November 2022 www.designworldonline.com inside: LINEAR MOTION : Linear motors find a home in CNC machines p. 52 ADDITIVE MANUFACTURING : Metal 3D printing materials under review p. 64 WAREHOUSE AUTOMATION Covering the latest motion and control components, equipment and systems in ASRS design p. 71 with power-off brakes page 44 Game on

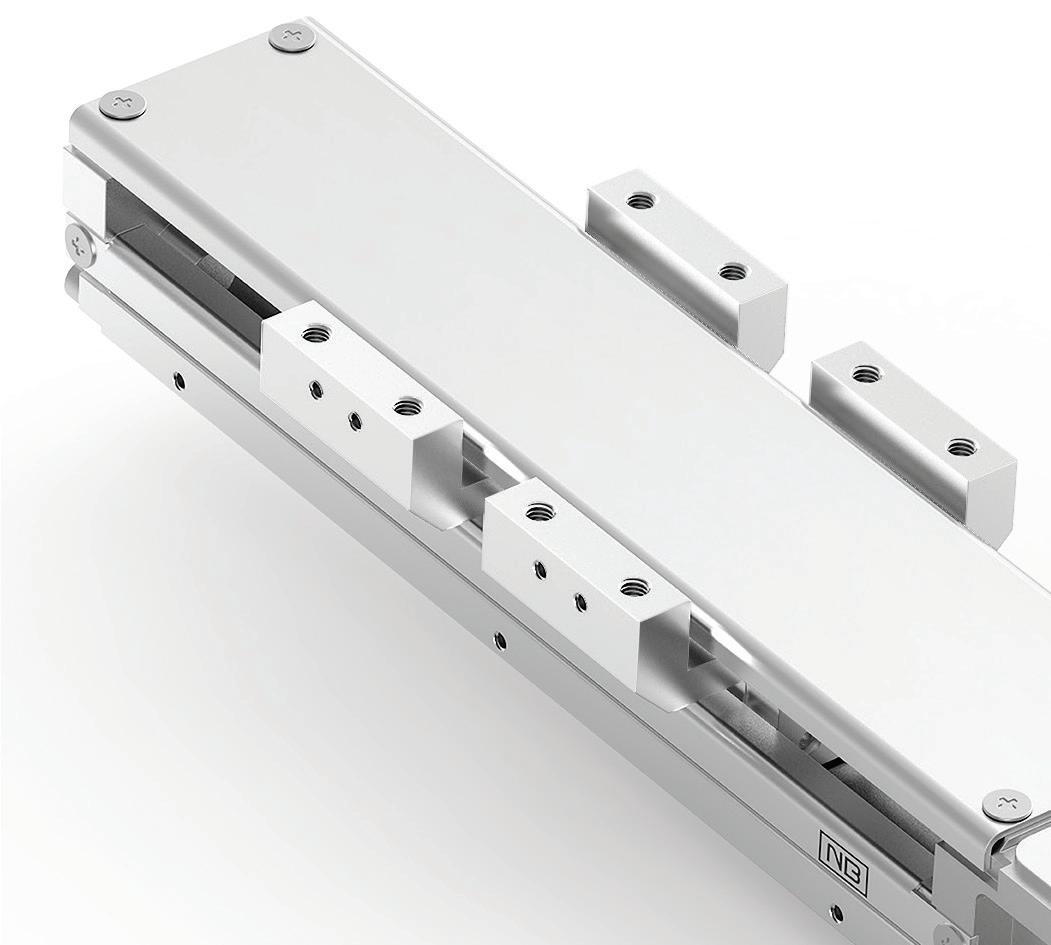

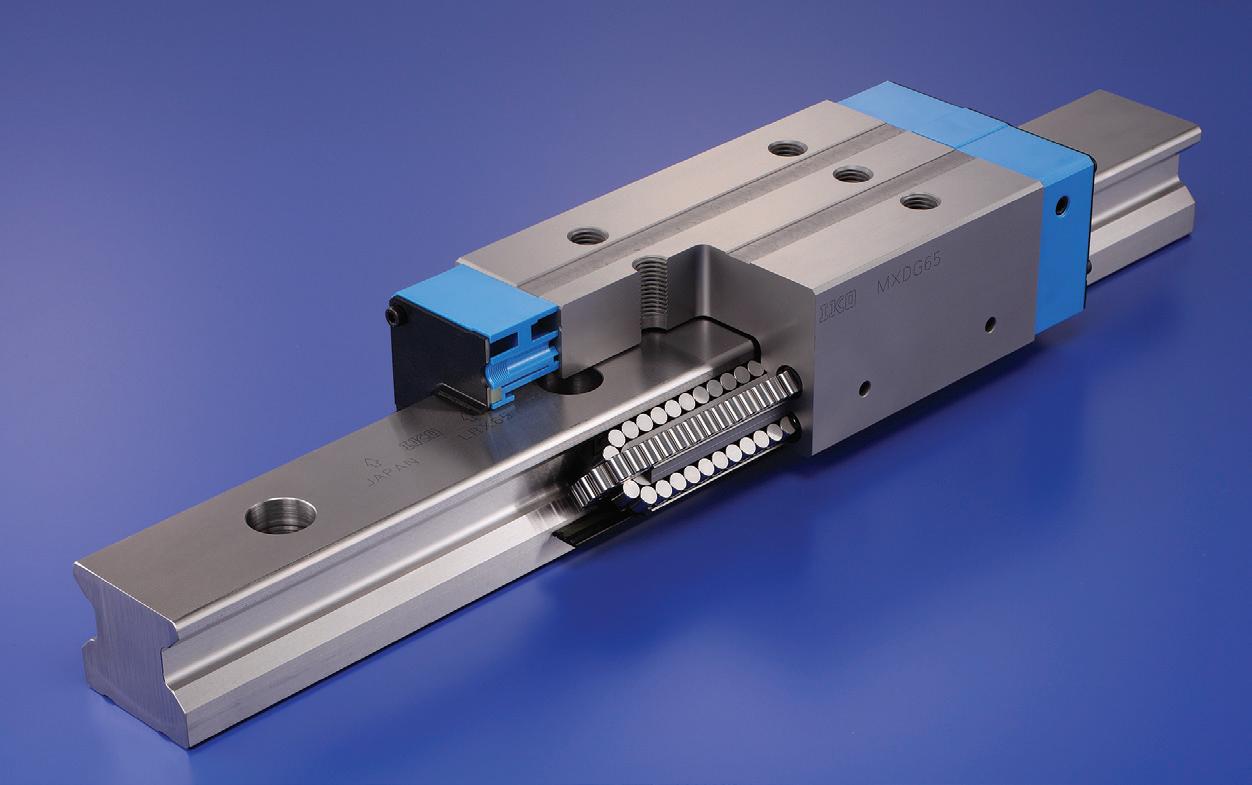

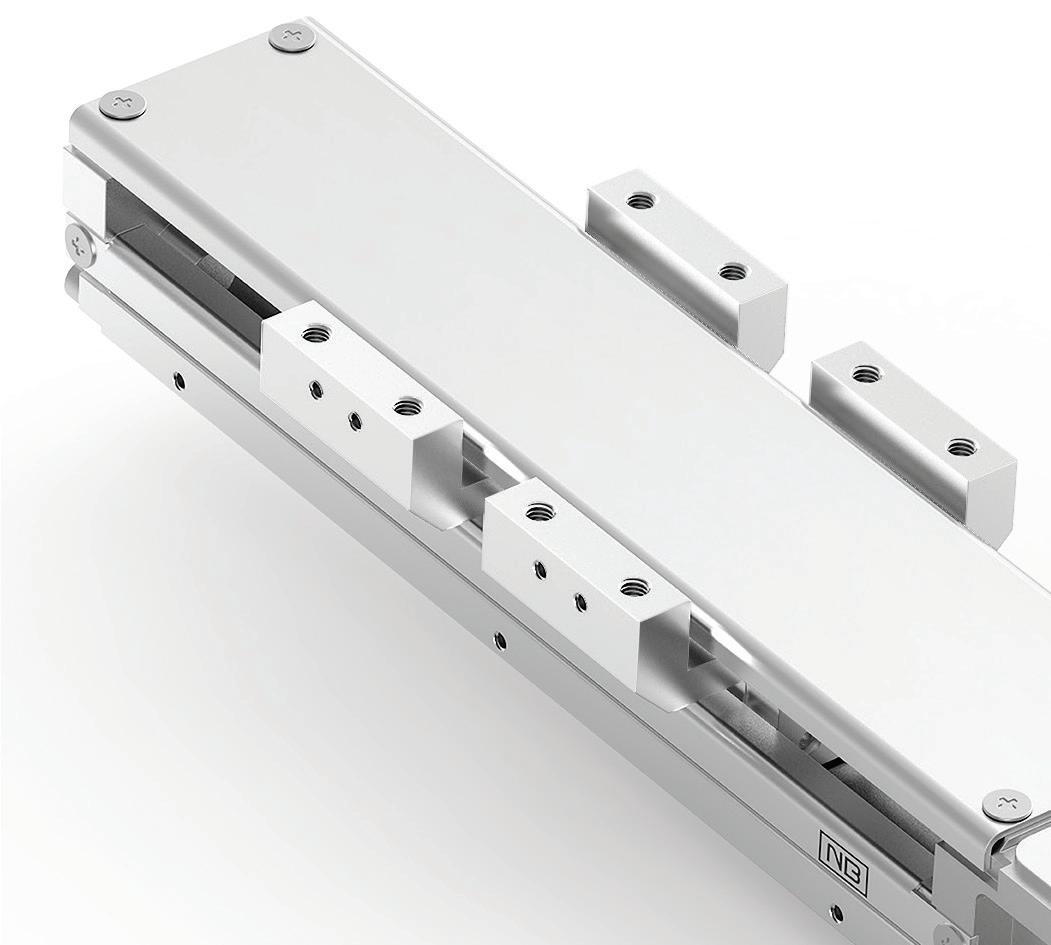

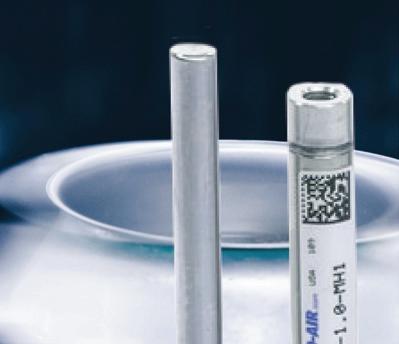

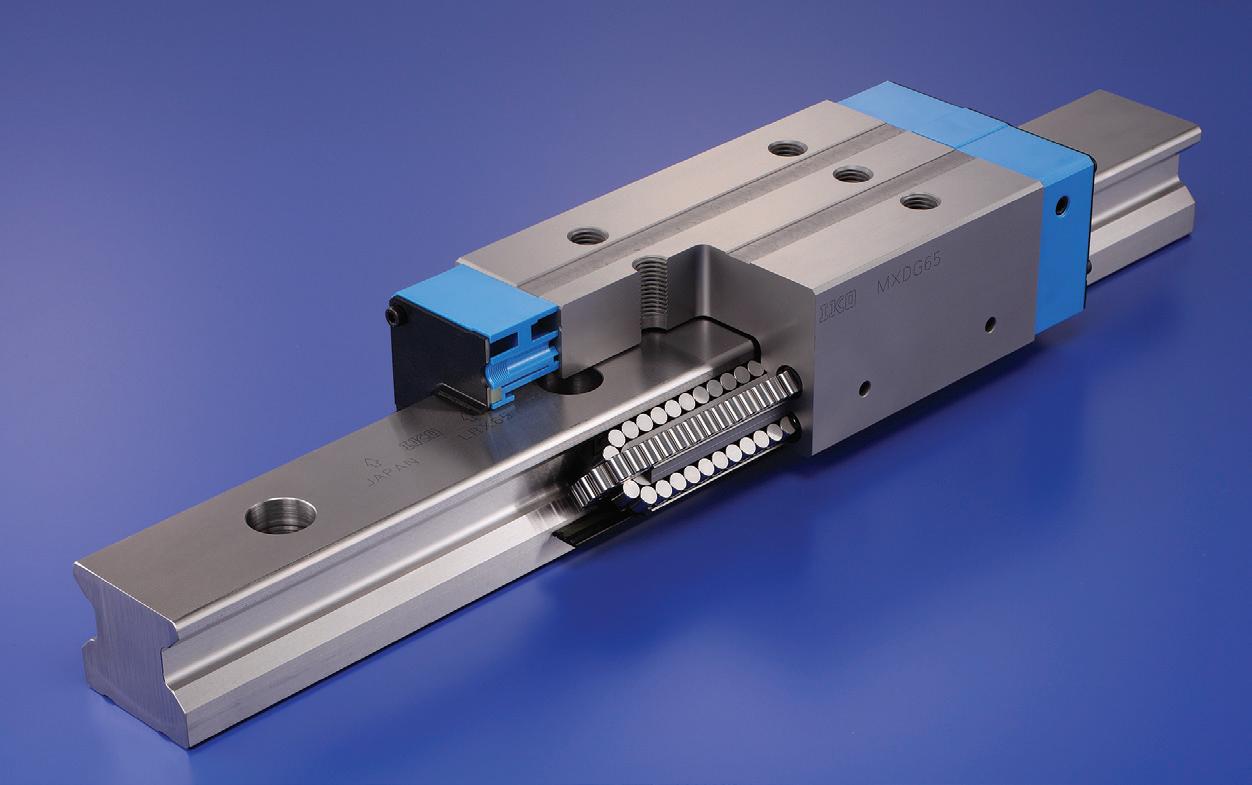

THK is committed to meeting the worldwide demand for linear motion products. At THK Manufacturing of America, Inc (TMA), we manufacture, assemble, and ship all over North America from our location in Hebron, Ohio. We’ve also ramped up our automating processes at existing facilities including our U.S. manufacturing plant where over 70% of THK Robotics Components are manufactured. Automated processes at this state-of-the-art facility enable increased production while maintaining the high standard of precision associated with our products.

To learn more, call us at 1-800-763-5459 or visit www.thk.com.

Quality Linear Motion Solutions from THK LOCAL MANUFACTURING WORLD-CLASS LINEAR MOTION 1–2 Week Delivery of Select LM Guides and Actuators QUICK SHIP COMPONENTS THK Manufacturing in Hebron, Ohio See Us at Booths 134802 & 134803

