Discover the advantages www.belimo.com

Belimo’s gas monitors are factory calibrated and measure single or dual gas combinations to help maintain adequate ventilation. The monitors can be used as a standalone system or integrated into a building automation system using BACnet MS/TP.

If you only think of Greenheck as a fan company, think again. We engineer and manufacture the industry’s most comprehensive line of air movement, control, conditioning, and distribution products for commercial, industrial, and institutional buildings. Our energy-efficient products keep occupants comfortable, productive, and safe while supporting sustainability. Let us help with your next project.

5 | What do world travel and engineering have in common?

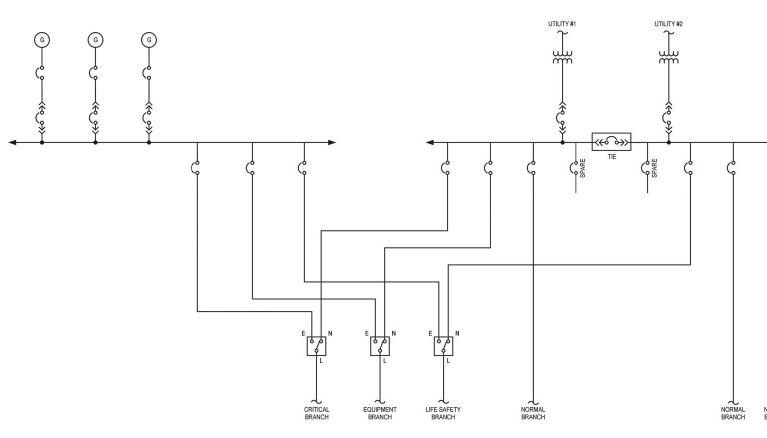

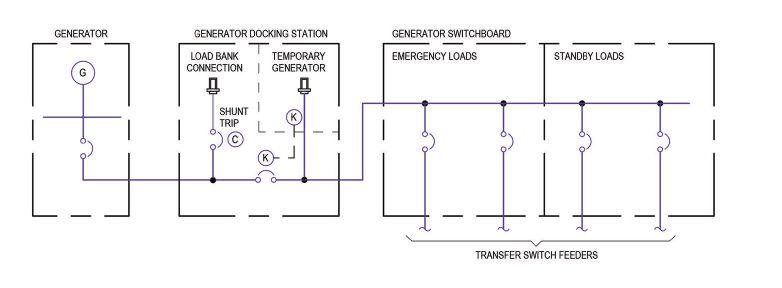

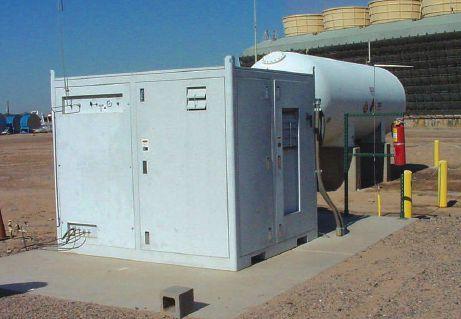

22 | Know specific, unique specifications of generators in mission critical facilities

Read on for more. See page 7.

ON THE COVER:

How does a 40 Under 40 winner balance work, innovation, community and family?

The 2024 40 Under 40 winners represent some of the top talent in the building community. Courtesy: Consulting-Specifying Engineer

How travel makes commercial buildings better

Electrical engineers should consider many factors when selecting generators and generator systems for mission critical facilities

28 | How to make generator fuel type selection in four steps

When selecting a generator, one of the first and most important decisions is which fuel type to choose

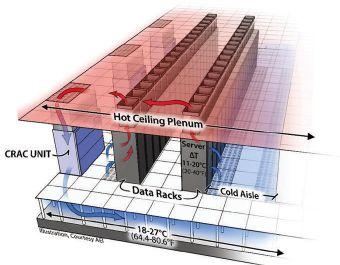

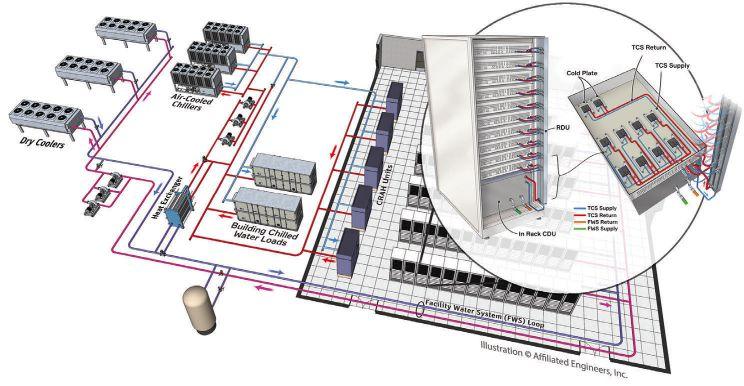

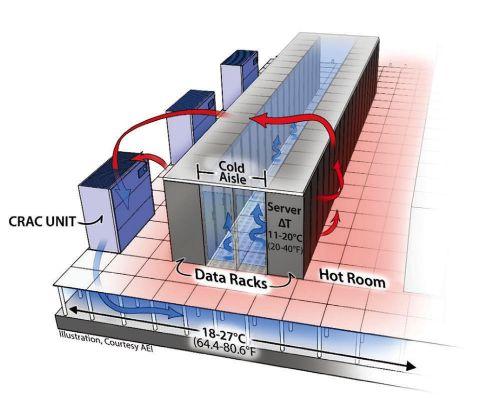

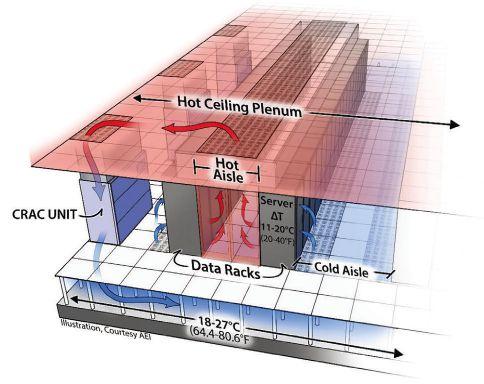

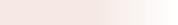

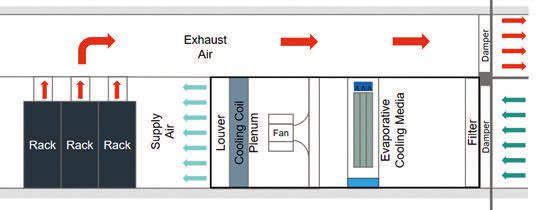

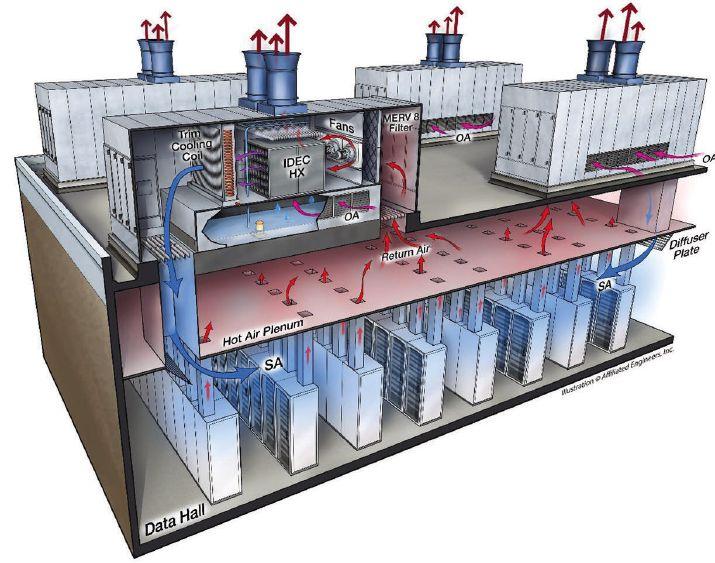

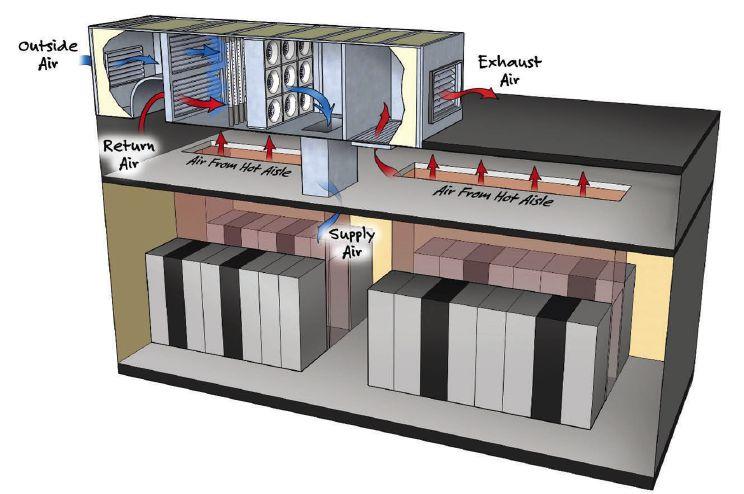

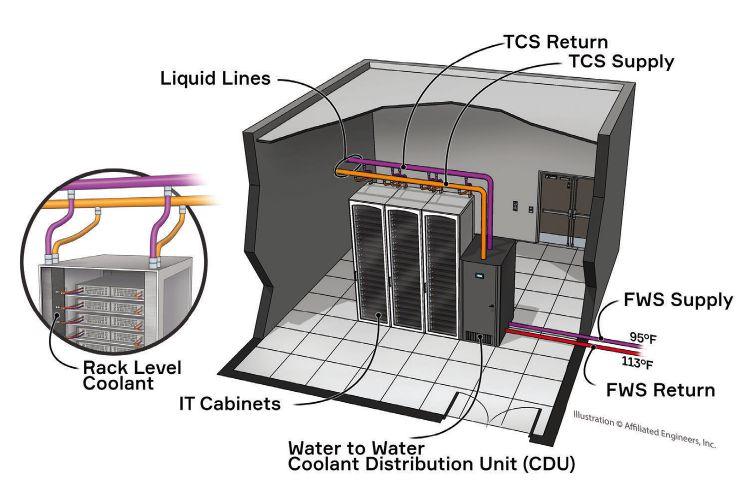

34 | Using fluid technology to address colling limitations in data centers

Increased focus on unique cooling solutions for data centers address the limitations of traditional systems

