plates to give consumers more options, while opening up new export opportunities to strengthen Australia’s white-flesh fish industry.”

Following promising initial market testing with chefs and consumers, the agency is working to scale production processes in commercial trials with industry.

A new Pompano industry would help Australian aquaculture reduce its reliance on around 100,000 tonnes of white-flesh fish imports, while helping to sustainably meet growing demand for seafood, according to CSIRO.

By partnering with the industry to bring Pompano to the mainstream market, CSIRO hopes to create a new, sustainable Australian white-flesh fish industry in the near future to diversify the market and reduce reliance on imports.

“We’re applying innovative circular economy approaches designed around welfare that make use of resources end-to-end — from capturing value from production processes, through to utilising the whole fish at the consumer end,” Hilder said.

“For example, fish waste is high in phosphorous and nitrogen nutrients and can be turned into valuable by-products such as fertiliser capsules.”

Aligning with its goal of achieving net-zero emissions by 2050, Mars Incorporated has announced that its Wodonga pet food manufacturing facility is set to become the first large-scale steam-based manufacturing site in Australia to deploy a 100% renewable energy solution, for both electricity and process steam, within the next two years.

The $39.3 million Mars Wodonga Solar Thermal Plant will spearhead this transition, including the installation of an 18-megawatt parabolic trough concentrated solar thermal (CST) plant that will provide up to 10 hours of thermal energy storage for cooking pet food. The project, which includes a $17.2 million grant from the Australian Government through The Australian Renewable Energy Agency (ARENA), is claimed to be the first commercial deployment of parabolic trough CST technology in Australia.

The pet food manufacturer will use the parabolic trough technology to harness thermal energy from the sun, discharging a heated water/steam mixture to a steam drum, to be directed to a series of steam accumulator tanks.

Mars Petcare Australia and New Zealand General Manager Craig Sargeant said investing in this technology is a significant step for Mars in Australia and globally.

“Decarbonising site-based process heat, coupled with Mars Australia’s 100% renewable electricity use, is a significant achievement that not only reflects our ongoing commitment to sustainability but also positions our Wodonga facility as a leader in green process heat manufacturing

on a national scale,” Sargeant said.

“Investing in renewable energy technologies like CST is critical to decarbonising industrial processes, particularly in sectors that heavily rely on gas for steam-based manufacturing,” Sargeant continued. “CST offers a powerful solution by capturing and storing solar energy, in the form of high temperature heat, for use at any time, making it an ideal fit for our steambased manufacturing needs.”

The steam accumulator tanks will provide up to 150 MWh steam thermal energy storage system to provide round the clock process heating even when the sun doesn’t shine.

The project will use water as the heat transfer fluid, storage medium and energy carrier to avoid the requirement for heat exchangers and thermal oil systems commonly utilised in CSP plants.

The project also builds on Mars’ implementation of electric thermal energy storage (eTES) technology, which allows the facility to use low-cost, grid-connected renewable electricity during off-peak times to generate and store heat that can produce steam at any time of day or night. This eTES system, supported by CSIRO, provides a cost-effective, renewable alternative to gas.

ARENA CEO Darren Miller said the project aims to prove what the technology can offer Australian businesses.

“We’re excited to be working with Mars Petcare to demonstrate the potential of concentrated solar thermal as a viable option for Australian industry to generate renewable heat, making use of our abundant sunshine to provide the energy required," Miller said.

“With industry currently accounting for around 44% of Australia’s total emissions, we need to look at all renewable energy technology options to generate enough energy to power industry and solve this challenging piece of the puzzle.

“Concentrated solar power has been used for electricity and heat generation for decades overseas, so it’s great to see the renewed interest in it from Mars Petcare in what could be a growing trend for Australian industry in its journey to net zero.”

The promise of concentrated solar thermal as a renewable heat source lies in its smaller land requirements when compared to electric heating backed by solar photovoltaic (PV) and the ability to avoid upgrading power supply infrastructure.

ARENA funding will support Mars to install the 18 MW (thermal) concentrated solar thermal plant to provide industrial process heat to the pet food factory.

“Mars would like to thank the Australian Government for its range of clean energy initiatives and is proud to be partnering with ARENA to develop Australia’s first commercial deployment of Concentrated Solar Thermal at Mars Petcare Wodonga,” Sargeant said.

Set to be completed in 2026, the new plant is designed to halve the facility’s gas use and create approximately 80 jobs in construction.

ARENA has funding available for industrial energy projects through several active programs, including the $400 million Powering the Regions: Industrial Transformation Stream. For more information on existing ARENA projects or to apply for funding, visit ARENA’s funding page.

Coca-Cola Europacific Partners (CCEP) Australia officially opened its upgraded can line at its production site in Richlands, Queensland, on 31 November 2024.

Supported by a multi-year $22.2 million investment, the upgraded can line caters for increasing consumer demand for canned beverages; allowing CCEP to scale its local can production and to deliver beverages more quickly and sustainably to Queenslanders.

It is the company’s most efficient can line to date and has the capacity to make up to 2000 cans per minute in a variety of formats, including Coca-Cola Zero Sugar, Sprite and Mount Franklin Lightly Sparkling.

The upgraded line is complemented by an additional multi-year $75 million investment into a new can line at the same facility, which will help boost the local production of Monster Energy Company products. Anticipated for completion in mid-2025, this new can line will use world-class equipment and the latest technology to increase CCEP’s energy drink production capabilities.

Orlando Rodriguez, Managing Director at Coca-Cola Europacific Partners Australia, said: “It’s important to us that we’re

continually improving our operations to drive efficiencies, both in terms of sustainability and costs. These latest, stateof-the-art investments in manufacturing technology at Richlands represent a leap forward in productivity, safety, quality and environmental stewardship, which are key pillars of our business and essential to our future.”

The site’s upgraded can line is projected to conserve more than three Olympicsized swimming pools of water annually compared to other existing can lines. Energy savings will also be unlocked thanks to its ability to fill cans at room temperature, eliminating the need for energy-intensive cooling processes; a feature that is expected to reduce energy consumption by approximately 23% compared to the previous line.

Safety is also front and centre, with the team having undertaken a rigorous design validation process, using virtual reality to refine equipment layout and proactively identify and address potential risks.

The investment at Richlands forms part of broader investments by CCEP in its Australian operations. Earlier this year, the company announced a $105.5 million investment in a new Warmfill Line to produce Powerade and Fuze Tea products at its Moorabbin plant in Victoria, while in 2022 the company

completed a $43.7 million upgrade of an existing can line at the same site.