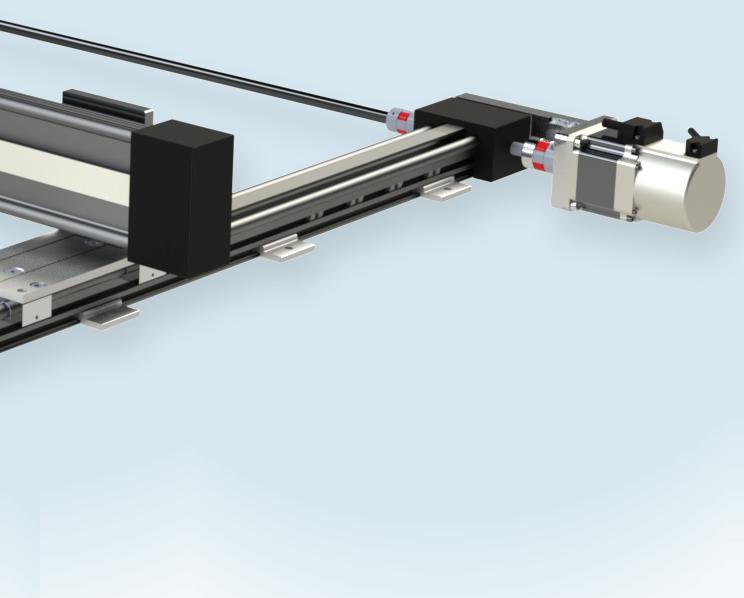

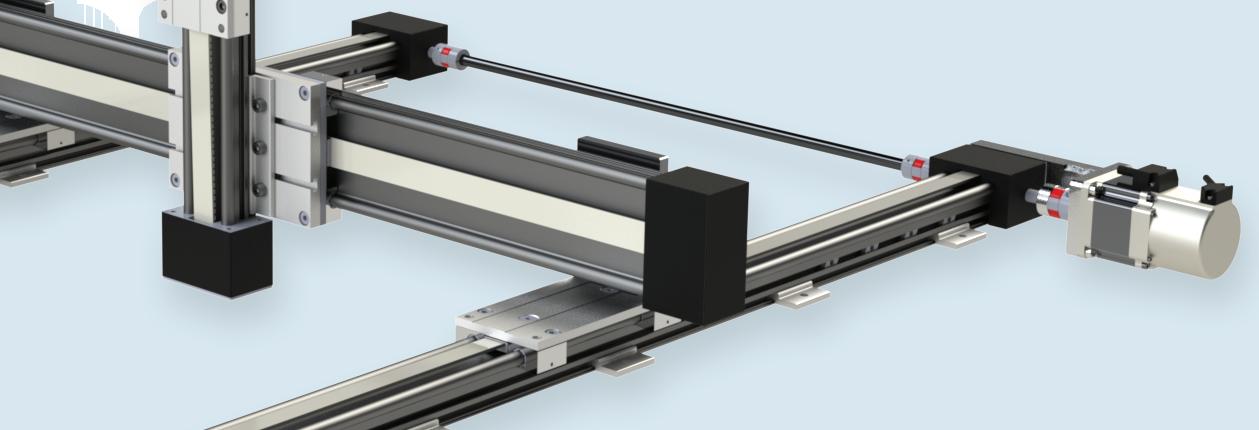

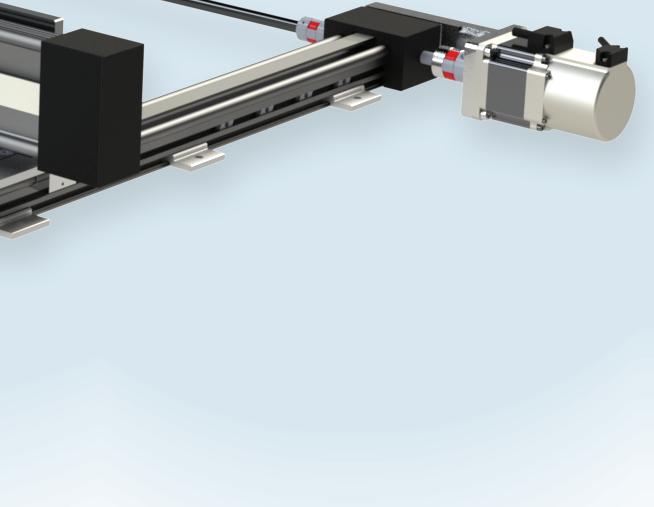

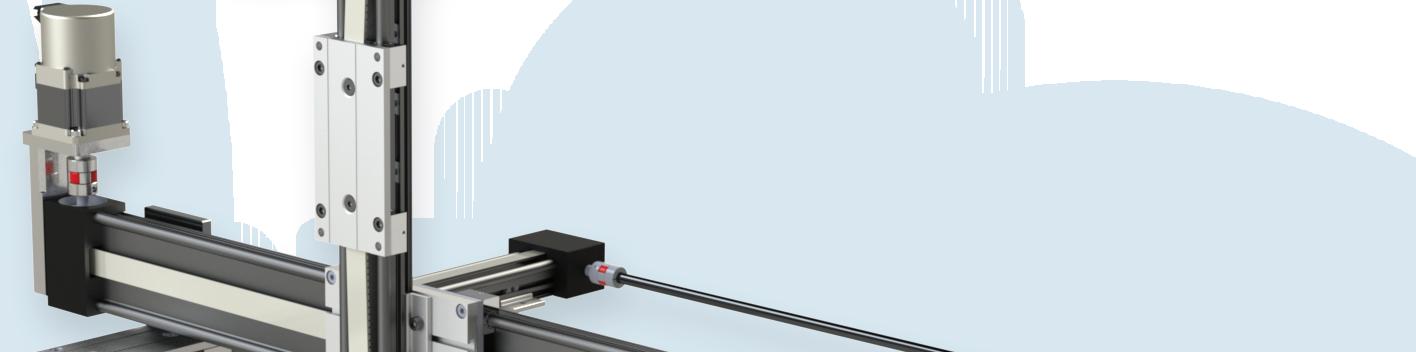

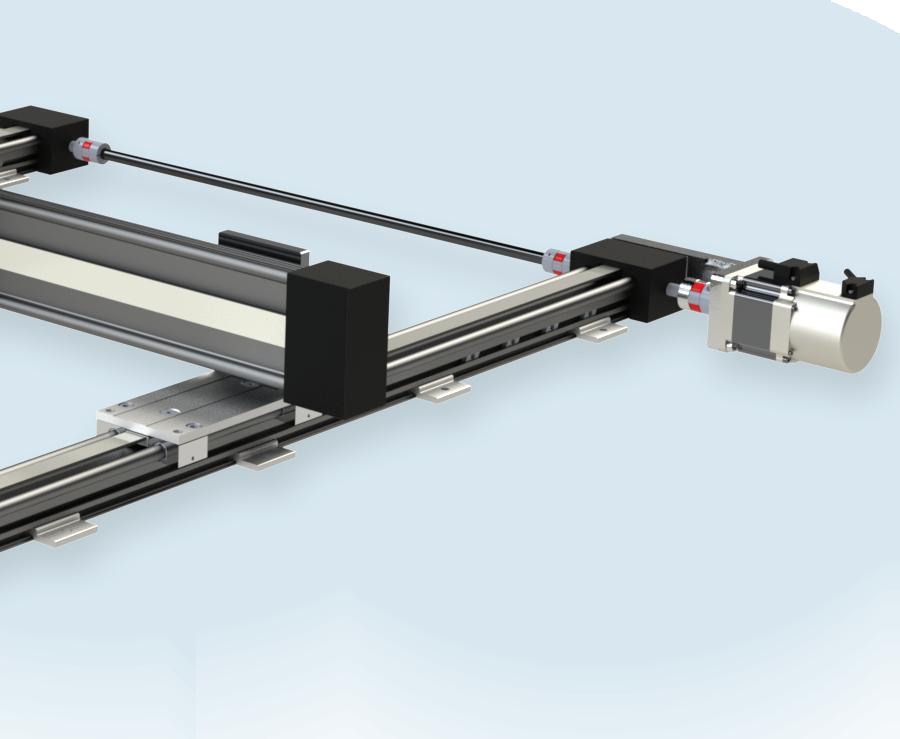

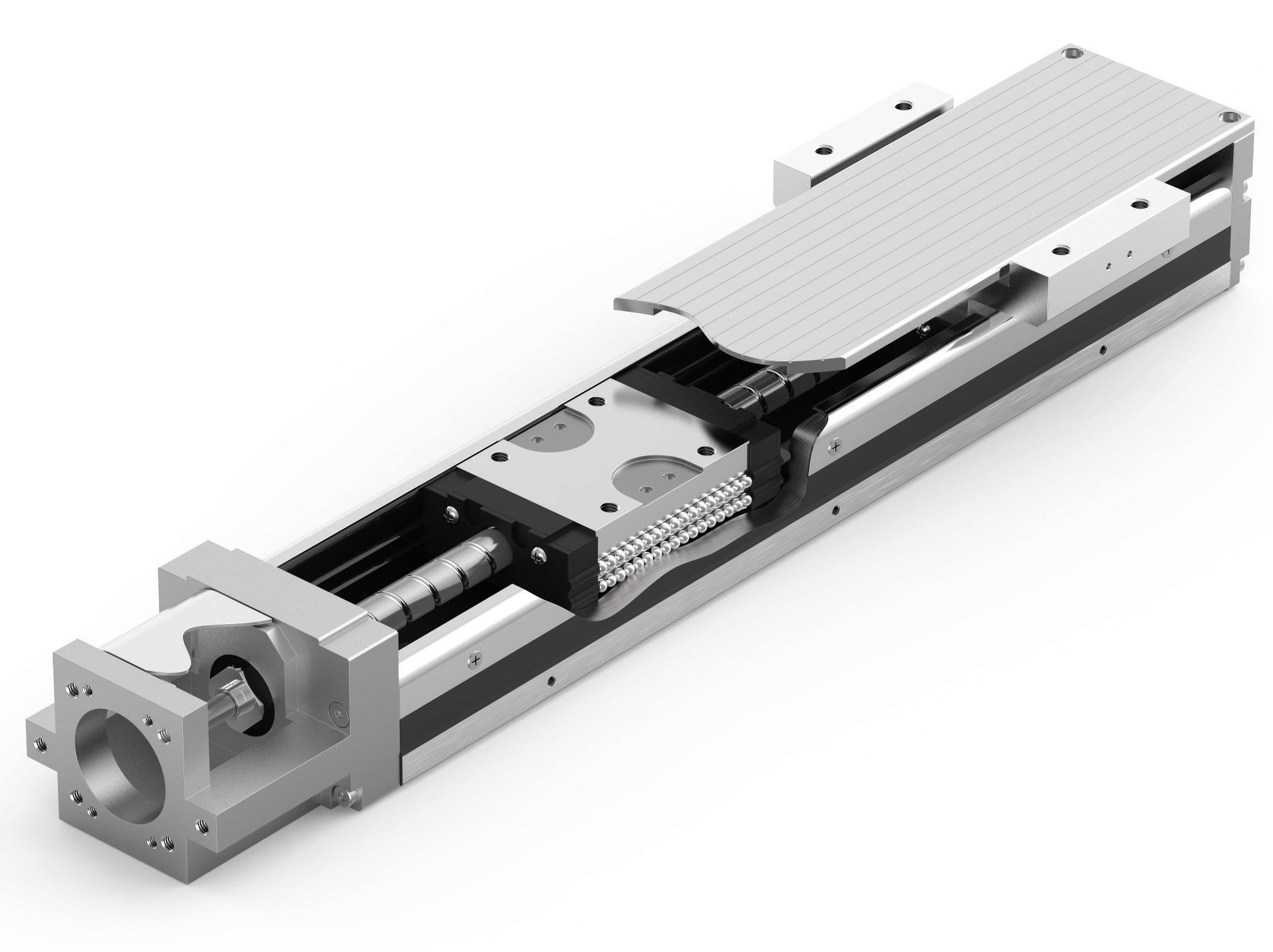

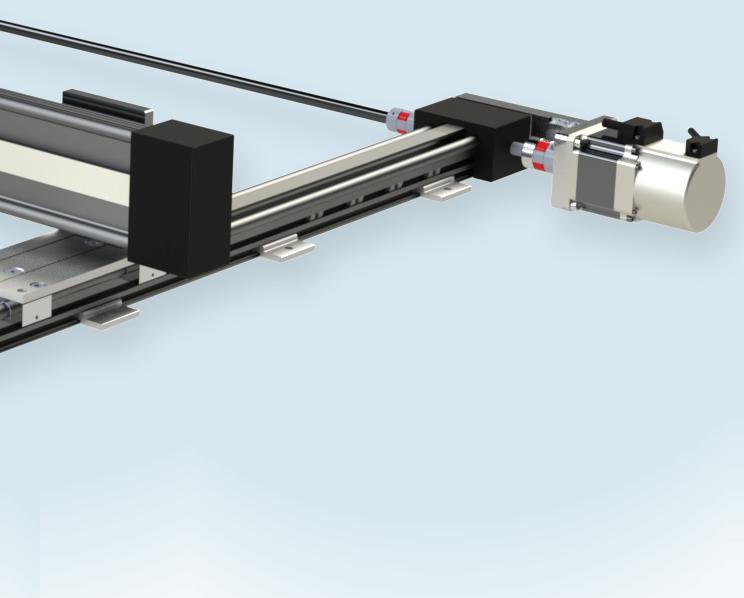

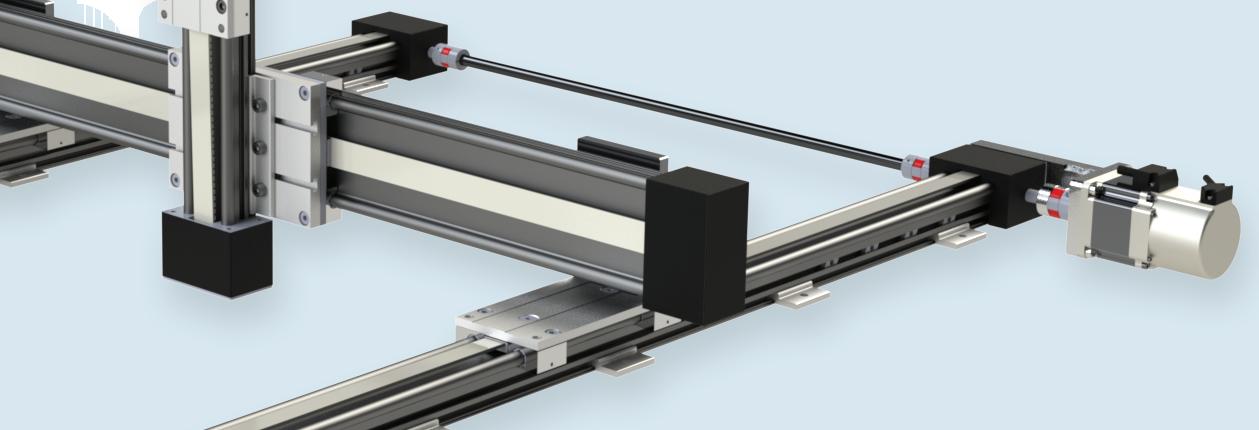

Linear Motion Actuators

Starting at $355.00 (SAW1040-05-B)

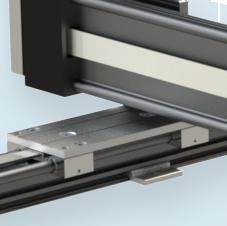

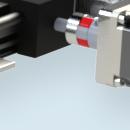

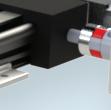

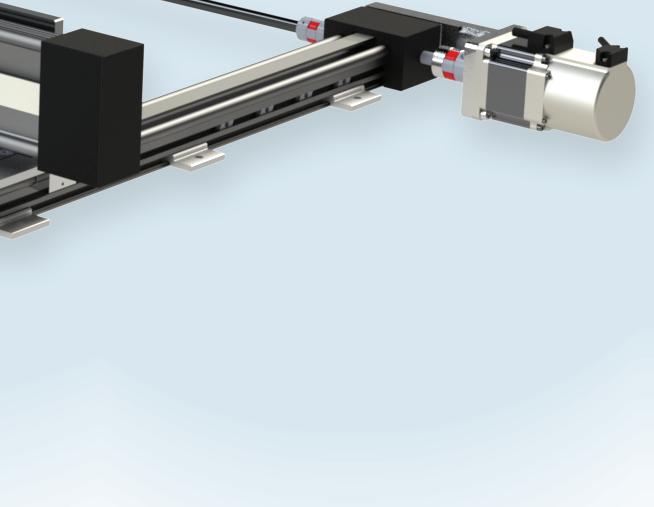

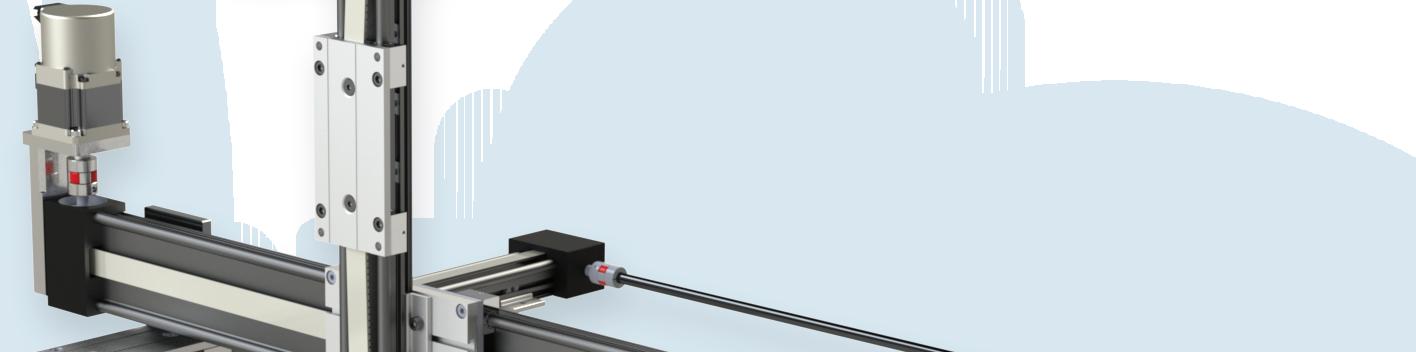

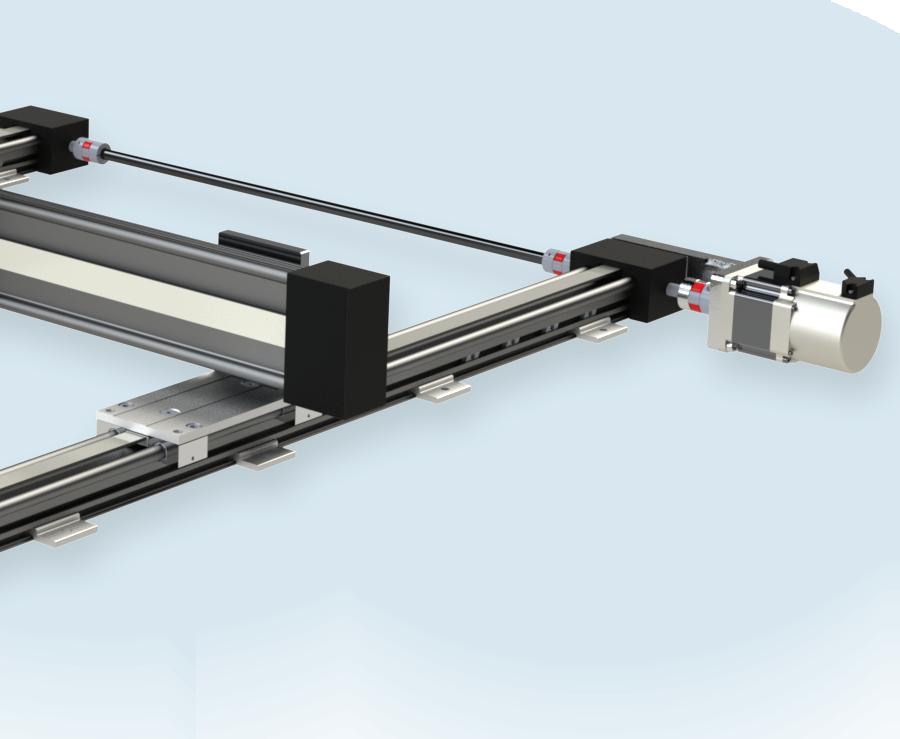

igus XYZ gantries offer an economical solution for creating a motion system with up to 3 axes of motion. These systems are available with belt driven or lead screw driven slides. They are easy to assemble, are stackable, and can be used as a single axis, double axis, dual drive axis, or as a complete 3-axis XYZ system.

