14 minute read

FUEL CELLS FOR MINING

Everyelement which is important to sustaining life in the modern world – from a mobile phone to a refrigerator to a wedding ring – is made from minerals which are extracted from mining sites across the globe. In the coming years, as the world transitions from gas and diesel-powered equipment to power sources involving batteries and hydrogen, the need to mine minerals to support this technology will become even more critical.

It is also true that 1.5%to 2 % of carbon-dioxide (CO2) emissions worldwide are generated from the mining industry. In the face of these realities, an important question being raised is: considering the importance of mining to obtaining the minerals we need for all of the things we need, how do we go about mining in an innovative, sustainable way, without significant increases in production costs?

The answer to meeting this challenge may be in new technology being developed for heavy-duty equipment by L&M Radiators.

Electric motors which source energy from hydrogen fuel cells (often called a stack), as opposed to the traditional choice, diesel fuel, is making its way into the mining industry and leading the charge for increased sustainability and efficiency, safer operations, and the possibility of cost savings for mining operations across the globe. Hydrogen fuel cells operate by transforming hydrogen into clean energy, whose only output is electricity, water, and heat.

Though the environmental advantages of hydrogen fuel cell technology are clear, the use of fuel cells and batteries in heavy-duty mining equipment is so new that few companies are prepared to take on the challenge. But not L&M Radiator.

The Hibbing, Minnesota-based heat exchanger manufacturer has proven itself instrumental to the implementation of this new, green technology for the mining industry with its recent projects developing coolers for fuel cell-powered mining equipment.

“It’s an exciting time for greener applications in the oil and gas and mining industries,” said Tim Cass, L&M Radiator Applications Engineer for Truck and Underground. “L&M is ready and we are poised to be at the forefront of developing cooling solutions for our customers which provide the best green alternatives that not only help our planet but maintain and maximize our customers’ operating efficiencies - just as our customers have come to expect from L&M Radiator and our Mesabi-brand products for more than 60 years.”

Approximately 8,950 miles across the globe and just north of Pretoria and Johannesburg in South Africa, an open-pit platinum mine called Mogalakwena is making history with the testing of hydrogen fuel cell based equipment. L&M Radiator was called upon by the mine’s owner, AngloAmerican, to develop a first-of-its-kind radiator solution for a vehicle test project.

AngloAmerican operates a number of haul trucks at Mogalakwena. As a test to develop a long-term green energy solution for its mining operations worldwide, the company converted the diesel engine powertrain on a 930E into a powertrain driven by a hydrogen fuel cell stack.

“After the ‘proof of concept’ was finished in Seattle,” said Laura Ekholm, Executive Vice President of L&M Radiator, “AngloAmerican shipped the power train - eight hydrogen fuel cells, a battery pack and our cooling package - off to the mine in South Africa. It is amazing to see new technology our team was a huge part of coming to fruition.”

“The primary goal of this test was to determine if hydrogen will be able to provide the necessary power for the mine’s operation and to determine the overall efficiency of the hydrogen fuel conversion,” said Cass.

This singular converted 930E is only the beginning of what will become structural change for the industry at large. AngloAmerican intends to transform its entire fleet of converted 930Es at Mogalakwena (and at its other mines worldwide) into hydrogen fuel cell-powered electric equipment.

“The data from this successful test will be used to implement future applications for the Mogalakwena fleet as well as additional green initiatives for haul trucks and other mining equipment,” added Cass.

“For this initial 930E conversion, it was necessary to take the whole engine module out and replace it with fuel cells and batteries,” Cass explained. “Space constraints were definitely a challenge for our engineers. Designing the fans and motor mounts and getting the air flow to work in that limited space took some engineering ingenuity.”

“Another challenge was the very strict set of guidelines for limiting contamination, including materials that fuel cell manufacturers have in place,” added Josh Mitchell, an Applications Engineer with L&M Radiator. “That’s where the Mesabi All-Aluminum M-Tube came in.”

