18 minute read

Freeport McMoRan: Foremost in Copper

Freeport McMoRan

Foremost in Copper

Advertisement

A leading international mining company with assets including the Grasberg minerals district in Indonesia, and significant mining operations in North and South America, Freeport McMoRan is proud of its commitment to responsible production, as witnessed by the award of the Copper Mark at three of its sites

Headquartered in Phoenix, Arizona, Freeport-McMoRan Inc (FCX) is one of the world’s largest publicly traded copper producers.

The Freeport connection derives from a company founded in 1912 in the city of Freeport, Texas, to mine sulphur, while the McMoRan element comes from McMoRan Exploration, an independent oil and gas exploration and production company in South Louisiana formed in 1969 by Ken McWilliams (‘Mc’), Jim Bob Moffett (‘Mo’) and Mack Rankin (‘Ran’).

After a series of mergers, spin-offs, acquisitions and changes of direction, the company has grown to be a leading international mining company, with a portfolio of assets that includes the Grasberg minerals district in Indonesia, one of the world’s largest copper and gold deposits, and significant mining operations in North and South America, including the large-scale Morenci minerals district in Arizona and the Cerro Verde operation in Peru.

It was the discovery of the Grasberg copper and gold deposit in Papua, Indonesia, that led to the creation of Freeport-McMoRan Copper Company in 1988, and subsequently to Freeport McMoRan Inc, which we know today. The acquisition of Phelps Dodge in 2007 transformed Freeport McMoRan into a dynamic industry leader, combining the assets and technical teams of two great companies into a unique portfolio of mining assets developed and acquired by several predecessor companies, including Freeport Minerals, Cyprus Minerals, American Metal Company (AMAX), and Climax Molybdenum, among others. In December last year, FreeportMcMoRan announced that the Copper Mark had been awarded to three of its sites: the Cerro Verde mine in Peru, the El Abra mine in Chile and the Atlantic Copper smelter and refinery in Spain. The Copper Mark is a new, comprehensive assurance framework that promotes responsible production practices and demonstrates the industry’s contribution to the United Nations Sustainable Development Goals.

NORTH AMERICAN OPERATIONS

In North America, FCX operates seven open-pit copper mines — Morenci, Bagdad, Safford, Sierrita and Miami in Arizona, and Chino and Tyrone in New Mexico; and two molybdenum mines — Henderson and Climax in Colorado. Molybdenum concentrate, gold and silver are also produced by some of FCX’s North American copper mines. All are 100 per cent owned, with the exception of Morenci, in which the company has a 72 per cent share.

Morenci

Located in Greenlee County, Arizona, Morenci came to the Freeport McMoRan portfolio with the Phelps Dodge acquisition. An open-pit copper mining complex in continuous operation since 1939, it was previously mined through underground workings. The Morenci mill expansion project expanded mill capacity from 50,000 metric tons of ore per day to approximately 115,000 metric tons of ore per day, which results in incremental annual production of approximately 225 million pounds of copper and an improvement in Morenci’s cost structure. The Morenci mine is a porphyry copper deposit that has oxide, secondary sulphide mineralization, and primary sulphide mineralization. The predominant oxide copper mineral is chrysocolla. Chalcocite is the most important secondary copper sulphide mineral and chalcopyrite the dominant primary copper sulphide. The operation consists of two

concentrators capable of milling 115,000 metric tons of ore per day (mtd), which produce copper and molybdenum concentrate; a 68,000 mtd, crushedore leach pad and stacking system; a low-grade run-of-mine (ROM) leaching system; four SX (solution extraction) plants; and three EW (electrowinning) tank houses that produce copper cathode. Total EW tank house capacity is approximately 900 million pounds of copper per year. Morenci’s available mining fleet consists of one hundred and twenty-six haul trucks loaded by 13 shovels with bucket sizes ranging from 47 to 57 cubic meters, which are capable of moving an average of 815,000 metric tons of material per day.