“The site’s upgraded can line is projected to conserve more than three Olympic-sized swimming pools of water annually compared to other existing can lines.

Rodriguez emphasised: “At a time where local manufacturing is so critical, CCEP is proud to announce another significant investment in the industry. This enhancement to our Richlands facility is a key part of our broader strategy, following our landmark investment in Victoria — our largest ever in Australia.

“In the short term, investing in our local manufacturing infrastructure significantly enhances our ability to meet the needs of our valued customers. In the years to come, these efforts to build our operational presence nearer to the end-consumer will help make our ambition to reach net zero emissions a reality.

“The initiatives come at a cost, but ensuring our operations are as sustainable as possible is a responsibility we’re firmly committed to. It’s part of the value-chain approach we take to doing business and is something we take very seriously.”

CCEP has been manufacturing beverages in Australia for more than 85 years and has operations in every state and territory across the country. The Richlands site is one of 20 CCEP-managed sites in Queensland, with the company’s property footprint spanning as far north as Cairns.

Do you have a design story to share? Please email wnift@wfmedia.com.au if you'd like to contribute.

Peptides formed during cheese ripening are crucial for the full-bodied flavour of aged cheeses, known as kokumi. A research team led by the Leibniz-Institute for Food Systems Biology at the Technical University of Munich has now developed a new method to efficiently analyse these flavour-relevant peptides. Based on more than 120 cheese samples, the team has also created a database that can be used in the future to predict flavour development during cheese ripening.

Of the thousands of cheese types available today, aged cheeses are preferred by around 54% of consumers, with only 16% preferring shorter-aged varieties.

The term kokumi derives from Japanese and refers to a full-bodied and long-lasting rounded and balanced taste experience, which is distinct from usual taste quality such as sweet, sour, bitter, salty or umami.

The kokumi taste impression is particularly pronounced in aged cheeses, mainly due to the increasing concentration of gammaglutamyl dipeptides. These are small molecules that consist of a link between glutamic acid and another amino acid.

Depending on how the two amino acids are linked, researchers distinguish between gamma-, alpha- and X-glutamyl dipeptides, with the latter two not contributing to the kokumi effect. The high polarity of the glutamyl dipeptides, as well as their great structural similarity with different flavour contributions, represent a major challenge for food analysis.

Nevertheless, the team led by principal investigator Andreas Dunkel of the Leibniz Institute has succeeded in developing a new efficient analysis method based on ultrahigh-performance

liquid chromatography-mass spectrometry. It can now selectively determine the concentrations of all 56 gamma-glutamyl dipeptide variants in just 22 minutes. Optimised sample preparation makes it possible to analyse 60 cheese samples per day.

“This is a significant improvement compared to other methods,” said first author Sonja Maria Fröhlich, a doctoral student at the Leibniz Institute. “Our tests have shown that our method is faster, more efficient, and yet reliable — it delivers reproducible results and detects even the smallest concentrations.” To further investigate the influence of ripening time on gamma-glutamyl dipeptide concentrations, the researchers applied the method to 122 cheese samples from Europe and the US after the test phase. The ripening times of the cheese ranged from two weeks to 15 years.

The results show that, as expected, the concentrations of glutamyl dipeptides increase with increasing ripeness. “Interestingly, the addition of blue and white mould cultures led to significantly higher gamma-glutamyl dipeptide concentrations, even at shorter ripening times,” said Dunkel, who heads the Integrative Food Systems Analysis research group at the Leibniz Institute.

The food chemist added: “The concentration profiles we have determined for different stages of ripening and different types of cheese can be used in the future as a database for prediction models. The latter could, for example, be used to objectively monitor flavour development during cheese ripening, to shorten ripening times, or to develop new plant-based cheese products with high consumer acceptance.”

“In the sense of an interdisciplinary, food systems biology research approach, one of our goals is to combine analytical research results with bioinformatic methods to develop predictive models suitable to support sustainable food production. This is also the starting point of the project led by Andreas Dunkel,” said Veronika Somoza, director of the Leibniz Institute.

The findings of the research have been published in Food Chemistry

Food engineers have used Australian sweet lupins (legumes) to create a yoghurt that is claimed to rival dairy in taste and texture, while delivering more nutrition than typical plantbased yoghurts.

Made from Aussie lupins and oats, the ‘super-yoghurt’ formula is highlighted in a Monash University study due to its fast fermentation time, dairy-like texture and nutritional profile.

Led by Associate Professor Sushil Dhital and PhD candidate Damodar Dhakal at Monash’s BioPRIA institute, the study analysed yoghurts over seven days of refrigerated storage after fermenting them with various combinations of probiotic strains. The investigation aimed to understand how different probiotic mixtures influenced yoghurt quality over time.

It found the lupin-oat milk yoghurt fermented with a combination of Lactobacillus plantarum and Bifidobacterium probiotics was the standout.

Dhital said the high protein and fibre content of lupins, along with the unique probiotic combination used in the yoghurt, contributed to its thick creamy palate, along with its good nutritional profile and texture.

“It’s also lower in saturated fats compared to most coconutbased yoghurts, and potent with other micro-macro nutrients and beneficial bacteria that make it an enticing alternative for the yoghurt industry,” Dhital said.

“Manufacturers interested in developing the lupin-oat yoghurt into a commercial product are free to utilise our research and we are happy to offer technical support to industry.”

The Australian sweet lupin is iconic to Western Australia which is responsible for 85% of the world’s lupin crop. Once an ancient staple, lupins are experiencing a resurgence in popularity due to their high protein content and nutritional benefits, as well as their ability to improve soil health.

The full research findings can be found in the journal Food Hydrocolloids

Māori-owned milk company Miraka is using Rockwell Automation Plex ERP technology for its dairy business, which has been powered by renewable geothermal energy since 2010.

The dairy business will be using the enterprise resource planning (ERP) system to enhance its operations.

Miraka CEO Karl Gradon said, “In real time, Plex will seamlessly integrate and manage all of our transactions and systems from the farm, to factory, to customer. It will help us to become even more efficient, resilient, agile and sustainable.”

“Miraka has always taken a long-term, intergenerational view about everything we do. We’re focused on success and partnering with businesses which share our values. We look at where we’ve come from, where we are now, and where we want to be in the future,” he said.

Rockwell Automation Regional Director, South Pacific Anthony Wong said, “What sets Plex apart is that it was designed by manufacturers and processors with deep knowledge of these industries. Companies like Miraka can use these intuitive ERP tools to gain efficiencies across their operations.”