L&M Radiator engineered an All-Aluminum M-tube cooler for fuel cell cooling compatibility with the existing coolant on the 930E as brass and copper were not viable options.

According to Chris Domogalla, an L&M Design and Applications Engineer, hydrogen fuel cells operate at a lower maximum temperature than diesel engines, and they have a narrower coolant operating range. When outside of that operating range, the output of the fuel cell stack decreases.

In addition, approximately 40% of the energy produced by hydrogen fuel cells is heat, which must be removed. This posed a unique challenge for engineers at L&M Radiator. Hydrogen fuel cells emit a lot of heat, especially towards the end of their operating life.

ROBUST GENSET SOLUTIONS WITH THE NEW V-TYPE ALTERNATOR RANGE

Mecc Alte works hard with its clients to continually develop a high-level of insight into what challenges the power generator market faces with their generator sets and where/how they are operated.

The company’s latest heavy-duty alternator range ‘The V-Type”’meets a demand from the markets for a product that offers increased resilience for use in gensets where environment or operation affects performances and could reduce performance.

Through continually speaking with Original Equipment Manufacturers (OEMs) and end-users and gathering intelligence, Mecc Alte says it has been evolving its range with technical expertise and aftersales experience to bring you our most resilient product ever. The V-Type is built for optimum performance and reliability in tough environments. Having undergone rigorous testing, the V-Type is designed to operate in ‘harsh’ environments, so you can be sure of reliable power generation, regardless of the operational conditions.

Mecc Alte has incorporated several durability features to deliver maximum uptime for power requirements needed in severe environments:

•V-Type TOTAL+ is an exclusive winding treatment designed specifically to be more resilient, this insulation system upgrade further enhances the VPI impregnation which is standard on the range.

•Reinforced tape around the lower radius of the stator, plus an additional internal and external covering adds further durability to the NDE stator winding head

•Upgraded excitor stator, which are taped and given the VTP treatment

•30,000 premium bearing hours, for increased reliability

•Lower lamination slats reinforced with TOTAL+ insulation protection

•MxK digital regulators for safe setting/interrogation and offering integration to genset controllers

•Premium paint with anti-rust treatment

•Extended warranty

Mecc Alte UK’s Group Marketing Director, Jonathan Stokes, comments:

“Power generation has become much more about complete solutions rather than individual products, we’re now supplying OEMs with alternators, controllers, battery chargers and governors that are required for their power generation applications.

“The result is an integrated solution that very closely matches the unique demands of each and every power requirement. Understanding the full product lifecycle enables us to further evolve products from new perspectives.”

He concludes: “We pride ourselves on being the Power from Within the systems and generator sets that our customers produce; the V-Type is built for optimal uptime across the whole product lifecycle. Choose wisely … Choose the V-Type.”

Mecc Alte is a high-volume manufacturer producing in Italy, the UK, China, and India. The diverse range includes small 2-pole and large 4-pole alternators, as well as medium and high voltage machines, DC units, custom builds and multipole units, spanning 1 – 5000kVA.

Green Hydrogen Facility In Texas Helps Energy Network

ABB has been selected to join the Bair Energy Green Hydrogen and Technology Alliance to provide expertise on turnkey automation, electrification and digitalization solutions that support the optimization of low-cost green hydrogen production at the 1 GW Clear Fork Texas facility.

Phase one of the project will utilize renewable power to produce up to 33,000 kg of green hydrogen per day initially, with daily capacity designed to increase to 132,000 kg by 2028. The green hydrogen, which emits zero carbon when used as an energy source, will be liquefied on site, stored and transported to customers to help establish hydrogen networks in the mobility and transportation industry.

ABB Adaptive Execution™, a project methodology from design through to operations, will be employed.

