Leadership in Engineering 2023

January 2023 www.designworldonline.com

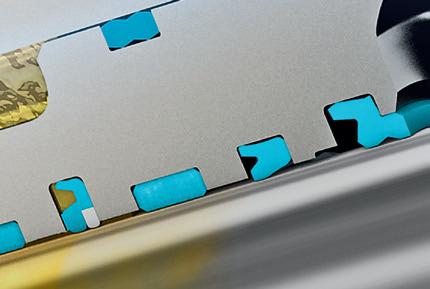

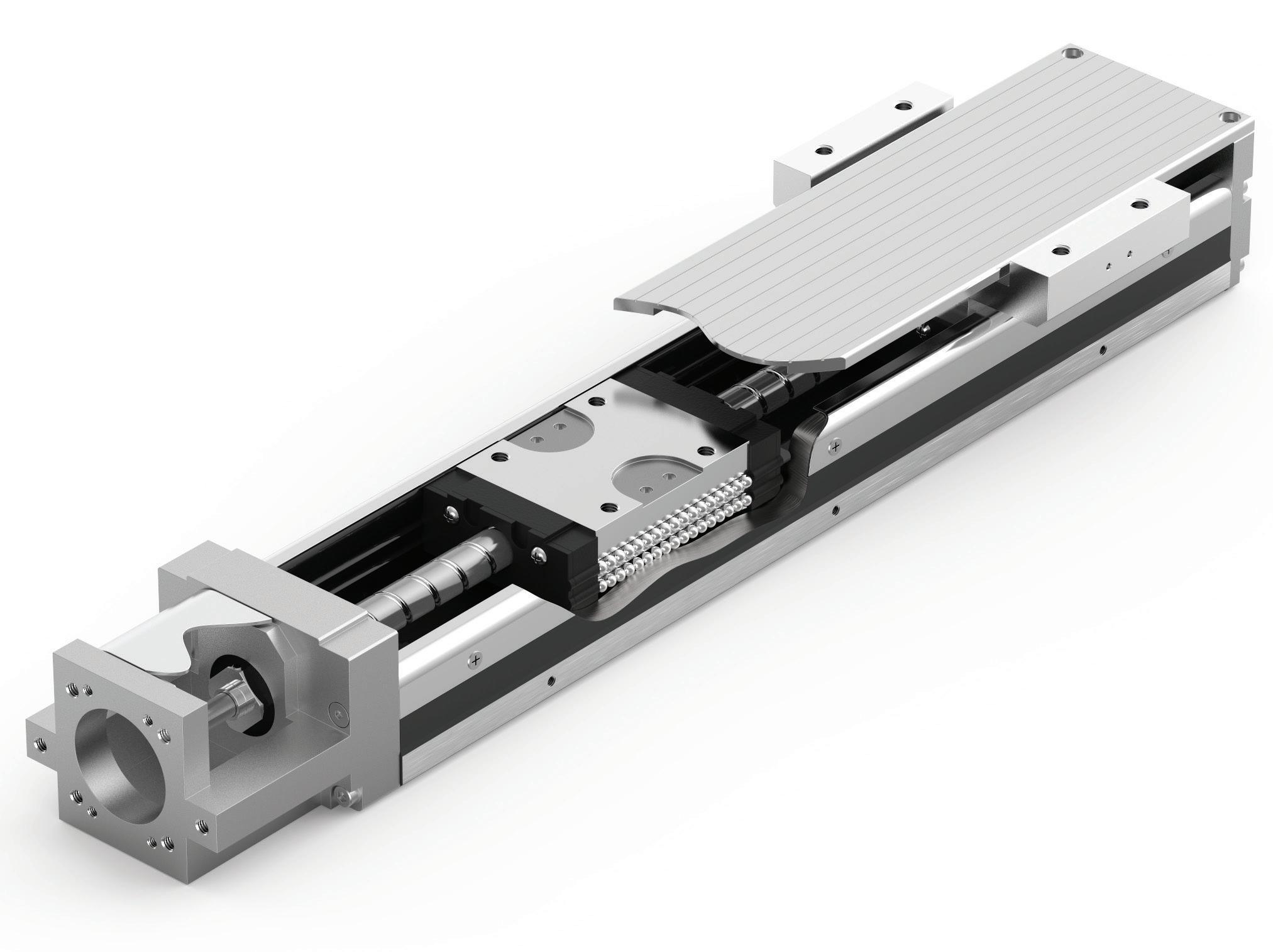

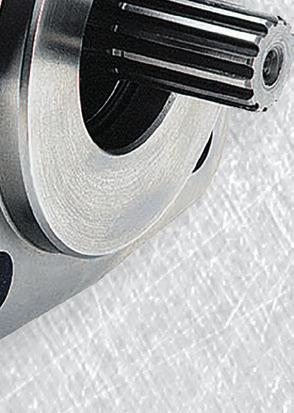

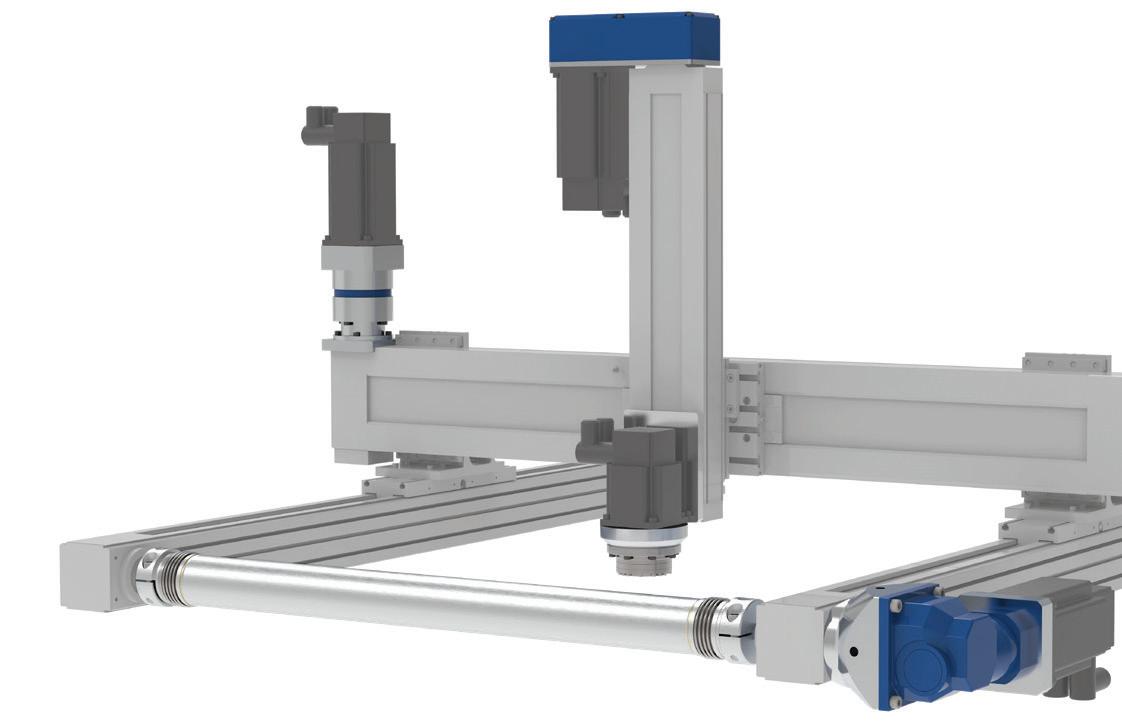

THK is committed to meeting the worldwide demand for linear motion products. We manufacture, assemble, and ship across North America from our location in Hebron, Ohio. We’ve also ramped up our automating processes at existing facilities, including our U.S. manufacturing plant, where over 70% of THK Robotics Components are manufactured. Automated processes at this state-of-the-art facility enable increased production while maintaining the high standard of precision associated with THK products. To learn more, call us at 1-800-763-5459 or visit www.thk.com. See us at ATX West, Anaheim CA, Feb. 7 - 9, Booth #4254

LOCAL MANUFACTURING WORLD-CLASS LINEAR MOTION 1–2 Week Delivery of Select LM Guides and Actuators QUICK SHIP COMPONENTS THK Manufacturing in Hebron, Ohio

Quality Linear Motion Solutions from THK

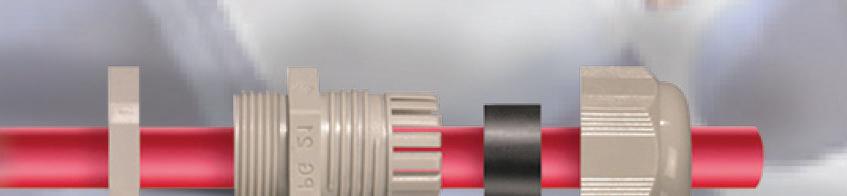

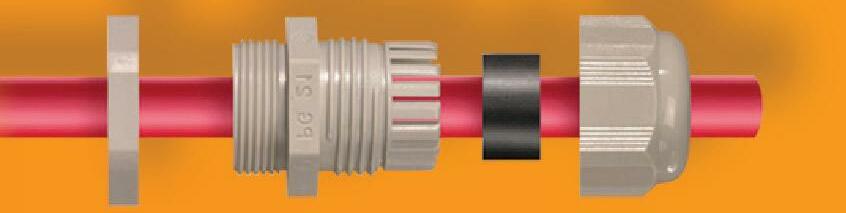

Need Pneumatic Components?

Everything you need at great prices, in stock and ready to ship same day

Pneumatic Air Preparation

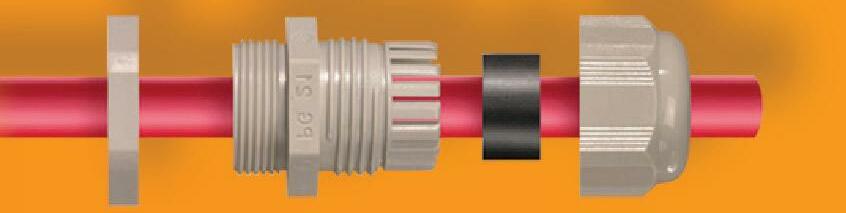

All pneumatic motion requires clean and dry air. The process of filtering, regulating and lubricating compressed air is known as air prep. The Norgren and NITRA family of air preparation components include:

• Particulate filters with 40 micron filter element (5 micron option), coalescing type and oil vapor removal in sizes from 1/8” to 1” NPT port sizes

• Regulators with adjustment from 4-58 PSI, 7-60 PSI, 7-130 PSI and 4-145 PSI

• Combination filter/regulators available with same options in one unit

• Lubricators in 1/8” to 1” port sizes

• Total air prep units that combine all air preparation functions in one compact unit

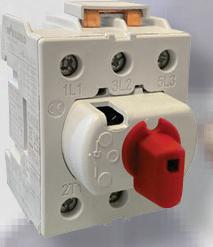

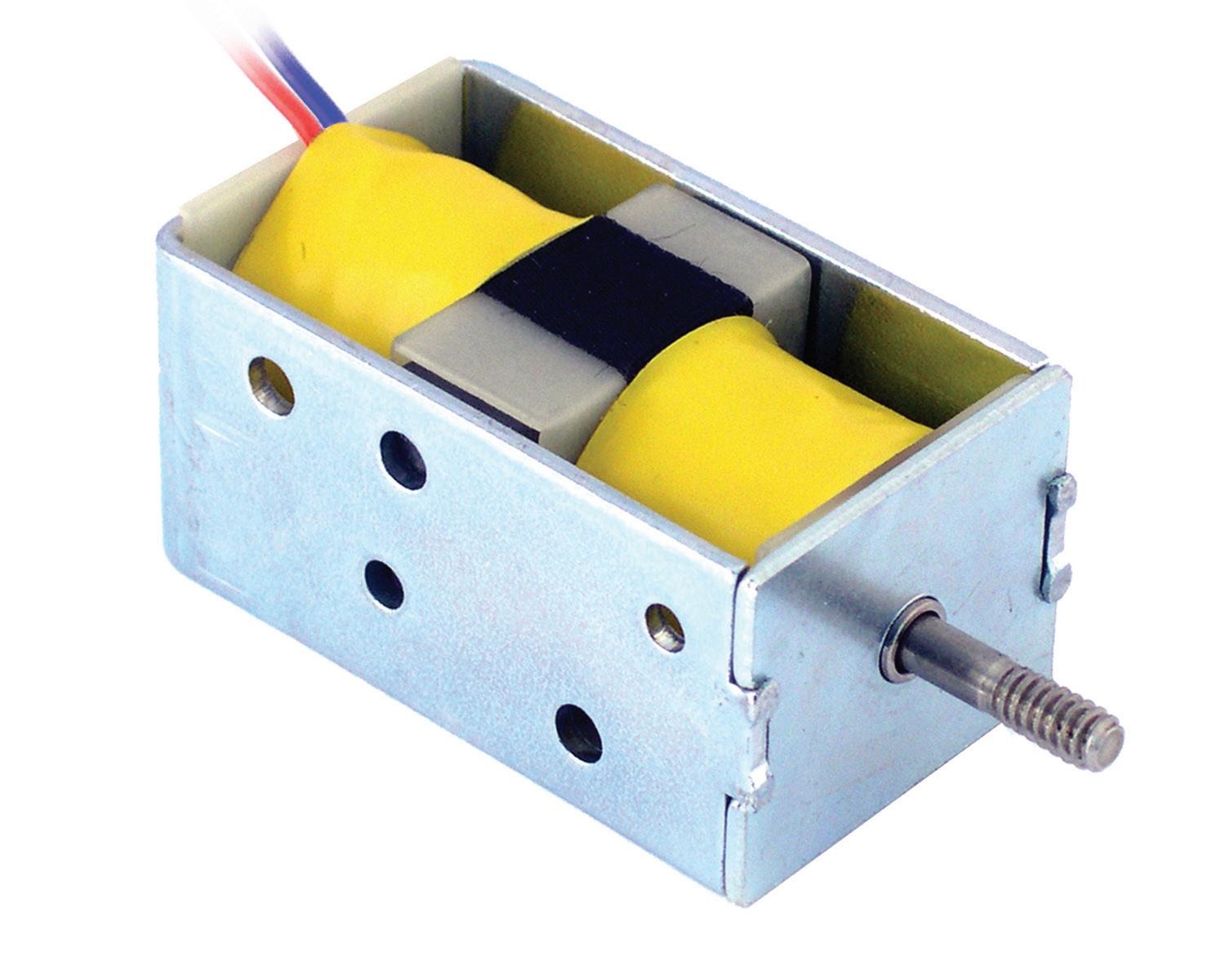

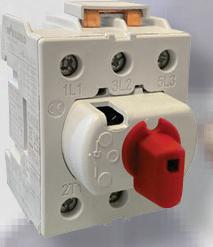

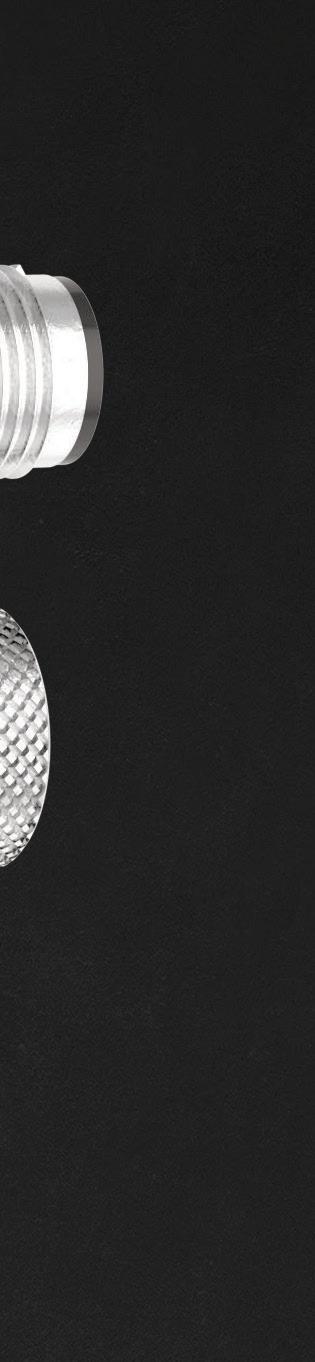

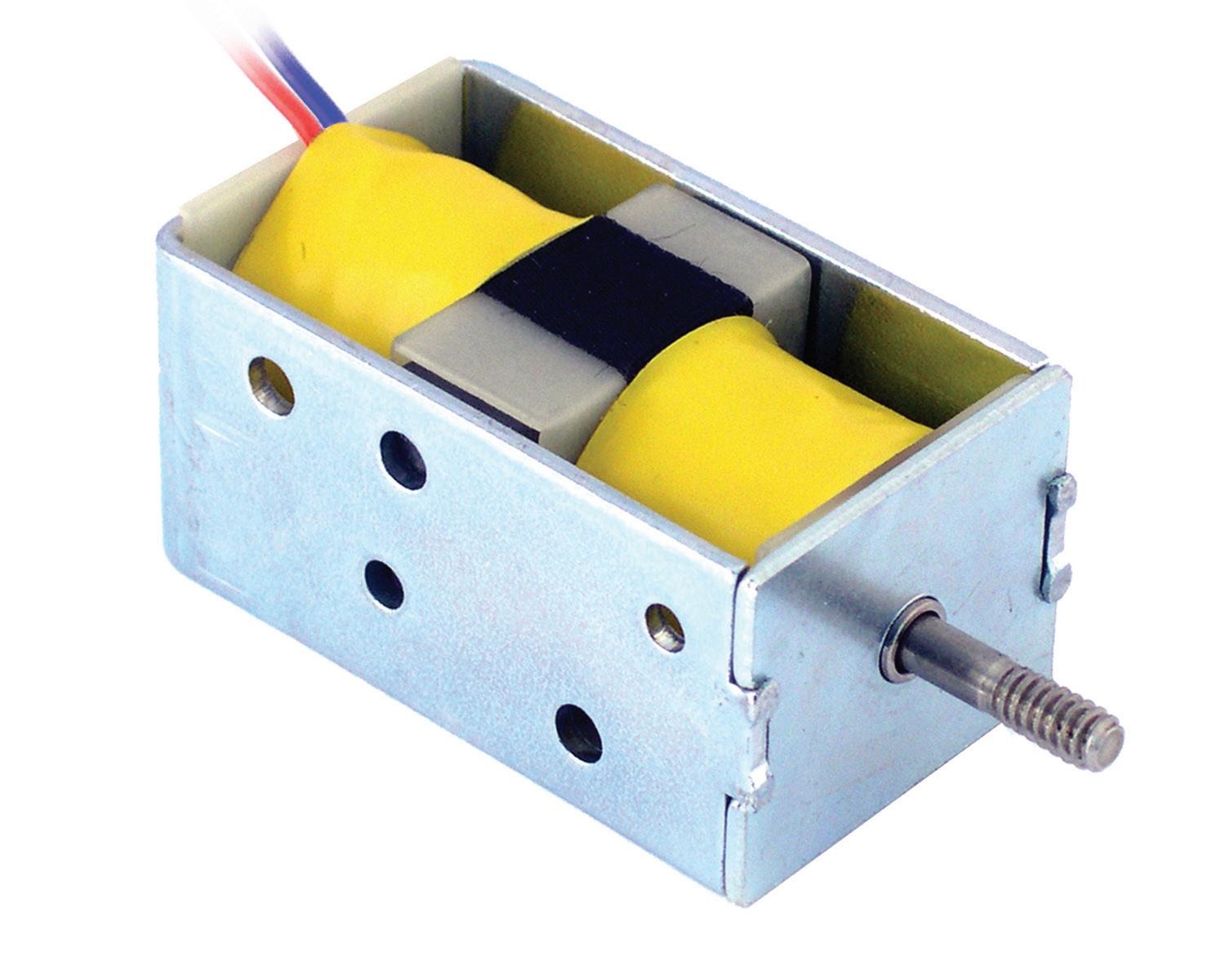

Solenoid Valves

Solenoid valves are electrically controlled to direct air flow to sequence operations in pneumatic systems. Solenoid valves are used to control cylinders, rotary actuators, grippers and other pneumatic devices. Use a manifold to simplify plumbing for a bank of valves. Modular systems even allow networked control of valve group.

• Available as stand-alone units or as part of a compact modular valve system

• Stand-alone units can be used with optional manifolds to make system configuration simpler

• Available in 3-port/3-way, and 5-port/4-way styles

• 4-way valves come in 2-position or 3-position styles with center closed or center open

Pneumatic Cylinders

The most popular style of pneumatic actuator uses compressed air acting on a piston inside a cylinder to move a load along a linear path.

• Round body cylinders available in single-acting or double-acting styles, with up to an 18-inch stroke and 2-inch bore. Also available in stainless steel. Magnetic pistons are optional.

• NFPA tie rod air cylinders come in double-acting style, with up to a 32-inch stroke and 4-inch bore. All include a magnetic piston. Adjustable ai cushions are an option.

• ISO 15552 air cylinders are double-acting cylinders with up to a 600mm stroke and 100mm bore. All include magnetic pistons and adjustable air cushions.

• Metric and Inch compact air cylinders as well as dual rod guided air cylinders also available.

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Research, price, buy at: www.automationdirect.com/pneumatics

AIR PREP COMPONENTS STARTING AT $24.00 (AF2-223) SOLENOID VALVES STARTING AT $24.50 (AVS-3111-24D) ALL COMPONENTS AS SHOWN TOGETHER $418.75 PNEUMATIC CYLINDERS STARTING AT $13.50 (A07005SN)

• Engineering Assistance / Fast Delivery www.zero-max.com 800.533.1731 PRECISE. ROBUST.AVAILABLE.

Insights

A thank you to two impactful editors

With the new year always comes change. Here at Design World, we’re bidding adieu to two fantastic editors who are retiring after long and fruitful careers. Leslie Langnau, who served for more than a decade as this publication’s Managing Editor, has truly been my mentor here. She’s covered a bit of everything for us, with a special focus on the additive manufacturing space — and her insights there have always been must-reads for that part of the industry. You may still see Leslie’s name around now and again, as she’s agreed to help on a few projects moving forward.

The other editor is Lee Teschler, who came over to WTWH a handful of years ago from a competitor and planned to stay a short while — but he enjoyed his stay here so much that he decided to push o retirement a few years until now. Lee’s long been a respected voice in the industry, and his columns always have something important to teach. His insightful editorials, well-researched feature stories, and brilliant tear-down videos will be sorely missed.

