A Supplement to Design World theautomatedwarehouse.com MAY 2024 5G reliability enters the automated warehouse .........................................................................46 NFI’s drone deployment takes flight ................................................................................................ 52 Page 46 Inside: 5G reliability enters the automated warehouse

wandering the warehouse and possibly colliding or injuring someone.

comparison, the 4G network operates only in lower frequency ranges. The

www.designworldonline.com 46 DESIGN WORLD May 2024

benefit of 5G’s multiband operation is lower latency and higher speeds — up to 10 to 20 times faster than 4G — which makes it perfect for the data-intensive automated warehouse.

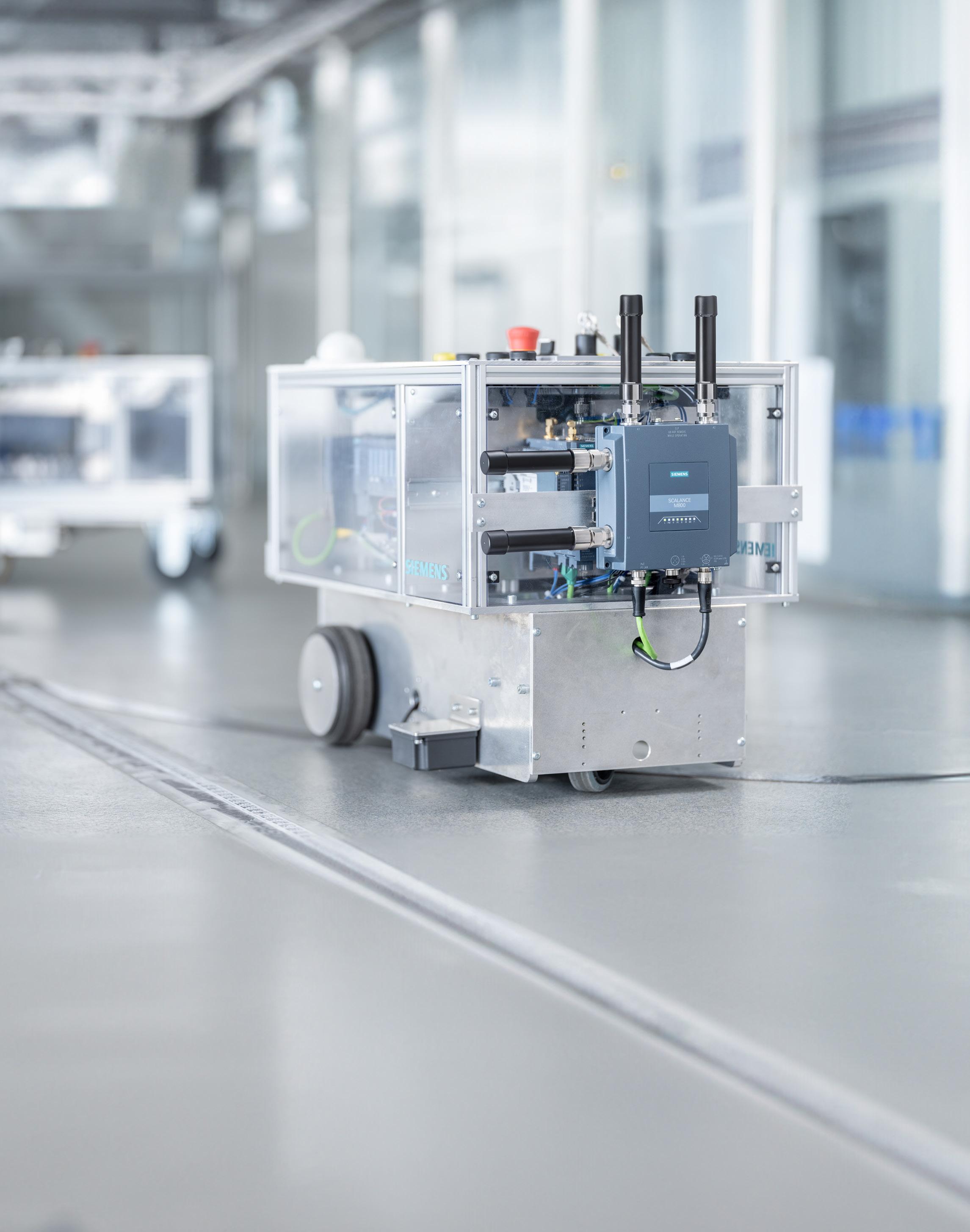

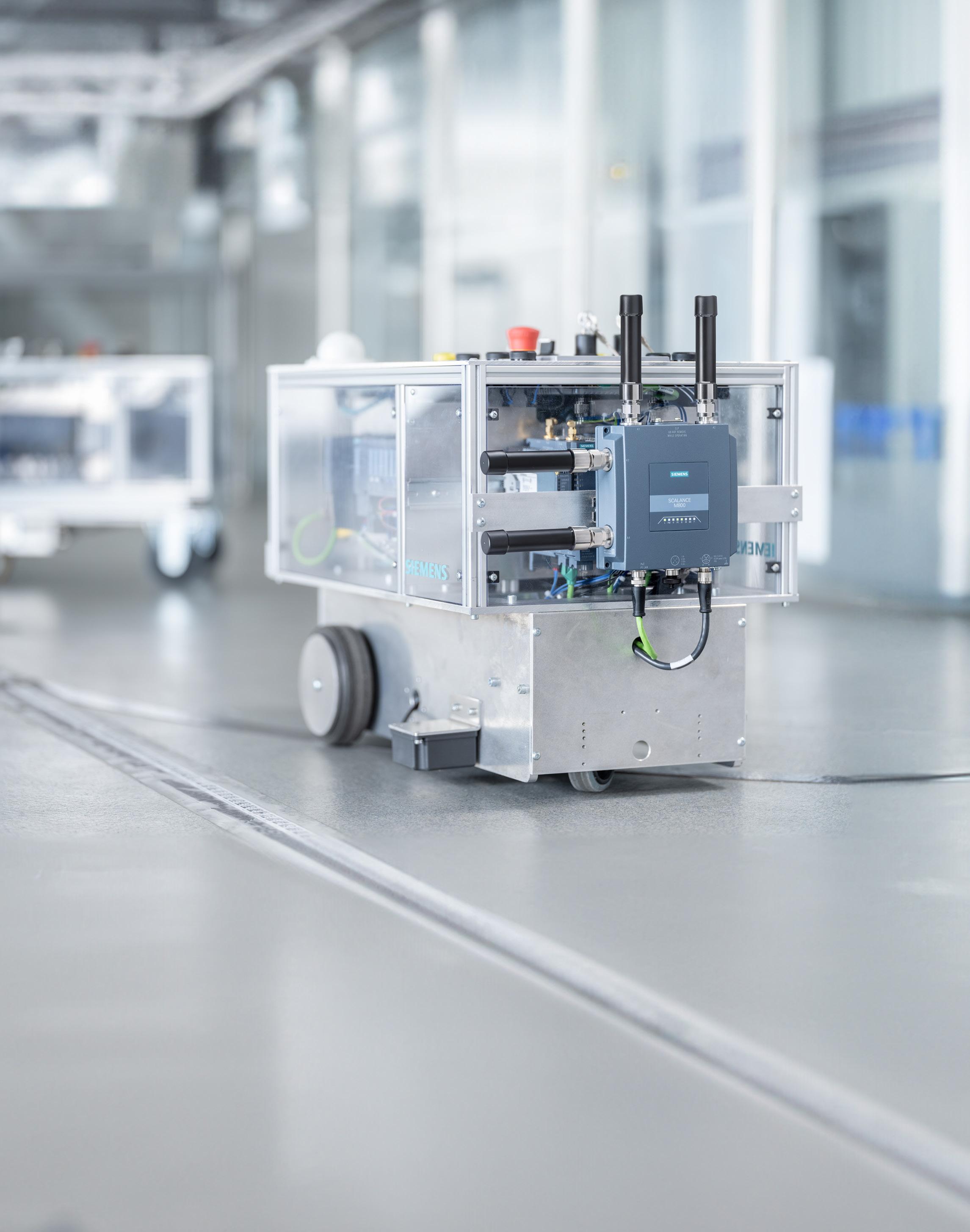

Of course, it wouldn’t be smart to plug into the public 5G network. But technology providers, such as Siemens and LG Electronics, are preparing private 5G infrastructures for industrial facilities, promising secure, reliable, and high-performance wireless networks that can transmit data between AMRs in milliseconds.

More importantly, this is not a ripand-replace scenario where the existing wireless network nodes become obsolete.