Company Celebrates Its 30th Anniversary In Brazil

Market Enhancements At Home And Abroad For Thermal Management Corporation

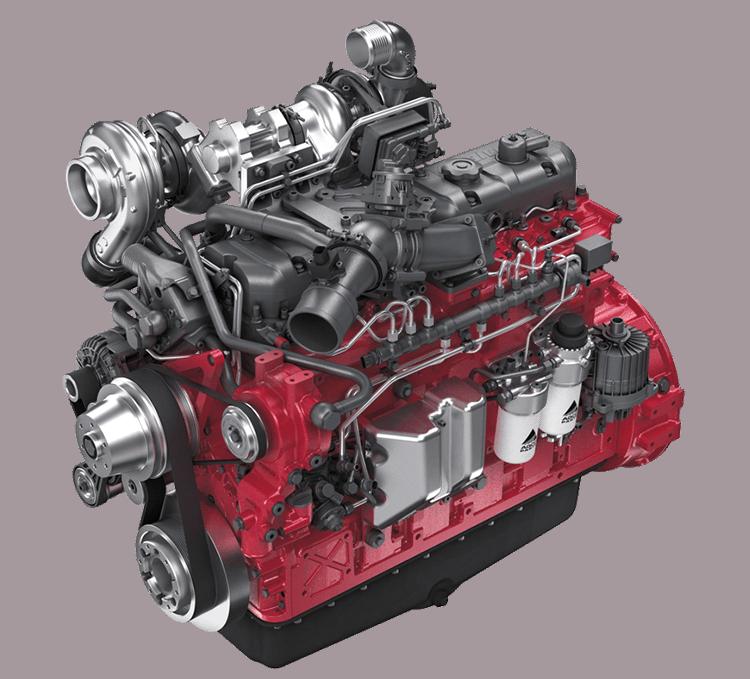

In 1993 AGCO Power expanded operations to Mogi das Cruzes, Brazil. and the company recently celebrated its 30th anniversary in Brazil and also the production of 300,000 engines at its factory in Mogi das Cruzes.

A spokesman comments: “This makes us even more proud and fills us with desire to produce another 300,000 engines. We certainly don’t need to wait another 30 years to reach this number, because considering the rapid growth of AGCO in the world, and consequently in Brazil, we will certainly reach the mark of 600,000 engines in little more than a decade – and we are getting ready for it.”

AGCO Power engines are recognized in the agricultural market for their fuel economy, superior performance, easy maintenance and quick access to spare parts due to its strong network of dealerships throughout Brazil and South America. Its after-sales team is always attentive and close to its customer base to provide fast technical support and assistance to farmers, reports the company.

The spokesman continues: “AGCO Power is investing heavily in technology and bringing the best in terms of machinery and equipment to its factory in Mogi das Cruzes. This ensures that the products we manufacture are high quality, robust and reliable. The same applies to our engine plant in General Rodriguez, Argentina. In addition to implementing new technologies, these investments will allow us to increase our volume of machined parts and engine production.”

AGCO Power has been manufacturing diesel generators since 1952. It has been in business for decades with applications for hospitals, industry, data centers, military and agricultural customers to name a few. This expertise and know-how means the company is able to manage even complex projects according to customer requirements.

AGCO Power’s product program features a power range from 60 to 2400 kVA consists of the AGseries up to 250 kVA PRP with our own AGCO Power engines and AG-series above that with 3rd party engines. When used as a stand-by power system, the automatic generating sets start providing electricity in less than 10 seconds from power grid failure and stop automatically once the electricity in the main grid is reliable again. Generating sets are typically used for prime power generation in locations where the main grid is not available. In a remote location, generating sets may even be a more cost-effective solution than a power grid connection, reports AGCO Power.

US$100 MILLION SERIES INVESTMENT ROUND FOR ENERGY STORAGE

FlexGen Power Systems, Inc. a leading integration services and software technology provider for energy storage solutions in the U.S. and globally, has announced the close of a $100 million Series C Investment round.

The investment is anchored by Vitol, the largest independent energy trading company globally, in partnership with existing investors. This latest investment further solidifies FlexGen as a leader in energy storage integration, and will support the execution of its large pipeline of projects across multiple regions.