Bagdad

Bagdad is an open-pit copper and molybdenum mining complex, home to the world’s first commercial scale concentrate leach processing facility and one of the longest continuously operating solution extraction/ electrowinning (SX/EW) plants in the world. An unincorporated community, Bagdad is one of two FCX ‘company towns’, the other being Morenci. The Bagdad mine is a porphyry copper deposit containing both sulphide and oxide mineralization. Chalcopyrite and molybdenite are the dominant primary sulphides and are the primary economic minerals in the mine. Chalcocite is the most common secondary copper sulphide mineral and the predominant oxide copper minerals are chrysocolla, malachite and azurite. The Bagdad operation consists of a 75,000 metric ton-per-day concentrator that produces copper and molybdenum concentrate, an SX/EW plant that can produce up to 32 million pounds per year of copper cathode from solution generated by low-grade stockpile leaching, and a pressure-leach plant to process molybdenum concentrate. The first claims were staked as far back as 1882 and property changed ownership many times through the first half of the 20th century. The first mill began operation in 1928 to process ore from the underground mine and the transition to open-pit mining began in 1945. A $240 million expansion in 1973 included new haul trucks, shovels, nearly 400 housing units and a concentrator.

Sierrita

Located 20 miles southwest of Tucson, Arizona, Sierrita is an open-pit copper and molybdenum mining complex. In addition to copper and molybdenum, the mine produces rhenium, a rare and highly valued metal. The Sierrita mine is another porphyry copper deposit with oxide and secondary sulphide mineralization, and primary sulphide mineralization. The predominant oxide copper minerals are malachite, azurite and chrysocolla. Chalcocite is the most important secondary copper sulphide mineral, and chalcopyrite and molybdenite are the dominant primary sulphides. The Sierrita operation includes a 100,000 metric ton-per-day concentrator that produces copper and molybdenum concentrate, along with copper from an ROM oxide-leaching system. Cathode copper is plated at the Twin Buttes EW facility, which has a design capacity of approximately 50 million pounds of copper per year. It also has molybdenum facilities consisting of a leaching circuit, two molybdenum roasters and a packaging facility. The molybdenum facilities process molybdenum concentrate produced by Sierrita, from Freeport McMoRan’s other mines and from third-party sources. Another mine with a long history, the first claims were recorded in 1895 and Sierrita was first worked as an

For more than four decades, our professionals have supported the mining community with permitting, environmental compliance, remediation, reclamation, due diligence, and title work at hundreds of mines and mineral processing sites in 39 states and in several Native American nations.

We excel at our business because we take the time to understand yours

Phoenix | Santa Fe 602-530-8000 www.gknet.com

underground mine in 1907. Open-pit development began in 1957. In 2009, FCX purchased the Twin Buttes copper mine, which had ceased operations in 1994 but is adjacent to the Sierrita mine. The purchase provides significant synergies in the Sierrita minerals district, including the potential for expanded mining activities and access to material that can be used for Sierrita tailings and stockpile reclamation purposes.

Miami

Ninety miles east of Phoenix, in the heart of Arizona’s historic Globe-Miami mining district, lies Miami, comprising an open-pit copper mine, a smelter and a rod mill. Miami is another porphyry copper deposit that has leachable oxide and secondary sulphide mineralization. The predominant oxide copper minerals are chrysocolla, copper-bearing clays, malachite and azurite. Chalcocite and covellite are the most important secondary copper sulphide minerals. Miami is no longer mining ore, but currently produces copper through leaching material already placed on stockpiles, which is expected to continue until 2023. The first prospecting typically produced by high technology industries, extending the useful life of valuable metals and reducing disposal of metal-bearing waste in landfills. Copper and other precious metals are extracted during this process.

expeditions visited the area in the 1860s. Copper was mined underground until after World War II, when the first openpit mining began. Miami was among the first to employ ‘vat leaching’ (in 1926) and precipitation plants to recover oxide minerals. It did this in conjunction with its flotation concentrator, which processed sulphide minerals. The plant’s smelter was modernized in 1974 to meet Clean Air Act standards and further modernized and expanded in 1992. The success of an SX/EW plant commissioned in 1979 led to the demise of vat leaching by the mid1980s and ultimately the concentrator in 1986. The Miami smelter processes copper concentrate primarily from FCX’s Arizona copper mines. In addition, because sulphuric acid is a by-product of smelting concentrates, the Miami smelter is also the most significant source of sulphuric acid for FCX’s North America leaching operations. Miami is the only smelter in the United States to achieve International Organization for Standardization (ISO) 9001:2000 certification. In addition to copper concentrates, the smelter also recycles inorganic metal-bearing waste