Features:

• Maintenance and lubrication free

• 14 belt driven actuators from 200mm travel length to 1000mm travel length

• 13 lead screw driven actuators from 100mm travel length to 750mm travel length

• Rails made from durable 6061-T6 aluminum with hard anodized finish

• Motor mounts for SureServo and SureStep motors

• T-slots in rails allow switches and sensors to be easily installed

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Gantry Components for Less Rugged industrial actuators & slides for demanding 24/7 applications Research, price, buy at: www.automationdirect.com/linear-motion Also Available Precision Gearboxes (for Stepper & Servo) Stepper Systems SureServo2 Servo Systems

More on China’s strange future

In June, I wrote about the insane-sounding predictions about China’s future and the repercussions they would have for the country’s manufacturing base. If you’ll recall, geopolitical analyst Peter Ziehan said the Chinese population is currently the fastest aging society in human history — and that, combined with a poor Covid-19 response, means the country will dip to a mere 50% of its current population level by 2050.

At the NFPA’s recent International Economic Outlook Conference, we heard more dire predictions for the country om Connor Lokar of IFR. Lokar explained that China is struggling, transitioning to a different reality of higher wages. Plus, similar to Ziehan’s comments, he said that China is now butting up to the same type of demographic challenges that Japan faced 12 years ago. The population is getting older — and the labor force pressures are going up. Plus, it’s unclear how China’s COVID containment policies are working … but they don’t seem to be doing all that well.

In 2010, Japan’s population maxed out — essentially hitting a brick wall — and has been decreasing ever since. That is what Lokar thinks is happening to China right now. Demographers had been estimating that the country would hit that population wall sometime between 2030 and 2032, but some now believe China may have hit it already.

Looking at tables of every country’s GDP in the 1990s, Japan had an apparent position of strength and seemed to be hurtling closer to the U.S.’s top spot. But the island nation has since plummeted to a distant third place in GDP and looks to keep falling. Lokar sees China’s future in a similar light, poised to drop dramatically in the coming decade or two.

Conversely, India is where China was 20 years ago, and the demographic trends for it are excellent. Expect that country to be a bigger and bigger player in global affairs as well as the manufacturing world. Lokar expects them to pass the U.K. and Germany in total GDP in the coming years.

A few other interesting nuggets that Lokar shared about current global economics include:

• On the positive but modest U.S. industrial growth … “You just got used to going 120 mph down the interstate over the last 12-18 months, and now we’re slowing down to 65 mph.”

• Russia is overrated as a world power except for the fact that it has nuclear weapons; the economies of California or Texas are bigger.

• There is no short-term fix for Western Europe’s energy crisis. They spent years making this bed, and it’ll take years for them to get out of it. DW

J. Heney - VP, Editorial Director pheney@wtwhmedia.com

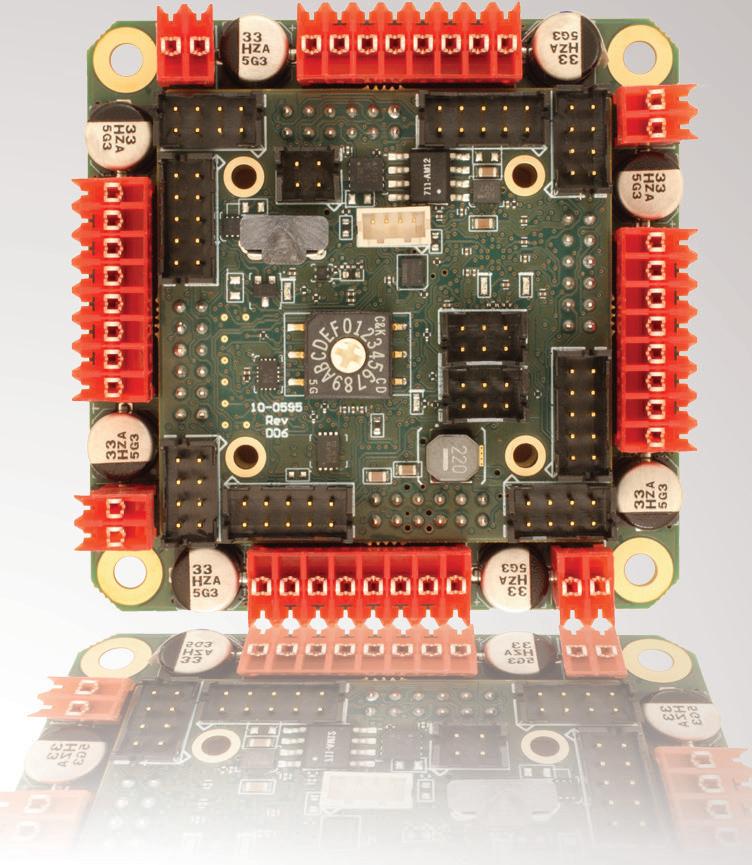

Insights 4 November 2022 www.designworldonline.com DESIGN WORLD - brushed or bldc motors - 5 amps per axis - 16 analog inputs - 16 on/off drivers - home and limit in - live tech support - made in the USA WWW.ALLMOTION.COM (510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action! 2.25” 4 AXIS SERVO from NEW!

On Twitter @wtwh_paulheney

Paul

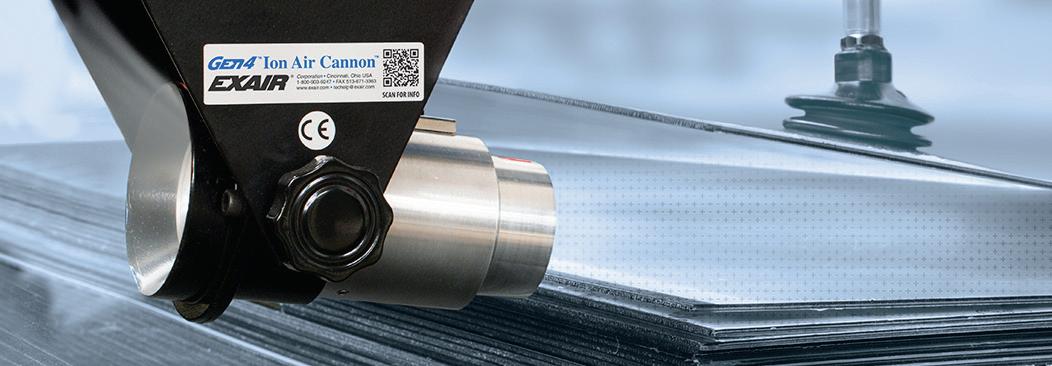

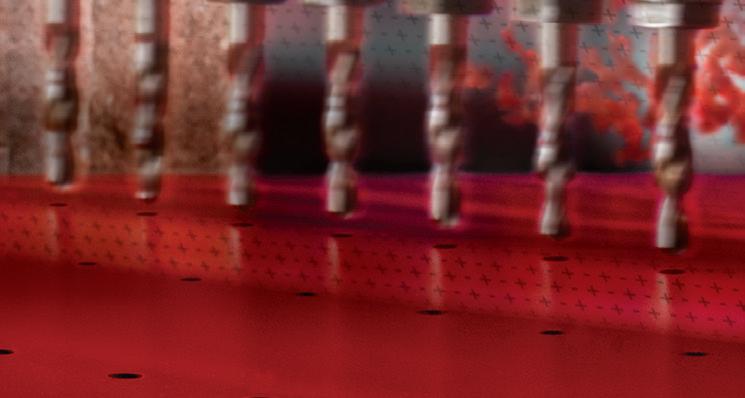

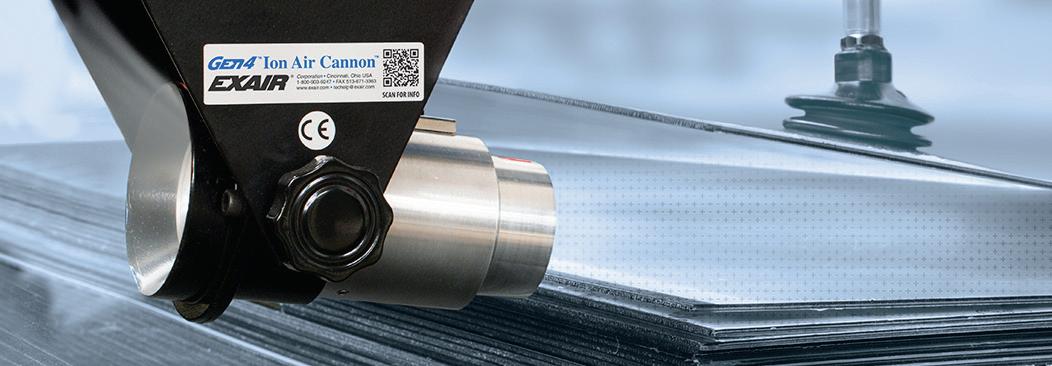

Ion Air Gun™ Eliminates static and dust from parts prior to assembly, packaging, painting or finishing. Ionizing Bars Eliminates static cling, dust attraction and jamming on paper, plastics and film. Super Ion Air Wipe™ The uniform 360° ionized airstream neutralizes and cleans continuously moving surfaces. Super Ion Air Knife™ Produces a laminar sheet of airflow that floods an area or surface with static eliminating ions. Ion Air Cannon™ Ideal for hard to reach spaces or confined areas that require a concentrated ionized flow. EXAIR manufactures a complete line of static eliminators to remedy common static problems. Many use our engineered airflow products to minimize air use and noise while delivering maximum results by moving more static eliminating ions to the product surface. • Materials tear, jam or curl • Webs and films cling to themselves • Electronic sensors fail, making false readings • Hazardous sparks or shocks occur • Product clings to itself, rollers and machine beds • Dust attraction ruins surface finishes Prevent Shocks, Jamming, Tearing and Static Cling! As humidity decreases, static electricity problems will increase. Ion Air Jet™ Delivers a concentrated blast of ionized air prior to shrink wrapping, packaging and printing. LEARN MORE ABOUT NEW STATIC ELIMINATORS NOW! 11510 Goldcoast Drive • Cincinnati, OH 45249-1621 • Phone (513) 671-3322 FAX (513) 671-3363 • E-mail: techelp@exair.com • www.exair.com Manufacturing Intelligent Compressed Air® Products Since 1983 @EXAIR Improved Performance and Greater Durability! Static Eliminators Remove Static Electricity and Dust! https://exair.co/58_470a Intellistat ® Ion Air Gun Patented handheld static elimination for sterile environments.https://exair.co/bose58adDownload our Basics of Static Electricity White Paper!

Teschler on Topic

How to crash a laptop hard drive

Back in the 1980s, I wrote an article about hard drives as the PC revolution brought them into the hostile environment of factories. They weren’t faring well. Most hard drives of the time were designed to sit in pristine main ame computer rooms. Putting them into industrial settings typically caused havoc. Not all disk drives had head carriage locks, and the locks on some units could only be actuated manually.

One drive maker I talked to described an elaborate configuration of elastomer spacers and rubber grommets designed to give the disk components a natural resonant equency well below the range where most severe vibration ampli udes arise.

Shortly a er the article published I got a letter om a mechanical engineering professor who had read it. He informed me that much of what the drive maker had said about vibration mitigation was nonsense, and he provided a few equations to prove it.

This episode exposed an unappreciated aspect of the electronics industry back then: In companies dominated by electronics engineers, the mechanical engineering on products o en wasn’t first rate.

Of course, the electronics industry has changed since then. And you would think that by now, resonance

problems now would be simulated and resolved long before hard drive designs got to the prototype stage. So I was surprised to find recently that resonant equncies can still be a problem on disk drives, though in what you might say is an off-beat way.

The issue was that playing the music video for Janet Jackson’s “Rhythm Nation” would not only crash certain laptop models, but also crash laptops sitting nearby that weren’t playing the video. It turns out the song contains one of the natural resonant equences for the 5,400 rpm laptop drive. The drive manufacturer eventually solved the problem by adding a custom filter in the audio pipeline that detected and removed the offending equencies during audio playback.

Still, the scenario seems weird: If a equency in a song causes problems, wouldn’t the same equency be present in a lot of other songs and do likewise long before now? This conundrum bugged NYC-based bass player and composer Adam Neely enough to explore it in a YouTube video.

Neely’s short answer to the riddle is that “Rhythm Nation” has a bass line that contains the equency that causes the problem. In music theory, a bass line is the foundation upon which all other melodies and chords are built. It is also the song’s lowest-

equency melody and is usually played on a bass instrument like a bass guitar.

Neely thinks the 2.5-mm laptop hard drives in question exhibit a strong resonant peak at 87.5 Hz. Analyzing “Rhythm Nation” for resonant peaks reveals one at 84.2 Hz. What’s interesting is that “Rhythm Nation” is written in the note of E, 82.4 Hz. Neely also notes that “Rhythm Nation” isn’t tuned as you might expect. Normally, standard tuning is A –440 Hz, meaning the A above middle C on a keyboard will vibrate at 440 Hz. Instead, Rhythm Nation is tuned to roughly A—450 Hz.

The different equency comes out of an effect called varispeed— basically a slight speeding up of the recording to make the music sound more exciting. This process also boosts the pitch by a small amount. In the case of “Rhythm Nation” the increase in pitch om varipeeding made the low E match the resonant equency of the drives.

You might wonder if other songs might have similar resonant peaks. Neely says the closest he’s found is Metallica’s “For Whom the Bell Tolls” with a peak at 84 Hz.

So you may have the creators of “Rhythm Nation” to thank for getting manufacturers to pay closer attention to resonances in the disk drives they design. DW

• Executive Editor lteschler@wtwhmedia.com On Twitter @ DW_LeeTeschler

6 November 2022 www.designworldonline.com DESIGN WORLD

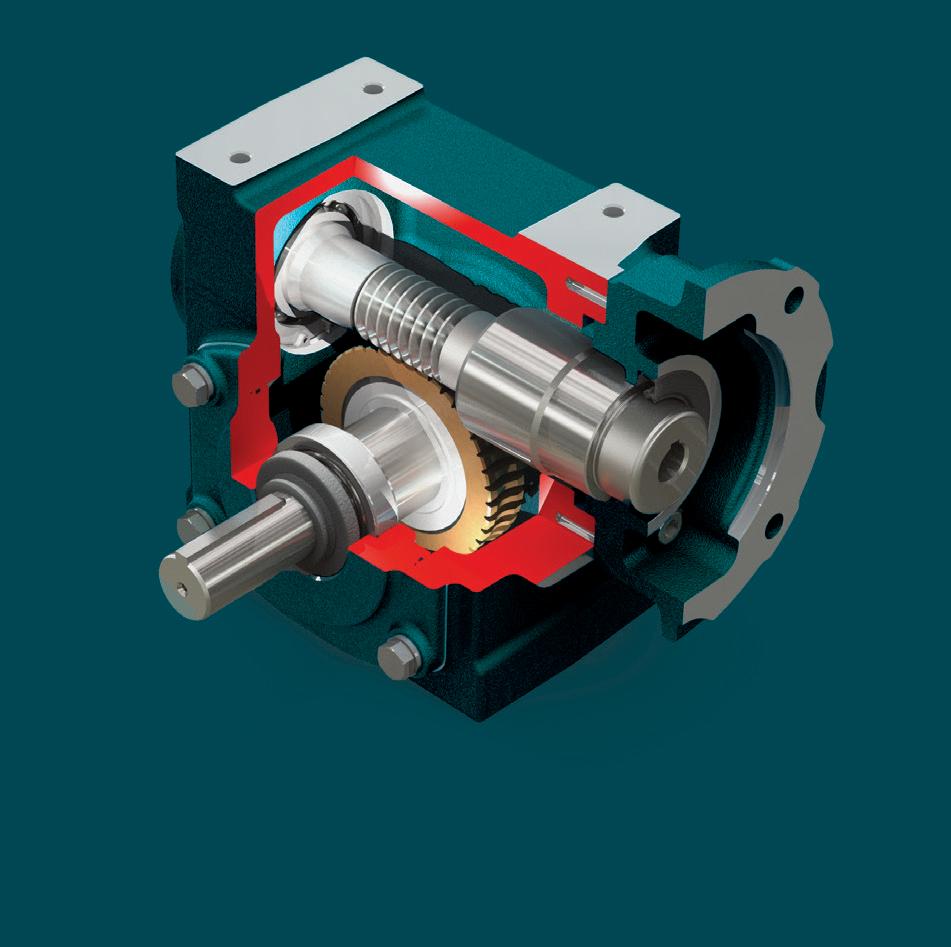

dodgeindustrial.com

watch

outperforms the competition.