At the same time, I’m a bit overdue to welcome Rachael Pasini, our newest sta member, as Senior Editor on both Design World and Fluid Power World. Rachael, a multi-degreed engineer from The Ohio State University, brings with her a natural talent for technical writing, as well as the experience of a fascinating career that has even included teaching math and physics in Hawaii. Rachael started with us in September.

Speaking of Rachael, she’ll be joining three longtime Design World editors — Lisa Eitel, Miles Budimir, and Mike Santora — in taking over Leslie’s Technology Forward column. The four editors will rotate throughout the year to bring you their latest thoughts and opinions in a variety of industry niches, from motion control to engineering ethics, and robotics to digital manufacturing advances. The first column in this new series appears in this issue.

There’s a lot more excitement to come in 2023, so please stay tuned. We’re planning some strategic ways to keep you better connected to the news, trends, and technologies that a ect your job every day. As always, I look forward to hearing your feedback and ideas for improving the publication and its websites. DW

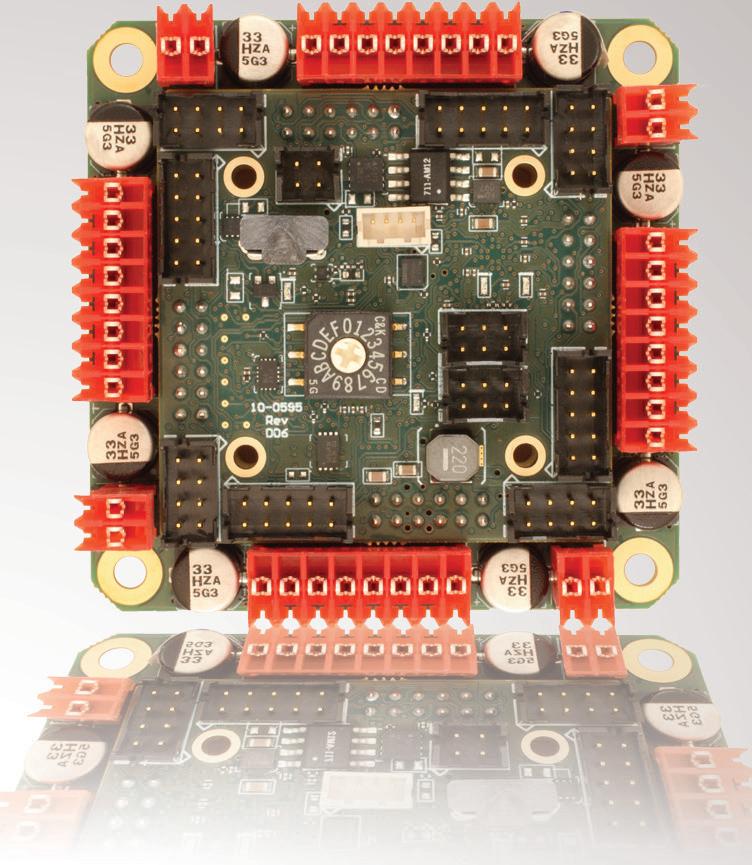

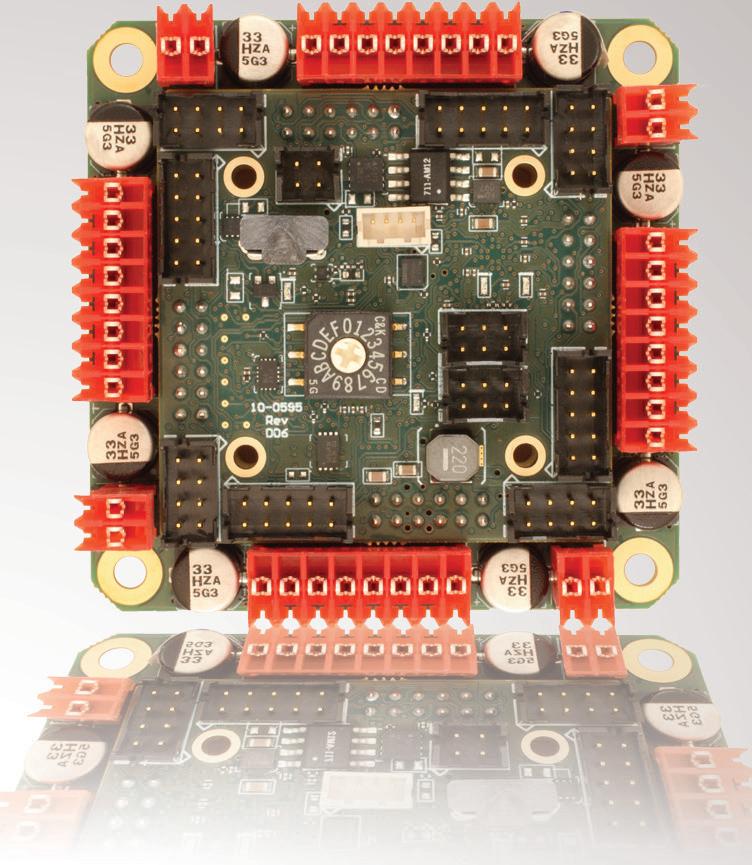

4 January 2023 www.designworldonline.com DESIGN WORLD - brushed or bldc motors - 5 amps per axis - 16 analog inputs - 16 on/off drivers - home and limit in - live tech support - made in the USA WWW.ALLMOTION.COM (510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action! 2.25” 4 AXIS SERVO from NEW!

On Twitter @wtwh_paulheney

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

Compare These Blowoffs

ere are a variety of ways to dry, clean or cool products and surfaces, but which method is best? To decide, we ran a comparison test on the same application using four different blowoff methods: drilled pipe, flat air nozzles, Super Air Knife (each using compressed air as a power source), and a blower supplied air knife (using an electric motor as a power source). Each system consisted of two twelve inch long blowoff options. The following comparison proves that the EXAIR Super Air Knife is the best choice for your blowoff, cooling or drying application.

e goal for each of the blowoff choices was to use the least amount of air possible to get the job done (lowest energy and noise level). e compressed air pressure required was 60 PSIG. e blower used had a ten horsepower motor and was a centrifugal type blower at 18,000 RPM. e table below summarizes the overall performance.

Drilled Pipe is common blowoff is very inexpensive and easy to make. For this test, we used (2) drilled pipes, each with (25) 1/16" diameter holes on 1/2" centers. e drilled pipe performed poorly. e initial cost of the drilled pipe is overshadowed by its high energy use. e holes are easily blocked and the noise level is excessive. Velocity across the entire length was very inconsistent with spikes of air and numerous dead spots.

Flat Air Nozzles is inexpensive air nozzle was the worst performer. It is available in plastic, aluminum and stainless steel from several manufacturers. e flat air nozzle provides some entrainment, but suffers from many of the same problems as the drilled pipe. Operating cost and noise level are high. For some flat air nozzles the holes can be blocked - an OSHA violation. Velocity was inconsistent with spikes of air.

Blower Air Knife e blower proved to be an expensive, noisy option. As noted below, the purchase price is high. Operating cost was considerably lower than the drilled pipe and flat air nozzle, but was comparable to EXAIR’s Super Air Knife. e large blower with its two 3" (8cm) diameter hoses requires significant mounting space. Noise level was high at 90 dBA. ere was no option for cycling it on and off to conserve energy. Costly bearing and filter maintenance along with downtime were also negative factors. and filter maintenance along with downtime were also negative factors.

EXAIR Super Air Knife e Super Air Knife did an exceptional job of removing moisture on one pass due to the uniformity of the laminar airflow. e sound level was very low. For this application, energy use was slightly higher than the blower but can be less than the blower if cycling on and off is possible. Safe operation is not an issue since the Super Air Knife can not be dead-ended. Maintenance costs are low with no moving parts to wear out.

Facts about Blowers

Energy conscious plants might think a blower to be a better choice due to its slightly lower electrical consumption compared to a compressor. In reality, a blower is an expensive capital expenditure that requires frequent downtime and costly maintenance of filters, belts and bearings.

Here are some important facts:

Filters must be replaced every one to three months.

Belts must be replaced every three to six months.

Typical bearing replacement is at least once a year at a cost near $1000.

• Blower bearings wear out quickly due to the high speeds (17-20,000 RPM) required to generate effective airflows.

• Poorly designed seals that allow dirt and moisture infiltration and environments above 125°F decrease the one year bearing life.

• Many bearings can not be replaced in the field, resulting in downtime to send the assembly back to the manufacturer.

11510 Goldcoast Drive • Cincinnati, OH 45249-1621 • Phone (513) 671-3322 FAX (513) 671-3363 • E-mail: techelp@exair.com • www.exair.com

Blowers take up a lot of space and often produce sound levels that exceed OSHA noise level exposure requirements. Air volume and velocity are often difficult to control since mechanical adjustments are required.

If you think compressed air is too expensive and noisy -

this. The facts will

you!

TRUTH

COMPRESSED AIR! Blowoff

Type of blowoffPSIGBAR Compressed Air Horsepower Required Sound Level dBA Purchase Price Annual Electrical Cost* Approx Annual Maintenance Cost First Year Cost SCFMSLPM Drilled Pipes 604.11744,92435 91$50$4,508$920 $5,478 Flat Air Nozzles 604.12577,27351 102$208$6,569$1,450$8,227 Blower Air Knife 30.2N/AN/A 10 90$5,500$1,288$1,500$8,288 Super Air Knife 604.1551,557 11 69$802$1,417 $300 $2,519 *Based on national average electricity cost of 8.3 cents per kWh. Annual cost reflects 40 hours per week, 52 weeks per year.

read

surprise

The

About

Comparison

Since 1983 @EXAIR

Manufacturing Intelligent Compressed Air® Products

https://exair.co/58_akv_ad SEE THE AIR KNIFE IN ACTION! https://exair.co/58_423

The Super Air Knife is the low cost way to blowoff, dry, clean and cool.

Technology Forward

If it isn’t broken, make it better

In late October, I had the pleasure of attending the 2022 PTDA Industry Summit in Nashville. As a new editor and first-timer, I arrived with an open mind and eagerness to learn. Still, my expectations were quickly shattered during the annual business meeting and with every interaction thereafter. I didn’t expect such a tough industry to start with so much kindheartedness for friends and family. Each person who took the stage paid warm gratitude to the people in their lives who supported them so that they could excel in their careers and elevate the industry.

During the opening keynote, Alan Beaulieu discussed economic data and industry forecasts, assuring that manufacturers struggling to manage backorders may feel a sense of relief as the market eases. “We’re not looking at a recession. We’re looking at opportunities, just at a decelerated rate of rise,” said Beaulieu. But he cautioned against getting too comfortable because things aren’t returning to “normal” anytime soon. Though inflation is expected to take a break, it’ll creep back up again.

Speaking of comfort, Risha Grant encouraged attendees to have uncomfortable conversations that promote inclusiveness and diversity

appreciation in the workplace. Tough industries need to have tough talks about accepting others — because whether anyone likes it or not, the markets are already diverse, and customers and employees from all walks of life expect to be treated fairly.

With the lasting e ects of COVID-19, manufacturers continue to rethink how they do business. Brick-and-mortar businesses used to be vital for connecting and building relationships. Now, digital presence is more valued since customers use virtual means to research and learn. Therefore, manufacturers are paying closer attention to people’s preferences to create digital experiences that help customers find desired products and services.

Manufacturers are also refining their processes and adopting new technology to serve their customers better. “If you don’t accept new technology, you’ll be run over by time,” said Beaulieu. However, customers don’t care if OEMs are innovative or flashy. They want the exact part with the exact specifications within the needed time

frame at the best cost. And they want to know that the OEM will be there to help when they call.

More than ever, each OEM is part manufacturer and part customer service provider. But that doesn’t mean they’re not innovating or thinking of the future. There’s a reason why products are still flying o the shelves, even at a decelerated rate.

Aside from production lines and economics, I learned more than expected at this year’s PTDA Industry Summit. And the most important lesson that we can all take away is this: When considering parts for any motion system, don’t forget the most important part — the people part. DW

On Twitter @WTWH_Rachael

Rachael Pasini rpasini@wtwhmedia.com

6 January 2023 www.designworldonline.com DESIGN WORLD

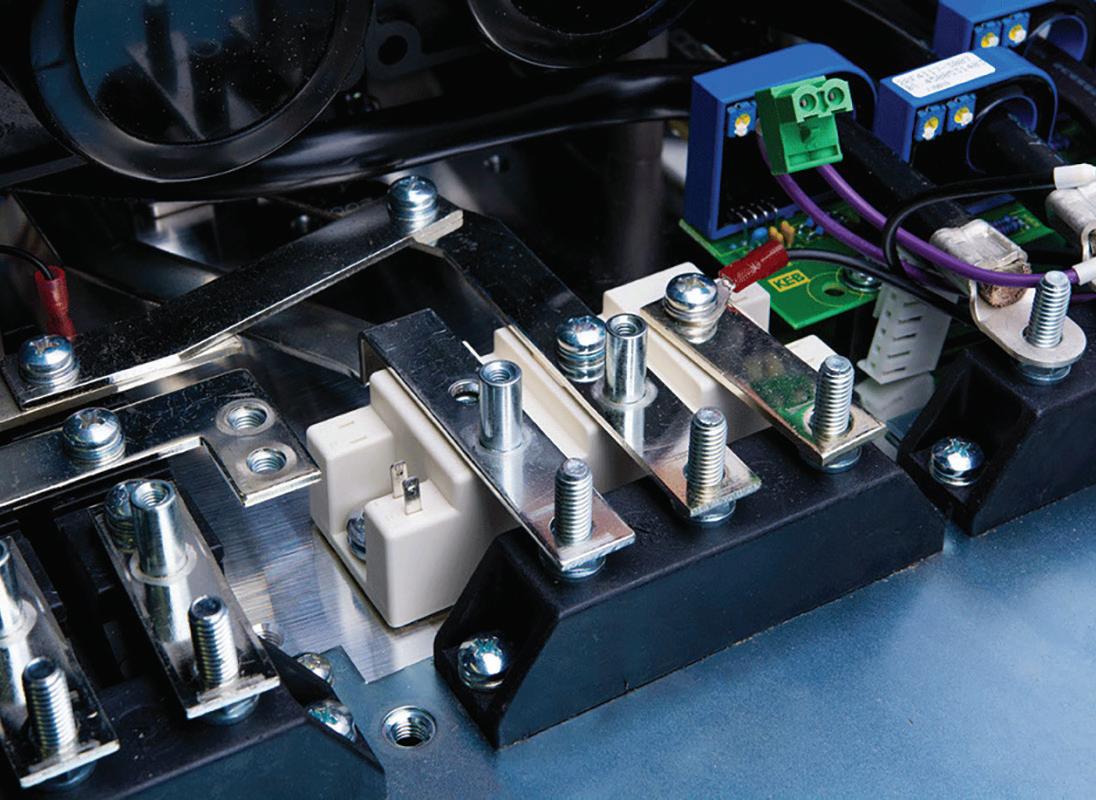

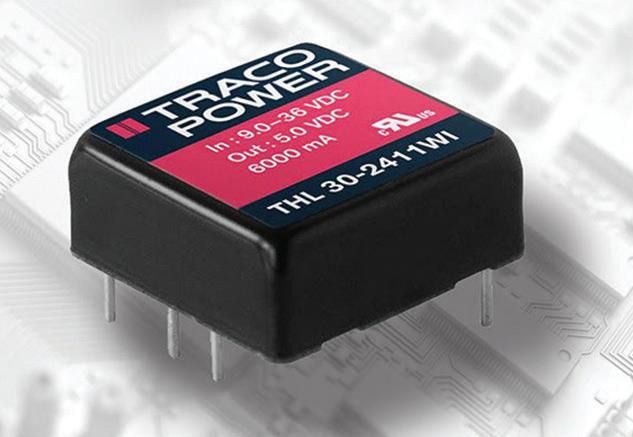

automation 24 .com – Your online supplier for automation technology 2 YEAR SUPPOR BACK 1 0 0 % NTEE 90 DAYS EXC FREEAPPLICA ODUC RODUCTS 2 YEAR S ONEY BACK 1 0 0 % GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREE HIGH QUALITY IN STOCK PRODUCTS PRICING $ YEAR 01 0 % MONEY BAC GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS UPPORT 2 YEAR SUPPORT 01 0 % MON GUA DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS 2 YEAR SUPPORT 01 0 % MONEY BACK 1 0 0 % GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS 01 % GUARANTEE DAYS 2 YEAR SUPPORT 01 0 % MONEY BACK 1 0 0 % GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS IN STOCK F N YEAR 0 % 1 0 0 90 Y HIGH QUALI EXCEPTIONAL REEAPPLICATIO 2 MONEY BACK The PROmax power supplies from Weidmüller are extremely durable and offer high levels of scalability. Their robust construction allow them to withstand brief and continuous overload conditions, ensuring reliable power to critical loads. Additionally, the integrated mounting system allows for easy installation into a preexisting control panel. 800-250-6772 (free) or 610-981-2900 mail@automation24.com automation24.com High-performance power for demanding requirements! Reliably operate in continuous overload conditions Small footprint for easy mounting in tight spaces Wide operating temperature range of -13°F to 158°F automation24.com/promax-power-supplies All products

Sustainable Engineering

Paul J. Heney • VP, Editorial Director

Paul J. Heney • VP, Editorial Director

Global carbon capture capacity to rise sixfold by 2030

According to research company BloombergNEF’s (BNEF) newly released 2022 Carbon capture, usage, and storage (CCUS) Market Outlook, the global capacity for carbon capture in 2030 is set to increase sixfold from today’s level, to 279 million tons of CO2 captured per year. Drastic growth in the market has led to a 44% increase in expected 2030 capacity compared to last year’s outlook.

CCUS is a key technology needed to decarbonize hard-to-abate sectors such as petrochemicals and cement, and to provide 24/7 clean power through gas plants fitted with capture equipment. Still, despite significant acceleration in the sector in the past two years, the world’s capacity for carbon capture is not being deployed fast enough to meet climate goals at the end of the decade, according to BNEF research.

8 January 2023 www.designworldonline.com DESIGN WORLD

Today, most capture capacity is used to collect CO2 from natural gas processing plants and used for enhanced oil recovery. By 2030, most capture capacity will be used for the power sector, for the manufacture of low-carbon hydrogen and ammonia, or to abate emissions from industrial sources.

The CO2 being captured today is 43 million tons, or 0.1% of global emissions. If all likely announced projects come online, there would be 279 million tons of CO2 captured every year by 2030, accounting for 0.6% of today’s emissions.

The destination for captured CO2 is also due to change significantly from the status quo. In 2021, some 73% went to enhanced oil recovery operations. By 2030, storing CO2 deep underground will overtake oil recovery as the primary destination, with 66% going to dedicated storage sites. This change is being driven by legislation that incentivizes storage over CO2 usage, and by projects that aim to use carbon capture and storage (CCS) as a decarbonization route and must store the CO2 to meet their goals.

“CCS is starting to overcome its bad reputation,” said David Lluis Madrid, CCUS analyst at BNEF and lead author of the report. “It is now being deployed as a decarbonization tool, which means the CO2 needs to be stored. A lack of CO2 transport and storage sites near industrial or power generation point sources could be a major bottleneck to CCS development. But we are already seeing a big increase in these projects to serve that need.”

The industry is still far from making a dent in global emissions. To be on track for net-zero and less than 2° C

of warming by 2050, between 1-2 billion tons of CO2 would need to be captured in 2030, an order of magnitude higher than current plans.

The Inflation Reduction Act passed in the U.S. increased tax credits for CCUS by 70%, making a viable business case for the technology in petrochemicals, steel, cement, and in some regions, power. Incentives like these mean that countries, such as the US, will remain global leaders for CCUS. The U.S. tax credits are now very generous, and the law is set to supercharge project announcements in the ethanol and petrochemicals sectors, as well as in direct air capture (DAC), to provide high-quality carbon o sets for the voluntary market.

“This 279 million tons of capacity in 2030 is just the tip of the iceberg,” said Julia Attwood, head of sustainable materials at BNEF. “We haven’t seen the full impact of these credits yet, making this outlook a fairly conservative view of the future of carbon capture and storage. We expect to see another jump in announcements in 2022, especially in the U.S. as developers there rush to make sure they meet the 2032 deadline for credits.” DW

BloombergNEF about.bnef.com

DESIGN WORLD www.designworldonline.com January 2023 9

62 MOTION CONTROL

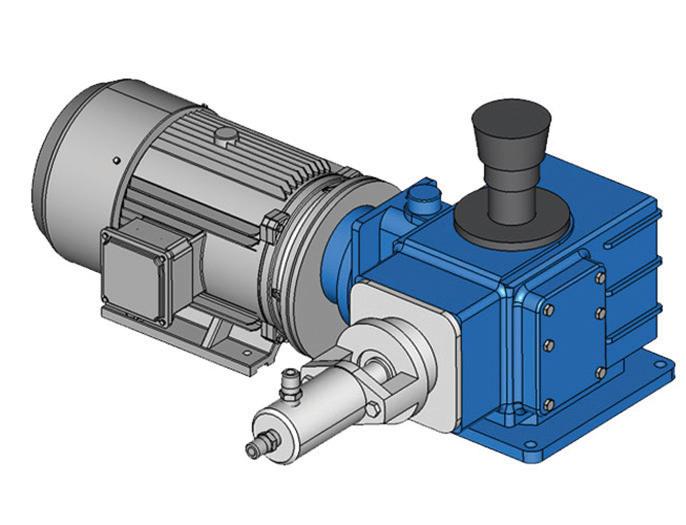

Sizing a dynamic brake resistor Dynamic brakes in electric motor drives divert rising DC bus voltage seen during load deceleration. Here we explain how to size the resistors that process that voltage.