“We are excited to have Vitol join our existing investors to help power our continued growth. It is clearer than ever that the future of energy relies on energy storage that is cost-effective, safe, and easy to manage. This latest round of investment expands the advantaged position that FlexGen has with our customers across the utility, IPP, and co-op markets,” said Kelcy Pegler, CEO of FlexGen. “We are laser-focused on delivering the industry’s best software and integration services to our valued clients.”

In late 2022 Hotstart acquired GEO-THERMAL SYSTEMS, INC. (GTS) - and the acquisition brought high efficiency heating systems using proven heat pump technology to maintain standby generators installed in the Americas.

The company acquisition further enhances Hotstart’s thermal management product portfolio. The heating systems provide up to 75% energy savings while adding a level of backup redundancy with the existing engine heaters which are often Hotstart systems.

GTS was founded in 1991 by Jim Whittlesey, a former Caterpillar employee, who saw an opportunity to improve the traditional engine heating process for standby generators. By adding a modified air-source heat pump to the existing block heater installation, a more energy efficient solution was possible. GTS supplied this solution to customers during 30 years of operation.

Thousands of heating systems have been installed on generators in facilities including commercial, industrial, government, military, universities, airports, hospitals, and data centers, saving end users significant energy and money.

Patrick Whittlesey, former GTS VP of Operations, joins Hotstart as Market Manager – High Efficiency Generator Heating - Americas. Patrick is responsible for sales of heating systems throughout North, Central, and South America. Jim Whittlesey serves as advisor to Hotstart in a consultant role.

“I’m was excited to have the GTS team join Hotstart,” said Terry Judge, CEO of Hotstart. “Their generator experience and strong customer relationships aligns well with our 80 years of engine heating expertise. We are already providing this technology to customers that seek energy savings and lower carbon footprints.”

“We have been thrilled to be part of the Hotstart team,” said Patrick Whittlesey. “Over the years, we’ve seen Hotstart products on numerous emergency generators in the field. It’s apparent they are the leader in the industry, which made joining them an easy decision to make.

“The GTS product line is now be offered as Hotstart High Efficiency (HE) Heating Systems. “

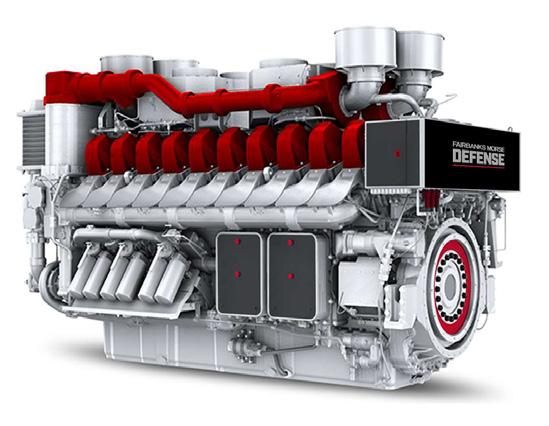

NFORCER ENGINE TESTED FOR AN ‘ALL-ELECTRIC SHIP’

Fairbanks Morse Defense (FMD), a portfolio company of Arcline Investment Management, has been contracted to provide and test one nForcer high-speed engine to qualify for the US Navy’s large unmanned surface vessel (LUSV) platform.

To qualify, the engine must perform for a minimum of 720 hours in a land-based test environment without human intervention. Testing on the new engine has already begun.

“The LUSV platform has unprecedented power and propulsion requirements, which means that the Navy needs a powerdense engine with a reliable track record,” said FMD CEO George Whittier. “While the nForcer is the most power-dense, high-speed engine on the market, this award will drive incremental design improvements to support extended unmanned operations in a marine environment. It’s an extraordinary example of the numerous technological solutions offered by FMD that align with the distinctive needs of the LUSV program.”