Safford

The Safford open-pit copper mine in Arizona has been in operation since 2007, with full production beginning in 2008. As a zero-discharge facility, Safford is one of the most environmentally advanced copper mines ever built. The Safford mine includes two copper deposits that have oxide mineralization overlaying primary copper sulphide mineralization. The predominant oxide copper minerals are chrysocolla and copper-bearing iron oxides with the predominant copper sulphide material being chalcopyrite. The property is a mine-for-leach project and produces copper cathode. The operation consists of two open pits feeding a crushing facility with a capacity of 103,000 metric tons per day. The crushed ore is delivered to leach pads by a series of overland and portable conveyors. Leach solutions feed an

SX/EW facility with a capacity of 240 million pounds of copper per year. A sulphur burner plant is also in operation at Safford, providing a cost-effective source of sulphuric acid used in SX/EW operations.

Chino

The historic Chino copper mine was among the first low-grade, open-pit copper mines in the world, located in Grant County, New Mexico, 15 miles east of the historic mining community of Silver City. Originally mined by Native Americans and later by the Spanish, the open-pit mine began production in 1910. The original concentrator went into operation in 1911, but was replaced by a new facility in 1982. A smelter was commissioned in 1939 and was modernized in 1985 to increase capacity and achieve compliance with the Clean Air Act. In 2005, the smelter was permanently closed. In April 2020, operations at Chino were suspended to address COVID-19 concerns. A review of options for restarting Chino was completed in the second half of 2020. In January 2021, FCX restarted mining activities at a reduced rate of approximately 100 million pounds of copper per year. The Chino mine is a porphyry copper deposit with adjacent copper skarn deposits. There is leachable oxide, secondary sulphide and millable primary sulphide mineralization. The predominant oxide copper mineral is chrysocolla. Chalcocite is the most important secondary copper sulphide mineral, and chalcopyrite and molybdenite the dominant primary sulphides. The operation consists of a 36,000 metric ton-per-day concentrator that produces copper and molybdenum concentrate, and a 150 million poundper-year SX/EW plant that produces copper cathode from solution generated by ROM leaching.

Tyrone

Situated in Grant County New Mexico, the Tyrone mine has been in operation since 1967. Also a porphyry copper deposit, mineralization is predominantly secondary sulphide consisting of chalcocite with leachable oxide mineralization consisting of chrysocolla. Tyrone’s copper processing facilities consist of a solution extraction/ electrowinning (SX/EW) operation with a maximum capacity of approximately 100 million pounds of copper per year. Prior to 1860, Native Americans mined turquoise at the site. Phelps Dodge Corporation acquired mining claims in the area from 1909 to 1916 and began concentrating ore produced from largescale underground mining in 1916. Operations ended in 1921, then in 1967 the property returned to operation as an open pit, with copper production from a concentrator.

Henderson

Approximately 42 miles west of Denver, Colorado, Henderson is an underground molybdenum mining operation. The Henderson mill site is located 15 miles west of the mine. The mine and the mill are connected by the world’s largest conveyor of its kind: a 10-mile conveyor tunnel under the Continental Divide and an additional five-mile surface conveyor. In operation since 1976, the Henderson operation consists of a large block-cave underground mining complex feeding a concentrator with a current capacity of approximately 32,000 metric tons per day. Henderson has the capacity to produce approximately 35 million pounds of molybdenum per year, but in response to market conditions, it has operated at reduced rates since 2015.

Climax

Climax is an open-pit molybdenum mining operation approximately 13 miles northeast of Leadville, Colorado. Freeport McMoRan operates both the Climax and Henderson molybdenum mines in a flexible manner to meet market requirements. The Climax mine is a porphyry molybdenum deposit with molybdenite as the primary sulphide mineral. The Climax mine was commissioned in mid-2012 and includes a 25,000 metric ton-per-day mill facility. Climax has the capacity to produce approximately 30 million pounds of molybdenum per year.

SOUTH AMERICAN OPERATIONS:

FCX’s South American mining operations include open-pit mining, sulphide ore concentrating, leaching and solution extraction/electrowinning. Production from these mines is sold as concentrate or cathode under long-term contracts. The South America mines also ship a portion of their copper concentrate to Atlantic Copper, the company’s wholly owned smelting and refining unit in Spain. FCX operates two copper mines in South America - Cerro Verde in Peru and El Abra in Chile. In addition to copper, the Cerro Verde mine also produces molybdenum concentrate and silver.