“5G will be an addition to already existing wired and wireless network infrastructures,” said Daniel Mai, industrial wireless communications director at Siemens. “And it will enable a broad range of new possibilities due to its capabilities. It can cope with multiple applications running on the same wireless network, has fewer interferences due to licensed spectrum, and will offer an easy and secure way of connectivity to digitalize brownfield applications.”

communicate where the AGV needs to transport parts.

DESIGN WORLD www.designworldonline.com

AUTOMATED WAREHOUSE

By implementing and operating the 5G prototype network in its production facilities, Siemens was able to extensively test and refine the technology, ensuring that it can withstand the requirements of warehouse environments, as well as support industrial applications.

In September 2023, Siemens made its private 5G infrastructure available to other manufacturers in Germany, with more countries to follow. One of the pilot sites for Siemens’ complete 5G infrastructure is the German steel group Salzgitter, which was looking for an industrial-strength wireless network.

"We don't just want to build any 5G network, we want an industrial 5G that meets the enormous requirements of the steel industry," said Gerd Baresch, CTO at Salzgitter Flachstahl, in a statement. "Wherever we need

to wirelessly transmit data reliably and securely — from real-time camera images to safety-relevant emergencystop signals for driverless transport systems — we need future-proof communication technology. Siemens has been a longstanding reliable partner for network solutions, and this is precisely why we decided to work with them."

Siemens’ Mai echoed the need for a network that will work with future applications. “Industry will not implement new technologies without a clear benefit. The benefit of 5G technology is reliable, wireless connectivity for digital transformation,” said Mai.

LG investing in 5G

LG Electronics is also getting ready to launch its own private 5G network in the U.S. at the end of 2024.

During MODEX 2024 in Atlanta, LG unveiled its newest family of mobile robots, the AI-powered CLOi CarryBot AMRs, which are now available in the U.S. It also highlighted its partnership with SVT Robotics, a middleware platform that enables the AMRs to seamlessly connect with almost any WMS. LG recognizes that for CLOi to do its job, they have to design a network in which the AMRs can operate reliably.

“To prevent collisions, you need to have very quick decision-making and communication between the robots and the robot management system,” said Anoop Kulkarni, senior director of business solutions at LG Electronics USA. “Our private network helps to solve all of these problems, so you don't need to worry about the network. You can have your WiFi network in place to do

NO BOUNDARIES, JUST CONNECTIONS CUSTOM CABLE FROM COAST TO COAST Manufacturing Custom Wire & Cable Solutions Since 1898 603-838-6624 • newenglandwire.com Lisbon, New Hampshire USA Since 1898, we've partnered with the most innovative companies around the world to solve complex challenges and advance technology.

industry leaders, you can depend on our decades of experience, unrivaled reliability, and custom cable solutions that power technology

coast to coast and around the globe.

As

from

what it was always doing, and now you have a new network that you can run the robots on.”

In addition, the LG private 5G industrial network includes a digital twin to diagnose problems in real-time, re-routing robots, or looking at historical data to optimize performance. "If you see that a robot is stuck, you can look at the history to see that last night there was a problem because the robot took too long, and you could optimize the routes of the robots based on the data collected from the digital twin," Kulkarni explained.

A private 5G network is also highly secure. First, it’s not accessing a public carrier so all of the data stays within the building. Second, WiFi access points can be compromised and data can be recorded even when encrypted. “With 5G, you can’t

do that,” said Kulkarni. “You can’t listen to anything, because if it's not addressed to you, there’s just no capability to listen to it. Therefore, it takes the security to a different level compared to WiFi.”

Update the network with ease

Adding private 5G is the logical next step for the automated warehouse in greenfield sites, but even more so in brownfield sites.

“In greenfield sites, manufacturers can begin from scratch,” said Mai. “But in brownfield sites, 5G will be an addition to an already existing system of various networking technologies and applications. And due to its huge capabilities, 5G is a perfect technology addition to connect and digitalize existing plants. There will be no need for cabling to add additional sensors or cameras to collect data from the shop floor to enable data-driven decision making.” AW

Solutions for Automation and Robotics

DESIGN WORLD www.designworldonline.com 51 May 2024

LG Electronics • Lg.com Siemens

Siemens.com LG’s CLOi CarryBot will help

of any size reduce lead times and enhance efficiency.