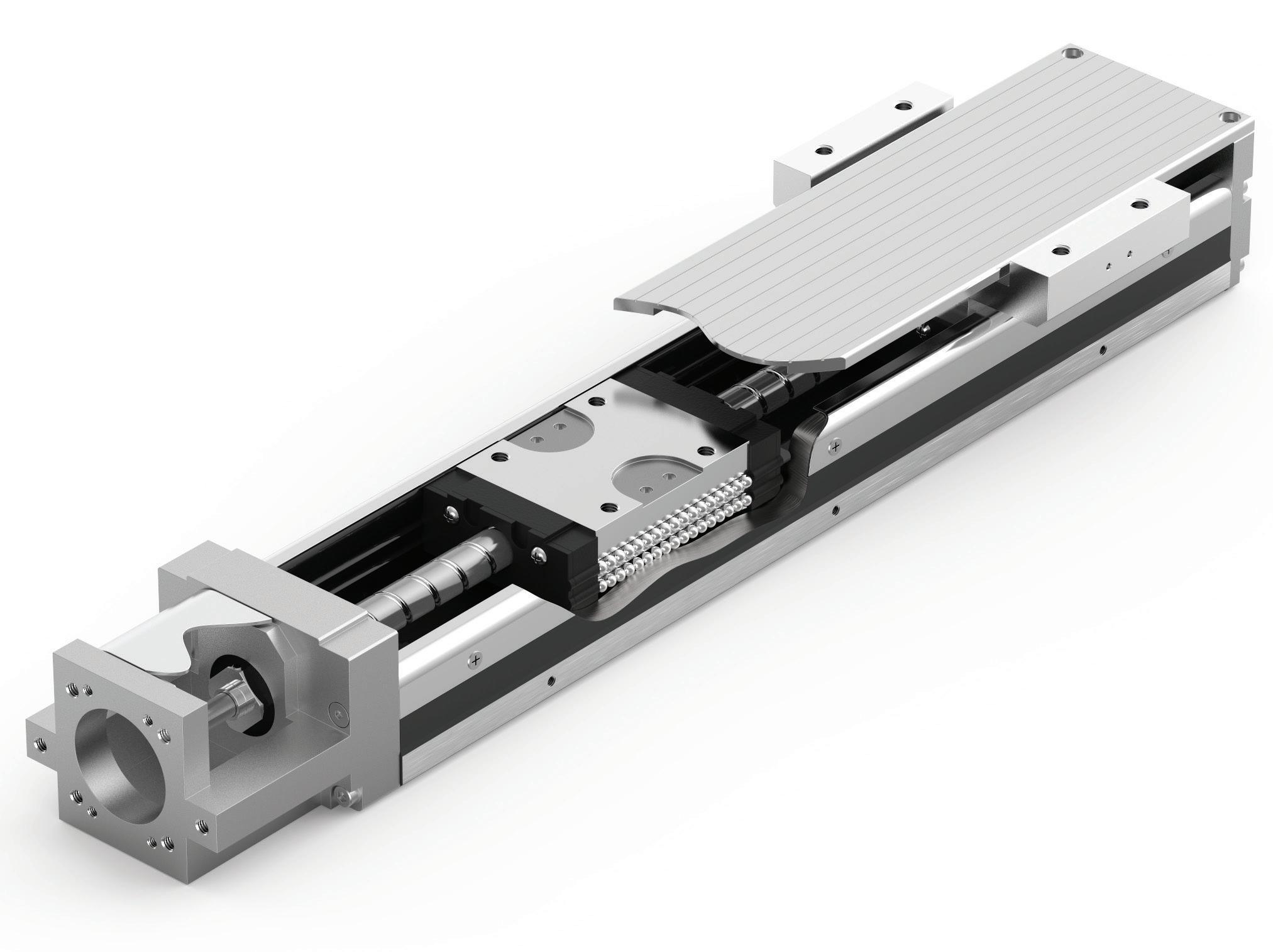

68 LINEAR MOTION A straight line to e ective linear motion

Servo- and stepper-driven electrical linear actuators are an e cient and economical way to provide accurate motion control for a wide variety of machine applications.

76 ELECTRONICS

Focus on embedded microcontrollers

What you need to know about embedded microcontrollers, the brains behind embedded systems.

84 ADDITIVE MANUFACTURING

94 MECHANICAL

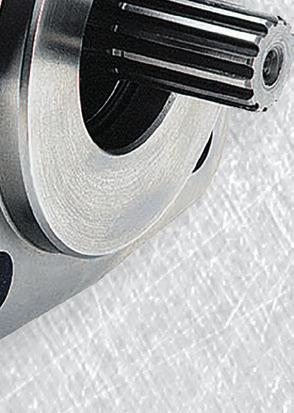

It is estimated that bearing faults account for around half of all failures in electric machines. The consequences of failure can result in unplanned downtime, machine breakdowns, equipment damage, and financial losses. To prevent this and ensure consistent performance, e ective bearing maintenance is essential. But when a single machine can contain hundreds of bearings, how can this be managed? Here, Chris Johnson, managing director of bearing supplier SMB Bearings explains.

120 PACKAGING

Order Up! New technology helps fry oil go green

Cooking oil is one of the most widely used products in restaurants and commercial kitchens. Nearly $80 billion of frying oil is used every year by the restaurant industry. That’s a lot of oil, which, unfortunately, ends up as waste once it degrades during the cooking process.

108 LEADERSHIP

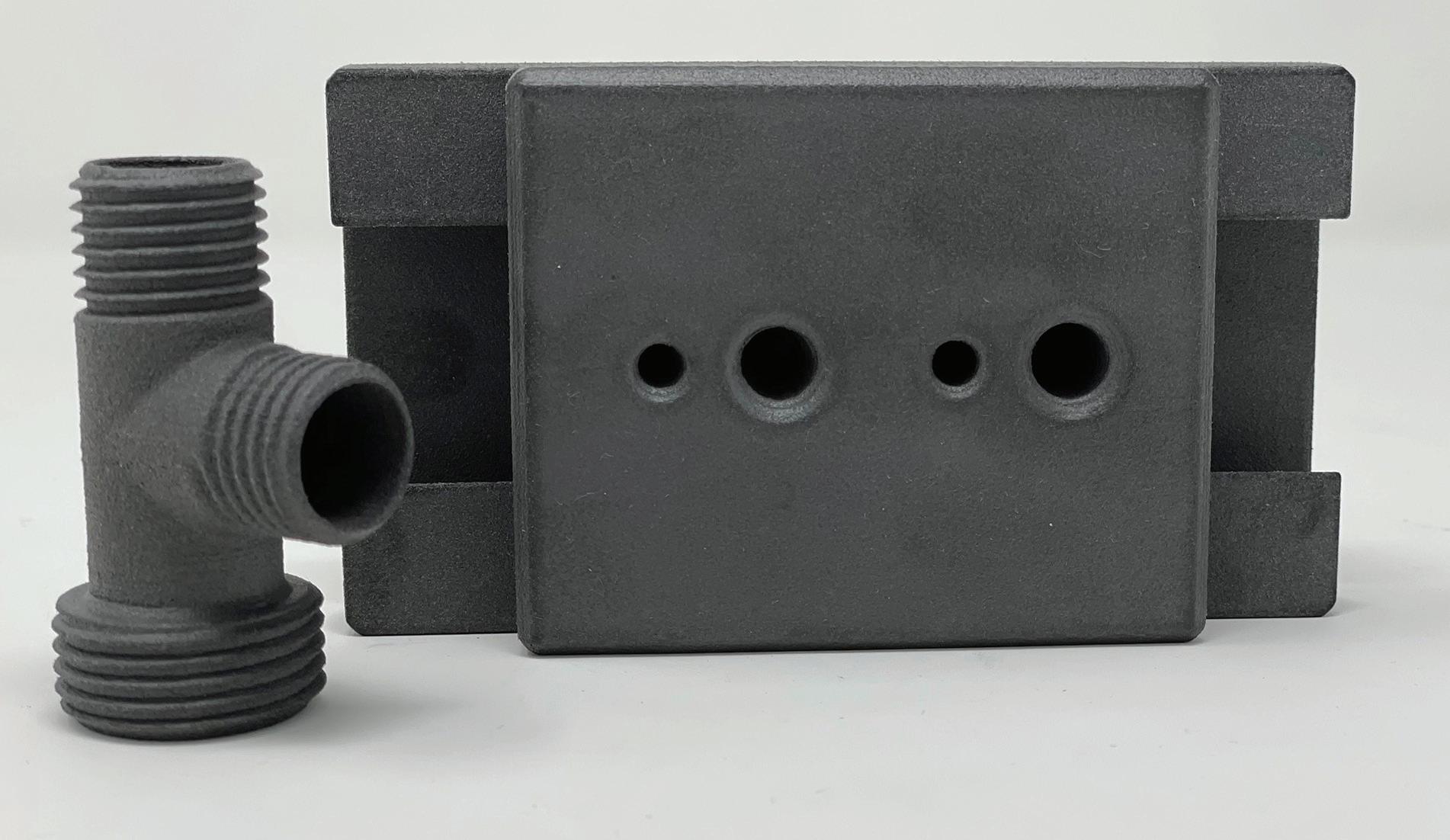

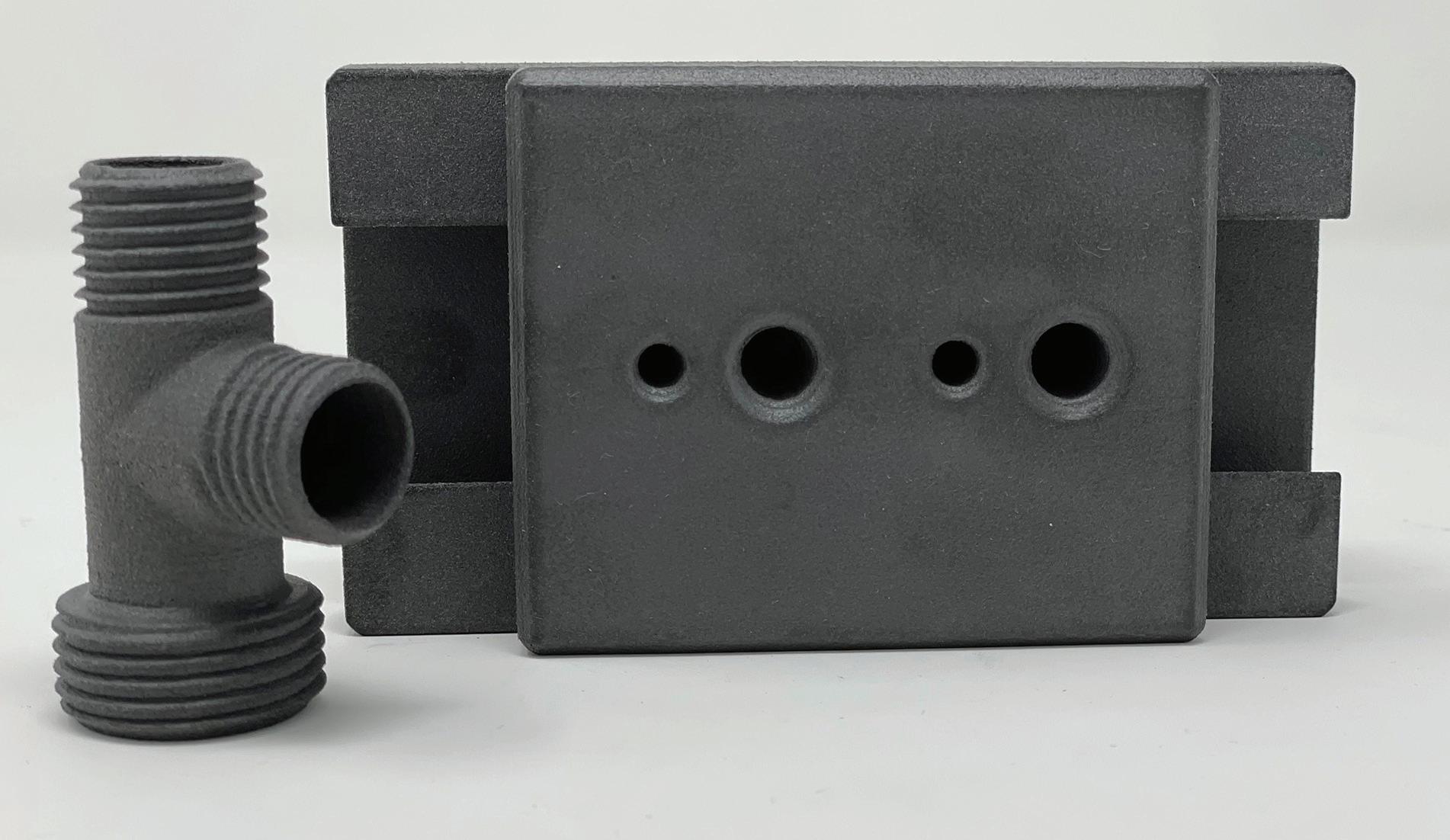

Combining the benefits of 3D printing technologies into a hybrid platform cuts costs and time compared to traditional sand casting processes.

The nation’s newest Brigadier General is looking beyond herself to build up future leaders.

Contents 10 January 2023 www.designworldonline.com DESIGN WORLD 1 • 2023 • vol 18 no 1 • designworldonline.com | © Printezis | Dreamstime

62

How to cut your bearing failures in HALF

2023 Leadership Pages 199-352

Pneumatics

These tips not only adhere to food safety guidelines, but also serve to improve machine usage and performance.

102 PNEUMATICS

in food packaging

Reduce sand casting lead times with hybrid 3D printing

A leader for the next generation: Antoinette R. Gant

asbpe rg SILVER REGIONAL AWARD 2022 asbpe rg GOLD REGIONAL AWARD 2022 asbpe rg BRONZE REGIONAL AWARD 2022 asbpe.org BRONZE NATIONAL AWARD 2022 asbpe rg GOLD NATIONAL AWARD 2022

Cover image AdobeStock

departments 04 Insights 06 Technology Forward 08 Sustainable Engineering 16 Design For Industry 32 Design Notes 44 3DP AM 58 CAE Solutions 128 Leap Award Winners 2022 168 Product World 353 Ad Index 1.23 • contents 12 January 2023 DESIGN WORLD THIN ENOUGH? BXR Brakes · Up to 480 in-lbs static · Up to a 1.125'' bore · 19 watts or less · Produced for over 10 years Our Innovative design features a very thin profile, reducing weight and space. For more information: Call: 800.533.1731 www.mikipulley-us.com

Follow the whole team on twitter @DesignWorld

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor

Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor

Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor

Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Services Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development

Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer

Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

EVENTS Events Manager Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager

Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Videographer Garrett McCafferty gmccafferty@wtwhmedia.com

Videographer Kara Singleton ksingleton@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

WTWH Media, LLC 1111 Superior Ave. 26th Floor Cleveland, OH 44114 Ph: 888.543.2447

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

TOP WORK PLACES 2022 DESIGN WORLD www.designworldonline.com January 2023 13

DESIGN WORLD Medical Design & OUTSOURCING

2011 - 2020 2013 - 2017, 2021 2014 - 2016

Booth #S-81817

YATES INDUSTRIES INC. 23050 Industrial Dr. E. St. Clair Shores, MI 48080 Phone: 586.778.7680 sales@yatesind.com

YATES CYLINDERS ALABAMA

55 Refreshment Place Decatur, AL 35601 Phone: 256.351.8081 alsales@yatesind.com

YATES CYLINDERS GEORGIA 7750 The Bluffs Austell, GA 30168 Phone: 678.355.2240 gasales@yatesind.com

YATES CYLINDERS OHIO 550 Bellbrook Ave. Xenia, OH 45385 Phone: 513.217.6777 ohsales@yatesind.com

Looking forward to handling all your cylinder needs. See you at the show!

Tie Rod Cylinders Welded Cylinders Mill Duty Cylinders Contact us today!Phone: 586-778-7680@yatescylinders