“Plex is also a modular system, so it can grow and adapt as needs change in the future, allowing companies like Miraka to remain agile and stay ahead of the competition,” he said.

said, “Plex will streamline the way we operate and will link into the existing Rockwell automation in the plant. It is next-level integration, and we expect it will provide beneficial outcomes for our team, our dairy farmers and customers.”

Rockwell Automation Australia www.rockwellautomation.com/en-au.html

As key players in the food supply chain set targets for reducing greenhouse gas (GHG) emissions, Australia’s dairy sector is grappling with how to best transition to lower-emissions production, and how the cost will be borne, Rabobank says in newly released research.

The report, ‘Who pays for GHG emissions reductions in Australian drinking milk markets?’, by the agribusiness banking specialist’s RaboResearch division, says addressing “enteric” (digestive tract) methane production in dairy cattle — particularly through the use of feed additives — has the greatest potential to deliver emissions reductions for the sector. And this will likely come at a cost.

However, the report says, the good news is this additional cost is relatively low for Australia’s drinking milk sector — estimated to total $35.1 million annually, or less than 2% (2.5 cents per litre) of the retail value of milk. And it could potentially be spread across dairy sector stakeholders — including farmers, processors, retailers and consumers. Emissions reduced for the sector could be as much as 226,000 tonnes of CO2 annually, or the equivalent of taking approximately 103,000 cars off the road.

The report’s author, RaboResearch sustainability analyst Anna Drake, says the issue of who pays within the value chain, though,

will need to be determined before the dairy sector can begin implementing effective emissions reduction practices.

“While progress has been made within the Australian dairy industry on engagement around emissions, the economic realities of putting the most impactful emissions-reduction technologies into practice are yet to be fully addressed,” she said.

“With the current lack of market signals to incentivise on-farm reductions, there is an uncertain path towards the best way for the dairy industry to move to a lower-emissions footprint.”

But the relatively low net cost of technologies like methanereducing feed additives indicates this cost burden is not necessarily insurmountable, she added.

The report says major companies in the dairy supply chain — including retailers and processors — have committed to reducing their GHG emissions by setting targets for both their operational (Scope 1 and 2) emissions, as well as their indirect value-chain (Scope 3) emissions, which are primarily from farm production.

“This is part of a global trend of large dairy companies taking a more comprehensive approach to disclosing and managing

“

The

report says major companies in the dairy supplychain—including retailers and processors — have committed to reducing their GHG emissions by setting targets for both their operational (Scope 1 and 2) emissions, as well as their indirect value-chain (Scope 3) emissions, which are primarily from farm production.

emissions associated with their business activities, as part of their broader sustainability strategies,” Drake said.

“In Australia, both major supermarkets have set themselves emissions reductions targets that require them to address the agriculture-related emissions in their value chains, while Dairy Australia, the national industry body, has also set an industry-wide target of reducing GHG emissions intensity by 30% (on the 2015 level) by 2030.”

on measurement, reporting and target setting. Research into new technologies and innovations to reduce emissions is also underway, but has typically focused on technical feasibility, rather than economic viability,” Drake said.

Options for reducing GHG emissions in dairy production can be broadly grouped into two categories — management-based and technology/innovation, the report says.

“Management-based options focus on maximising productivity through best practice approaches that can incrementally reduce emissions, particularly on an emissions-intensity basis, meaning fewer emissions per litre of milk produced,” Drake said.

“Even without an explicit focus on emissions, the GHG footprint of dairy farming can benefit from ongoing gains made in productivity through technology improvements and industry research and development. However, in developed countries, these gains tend to level off over time, with further gains becoming increasingly marginal and challenging to achieve.”

In terms of technology and innovation options — which rely on research and development — extensive work is being done to develop viable methods for inhibiting methane production in the rumen of livestock, the report says.

Methane-reducing feed additives are widely considered an important piece of the emissions-reduction puzzle for livestock, Drake said.

“Looking specifically at the feed additive 3-NOP, on the basis of its proven effectiveness and safety, it has been found in independent studies to reduce methane emissions from dairy cattle by around 30% on average without negatively affecting milk production,” she said.

Introducing this additive into dairy productions systems would come at a net cost, the report said, based on current market signals in Australia, in the absence of financial incentives and productivity gains.

“Assuming any technical barriers can be addressed, if 3-NOP were to be used across the full 1.4 billion litres of milk sold annually in Australian supermarkets, the estimated cost would be $35.1 million a year,” Drake said.

Although consumer willingness to pay more for products for their sustainability credentials is generally considered low when it comes to actual purchasing decisions, with the relatively small premium this cost would represent — less than 2% on private label milk in the case of 3-NOP — the prospect of passing it on to the consumers could be more feasible, she said.

Implementing multiple mitigation options —– to tackle the different sources of farm emissions — is set to be important in delivering maximum emission reductions for the dairy sector, Drake says.

“Recognising that costs are likely to be faced in order to achieve emission reduction targets raises questions about who pays,” she said.

“Discussions within the supply chain about how potential costs might be distributed are still in their early stages.

Dairy farm emissions account for approximately 3% of Australia’s overall national GHG emissions, the report says. And with 30% of Australian milk production entering the domestic drinking milk market, the Scope 3 emissions reduction targets of local retailers cover a substantial share of dairy production, it says.

“To date, when it comes to GHG emissions, efforts by commercial players within the dairy industry have so far focused

“The strategy that emerges is unlikely to neatly fall into one bucket. Multiple stakeholders beyond the farm gate have an interest in reducing on-farm emissions from dairy production — including industry, government, processors, retailers and financial institutions.”

“The development potential of cost-sharing models across valuechain stakeholders is yet to be properly explored,” Drake said.

“Collaboration looks to play an important role in enabling the resources required to solve the problem of emissions be divided rather than duplicated.”

On-site high-purity nitrogen (N2) generation can provide a sustainable alternative to bottled or bulk gas supplies. For a nitrogen generator to be successful on-site it must continuously produce the gas purity required. The precise measurement of gas purity confirms the quality of gas provided to downstream processes, and acts as an indicator of possible system faults.

In a nitrogen gas stream, the measurement of oxygen (O2) is normally used as an indication of purity. There are four key reasons for this: 1. Contaminant detection — oxygen is typically one of the most common contaminants in nitrogen gas streams; 2. Low concentration measurement — oxygen sensors and analysers are often highly sensitive and capable of detecting very low concentrations of O2; 3. Cost and practicality — measuring O2 concentration is more costeffective and practical than measuring N2 concentration directly; and 4. Measurement stability — oxygen measurement is less likely to be affected by the presence of other gases.

