PORTFOLIO

WILLIAM PATTERSON

HELLO I’M WILLIAM

WHO I AM:

As a designer, I hold great value in maintaining traditional values in a design whilst applying innovation and modern alterations which fit. I like ensuring that products best achieve their primary function whilst applying additional features where appropriate and justified. To achieve this in my projects, I am a hard worker and highly value feedback from my peers, clients and tutors. Learning at Nottingham Trent University has vastly improved my skills in CAD, sketching, and my technical understanding when it comes to conceptualising products. The experiences I have had at NTU along with the friendships I have formed have moulded me into not only a better designer but also a more confident person. This boost in confidence has made me an effective team player and has allowed me to keep pushing myself.

HOBBIES AND INTERESTS:

Supporting Aston Villa Football Club

Playing Video Games

The design and construction of modern technology such as Cars, Computers/Consoles and controllers.

Graphic design in football

Sketching

MY SOFTWARE SKILLS

MY EDUCATION:

GCSE’s - The Becket School:

4 - Grade 8’s

2 - Grade 7’s

3 - Grade 6’s

1 - Grade 4

A-Levels - The Becket Sixth Form:

Product Design - A*

Geography - A

Physics - C

Physics Practical Skills - Pass

Nottingham Trent University:

Product Design BSc

Highly Commended in Starpack Competitition.

CANOPY

SOLO PROJECT - 4 WEEKS

THE BRIEF:

To design a pot lid applicable to as many pots and pans as possible whilst also improving the functionality of the pot lid and as a result making the process of cooking in a pot or pan easier for a student. As well as this, the product should look to help preserve kitchen space, improve kitchen efficiency and sustainability through the products life span and reliability.

CONTEXTUAL RESEARCH

THE AIM:

£IMPROVE EFFICIENCY SAVE KITCHEN SPACE REDUCE USER EXPENDITURE ON OTHER PRODUCTS

PRIMARY RESEARCH - STUDENT SURVEY:

THE ENVIRONMENT:

50%

POT LIDS EITHER MISSING OR BROKEN

62.5%

IMPROVEMENTS IN ORGANISATION FROM A MULTIFITTING LID

87.5%

SAW FINANCIAL BENEFIT IN A MULTIFITTING LID

Coming into the final concept, multiple iterations of a multifitting lid was explored but ultimately the previous ideas where too mechanical. As such flexibility from silicone was chosen instead.

The ideation stage focused a lot on employing multifunctionality to best achieve improved efficiency in the kitchen. Many products where looked at for inspiration like scales and mixers, but ultimately a more refined spotlight was put on pot lids and colanders.

MARKET APPLICATION

COST BREAKDOWN: RETAIL PRICE:

£6.10 MANUFACTURING COST

£0.87 MATERIAL COST

£6.97 PRODUCTION COST PER

£9.99

INTENDED PROFIT MARGIN: ~45%

TECHNICAL INFORMATION

HANDLE

HANDLE STEM

LID TOP

COLANDER FILTER

LID BOTTOM

ADJUSTABLE MAIN BODY BASE

FUNCTIONAL OVERVIEW

HANDLE:

Designed to offer grip and security when the Canopy is held and in use. Applying enough force to lift the handle will also expose the colander hence the indentation for pulling.

LID:

The lid of the Canopy is split into two parts. These slot together via their form and each have indentations for housing the Colander filter within them.

COLANDER FILTER:

The colander filter is enclosed between the two halves of the lid when not in use, but when exposed it effectively drains liquid from the pots contents without the lid needing to be removed.

ADJUSTABLE MAIN BODY:

The main body is made from Silicone allowing it to be sunk into its segments and expand as well as rise and become more narrow. It is designed to give the user control over the shaping required for the multitude of tasks it could be used for.

BASE:

The base of the Canopy features 2 hooks which apply friction to the pot and secure it. As well as this, it contains an indentation further securing the pot reducing risk when using the colander.

SOLOIST

GROUP PROJECT - 2 WEEKS

THE BRIEF:

To explore methods of improving the packaging of the Soloist tent both in its sustainability and functionality. How might we achieve this through the utilisation of their current materials and manufacturing methods in order to make the changes sustainable in practice but also economically for Alpkit?

PROJECT AIMS

TACKLING THE PROBLEM:

REDUCE MATERIALITY OF PRODUCT

THE PRODUCT:

MAKE PRODUCT MORE INTUITIVE

PRODUCT DETAILS:

UTILISE SMARTER STORAGE METHODS

1.2 kg Total

FLYSHEET - 20d Si/PU Polyester r/s (3k HH)

MAKE USE OF MATERIAL OFFCUTS.

GROUNDSHEET - 20d PU Polyester r/s (5k HH)

INNER - 20d Nylon breathable, D33 Mesh

CONVEYING THE ETHOS:

FITTING THE BRAND

APPLYING THE GUIDELINES:

DO LESS HARM

DEVIL IS IN THE DETAILS

CARRY ON CAMPING

INNOVATION WITHOUT COST

Advertising the changes made to the packaging and really sending a message that fit Alpkits, brand was majorly important. It ensures that the message sent is effective and reflects the core values of Alpkit. Utilising their font and advertising style allows for the sustainable improvements to be associated with the brand, giving them a more positive image.