Design for Industry

Tips on applying robots in food and beverage applications

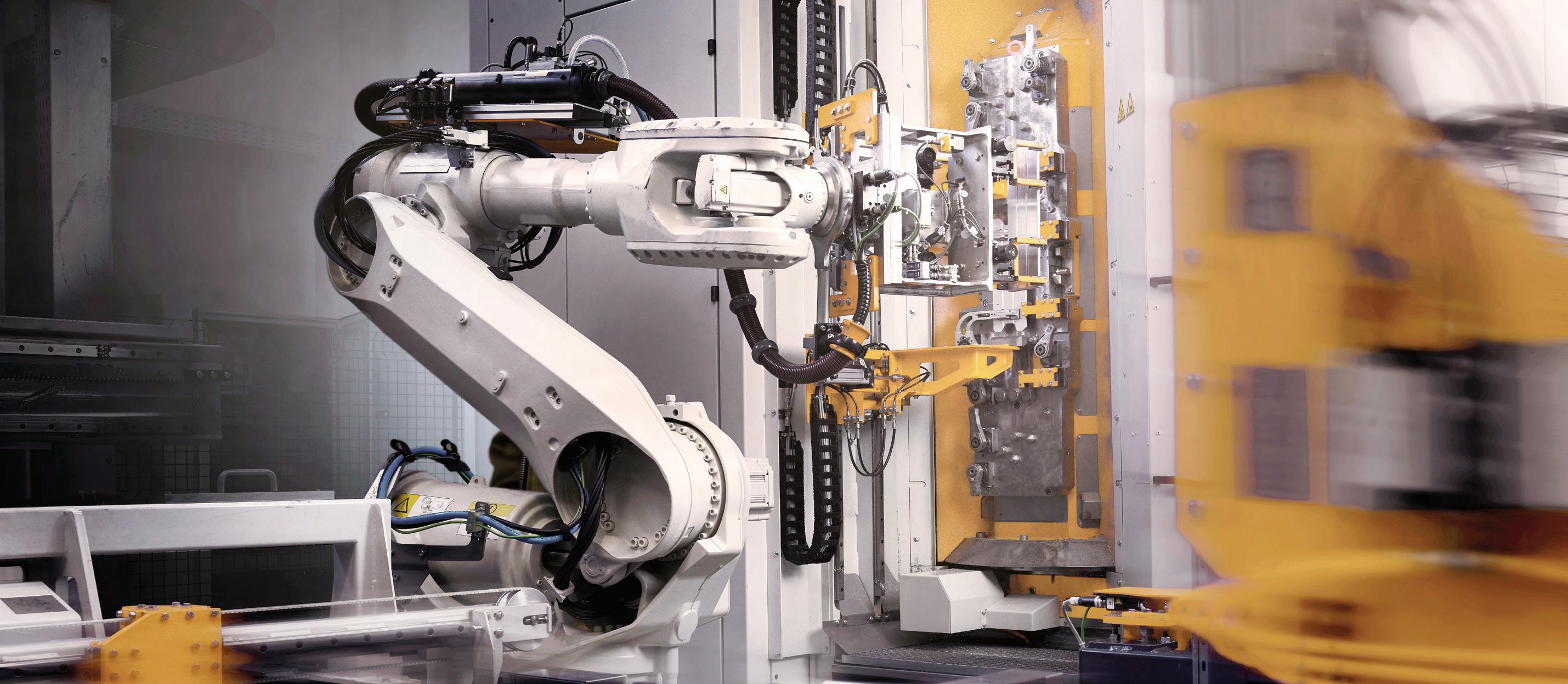

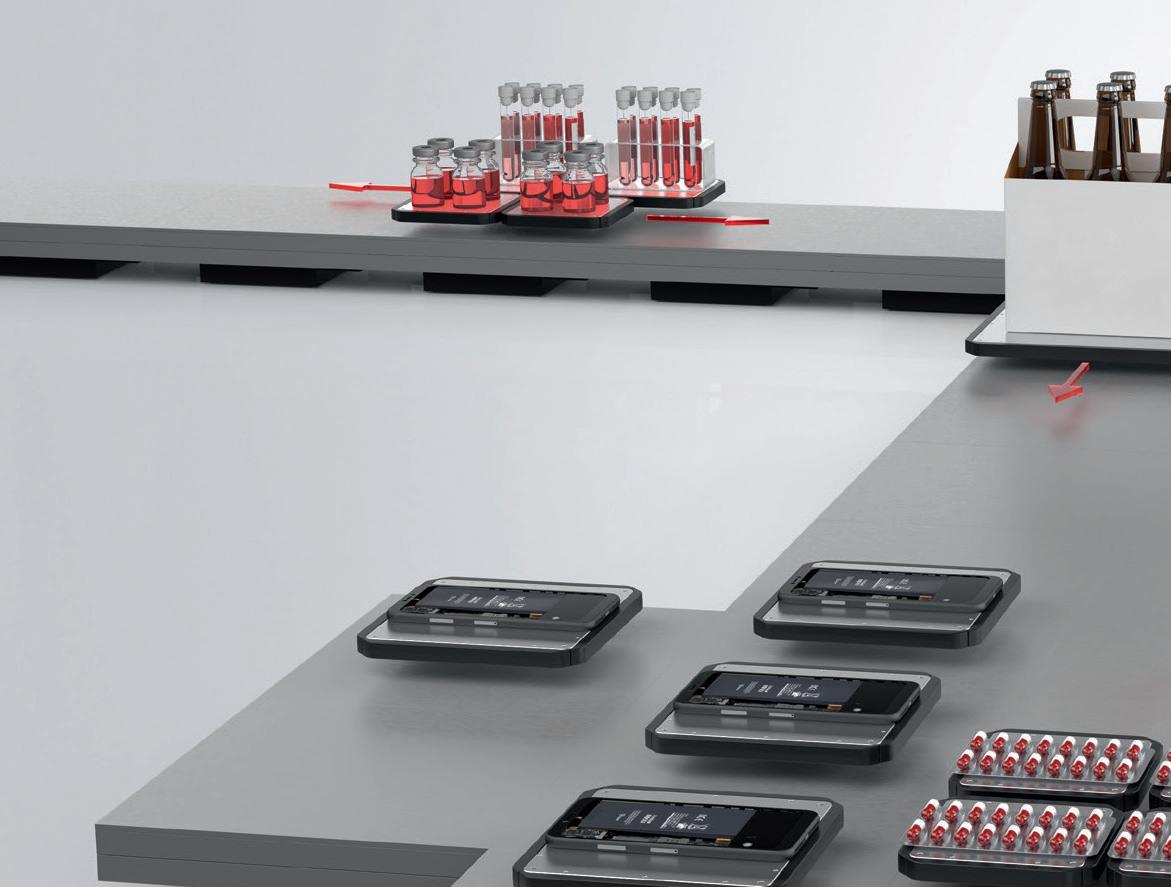

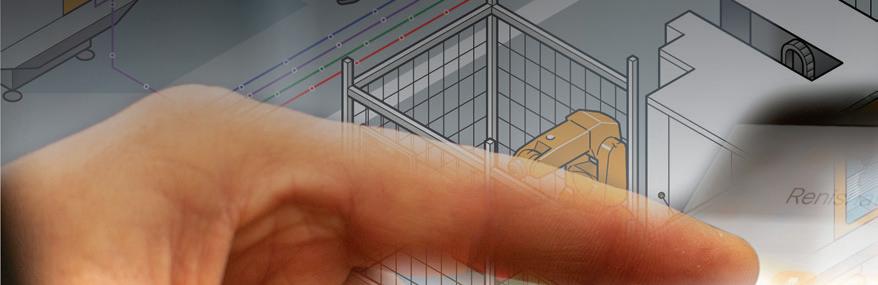

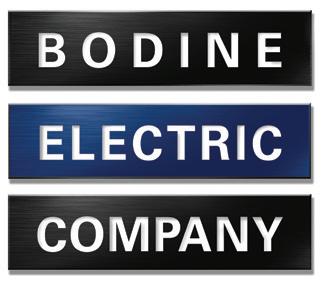

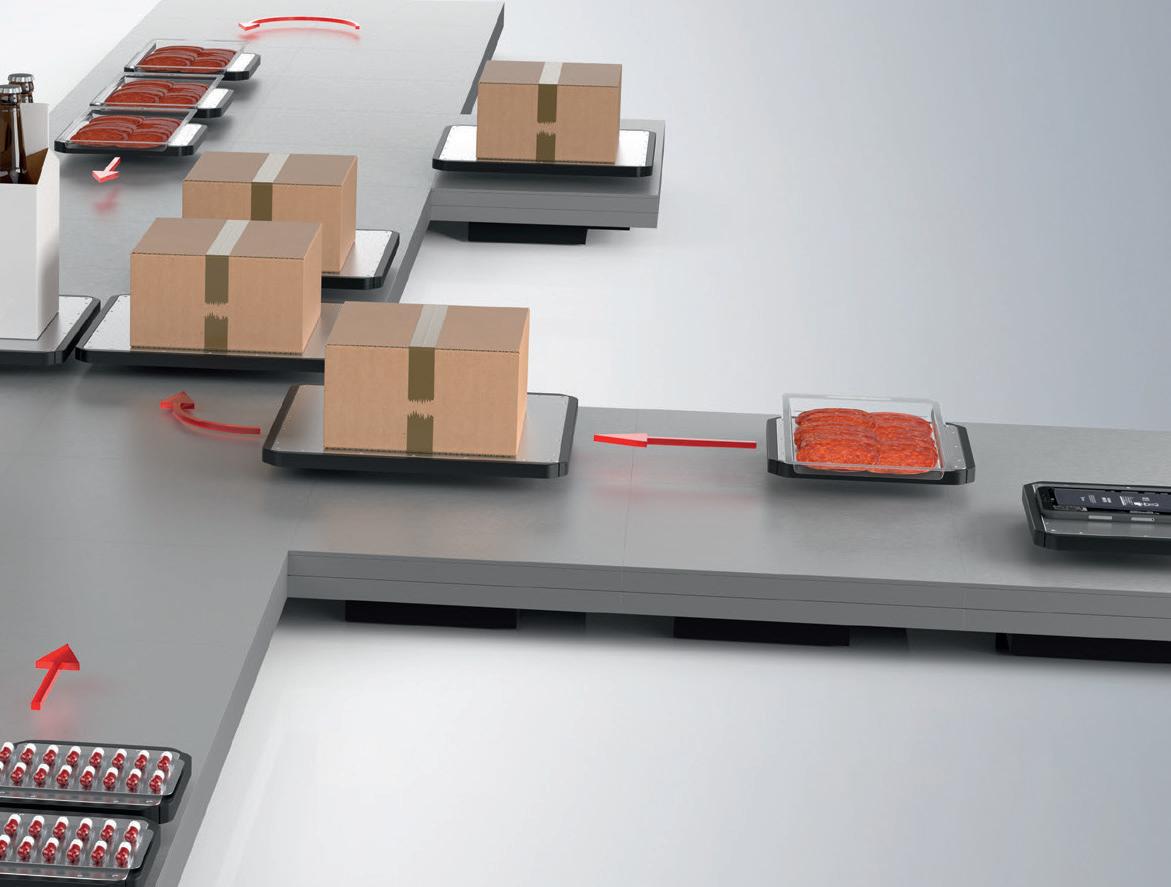

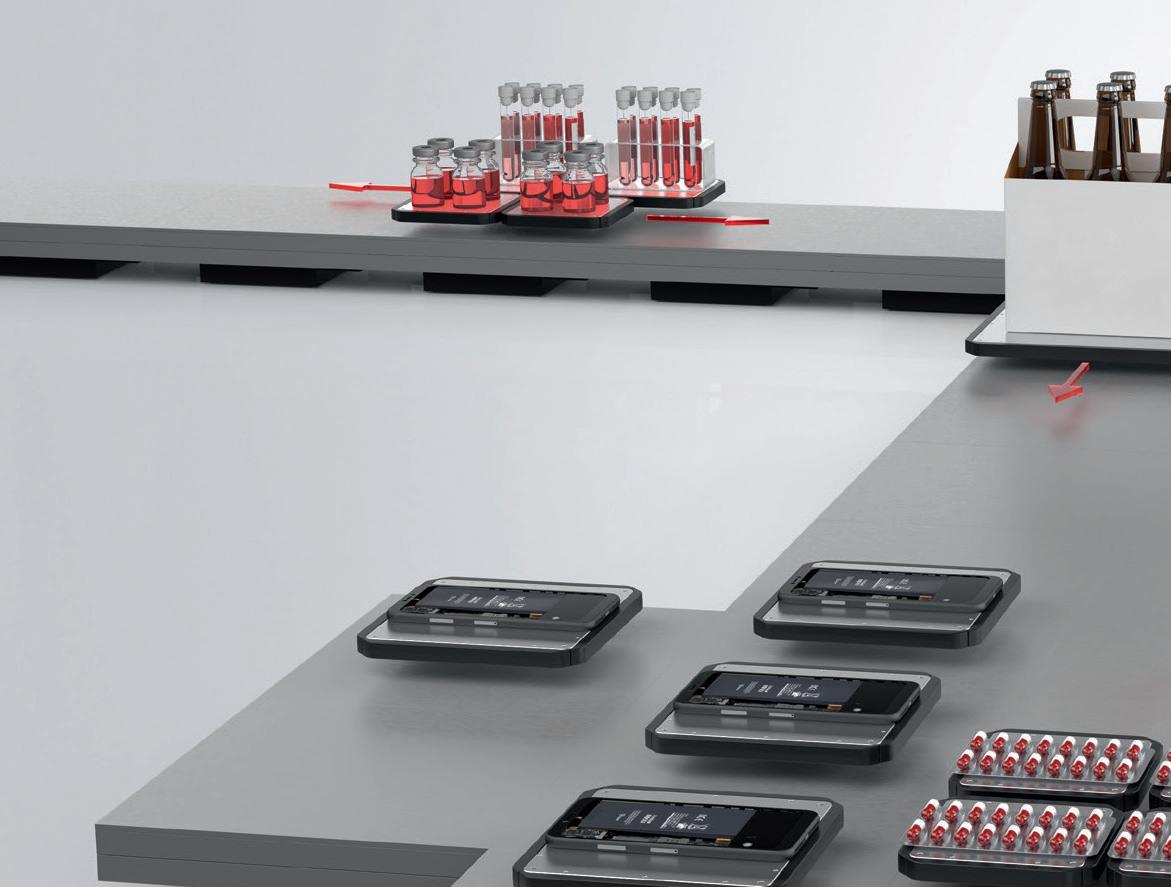

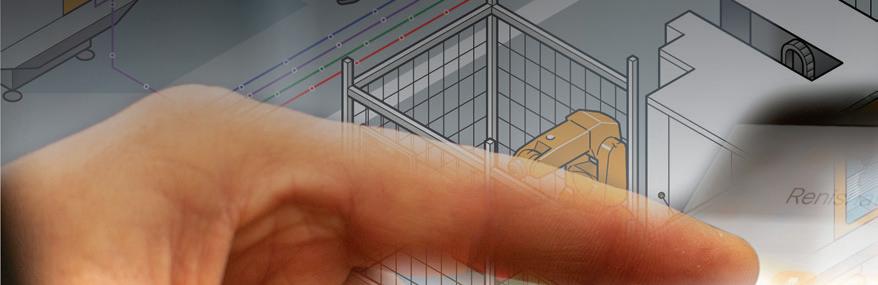

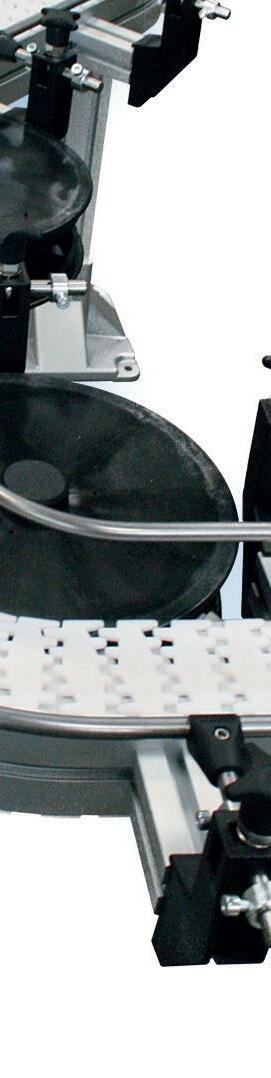

Designed to help users with their initial foray into robotic automation, the KUKA Robot Guide makes the process fast and easy to apply the right automation to specific application needs. In three steps, users are presented with KUKA robot options based on their industry, application and environment.

Within the guide, users can choose between various industries, including automotive, food & beverage, medical, plastics, electronics, and metal. Users

can then drill down to almost any application environment. In addition, users can choose from a large family of robots suited for applications requiring extreme precision and repetitive tasks with fast cycle times and for those within large foundry operations. Application categories include arc and laser welding, machining, measuring, and inspection and range from applying/gluing and painting, to handling and assembly. Users can also indicate whether the robot will work autonomously in an isolated environment or collaboratively with humans.

Food and Beverage

16 January 2023 www.designworldonline.com DESIGN WORLD

From there, customers can select case studies, application videos, white papers, parameters, and details of each suggested robot’s technical specifications. These include payload, reach, mounting positions, and other pertinent features for providing an instant recommendation walk-thru without entering a sales consultation. DW

KUKA | www.kuka.com/en-us/robot-guide

DESIGN WORLD January 2023 17

Two Part EP21TCHT-1 for bonding & sealing HIGH PERFORMANCE Epoxy Adhesive for HARSH ENVIRONMENTS CITED IN MULTIPLE RESEARCH ARTICLES NASA, Princeton University, University of Florida and more PROVEN IN VARIOUS COMMERCIAL & SCIENTIFIC APPLICATIONS PERFORMANCE PROPERTIES • NASA Low Outgassing • Cryogenically serviceable • Thermally conductive • Electrically Insulative • High bond strength Hackensack, NJ 07601, USA ∙ +1.201.343.8983 ∙ main@masterbond.com www.masterbond.com

Design for Industry

Aerospace

Motors help map the stars

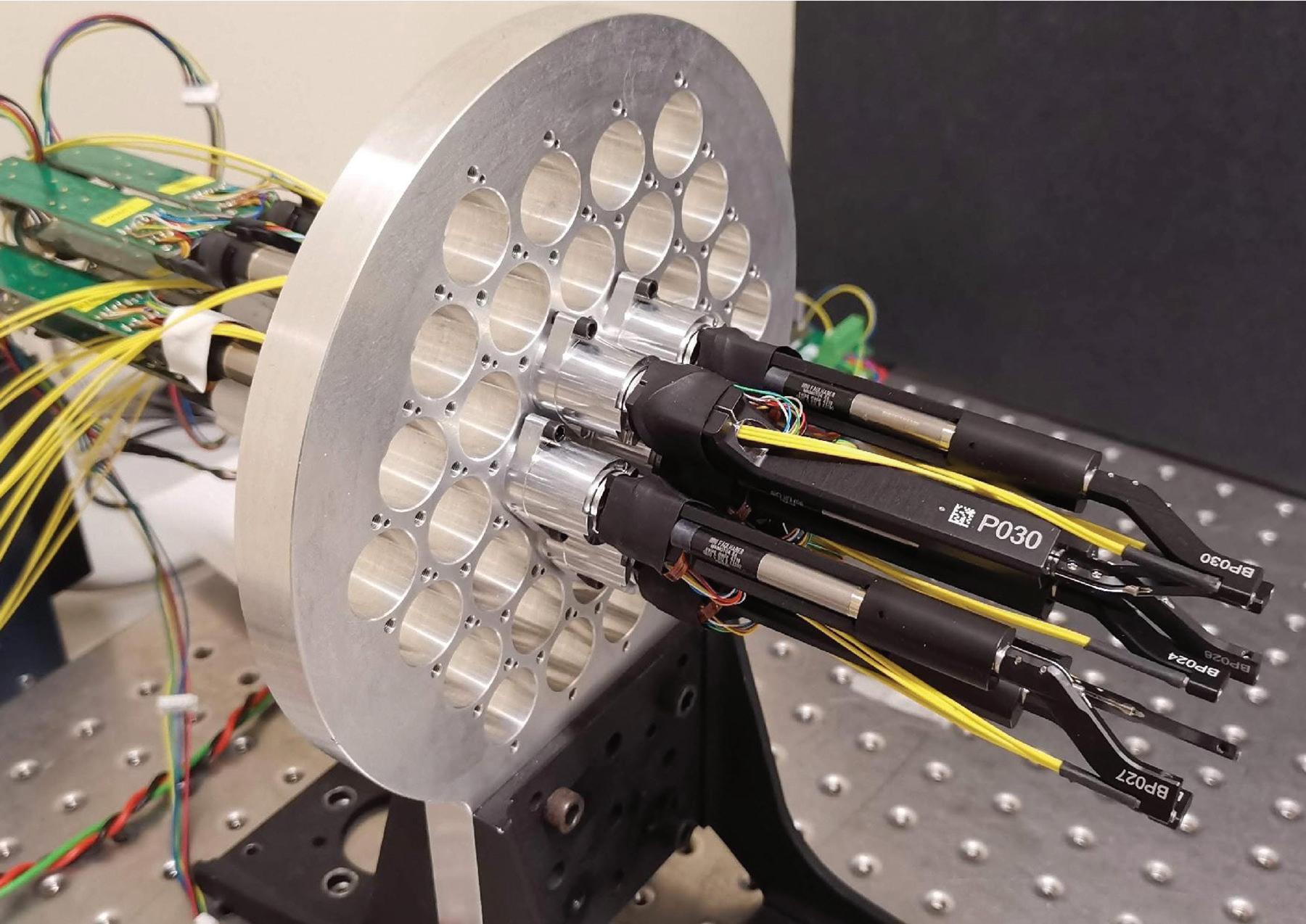

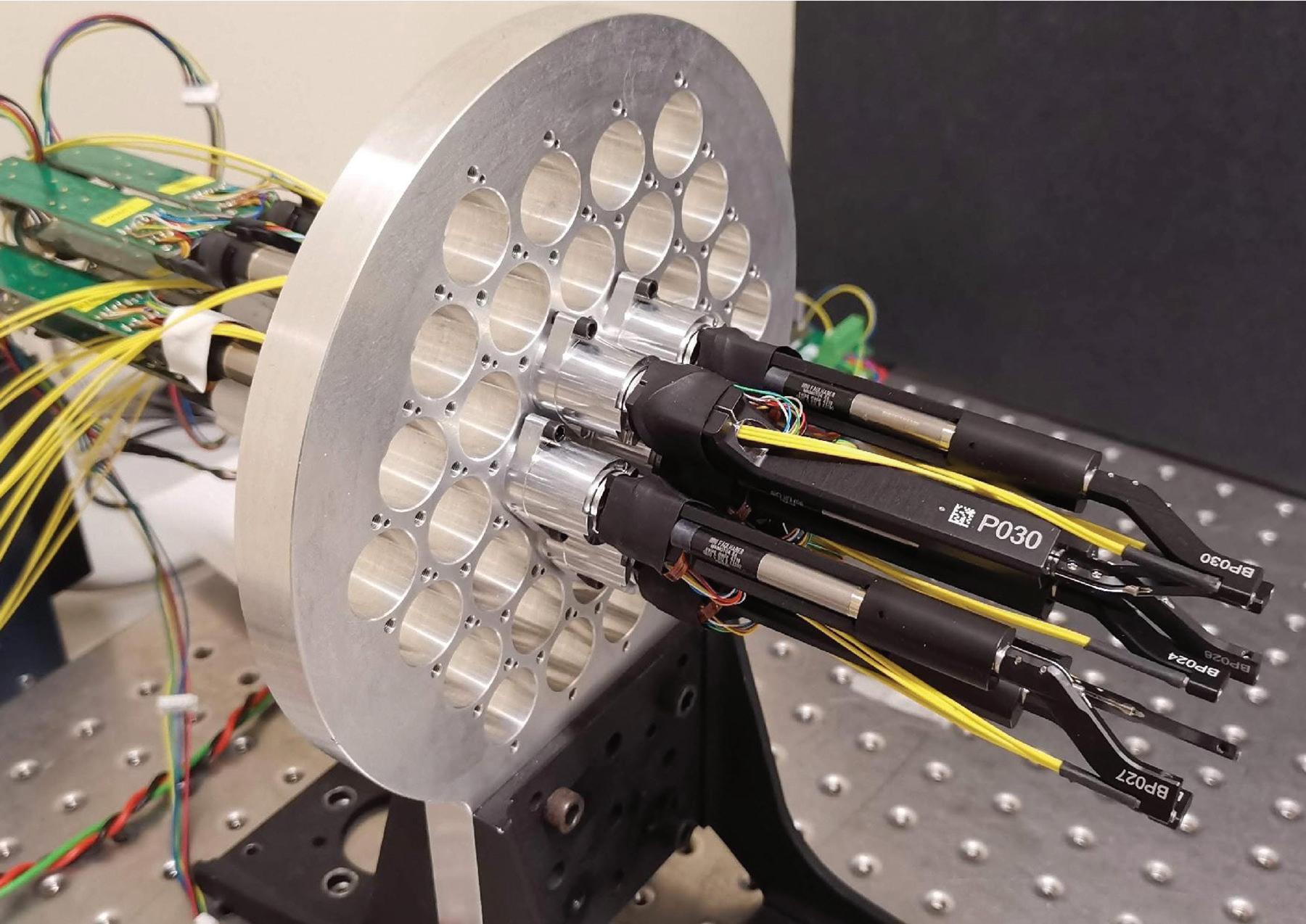

Fiber optics collect the light om the celestial bodies. The extremely precise alignment of each of the fibers is performed by 500 small robots, which are driven by FAULHABER motors.

Over the next five years, Sloan Digital Sky Survey (SDSS) V plans to observe four million stars and 300,000 black holes, analyze spectra and material composition, reconstruct cosmic development histories, and verify physical models of the birth of the galaxy.

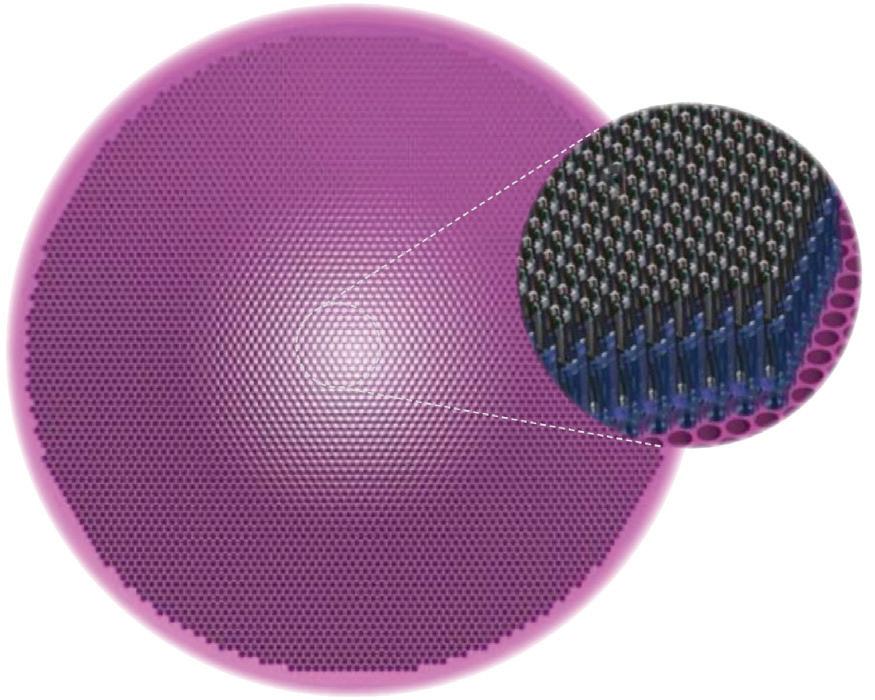

Two optical large-scale telescopes in the northern and southern hemisphere will be used for the major international project, among other things. Fiber optics collect the light from the celestial bodies. The precise alignment of each of the fibers is performed by 500 small robots, which are driven by FAULHABER motors.

SDSS is a cooperative alliance of astrophysicists from around the world. Over the past year, they have already presented the largest 3D map of the universe and thereby marked a milestone in astronomical research. Equipped with many telescopes and other scientific instruments, the researchers are working constantly on a range of projects.

The latest is SDSS V, which aims to enable another qualitative leap in the understanding of the physical processes in outer space. The project will make

possible the “first spectroscopic observation of the entire sky in various astronomical dimensions of time in the optical and infrared light spectrum.” In total, more than six million objects are to be targeted.

How planets are formed — Among the objectives of this endeavor is the reconstruction of the history of our home galaxy, the Milky Way. Moreover, researchers plan to retrace the formation of the chemical elements, decrypt the inner workings of stars, examine the formation of planets and answer many of the open questions that remain with

18 January 2023 www.designworldonline.com DESIGN WORLD

regard to black holes.

Another aspect is the mapping of the interstellar gas masses of the Milky Way — a thousand times more precisely than previously — to describe the “self-regulating mechanisms of galactic ecosystems.” The data related to black holes and for the measurement of the Milky Way are to be collected by two large-scale telescopes: Apache Point in New Mexico and Las Campanas in Chile.