Scan to

how Tigear-2

after 500 Hours of Overload Testing

of Tigear-2

COMPETITION

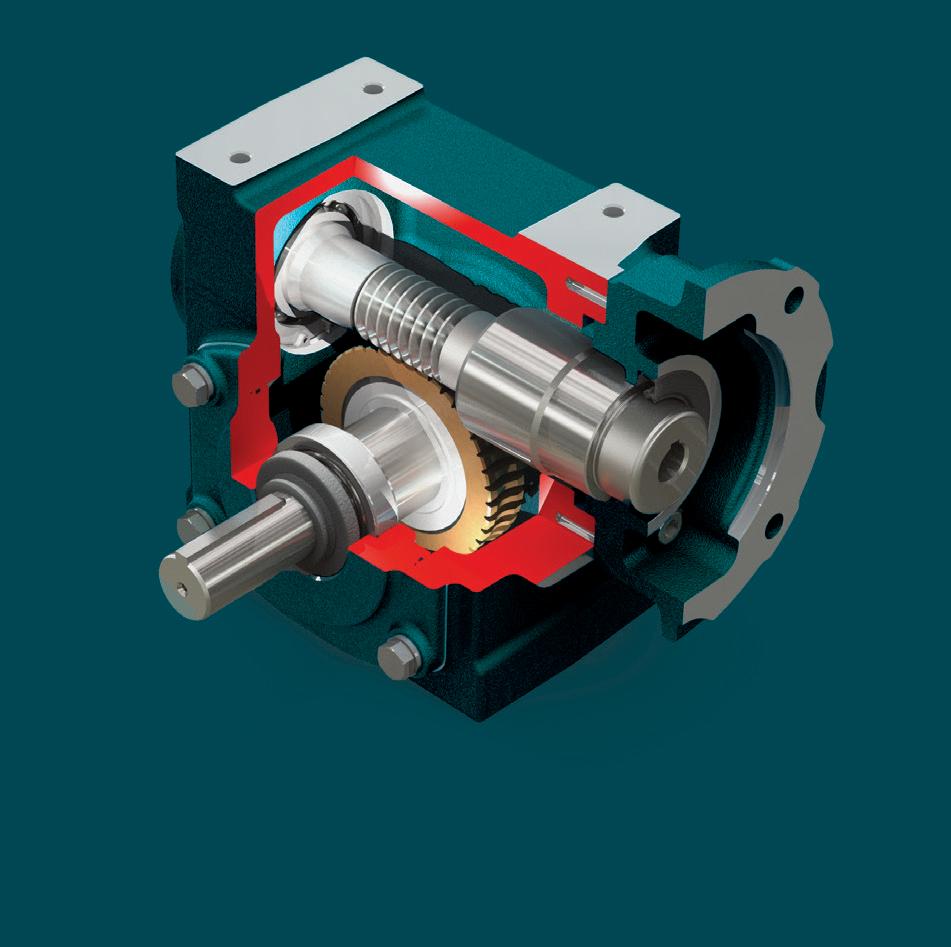

clear when comparing wear after the same 500 hours of testing, there’s no competition to Tigear-2. Tigear-2 is the proven solution to ensure you get the longest life out of your gearbox regardless of your application requirements.

Still Going Strong

That’s the power

THE

It’s

bearings and worm shaft Wider and more rugged worm gear

lubrication management

challenges

TIGEAR-2 What makes Tigear-2 the toughest in the industry? Larger

Advanced

Rated to meet the harshest

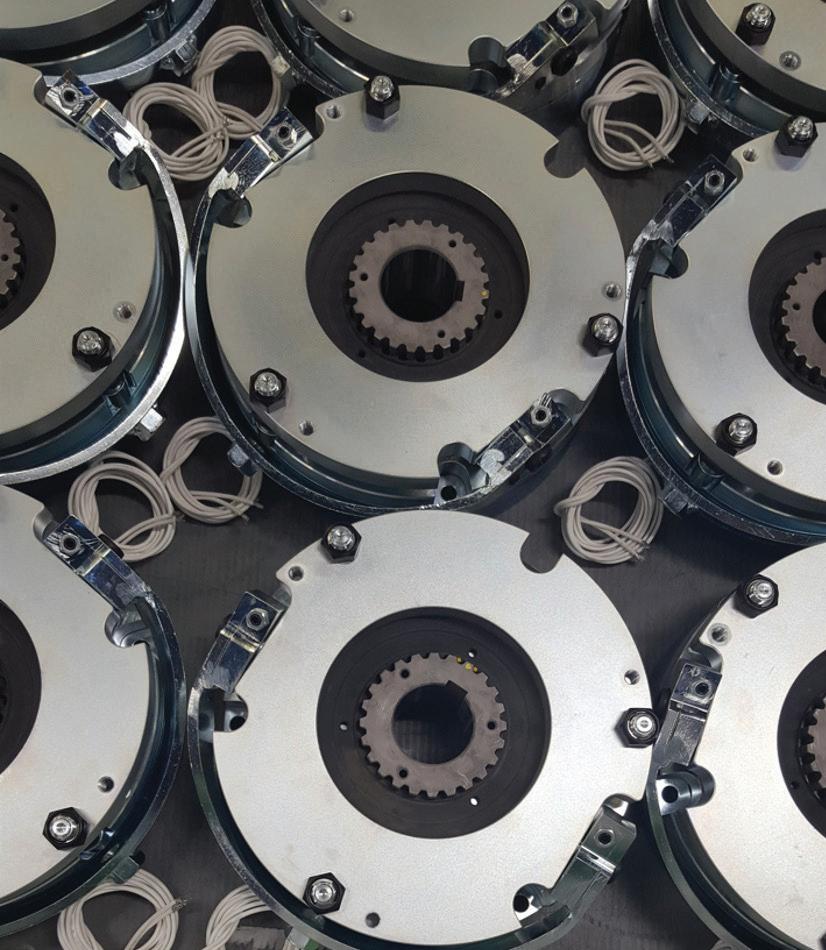

44 MOTION CONTROL

Top 12 design considerations for power-off brakes

The proliferation of new applications for power-o brakes demands fresh design approaches leveraging leading brake manufacturers’ accumulated design experience. Key to optimizing designs for life, cost, and performance is early collaboration with the brake manufacturer.