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh marine environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime, so you can be sure of reliable power generation, regardless of the operational conditions and compliant with all marine classifications. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

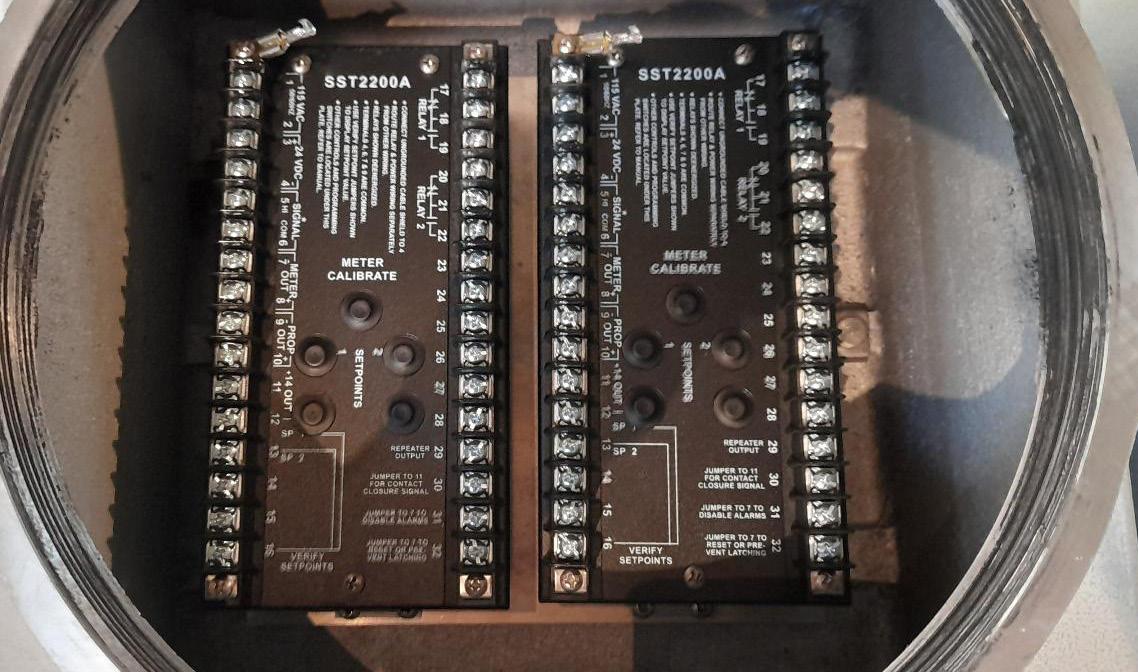

Precision Controls Ltd (PCL) announces a newly formed subsidiary, PCL USA, in Henderson, Nevada, US. Company Director, Kurlin Wilson, notes: ’’ This expansion is an important step for PCL to offer our line of Ex-d hazardous area RPM display and Alarm systems to USA customers. We will now be able to offer the same services and quality systems to customers with the additional options for shipping and delivery convenience and cost savings of not requiring import from PCL in the UK.’’

PCL has an established 30 years’ experience in the distribution of quality products in the engine/ generator control and accessory markets in the UK and Europe including products from such stalwart suppliers as Dynaclo, TDI, Woodward and Basler.

This new presence in the United States was the next logical step in ensuring the consistent and efficient service customers around the globe have come to know and expect after three decades in business.

PCL has brought quality components together for control systems for diesel and gas engines in the Industrial power generation industry. Applications in the industrial engine market include accessory products as magnetic pickup sensors and speed switches (overspeed/crank disconnect switches).

Microprocessor speed switches are now available for Engine / Generator Set Manufacturers that allow ‘base’ units held in inventory and to be calibrated easily with a software file for any engine model and generator set in production.

Specially designed EX-d magnetic pickups are supplied in the oil and hazardous area pipeline systems including off shore oil rigs, oilfield pumps and gas compressor stations. Application engineering for air starters applications in the marine industry along with parts and full service/overhaul support of air starters has been a mainstay of PCL.