“With the dual perspective from the northern and southern hemisphere, we can view the sky in all directions,” explained Jean-Paul Kneib, professor of astrophysics at Ecole Polytechnique Fédérale de Lausanne in Switzerland. “We have also used the two telescopes in the previous SDSS projects. With SDSS V we are now making a true quantum leap with regard to the efficiency of the observation and the amount of collected data.”

Spotting supernova — Placed in the telescopes are optical fibers that are targeted at specific objects in the universe. Individual stars or the luminous accretion discs of black holes can be precisely observed and analyzed. “Previously, we had to have special plates fabricated for each of the different observation tasks. It took several weeks for each plate to be prepared. The mounting of the fibers was then secured in the plate by hand — a very complex and time-consuming process,” said Jean-Paul Kneib.

With the new technology developed specifically for SDSS V, the rearrangement of the fibers will take no more than a minute instead of weeks. Because now the fibers are adjusted by means of 500 small machines — referred to by the astronomers as “robots” — in each of the two telescopes. This also allows the researchers to respond immediately to unpredicted cosmic events.

If, for example, other telescopes discover a current event such as a supernova, one of the optical elements can be aligned with it with practically no time delay. This enables a detailed analysis of the physical-chemical processes within a time span of supernova development that was not previously possible with this type of instrumentation.

Placed in the telescopes are optical fibers that

DESIGN WORLD January 2023 19

are targeted at specific objects in

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly. Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor. 33 Higginson Avenue, Central Falls, Rhode Island 02863 Telephone: (401) 728-0700 • FAX: (401) 728-0703 E-mail: info@whittet-higgins.com Web: www.whittet-higgins.com POWER TRANSMISSION RETAINING DEVICES & maintenance & assembly tools WHITTET-HIGGINS USA BEARLOK SHOELOK BEARLOK Shrink Disc BEARHUG CLAMPNUT TANGENTLOK PRECISION NUTS & WASHERS ADAPTER SLEEVE ASSEMBLIES NUTS & WASHERS HARDENED TONGUE WASHERS SPLIT COLLAR RETHREADING DIES ADJUSTABLE SPANNER WRENCH BEARING ASSEMBLY SOCKET INCH and METRIC THREADS LEFT HANDED as well as RIGHT -HANDED Materials of: CARBON, ALLOY and HARDENED ALLOY STEELS Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

the universe.

Innovate today for a new tomorrow

Realize your vision with Festo‘s approach to smart automation. Partner with Festo today.

www.festo.us Industry Leadership Superior Quality Products Global Training & Support

Aerospace Design for Industry

With micrometer precision. Each of the small robots consists of two slim cylinders arranged lengthwise with a curved extension at the front end. The rear, thicker cylinder is secured in the plate of the telescope. It forms the alpha unit and turns the central axis of the robot. Mounted eccentrically to the front of this is the beta unit. It likewise moves the fiber tips in the curved end in a circular path.

Through the combination of the two axial movements, the fiber tips can be freely positioned within a circular area. Each circle covered by one of the robots partially overlaps the circles of the adjacent units. In the detection range of the telescope, each point of the sky can thereby be automatically targeted.

Three optical fibers are arranged in the small robot. One is designed for light in the visible spectrum and one for the infrared spectrum. The third is used for calibration. With its help, the fiber tips are moved into position in three steps with an accuracy of just a few micrometers: In a first rough alignment, the two motors turn until the fiber intended for the observation is directed at the target object with a deviation of, on average, 50 micrometers. A camera in the telescope that is directed at the front ends of the robots now detects the tip of the calibration fiber and measures its position. In two further positioning steps, the robot head is then moved into position with a precision of better than five micrometers.

Researching faster — “Because we save an enormous amount of time with the automatic alignment, we can observe many more objects and perform a corresponding larger number of individual measurements,” explained Jean-Paul Kneib. “This e ect is raised to an even higher power through the high precision. The diameter of the optical fibers is one hundred micrometers. The diameter of the light spot from an observed cosmic object that hits the telescope is just as big. The more exact

these two small surfaces are aligned with one another the greater the light output we have for our measurements and the faster we obtain valid results.”

The technical prerequisites for this extreme accuracy are provided by motors and gearheads from FAULHABER as well as the mechanics developed specifically for this application by FAULHABER subsidiary MPS. The two robot axes are driven by brushless DC-servomotors of the 1218 ... B series for the alpha axis and the 0620 ... B for the beta axis. The first two digits of the type designation indicate the diameter of the microdrives: twelve and six millimeters. Their force is transferred to the robot mechanics by means of suitable planetary gearheads. The robot mechanics used here were developed and constructed by MPS. Integrated encoders report the rotary position of the motors to the controller.

Backlash-free precision. “To achieve the required precision, we had to eliminate the backlash in the system,” said Stefane Caseiro, who was responsible for the design of the components at MPS. The engineers accomplished this by, among other things, replacing the conventional coupling between the gearhead shafts and the mechanical axes of the robot with clamp connections and by installing a compression spring to make the gearhead backlash-free. “Finding the suitable springs alone took several months,” said the MPS engineer. DW

FAULHABER MICROMO LLC www.faulhaber.com

Harwin’s

n High-Rel connectors

n EMC shielding solutions

n Board-to-board interconnect

CONNECT TECHNOLOGY WITH CONFIDENCE.

connector products are proven to perform in extreme conditions, with shock, vibration, and temperature range rigorously tested.

// WWW.HARWIN.COM

DESIGN WORLD www.designworldonline.com January 2023 21

Design for Industry

Aerospace

Amplifier series covers broadband and ultra-broadband equencies

Temperature-compensated amplifiers address precision performance and test-and-measurement applications, including those in aerospace applications.

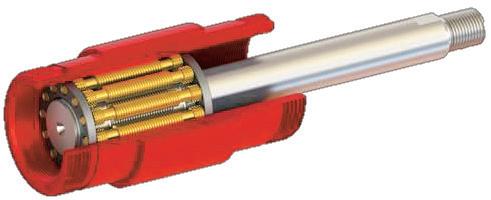

The coaxial packaged, temperature-compensated amplifiers cover broadband and ultra-broadband frequencies ranging from 0.5 GHz to 40 GHz. Designs incorporate pin diode attenuation circuitry that senses and adjusts broadband gain levels and maintains a minimum gain level of 35 dB over the full operational temperature range of -67 to +185° Fahrenheit.

These assemblies use MIC thin film and MMIC semiconductor technology in rugged, military-grade, compact coaxial packages that are designed for high reliability and meet a series of MIL-STD-202F environmental test conditions for altitude, vibration, humidity, and shock.

The comprehensive portfolio of temperature-compensated amplifiers is available with or without heat sinks to address multiple applications. Designs support internal voltage regulation that covers DC voltages ranging from +12 Vdc to +15 Vdc, an output of 1.0 dB compression and power levels from 15 dBm to 20 dBm. DW

Fairview Microwave www.fairviewmicrowave.com

22 January 2023 www.designworldonline.com DESIGN WORLD

IT’S WHAT’S ON THE INSIDE THAT COUNTS ® ELECTRONICS CORP.

Aerospace Design for Industry

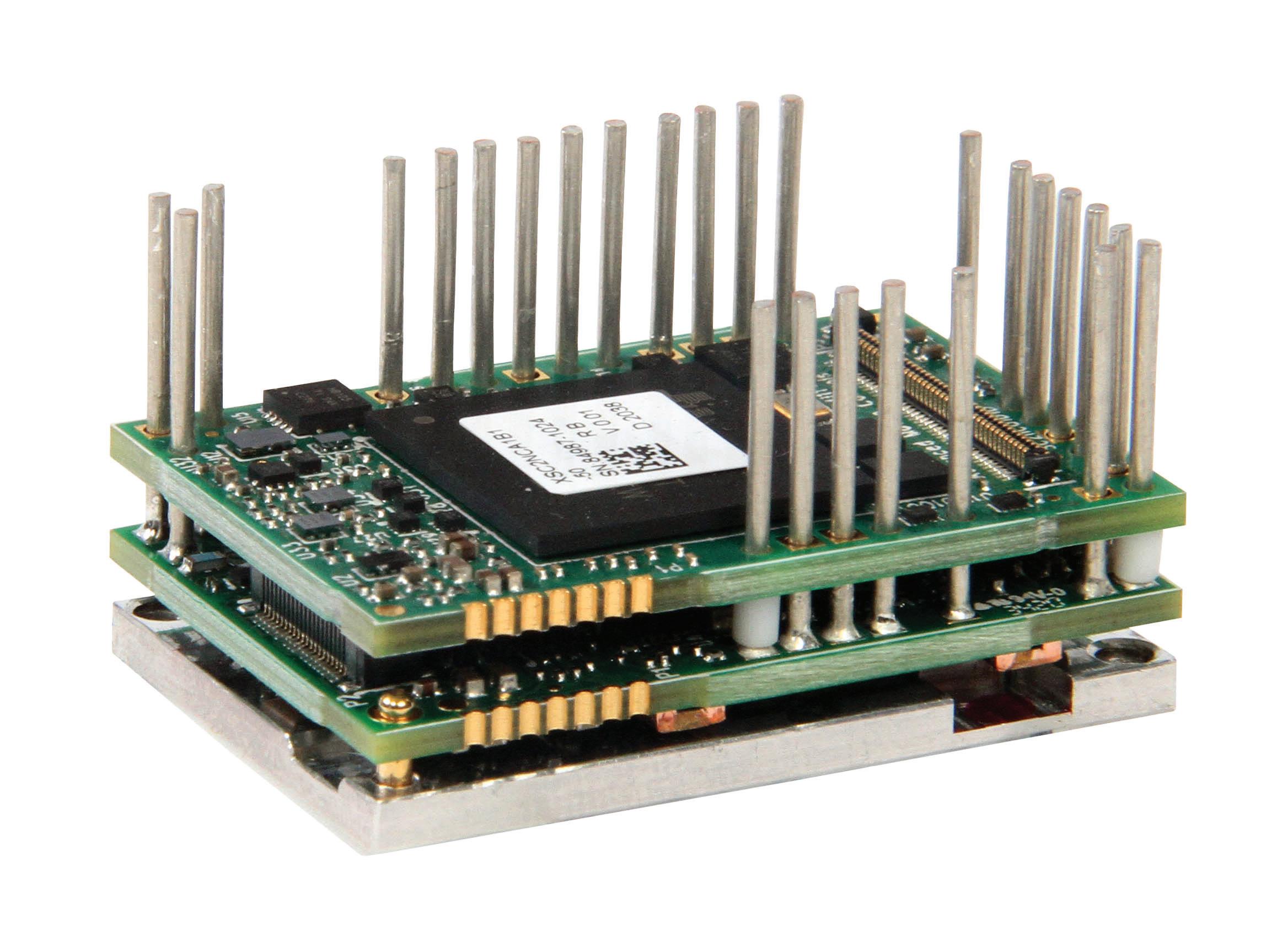

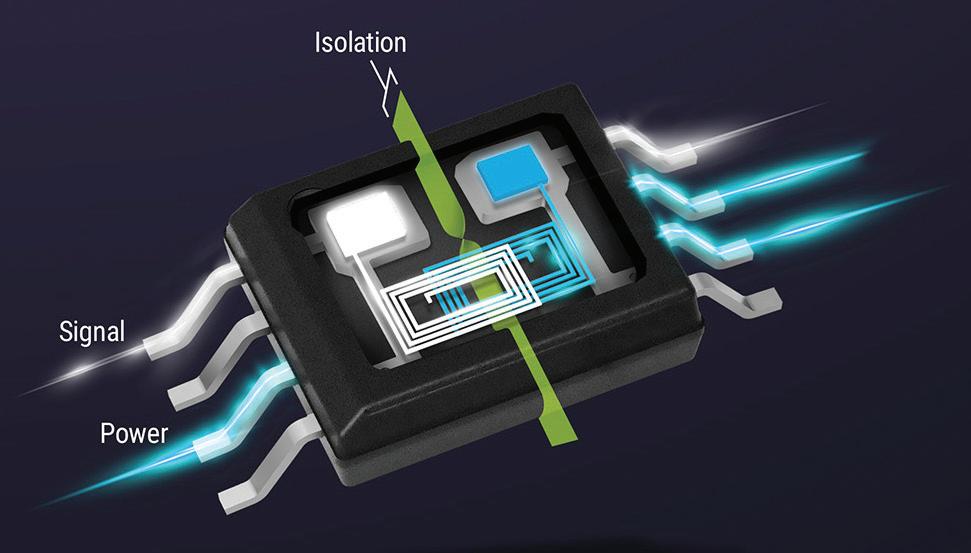

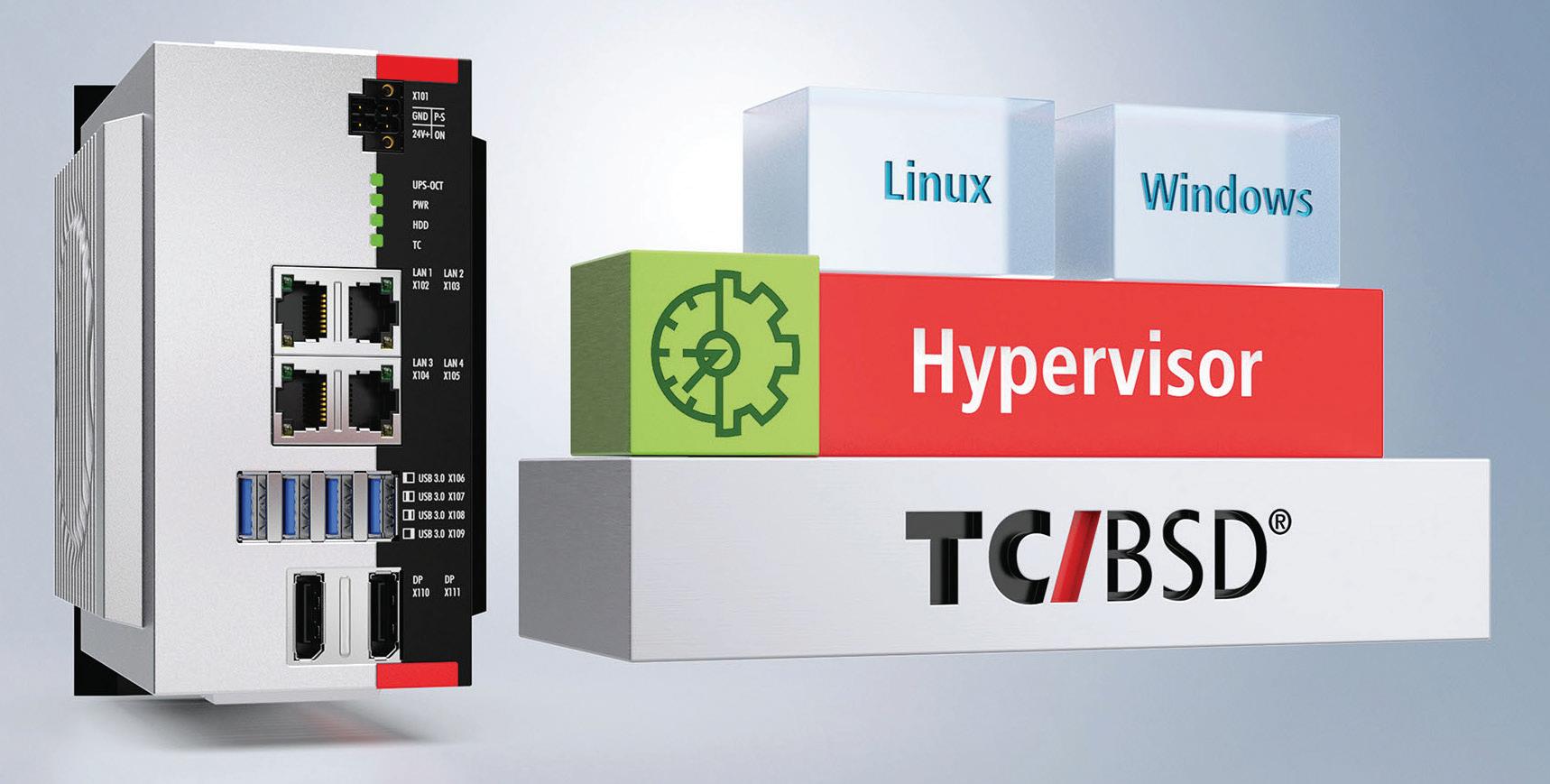

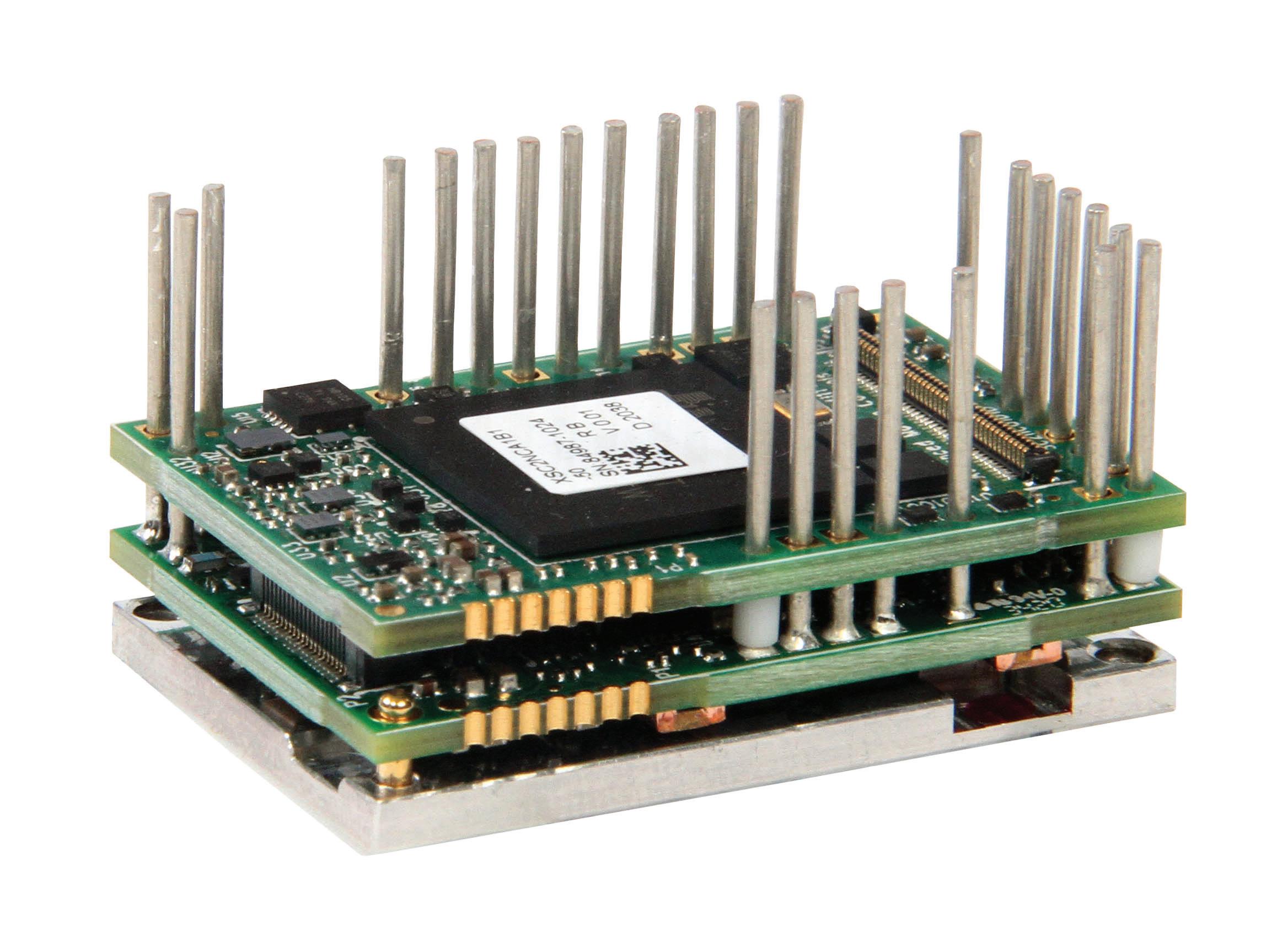

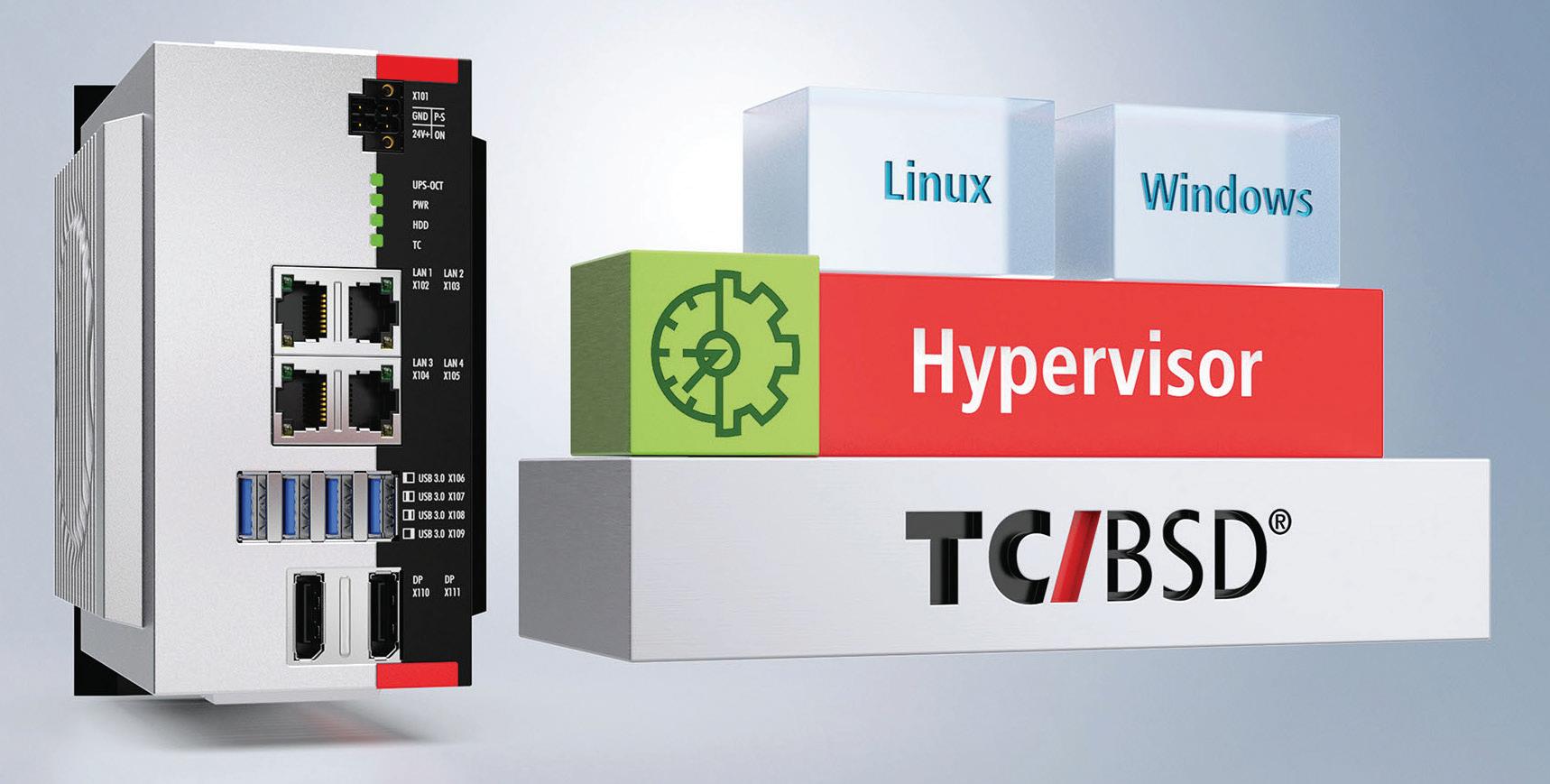

Accelerating real-time digitization

Various real-time connected industries must support high-bandwidth and low-latency communication from devices to real-time clouds and back again. Providers of such end-toend solutions need highly homogeneous platforms along these data supply chains, from the edge servers of the network infrastructure to the distributed and mobile devices, to make implementation as easy as possible. This ecosystem for TSN is aimed at networked factories and critical infrastructures. The goal of the comprehensive edge computing platform portfolio for TSN is to make it as easy to build time sensitive networks for smart factory and critical infrastructure operators deploying standard Ethernet infrastructures. Such entirely connected solutions need secure real-time gateway technologies to connect the brownfield and real-time clouds — both synchronized via Time Sensitive Networking (TSN) for various real-time services. These platforms are prepared for reliable low-latency communication at the edge and include real-time hypervisor support for deterministic and secure data processing and data exchange between the devices and real-time clouds in harsh industrial environments. Target applications of the new TSN enabled ecosystem include industrial manufacturing, healthcare,

24 January 2023 www.designworldonline.com DESIGN WORLD

energy and utilities, transportation and logistics, aerospace, government, and public safety.