LG A Siemens Scalance Industrial 5G router mounted on an AGV. | Siemens

•

warehouses

|

Learn more today. 847-215-0591 smw-electronics.com | Pneumatic Grippers | Robotic Quick Change Systems | Inductive Coupling Systems | Mechatronic Grippers

drone deployment takes flight NFI’s

EDITED BY:

STEPHANIE NEIL EXECUTIVE EDITOR

NFI

Industries, founded in 1932, is one of the oldest and largest privately held and family-owned 3PLs in North America. The company serves a variety of segments, including food and beverage, retail and e-commerce, manufacturing, and consumer packaged goods, offering everything from transportation, distribution, brokerage, port drayage, intermodal, global logistics, and real estate. To accommodate the ever-evolving needs of its customers, NFI continues to grow its warehouses, operating more than 50 million square feet of space across North America.

Scaling operations come with its own set of obstacles, however, such as finding skilled workers. There’s also the high cost of real estate which has NFI

adding more racking to maximize the use of the space. Doing more within the facility makes logistical sense, but it can present a safety hazard for individuals conducting inventory cycle counts on lifts. There’s also the issue of efficiency, as many of NFI’s customers have contractual KPIs around inventory accuracy.

One way to solve the problem is by adding more automation to the warehouse. Of course, autonomous mobile robots (AMRs) are great on the floor, but NFI needed something in the air, such as a drone.

Drones, otherwise known as uncrewed aerial vehicles (UAV), have traditionally been delegated to outdoor activities in the agriculture, construction,

utilities, and energy industries, using GPS to navigate. However, advances in image recognition technologies and artificial intelligence (AI) are bringing these flying robots inside the four walls of the warehouse to provide automated inventory tracking and management.

Deploying drones in the warehouse

At NFI, the manual process of inventory management consists of scanning each location of the rack with an RF barcode reader to capture the information in the warehouse management system (WMS). It is a time-consuming task that is inefficient, with warehouse employees averaging about 40 pallet locations per hour. The flexibility of drones was an appealing option.

www.designworldonline.com 52 DESIGN WORLD May 2024 AUTOMATED WAREHOUSE

Gather AI’s warehouse drones fly autonomously through racking, taking pictures of inventory locations. | Gather AI

Following a successful proof of concept that improved productivity, safety, and inventory accuracy, the 3PL plans to roll out Gather AI’s drone technology in many of its warehouses.

In 2023, NFI, together with Gather AI, a provider of AI-powered autonomous inventory management systems for warehouses, put together a proof of concept with one of NFI’s retail customers. The goal was to use drones to increase cycle count times and to reallocate labor to other areas of the warehouse.

The scope of the project started with one aisle, where productivity, safety, intervention rate, accuracy, and indirect time were tracked daily for over two months.

“Coming out of that we did have really good results,” said Cody Merritt, director of solution design and innovation for NFI Industries, during a presentation at MODEX 2024 in

Solutions for Automation and Robotics

Atlanta. “Our productivity was five times faster than traditional methods, and this included indirect time of using the drones or getting them set up in the aisle.” To that end, Merritt and the team were expecting the drones to malfunction at some level, but that never happened, so there was no need for any interventions with the equipment. “They flew autonomously, and they came back. So that was something we stopped tracking at the beginning.”

From a safety standpoint, it kept the employees safely on the ground rather than on lifts, plus they enjoyed working with the drones which increased job satisfaction. As far as inventory management, in month two of tracking,

53 DESIGN WORLD May 2024 www.designworldonline.com

| Digitized Workholding Hybrid / Electric | Sensor Systems | Inductive Coupling Systems Energy + Signals | PLC Safety + Hardware Components

Learn more today. 847-215-0591 smw-electronics.com Our innovative automation systems will help you maximize productivity, reliability and profitability. – Process automation – Mechatronic drives – Reduced CO2 footprint – Reduced energy consumption

Powerful, multi-purpose solutions with easy installation and maintenance

High-speed, multi-code, multi-symbology barcode reading

Modular, standard structure gets you up and running faster

Advanced, real-time data and analytics

ACCELERATING WAREHOUSE AUTOMATION

See logistics solutions in action Scan the QR code or visit cognex.com/RobotReport-Nov

Sean Mitchell, Gather AI’s vice president of customer success (left), and Cody Merritt, NFI’s director of solution design and innovation (right), discuss the drone pilot project during a presentation at MODEX 2024 in Atlanta. | Design World

they had 99.98% accuracy for scanning license plate number (LPN) labels. “We could rely on the drone to get us the data that we were looking for,” Merritt said.