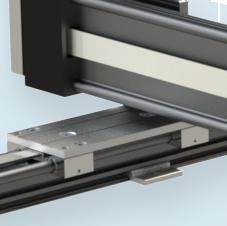

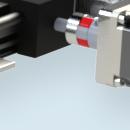

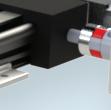

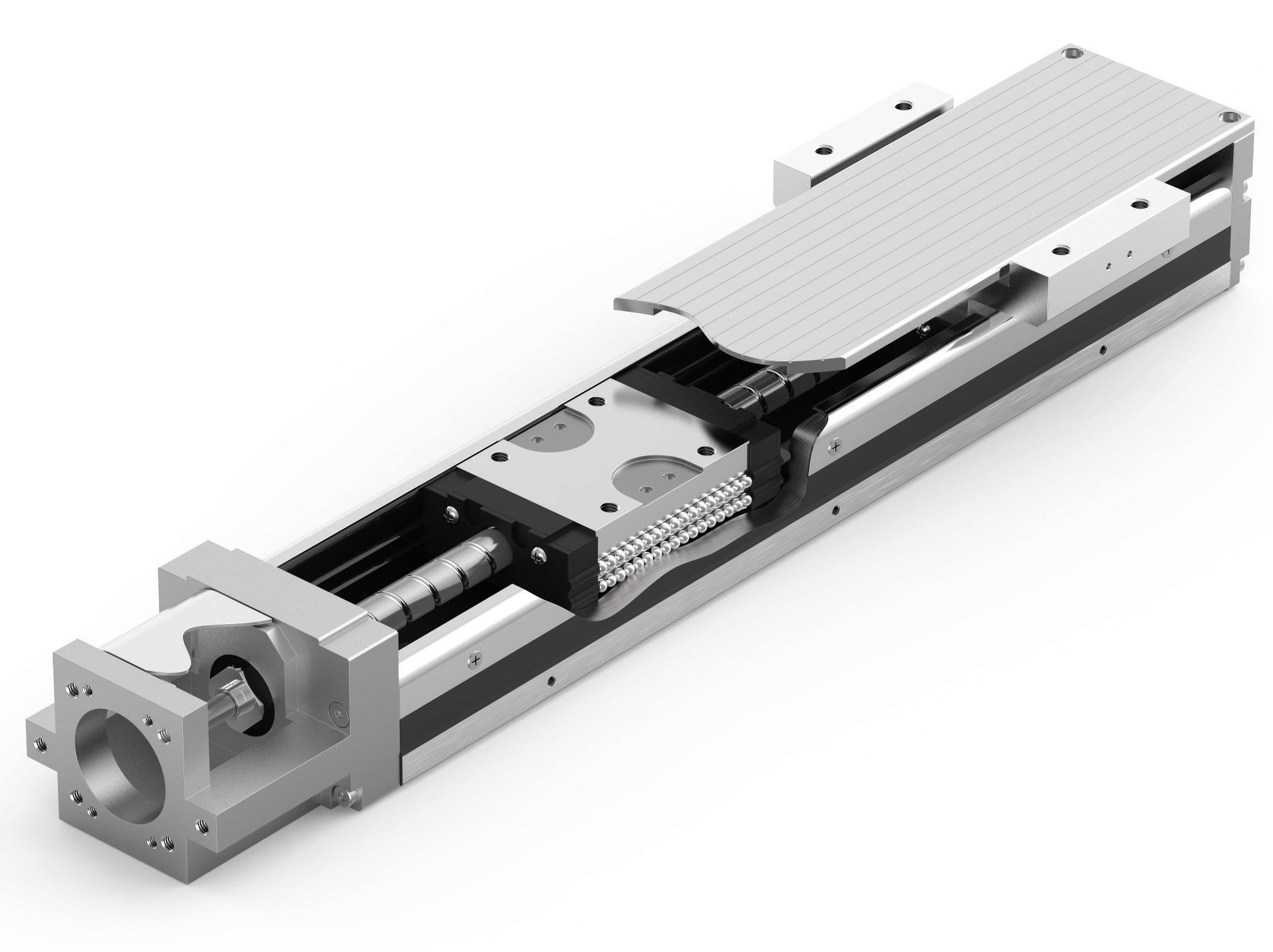

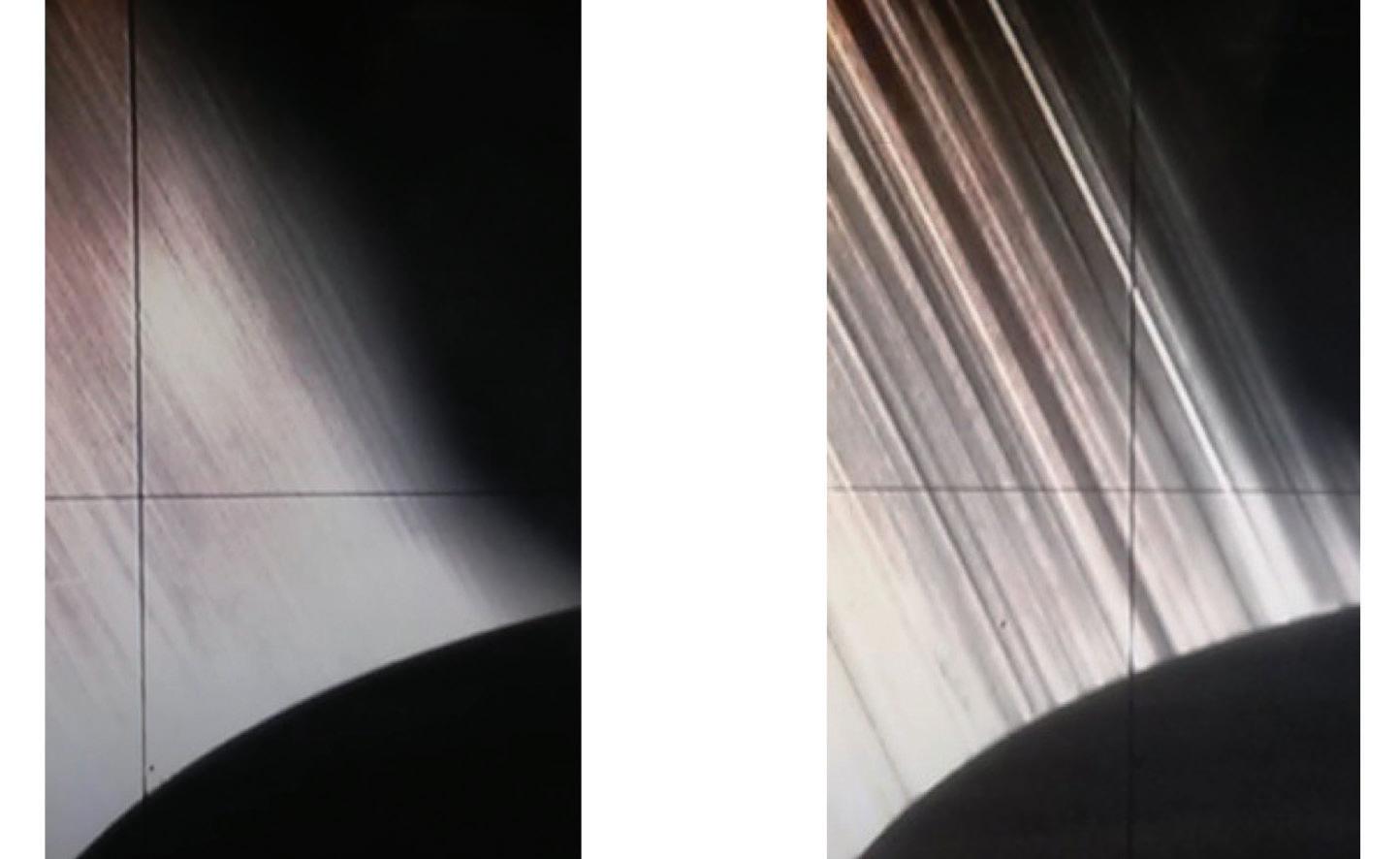

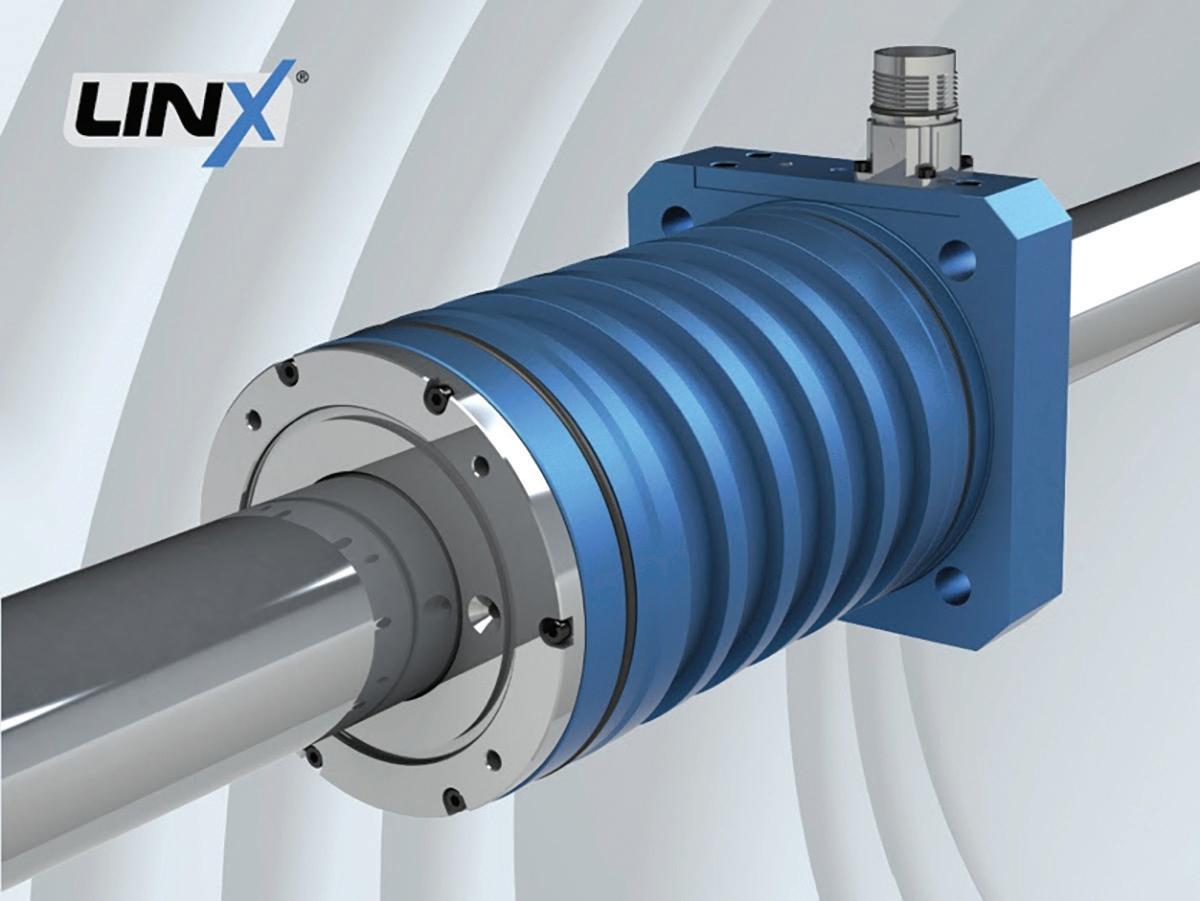

52 LINEAR MOTION

Linear motors find a home in CNC machines

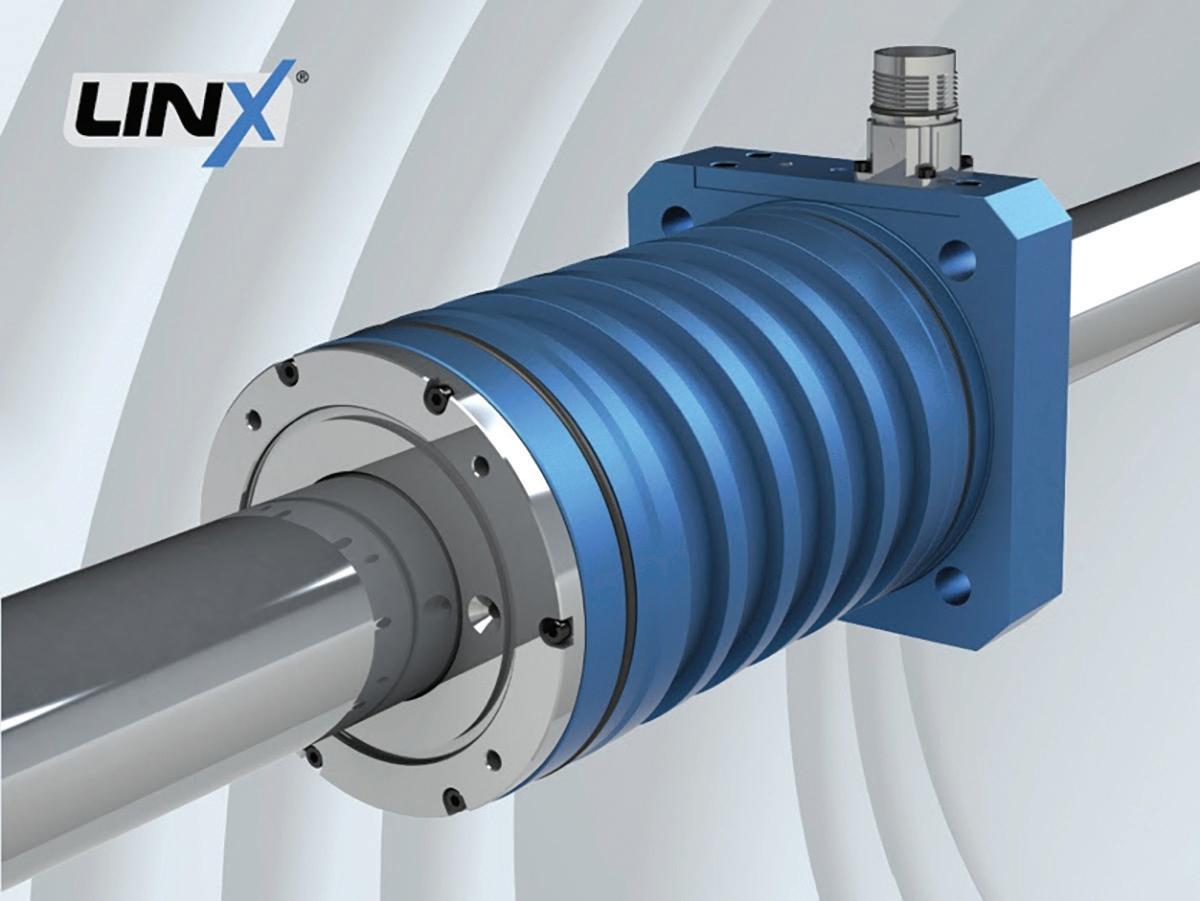

For one manufacturer of CNC grinding machines, new high-performance linear motors replaced ball-screws and improved machine performance.

56 ELECTRONICS

The top ten “green” programming languages

Software with the fastest execution time isn’t necessarily the greenest.

60 SENSORS

How does the PICMG IoT.1 specification for smart IoT sensors work?

The PCI Industrial Computer Manufacturer’s Group (PICMG) is developing a series of specifications to enable plug-and-play interoperability of smart sensors and e ectors.

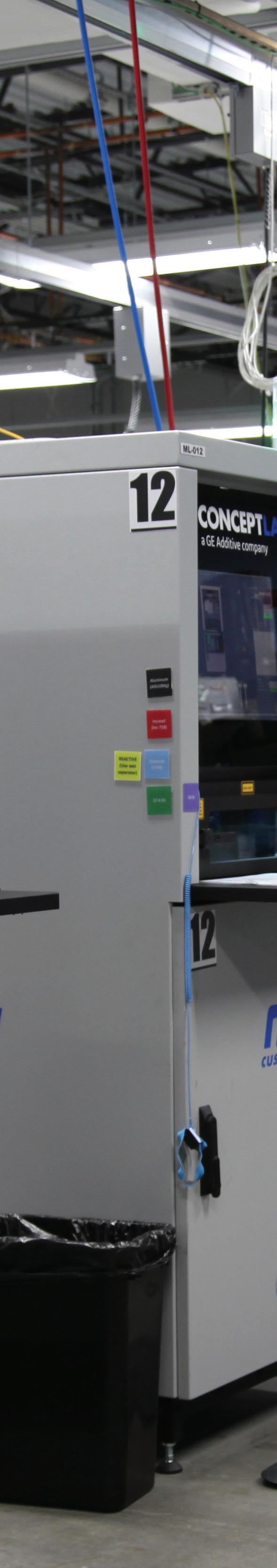

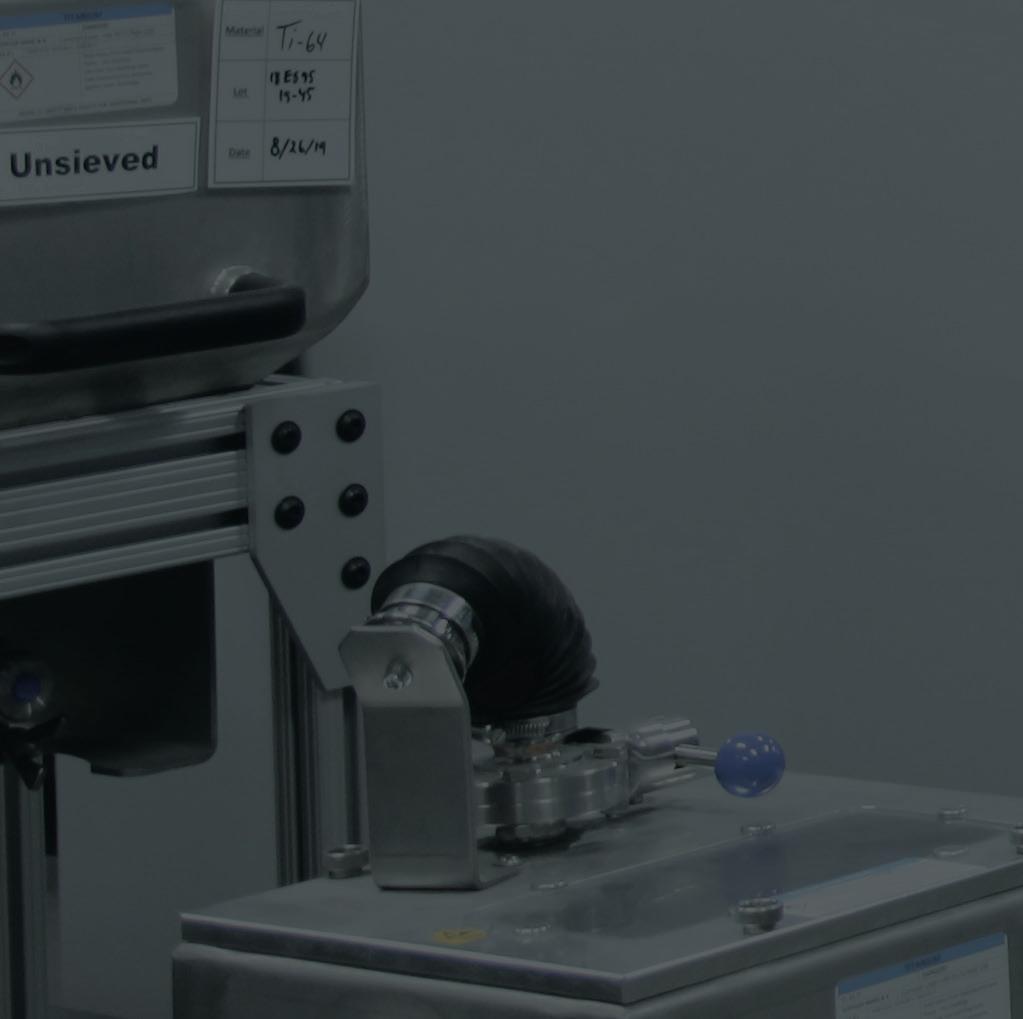

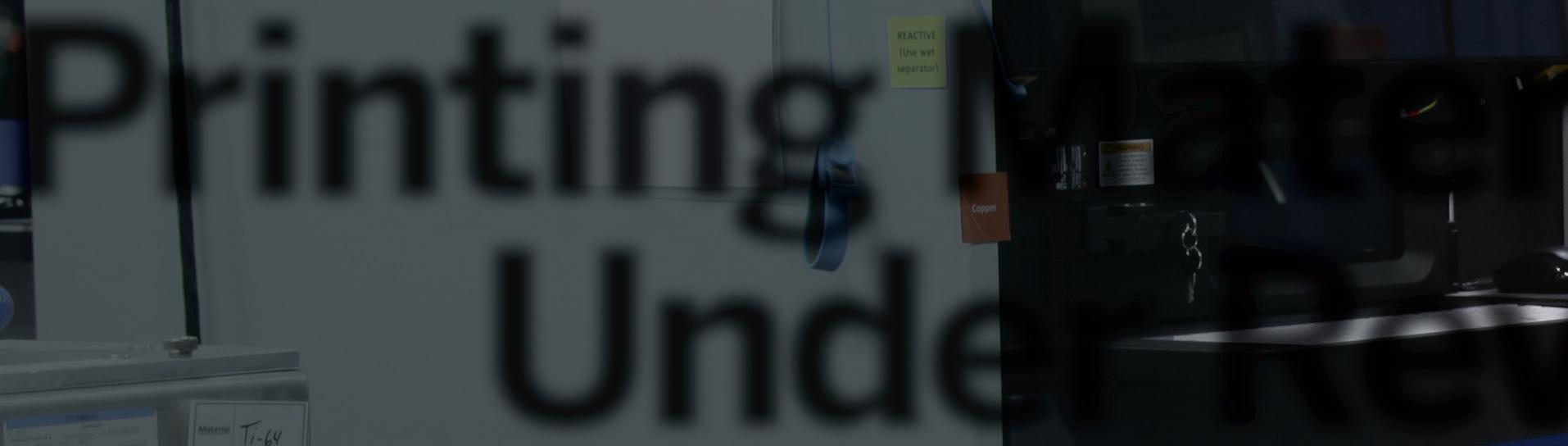

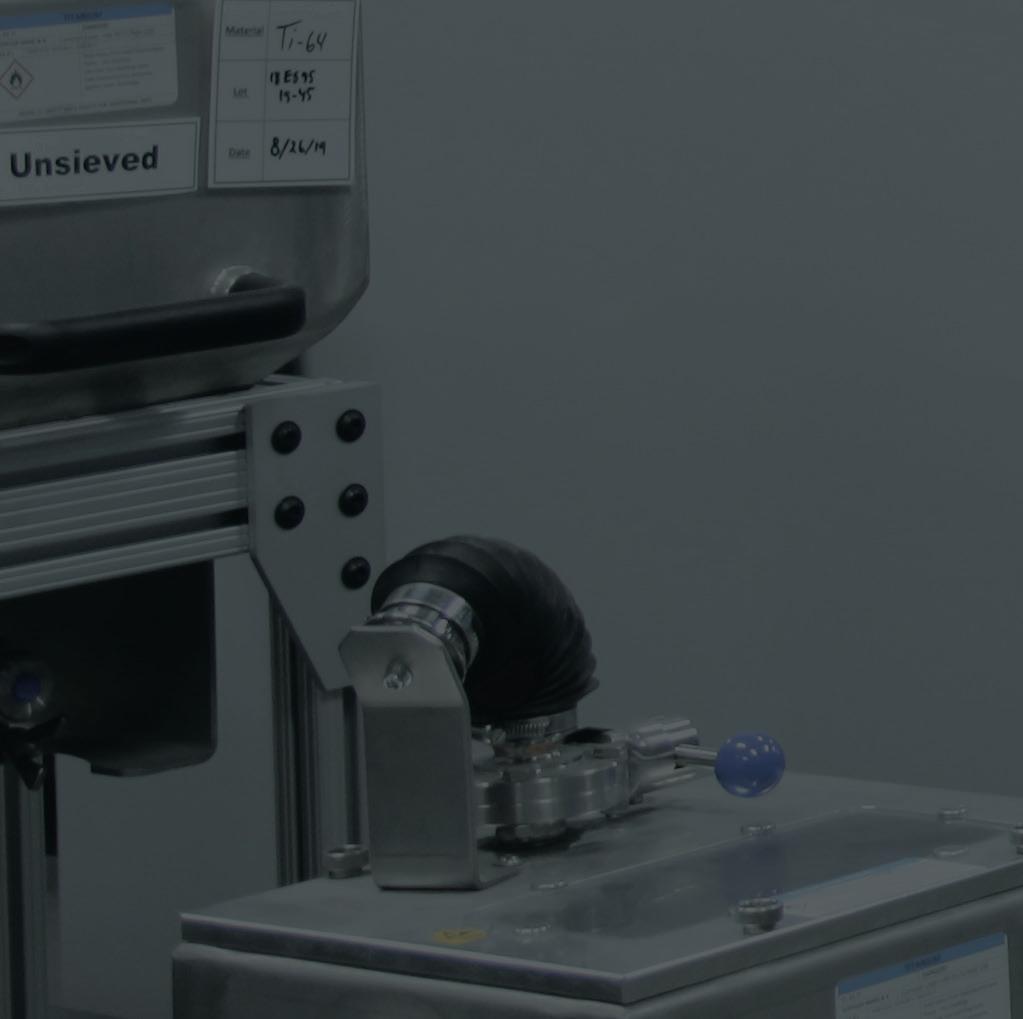

64 ADDITIVE MANUFACTURING

Metal 3D Printing materials under review

Achieving your design goals with metal 3D printing depends on finding the right material for your application. Here are tips on working with metal materials.