Oxygen analysers from Analytical Industries Inc (AII) are designed to be suitable for this task. They have a variety of measurement sensor styles and detect trace levels of gas as low as a few parts per million (ppm) using technology that is designed to be easy to calibrate and able to produce consistent results over time.

AMS Instrumentation & Calibration Pty Ltd www.ams-ic.com.au

The Optima Robotics Pudu T300 industrial delivery robot is designed to improve material handling and logistics operations in diverse environments such as the food and beverage industry. The industrial delivery robots are engineered to streamline operations and enhance productivity.

Equipped with advanced AI-driven navigation systems, the robots can autonomously navigate complex layouts, detect obstacles and adapt to changing environments, to help ensure safe and efficient material transportation. They come with robust payload capacities, making them suitable for transporting heavy and bulky items over long distances without the risk of damage or delay. The integration of high-precision sensors and machine learning algorithms allows the robots to optimise routes in real time, to help reduce energy consumption and operational costs.

Using the VSLAM+ navigation and localisation method, it requires no environment or network setup and the system can easily adjust maps for production line changes. Other features include ultimate clearance of 60 cm, being capable of crossing 20 mm thresholds and 35 mm gutters, and having the ability to manoeuvre smoothly through narrow spaces and shuttle between production lines.

The Pudu T300 can be customised with different attachments or software configurations to meet specific industrial needs so it can adapt to various tasks and environments without requiring multiple separate machines.

Optima Robotics www.optima-robotics.com

With rising lactose intolerance affecting an estimated 30–60% of the population in Australia and New Zealand, Kerry is meeting the demand for lactose-free dairy options in the region through its portfolio of lactase solutions.

Lactose intolerance remains a prevalent issue globally, with only a third of adults worldwide able to digest lactose effectively. By 2028, the Australia and New Zealand market for lactose-free dairy products and alternatives is projected to reach approximately AU$1.5 billion.

This shift is not solely driven by lactose intolerance but also by a broadening interest in lactose-free options due to perceived health benefits. This has contributed to impressive growth rates — in 2024, the lactose-free market in Australia is valued at AU$602 million, with a 31% CAGR between 2019 and 2023. In New Zealand, growth is significant with 52% CAGR from 2019–2023 and current market value of NZ$63 million.

Lactases are naturally occurring enzymes that break down lactose, the sugar found in milk, into simpler sugars — glucose and galactose, which are easily digestible. This enzymatic intervention is critical for those who lack sufficient natural lactase enzymes in their digestive system, a common

scenario among the lactose-intolerant population. By adding lactase to dairy products, the lactose is pre-digested, making these foods accessible and enjoyable without the usual adverse reactions.

The dairy industry has seen a revitalisation in its appeal, much of it thanks to innovations such as lactase enrichment. Traditional dairy products previously thought to cause discomfort are back on the menu, changing the dietary landscapes for many. With these innovative changes, lactose-free is now one of the fastest-growing dairy categories, while low-sugar options are increasingly top of mind for consumers.

Kerry’s newly expanded portfolio of lactase solutions includes the NOLA Fit and Ha-Lactase, alongside LactoSens, a rapid residual lactose test, designed to enhance production accuracy and efficiency. Kerry’s expertise, strengthened by its recent acquisition of lactase technologies and C-lecta’s enzyme research capabilities, allows the company to deliver lactases that support lactose removal and sweetness optimisation without additional sugars. This clean-label approach meets the demand for better nutrition while ensuring that lactose-

free products satisfy consumer taste and texture expectations.

Building on its 50-year legacy in dairy innovation, Kerry’s solutions for lactose-free and sugar-reduced products are backed by proprietary consumer insights, taste modulations and natural flavour technologies.

Christine Giuliano, General Manager of Kerry Australia and New Zealand, said: “Kerry’s lactose-free solutions are designed to meet growing regional demand for convenience and nutrition. As busy consumers increasingly rely on yoghurt pots, flavoured milk and other dairy products for quick snacks and meals, Kerry’s lactase technology supports the development of products that are both indulgent and health conscious.

“We want to provide dairy producers with solutions that not only overcome lactose intolerance but also meet consumers’ desire for products that taste authentic and delicious. By optimising sweetness naturally, these solutions maintain the quality and nutritional value of dairy with significantly less added sugars, ensuring better, delicious dairy products everyone can enjoy.”

Bare*ly Mylk, a startup founded by Monash University alumni, has developed powdered plant milk to reduce packaging and related transportation emissions.

The company was a participant in the university’s Generator Accelerator program, designed to challenge startup founders to accelerate traction and achieve significant and sustainable growth for their business.

According to the company, plant milk packaging has two problems: first, liquid plant milks are over 90% water by volume, increasing the packing and transportation emissions produced; and second, that water means long-life liquid plant milks need to be packed in aseptic cartons that cannot be easily recycled in Australia.

“Aseptic cartons are made from a composition of paper, foil and plastic, making liquid contents shelf stable. They require specialised hydropulping processing facilities very few recycling facilities in Australia are equipped with, and therefore the cartons are sent to landfill,” the company said.

The new powdered alternative is said to be lighter to transport, reducing energy, resources and emissions as well as the problematic packaging. It also greatly increases the shelf life, without needing refrigeration.

According to the Australian Packaging Covenant Organisation (APCO) Australian Packaging Consumption & Recovery Data 2021–22, this year 55,000 tonnes of aseptic polymer-coated paper board (PCPB) will go to landfill. Bare*ly Mylk estimates that 25% (13,750 tonnes, or 344 million units) of this is from plant milk cartons. A Tetrapak life cycle analysis of aseptic cartons shows that this will create 25,000 tonnes of CO2 this year, amounting to a total of 180,000 tonnes of packaging waste by 2034.

Bare*ly Mylk founders Mark Prewer (Monash Alumni, Business and IT), Kaylee Jones (Monash Alumni, Commerce and Global Studies) and Ryan Gan (Monash Alumni, Commerce and Finance) are on a mission to reduce this waste and make plant milk even better for the planet and for people. Their vision is to make plant milk ‘barely packaged’.

Jones said, “Our powder importantly reduces the environmental impact of liquid plant milks, and is made with the planet in mind. But our product is also made for people; it’s great-tasting, versatile, convenient and long-life without any need for refrigeration. Just add water, shake and enjoy.”