This particular platform from congatec provides everything needed for an all-encompassing solution platform — including all interface options to connect the distributed equipment and its peripherals and I/Os via 100Base-T1.

The TSN enabled edge computing ecosystem spans the entire range of latest Computer-on-Modules supporting even real-time enabled 5G cellular connectivity for real-time 5G clients and gateways, as well as server-grade real-time cloud and base station Serveron-Modules. All those modules are TSN enabled, support Real-Time Hypervisor technology and are prepared to host any third-party real-time enabled cellular 5G connectivity. OEMs can use these platforms to deploy their real-time applications in pre-configured realtime virtual machines, focusing all their attention on the development of the application instead of having to concern themselves with the specific settings required to enable the hardware to communicate via TSN. For local wired infrastructures between servers and clients, TSN enabled smart switching platforms are available as well. DW

congatec | www.congatec.com

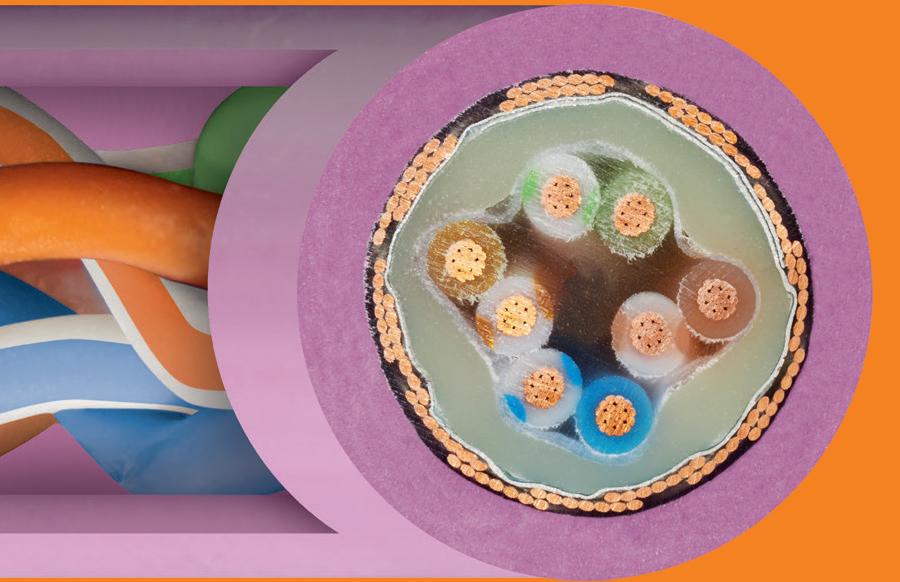

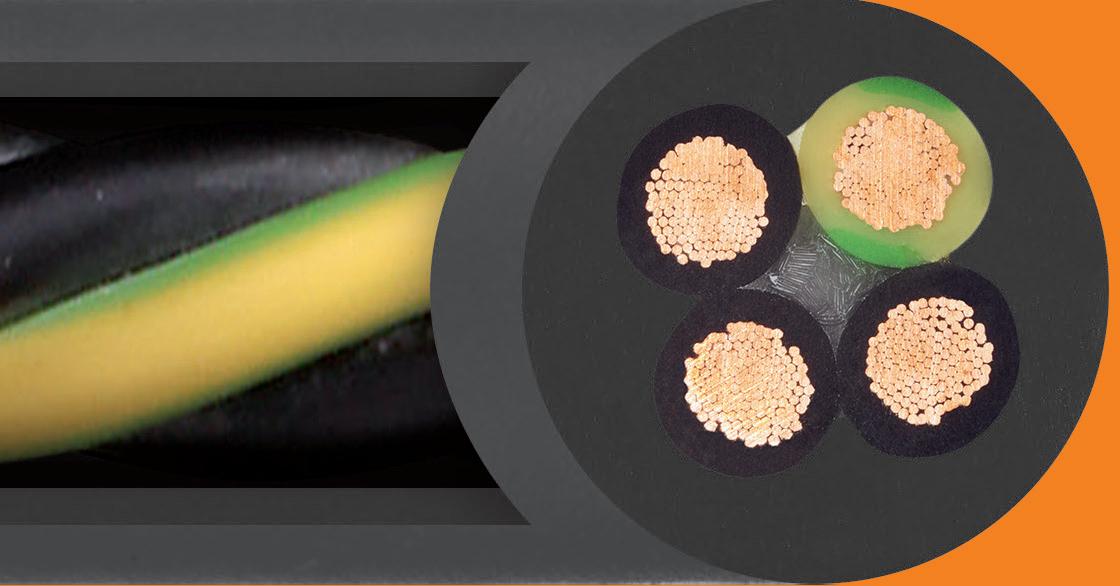

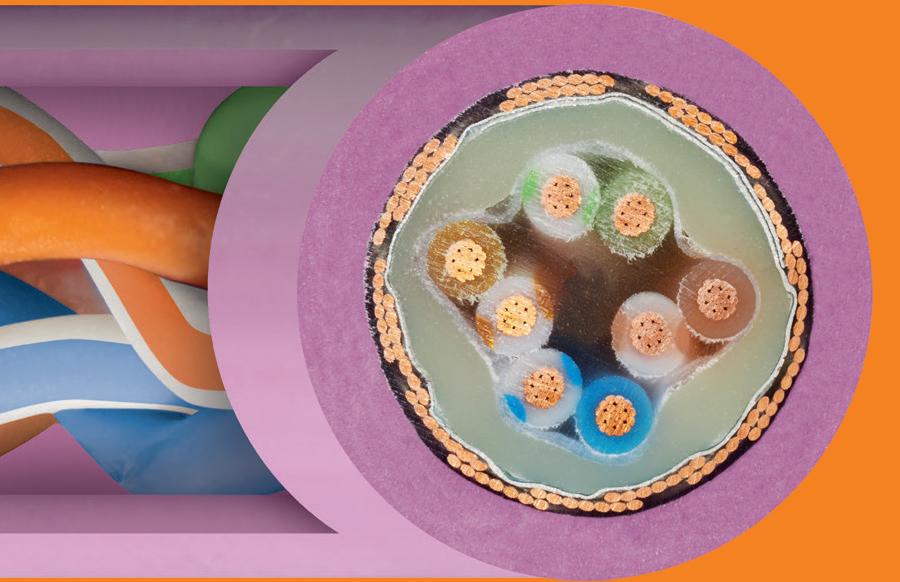

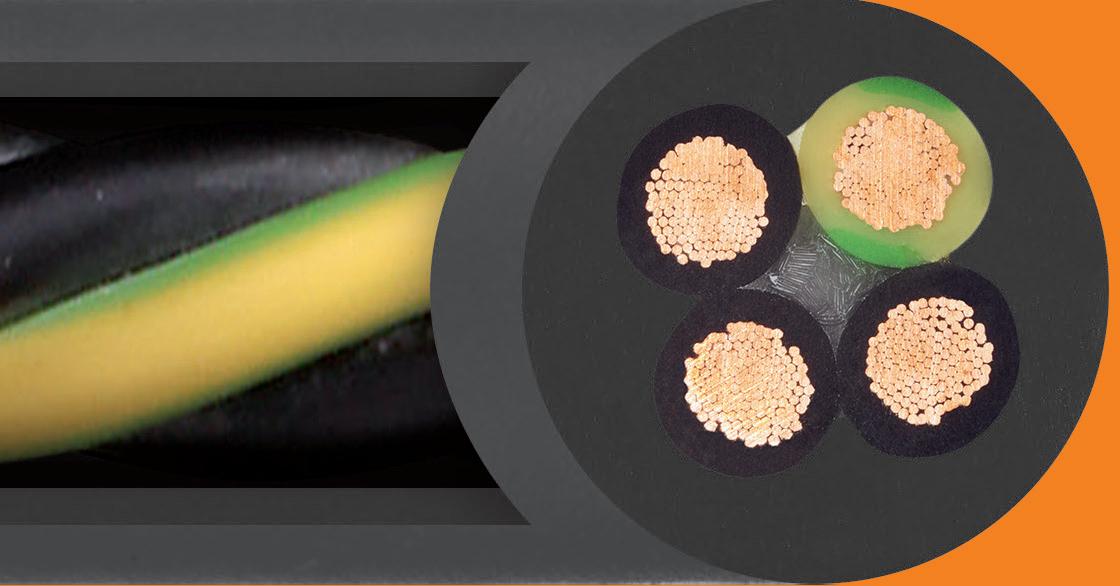

CABLE SYSTEM SOLUTIONS FOR INDUSTRIAL AUTOMATION

HELUKABEL is a global cable system solutions provider specializing in the production of cables, wires, accessories, cable assemblies, robotic dress packs, and drag chains. Our electrical solutions consistently and reliably bring power and transmit data to our customer’s applications in various automation-focused industries including food and beverage, material handling, and machine building, among many more.

With a comprehensive product portfolio of more than 33,000 stock items, and the capabilities to design and build custom solutions, HELUKABEL is your one-stop source for electrical connection technology.

DESIGN WORLD January 2023 25

HELUKABEL® USA, Inc. | West Dundee, IL | www.helukabel.com | sales@helukabel.com

Design for Industry Medical

New requirements for connectors for medical devices

Fundamental market and competitive changes are expected in the future, partly as a consequence of the COVID pandemic, bringing with them opportunities and challenges in equal measure, according to the “Medical Technology Trend Report” study by SPECTARIS. Accordingly, adjustments to the way companies work, expansion of digital sales channels, and digital service solutions were described as the three most important e ects. Likewise, corporate functions such as research and development and IT services are in particularly high demand - which poses renewed challenges for companies due to the shortage of skilled workers.

The political demands left clear traces in the health care system. A drastic shortage of health care and nursing professionals is driving the need for supportive processes. This increases the need to maintain productivity through the increased use of medical technology. The requirements for medical devices have changed significantly, and the focus is on the safety of patients and medical sta when operating medical devices. Added to this are the changed technical requirements. Possible problems due to human operator error should be reduced to a minimum.

“This also increases the demand for robotics and automation to make medical devices even more powerful and safer,” said Mathias Wuttke - Business Development Manager Medical Europe at ODU. Particularly with regard to plugin connections, this does not result in completely new products, but the detail requirements are increasing. From IEC 60601 requirements for MOOP and MOPP to product remanufacturing, extensive product testing is required. In addition, quality management controls are increasing, as defect-free, reproducible products are required more than ever.

26 January 2023 www.designworldonline.com DESIGN WORLD

From a technical point of view, one of the biggest challenges customers currently face is with regard to clearance and creepage distances. These take on a completely different meaning due to the new evaluation of the products based on the MDR. For example, the insulation diagram must be considered for the product and all safety-relevant points from IEC 60601-1 must be observed. In addition, there are the adapted requirements from the MDR, which demands not only the medical device manufacturers, but also the suppliers. To implement the MDR, ODU maintains appropriate technical documentation, risk and change management, and CMR substance management. Furthermore, complete traceability is ensured and there is the option of applying the Unique Device Identification (UDI) by laser

marking. The topics of patient and user protection (2 MOOP and 2 MOPP) are implemented in the products in compliance with IEC60601-1. Customer and application-specific applications or special designs with confections increase.

In general, companies face difficulties in procuring raw materials and correspondingly much longer lead times. Supply bottlenecks for raw materials and components are delaying production in all industries, and additionally rising costs for energy are making products more expensive. The mood of crisis is forcing companies to increase inventories, cut investments and attract more suppliers. Due to ODU’s high vertical range of manufacturing, challenges in the supply chain can be better balanced. The manufacturing sites on different

continents support and complement each other.

Collaboration has changed due to digitalization. “Customer and supplier have moved even closer together, and digital communication and cooperation options make processes more effective and faster,” said Stefan Wittmann, Application Manager at ODU. Nevertheless, personal contact is important, especially during initial contact and project start-up, in order to define requirements concretely and discuss possibilities. DW

MEDICAL MOLDED

CABLE ASSEMBLIES

Turn your design challenges into next-generation, marketleading medical devices with our extensive manufacturing capabilities and engineering expertise. We have facilities in Fremont, CA and Santa Ana Sonora Mexico.

46840 LAKEVIEW BOULEVARD, FREMONT, CA 94538 • 510-933-3800

bayinfo

ISO

Cables : Cardiac Monitoring Device Endoscopy Camera Generator Interface Cable Molding Materials Include: • Silicone Rubber • PVC • Polyurethane • TPE • Polyester • Santoprene Product Categories: • Video Cables

Patient Monitoring Cables

Sensor Probe Cables

RF Generator Cables

Robotic Surgery System Cables

Aesthetic Surgery Cables

Single Use Cables DESIGN WORLD www.designworldonline.com January 2023 27

•

@baycable.com •

9001:2015 ; ISO 13485:2016 WWW.BAYCABLE.COM

•

•

•

•

•

•

Medical Design for Industry

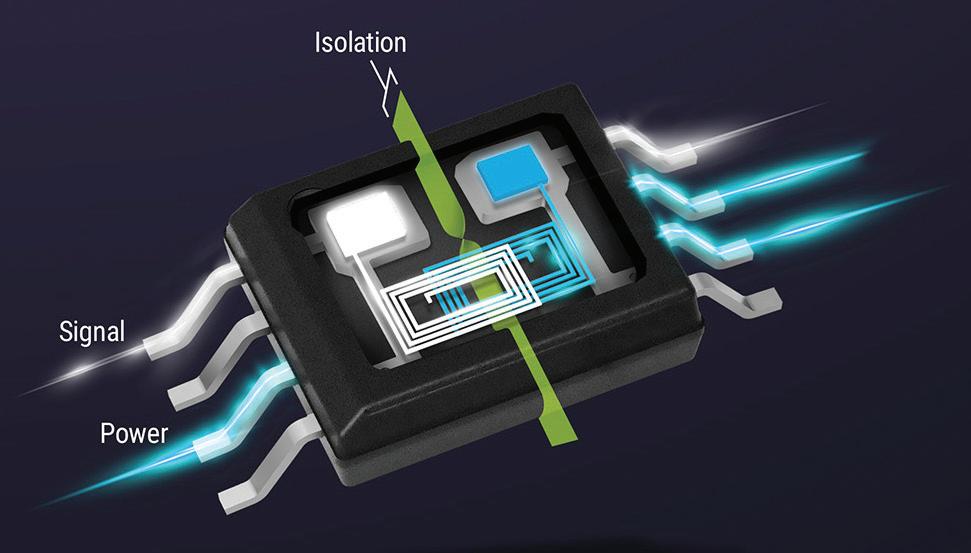

Sensor breaks new ground for prostheses

French startup Kurage is an industry leader in combining innovative medical technology and top-class sports in a more inclusive world. It uses intelligent products to help people with limited mobility move their paralyzed limbs. One key element of their neuroprosthesis is the silicone force sensor SXTSC1 from Sateco.

The sensor is integrated into the sole of a shoe and provides data on walking behavior. This information is evaluated by an AI-based algorithm that powers a system of neuromuscular electrostimulation electrodes. As a result, the system is able to reproduce functional movements in a personalized and secure manner to o set flaws in the sensomotoric performance of the movement apparatus.

The key is the soft structure of the sensor, which enables sensor integration in the shoe, and the force distribution on the foot can be measured across a large area. As a result, an exceptionally clear signal is created. The signal is created in conjunction with the sensor’s silicone material and the appropriate evaluation electronics. DW

Sateco | www.satecogroup.com

The eely designable base area and dimensions of the silicone sensor allow for an ergonomic design of input devices, prostheses, and exoskeletons.

DESIGN WORLD www.designworldonline.com January 2023 29

Innovate faster.

Test more design iterations before prototyping.

Analyze virtual prototypes and develop a physical prototype only from the best design.

Innovate with multiphysics simulation.

Base your design decisions on accurate results with software that lets you study unlimited multiple physical effects on one model.

Simulate real-world designs, devices, and

with COMSOL Multiphysics®

processes

Innovate smarter.

comsol.com/feature/multiphysics-innovation

Off-shore

An alternative to silicon carbide bearings for off-shore applications

Water-lubricated elastomeric polymer bearings have been installed to well pumps aboard an undisclosed o shore oil platform operated by Abu Dhabi National Oil Company (ADNOC).

Five KSB three-stage mixed flow impeller-type pumps were each retrofitted with Thordon pump bearings — 13 SXL intermediate bearings, four Composite bearings and a single SXL throttle bearing — replacing the original silicon carbide bushes.

An issue with silicon carbide bearings is that they have a long lead time, and are brittle which means there is a risk of the bearings chipping and breaking. They are simply not as robust and can be expensive to replace.

The new bearings resolve the price and lead time issues, are durable,

and are also more considerate to the environment as they don’t require lubricating oil or grease.

After OPI gathered all the parameters and reviewed the pump drawings, the bearings were delivered well within the requisite time frame, allowing KSB, the original equipment manufacturer (OEM), to carry out the retrofit installation work and commission the pumps in quick time, avoiding any rig downtime.

KSB Abu Dhabi has now refurbished all five pumps with the bearings, the last of which was completed in August 2022. However, the company has been converting its pump bearings over to the Thordon polymer material over the course of the last 10 years. DW

Thordon Bearings www.thordonbearings.com

Industry

Design for

SIKO Products Inc., www.siko-global.com Contactless, no wear and maintenance-free High positioning accuracy and resolution Economical, small, compact designs and custom solutions Flexiblering diameters and measuring lengths FOR POSITION FEEDBACK MAGNETIC ENCODERS Lead times as low as 6 weeks on custom encoders Local stock of absolute and incremental encoders

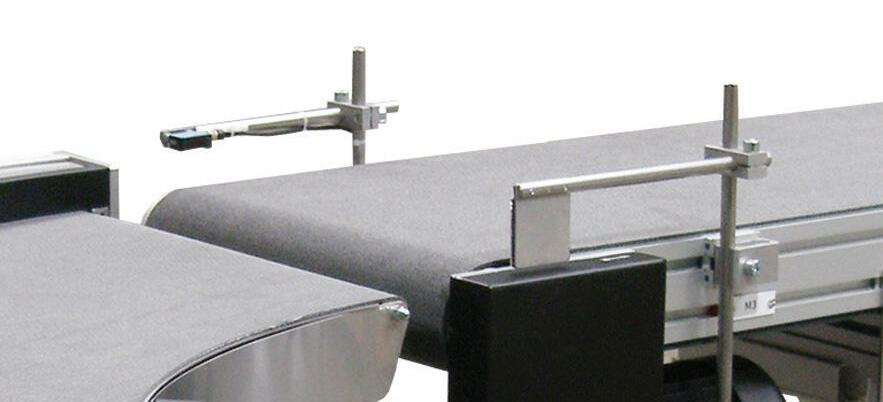

Raise a glass: pneumatic control panel solution helps winemaking production winemaking

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

The AVENTICS CL03 Clean Line Valve System features a high protection class of 1P69K, suitable for sanitary design in beverage processing applications.

| courtesy of Emerson

Design Notes 32 January 2023 www.designworldonline.com DESIGN WORLD

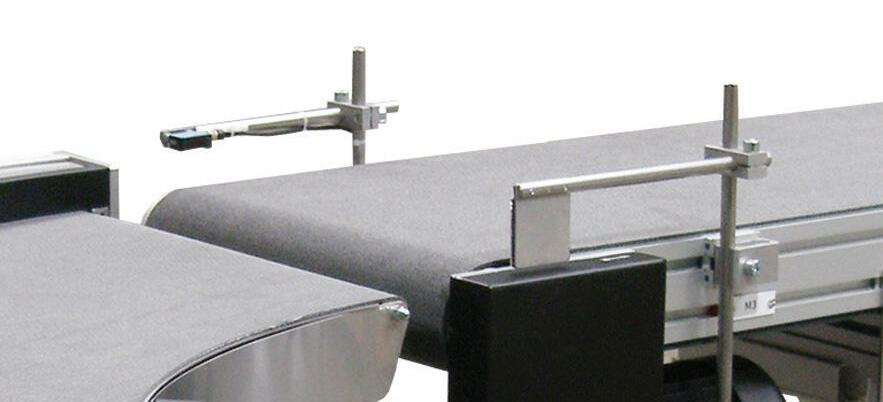

Fourage CTI is a designer, manufacturer, and distributor of equipment for the beverage industry. One of their key products is a wine filtration skid, a complete filtration system used to perform several filtration functions.