Gather AI’s inventory monitoring

Using the technology was straightforward, as Gather AI handles installation and creates a digital map of the warehouse. No additional lighting, power drops, WiFi, or beacons are needed, and it works with any WMS, as well as existing labeling and workflows.

Once the setup is complete, an operator with an iPad app can simply choose the area of the warehouse to be scanned, place the drone on the ground, and press takeoff. The drone flies autonomously — no pilot required — using labels placed on the racks to navigate and take pictures of the bins selected.

One drone can scan 300 pallets per hour, but an individual can operate three drones simultaneously to scan 900 pallets per hour. The drones, which are off-theshelf hardware, can fly without modifications and land itself when it’s done collecting data, or when the battery is low and needs to be swapped.

After the drone mission is complete, images are uploaded to the cloud for processing by a machine learning algorithm and displayed on a dashboard that

operators can use for inventory matches, to identify empty bins, or to search for missing LPNs.

“It’s going through and determining what is there in real time, and then comparing it directly with a warehouse management system,” said Sean Mitchell, Gather AI’s vice president of customer success. “So anytime in which things do not match, we’re raising an exception.”

Finding things faster, improving productivity, and providing engineers and operators with more information are the goals of the Gather AI technology.

For NFI, for example, instead of having someone conducting a cycle count using a barcode scanner on about 40 to 60 pallet locations per hour, that individual can operate three drones scanning up to 900 locations per hour. “That means you’re taking your resources and turning them into something that is 15 times more efficient,” said Mitchell. “And in doing so, you’ve got full traceability, you have a picture of every location, and you can also determine, using AI, whether something is located there or whether it’s empty. We can also do estimations when it comes to case counting and occupancy of every location. And everything is visual. It’s no longer just lines on the spreadsheet.”

Merritt confirms that Gather AI was a seamless implementation. “It was quick. Within a couple of weeks,

Solutions for Automation and Robotics

transmission of

Safe and fast data communication

transmission

55 DESIGN WORLD May 2024 www.designworldonline.com

| Inductive Coupling Systems (Energy + Signals) | Linear Positioning Systems | PLC Safety + Hardware Components | USP-Ultrasonic Positioning Measuring System

Learn more today. 847-215-0591 smw-electronics.com Non-contact

both power and data offers –

Ethernet

Ethernet IP, etc.) –

F180

Coupler

via

Signals (Profinet,

High energy

(up to 400 Watts) – Totally wear and maintenance free

Inductive

Autonomously transport materials up to 4,200 lb with the industry’s most comprehensive autonomous mobile robots and fleet management software.

THE INDUSTRY’S MOST COMPREHENSIVE

AMR FLEET

saved in the first year

an aerospace facility

customer payback period at an automotive facility 11 month throughput increase at a CPG facility 6x

at

$1.5M

www.ottomotors.com

we’ve got the building set up with the labels and we’re flying. It became a nice tool to our kit of other technologies that we can apply to other customers quickly. And there’s no integration with WMS systems, which can be cumbersome.”

The unexpected upside of drones Following a successful pilot project, NFI mapped the Gather AI across the entire building, using one to two drones. The next phase is scaling this to its West Coast facilities, which is more of a campus environment for multiple clients, with a long-term goal of deploying drones in any site they have in North America, based on customer requirements.

As more locations are added, NFI will also be looking at how accurate inventory cycle counting impacts outbound productivity. “That’s something that, as we work more with this ops team on the West Coast and other sites, we’re

excited to see how that adds into our payback in our business case,” Merritt said.

One area that can’t necessarily be measured, but is important to the success of the project, is how it impacts people. In the beginning, NFI employees resisted the drone deployment, believing it could take their jobs. But by the second month of the deployment, there was an attitude change. “They were excited about it. They got to go home and tell their families about using the drone or working in another area of the warehouse. And, you know, it became a win,” said Merritt.

NFI Industries nfiindustries.com

Enidine is your Trusted

Gather AI’s dashboard provides live visibility into the facility, sharing pictures of inventory locations with customers.

| Gather AI

Source for HighlyEngineered Energy Absorption and Vibration Isolation Solutions for Critical Applications

Enidine is a premier supplier of highly engineered products to extend equipment life, improve comfort, and increase safety and reliability throughout the global industrial, aviation, defense, and infrastructure markets.