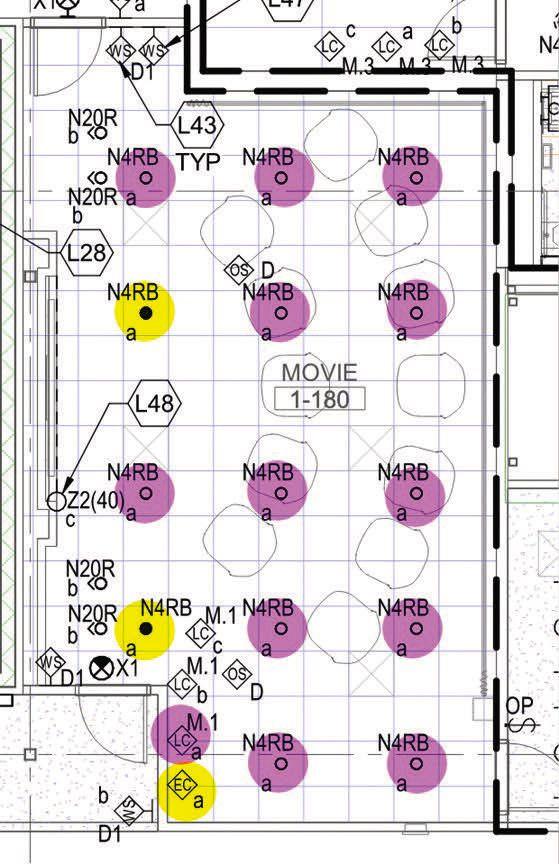

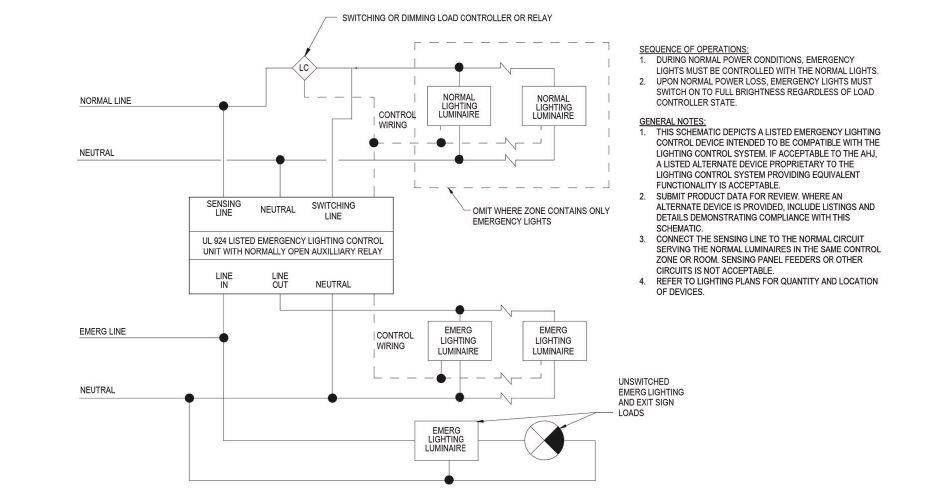

40 | How to specify emergency lighting controls under new standards

Understand how to approach revised UL listing requirements when specifying emergency lighting controls

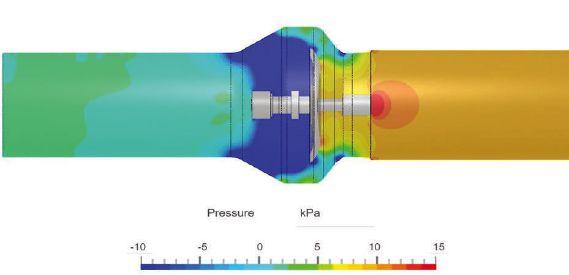

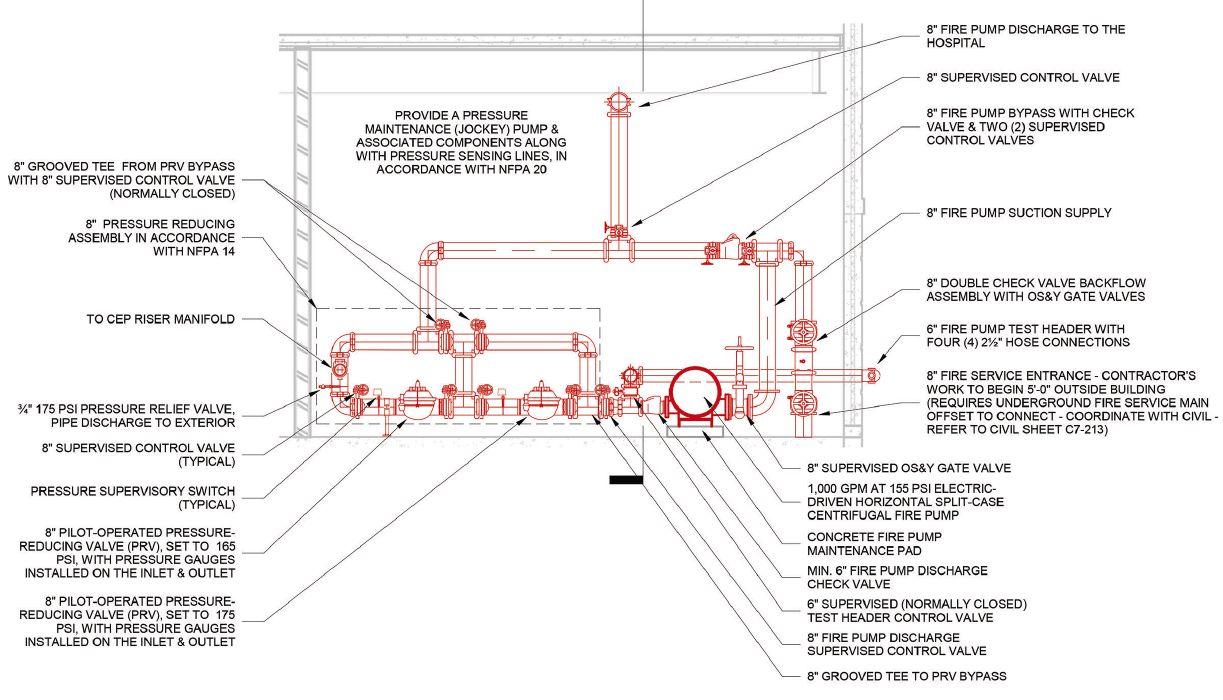

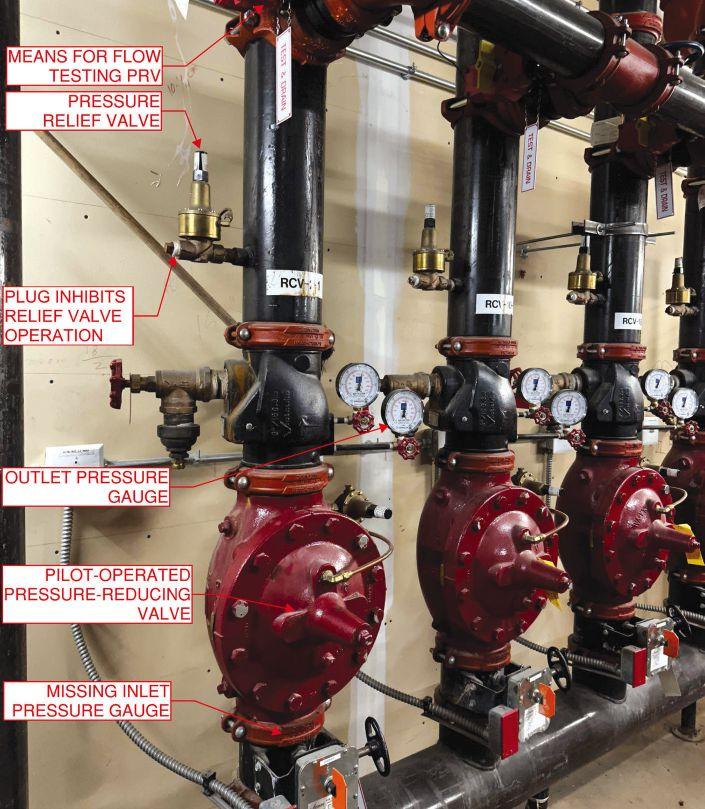

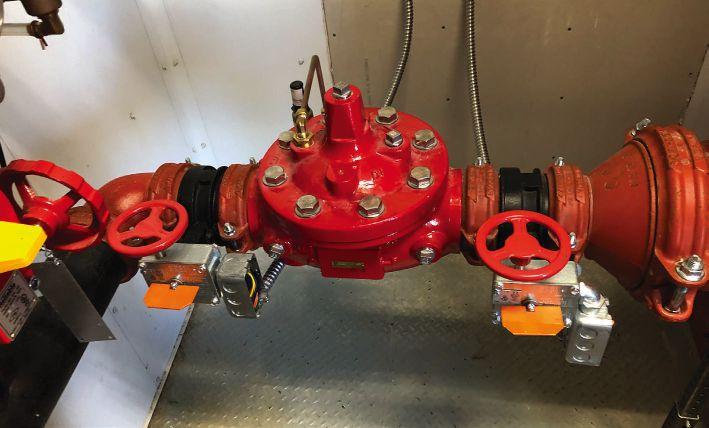

44 | Learn to specify pressureregulating devices in waterbased fire protection

Understand why pressure-regulating devices are required to maintain safe system working pressures in fire protection systems

53 | Trends and challenges unique to modern data center design

In this roundtable, experts answer common questions about the challenges and considerations of designing data centers in our highly connected world

Optimizing the harmonic load on your systems increases their lifespan and decreases downtime.