ON THE

Contents 11 • 2022 • vol 17 no 11 • designworldonline.com

60 asbpe.org SILVER REGIONAL AWARD 2022

asbpe.org GOLD REGIONAL AWARD 2022 asbpe.org BRONZE REGIONAL AWARD 2022 8 November 2022 www.designworldonline.com DESIGN WORLD asbpe rg BRONZE NATIONAL AWARD 2022 asbpe.org GOLD NATIONAL AWARD 2022

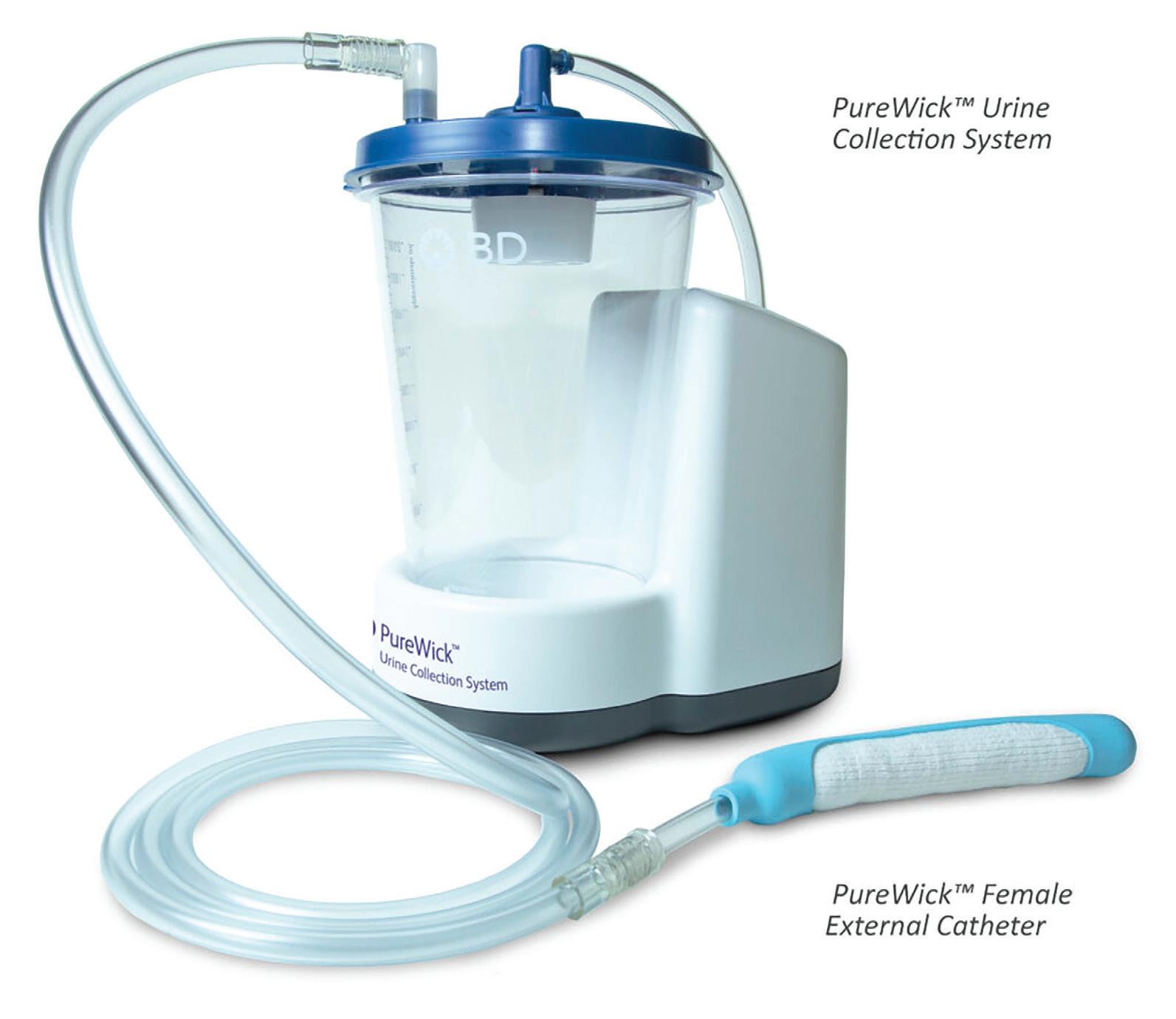

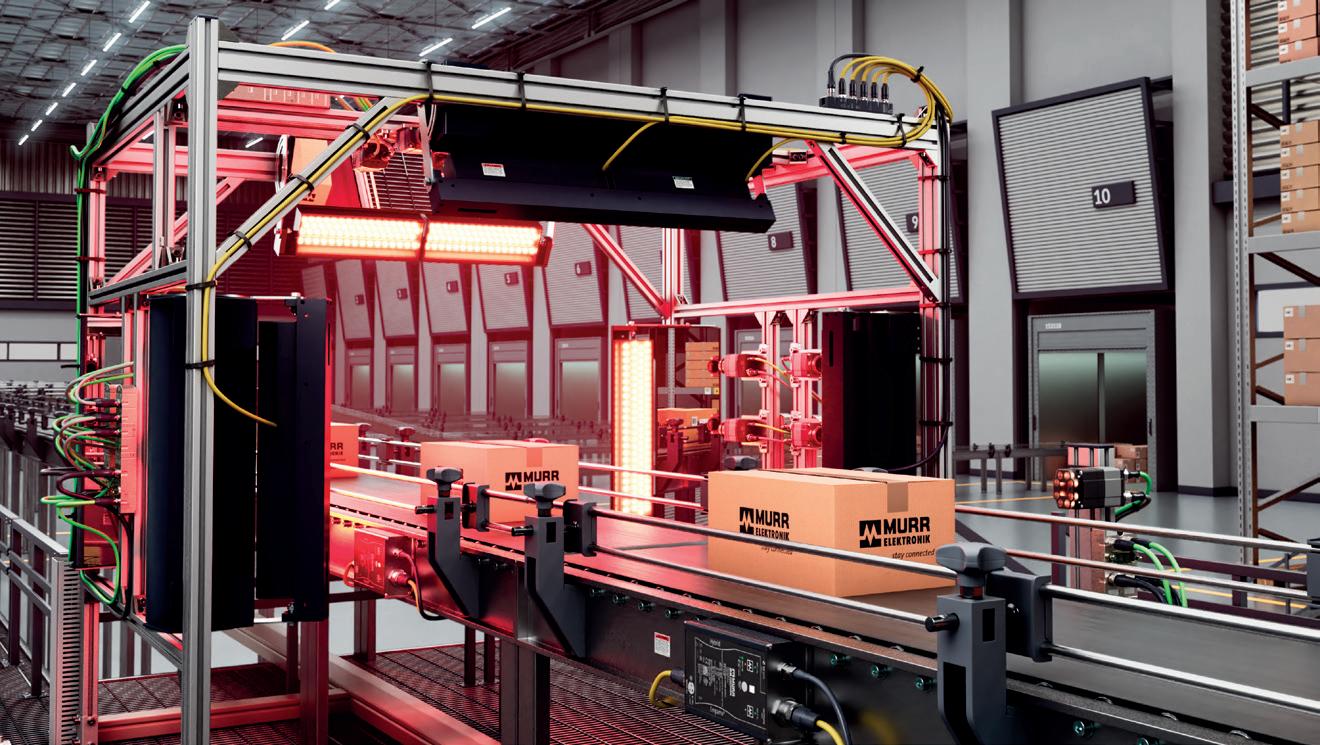

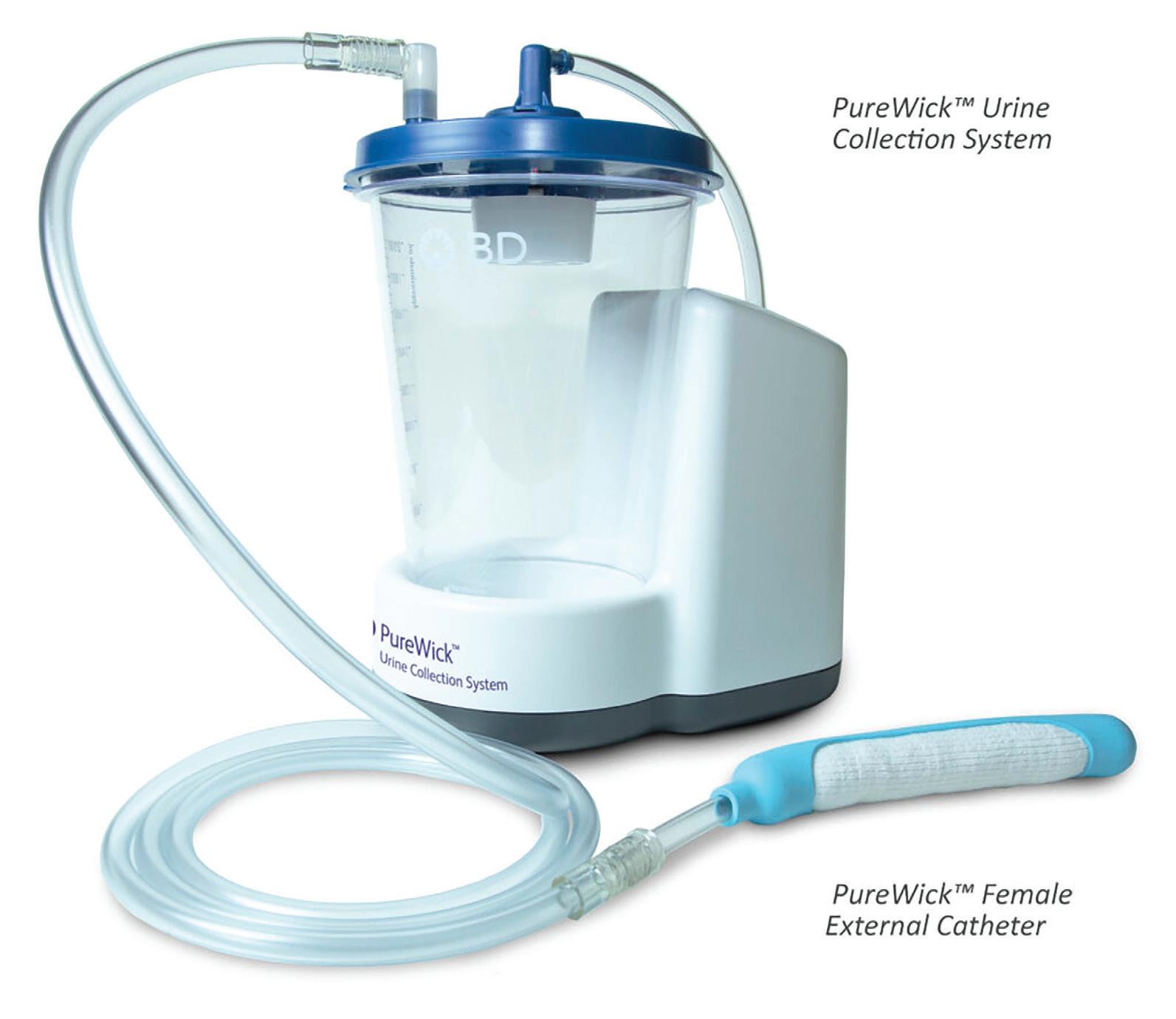

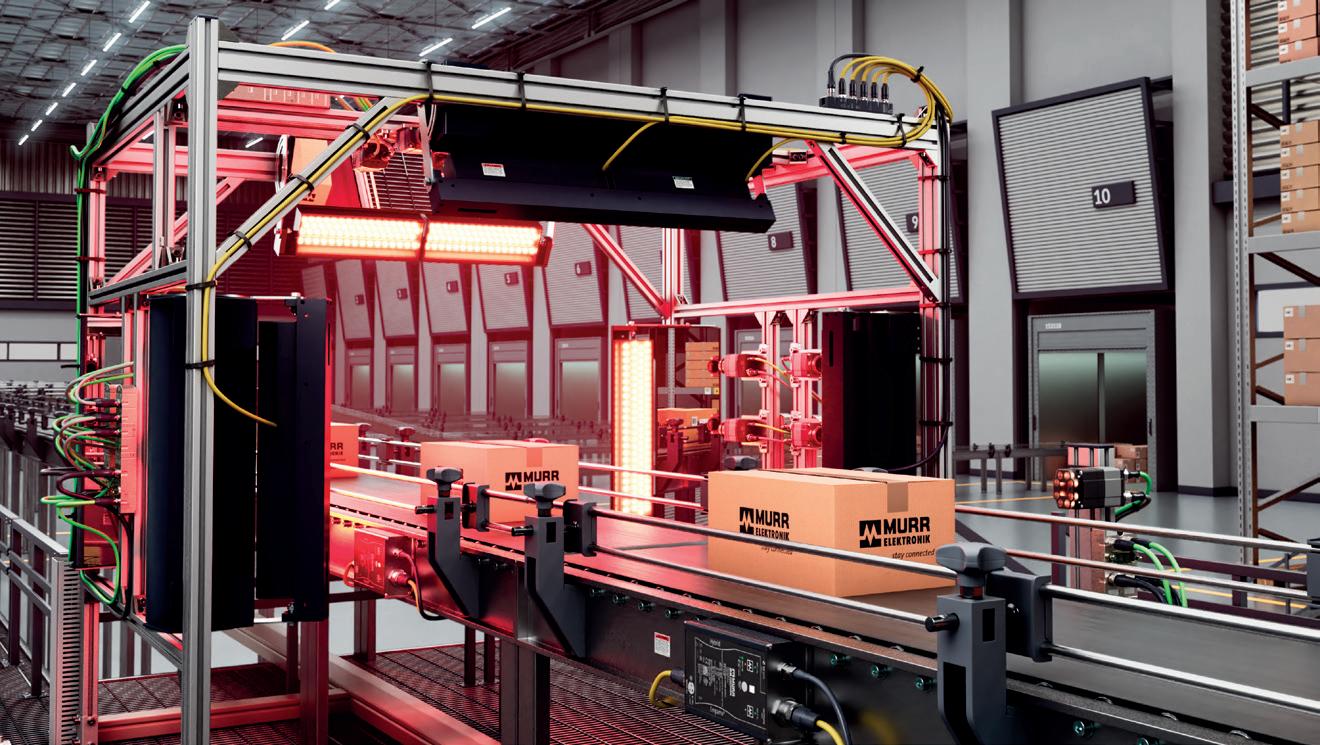

COVER Autonomous ground vehicles (AGVs) and other mobile designs rely on power-off brakes with top efficiency and response time. 71-93 www.designworldonline.com A Supplement to Design World - November 2022 ASRS WAREHOUSE AUTOMATION Covering the latest motion and control components, equipment and systems in ASRS design WAREHOUSE AUTOMATION COVER 11-22_FINAL2.indd 71 95-103 Medical www.designworldonline.com A Supplement to Design World A half-dozen catheters, stent systems and related medical tubing products are up for high honors at next month’s 2022 Prix Galien USA awards. Page 100 Six top tubing technology innovations

Adobe Stock Adobe Stock

departments 04 Insights 06 Teschler on Topic 12 Design For Industry 24 Design Notes 32 Internet of Things 36 CAE Solutions 104 Ad Index 11.22 • contents 10 November 2022 www.designworldonline.com DESIGN WORLD

BXR Brakes · Up to 480 in-lbs static · Up to

bore · 19 watts or less · Produced

years Our Innovative design features a very

profile, reducing weight and space. For more information: Call:

www.mikipulley-us.com

THIN ENOUGH?

a 1.125''

for over 10

thin

800.533.1731

Follow the whole team on twitter @DesignWorld

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor

Leland Teschler lteschler@wtwhmedia.com @dw_leeteschler

Executive Editor

Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor

Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor

Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com

Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

Senior Contributing Editor Leslie Langnau llangnau@wtwhmedia.com @dw_3dprinting

CREATIVE SERVICES

VP, Creative Services

Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director

Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer

Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer

Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development

Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer

Melissa Annand mannand@wtwhmedia.com

Software Engineer

David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator Jill Bresnahan jbresnahan@wtwhmedia.com @WTWH_Jill

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

EVENTS

Events Manager

Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager

Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist

Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Video Manager Bradley Voyten bvoyten@wtwhmedia.com @bv10wtwh

Videographer Garrett McCafferty gmccafferty@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

WTWH Media, LLC 1111 Superior Ave. 26th Floor Cleveland, OH 44114 Ph: 888.543.2447 2014 Winner2011 - 2020 2013 - 2017, 2021 2014 - 2016

TOP WORK PLACES 2022 DESIGN WORLD www.designworldonline.com November 2022 11

DESIGN WORLD

Medical Design& OUTSOURCING

Design for Industry

Aerospace

Metrology kit for inspection and deformation analysis in aerospace

High-accuracy optical measurement systems are essential for easy and reliable inspection of aircra components, ships, and wind turbines. With this Metrology Kit, users can obtain more precise datasets and confidently perform inspection in use cases where requirements on repeatability are high. This can be at almost any production step — even when the part itself is in motion. For example, UK, German, and Japanese defense organizations use the Metrology Kit for deformation analysis on the main and sub panel systems of large satellite antennas tilted at various angles. Available in two versions, Professional and Entry, the Metrology Kit offers an easy-to-use and versatile photogrammetry solution with metrologygrade precision and high-end accuracy for inspection and reverse engineering.

The Kit can operate as a standalone optical measurement solution, or as a referencing tool for 3D scanning over distance. The whole kit is portable and provides high-precision measurements in under 15 minutes.

The Kit is both DaaKS and VDI certified and provides point-based accuracy (RMS) up to 0.002 mm + 0.005 mm/m and length measurement accuracy up to 0.015 mm + 0.015 mm/m.

It includes a camera with resolution of up to 30.3 megapixels and a 28 mm wide-angle lens, measurement targets, adapters, scale bars, and a plugin, giving users the entire photogrammetry workflow right inside Artec Studio. The kit is also compatible with industry-leading inspection so ware solutions like Geomagic Control X, PolyWorks, and more.

In addition to aerospace applications, the kit suits automotive and off-shore markets. For quality control in automotive manufacturing processes, for example, the Kit analyzed the position of welding studs on every fourth chassis in a major car manufacturing production line in Germany, and the results were then used to program the welding robot. Additionally, as part of tests and research for autonomous driving, the kit helped determine the positions of sensors on a car body and correctly place them within the car’s coordinate system.