Our engineering team has designed custom energy absorption, vibration isolation and noise attenuation solutions for a wide variety of challenging applications, including automated storage and retrieval systems (ASRS) and shock absorbers for material handling. These application solutions have proven to be critical to our customers’ success. Let Enidine do the same for you with the highest level of quality, service and support. Contact us today to learn more.

Gather AI • gather.ai Enidine 7 Centre Drive Orchard Park, NY 14127

Tel.: 716.662.1900 • Fax: 716.662.1909

industrialsales@enidine.com www.enidine.com

AUTOMATED WAREHOUSE

IE5+ Technology

Intelligently controlled, h igh efficiency solutions for conveyor applications

Reduced Total Cost of Ownership and fast Return on Investment

Reduction of variants through constant torque over a wide speed range

Ventilated synchronous motors for quiet, cool operation

Engineered for Horizontal Conveyor Applications

today! 888-314-6673 or info.us@nord.com www.nord.com

Contact us

How Cognex Is Accelerating Warehouse Automation

To move fast this year, logistics companies will be looking for solutions that automate processes and increase throughput while decreasing costs. End users and OEMs need technologies that don’t require custom design and installation, but rather are standardized, easy to install, operate, and maintain; and solve multiple applications, in place of discrete devices that only satisfy a single need. Also, it will be table stakes for leading companies to expect solutions to include advanced data and analytics capabilities to enable better decision-making and troubleshooting.

While the ultimate goal of logistics companies is to have “dark warehouses” that require few workers and rely on automation and robotics, the reality is that many companies are simply trying to increase the amount of

automation at their warehouses to gain an incremental competitive edge. This is why technology providers have shifted their focus toward the development of standard, easy-to-use vision solutions for logistics, enabled in large part by advanced technologies — such as AI (Artificial Intelligence).

Partnering on Standardized Solutions from Inbound to Outbound

At Cognex Corporation, we’ve committed to creating standard solutions that help facilities advance operations with automation. Most recently, we’ve released our new Modular Vision Tunnels. These flexible scan tunnels offer one-to-six-sided barcode scanning for a range of speeds and box gaps. These solutions are quick and easy to install for reduced

downtime and risk, and address multiple challenging applications, such as inbound receiving, outbound truck loading, and ship sorting.

These solutions are modular, yet compact; customers can set up tunnels with different configurations, add on vision tools such as dimensioning, and choose between DataMan 380 or DataMan 580 image-based barcode readers, which offer multi-symbology decoding, the ability to read multiple codes, and 99.9% read rates. Edge Intelligence data analytics software is built within these tunnels, allowing customers to easily set up and maintain them with real-time insights into performance and maintenance. Since both end users and OEMs want to increase throughput while ensuring traceability and keeping costs down, it’s important to choose solutions that are standard, yet flexible. Solutions that require custom installation and starting from the ground up each time can be costly and riddled with risk. Logistics companies that want to get ahead need to future-proof their technology investments to ensure that they’re able to scale as their business grows.

For more information, visit www.cognex.com/RobotReportNov and view our Logistics Solutions Guide.

ADVERTORIAL 59 DESIGN WORLD May 2024 www.designworldonline.com

Article by Ben Carey • Director, Logistics Vision Products • Cognex Corporation

NORD LogiDrive Complete Drive Solution with New IE5+ Motor Technology

LogiDrive® is a complete decentralized drive package that greatly reduces engineering and commissioning efforts. With this modular system, the number of variants can be minimized, making maintenance easier and reducing Total Cost of Ownership (TCO) for the operator. The LogiDrive interface is intuitive and allows for easy control and monitoring of all units within the system. When paired with the NORDCON APP with NORDAC ACCESS BT Bluetooth stick, LogiDrive systems can provide real or near-real time drive status to proactively predict maintenance issues and keep systems running smoothly. LogiDrive systems can be configured with IE3, IE4, and latest IE5+ permanent magnet synchronous motors that maintain extremely high efficiency, even at partial loads.