“The Generator Accelerator Program has given us a framework to develop our product and business strategy. It will put Bare*ly Mylk in a strong position to go to market,” added Prewer.

“Bare*ly was born from our desire to learn, grow and make a positive impact — we’ll always push ourselves and never want to let off the innovative throttle,” he said.

Gan concluded, “Powdered options are all taste and less waste. Not only can we put greater volumes of milk in less packaging, but we can use packaging materials that can go in your mainstream recycling bins.”

Bare*ly Mylk’s first product, available in 2025, is powdered oat milk. It has the same flavour, taste and froth-ability as typical liquid versions, but with a longer shelf life. The versatility also makes it perfect to take travelling or even camping.

The Optima Robotics palletising solution using Universal Robots’ collaborative robot is designed to help manufacturers simplify their processes with easy-to-use automation solutions.

End-of-line automation is critical nowadays with increased labour costs and staff shortages in Australia. Data shows 8 billion pallets are being counted lost due to uncertain pallet pattern, damage of cartons, etc. As such, palletising cells are crucial for the end of line, not just to increase the efficiency and capacity, but also to ensure a steady pallet being stacked.

Suitable for SMEs to multinational companies, the Optima Robotics palletising solution using Universal Robots’ collaborative robot is designed to allow users to automate their end of line with minimal effort and integration time.

Integration is easy as the product comes fully integrated with hardware and software for rapid deployment. Other features include fast adjustments that change production settings in just five minutes to adapt to new products; user-friendly interface with no need for technical expertise or external engineers; and versatile capabilities, from palletising and depalletising to handling internal layers and ensuring precise label orientation.

The solution is designed for a quick ROI (less than 16 months) and maximum payload of up to 35 kg. It is available with 7th axes to reach palletising height of 2.75 m.

Optima Robotics www.optima-robotics.com

PPM Technologies (PPM), a member of Duravant’s Food Sorting and Handling Solutions group, has introduced its FlavorWright SmartSpray food coating system.

Designed specifically for vitamins, gummies and other confectionery goods, the system applies oil and other liquids through continuous operation. It combines a robust belt conveyor, liquid applicator and tumbling drum with a fully integrated control system, enabling processors to achieve consistent coating applications while reducing labour requirements and minimising waste.

The system is an adaption of the company’s FlavorWright All-in-One seasoning system, with a specialised belt conveyor designed for wet, sticky and hard-to-move confectionery products.

The system uses a continuous coating process that begins as product enters the tumbling drum via the belt conveyor. The adjustable liquid applicator creates controlled spray patterns for uniform coverage while preventing oversaturation, and the tumbling action is designed to ensure even distribution across all product surfaces.

Other features include recipe-driven operation, interchangeable components, and control over production parameters to allow processors to fine-tune both conveyor speed and drum angle.

Two drum sizes are available in plastic and stainless-steel construction. Plastic drums feature seamless, FDA-approved construction with a non-stick finish to prevent product build-up and are easily interchangeable using PPM’s EZ-swap magnetic technology.

Built with sanitation in mind, the system is equipped with NEMA 4X-rated components for wash-down environments and food-grade stainless-steel construction throughout. Its compact footprint allows for easy integration into existing production lines.

PPM Technologies www.ppmtech.com

Low-moisture foods such as dried fruits, seeds, tree nuts and wheat flour — once considered to carry minimal microbial risks — are facing increasing food safety risks, but research on this food sector remains limited.

To tackle this, Purdue University researchers looked into key barriers in ensuring the safety of low-moisture foods. Their study — aimed at better understanding the food safety culture, research and education needs, and barriers to adopting food safetyenhancing technologies — found issues with hygienic design, risk communication, behavioural change and limited resources as some of the key barriers.

The team focused on the human factors influencing food safety, specifically people’s expectations, perceptions and behaviours surrounding low-moisture food handling. The participants included professionals from government agencies, food industry companies and academia.

Associate Professor Yaohua Feng and PhD student Han Chen, along with colleagues at other institutions, developed a two-part needs assessment in collaboration with the Center for Low-Moisture Food Safety, which is funded by the US Department of Agriculture’s National Institute of Food and Agriculture.

“When it comes to food safety, unfortunately, we usually react rather than being proactive,” Feng said. “And, for a long time, sanitation technologies and validation data were developed based on high-moisture food matrix. There’s more literature on those foods — how to conduct validation studies and sanitise properly. For example, while water is essential for washing and sanitising equipment in a facility producing high-moisture foods, you wouldn’t want to introduce water into low-moisture food processing — it can crosscontaminate and create more problems.”

Stakeholders were eager to contribute insights and collaborate on the project. According to Feng, “We don’t often see the industry being so open, especially bigger players. Having stakeholders willing to participate and talk about their weaknesses is a new approach.”

Based on feedback from the 25 participants, a conceptual framework for food safety culture was developed that includes three key components: infrastructure conditions; an individual’s food safety knowledge, attitudes and risk perceptions; and organisational conditions.

The study also revealed several infrastructure-related challenges, noting that food safety is often not prioritised when facilities are first designed.

“In the past, microbial food safety in low-moisture foods wasn’t a focus for consumers and most manufacturers,” Feng said. “Hygienic design was not being considered in many legacy manufacturing facilities when building plants.

“On the other hand, low-moisture food safety to consumers is also even newer than to the industry. There are no inspectors to regulate or educate consumers in their home kitchen.”

Another critical finding is the challenge of communicating food safety risks within the industry. Since low-moisture foods are often perceived as inherently safe, convincing upper management and employees to invest in food safety initiatives can be difficult.

“With these communication challenges, you should tailor the risk-communication messages to your target audiences,” Chen said. “For example, upper management is usually the decision-maker of resources spent on changes toward food safety. The consequences of being involved in an outbreak or recall can be emphasised when communicating the risks with them.

“One outbreak could have a detrimental impact on the company and even on the entire industry.”

As environmental concerns escalate and regulations become stricter, the importance of sustainability and efficient resource management in the manufacturing sector has never been greater. In response to these pressures, one Spanish ice cream producer has embraced an innovative solution to tackle its challenges head-on.

The manufacturer, known for producing a wide variety of ice cream products for various third-party brands and retailers, recently encountered significant obstacles in managing its wastewater treatment process. Striving to maintain a balance between effective treatment and environmental sustainability was essential to its operations.