The Metrology Kit is also for analyzing the geometrical changes of storage tanks, vehicle components, or design prototypes. It can analyze the deformation characteristics of materials under different environmental conditions such as high temperatures and humidity where short measuring time is crucial.

12 November 2022 www.designworldonline.com DESIGN WORLD

An ISO-certified German offshore and maritime engineering company surveys and inspects flanges on offshore sites in the North Sea and Baltic Sea. The short measuring time, easy workflow, and dynamic referencing make the Metrology Kit a good solution for such high-accuracy applications in unstable conditions. The company measures the flatness and inclination of large flange faces, drill hole diameters, and inner and outer diameters. The full measurement process is carried out within 60 minutes.

The Metrology Kit produces a point cloud with high volumetric accuracy that can be used as a reference for 3D scanning results over distance, particularly when capturing large objects or areas with an Artec 3D scanner. Ensuring minimal error accumulation, the kit allows users of Artec Leo or Artec Eva to increase volumetric accuracy by up to 14X. DW

Artec 3D www.artec3d.com

DESIGN WORLD November 2022 13

Design for Industry

Aerospace

Optical links for harsh environments

High-speed embedded network backbones in harsh environments, such as aerospace, need robust connectors. The SOCAPEX’s MPO Field solution lets users transform a standard MPO patchcord into a robust connector that resists the harshest environments. The MPO patchcord is integrated into a metallic plug based on MIL-STD-38999 Series III, a shell size 13 Military connector, to protect it om shocks, dust, and fluids. There is no requirement for field termination.

MPO Field TV connector combines high speed and high density of wellknown MPO/MTP Fiber Optic connectors using MT ferules, with high resistance of MIL-DTL-38999 Series III Military shells for various harsh environment applications such as high speed embedded network backbones for battleships, armored vehicles or airplanes and trains, datacenters in harsh environments, trackside measuring, and inspection systems for trains, and high resolution realtime video.

The connector features include:

• High density and speed: High data rates and optical density are offered through the use standard Fiber Optic MT Ferrules

• High density and robustness: The 12 or 24 fiber channels are integrated into 28 mm diameter 38999 metal shells, with tri thread coupling mechanism. The solution is IP68 sealed when mated and shocks & vibration resistant

• Easy to implement: No tool or field cabling are required. The solution allows anyone to transform a standard MPO Patch cord or more complex assembly into a harsh environment connector easily. DW

Amphenol www.amphenol-socapex.com/en/

14 November 2022 www.designworldonline.com DESIGN WORLD

Improve the service life of offshore wind turbines with seals

The European Union aims to expand the capacity for wind power generated at sea to at least 60 GW by 2030. Sealing solutions for the foundation structures help ensure that new wind turbines reach a service life of at least 30 years or more despite the rough conditions at sea.

The highest wind velocity ever measured in the German North Sea was 119 mph (191 km/h). While wind turbines erected in the ocean are shut down even at considerably lower wind speeds, the structures still have to withstand the enormous force of a hurricane no matter what and throughout their entire service life.

The foundation that anchors the towers in the seabed plays an important role. In the shallow waters predominant in the North and Baltic Seas, the foundation is usually constructed using so-called “monopiles.” These are steel piles driven into the seabed until only the upper ends are above the water surface. Even for a 10-MW turbine, the tower can reach a height of 493(150 m) to the rotor hub and is usually not mounted directly on the piles but supported by a flange. This flange is attached with several dozen bolts that become inaccessible for any maintenance once the tower is installed. To prevent the screw connections om corroding in the harsh environment at sea, they have to be protected against the ingress of moisture. Seals, such as those om Freudenberg Sealing Technologies are already handling this crucial task in more than 800 offshore wind turbines.

The most important function is performed by a ring seal at the top of the pile. It encloses the interior part of the linking piece that supports the screw connection. In modern installations,

Off-shore

Off-shore Design for Industry

the flange seal — with the abbreviation MP-TP (monopile transition piece) — can reach a diameter of 8 to 10 m. In recent years, Freudenberg Sealing Technologies has also offered this seal in a double version. The main advantage of the double-row design is the resulting redundancy. “If minor damage occurs at one of the two seals during the transport or installation, the function is still ensured,” said Manuel Hille, Freudenberg expert. “In addition, this makes it possible to optimally combine different designs and materials with each other.” However, the specific design is almost exclusively customer-specific to make optimum use of the available assembly space.

In a conventional design, a gap remains between the lower end of the connecting piece and the pile. One or two ring seals interspersed with air chambers designed as elastic

breakwaters ensure no seawater can enter. On the other hand, if the gap is filled with cement, a ring seal can keep the cement in the desired position during the curing and later protect it against damage om saltwater. Maintenance platforms, which are o en positioned above the water surface inside the monopile, can additionally be protected against the ingress of gases with a specially designed seal. These kinds of gases may form due to biological seawater processes in the pile.

In recent years, there has been a sharp increase in the expected service life of components used for sea-based wind turbines. While 25 years were initially considered a good lifespan, this standard has now risen to up to 35 years. Such a long operating life can’t be ensured using bench tests. This is why Freudenberg uses an adapted Arrhenius algorithm

to extrapolate the results of six-week intensive stress tests. This quite familiar procedure, named a er the Swedish chemist and Nobel laureate Svante August Arrhenius, has been consistently refined by Freudenberg experts in recent years. They significantly improved the service life model by coupling chemical and physical effects with the structural mechanical behavior of the material. DW

Sealing Technologies fst.com

Freudenberg

Freudenberg

IT’S WHAT’S ON THE INSIDE THAT COUNTS ® ELECTRONICS CORP.

Packaging Design for Industry

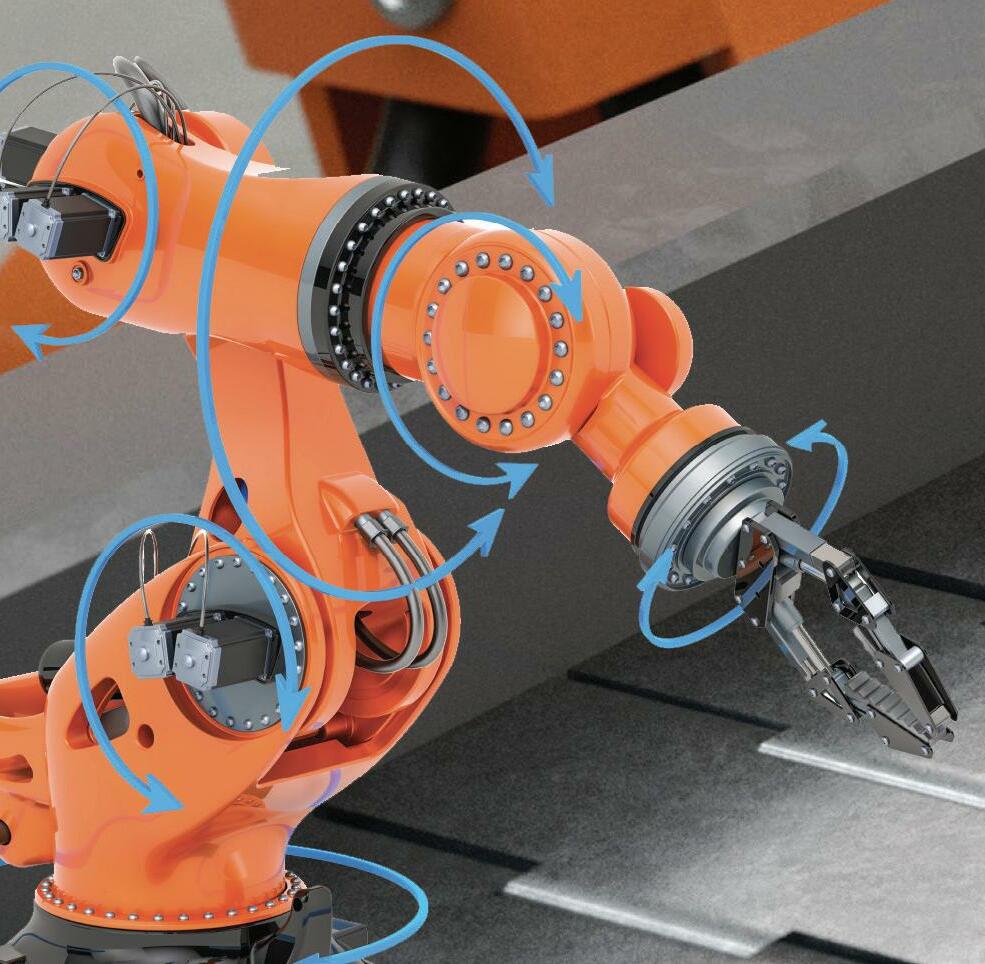

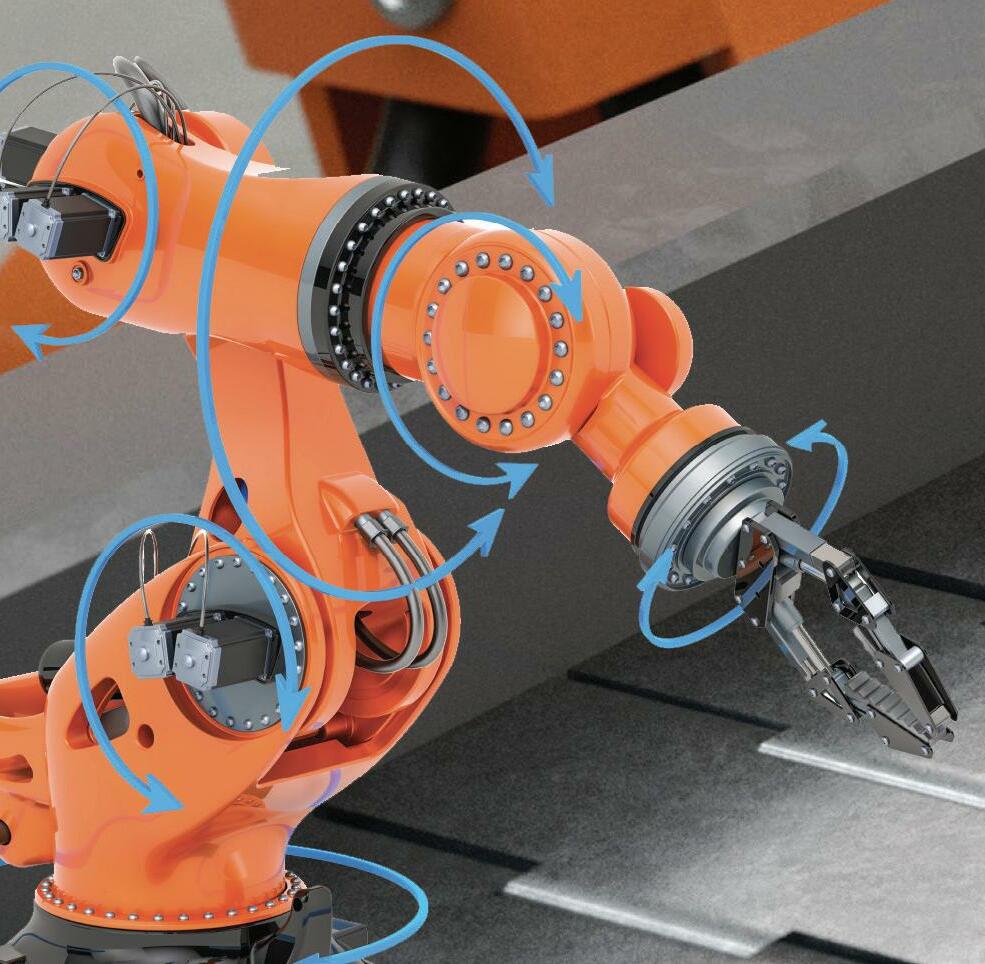

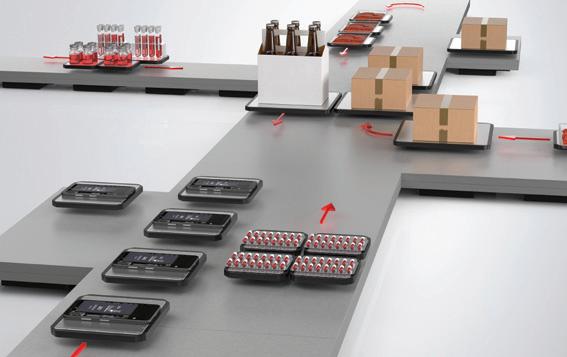

A range of fully hygienic robots for picking, packaging, and palletizing

For fully automated palletizing/depalletizing, the KR IONTEC medium payload robot can be mated with a robotic pick-and-place solution. The KR IONTEC is a highly flexible robot with a good work envelope. It can be integrated with 3D-vision to detect stationary items with rectangular surfaces and determine their position, orientation, and size for picking. Once the box locations are identified, the robot, which is suitable for an array of industrial applications including handling, packing, and palletizing, will complete the next pick action for fast, e cient stacking.

Designed to simulate a real production environment and automation solutions for each step — moving material om receiving and sorting to packing and distribution — this end-to-end automation cell includes the KR 3 DELTA Hygienic robot, KR 6 SCARA and KR 6 AGILUS robots and KUKA. VisionTech advanced vision so ware. The KR 3 DELTA hygienic robot provides outstanding performance and value for pick-and-place applications for the food, packaging, electronics, and pharmaceutical industries, while the KR 6 SCARA is strong, fast, highly-e cient and delivers maximum economy. KUKA will pair both robots with its KUKA.VisionTech. DW Kuka www.kuka.com