Energy Efficient

• Compliance with the most stringent efficiency regulations

• Considerable reduction of Total Cost of Ownership (TCO)

• High efficiency, even in partial load ranges and at low speeds

• Permanent Magnet Synchronous Motor (PMSM) technology

Variant Reduction

• Standardization of gear motor versions designed for intralogistics and airport technology

• Simplified engineering and selection

Service and Maintenance Friendly

• Considerable reduction of spare parts inventory

• Plug-and-Play technology

• Compact, space-saving design

• 25% weight reduction with lightweight aluminum housing

• Replacement of individual components possible

NORD offers unmatched product versatility, fast, reliable sales and support, and direct access to our engineering team. We also offer online tools for easy configuration and ordering of gear motors and spare parts, as well as 24/7/365 emergency breakdown service.

• Constant torque over a wide speed range through variable frequency drive technology CALL 888-314-6673 OR VISIT NORD.COM FOR MORE INFORMATION.

ADVERTORIAL www.designworldonline.com 60 DESIGN WORLD May 2024

The Data Driven Warehouse

How real-time data collected at every touch point smooths out operations

Emerging technologies are revolutionizing supply planning, enhancing supply chain efficiency, agility, and resiliency. Real-time data and advanced analytics driven by connected assets and systems help identify potential disruptions, mitigate risks and make informed decisions. We will discuss key insights into today's supply chain challenges.

What are today’s supply chain challenges?

The constantly evolving global supply chain landscape poses a range of challenges for businesses today that can impact their operational efficiency and effectiveness. Here are the biggest challenges:

• Business disruptions and market volatility: Over the past five years, supply chain operations in various industries faced unexpected events, which resulted in reactive responses. This can impede the ability to meet demand, leading to lost revenue, increased costs, and a decline in overall profit margins.

• Demand predictability: Social media, COVID driven direct-to-consumer (DTC) models, market volatility, and now inflation have made traditional demand forecasting insufficient. Operations are leaning on outdated forecast approaches that also lag and fail to respond adequately to current market dynamics.

• Holistic inventory visibility and optimization: Inventory management is complex and dynamic. The end of 2022-2023 saw excess inventory across many organizations due to COVIDrelated supply chain constraints. This led to higher costs, lower margins, and waste. The long term impact will lead to lost sales, and loss of differentiation, loyalty, and market positioning. Adopting an integrated approach and leveraging advanced technology and best practices, businesses can overcome these challenges - improving supply chain efficiency and resilience.

What is lacking in today’s supply chain strategies?

Supply planning today involves technology, data analysis and stakeholder collaboration. While technical and data analytic advancements have been made, there are still several areas that need improvements in the industry:

• Accurate transparency of data

• Dynamic supply planning and execution based on integrated intelligence and automated decision-making

• Convergence of network modeling, scenario and traditional planning and planning

Businesses want to improve supply chain visibility, predict, and mitigate risks, and optimize performance. Incorporating advanced concepts can enhance agility and resilience, meet customers’ evolving needs, and optimize performance. Below are a few advanced technologies and characteristics that must be included in an organization’s growth plans for supply chain optimization.

• Artificial intelligence and machine learning: Artificial Intelligence (AI) and Machine Learning (ML) can help businesses analyze data, find patterns, and make proactive decisions to mitigate risk. Many planning solutions have already integrated AI/ML into their core plans, but further integration of this can enhance algorithms. This could include detecting shifts and anomalies -- optimizing execution, automating operations such as key planning processes and real time decisions, and more.

• Digital twins and advanced simulation: Digital twins and simulation create virtual versions of physical assets, processes, and systems. These outputs can be used to evaluate scenarios and risk, identify key constraints, optimize, and evaluate alternative configurations.

With data and AI/ML, digital twins can continuously evaluate supply chains and networks, informing businesses in an unprecedented way.

• Automation and autonomous systems: The targeted deployment of automated storage retrieval systems (ASRS), autonomous mobile robots (AMR) and other assets with IoT connectivity, RFID asset tracking and machine vision can mitigate risks ranging from labor shortages to inventory loss. Working in tandem with digital twin and AI/ML, these assets comprise self-optimizing systems that drive higher output and efficiency by learning from both physical and simulated scenarios in the connected warehouse.

The future of supply chain planning requires digitization, automation, connectivity, and data-driven decision-making. Organizations that embrace these technologies create agile, transparent and efficient supply chains that are resilient to market changes and disruptions.

You can read more in our recent whitepaper, Synchronizing Supply & Demand in 2023 and Beyond.

ADVERTORIAL 61 DESIGN WORLD May 2024 www.designworldonline.com

KALYPSO.COM