Cerro Verde

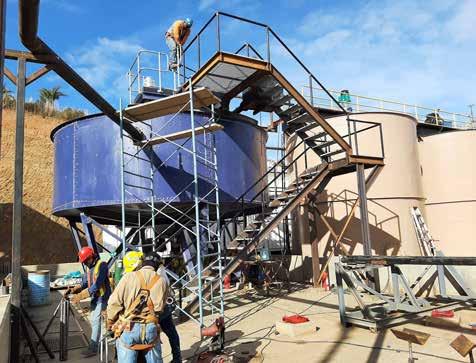

Construction activities associated with a large-scale expansion at Cerro Verde were completed in September 2015. The project expanded the concentrator facilities from 120,000 metric tonsper-day (mtd) to 360,000 mtd and provides incremental annual production of approximately 600 million pounds of copper and 15 million pounds of molybdenum. Cerro Verde’s operations benefit from its large-scale, long-lived reserves and cost efficiencies. During 2018, Cerro Verde received a modified environmental permit allowing it to operate its existing concentrator facilities at rates up to 409,500 metric tons of ore per day. The Cerro Verde mine is a porphyry copper deposit that has oxide and secondary sulphide mineralization, and primary sulphide mineralization. The predominant oxide copper minerals are brochanite, chrysocolla, malachite and copper ‘pitch’. Chalcocite and covellite are the most important secondary copper sulphide minerals. Chalcopyrite and molybdenite are the dominant primary sulphides. Leach copper production is derived from a 39,000 metric ton-per-day crushed leach facility and a 100,000 metric ton-per-day ROM leach system. This SX/EW leaching operation has a capacity of approximately 200 million pounds of copper per year. Ownership of Cerro Verde is shared by FCX (53.56%), SMM Cerro Verde Netherlands BV, a subsidiary of Sumitomo Metal Mining Company Ltd (21%), Compañia de Minas Buenaventura SAA (19.58%) and 5.86% by other shareholders.

El Abra

El Abra is located 47 miles north of Calama, in Chile’s El Loa province, Region II. An open pit copper mining complex, mining operations began in 1996. The El Abra operation includes a solution extraction/electrowinning facility with a capacity of 500 million pounds of copper cathode per year, a 125,000 metric ton-per-day crushed leach circuit and a similar-sized run-ofmine leaching operation.

FCX continues to evaluate a largescale expansion at El Abra to process additional sulphide material and to achieve higher recoveries. El Abra’s large sulphide resource could potentially support a major mill project similar to facilities constructed at Cerro Verde. Technical and economic studies continue to be advanced to determine the optimal scope and timing of the project in parallel with extending the life of the current leaching operation.