HPS has the portfolio of power quality solutions and the engineering expertise to deliver the efficiency, reliability, and longevity to help ensure that your operations keep flowing smoothly.

AMARA ROZGUS, Editor-in-Chief/Content Strategy Leader ARozgus@CFEMedia.com

CHRIS VAVRA, Web Content Manager CVavra@CFEMedia.com

ANNA STEINGRUBER, Associate Editor ASteingruber@CFEMedia.com

AMANDA PELLICCIONE, Director of Research APelliccione@CFEMedia.com

MICHAEL SMITH, Creative Director MSmith@CFEmedia.com

DARREN BRUCE, PE, LEED AP BD+C, Director of Strategic Planning, Mid-Atlantic Region, NV5, Arlington, Va.

MICHAEL CHOW, PE, CEM, CXA, LEED AP BD+C, Principal, Metro CD Engineering LLC, Columbus, Ohio

TOM DIVINE, PE, Senior Electrical Engineer, Johnston, LLC, Houston

CORY DUGGIN, PE, LEED AP BD+C, BEMP, Energy Modeling Wizard, TLC Engineering Solutions, Brentwood, Tenn.

ROBERT J. GARRA JR., PE, CDT, Vice President, Electrical Engineer, CannonDesign, Grand Island, N.Y.

JASON GERKE, PE, LEED AP BD+C, CXA, Mechanical Engineer, GRAEF, Milwaukee

JOSHUA D. GREENE, PE, Associate Principal, Simpson Gumpertz & Heger, Waltham, Mass.

RAYMOND GRILL, PE, FSFPE, LEED AP, Principal, Ray Grill Consulting, PLLC, Clifton, Va.

DANNA JENSEN, PE, LEED AP BD+C, Principal, Certus, Carrollton, Texas

WILLIAM KOFFEL, PE, FSFPE, President, Koffel Associates Inc., Columbia, Md.

WILLIAM KOSIK, PE, CEM, LEGACY LEED AP BD+C, Lead Senior Mechanical Engineer, kW Mission Critical Engineering, Milwaukee

KENNETH KUTSMEDA, PE, LEED AP, Engineering Manager, Jacobs, Philadelphia

DAVID LOWREY, Chief Fire Marshal, Boulder (Colo.) Fire Rescue

JASON MAJERUS, PE, CEM, LEED AP, Principal, DLR Group, Cleveland

JUSTIN MILNE, PE, PMP, Senior Engineer, Southcentral Region, Jensen Hughes, Allen, Texas

GREGORY QUINN, PE, NCEES, LEED AP, Principal, Health Care Market Leader, Affiliated Engineers Inc., Madison, Wis.

BRIAN A. RENER, PE, LEED AP, Principal, Electrical Discipline Leader, SmithGroup, Chicago

CRAIG ROBERTS, CEM, Account Executive, National Technical Services, McKinstry, Powell, Tenn.

SUNONDO ROY, PE, LEED AP, Director, Design Group, Romeoville, Ill.

JONATHAN SAJDAK, PE, Senior Associate/Fire Protection Engineer, Page, Houston

RANDY SCHRECENGOST, PE, CEM, Austin Operations Group Manager/Senior Mechanical Engineer, Stanley Consultants, Austin, Texas

MATT SHORT, PE, Project Manager/Mechanical Engineer, Smith Seckman Reid, Houston

MARIO VECCHIARELLO, PE, CEM, GBE, Senior Vice President, CDM Smith Inc., Boston

RICHARD VEDVIK, PE, Senior Electrical Engineer and Acoustics Engineer, IMEG Corp., Rock Island, Ill.

TOBY WHITE, PE, LEED AP, Associate, Boston Fire & Life Safety Leader, Arup, Boston

APRIL WOODS, PE, LEED AP BD+C, Vice President, WSP USA, Orlando, Fla.

JOHN YOON, PE, LEED AP ID+C, Lead Electrical Engineer, McGuire Engineers Inc., Chicago

How travel makes commercial buildings work better

If you know me, you know I can talk about travel all day — upcoming trips, packing recommendations and funny connection hiccups. I can also share what I’ve learned from visiting buildings around the world.

Traveling is a great way to expand your mind and experience new things. But for people who work in mechanical, electrical, plumbing (MEP) and fire protection engineering, it can be even more meaningful. When you get to see how buildings are designed and built in different parts of the world, it can really change how you think about your own work.

In Canada, where it’s freezing, they know all about heating and keeping buildings insulated. After experiencing these different environments, I’ve learned to think about all kinds of solutions when designing systems for commercial buildings.

Amara Rozgus, Editor-in-Chief

I’ve traveled to all seven continents and seen all kinds of buildings, from supertall skyscrapers to small research stations in the coldest places on Earth. Here’s why I think traveling helps improve engineering.

One of the best things is that you get to learn from other cultures. In Europe, for example, you often see old buildings that have been updated with modern MEP systems. This shows that you can keep a building’s character while still making it work. In Asia, places like Shanghai are so crowded that they’ve had to come up with some clever ways to save space and energy. When you see these solutions in person, it makes it easier to come up with smart ideas for your own projects.

Traveling to different places lets you see what challenges they face and how they solve them. In Kenya, which straddles the equator, they have ingenious ways to save energy and water.

Visiting famous buildings can give you tons of new ideas. On my travel wish list is a visit the Burj Khalifa in Dubai — the tallest building in the world — where you see how they handle plumbing and fire protection at crazy heights. Or in Melbourne, Australia, there are healthy commercial indoor workplaces. Seeing things like this up close can really get your creative juices flowing.

Traveling also lets you meet people from different countries who do the same work. When you go to conferences, you can talk with others and share what you know. Building these connections helps you stay on top of new trends and technologies. It’s a great way to make sure you’re not stuck doing things ineffectively.

If you work in MEP engineering, traveling can be a game-changer. This mix of new ideas and fresh perspectives makes commercial buildings more efficient and innovative, which is important as we move into a future where we need to think about things like energy use and climate change. In all, travel is a great way to make sure you’re always learning and improving. cse

Look familiar?

If your power infrastructure includes renewables, battery storage and/or EV charging, a microgrid may be the missing piece you need to bring it all together.

At the heart of such a system is an intelligent microgrid controller that maintains overall system stability and dynamically manages

generating assets and loads to optimize power flow based on user-defined goals.

Eaton’s Power Xpert microgrid solutions provide reliable power that delivers operational resilience, minimizes carbon emissions and reduces energy costs.

To learn more go to: Eaton.com/microgrid

Each year, Eaton has the pleasure of recognizing the most talented young individuals across the engineering community as the title sponsor of Consulting-Specifying Engineer’s 40 Under 40 Awards. Your dedication, expertise, and commitment to the engineering industry have truly set you apart.

As we celebrate your achievement, we want to recognize the ever-growing complexity of engineering challenges you have so successfully navigated. The construction and engineering landscape is evolving rapidly, with new technologies and sustainability practices, and project complexities growing every day.

As this year’s winners, you have shown you are up for the challenge to stay ahead of the curve and equip yourselves with the knowledge and tools needed to thrive in this dynamic environment.

Eaton shares your passion for continuous learning and growth and is proud to see all you have accomplished. To support our commitment for continuous learning and growth, we are actively involved in designing educational resources to enable you to solve the next iteration of engineering challenges.

Once again, on behalf of all of us at Eaton, congratulations on this remarkable achievement! Your passion, leadership, and innovative spirit inspire us all. And we look forward to witnessing your continued success and contributions to our industry.

Chris M. Finen, P.E. Manager, National Application Engineers

Liz Alford .

Lauren Alger . . . . .

.10

.10

Yevgeniya (Jane) Baikadanova .10

Jodi Balido . . .

Victor Bonachea .

Zac Buckmiller

Jamison Caldwell . . . .

John Constantinide . . .

Devanshi Dadia

Michelle DeCarlo .

Katelyn DePenning . .

Tony Dupsky

Jeffrey Engelstad

Alyse M . Falconer

Michelle Fennell

Paul Foerth

Lauren Foster

Christoph Gisel

Robin Graves . . . .

Todd Green .

Kenneth Griffin

Morgan Heldstab

Katelyn Jones

Hunter Koch

Tzu-Hao Kuo

Christopher Lau . . . . . . .

Matthew J . Lick

Amar Maniar

Ali Moussawi

Liam Murphy

Cole Parkinson

Alex Quast

Brandi Sauter

Mariah Seaboldt

Greg Sherman

Alex Sibila

Johnathan Stewart

Lilly Vang

Katie Wholey

Mary Wurst

.10

.11

.11

. 11

.11

.12

.12

. .12

.12

.13

.13

.13

.13

.14

.14

.14

.14

.15

. .15

.15

.15

.16

.16

.16

16

.17

.17

.17

.17

.18

.18

.18

.18

.19

19

.19

.19

THow does a 40 Under 40 winner balance work, innovation, community and family? Read on for more

he 2024 40 Under 40 program celebrates engineers and building professionals who have excelled in various disciplines within engineering and construction, showcasing innovation, leadership, mentorship, sustainability and community involvement. Despite their diverse backgrounds, these individuals share common values and have made significant contributions to their fields and to society. Beyond their professional accomplishments, the winners are dedicated to giving back to their communities. Collaboration is another common thread among this year’s 40 Under 40 winners, who excel at building strong relationships with clients and project stakeholders. And despite their demanding careers, these professionals lead fulfilling personal lives.

Mechanical Engineer, CMTA; BS, Engineering, University of Kentucky

lford joined CMTA in 2015 as an engineering co-op student and became a full-time employee upon graduating in 2017. Since then, Alford has worked with Jefferson County Public Schools and has been an integral part of the HVAC renovations design team for seven existing high schools and two existing middle schools, totaling over $200 million in project construction costs. Additionally, she has designed two high-performance, new construction educational facilities with geothermal HVAC systems for the district. She recently led building information modeling coordination efforts for a new five-story patient tower addition to an existing hospital, as well as for a new 3,750-ton central energy plant serving an existing hospital. Alford is passionate about finding unique design solutions and learning new ways to optimize central plants. In 2019, she began investing in CMTA’s co-op program by conducting employment interviews and has attended numerous university recruiting events to develop the next generation of young engineers. Alford has spoken to several Society of Women Engineers (SWE) chapters about high-performance mechanical systems and participated at the SWE conference in Los Angeles. She is passionate about reaching women in the engineering field and educating them about opportunities in the built environment. Alford is committed to both engaging future generations of engineers and working to provide an occupant-focused built environment that serves the needs of her clients. Outside of the office, Alford enjoys playing on adult league soccer indoor teams or playing beer league softball with her wife’s law firm.