PRODUCTS FIT FOR PURPOSE

Through exploring the ideas, emphasis was put on functional improvement alongside the sustainable improvement. It was important to give the sustainable alterations a positive connotation. This was reached eventually in an effective manner with some of the first ideas being over complicated.

PRODUCT IMPROVEMENTS

SUSTAINABILITY IMPROVEMENTS: DESIGN IMPROVEMENTS:

c02, reduced by

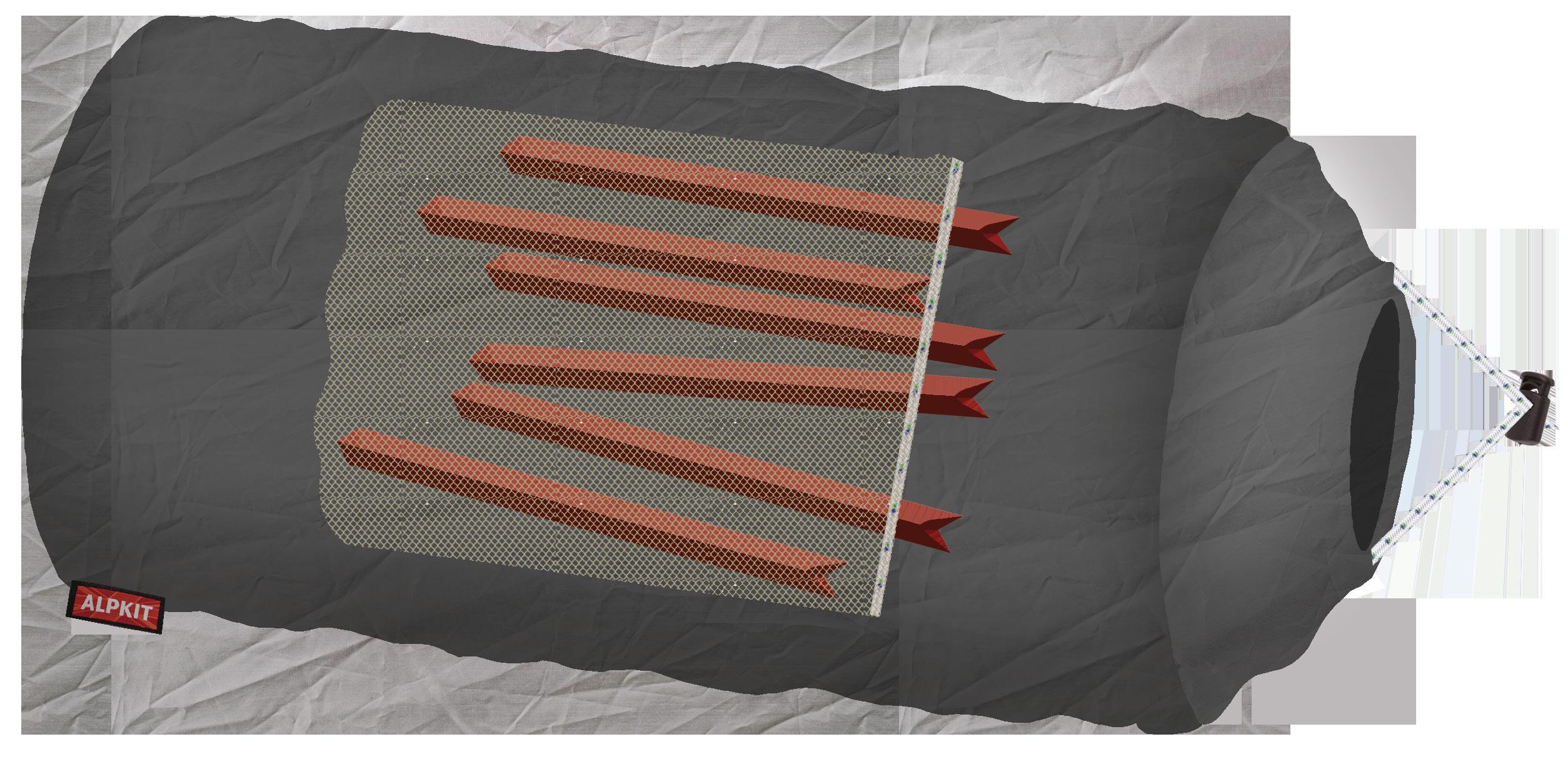

REMOVAL OF TENT AND POLE BAG, WITH THE POLES NOW BEING STORED WITHIN THE TENT WHEN ROLLED UP.

732.34kg per year

co2 reduction breakdown

materials: 206.73 grams

transport: 6.06 grams

processing: 10.43 grams

end of life: 0.27 grams

packaging materials: 9.60 grams

distribution: 8.54 grams

INSTRUCTIONS DISPLAYED ON FABRIC

OFFCUTS OF FLYNET USED TO EXTERNALY STORE PEGS. KEEPS TENT CLEAN FROM DIRT.

