13 minute read

SOFTWARE

All Systems Go

For Touch Portal At Comp Door

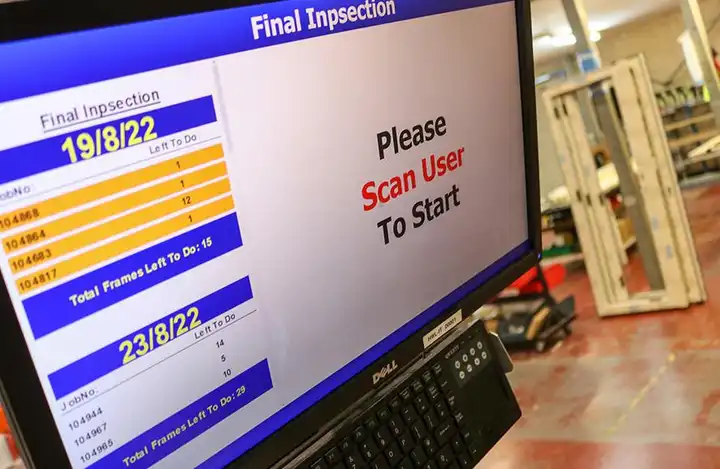

Comp Door, already a G-22 Product of the Year finalist, has become a key launch partner for Business Micros’ new Touch online software platform.

The Staffordshire-based composite door fabricator is one of the first in the UK to have Touch fully integrated right across its operation, with design, quoting and ordering all now linked directly to its Evolution manufacturing and EvoNET business management software.

Customers who log in at: www. thecompstore.co.uk can access Comp Door’s Touch Portal system and quote and order their composite doors online via a simple, user-friendly interface, complete with accurate, high-res imagery. Crucially, because it’s an end-to-end Business Micros product, they can relax knowing that all the product, stock, pricing and discount data they are using is completely live and up to date.

Richie Thornton, head of operations for Touch, said: “Comp Door has become a perfect showcase for what the end-to-end Touch platform can do. All the current features within the software are fully operational and they’re really helping Comp Door optimise their own and their customers’ efficiency. As well as the automated ordering linked to Comp Door’s internal sales processing, there is a dealer network lead generation function with a home visualiser tool which is already generating warm retail enquiries for installers.

“There is also shared access via Touch to the Comp Door resource centre, packed with downloadable sales and technical literature, videos and photos, and even an automated tool for sharing news online.

“For installers who set up an online account with Comp Door, there is the option to create personalised, professional looking paperwork which they can use to simply overbrand and uplift the quote generated from within Touch Portal and send direct to homeowners. This effectively works like a mini-CRM system for them as well, because they can track, store and edit their quotes 24/7 from any mobile device.”

head of IT, says that the timing of the Touch Portal roll out was perfect for the business, which only opened the doors of its new 46,000 sq ft factory back in March. He said: “We’re manufacturing what we think is the most advanced composite door on the market, so it makes sense that we would align with the newest and most advanced online pricing solution, and that is Touch.

“I have worked closely with all the companies within the Business Micros Group in the past – including with the team at The Consultancy on the creation of our impressive website at https:// compdoor.co.uk/ – and had no doubt that they could deliver a high-quality product and provide excellent customer service. Touch’s built-in integration with our existing Evolution/EvoNET platform and its compatibility with our own ERP system meant it was easy to plan out the implementation of the Touch customer-facing pricing portal and the whole project has gone very smoothly.”

He added: “We’ve getting great feedback from our trade customer base about how intuitive they find the Portal to use and especially the advantages of having a dynamic, interactive image of the door – something which other configurators don’t offer. This, along with the advanced Home Visualiser feature, allows them to give the homeowner a much truer representation of the final product which they can present on screen and in their personalised quote – and that is helping them to win business

“We’re ahead of the game on Touch but that doesn’t mean the project is finished – we’ve got lots more planned and plenty for customers still to get excited about.”

ARC Design Upgrade

To Help Boost Installer Sales

Augmented Reality Conservatory Design, the visualisation tool that helps installers sell more conservatories, claims the company, has been upgraded to include brand new features that will help users benefit further.

Sitting within an installer’s website, ARC Design helps homeowners design and fully customise their own conservatory within minutes, before submitting the design to the installer to request a quote.

With the click of a button, the homeowner can then view their design in 3D augmented reality, allowing them to view the conservatory in situ on their house, helping them make their final decision.