Principal/Owner, IPQ LLC; MS, Systems Engineering, George Washington University

Director of Sustainable Design, STV; BS, Civil and Infrastructure Engineering, George Mason University

The foundation of Alger’s career is based in civil engineering, as she was inspired to follow in her father’s footsteps. Since graduation, she embarked on a path to redefine sustainable design practices and has worked on many projects that incorporated green design elements. Determined to have a more significant impact on sustainable practices in the early planning and design stages, so Alger earned her professional engineering license and accreditation as an Envision Sustainability Professional. In 2022, Alger joined STV in the newly established position of sustainability manager where she embarked on building the firm’s national sustainability practice and quantifying sustainable design efforts across projects, charting a course for future action while tackling the firm's carbon footprint head-on. Alger led the multidisciplinary team that developed STV’s new Embodied Carbon Action Plan, acting as the first step in fulfilling the firm’s Structural Engineers 2050 Commitment for colleagues to reduce embodied carbon, track data and analyze findings through STV’s Carbon Dashboard. She is also the chair of the American Society of Civil Engineers Infrastructure 2050 group. Outside of her work, Alger is a student research mentor for Columbia University’s Center for Buildings, Infrastructure and Public Space. She also volunteers with the Salvadori Center, an esteemed organization that partners with schools to provide math, science and arts programs to K-12 students. In her downtime, she enjoys hiking at national parks, rock climbing and attending concerts when she is at home in New York City.

fter moving to the United States in 2008 from her home country of Kazakhstan, Baikadanova worked several odd jobs to put herself through graduate school. Most notably, she worked as a receptionist for a prominent engineering firm in Virginia, confident that her dedication to the industry would land her an engineering role. In 2011, her confidence was rewarded with her first job as a junior engineer. Since then, she has worked as a senior electrical engineer and project manager, where she has designed and calculated lighting and power systems for health care facilities, government, commercial facilities and more. As a senior electrical engineer, Baikadanova led a team of junior engineers and drafters to prepare schematic and detailed construction documents. She also has contributed to Consulting-Specifying Engineer as an author, webcast host and podcast guest. She credits her time in the service industry for her strong people skills that make her stand out as an engineer. In 2023, she made the daring switch to entrepreneurship and opened her own firm, which she hopes will show her 3-year-old son that with hard work and perseverance, anything is possible. Her current and past colleagues highlight not only her magnetic personality and work ethic, but also the resiliency in her story and how it can help inspire others. Baikadanova herself hopes to do the same in the day-to-day of her career. Outside of work, Baikadanova enjoys riding motorcycles and dirt bikes, hosting cookouts and training her Swiss Shepard on dog agility courses

Global Fire Safety Manager, The LEGO Group; BS, Architectural Engineering, Illinois Institute of Technology

Balido has made strides in fire safety management within The LEGO Group since joining as global fire safety manager in 2023. His prior engineering experience includes both design and owner representation roles. His proactive approach to risk management and his can-do mindset have earned him respect among colleagues and stakeholders in the different countries where The LEGO Group operates. He participates in risk inspections, providing recommendations to enhance operational resilience across multiple sites. He is involved in the design of large-scale factory expansions, coordinating and developing comprehensive fire safety strategies. Balido also holds a Graduate Certificate in Fire Protection Engineering from University of Maryland. He has written articles on fire protection and risk management topics. Balido was a former Toastmasters Club President in 2020, and hosted the Winter Leadership Institute Seminar in Richmond, Virginia. In 2023, Balido volunteered as a panelist for the Midwest Filipino American Summit, a networking and development event for Filipino American students at various Midwest U.S. universities. He also serves as one of the voting principal members on the Building Service and Fire Protection Equipment committee for NFPA 101 and NFPA 5000. Beyond his professional endeavors, Balido remains committed to his family and community. As a loving husband and father of three, he prioritizes his role at home while also engaging in activities such as running marathons, breakdancing, coaching basketball and supporting his children's interests. He also self-published a fantasy novel to Amazon in 2018 under a pseudonym.

Product Strategy Director, ASCO Power/Schneider Electric; MS, Engineering Management, New Jersey Institute of Technology

Bonachea has been an integral part of ASCO Power Technologies, a brand within Schneider Electric, since 2011, joining during his senior year as an electrical engineering undergraduate student. Bonachea’s work focuses on power distribution and emergency power systems. During his time in offer marketing and product development, he has secured multiple patents, including methods and systems for autonomous redundant control, methods of predictive outage detection and systems for controlling a generator. These patents, along with his work on products like source isolation switches, load management solutions and engine start monitoring systems, demonstrate his commitment to making power continuity more accessible for all organizations. The innovations he has worked on have increased power reliability, resilience and sustainability. Outside of his work with ASCO, Bonachea contributes to his field as a voting technical member of NFPA. He is an IEEE Senior Member and involved with several IEEE 3005 Standards, demonstrating his expertise in electrical power management and control, generator paralleling and transfer switching. Bonachea has also contributed and delivered numerous articles and technical speaking events and is enthusiastic about sharing his knowledge with in-house teams, corporate divisions and the larger backup power community. Bonachea served as a volunteer firefighter in his New Jersey hometown for 15 years. Outside of work, he spends a lot of time on home automation projects. He is currently finishing his gaming room and deck, with the hopes of hosting barbecues and science-fiction movie nights.

Principal, Mechanical Engineer, SmithGroup; BS, Lafayette College

Kansas City MEPF Practice Leader, Garver; MBA, University of Arkansas

As Garver’s Kansas City Buildings Practice Lead, Buckmiller has dedicated his career to bringing to life the foundations of a strong community. From hospitals to sports parks, Buckmiller’s work as an architectural engineer is focused on designing the buildings that contribute to the Kansas City region’s rich architectural history. He has designed buildings across industries, including new health care centers, large corporate office spaces and over 6,800 multifamily apartments. A mechanical engineer by trade, Buckmiller’s expansive experience makes him a generalist in his field, with the ability to design many facility types. Garver has been present in the Kansas City area for years, and Buckmiller has been a lead on expanding the firm’s brand into new markets across the region. He offers clients a local expert and “one-stop shop” for structural, civil, mechanical, electrical, plumbing and fire protection engineering services. He has also led the charge to improve the Revit and BIM standards, as well as a consistent process to create documents for Garver’s Buildings Team. In addition to drawing standards and processes, Buckmiller has also created several engineering calculations that assist in project documentation and reduce project errors. Looking toward the future, he is working to integrate BIM and calculations to further provide a higher quality product while also maximizing technology. Outside of work, Buckmiller enjoys being as active and spends his time playing and coaching ice hockey.

aldwell is a distinguished mechanical engineer renowned for his contributions to decarbonization and high-performance building design. Based in Washington, D.C., he is a leading figure at SmithGroup, driving innovation and sustainability in engineering solutions. Caldwell’s journey began in central Maryland, where a high school engineering class ignited his passion for design. At Lafayette College, he pursued mechanical engineering while playing varsity lacrosse. After college, his focus shifted to high-performance building design and sustainability and he swiftly gained expertise in the mission critical field. Caldwell’s portfolio spans diverse sectors including higher education, science and technology, health care and cultural institutions. Notable projects include the Henry Ford Cancer Institute Brigitte Harris Cancer Pavilion and the Virginia Tech Innovation Campus. He also has contributed to campuswide carbon emission reduction planning, exemplified by his work at North Carolina State University. Caldwell also has worked on R&D initiatives, focusing on patentable concepts for increased building efficiency. He has served on SmithGroup's national engineering standards team. His passion for sustainability extends to several articles he has written with an emphasis on evidence-based operational decision-making and the potential of heat pumps in environmentally conscious design. Caldwell enjoys being outside with his family, opting for sailing, kayaking, biking or just chasing their German Shorthaired Pointer dog. Caldwell lives with his wife, who he met in high school, and their two young children.

Range Engineer, U.S. Space Force; MS, Environmental Resource Management, Florida Institute of Technology

Constantinide’s training and experience spans the sciences, engineering and leadership. In his role with the U.S. Space Force, he is the subject matter expert advising squadron and installation leadership on facility and infrastructure resolutions, leading engineering innovation projects for Space Launch Delta 45. He oversees work by energy managers on energy reduction and resilience for the Delta’s utility program supporting the world’s most active spaceport. His work has resulted in hundreds of thousands of dollars saved in process efficiencies and contract modifications. He also oversees pilot, innovation and resilience programs investing millions of dollars in facilities and infrastructure. Constantinide has contributed to the built environment knowledge base of the government and the industry through several publications. He also has been a guest lecturer at several universities and participated in podcasts, conferences and local seminars on topics ranging from how indoor air quality improves workforce health and resilience to environmental controls of space habitats and transport vessels. He is a director and regional chair of ASHRAE, chair of ASHRAE Technical Committee 9.13 Space and public sector co-chair and incoming vice chair of the Society of American Military Engineers Energy and Sustainability Community of Interest. Outside of work, Constantinide enjoys playing tennis with friends, hiking on natural parks and trails, prayer, meditation and reading on philosophy and theology.