System design and drawing services are provided in support of customer special applications or modifications of PCL products. Quotations are provided in accordance with a customer’s application outlining the best and most cost effective solutions considering the option of local delivery in either the US or UK.

PCL USA utilizes the decades of PCL experience to provide customer application assistance and products in the US markets.

PCL USA can offer customized Ex-d systems like the Dual Turbocharger RPM display and Alarm system which utilizes high quality Dynalco components. The central control system has two remote RPM displays that are conveniently mounted for easy RPM reference by the operating engineer. Customized solutions for hazardous area assemblies are supplied to either ATEX, IECEx, UL or c/UL certification.

Along with the Ex-d systems, PCL USA offers the established range of Goetze valves, including the Goetze 812 Safety Valve as an option for the no longer manufactured Honeywell S245 Safety Valve. Additionally, OEM low cost, high quality magnetic pickup sensors and engine thermocouples can be supplied to customer specifications.

All OEM products are offered with quantity pricing and scheduled deliveries to best economically optimize OEM costs and on time production.

313.34 MWH BATTERY STORAGE SYSTEM DEPLOYED

Ameresco has signed a deal with United Power for a multiple site, 78.3 MW, 313.34 MWh battery storage system to be deployed in three Colorado counties.

The deal includes a 20-year agreement between Ameresco and United Power. Locating battery arrays across United Power’s service territory is expected to help the cooperative balance its load and integrate renewable resources into its operations.

Ameresco is expected to provide four 11.75 MW and four 7.84 MW battery arrays across eight different substation sites owned by United Power in Adams, Broomfield, and Weld counties, north and northeast of Denver.

In June 2023 , a joint venture between Atura Power, a unit of Ontario Power Venture, and Ameresco was selected to build a 250 MW / 1,000 MWh battery energy storage system (BESS) by the Independent Electricity System Operator (IESO) in Canada.

Under terms of that award, the JV was expected to enter into a 20-year capacity agreement with the IESO.

Ameresco is a 10.1% minority partner in the JV and will provide engineering and construction services under a separate contract.

Ameresco, Inc. is a leading cleantech integrator and renewable energy asset developer & operator.

The company’s comprehensive portfolio includes energy efficiency, infrastructure upgrades, asset sustainability and renewable energy solutions delivered to clients throughout North America and Europe.

A company spokesman commented: “Our solutions range from upgrades to facility’s energy infrastructure to the development, construction and operation of renewable energy plants combined with tailored financial solutions.

“We work with customers on both sides of the meter to reduce operating expenses, upgrade and maintain facilities, stabilize energy costs, improve occupancy comfort levels, increase energy reliability and enhance the environment.”

Today, Ameresco leverages budget neutral solutions - including energy savings performance contracts (ESPCs), power purchase agreements (PPAs) and off-balance sheet Energy as a Service (EaaS) contracts. It seeks to eliminate the financial barriers which traditionally hamper energy efficiency and renewable energy projects.

Ameresco has successfully

SILENT AND ANTI-HURRICANE GENERATOR SETS FOR HOSPITAL

Providing emergency backup power to hospitals is one of Genesal Energy’s key achievements in both international and domestic projects such as the refurbishment of the 12 de Octubre Hospital in Madrid.

On the international market, one of Genesal’s latest projects has taken it to the island of Trinidad and Tobago where they have reinforced the safety of a hospital complex.

Two 1.500 kVA generators capable of overcoming power failures in just seconds.

Genesal has supervised the design, manufacturing, commissioning and maintenance of the GEN1500TC gensets which work effectively in a fail-safe environment. Two 1500 kVA gensets with a low noise level soundmitigation features have already been installed in a hospital complex. Besides, Trinidad and Tobago, represented a greater challenge for their engineering department as it is a Caribbean hurricane zone where power cuts occur annually.

The two 1.500 kVA generator sets are rugged, powerful and welladapted to withstand severe adverse weather conditions. Furthermore, the generator sets were fitted with - 40 decibel baffles to ensure a low noise level.