Ice cream manufacturers often struggle with managing wastewater effectively, especially when using traditional aluminium-based coagulants. These treatments, although occasionally effective, can be markedly unstable and highly sensitive to pH changes. The process also demands substantial amounts of caustic soda for pH homogenisation, which increases the discharge conductivity, frequently surpassing legal limits. Furthermore, these aluminium treatments can lead to unwanted effects in downstream biological treatment processes, complicating the overall wastewater management. For this Spanish ice cream manufacturer, these challenges were particularly pronounced during the dissolved air flotation (DAF) step of its wastewater treatment line.

An organic solution

Recognising the need for a more stable and environmentally friendly solution, the manufacturer engaged Veolia Water Technologies to recommend a solution. Veolia’s Hydrex team in Iberia, Spain, proposed replacing the metal-based chemicals with a Hydrex plant-based coagulant. Traditional metal-based coagulants, while effective at removing suspended solids and contaminants, have several drawbacks, including significant changes to the pH of water, high sludge production, and increasing regulatory restrictions on their use.

The Veolia team conducted extensive trials and jar tests to demonstrate the efficacy of the plant-based coagulant. Impressed by the results, the manufacturer signed a contract for the supply of 100 tons per year of the Hydrex plant-based coagulant.

Derived from renewable sources, Hydrex plant-based coagulants are designed to provide a sustainable and costeffective alternative. These products are formulated to mitigate

the drawbacks of inorganic chemicals, particularly in the oily effluent generated by the food and beverage (F&B) industry.

The results

Chemical dosage reduction: The dosage of poly aluminium chloride (PAC) was reduced from 1000 to 300 ppm, while the dosage of caustic soda was reduced from 1000 to 300 ppm (v/v). This led to a 40% reduction in chemical costs for the manufacturer. Improved stability: The plant-based coagulant provided a more stable treatment process, less sensitive to pH variations. Sludge production reduction: The DAF system produced less oily sludge, easing the burden on downstream treatment processes. Enhanced performance: The treatment achieved similar performance to PAC, with a 50% reduction in chemical oxygen demand (COD) and an 85–95% reduction in total suspended solids (TSS).

Conductivity improvement: The conductivity of the discharge was reduced from 6000–7000 µS to 4500 µS, a critical improvement for meeting legal discharge limits.

A spokesperson for Veolia Water Technologies Ibérica said, “With our Hydrex plant-based solutions, Veolia has resolved the ice cream producer’s DAF performance issues and reduced their total costs. As a result, the customer will save approximately €80,000 per year if all circumstances remain consistent over time.”

The success of this project underscores the broader industry trend towards sustainable practices in the food and beverage sector. Wastewater treatment plants in food and beverage facilities often face challenges such as load shocks, temperature changes and production increases. Conventional activated sludge treatment systems are often inadequate for handling the large variations in Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and nutrients caused by ingredients like sugars, proteins and starches.

Removing COD, BOD and nutrients from wastewater is crucial for protecting aquatic life and the environment. The adoption of advanced wastewater treatment technologies can help companies in the food and beverage industry meet these challenges.

By adopting Veolia’s plant-based coagulants, the Spanish ice cream manufacturer not only improved its wastewater treatment process but also took significant steps towards environmental sustainability and cost savings.

Veolia Water Technologies www.anz.veoliawatertechnologies.com

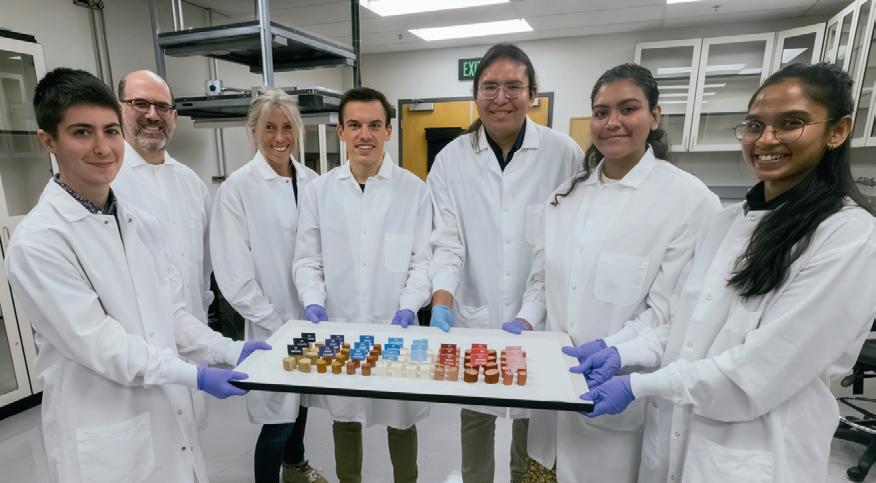

Stanford engineers are developing an approach to food texture testing that could pave the way for faux meat that could win over meat eaters.

In a paper published in Science of Food, the team demonstrated that a combination of mechanical testing and machine learning can describe food texture with a similarity to human taste testers. The team also found that some plant-based products are already nailing the texture of the meats they’re mimicking.

Ellen Kuhl, professor of mechanical engineering and senior author of the study said: “We were surprised to find that today’s plant-based products can reproduce the whole texture spectrum of animal meats.”

“People love meat,” said Skyler St. Pierre, a PhD student in mechanical engineering and lead author of the paper. “If we want to convince the hardcore meat eaters that alternatives are worth trying, the closer we can mimic animal meat with plant-based products, the more likely people might be open to trying something new.”

To successfully mimic animal meat, food scientists analyse the texture of plant-based meat products.

“Unfortunately, traditional food testing methods are not standardised and the results are rarely made available to science and to the public,” said St. Pierre.

The research grew out of a class project by St. Pierre. Looking for affordable materials to use in mechanical tests, he turned to hot dogs and tofu. Over the summer of 2023, undergraduate researchers joined in to test the foods and learn how engineers depict material responses to stress, loading, and stretching.

Realising how this work could aid the development of plant-based meats, the Stanford team debuted a three-dimensional food test. They put eight products to the test: animal and plant-based hot dog, animal and plant-based sausage, animal and plant-based turkey, and extra firm and firm tofu. They mounted bits of meat into a machine that pulled, pushed, and sheared on the samples.

“These three loading modes represent what you do when you chew,” said Kuhl.

Then, they used machine learning to process the data from these tests. They designed a new type of neural network that takes the raw data from the tests and produces equations that explain the properties of the meats.

To see if these equations can explain the perception of texture, the team carried out a test survey.