Associate Energy Analysis Practice Lead, Atelier Ten; MSc in Sustainable Design, Carnegie Mellon University

adia has established herself as a leader in energy analysis and environmental design and is dedicated to advancing sustainable practices within a built environment. Dadia oversees a team of 14 energy analysts, shaping project assignments and framing energy analyses as an associate and energy analysis practice leader at Atelier Ten. Dadia has demonstrated versatility across various roles, including mentorship, supervision, technical leadership and project management. Her expertise spans diverse building typologies and climate zones, where she consults on energy analysis, existing building retrofits and decarbonization strategies. She employs her analytical prowess to advocate for informed investment decisions, as showcased in a recent project where an analysis led to significant cost and space savings through dynamic blinds implementation. Her contributions to developing calibrated energy models and testing efficiency measures have empowered institutions like K-12 schools, museums and hotels to formulate comprehensive decarbonization plans. Dadia contributes to the ASHRAE Sustainability and the LEED Energy and Atmosphere Technical Advisory Group. Dadia also remains very active in community service and has volunteered with organizations like Shrimad Rajchandra Love and Care. She has been involved in fundraising for COVID-19 relief to organizing environmental cleanup drives and aiding earthquake victims. Dadia enjoys exploring new restaurants and cooking with her husband. She is an avid hiker and enjoys exploring the world.

MEP Manager, McCown Gordon; BS, University of Kansas

Associate Partner, Jaros, Baum & Bolles; BS, Mechanical Engineering, Villanova University

As the first female partner at JB&B, DeCarlo has emerged as an indomitable leader in the New York real estate industry, blazing a path for countless women, leaving an indelible mark on the industry and inspiring generations to come. She wrote the firm’s parental leave policy in 2015, championing work-life balance and spearheaded a groundbreaking diversity, equity and inclusion resource. Her career arc encompasses many building types and market sectors, chief among them commercial office buildings, laboratories and transportation facilities. She has shone in projects emblematic of profound transformation, of dramatic shifts to the new. Recent projects include the new core and shell office design for 30 Hudson Yards, the commercial office redevelopment of the landmarked Moynihan Train Hall and the New Terminal One at John F. Kennedy International Airport. DeCarlo is very involved in the advancement of women in the industry. In 2018, she launched the JB&B Women’s Initiative, an in-house membership group whose mission is the empowerment of women, positioning them as leaders inside and outside the firm and promoting their retention through leadership and professional development. She also serves on the board of directors for the Commercial Real Estate for Women of New York. She recently completed four years of service on the ASHRAE New York Board of Governors, serving as chairperson of its Women in ASHRAE Committee. Yet for all her leadership roles, DeCarlo is perhaps most proud of one closer to home: She is the Girl Scout troop leader for her twin daughters’ troop.

ePenning is a pioneering force reshaping the sports and engineering realms through her innovative work and tireless advocacy for diversity and inclusion. Beginning her career at Henderson Engineers in 2011, she has showcased project management prowess in the retail sector before transitioning to specialize in sports venue design. DePenning’s notable projects include the groundbreaking KC Current’s Training Complex, the first-ever purpose-built facility for a U.S. women’s professional sports team. Her leadership extends to the upcoming CPKC Stadium, a $117 million venue that opened in March 2024 for the Kansas City Current, a National Women’s Soccer League team. DePenning also is dedicated to uplifting underrepresented groups. She co-founded UNITE, a resource group supporting LGBTQIA+ employees and allies and played a pivotal role in EMPOWER, advocating for gender equity and organizing impactful events like the "Learn to Golf" initiative. DePenning also is involved with the ACE Mentor Program and the Women in Leadership program, where she empowers high school students to pursue careers in engineering and other impactful industries. She provides firsthand knowledge of what it is like to work in the architecture, engineering and construction industry and helps future engineers with guidance on college preparation, networking and more. DePenning also has been a panelist and guest on empowering and encouraging women in STEM. DePenning remains a passionate basketball and soccer fan, sports she played in her youth. She also enjoys playing golf. She likes visiting local parks and the playgrounds with her wife and their three young children.

Principal Mechanical Engineer, Engineering Technologies Inc.; Master of Mechanical Engineering, University of Nebraska-Lincoln

Dupsky is a dedicated professional known for his commitment to excellence, technical prowess and generous spirit, and has carved a career path marked by profound achievements and impactful contributions. Throughout his tenure at ETI, which started in 2007 as a CAD technician, Dupsky has ascended to principal and partner status in 2023, bolstered by his professional engineering licensure in 2018. Renowned for his innovative problem-solving acumen, he has spearheaded numerous projects, including the transformation of energy systems in facilities such as detention centers and schools. He specializes in solving unique challenges with existing systems. In one case, Dupsky led a project to install hydronic glycol preheat coils for a high school district because they were losing cooling capacity. The installed coils rejected heat directly from the geothermal loop in the winter to preheat the outside air before the heating coil helping to lower the loop field temperatures and reduce compressor operation. Dupsky also is involved in leadership positions in the controls, details, specification and CAD/Revit committees focused on the advancing ETI’s quality of work. He also has presented at an American Institute of Architects conference on energy code changes helping to further advance the technical knowledge of the building design industry. Dupsky is actively engaged in organizations such as ASHRAE and volunteering for charitable causes such as the Micah House Homeless Shelter and Capital Humane Society. Dupsky also finds joy in leisure pursuits, indulging in family game nights with his wife and children, and embarking on adventures to scenic locales.

Director of Engineering Services, Encore Electric Inc.; MBA, University of Denver

Engelstad is a dedicated and accomplished engineering professional with a passion for impactful projects. As Director of Engineering Services at Encore Electric, Engelstad oversees all engineering and life safety aspects, emphasizing projects with purpose and impact. Before his tenure at Encore Electric, Engelstad demonstrated leadership and adaptability while working for the United States General Services Administration. Following an unexpected transition, he managed electrical engineering responsibilities for a significant six-state region, handling numerous federal projects. At Encore Electric, Engelstad has spearheaded critical innovations in electrical safety protocols, enhancing construction worker welfare and future building occupants' safety. In one case, he used his expertise to redevelop the energized electrical process and Encore’s entire electrical safety policy and procedures to include zero voltage verification as well as the entire process for systems energization. He also works to improve design-build standards and requirements, the quality and accuracy of coordination and engineering studies and continuing education courses to support professional electrician licenses for more than 800 electricians in five states. Engelstad’s expertise extends beyond traditional engineering roles; he actively contributes to industry organizations, including the Rocky Mountain Automatic Fire Alarm Association and the Society of Fire Protection Engineers. Engelstad is engaged in community service and volunteers with outdoor organizations and educational initiatives. He is passionate about passing on his love for the outdoors to his son and ensuring accessibility to natural spaces for future generations.

Senior Associate, BR+A; BS, Wentworth Institute of Technology

Principal, Point Energy Innovations; BAE, Architectural Engineering, Pennsylvania State University

As the managing principal and co-owner of Point Energy Innovations, Falconer works to provide an innovative and affordable approach to decarbonizing buildings. Falconer designs all-electric mechanical, electrical and plumbing systems with the hope of accelerating the adoption of resilient and zero-carbon strategies. She has completed multiple LEED Platinum, Net Zero Energy and Passive House projects across schools, offices and laboratories. Falconer’s leadership balances her technical design skills with a focus on market analytics, business development and client cultivation. Her commitment to sustainable systems is seen in her thoughtful and unique designs, including an all-electric laboratory that was one of the first to pair thermal energy storage tanks with heat recovery chillers to provide heating and cooling to the building. Falconer prides herself on building long-term relationships with architects, developers and institutions to ensure the integrity of a project from design to completion. She is a member of ASHRAE and the Urban Land Institute and sits on the San Fransisco Urban Land Institute Sustainability Committee. Outside of work, Falconer spends time with her husband and their two small children, ages one and four. She has also been deeply involved in the organization First Graduate, where she mentors middle and high school students through their academic journeys, leading them to college. She loves to cook and garden and finds it especially rewarding to use the freshest seasonal vegetables in her own meals.

ennell has over 15 years of experience in the fields of HVAC engineering, energy and sustainability. As a senior associate of BR+A, she has been involved in the engineering of HVAC systems, energy modeling and sustainable project management on many project types including health care, corporate, research and academic facilities. Fennell is a member of ASHRAE, NEHES and has served as secretary of the International Institute of Sustainable Laboratories Laboratory Benchmarking Working Group. Outside of BR+A, Fennell is engaged with various industry groups, including the International Institute for Sustainable Labs (I2SL), which aligns with her passions in the industry. She was founding member of the I2SL New England Chapter, served on the chapter’s board and has regularly attended annual conferences as a speaker. Fennell has also presented at other industry events, including the Massachusetts Hospital Association Annual Design Operations and Construction Conference and an Efficiency Vermont Seminar. Fennell was chosen out of over 250 BR+A employees for the Mario J. Loiacono Jr. Award in 2014 for her dedication to sustainability. She works to mentor and train younger engineers within the company, with a strong commitment to pass her knowledge to the next generation. Outside of work, Fennell enjoys photography, travel and spending time with her family. Some of her favorite places she is visited include the Salt Mines in Poland and Italy.

Associate, Senior Project Engineer, H2M architects + engineers; BS, Messiah College

Foerth is an esteemed professional whose journey at H2M architects + engineers epitomizes dedication, innovation and technical prowess. Foerth has made significant contributions that extend to notable clients, where he spearheads building renovation projects with meticulous attention to detail. He has vast experience in the real estate market, specifically with assisted living facilities. He has designed the HVAC systems at over 10 assisted living facilities throughout the tri-state area of New York, New Jersey and Connecticut. These systems have varied from standalone air conditioning units to multiple air conditioning systems to hot water boiler plants for multizone systems. Foerth’s passion for the energy field and commitment to maximize efficiency remains strong. He continuously engages in energy analyses, helping clients choose optimal mechanical systems. His inventive approach is evident in the diverse projects, from HVAC designs to complex utility regulations. Recognized for his outstanding character and professional achievements, Foerth’s promotion and involvement in H2M's mentorship program underscore his indispensable role within the company. His leadership shines through in every project he undertakes. Beyond his technical prowess, Foerth’s passion for community service is remarkable. Active in local philanthropic endeavors and his church, where he leads the parking team, he embodies a commitment to positively impacting the lives of those around him. He also is an avid sports enthusiast, having played college baseball. He enjoys going to the gym and playing sports with his friends and enjoys writing music in his spare time.