In winemaking and the production of distilled spirits, clarification and stabilization are critical processes by which insoluble matter suspended in the wine or spirits is removed before bottling.

Filtration, especially through carbonbased filters, contributes to the stability and long shelf life of the wine or spirits. Filtration also helps winemakers and distillers achieve specific, delicately refined tastes and aromas for their products and saves time waiting for spirits to age. These high-volume filtration systems can filter up to 23 liters in a few minutes and can filter multiple batches using just one set of carbon pads.

Conventional filtration systems from the beverage industry are also used in the spirits industry. These include sheet or stacked disc cartridge filters fitted with depth filter sheets or stacked disc cartridges made up of

depth filter sheets. Other filtration options include cartridge filters, crossflow filters, and pre-coat filters, in which diatomaceous earth, perlite, or cellulose are used as filter additives.

Fourage CTI provides these kinds of filtration products for the wine industry. However, some spirits and wine manufacturers require more advanced filtration capabilities. A high degree of initial haze may require multistage filtration with the same or di erent filtration systems used in combination. Beverage producers must assess what colloidal haze-causing substances need to be removed — materials such as polyphenols, proteins, polysaccharides, sugars, and microbiological loads — while preserving valuable ingredients that contribute to taste, aroma, and color.

Fourage works with its end-user spirits and wine producers to provide the most cost-e ective and e cient filtration skids based on the producers’ unique product and process requirements. As a result, they must have the right resources to let them

& International Power Cords

Interpower® manufactures durable American-made North American 5-15, 5-20, 6-15, or 6-20 cords and international cord sets. Interpower cords provide the correct amperages and voltages to connect to country-specific power mains right out of the box.

Every Interpower cord and component undergoes hipot testing, continuity testing, ground testing, and multiple inspections after each manufacturing process.

• No minimum orders

• World-class customer service

• Value-added options such as lengths, colors, packaging & labeling

• Blanket and scheduled orders availa

®

®

7 a.m.–6 p.m. CST

DESIGN WORLD www.designworldonline.com January 2023 33

Fourage collaborated with Emerson to create a complete pneumatic control panel solution.

| courtesy of Emerson

Order Online! www.interpower.com

refine their designs and build filtration skids without having to make extensive investments in finding and integrating multiple components.

The Solution: A complete pneumatics control panel

Fourage CTI faced a complicated challenge: There was strong demand for its filtration systems, but supply chain constraints made it di cult to source all the components to operate the filtration skid. The time and e ort to obtain and integrate these components threatened to interrupt skid manufacturing and delivery to its customers.

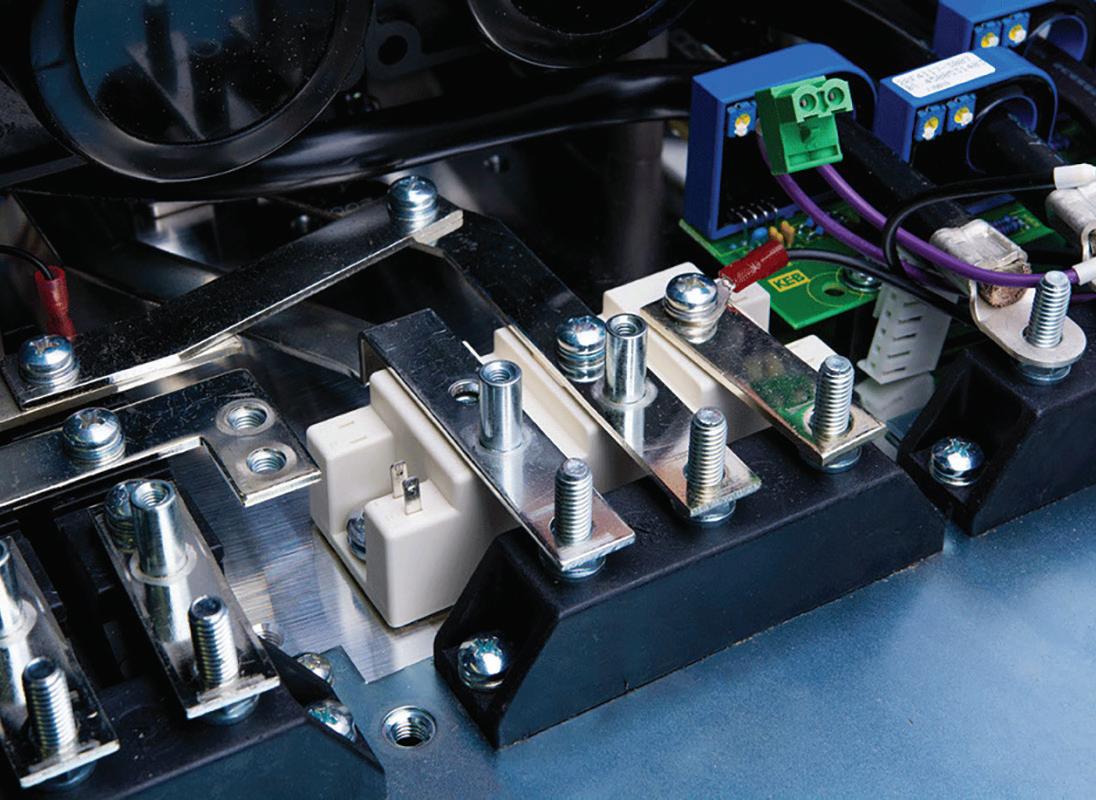

That’s why Fourage partnered with Emerson to create a complete turnkey pneumatic control panel solution with all valves and other control devices preassembled and ready to install. The integrated panel includes a full cabinet with panel mounting and plexiglass door. While Fourage CTI and Emerson had partnered ten years prior, this was the first time Emerson provided a complete solution for Fourage.

The panel combined a range of Emerson devices with products sourced from other suppliers. The components include:

Filter: For the skid, Fourage needed prefiltration, coalescent filtration, charcoal filters, and nitrogen filters

Regulator: The AVENTICS AS2 pressure regulator used in the panel provides significant flexibility. Multiple regulators can be set in line while custom-configuring the pressure required from each regulator. On top of the AS2

pressure 34 January 2023 DESIGN WORLD Design Notes

AVENTICS

AS2 used in the panel provides reliability, safety, and e

Spring Applied Brakes For stopping or holding, safety and positioning Thin profile Light weight Low power Customization Manual release Low heat Motor integration Sealing High cycle rate Trending topics include: 100 Randolph Road • Somerset, NJ 08875-5790 • Tel: (732) 271-7361 www.ogura-clutch.com “What You Need in a Clutch®” Ready to Experience the Best? Transportation Motors Robotics Medical Outdoor Power Warehouse Automation Make your machine move • 10mm-300mm stroke • 25kg+ available force • 6v-12v power supply • 15g-100g net weight ACTUONIX.COM MICRO LINEAR ACTUATORS L12 - 30mm Actual size

The

Series

ciency for Fourage operators. | courtesy of Emerson

regulator is a bicolor screen. If there is a pressure issue, the screen turns red to provide a quick and simple visual diagnosis for the operator.

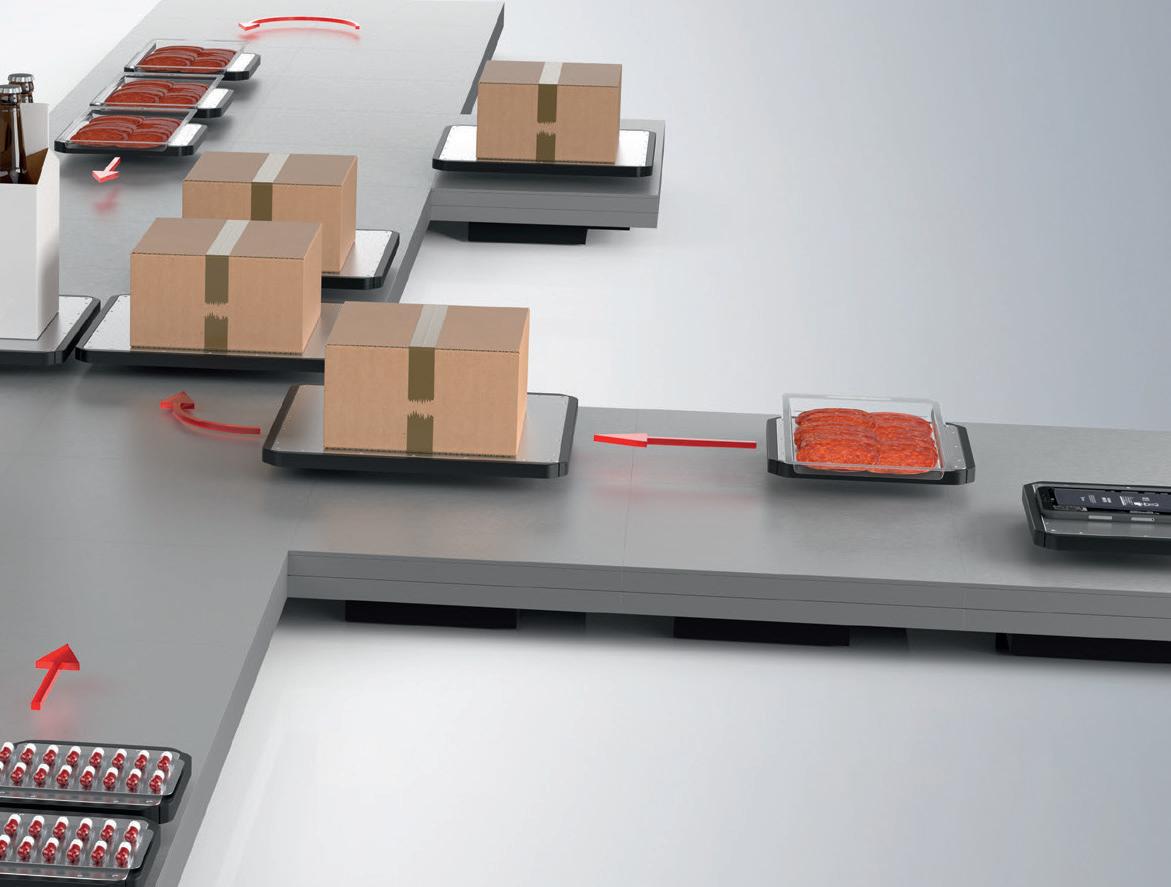

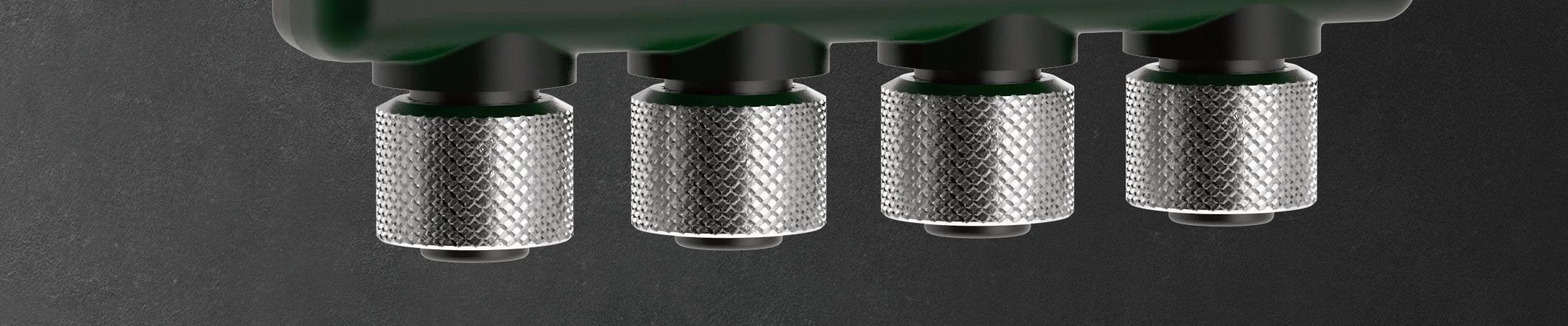

AVENTICS G3 Electronic Fieldbus Valve Platform: A modular and flexible solution designed to replace conventional hardwired systems, the G3 platform provided an easy-toassemble and easy-to-commission solution to pilot the process valves and the filtration system’s pumps.

The G3’s functionality allows programmable logic controllers to more e ciently turn valves on and o and to channel data from sensors, lights, relays, individual valves, or other I/O devices via various industrial networks.

Proportional Control Valves: Two types of proportional control valves were needed as part of the complete panel. Proportional pressure regulation allows the aseptic valve opening to regulate the filtered fluid. To do this, Emerson’s AVENTICS 617 Sentronic LP was chosen, as it provides better regulation, response time, and precision. Emerson’s FlowtronicD 607 flow rate control valve regulates the movement of cleaning shell into the pipes. The product provides real-time control, giving Fourage precise control of the cleaning system’s speed.

The Impact: Simplifying sourcing and speeding time to market

In total, Emerson provided three complete panels. The installation

took only eight weeks and proved to be seamless; there were no issues with skid integration. The complete panel solution eliminated multiple headaches for Fourage: Rather than scour suppliers looking for di erent components and then spending engineering time integrating them all together, the solution saved time and provided a tested and proven solution with all pneumatic control functionality pre-installed and ready to be integrated into each filtration skid. Emerson worked closely with the Fourage team to develop a solution that would work specifically for the company’s needs. DW

Never Bring Unreliable Cords to a Supply-chain Fight —U.S.A.-made Power Cords!

Interpower® manufactures dependable, mission-ready North American 5-15, 5-20, 6-15, or 6-20 cords and international cord sets. Interpower cords provide the correct amperages and voltages to end users when connecting to country-specific mains power.

Our American-made cords are ready to use right out of the box—and downrange ready. Every Interpower cord and component undergoes hipot testing, continuity testing, ground testing, and multiple inspections after each manufacturing process.

“We test more than the standards require for our own benefit,” Interpower Product Development Manager Ron Barnett said. “We do so because it lends better reliability to our design.”

Emerson emerson.com/en-us ® ®

7 a.m.–6 p.m. CST

The AVENTICS G3 Platform provided Fourage with a modular and easy-to-assemble solution.

The G3 o ers application performance and maintenance improvements, making it a reliable solution in the panel.

DESIGN WORLD www.designworldonline.com January 2023 35

| courtesy of Emerson

Order

www.interpower.com

Online!

How to make a diesel truck greener

Edited by Mike Santora • Managing Editor

For decades, the EPA has mandated that every diesel truck in America have a Diesel Particle Filter (DPF) to catch the huge plumes of black smoke emanating from the exhaust system. This smoke is harmful to our everyday environment and a major pollutant to the world’s atmosphere.

The problem with DPFs is that while they are good at catching smoke and soot, they shut down the truck’s engine when they become full. Thus, whether you are an independent trucker or own a fleet of trucks, it is essential to keep a tab on the filters and clean or replace them before they halt trucking operations.

CHALLENGE

The traditional way to clean DPFs has always been to bring them to a facility that bakes them at 1150°F for 12 hours. The problem is that they can only be cleaned 3-4 times before the high heat cracks and breaks apart the ceramic parts of the filter. When this happens, the filter must be replaced at a hefty cost of $3-7K.

Design Notes 36 January 2023 www.designworldonline.com DESIGN WORLD

EcoClean installed two of the Bishop-Wisecarver devices in each of its cleaning machines, and their business success has been remarkable.

After 15 years of this dilemma, EcoClean Advantage set out to develop a new and better way to clean the filters — one that was fast and would not destroy them in the process. Their idea was to design a machine that could inject a powerful stream of water perpendicular to the surface of the filter and then move it in a back-and-forth motion to ensure all the filter’s deep channels and pockets got cleaned. They knew that if the water was not injected perpendicular to the filter’s surface, it would simply spew o the filter. However, finding a mechanism with this flexibility, while also being rugged and durable, was not an easy endeavor. While there were many options to choose from, many were too expensive and had added features that were unnecessary and unusable for this process. Other low-cost solutions simply could not hold up the under intense use and in dirty conditions that EcoClean required.

SOLUTION:

To develop their new cleaning machine, EcoClean Advantage needed a solution that was not too expensive but was high quality and robust so it would work well in a harsh, dirty, and wet environment. The device needed to provide maximum flexibility to inject the water precisely perpendicular to the filter and then move the hose back-and-forth around the filter for a deep clean.

After looking at all other solutions on the market, EcoClean Advantage chose

DESIGN WORLD www.designworldonline.com January 2023 37

The ECO60TM Linear Actuator.

With over 1,400 standard products to choose from you can count on the engineers at Bodine to help you find a gearmotor with the right torque, power and speed for your application. We’ll get your design moving. bodine-electric.com

visit us at bodine-electric.com | info@bodine-electric.com | 773.478.3515 (USA)

your application OEM SOLUTIONS

The right gearmotor for

the Bishop-Wisecarver ECO60 linear actuator. The flexibility of this device allowed the hose to be positioned exactly where EcoClean needed it, and it allowed a smooth back and forth motion. It also had a strong, rugged design that was perfect for withstanding the rough handling and dirty conditions that the cleaning device would be operating in.

EcoClean installed two of the BishopWisecarver devices in each of its cleaning machines, and their business success has been remarkable.

RESULTS:

By leveraging linear motion technology from Bishop-Wisecarver, EcoClean Advantage has developed a new generation of cleaning machines that

enables the filters to be cleaned as often as the truck driver or fleet owner wishes. With a process so unique that it has several pending patents — these machines can clean in as little as an hour and eliminate the need to replace the filters every 3-4 cleanings. This enables fleet companies to save hundreds of thousands of dollars in DPF cleaning fuel costs and uptime per year! It’s also been proven that clean filters positively impact fuel mileage, increasing fuel economy by nearly 5%.

EcoClean Advantage has had its cleaning machines running for more than a year with excellent results. In fact, the cleaning machine has been so successful that EcoClean Advantage has expanded its business to develop the machines and o er cleaning

services. The company has already opened cleaning facilities in Orlando and Indianapolis and plans to expand even more in the future. In less than an hour, trucks can have their filter cleaned, keeping their vehicle running smoothly and minimizing any downtime due to dirty filters. DW

Bishop-Wisecarver BWC.com

Bishop-Wisecarver BWC.com

DESIGN WORLD www.designworldonline.com January 2023 39

Design Notes

Cadence proudly announces the acquisition of cadenceinc.com /utitec | 800.252.3371 COMPLETE INTEGRATION Deep Draw TechnologyFlat Stamping ExpertiseNearshore Cleanroom Manufacturing Visit us at MD&M West Booth #1801

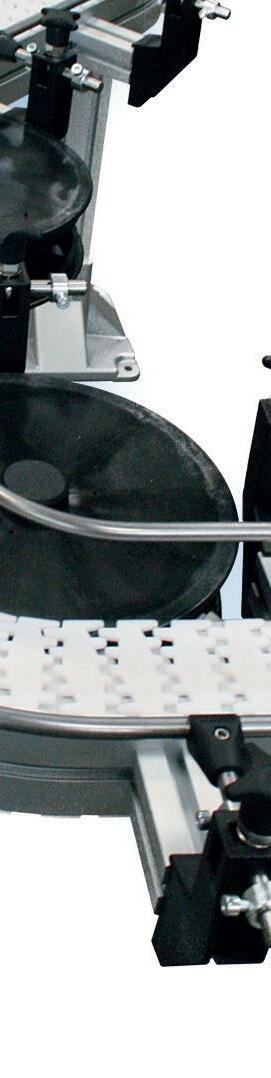

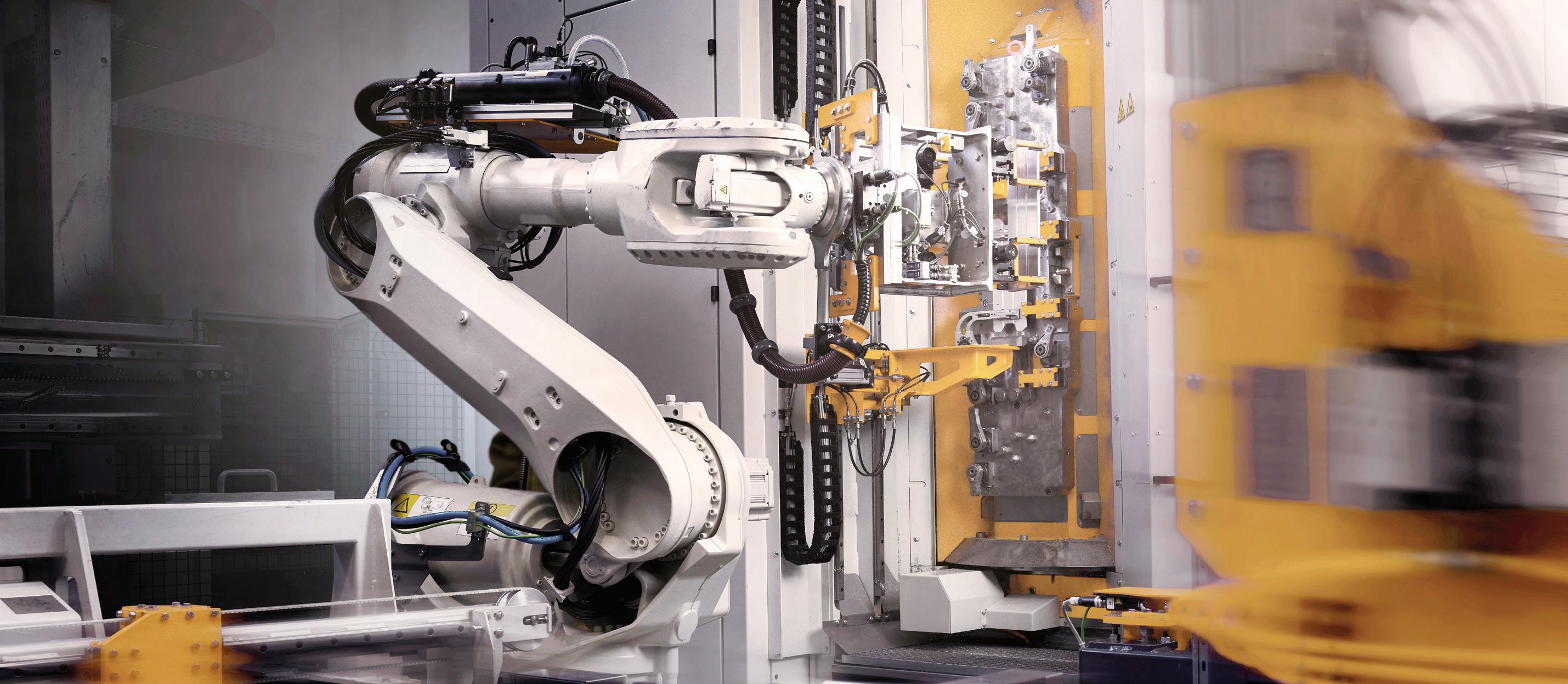

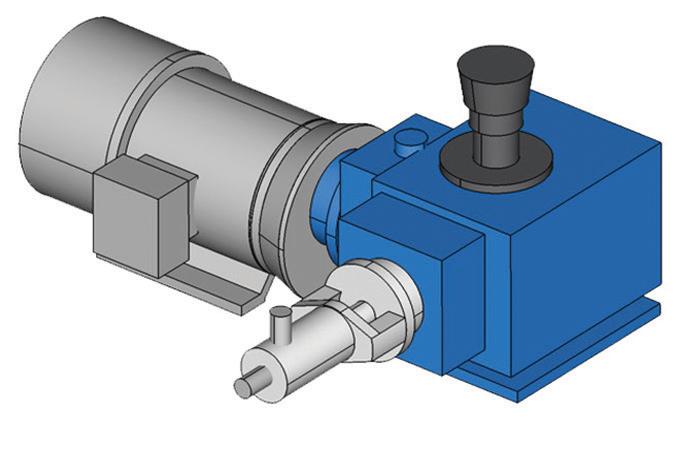

Automation tool for robot production

Edited by Mike Santora • Managing Editor

When first implementing cobots, the engineers at Applied Cobotics quickly realized that the vision systems for picking parts from a bin lacked the sophistication to consistently complete tasks and the a ordability for further expansion. Without an automated loading and unloading system, cobots were sitting idle and falling far short of their potential.