ARC Design now features a realistic looking sky, as well as a function to add furniture to conservatory designs, giving customers an even better feel for their investment.

ARC COO and Co-founder Andy Clear comments: “Augmented reality has really taken off within the glazing industry, with long standing software developers following our lead. With ARC Design, we’ve created something that is proving a huge benefit to our customers across the country, and seems to be driving technological innovation forward.

“Installers that have ARC Design installed on their website have reported increased sales, increased lead generation, and a real boost to their brand reputation, and a lot of that is down to the realistic aspects of the software.

“We’ve always strived to make the software as accurate as possible, and by adding a realistic sky and furniture options to the mix, we’re helping homeowners get a very good idea of what their conservatory will look like in real life. This in turn will help conservatory installers secure new customers with their offerings, and ultimately boost their business.

“As we move into an increasingly digitised world, ARC Design provides an opportunity for installers to position themselves as the best choice for a homeowner, and we want to enhance this by constantly improving the software to engage as many potential customers as possible.”

Graham pointed out that handing the design processing element is just one piece in a complex manufacturing jigsaw, and that using your software to create efficiencies elsewhere in the production process saves money on additional resources. This makes fabricators more HWL Reveals profitable, and Graham said that processing the Sheerline aluminium designs with Window Designer was a logical decision to make.

Tip For Efficient Manufacture

Leeds-based trade fabricator HWL Windows has revealed that processing all of its product designs – regardless of system and profile material – with Window Designer from First Degree Systems is key to efficiency within the business.

“Using a single piece of design processing software across multiple systems and profile types is an important part of running our business efficiently,” HWL director Graham Howatson said.

“When we first started manufacturing aluminium products, we ran other forms of software to process those designs, because some of the systems companies had their own software, or their material list was only available on a specific software.

“But you end up having different processes on your aluminium products than you do on the other products running through your factory, and that doesn’t

Graham Howatson

make sense.”

HWL has been in operation for 20 years, and has used Window Designer to process its designs for all of that time. In the last five years, the company has switched its purchase agreement to a subscription model, which has given the fabricator access to more functions within the Window Designer suite of software, such as Stock Assistant and Barcode Tracking.

“In the last five years, we’ve changed our approach to software,” Graham said. “We recognise that it is a necessary requirement in the business, and it’s becoming even more important.”

“As a result of running our high-end Residence Collection PVC-U products through the Window Designer suite of software, we knew it worked,” he said. “For example, we experienced the accuracy of having all the components available for manufacture thanks to Stock Assistant; we successfully managed all our orders and customer relations thanks to the Zandi CRM software; and the design processing is fast and efficient. We’ve got confidence in it because we know it works.

“In fact, a pre-requisite for us is that before we would look at any system, we would check that the material file was available on First Degree Systems.

“If you used different pieces of software for different materials, all you are going to do is add labour in your admin team and other functions. So, 100%, one of the biggest benefits is that our operation runs on one piece of software – Window Designer.”

Window News & FIT Show – Win A Stand

Entries are coming through thick and fast for the inaugural ‘win a stand’ competition with Window News and FIT Show.

The campaign has been launched to entice new and emerging brands to exhibit at FIT Show 2023, which returns to the NEC from 23 - 25 May next year.

Window News and FIT Show are offering one lucky brand the chance to win an exhibitor space at FIT Show 2023, an extra special edition of the trade show which is celebrating a decade of innovation since its 2013 launch.

Over 20% of the lineup for FIT Show 2023 is made up of debut brands ranging in sizes from small startups through to more established brands who have chosen the 2023 event as an integral part of their marketing strategy next year.

The campaign with Window News is specifically designed to encourage brands who may have thought about exhibiting before but might not be sure if they’re quite ready, those who might believe that the cost of exhibiting is too prohibitive, or those who have never considered exhibiting before and would like to take their first step on the FIT Show ladder.

Speaking about the competition, FIT Show event director Nickie West said: “This is a really important campaign for us on two levels: firstly, we’re always looking at new ways to encourage and support new and emerging brands to take the plunge and reap the benefits of exhibiting at FIT Show and, secondly, we really want to shine a spotlight on how much new there is to see at FIT Show. special one for us as we celebrate ten years of being the UK’s number one trade show for the glass, glazing, window, hardware and components industry. The fact that 20% of our 2023 lineup is already made up of brands who will be exhibiting at FIT Show for the first time reinforces the fact that a trip to FIT always delivers something new for our audience.