Senior Electrical Engineer, AKF; BS, Electrical Engineering, SUNY New Paltz

ith diverse experience in electrical engineering consulting, Foster has an instinctive grasp of local building codes, standards and the electrical design and construction process. She is valued by clients and colleagues for her insightful designs, efficient project management style and personable nature. Foster is a graduate of AKF’s Emerging Leaders Academy, an internal training program where participants must be recommended by the firm’s partnership. Foster joined AKF in 2016 as an electrical engineer and has grown from design engineer to project manager to engaging in business development efforts, especially at their new office in Washington, D.C. She also is a group coordinator at AKF, overseeing a team of fire and life safety engineers, helping them manage priorities and workload and assisting with assigning staff to projects. Foster specializes in the design of fire alarm and life safety systems in high-rise residential and commercial buildings and is committed to ensuring safety for the occupants who live and work within them. She is a sought-after resource for technical skills and knowledge. Foster enjoys serving as a mentor and advocate to new engineers, ensuring her colleagues are recognized and rewarded for their achievements. She is a dedicated committee member of WiMCO and Women in Healthcare D.C., two industry organizations geared toward engaging and empowering women in design and construction. Outside of work, she enjoys spending time with her husband, son and daughter, as well as doing yoga and fiber art. She buys washed and dyed wool at the annual Maryland Sheep and Wool Festival and spins it into yarn using a handmade spinning wheel her husband built.

Mechanical Department Facilitator and Engineer, Affiliated Engineers Inc.; BS, Mechanical Engineering, University of Wisconsin – Madison

Associate/Americas South Lighting Leader, Arup; BFA, Interior Architecture and Furniture Design, Konstfack University College of Arts, Crafts and Design

Atarting as an intern at Affiliated Engineers Inc., Graves has swiftly advanced her career. Initially focusing on prominent health care projects, she now spearheads some of the firm’s most intricate science and technology endeavors, notably in technically complex laboratory and research facilities. Recognized for her expertise in HVAC systems and unwavering commitment to sustainability, Graves now manages AEI’s largest mechanical department. Her portfolio boasts cutting-edge designs such as chilled beams, underfloor air distribution, natural ventilation and atrium smoke control systems. Beyond her technical prowess, Graves is instrumental in talent development, having pioneered a training program for new hires in partnership with her alma mater. Graves is also a dedicated educator, teaching an extension course for adults at UW-Madison. In addition, on the UW-Madison campus, she has taught an introductory mechanical engineering course since 2015, as well as partnered with numerous student organizations, including the American Society of Mechanical Engineers, ASHRAE, the Society of Women Engineers and Women in Science and Engineering. Recognized by ASHRAE, Graves received the 2024 ASHRAE First Place Technology Award for her invaluable contributions to Promega’s Kornberg Center. Beyond her professional accolades, Graves maintains a fulfilling personal life. She volunteers, finds joy in hiking and gardening and actively participates on her local library’s community board. Graves exemplifies a dynamic industry leader, blending technical excellence with a commitment to mentorship and community engagement.

s a lighting designer, Gisel has worked on projects across Berlin, New York City and Austin, Texas, to improve public spaces and give marginalized communities a sense of safety and equity. Gisel has worked on significant projects like the Governor Mario Cuomo Bridge for the New York State Thruway Authority and Brooklyn Bridge Plaza that demonstrate his key values of freedom and curiosity. Gisel’s mission on these projects was to define the future of New York City from a public lighting perspective by designing public spaces that would give communities the freedom to be themselves and feel safe. After his time in New York, Gisel moved to Austin, where he works as the office leader for Arup. His time in Texas has allowed him to explore the impact of lighting design beyond supporting people and to focus on diminishing light pollution. Most notably, his project with the city of Sunset Valley to reimagine a commercial and transportation corridor, Brodie Lane, uses lighting that does not disrupt animals or the natural environment. Gisel also volunteers for the Dark Sky Society in Texas, where he provides input to communities that seek to adopt dark-sky friendly codes. Outside of work, Gisel spends a lot of time in nature and enjoys exploring national parks and the greenery around him in Austin. His move to Texas also brought him to rowing and he enjoys taking moments on the lake as a self-care practice and an opportunity to connect with nature while still enjoying Austin’s urban setting.

Associate Director, Matrix Technologies Inc.; MS, Engineering, University of Toledo

Green began his career at Matrix Technologies Inc. 16 years ago, starting as an entry-level engineer. He progressed through several levels of the company and worked his way up to become an associate director and principal shareholder. Green has held client-facing roles during his career at Matrix and typical projects include industrial infrastructure, building projects for manufacturing clients and complex fire water systems projects. Green then used his knowledge and experience as the Matrix project manager for large, multidiscipline design projects that range from $500,000 to $50 million in total installed cost. Currently, he is the associate director in the mechanical and facilities design section, where he leads two groups of managers and technical staff, totaling 70 direct and indirect reports within seven regional offices. One group includes corporate engineering managers who develop design standards, deploy engineering technologies, provide training and maintain quality assurance on active projects. The second group consists of department managers, engineers, designers and drafters that provide process piping design, mechanical engineering and industrial facility designs to clients. Green is a member of the National Society of Professional Engineers. He is responsible for the maintenance of Matrix’s professional licenses and administers new license applications for engineering and architectural design services. Green enjoys preparing smoked meats with his wood-fired smoker including ribs, pulled pork, brisket, whole chicken, wings and vegetables. He is also a passionate sports fan, rooting for professional, amateur and high school teams.

Senior Building Analyst, Stantec; M.BS, University of Southern California

Griffin has been integral to informing the design of high-performance buildings in Asia, the Middle East and North America through his 15 years of building performance analysis. When he joined Stantec, Griffin established the Building Analytics services group, which he has led for the past eight years. The group’s focus includes energy modeling, parametric analysis, computational fluid dynamics and renewable energy. In this position, Griffin developed the Building Analytics service structure, energy modeling standardization, quality analysis and control process and onboarding procedures. This experience with building analytics and energy modeling has led Griffin to focus on holistic building optimization, net zero design and future climate analysis. Griffin has since developed a climate analysis tool for supertall buildings and worked with a colleague to develop a data center future climate sustainability plan focusing on improving power usage effectiveness. Griffin was Stantec’s first Energy+ECO group ambassador and is a part of the electrification, decarbonization and environmental, social and governance task force. Griffin is also a board member of the International Building Performance Simulation Association’s Chicago chapter (CHIBPSA) and is a member of ASHRAE and the Illinois Green Alliance. In 2019, Griffin and the CHIBPSA board developed the Dr. Ralph T. Muehleisen Scholarship Fund, which supports students interested in the field of building performance simulation. Outside of work, Griffin loves going on adventures with his wife and daughter. He is also an avid runner and loves to golf.

Electrical Engineer, Integrated Consulting Engineers; BS, Architectural Engineering, Kansas State University

Senior Mechanical Engineer, Interface Engineering Inc.; BS, Mechanical Engineering, Washington University in St. Louis

From learning the basics of engineering and Revit modeling as a college intern, to being a newly licensed senior mechanical engineer today, Jones enjoys learning and challenging herself to continue her career growth. Obtaining professional licensure, attending educational seminars on the latest industry technologies and maintaining healthy client relationships are all part of her overall goal to be an asset and resource for any design team she works with. Jones prioritizes iterative design with architects and other engineering disciplines to ensure smooth coordination and communication. She also prides herself on knowing the details of systems to better explain their specifics and make them understandable to any team member. Jones enjoys working in an industry where energy efficiency is at the forefront and where sustainability choices are visible and impactful on building- and community-level scales. She has experienced the benefits of both being mentored by more experienced engineers and providing mentorship to younger engineers. She sees particular value in encouraging and building the next generation of engineers — especially women interested in engineering fields. Jones is an active member of ASHRAE and Society of Women Engineers and has served as a Whitworth University Engineering Advisory Board member since 2018. Outside of work, she volunteers in her community, providing respite foster care for local families, donating platelets at the Red Cross and serving meals to the unhoused. She also enjoys exploring the outdoors, crafting and sewing, reading a good sci-fi novel and eating at the many Portland, Oregon, food carts.

Associate, Certus Consulting Engineers; BS, Architectural Engineering, Kansas State University

Weldstab's journey into engineering began at an early age, fostered by her stepfather's career as a general contractor. Her early exposure to job sites and hands-on experiences ignited a passion for understanding how things work and set the foundation for her remarkable career in the field. Having been with ICE for a decade, Heldstab values the collaborative and diverse nature of their projects, which ensures that no two days are the same. As a certified electrical safety technician, Heldstab provides an additional service by ensuring electrical safety standards are met on each project. Serving as the primary point of contact for all project-related matters, Heldstab has developed collaborative working relationships with architects, general contractors and other stakeholders. Her client-focused approach and open communication style have resulted in enduring partnerships with clients who trust her expertise. Drawing on her experience in construction administration and quality control, Heldstab excels in coordinating various aspects of complex projects. Active in professional societies, she holds positions such as the program chair for the Illuminating Engineering Society and is affiliated with the International Association of Electrical Inspectors and the NFPA. Heldstab also engages in community service with organizations such as Habitat for Humanity and Warming Souls, a partnership between HumanKind Ministries and the Catholic Diocese of Wichita to provide food and shelter for the homeless and hungry. She enjoys spending time with her husband and two children, who all share a love for concerts, camping and travel, particularly to destinations with a beach.

ith six years of experience as a consulting engineer, Koch is now a lead electrical engineer and project manager. With his expertise in health care design, he has worked on projects of all sizes and complexities, including ambulatory surgical centers, medical office buildings and mixed license facilities. He also has extensive experience in facility assessments, commissioning and infrastructure work that translates into his health care designs. Notable projects include the 77,000-square-foot new building design for Baylor Scott & White Heart and Vascular Hospital, where he was the lead electrical designer, and multiple projects with the Texas Health Huguley Hospital, as an electrical designer across the 110,000-square-foot campus. Projects like these demonstrate his leadership abilities and client-centric approach to ensuring a project is completed to a standard beyond client expectations. Colleagues note Koch’s commitment to collaboration as a key to his success as a leader and mentor. Outside of his duties to the firm, Koch is committed to continuing his own education and inspire others in the process. He has spoken on several webinars and internal learning sessions, conveying the significance of complex topics articulately and clearly. In his free time, Koch is dedicated to his community and is an active member of Green Space Dallas, an organization that works to keep forests and rivers clean and well preserved. He also loves to cook and is often found experimenting with new recipes and cooking techniques. His favorite part is sharing his creations with loved ones, including his signature seafood paella.