The testers — who first completed surveys on their openness to new foods and their attachment to meat — ate samples of the eight products and rated them on 5-point scale for 12 categories: soft, hard, brittle, chewy, gummy, viscous, springy, sticky, fibrous, fatty, moist, and meat-like.

In the mechanical testing, the plant-based hot dog and sausage behaved very similarly in the pulling, pushing, and shear tests to their animal counterparts, and showed similar stiffnesses.

Meanwhile, the plant-based turkey was twice as stiff as animal turkey, and the tofu was much softer than the meat products. The human testers also ranked the stiffness of the hot dogs and sausages very similarly to the mechanical tests.

“What’s really cool is that the ranking of the people was almost identical to the ranking of the machine,” said Kuhl.

“That’s great because now we can use the machine to have a quantitative, very reproducible test.”

The findings suggest that new, data-driven methods hold promise for speeding up the process of developing tasty plant-based products.

“Instead of using a trial-and-error approach to improve the texture of plant-based meat, we could envision using generative artificial intelligence to scientifically generate recipes for plant-based meat products with precisely desired properties,” the authors wrote in the paper.

But artificial intelligence recipe development, like other AIs, needs lots of data. That’s why the team is sharing their data online, making it open for other researchers to view and add to.

“Historically, some researchers, and especially companies, don’t share their data and that’s a really big barrier to innovation,” said St. Pierre. Without sharing information and working together, he added, “How are we going to come up with a steak mimic together?”

The team is continuing to test foods and build a public database. This summer, St. Pierre oversaw undergraduates testing veggie and meat deli slices. The researchers also plan to test engineered fungi developed by Vayu Hill-Maini, who recently joined Stanford as an assistant professor of bioengineering. “If anybody has an artificial or a plant-based meat they want to test,” said Kuhl, “we’re so happy to test it to see how it stacks up.”

Astudy published in The Journal of Nutrition found that substituting two tablespoons of pure maple syrup, instead of refined sugars, reduced several cardiometabolic risk factors in humans. The placebo-controlled clinical trial explored potential health benefits of maple syrup in humans.

“We know from decades of research that maple syrup is more than just sugar. It contains over 100 natural compounds, including polyphenols, that are known to prevent disease in part through their antiinflammatory effects,” said Dr André Marette, lead scientist on the study. “Because the fundamental chemistry of maple syrup is unique, I wondered if ingesting maple syrup instead of an equivalent amount of refined sugar would differently impact the cardiometabolic health and the intestinal microbiota in humans. The results were extremely encouraging. I did not expect to see so many improvements of risk factors within a relatively short treatment period.”

The study was conducted by a Laval University team led by Marette at the Quebec Heart and Lung Institute and Dr Marie-Claude Vohl at the Institute of Nutrition and Functional Foods.

Forty-two volunteers from the Québec area, between the ages of 18 and 75 in good health, and with a BMI of 23–40, participated in the study. Participants substituted 5% of their daily caloric intake (corresponding to two tablespoons) from refined sugars with either Canadian maple syrup or an artificially flavoured sucrose syrup. Each phase lasted eight weeks with participants switching between maple syrup and sucrose syrup groups after a four-week washout period.

Study participants who consumed pure maple syrup are reported to have had an improved response to the oral glucose tolerance test (OGTT) than those who received a flavoured syrup of refined sugar. Their bodies managed blood sugar levels better after eating (-50.59 vs +29.93).

Blood pressure was also lowered in the subjects who consumed maple syrup during the trial. “Lowering blood pressure continues to be an important factor in lessening the risk of cardiovascular disease,” Marette said. “Natural sweeteners, such as pure maple syrup, when substituted for refined sugars, can be part of an overall solution in helping to prevent metabolic diseases.”

The maple syrup trial showed that android fat mass, the fat in the abdominal region, significantly decreased in the maple syrup group as compared to an increase in the group consuming the sucrose solution (-7.83 g vs +67.61 g).

An unexpected discovery was the improved levels of potentially beneficial gut bacteria and a decrease in levels of potentially harmful gut bacteria in the maple syrup participants. The study showed a reduction in Klebsiella species and Bacteroides pectinophilus, which are linked

to inflammation and metabolic disorders, and the increased growth of beneficial bacteria like Lactocaseibacillus casei and Clostridium beijerinckii.

“Both individually and collectively, the study findings are quite significant,” Marette said. “The combined decrease of such key risk factors may help to reduce the risk of diabetes and cardiovascular disease.”

“While this study was limited to a relatively small sample size (42 men and women) and took place during a relatively short duration of time, the results are still significant,” Marette said.

“We now have human evidence to support replacing refined sugars with maple syrup, a natural sweetener, for preventing metabolic diseases. Our next goal is to conduct larger studies with other populations to explore how replacing refined sugars with maple syrup might impact their unique health conditions.”

The SLL210 AnyLevel™ gravimetric level sensor is a groundbreaking advancement in level measurement technology, meticulously designed to streamline and elevate the efficiency and precision of monitoring levels across various applications. Its cutting-edge features and user-centric features make the SLL210 AnyLevel suitable for various sectors, especially the food and beverage industry. This innovative device empowers companies to thrive in a dynamic industry landscape by significantly improving operational efficiency and product quality, ultimately strengthening their competitive advantage in the marketplace.

The SLL210 AnyLevel sensor is known for its versatility. It is capable of measuring levels in a broad spectrum of materials ranging from liquids, powders, slurries, and granules — making it an exceptional solution for facilities with multifaceted processes and material types. The SLL210 AnyLevel is designed to provide precise measurements, ensuring that operators can maintain optimal levels in tanks and silos without the sensors being in contact with the content inside, which is critical for process control and product quality.

Designed to be user-centric, the SLL210 AnyLevel features a compact and lightweight construction that facilitates straightforward installation, even in confined spaces, ensuring a smooth transition without major overhauls or

disruptions to operations. Positioned below the tanks or silos, the sensor eliminates measurement distortion caused by environmental factors, such as sidewall adhesion, dust, or foam. Not only does this eliminate contamination and corrosion, having an external level-detection solution increases safety where operators can avoid climbing the tank to obtain data and do testing. Additionally, the sensor’s surface is designed with a slight tilt, enabling easy cleaning and seamless water drainage during washdown procedures in hygienic environments. With an intuitive interface for configuration and operation, the SLL210 AnyLevel minimises downtime and reduces operational costs.