BRANDING IS MINIMAL AND EFFECTIVE

SHOCK CORD USED TO SECURE PEGS

BRINGING IT TO LIFE

FINAL ALTERATIONS:

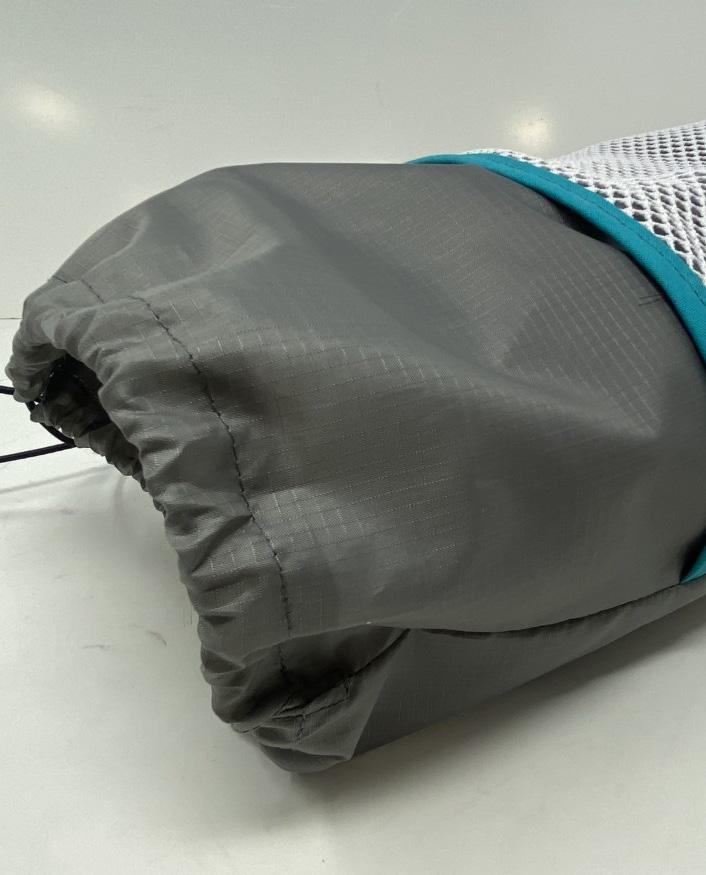

When producing the model for the bag redesign, it was found just how complex it would be to attach the external pouch centrally and further away from the pre existing seams. By making the pouch much larger, it not only utilises more of the flynet offcuts but also means that the manufacturability of the bag is more efficient as the pre existing seams are utilised to attach the pouch. It also makes the bag more functionally sound with more room available for repair materials , spare parts and even more pegs.

NOVEL.1

SOLO PROJECT - 4 WEEKS

THE BRIEF:

Connor a 29 year old father of 2, wants to find a way of spending more valuable time with his children whilst also helping them go to bed so that there’s less disruption in his busy work life. How might we produce a portable record player with a sufficient wind up action which can allow Connor and his children to bond and help them go to sleep without the distraction of digital devices?

PROJECT CONTEXT

THE TARGET:

ENCOURAGE VALUABLE FAMILY TIME

LIMITING SCREEN TIME

RECLAIMING BED TIME

THE FACTS:

WORSENED WORK ETHIC

THE FEEL:

FAMILY CENTRIC

MAGICAL

LASTING WARMTH

CONSTRUCTING A CONCEPT

To get to the final concept, inspiration was taken from various aspects seen in the ideation phase. From there, an initial concept was produced which then was improved upon with feedback from peers, clients and further sketch development.

KEY CHANGES:

REDUCED FOOTPRINT

BRIGHTER COLOUR SCHEME

MORE PROTECTIVE OF PARTS

DEFINING AN IDENTITY

SORRELL BROWN

DORADO WHITE ROCK

SILVER SAND

MINE SHAFT

WILD RICE

The colouring of the final design was altered in order to best emmit the warm, family centric and lasting themeing reuired in order to best suit the product to the intended user base. The colour pallete is bright enough to be appealing to the younger user base whilst also matching the maturity of the parent. Having a darker brown also provides that hint of lasting. The interaction of the product would be the key to ensuring the magical aspect was met.

SLIDING COVER STAND

DESIGN TECHNICALITIES

COVER LOCK

PROTECTIVE COVER

COVER HINGE

HINGE PIN

RB110 TONEARM

CORK PLATTER WIND UP MECHANISM

BELT DRIVE

TT MOTOR

TOP HALF PLINTH

SIDE HANDLE

CARRY STRAP

SPEAKER MESH

BOTTOM HALF PLINTH RUBBER FEET

ALUMINIUM 6061, T62

PINATEX

NATURAL RUBBER (15-42%)

CORK (HIGH DENSITY)

NYLON WEBBING - PA612

BRASS, SOFT, WROUGHT

PRODUCT INTERACTION