“We’ve already had some brilliant entries and I’m excited to see the campaign evolve ahead of the end of January closing date.”

Window News editor Gerald Batt commented: “We’re excited to team up with FIT Show to offer the very first exhibitor stand giveaway. As a publication, we are committed to supporting our industry event and believe in the importance of encouraging and supporting new brands as they look to develop – this campaign will allow us to do just that.”

FIT Show & Window News will take the hassle out of your FIT Show debut by providing a Crystal Stand Package with 12M2 of stand space*. All we need from you is a business case which outlines:

• Company name, website and overview of nature of business

• Target audience

• Background of your company when you started, why you started and what your goals are for the next five years

• A 500 word overview of why you think you should win a free place on the floorplan for the FIT Show 2023 - whether it’s your innov tions, sustainable credentials or grass roots initiative - tell us what sets you apart from your competition.

Find out more and enter at WindowNews.co.uk Entries close 31 January 2023.

Deadline for submission

Entries open November 1st 2022 Winner announced February 28th 2023

What You’ll Win

• Crystal Stand Package with 12M2 of stand space, which includes walling, lights, electrical connection, carpet and furniture ready for you to arrive, add your company branding and product and be ready to meet 10,000 potential customers!

• Press release announcing that you are exhibiting

• Marketing support in the run up to the show

• FIT Show TV interview at the event

Terms and conditions:

• Only open to first time exhibiting brands

• Must be a service or product provider relevant to the fenestration industry

• Entrants cannot be employed, family or friends of either Mon gomery Group or Windows News

• One entry per company

• One winner will be selected by FIT Show organisers and the editor of Window News before being notified in February 2023

The Judges

Representatives from FIT Show & Window News.

The Emmegi T3A installed at Cube Commercial

Cube Commercial

Chooses Emmegi Machining Package

Until it invested in an Emmegi Phantomatic T3A CNC machining centre, Cannock-based Cube Commercial had been carrying out all its aluminium profile preparations using punch tooling and a copy router. The fabrication team were skilled and experienced so the quality was good, but Paul Grenfell, Cube’s director knew it could be even better.

He said: “Our mission as a new full-service business providing design, consultancy, fabrication and installation services is to delight customers on every step of their journey with us. That has to start with the quality of the windows, doors, shopfronts and facades we fabricate, so choosing top quality machines was always our plan.

“Emmegi has an outstanding reputation in this industry for the usability and reliability of its machines, and when we spoke to a couple of other aluminium fabricators in our area, they had no hesitation in recommending them. In fact, it was a friend of mine in the industry who suggested the Phantomatic T3A and said it would

The Cube Commercial factory in Cannock

suit the structure and vision of our company perfectly.”

The Phantomatic T3A three axes machining centre contains an angular machining head and a saw blade for machining on all five faces of the workpiece and comes with an eight-piece tool magazine. It also has an automatically positioned clamp unit and a high torque 5.5kW electro-spindle. the T3A was installed, we have certainly seen a significant improvement in our productivity and better precision, accuracy and overall quality in our frames. As you would expect, our fabrication team are very pleased with our investment – they can focus more on efficiency and quality control now and on delivering the repeatability and consistency that our commercial clients demand.

“From the moment we contacted them, the Emmegi team couldn’t have been more helpful. They have surpassed our expectations at every stage – not just in terms of the machine itself, but also the promptness and efficiency of their commissioning and service visits.

“In fact, we have been so impressed that we have also now purchased an Emmegi bead saw and crimper and various trolleys and ancillaries to add to the facilities here and continue our programme of ongoing investment. Moving forward, we plan to make Emmegi our machinery partner so that they can help us as we grow and ensure that our set-up suits our needs.

“We work hard to build strong partnerships with our suppliers because we recognise that they can make a huge difference to the quality of the service we can provide. We are currently planning on broadening our offering to include supply only framing solutions to installation companies in the UK, so those supplier partnerships will be more important than ever.”

Ian Latimer, Emmegi (UK)’s managing director who advised Cube on its investment, commented: “The Cube facility is already a great showcase for our products – absolutely immaculate and really well organised, and we’re very much looking forward to seeing how it develops in the future.”

Delivering the best

WINNER

Seamless Welding Technology

• Superior transom welding quality • Utilising patented

V-Perfect® transom welding • Precision accuracy – delivering a perfect weld every time • Weld seam elimination • No imperfections, even on curved profiles • Suitable for both V Joints and Butt Joints

• Faster fabrication

• Fully automated processes