Lighting Designer, BR+A; MFA Lighting Design, Parson’s School of Design

aving earned a Bachelor of Architecture from Tamkang University and garnered several years of experience in architectural design in his home country, Kuo left for the United States at age 28. After earning his master’s degree, Kuo joined BR+A, where he has brought an innovative and dedicated approach to his role. He has contributed to critical projects, including the Residences at Sterlington by Watchtower Bible & Tract Society, OSF Comprehensive Cancer Center and the Mass Bay Community College Health Science Center. Outside of BR+A, Kuo has shared his expertise at industry events such as LEDucation and LightFair and his presentations have been published on the Northeast Sustainable Energy Association website. As a board member at the Designers Lighting Forum of New York, Kuo orchestrates lighting design tours, showcasing award-winning projects in the city. His expertise extends to lighting design software, where the development team of LightStanza expressed keen interest in partnering with BR+A and Kuo for an in-depth evaluation. Kuo’s hands-on involvement during construction and effective communication throughout the design phase is one of the keys to his success and has led to his recognition by the Illuminating Engineering Society. Colleagues commend Kuo for his ability to collaborate seamlessly within global teams, navigate cultural sensitivities and resolve professional challenges, proving invaluable in project completion. Kuo maintains strong connections with family and friends in Taiwan, prioritizing annual visits. Committed to a healthy lifestyle, he enjoys dancing, bouldering and quality time with friends.

OT Cybersecurity Discipline Leader, CDM Smith; MS, Network Information and Computer Security, New York Institute of Technology

Senior Manager, Mott MacDonald; MS, Electrical Engineering, Fairleigh Dickinson University

Ltarting with CDM Smith in 2011 as an automation engineer, Lick was originally responsible for designing and programming industrial control systems, most commonly at water and wastewater treatment facilities. In his 13 years with the firm, Lick has gained expertise in programmable logic controllers, human machine interface systems and cybersecurity planning and risk management. His interest in cybersecurity came soon after starting his career as an engineer, leading him to a master’s degree and the ISC2 Certified Information Systems Security Professional certification. With these qualifications, Lick dedicated himself to developing cybersecurity standards and practices. In 2023, he was promoted to the national role of operational technology cybersecurity discipline leader, where he focuses on staff development, advancing the cybersecurity capabilities in the automation practice and the proper application of technology. Dedicated to spreading knowledge, Lick is a mentor within CDM Smith and speaks at conferences, webinars and client meetings. He has presented on various topics including enhanced chemical feed control, ammonia-based aeration control, cybersecurity and high-performance human machine interface graphics. Lick is an active participant in ISC2’s Long Island, New York, chapter, providing a unique perspective to a membership comprised mostly of information technology professionals. Outside of work, Lick is a devoted family man and his wife and two children are at the heart of everything he does. He also loves to explore, whether that is the natural beauty and towns of Long Island or the national parks out West.

au is currently a senior manager and project engineer in electrical and power for Mott MacDonald and holds active licenses in three states. Lau is a Nationally Certified Tunnel Inspector to Federal Highway Administration standards. He is also involved in the Illumination Engineering Society through various subcommittees, with expertise in tunnel and roadway lighting. Lau provides technical subject matter design for electrical, lighting and fire/life safety systems to major multibillion-dollar infrastructure projects. He has worked with the Department of Transportation and private clients on mile-long vehicular tunnels and both above- and belowground rail stations. Lau designs and inspects critical systems to ensure public safety for all facility and roadway users and provides numeric and rendered solutions to deliver accurate and detailed building inform/3D modeling. Most recently, he was promoted to team lead, where he supports and mentors a corporate team. His latest design venture is in Canada managing an electrical, lighting and fire alarm design team for the Scarborough Subway Extension, a project valued in the billions for construction costs. Outside of his work duties, Lau is the chairperson of Mott MacDonald’s Intelligent Modelling Design and Smart Processes committee, which helps pave the way for innovative approaches and streamlined processes to deliver daily or lengthy tasks in a faster, more efficient way. In his free time, Lau enjoys robotics and tries to incorporate his engineering prowess for any challenge that comes his way. He partakes in different robotic competitions to put his skills to the test.

Principal/Senior Engineering Operations Manager, STV; BS, Drexel University

Maniar’s multifaceted expertise and unwavering commitment to excellence have earned him widespread recognition in the field of electrical and computer engineering. At STV, Maniar leads a team of six engineers, guiding their professional growth and fostering a culture of innovation and collaboration. Maniar’s impact extends beyond his workplace, as evidenced by his pivotal roles in groundbreaking initiatives such as the development of NYC's Waterfront Code and participation in LEED exam maintenance activities. His contributions to projects like the innovative lighting control system for a pharmaceutical client, which is designed to be scalable in capabilities showcase his talent for developing practical and cutting-edge solutions to meet specific client needs. Maniar has also developed sophisticated electrical engineering designs for the NYC Department of Environmental Protection, which reduced points of failure and increased flood resiliency for wastewater pumping stations across four New York City boroughs. Dedicated to nurturing the next generation of engineers, he actively mentors students through various programs, including ACE and NFTE, while also sharing his insights through presentations and seminars. Maniar has published articles on complex topics such as low-voltage switchboard design and medium-voltage switchgear design. He maintains active involvement in esteemed professional organizations such as IEEE and PMI. In his downtime, Maniar indulges his passions for hiking, travel and Formula 1 racing.

Moussawi, a native New Yorker, has been a scientific explorer at heart from early childhood. After defending his doctorate, Moussawi joined the building envelope division of Simpson Gumpertz and Heger, where he contributed to large building projects shaping New York City. He was the lead on several curtainwall forensic investigations, each involving a dispute with high potential remediation costs. Moussawi also developed the basis of design for the envelope at the Delta terminal at LaGuardia Airport and contributed to the design of the renovation at the Air and Space Museum in Washington, D.C. In 2019, he joined the Turner Engineering Group at Turner Construction, where he works closely with builders, architects and engineers to provide risk mitigation and cost optimization and to improve sustainability. In late 2020, he started leading the building physics discipline. He has since led envelope numerical modeling and whole building energy modeling, advising on design risk management and optimization as well as cost of ownership and carbon emissions for more than 50 projects. In January 2024, he earned his building energy modeling professional certification from ASHRAE. Outside of work, Moussawi is a dedicated volunteer who has done dog shelter walks, helped put food together for the vulnerable in the community and helped prepare aid packages for victims of the Turkey/Syria earthquake. Moussawi and his wife do not have children yet, but they do take care of 15 hens in their backyard coop and maintain a garden. They also enjoy hiking, biking and baking homemade pizza.

Managing Partner, CMTA; BS, Electrical Engineering Technology, Algonquin College

Associate Principal, BR+A; BS Mechanical Engineering, Villanova University

Murphy is a dedicated and driven engineer who has emerged as an exemplary leader for both his colleagues and his counterparts in the industry. Beginning his career at BR+A, Murphy advanced through hard work and ingenuity to become a leading Project Manager and Associate Principal. During time as a Project Manager, he effectively communicates with internal and external mechanical, electrical and plumbing (MEP) partners. He also collaborated with owners, architects, contractors and project consultants to ensure delivery of high-performing MEP design that align with schedule, budget and building performance goals. Murphy cultivates client relationships for new business, serves as a mentor and resource for design staff, coordinates staffing and works on implementing new company initiatives. He works on a wide range of projects, including small health care renovations, several academic science buildings, infrastructure replacement and large-scale health care projects. Murphy manages electrical, plumbing, fire protection and technology systems designs, while also leading the HVAC design on most projects. Murphy strives for sustainable designs, as seen in his work on an AIA Committee on the Environment award-winning building. He has also worked with members of BR+A to educate owners and architects on sustainable design practices. In 2016, Murphy began an office toy drive for the Christmas in the City charity and has been leading the annual effort ever since. He enjoys golf, traveling with his wife to experience other cultures, nature and food. Their recent travels included time in southern France where they were able to experience the Calanques near Marseille.

ith over 18 years of experience, Parkinson has worked as an electrical designer, project manager and director. In his role with CMTA, he manages a team of 20 people, demonstrating his strong technical background and leadership ability. Parkinson values relationships with colleagues, especially since they spend the same amount of time with each other as they do with their families. He is passionate about leadership and hopes to foster a culture where everyone works cohesively toward common goals and assists one another in reaching their full potential. After working in companies that fostered a structured leadership approach to work, Parkinson firmly believes in encouraging employees to actively contribute rather than waiting for opportunities to arise. From down-and-dirty renovations to large-scale greenfield spaces, Parkinson’s diverse experience and interest in others ensures that clients feel understood, particularly when discussing their needs and pain points. As a consulting engineer, he is always trying to find ways to provide value to clients, sometimes even through unconventional means. An example of this is when Parkinson and his team assisted Grady Hospital staff in relocating patients and equipment when it flooded, then collaborated closely with Grady Health, architects and contractors to redesign the flooded floors. Given the urgent need to resume operations, they completed the permit drawings in just two months, enabling all floors to be operational within a remarkable eight-month period. In his free time, Parkinson has always found joy experimenting in the kitchen, while also finding time to travel to Napa Valley, California, each year, where he immerses himself in the rich culture of wine and cuisine.