Moreover, the SLL210 AnyLevel sensor offers significance to the food and beverage sector where operational efficiency and reliability are paramount. Constructed from robust materials, it is designed to withstand harsh conditions. This resilience ensures that the sensor maintains its performance over time, reducing the likelihood of sensor failure that could disrupt production processes. In saying this, by minimising the need for frequent replacements and maintenance, the durability translates to lower costs and reduced downtime, which allow businesses to operate more efficiently.

Incorporating innovative technology, the SLL210 AnyLevel supports continuous, local, and remote level monitoring through

various automated connectivity options including IO link, 4-20mA and HART. It also saves space by having direct PLC/ DCS connectivity which reduces system complexity with integrated connectivity. This feature is crucial for applications where maintaining specific levels is essential for operational efficiency and safety. In addition to this, continuous monitoring levels help prevent overflows and dry runs, which can lead to costly downtime and potential damage to equipment. Operators have the options to set up SMART5 alarms where alerts can be set and notifications based on predefined thresholds, ensuring that they are immediately informed of any deviations from normal operating conditions.

The SLL210 AnyLevel sensor is a versatile, reliable, and user-friendly solution for level measurement across a wide range of sectors. As industries continue to evolve and demand greater precision in their processes, its advanced technology, robust design, and continuous monitoring capabilities make it an ideal choice for companies looking to achieve operational excellence in their processes and deliver product quality for its consumers. This combination of features solidifies that the SLL210 AnyLevel sensor is truly the universal choice for inventory control in the industry.

If you would like to learn more about this innovative technology, please feel free to visit mt.com or call 1300 659 761.

Specialty coffee brand

ST. ALi is scaling up its operations to meet growing demand for its product — introducing a second Goglio G21 vertical form fill seal (VFFS) coffee packaging machine from Jet Technologies.

The installation of the second Goglio machine comes four years after its initial investment in the technology. The additional system has allowed the company to double its packing capabilities — streamlining the packaging process to enable an output of 20 coffee bags/min, per machine.

ST. ALi expanded into mainstream retail this year, launching its coffee range nationwide in Coles supermarkets.

Lucy Ward, Head of Operations and Sourcing at ST. ALi, said the business is now well equipped to meet the demands of its growing retail and wholesale channels.

“This machine allows us to increase our packaged coffee output and maintain the same exceptional quality our customers have come to expect, whether they’re picking up a bag of our coffee in Coles or ordering from our online store,” she said.

Jet Technologies also provides the flexible coffee packaging laminates and degassing valves that maintain the freshness and quality of coffee, and its sustainable packaging solutions have been recently adopted by the coffee maker.

Jet Technologies’ General Manager, Daniel Malki, said, “ST. ALi is a true leader in Australia’s specialty coffee scene. Their ability to constantly evolve and innovate is inspiring, and we’re proud to continue supporting them as they expand their operations and break new ground.”

ST. ALi is using ShieldCycle packaging from Jet Technologies, which features a polyolefin-based plastic structure that replaces the nonrecyclable aluminium layer in traditional coffee bean packaging with recyclable layers. The packaging is designed to ensure that all components can be easily melted down and reused.

“The expansion into Coles has been a huge milestone for us, and with the addition of the second Goglio G21, we’re ready for whatever comes next,” Ward said.

Jet Technologies www.jet-ap.com

In the UK and Ireland, Mondelēz International is moving to 80% recycled plastic packaging for its Cadbury sharing bars.

Starting from 2025, in a phased approach, the project aims to cover approximately 300 million Cadbury sharing bars.

The packaging, created in collaboration with Amcor, is made using AmPrima recycle-ready solution and incorporates AmFiniti recycled material.

To help consumers understand more about the packaging and how to recycle it, the Cadbury wrap features on-pack labels plus a QR code to access more information about the brand's initiatives, including a consumer-friendly explanation of mass balance. Consumers can also access a tool for the local recycling locations.

Australian tomato sauce brand MasterFoods is trialling paperrecyclable, single-serve tomato sauce packs — which use 58% less plastic than the original packaging and can be recycled via traditional kerbside recycling.

Made in Mars Food & Nutrition’s manufacturing site in Wyong on the NSW Central Coast, the MasterFoods Recyclable SqueezeOn Tomato Sauce packs are a result of five years of research and development trials, with $3 million invested in the project so far.

The packs have been designed to be easy to use so that consumers can still hold a pie in one hand and their sauce in the other. Once empty, the packs can be disposed of in the recycling bin.

Over 240 million of the company’s tomato sauce packs are currently used each year, so the trial is an important part of the company’s sustainable packaging initiative.

The General Manager of Mars Food & Nutrition Australia, Bill Heague, said, “The trial of paper-based MasterFoods Recyclable Squeeze-On Tomato Sauce packs marks another important milestone in Mars’s sustainability journey, and demonstrates the role the food industry can play in working towards a circular economy.

“This trial will allow us to better understand how this new paper-recyclable squeeze-on performs so we can take these learnings forwards. If we transition our full portfolio to this new format over time, Mars Australia would be set to eliminate around 190 tonnes of plastic from our value chain a year.”

The trial has been designed in partnership with the Australian Packaging Covenant Organisation (APCO) and will allow MasterFoods to collect important data on the performance of the new pack, including how to best educate consumers to recycle the product after use.

Chris Foley, CEO of APCO, said, “I commend Mars for collaborating with APCO throughout the development process, taking a thoughtful and iterative approach to trial and refine the new packaging format. By focusing on real-world testing, this trial will help ensure the packaging can be effectively recycled

post-consumer use. We look forward to seeing the results and continuing to support their efforts in achieving the best environmental outcomes for their packaging.”

The packaging has been designed and produced in partnership with Easysnap Technology, an Italian packaging company specialising in recyclable one-handed packaging technology and part of Gualapack.

Starting in November 2024, the trial will take place across a variety of locations and should be available through to April 2025. More than a million units of the paper-based packaging will be evaluated by consumers during the trial.

As preparations ramp up for the next major New Zealand industry trade event, Foodtech Packtech, scheduled for 2–4 September at the Auckland Showgrounds, event organiser XPO Exhibitions has observed a fascinating industry landscape. While some sectors are continuing to navigate challenges caused globally by high inflation and the cost of living crisis, improvements are on the horizon, and the food and beverage manufacturing sector is already brimming with potential.

What’s New in Food Technology & Manufacturing, an official media partner for the event, spoke with exhibition event and sales manager Deb Haimes to gain insights into the current climate, future outlook, and the significance of maintaining a strong market presence during uncertain times.