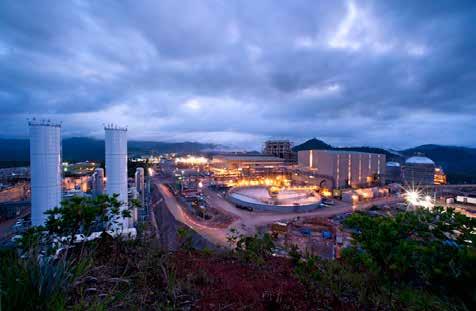

INDONESIAN OPERATIONS

Grasberg

Located in the remote highlands of the Sudirman Mountain Range in the province of Papua, Indonesia, on the western half of the island of New Guinea, the Grasberg minerals district includes open-pit and underground mines. Its history dates back to 1972, when PT Freeport Indonesia (PTFI) commenced mining operations, followed in 1988 by the discovery of the Grasberg mine. Today, after significant production, the Grasberg mining district contains one of the world’s largest recoverable copper reserves and the largest gold reserve. PT-FI is owned 48.8% by FreeportMcMoRan and 51.2% by PT Indonesia Asahan Aluminum, a state-owned enterprise wholly owned by the Indonesian government. The Grasberg minerals district has three operating mines, the Grasberg open pit, the Deep Ore Zone underground mine and the Big Gossan underground mine. In September 2015, PT-FI initiated pre-commercial production, which represents ore extracted during the development phase for the purpose of obtaining access to the ore body, at the Deep Mill Level Zone underground mine. PT-FI also has several projects in progress in the Grasberg minerals district related to the development of the large-scale, long-lived, high-grade underground ore bodies located beneath and nearby the Grasberg open pit. PT-FI began open-pit mining of the Grasberg ore body in 1990 but has now transitioned to the Grasberg Block Cave underground mine. The Deep Ore Zone (DOZ) ore body lies vertically below the now depleted Intermediate Ore Zone. PT-FI began production from the DOZ ore body in 1989 using open-stope mining methods, but suspended production in 1991 in favour of production from the Grasberg open pit. Production resumed in September 2000 using the block-cave method. The DOZ is a mature blockcave mine that previously operated at 80,000 metric tons of ore per day. Current operating rates from the DOZ underground mine are driven by the value of the incremental DOZ ore grade compared to the ore from the Grasberg open pit and ore grade material from the development of the DMLZ and Grasberg Block Cave underground mines. The DMLZ ore body lies below the DOZ underground mine at the 2,590-metre elevation and represents the downward continuation of mineralization in the Ertsberg East Skarn system and neighbouring Ertsberg porphyry. During third quarter 2018, PT-FI commenced hydraulic fracturing activities to manage rock stresses and pre-condition the DMLZ underground mine for large-scale production following seismic activity experienced in 2017 and 2018. Production at the DMLZ underground mine is expected to continue through 2041. To mitigate the impact of seismic events, PT-FI implemented a revised mine sequence; upgraded support systems, blasting and re-entry protocols; and improved mine monitoring and analysis processes. Development activities and mining are taking place in unaffected areas while impacted areas are being assessed, rehabilitated and prepared to be placed back into use. Targeted production rates once the DMLZ underground mine reaches full capacity are expected to approximate 80,000 metric tons of ore per day in 2021. Production at the DMLZ underground mine is expected to continue through 2041.

Big Gossan

The Big Gossan underground mine was on care-and-maintenance status during most of 2017 and production restarted in fourth-quarter 2017. The mine lies underground, adjacent to the current mill site. It is a tabular, near vertical ore body. The mine utilizes a blasthole stoping method with delayed paste backfill. Stopes of varying sizes are mined and the ore dropped down passes to a truck haulage level. Trucks are chute loaded and transport the ore to a jaw crusher. The crushed ore is then hoisted vertically via a two-skip production shaft to a level where it is loaded onto a conveyor belt. The belt carries the ore to one of the main underground conveyors where the ore is transferred and conveyed to the surface stockpiles for processing.

Outlook

Reporting strong financial results and cash flow generation in its secondquarter and six-month 2021 results for the period to 30 June 2021, Freeport McMoRan said that the ramp-up of the Grasberg underground mines was advancing on schedule. Production approximated 78 per cent of the projected ultimate annualized level and is expected to reach 100 per cent by year-end 2021. During second-quarter 2021, milling rates at Cerro Verde’s concentrator facilities were slightly above forecast and averaged 374,100 metric tons of ore per day. Cerro Verde expects milling rates to return to pre-COVID-19 pandemic levels of approximately 400,000 metric tons of ore per day in 2022. The company successfully completed the initial development of the Lone Star copper leach project in Arizona in the second half of 2020 and achieved design capacity approximating 200 million pounds annually. FCX continues to advance opportunities to increase Lone Star operating rates and is evaluating a potential additional incremental oxide expansion to increase volumes to over 300 million pounds of copper per year. The oxide project advances the opportunity for development of the large-scale sulphide resources at Lone Star. “Our global team continues to execute our operating plans safely, efficiently and responsibly, providing strong cash flows and a solid foundation for future profitability and growth,” said Richard C Adkerson, Chairman and Chief Executive Officer. “During the first half of 2021, we reduced our net debt by $2.7 billion and achieved our targeted net debt level, positioning us for increasing cash returns to shareholders and investments in future growth in accordance with our financial policy. As a leading responsible producer of copper, we are optimistic about the prospects for our business and our role in supporting a growing global economy and the transition to clean energy. We remain focused on building value for all stakeholders through solid management of our long-lived and high-quality portfolio of copper assets.”