Their solution was to build the Cobot Feeder around dunnage trays and combine it with a parts tray rack to continuously feed the robot. This automation package provided solutions to common core challenges:

• Provide the correct orientation for cobot grippers

• O er organized and repeatable placement of parts

• Allow for easier programming of cobots

• Increase the overall e ciency of cobots

The experience of PBC Linear and their e orts to automate with cobots illustrates how essential it is to have a unique machine like the Cobot Feeder. This is especially poignant when considering how the pandemic has amplified the shortage of skilled workers and exposed a supply chain fraught with severe backlogs and delays.

What started as a reconnaissance e ort into possible solutions quickly turned into a must-need imperative for the PBC Linear team due to the pandemic. With CEO Bob Schroeder’s backing, seasoned engineers, alongside a group of enthusiastic interns at

Design Notes

40 January 2023 www.designworldonline.com DESIGN WORLD

A cobot with a Cobot Feeder from Applied Cobotics can pay for itself in roughly two months on the power of the productivity boost that comes with added lightsout manufacturing.

Unique system solutions for motor & drive technology.

The facts at a glance:

– Highly diverse motor range for virtually all drive applications:

– AC or DC motors

– Internal or external rotor

– Mechanical or electronic commutation

– EC motor with integrated or external operating electronics

– System solutions including transmission, brake and encoder

– Drive units capable of communication with bus interface

– Customized motor solutions, motor parts sets and drive assemblies

– Motors for automotive applications: Power steering drives, drives for clutch actuators and various pumps in the areas of transmission lubrication and exhaust aftertreatment and more

For more information visit us online: www.ebmpapst.us

Applied Cobotics, began designing and building prototypes while investigating di erent materials and linear motion systems. The highly repetitive tasks targeted for the initial automation were the CNC mills and lathes used to produce many of their signature bearings. With roughly 80 CNC machines in the PBC Linear shop and 15 cobot stations in operation, there was plenty of room to experiment.

Results

Over a recent span of twelve months, PBC Linear was able to increase its sales by 33%. In contrast, their labor has only increased 3%. This is represented anecdotally in several examples:

Project schedules: Often, lot sizes are gauged for a single work shift. The reality

The solution was to build the Cobot Feeder around dunnage trays and then combine that with a parts tray rack to continuously feed the robot.

Design Notes 42 January 2023 www.designworldonline.com DESIGN WORLD

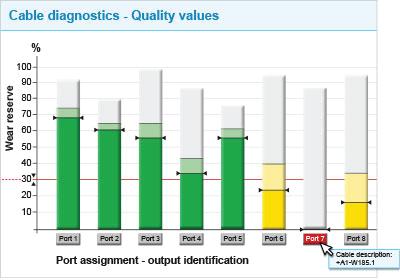

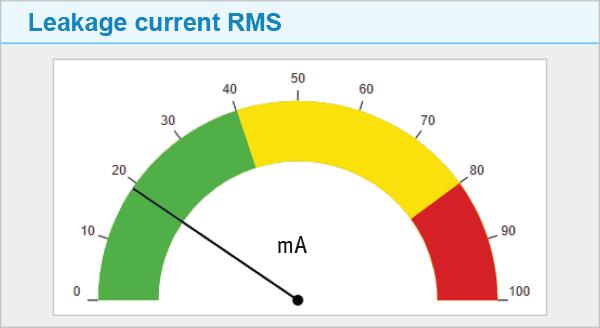

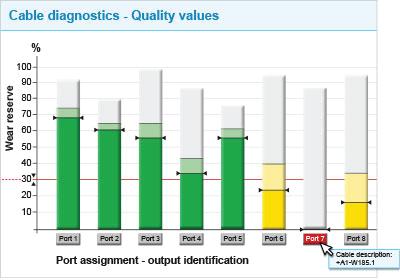

PROmesh Diagnostic Industrial Managed Switches +1 678.880.6910 info@indusolamerica.com www.indusolamerica.com/switches IN STOCK BEST PRICE The latest generation of switches ...with automated condition monitoring Cable Diagnostics Performance Monitoring EMC Issue Alarms

is that a job rarely finishes within the allotted time. In essence, a five-day job can often really take eight or nine days to complete. The Cobot Feeder allows those jobs to finish overnight so that every day is a fresh setup, and each job stays in step with the production schedule.

Parts organization: The reliance on custom dunnage parts trays replaces the old tedious process of a worker stacking/restacking parts to and from a bin or machine and then repeating that process multiple times throughout that project’s timeline. In addition, quality-sensitive parts can be compromised using part bins. The Cobot Feeder model avoids quality issues, downtime, and potential costs.

Multiple parts processing: The options for multiple configurations of parts trays on the rack means di erent parts can be run during the same job run. This greatly reduces the setup and changeover time required, o ering greater e ciency on the shop floor.

An additional benefit is that their workforce has full buy-in to this new manufacturing model, supporting a higher degree of job satisfaction, skill sets, and potentially higher wages. Workers now act more as managers of multiple stations. They can load several machines and then either check on the quality of parts or go to lunch while the cobot and Cobot Feeder continue to operate without a break.

Regarding ROI, the complete Cobot Feeder solution can increase the e ciency of cobots and other types of robots by up to 1600%. Generally, a cobot can pay for itself within six months. A cobot with a Cobot Feeder from Applied Cobotics can pay for itself in roughly two months on the power of the productivity boost that comes with added lights-out manufacturing.

DW PBC Linear www.pbclinear.com

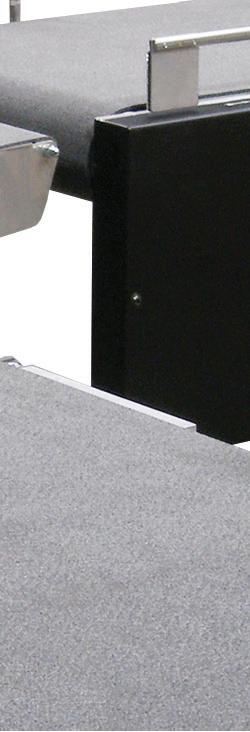

DESIGN WORLD January 2023 43 Design a Conveyor in Minutes!

can design a conveyor

TRANSFORMING CONVEYOR AUTOMATION

Innovative belt, modular belt and flexible chain conveyor solutions

Custom conveyor systems built to your exact specifications

Designed

your production output and decrease waste

Highly experienced service team and distributor network provide

support 800-397-8664 | dornerconveyors.com

Using Dorner’s Online Configurator, you

for your application. The industry leading tool delivers a complete 3D CAD assembly model.

•

•

•

to maximize

•

complete post-sale

3D printing helps drive the future of sustainable mobility

44 January 2023 www.designworldonline.com DESIGN WORLD Design for 3D printing and Additive Manufacturing • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

At the recent Formnext conference, nFrontier, the Berlin-based innovation studio and venture builder, unveiled UILA, a new vehicle and brand concept.

As an industry first, the fully functioning prototype is a hybrid between an electric cargo bike and a small Electrical Vehicle (EV). Extensively leveraging 3D printing, UILA was presented in cooperation with nFrontier industry partner Stratasys Ltd. and is a showcase for integrating disruptive technologies into a sustainable mobility solution.

With a chainless electrical drive train, the vehicle e ortlessly accelerates to top speeds of 25 km/hr and has a range of 60-70 km. The four-wheeled two-seater also provides a cargo payload of up to 250 kg. With a length of 230 cm, the vehicle is only 170 cm high and 90 cm wide, weighing a total of 70 kg. With renowned engineering and manufacturing partners on board, nFrontier is preparing UILA for serial production and tra c registration in Germany some time in 2024.

“UILA is our response to some of the most pressing challenges of our time such as climate change and the current energy crisis. UILA is not only radically changing the way we are commuting, but also provides a truly sustainable, game-changing mobility solution. At the same time, it delivers a feature set of digital functions and assets exceeding current bicycle industry standards,” said nFrontier CEO Daniel Buening.

Current studies suggest that by 2040 there will be more than 750 million electric two- and three-wheelers on the road globally. Ultimately, the market for vehicles such as UILA is unlimited: Due to its dimensions and pedal-operated drive train it is technically a bike, so there is no need for a driver’s license, allowing users to drive it on bike lanes. Contrary to cargo bikes, UILA features additional comfort usually only o ered in small EVs: a modern infotainment system, including BYOD (smartphone) functionalities that will connect the internal display solutions. With the help of the UILA App, users will be able call the parked vehicle so it will drive autonomously towards you (‘Come to me Mode‘) or follow you without driver (‘Follow me Mode‘).

“UILA is designed to be a digital device featuring many useful digital features that will make driving from A to B more enjoyable. We like to call it an ‘urban device’ because we believe that these features will unlock UILA’s full potential as a product with a potentially huge impact on urban transportation” added nFrontier CVO Dr. Stephan Beyer.

UILA is an example of how 3D printing is transforming not only the product development process but also production. Using Stratasys FDM technology to 3D print large format body components significantly reduced the cost of producing those same parts using traditional manufacturing, such as injection molding, while also saving time because parts could easily be produced inhouse at nFrontier. In addition, the nFrontier team has designed UILA to also use 3D-printed parts in the production process by leveraging higher volume additive manufacturing technologies such as powder-based SAF or photopolymer-based P3 systems. This reduces costs and improves sustainability by printing fewer components with less material and doing so locally — in the markets where the UILA vehicles are sold — reducing supply chain challenges and transportation emissions.

UILA was designed by nFrontier lead designer Joschua Kranke and is a development by nFrontier’s EmTeCe (Emerging Technology Center), a leading facility of creatively applied Emerging Technologies in soft- and hardware in which Stratasys is a founding partner. (The EmTeCe converges the “Eight EmergingTechnologies” in one single facility: Additive Manufacturing, Augmented Reality/ Virtual Reality, Artificial Intelligence, Internet of Things, Robotics, Generative Design, Drones, and Advanced Visualization.) DW nFrontier | n ontier.de Stratasys | www.stratasys.com

DESIGN WORLD www.designworldonline.com January 2023 45

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

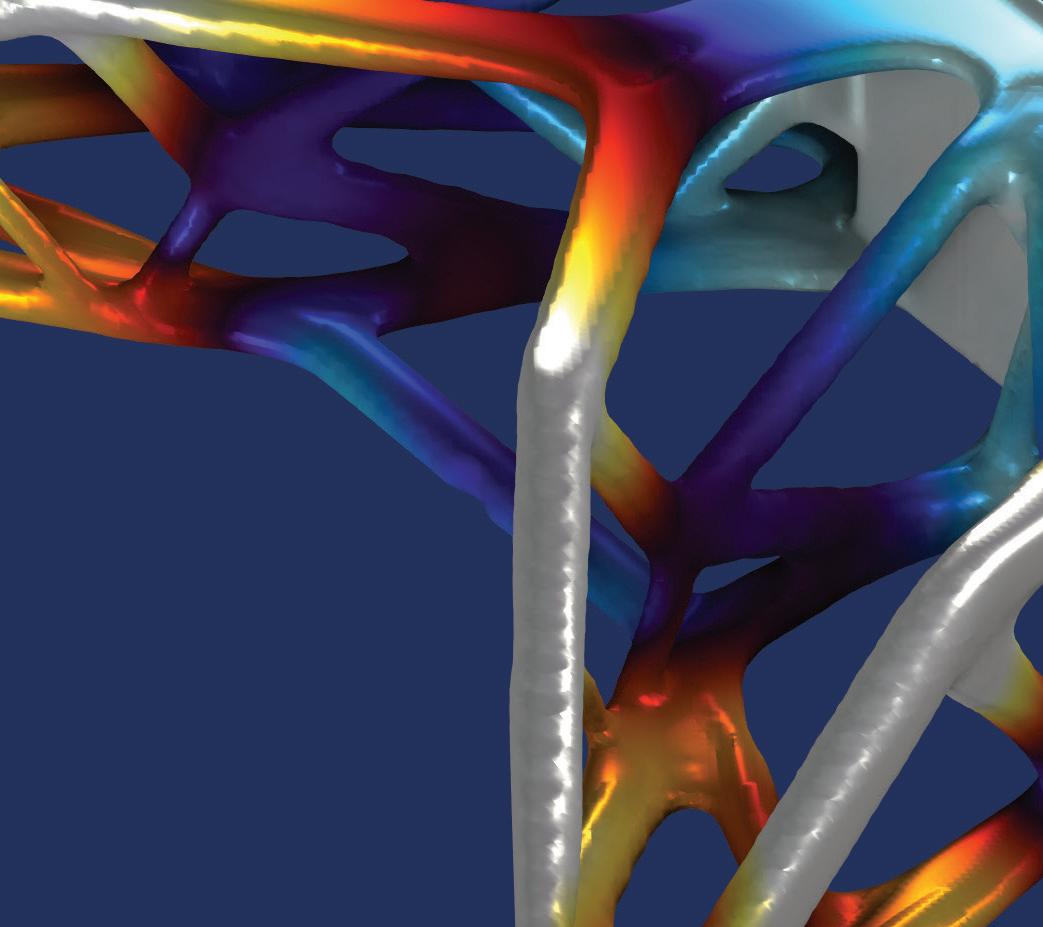

for 3D printing and Additive Manufacturing GE Additive and Shell use additive technology to create an oxygen hydrogen micromixer

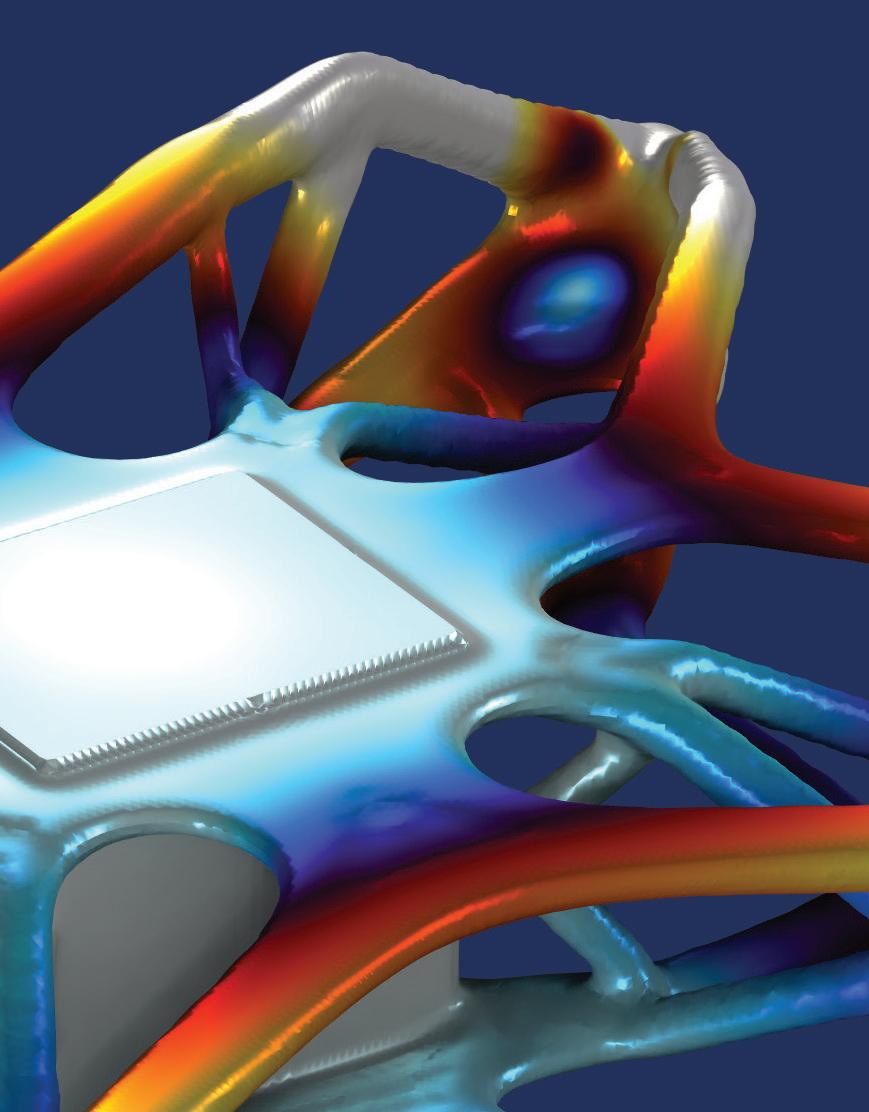

This complex oxygen-hydrogen micromixer demonstration part was printed in nickel alloy 718 on a GE Additive Concept Laser M Line. This part needed to have multiple channels for hydrogen and compressed oxygen.

uring last year’s Formnext conference, Shell International B.V. and GE Additive unveiled the results of a joint design and engineering project — an additively manufactured oxygen hydrogen micromixer.

This complex, non-functional, demonstration part, was printed in nickel alloy 718 on a GE Additive Concept Laser M Line system, and installed at Shell’s 3D Printing CoE and Workshop, part of the company’s Energy Transition Campus Amsterdam (ETCA) in the Netherlands.

Shell maintains a 3D printing facility at ETCA in proximity to its scientists and partner companies to leverage additive manufacturing to prototype, and print functional parts. Having its own printing capability grants Shell’s R&D department the freedom and speed to create novel parts not available in the market, and solve new technical challenges in support of the energy transition.

Joost Kroon, an additive technology subject matter expert at Shell explained, “We really wanted to put the M Line through its paces and test it to its limits. Working with the GE Additive team we agreed to apply additive technology to reimagine a large, complex part, incorporating channels that would be di cult to manufacture conventionally. Working on an oxygen hydrogen micromixer aligns well with our companies’ strategies to play a positive role in the energy transition.”

46 January 2023 www.designworldonline.com DESIGN WORLD Design

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

D

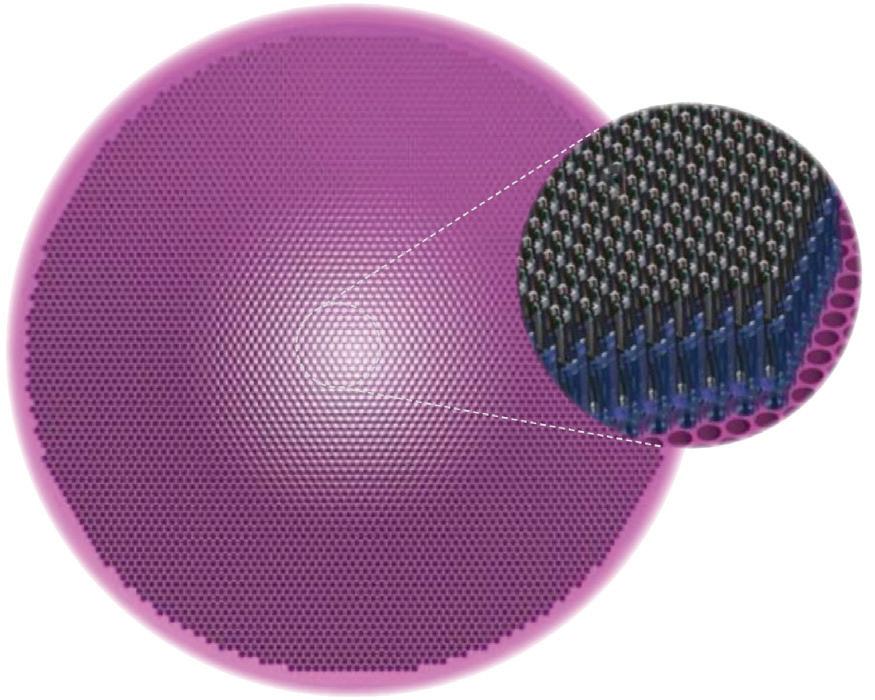

Lead design engineer Sonali Sonawane Thakker at GE Additive’s AddWorks team based in Munich took inspiration from the ways pollen grains form in a flower head to arrange the more than 330 individual nozzles in a circular pattern. The curved wall and the conical shape also reflects the shape of a petal.

Taking inspiration from geometry in nature