3 minute read

WB Looks Back

by WorkBoat

LOOKS BACK

FEBRUARY 1961

• Built at a cost of approximately $1.5 million, the new 6,630-hp Austin S. Cargill, described as the third most powerful river towboat in the world, was christened at St. Louis recently and immediately placed in service. Built to comply fully with all ABS requirements, the 182'×55'×12' Cargill, whose three 108", 4-bladed propellers are driven by a trio of 2,210-hp Cooper-Bessemer direct-recersing marine diesels, cooled by clear water circulated through a St. Louis Ship-designed skin cooling system. • A West Coast tug went back to work for her owner, General Construction of Portland and Seattle, after undergoing an unusual alteration performed by L.S. Baier and Associates. Raised after Ruby VIII capsized with

FEBRUARY 1971 the loss of two lives, Baier designed and installed sponsons carrying from the turn of the bilge to the main deck, thus adding 2' to its original beam and signifi cantly increasing the boat's stability.

• The Fremont Tugboat Co., Seattle, has rebuilt and refurbished its 20' harbor tug Spanner, changing everything from the fenders to the deckhouse to the name, which prior to the rebuilding was the Stubby. The Spanner can top seven knots with its Gray Marinesupplied 60-hp gasoline engine. The reduction gears are Paragon — as is

• A new 32' sightseeing boat, Bonanza, will become part of the scenery in Alcapulco, Mexico. Designed and built at Blount Marine in Warren, R.I., for Yates Bonanza de Turismo S.A., the boat is powered by two Detroit Diesel 16-V 71 rated diesel engines and made 12 knots during sea trials. The vessel can carry up to 750 passengers. • Gulf Northern Company Inc.’s barge fl eet has FEBRUARY 1981 been

the clutch — and the steering controls are Marol. • Halter Marine Inc., New Orleans, has delivered the OSV Tara Alyene to Briley Marine, Lafayette, La. The new 180'×38' boat has a 14' draft. It can carry up to 3,600 cu. ft. of drilling mud in her four bulk mud tanks and 1,700 bbls. of liquid mud in four other tanks. augmented by a 195'×35'×12' semiintegrated, single-skin tank barge built at Hillman Barge and Construction Co.’s Brownsville, Pa., shipyard. The new tank barge is named FTS 26.

Engineering Cooling Systems with Superior Craftsmanship and Technology.

Trust Duramax Marine® Heat Exchanger Solutions.

If you’re building a new vessel, repowering, or repairing a damaged heat exchanger system, you can trust Duramax Marine® to guide you every step of the way.

Duramax® cooling experts have the knowledge, experience and the latest in efficient cooling solutions. We will recommend and engineer the perfect, efficient long-lasting cooling system for your vessel.

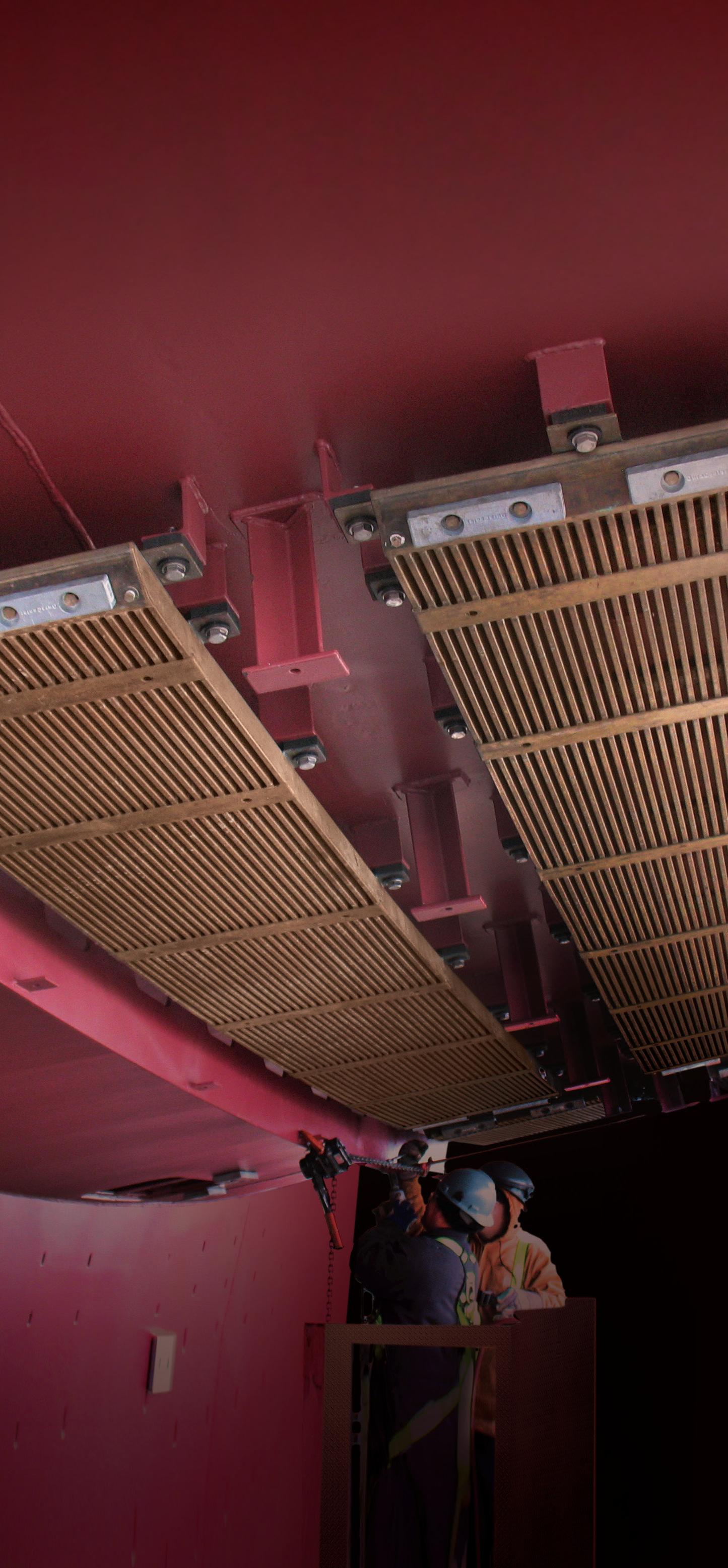

DuraCooler® Keel Cooler

One piece 90/10 copper-nickel One piece 90/10 copper-nickel streamlined header design for streamlined header design for improved efficiency. improved efficiency.

DuraCooler® SuprStak™ System

Custom stacked design Custom stacked design DuraCooler® doubles heat DuraCooler efficiency in half the hull space.

Duramax® Demountable Keel Cooler

Expandable copper-nickel spiral tube system for steel hull vessels.

Duramax® BoxCooler

In-hull protection from damage, design flexibility, and large cooling capacity, with anti-fouling prevention systems.

www.DuramaxMarine.com

Duramax Marine® is an ISO 9001:2015 Certified Company