Project Executive, IMEG; MBA, Bethel University

How often do you sell a company? Quast did it at just 31 years old. He was a project electrical engineer and director of finance and administration at LKPB Engineers Inc., in Minneapolis, where he headed the company’s merger with IMEG. His career started at LKPB in 2010 after earning a degree in electrical engineering from the University of Minnesota, where he also was a Division I gymnast. Quast designed and analyzed power distribution, lighting systems and fire alarm systems for clients in the education, corporate and commercial sectors, while earning his MBA in 2014 and his professional engineer’s license in 2016. In addition to managing the merger, Quast drove the organization’s financial operations and managed the administrative staff, outsourced IT, human resources and payroll operations. In 2019, he began serving as IMEG’s operations manager for the Minneapolis mechanical, electrical and plumbing engineering team. In 2023, he was promoted to project executive, managing approximately $3.3 million in fees — the largest of his local team. Quast also sits on two Ebenezer Management boards that oversee federal Housing and Urban Development low-income senior housing apartment complexes in suburban Minneapolis-St. Paul and is a member of the North Central Electrical League and the Minnesota Chapter of Association of Physical Plant Administrators. Outside of work, he volunteers with Give Kids a Smile, an American Dental Association program that offers free annual dental clinics for children. Quast also enjoys spending time with his wife, two children and two dogs.

Section Manager, Burns & McDonnell; Masters of Architecture, The Ohio State University

auter is an Associate Project Manager at Burns & McDonnell, where she leads multidisciplinary teams through complex campus designs in critical environments for hyperscale data center clients on accelerated schedules. When Burns & McDonnell opened a new office branch in Columbus, Ohio, in 2017, she was the sole project manager and tasked (alongside a few others) with building a team. Today, the Mission Critical team is flourishing with over 240 people globally, including a dedicated team of approximately 40 people in Columbus with Sauter. She works closely with clients and project teams to establish project goals and schedules and ensure client expectations are exceeded throughout design and construction. She regularly facilitates design team meetings, client presentations, milestone deliverable page turn reviews and quality review sessions with internal and external parties. With a background in architectural design and master planning, Sauter approaches projects holistically, with a keen attention to detail that results in high-quality, reliable design deliverables coordinated for immediate construction. Drawing from experience early in her career, Sauter also has a strong understanding of building information modeling processes and often works closely between disciplines to review, analyze and refine designs. Sauter is profoundly committed to the success of her projects and to her teams. Beyond her commitment to clients and projects, Sauter also dedicates time toward training junior staff and participating in career development programs and professional organizations. Outside of work, Sauter spends time with her husband, three children and golden retriever.

Engineering Practice Leader, Hellmuth, Obata & Kassabaum; BS, Mechanical Engineering, University of Texas

Senior Code Consultant, AKF; MS, Fire Protection Engineering, Worcester Polytechnic Institute

Seaboldt has dedicated her career to delivering safe solutions for successful design and construction projects. She is a licensed fire protection engineer in Connecticut, Massachusetts, Rhode Island and Vermont and a certified plans examiner with the International Code Council.

herman has more than 13 years of experience designing mechanical systems for various project types, including commercial, corporate, science and technology, industrial facilities and government. He serves as the leader of mechanical engineering for the Houston HOK studio on many projects, overseeing the preparation of working drawings and specifications, coordination with consultants/clients and final design acceptance. Sherman’s expertise includes design, documentation and oversight of HVAC systems, coordination of design efforts between disciplines, energy modeling and sustainable design and schedule and budget issues. Sherman is an innovator who led the mechanical engineering on one of General Services Administration’s first renovations to make a historic courthouse fully electrified and on the first project in Guyana designed to be net-zero energy. He is on HOK’s Global Decarbonization Taskforce and spearheads the firm’s efforts to meet the challenge. In 2014, he and a group of coworkers established HOK’s mentoring program for the Houston studio; it has since been adopted firmwide. Sherman began his career at HOK in the Houston office as an engineering designer. He became engineering practice leader at 35, making him the youngest person in that role, which oversees all work in the Central and Eastern regions. Outside of the office, he spends most of his time with his wife and their two sons. He also loves to cook and is a huge sports fan. He enjoys college football and everything that goes with it — especially tailgating.

Seaboldt is an expert in building, fire and accessibility codes and standards, regularly navigating complex fire and life safety requirements, jurisdictional amendments and evolving regulations affecting both new and existing buildings. She is a sought-after resource for health care, residential, higher education and transportation projects, as well as challenges involving hazardous material storage, mass timber construction and lithium-ion battery protection. She has a passion for teaching and is a reliable technical resource for younger engineers and engineers of other disciplines. She presents at conferences and client offices, has written for industry publications and produces AKF’s quarterly code consulting newsletter.

Seaboldt is a graduate of AKF’s Emerging Leaders Academy and is a member of the firm’s mentorship committee, serving as both a mentor and an ambassador for the program. Seaboldt is active in Professional Women in Construction’s Boston Chapter and is a member of the Society of Fire Protection Engineers and NFPA. She is often involved in events to promote the role of female-identifying individuals in engineering, including planning a local Women in STEAM event. In her free time, Seaboldt is an avid swimmer, home cook, reader and writer. She has a growing collection of old books and regularly participates in creative writing competitions, with several published short stories of her own.

Manager of Sales Engineering, Noodoe; BS, Electrical Engineering, Ohio Northern University

Sibila’s core focus in his career has been on helping others understand the benefits of electric vehicles (EV) and charging infrastructure. He has a unique perspective to share and works to educate others in a way that is clear and understandable regardless of their background. Sibila has gone about this from all angles, from community service, to building personal and professional relationships, to creating an online presence as a voice of the EV industry. Starting his career in utilities with American Electric Power, he gained experience on electrical transmission, a crucial piece of building EV infrastructure. He then made the jump to the EV industry as a sales engineer with Shell Recharge Solutions, where he grew his speaking and presentation skills while still leveraging his engineering background. As manager of sales engineering with Noodoe, Sibila leads North American efforts for an up-and-coming EV company. He also has built a large online audience where he teaches the public about the driver experience of EVs. His YouTube channel has more than 30,000 subscribers and he has large followings on other social media platforms as well. Sibila volunteers with Tesla Owners Columbus and Drive Electric Columbus in the greater Ohio area, where he helps plan events and engages with community members to educate them about EVs. With Tesla Owners Columbus, he has a leadership role as club secretary. Outside of work, Sibila is recently married to his wife, who he met in engineering school. In his free time, he enjoys working out, running and playing basketball around Columbus.

Partner & Electrical Engineer, CMTA; BS, Electrical Engineering, University of Kentucky

Stewart has designed a variety of lighting, power and photovoltaic projects, specifically in new and renovated K-12 facilities. He concentrates on high-efficiency electrical systems that reduce the operating costs of the building. In the fall of 2006, Stewart successfully interviewed for a college co-op position with CMTA while attending the University of Kentucky. In the first few years as a consulting engineer, Stewart honed his skills in fundamental electrical engineering practices in and mastered the drawing software he used daily. His projects spanned eastern Kentucky, including designing the 240,000-square-foot student center at Morehead State University and the new 72,000-square-foot Pikeville County Public Library. These experiences not only introduced him to remarkable colleagues and peers, but also led to the establishment of lasting relationships that still thrive. When CMTA developed an office in Richmond, Virginia, Stewart was asked to spearhead the electrical engineering department, which now has six engineers. Stewart leads day-to-day electrical operations and is dedicated to mentoring and teaching the younger engineers. In 2019, Stewart became a partner in the firm and is now heavily involved in business development and staff growth in the Richmond office. Additionally, he continues to work closely with CMTA’s Lexington, Kentucky, office where he started. When he is not busy working, he likes to golf, travel and follow horse racing.

Associate, Boston Resilience Leader, Arup; M.U.P., University of Michigan

Electrical Engineer, CDM Smith; MS, Electrical Engineering, North Carolina State University

In her short tenure as a power electrical engineer, Vang has already left a significant mark both in designing electrical distribution systems for water/wastewater treatment plants and pump stations and through her analysis of power systems. She has contributed to projects encompassing arc flash, load flow, short circuit and coordination studies, with notable assignments on naval bases in Italy, Colorado and Virginia. In her wastewater experience, Vang looks for projects involving generator-utility paralleling and upgrades to existing electrical equipment. Her work across these disciplines demonstrates her technical expertise, interpersonal communication skills and creative problem-solving. After graduating in 2017, she completed an accelerated master’s program only a year later. In her studies, she conducted and presented research on power reliability. Her dedication to the field was further evident when she obtained her professional engineer license within five years of beginning her career, showcasing not only her commitment but also her intelligence and strong work ethic. Vang served in the inaugural class of quality appraisers and in the specification cross-training program at CDM Smith. Through these initiatives, she assisted project management teams and helped develop and standardize specifications among engineers. Like many in the field, Vang has always had a passion and proficiency for math, which she now extends to volunteering for local MATHCOUNTS competitions and tutoring her many nieces and nephews. Outside of work, she enjoys hiking, trying out new cuisines and spending time with her family. As the youngest of 14 children, there is no shortage of family activities to keep her busy.

n urban planner by trade, Wholey has built a career focused on preparing the built environment for the impacts of climate change. Wholey’s interest in climate resilience started while growing up in a coastal town prone to flooding and continued to grow through her research and studies on disaster recovery and community planning in her master’s program. While completing this degree, she interned for a nonprofit organization working on Superstorm Sandy recovery efforts in New York and then began her professional career with the New York Governor’s Office of Storm Recovery following graduation. This work provided Wholey with valuable insights into the unique challenges of post-disaster recovery efforts and the critical importance of protecting communities before disaster hits. She joined Arup in 2016, where she has worked on projects at all scales, from resilience design for buildings to climate risk and resilience assessments for major infrastructure owners, municipalities and large portfolios of buildings. Much of Wholey’s resilience planning and design work is grounded in social equity, seeking to center community voices in the planning and design process. She leads the Boston office’s sustainability, climate, resilience and environment team and is the global learning manager for Arup’s resilience skills network. Outside of work, Wholey spends time volunteering with organizations like Horizons for Homeless Children and Habitat for Humanity. She also enjoys spending time outdoors and traveling and hopes to visit the Patagonia region, Japan, Cambodia and Vietnam.

Associate Principal, Alvine Engineering; Master Architectural Engineering, University of Nebraska-Lincoln