18 November 2022 www.designworldonline.com DESIGN WORLD

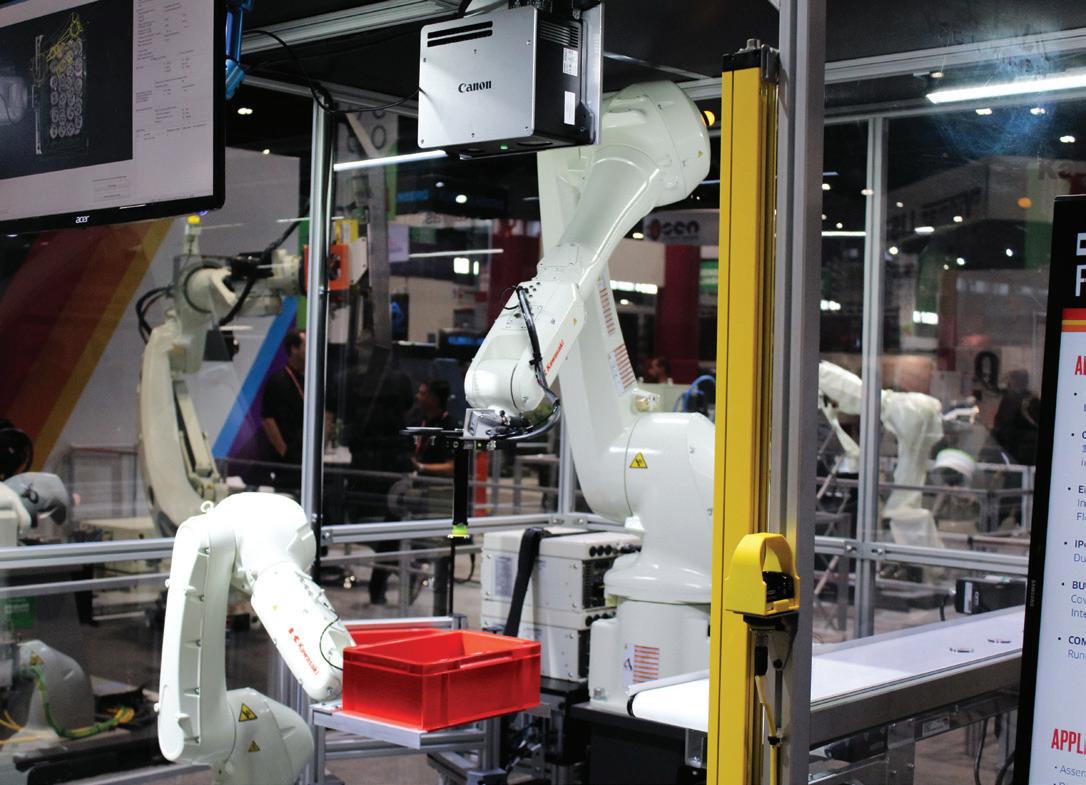

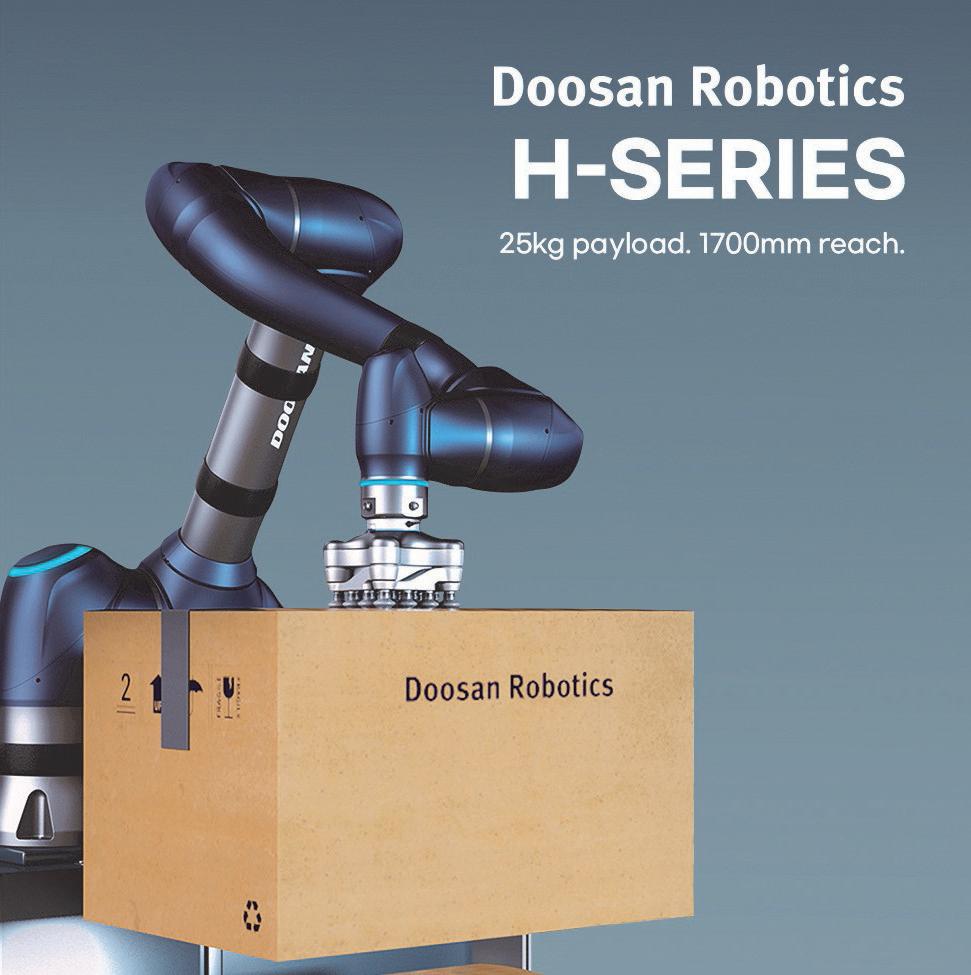

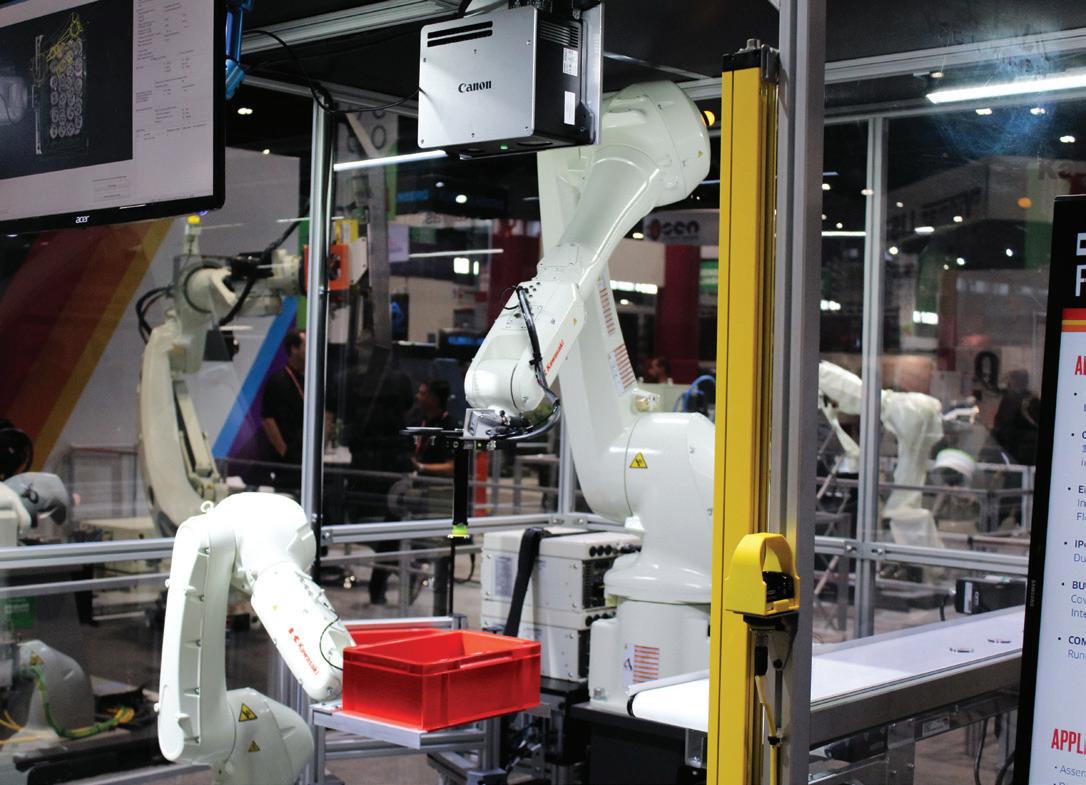

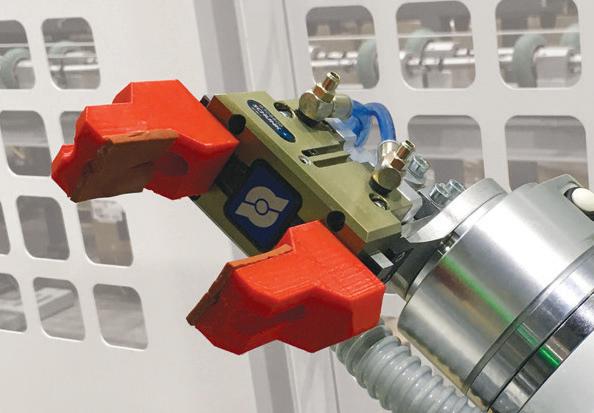

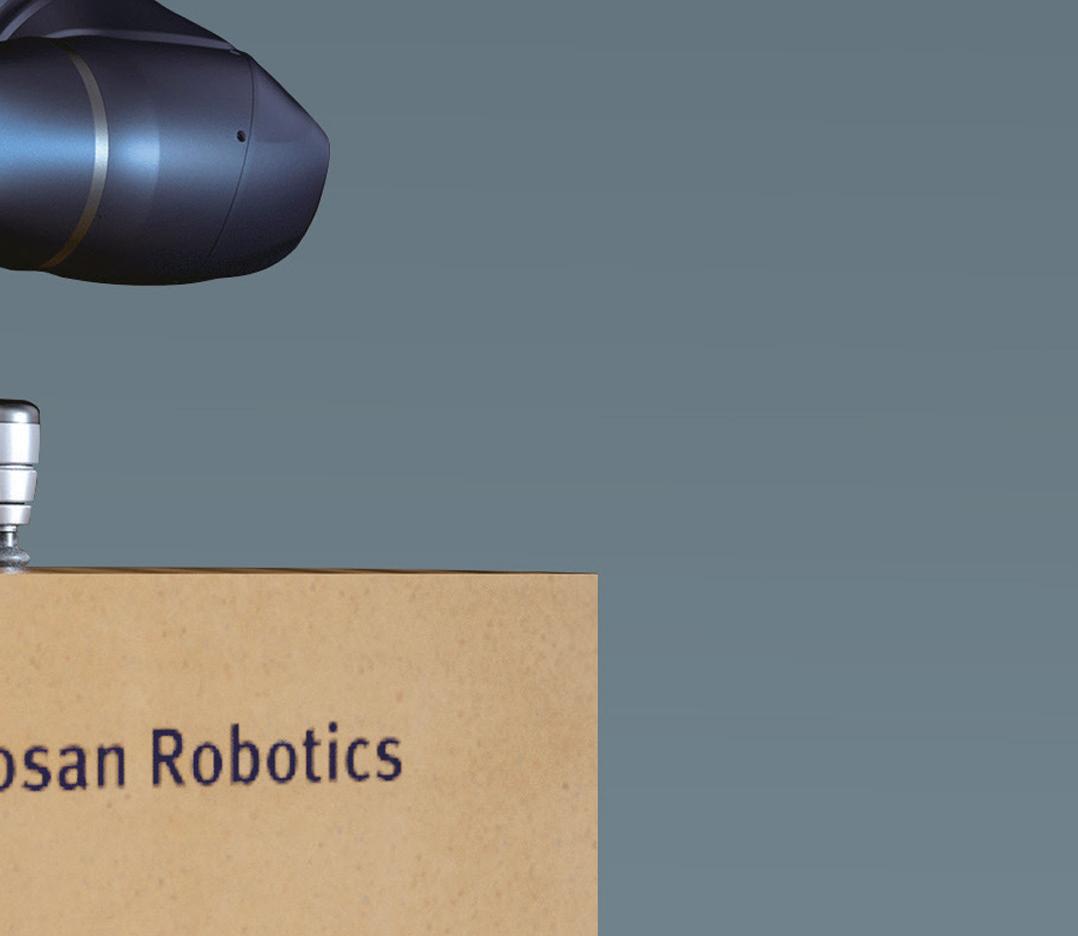

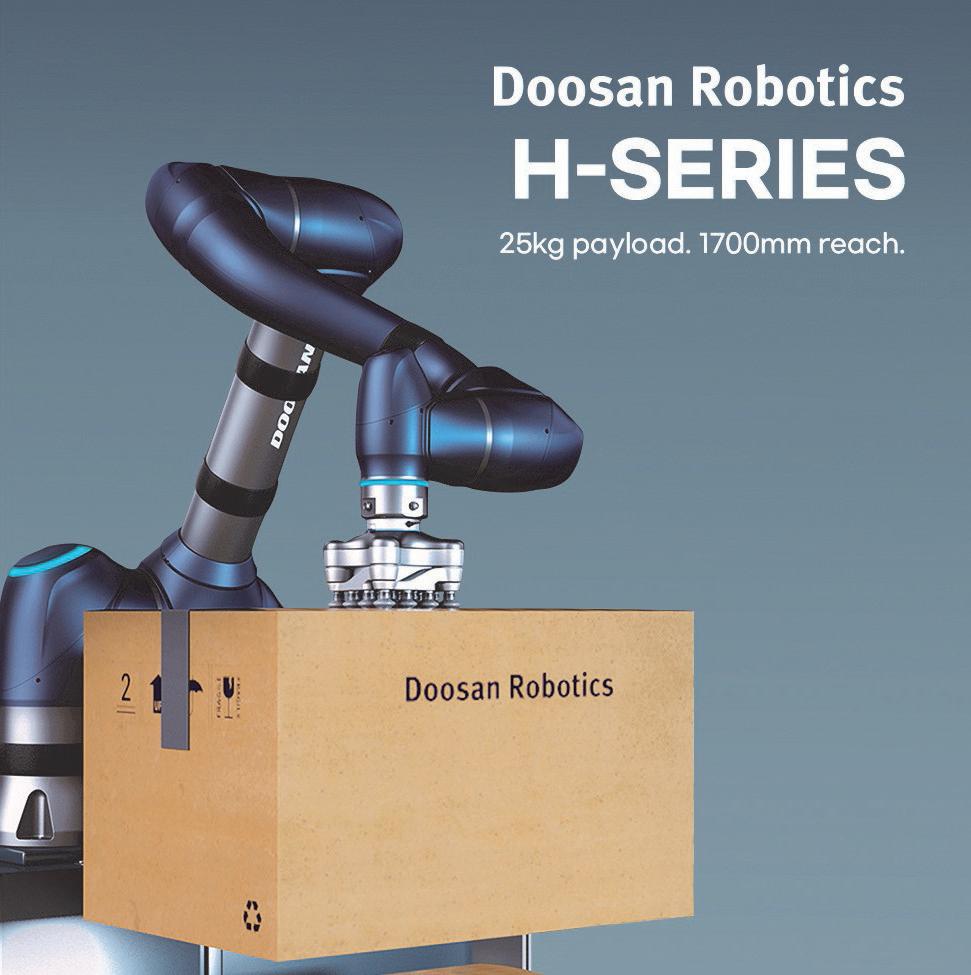

Robot easily handles bin picking

Bin picking processes are known to be laborious, tiring, and even dangerous in some situations. These tasks are suited for automation in nature but can be challenging to automate due to factors such as shi ing part locations and complex path calculations. This bin picking solution that can save time and money.

The robot’s design includes an arm structure and lighter main unit for high speeds and a large working area. Its 1,460 mm reach is the largest in its class, allowing for installation flexibility and use in a wider variety of applications. The RS013N robot also leads its class in speed, resulting in reduced cycle times and increased productivity.

In addition to its expanded work area, the robot’s wiring and installation options contribute to its overall flexibility. The robot’s internal Ethernet wiring enables easy connection to a vision system or other peripheral devices, and its floor, ceiling, and wall mount options provide installation flexibility for any layout. The dust-tight RS013N offers a full-body IP67 rating, fully

connections allow the robot to be used in virtually any environment. The R series robots (RS007N/L and RS013N) also have reduced interference zones around the robot base, which allows the user to maximize their floor space and working area. DW

motors and waterproof

Kawasaki Robotics (USA), Inc. KawasakiRobotics.com

DESIGN WORLD www.designworldonline.com November 2022 19 WWW.TRIMLOK.COM INFO@TRIMLOK.COM 6855 HERMOSA CIRCLE BUENA PARK, CA 90620 SEALSTRIMS AND 800-933-4915 CELE B R ATING YEARS CELE B R ATING 50 YE ARS AND STILL GROWING!50 YE ARS AND STILL GROWING!YEARS NEW FACILITY COMING FALL 2022 ELKHART, INDIANA Packaging

covered

electrical

Lights-Out Manufacturing

Tools for Future Growth

The Automated Storage & Retrieval System is built to continuously feed parts to the cobot. This machine solves cobot downtime. Without some sort of automated loading and unloading system, cobots will inevitably sit idle, falling far short of their desired potential.

Traditional desktop 3D printers are fine for prototyping parts, but can be costly in terms of volume production. The WorkSeries 300 (1000 x 1000 x 700 mm build area) can produce near-net shape parts and have greater ability to customize, resulting in decreased costs and reduced time-to-market for industrial manufacturers.

6402 E. Rockton Road, Roscoe, Illinois 61073 USA +1.800.962.8979 pbclinear.com • appliedcobotics.com • 3dplatform.com

by

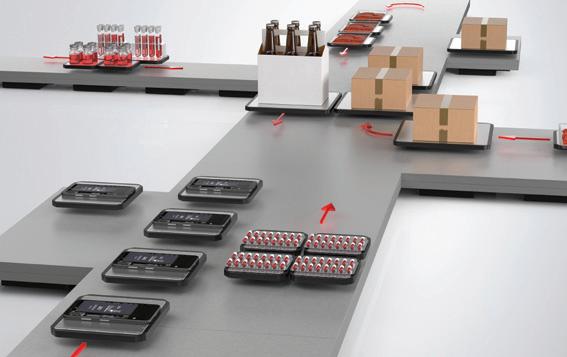

Modular robotic system for packaging

A breakthrough concept for packaging, microfulfillment, and beyond, ATRO provides a flexible, fully modular system for robot kinematics with simplified assembly and path teaching. Users can select the number and type of axes required for robots with payloads up to 10 kg and reach of up to 1.3 m. A media feed concept routes data, power, and fluids internally with infinite rotation available for all axes, which never need to stop to unwind cables.

For countless packaging applications, ATRO enables wideranging robot kinematics, including expansive configurations with as many as eight robotic arms. The TwinCAT control so ware scans the user-created robot mechanical assembly, and TwinCAT robotics functions automatically create the corresponding control application — including a digital twin. DW

Beckhoff Automation www.beckhoffautomation.com

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly. Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

33 Higginson Avenue, Central Falls, Rhode Island 02863 Telephone: (401) 728-0700 • FAX: (401) 728-0703 E-mail: info@whittet-higgins.com Web: www.whittet-higgins.com

DESIGN WORLD November 2022 21

Packaging Design for Industry

POWER TRANSMISSION RETAINING DEVICES & maintenance & assembly tools WHITTET-HIGGINS USA BEARLOK SHOELOK BEARLOK Shrink Disc BEARHUG CLAMPNUT TANGENTLOK PRECISION NUTS & WASHERS ADAPTER SLEEVE ASSEMBLIES NUTS & WASHERS HARDENED TONGUE WASHERS SPLIT COLLAR RETHREADING DIES ADJUSTABLE SPANNER WRENCH BEARING ASSEMBLY SOCKET INCH and METRIC THREADS LEFT HANDED as well as RIGHT -HANDED Materials of: CARBON, ALLOY and HARDENED ALLOY STEELS Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

Safety Design for Industry

Smart sensor keeps an eye on the health of machinery

Remotely monitor the health and performance of general machinery with the ABB Ability Smart Sensor, an element of the ABB Ability Digital Powertrain.

The smart sensor turns rotating equipment including drives, motors, and applications such as pumps, into smart, wireless connected assets. It is also designed to detect potential asset disturbances and planned maintenance before the reliability, productivity, and safety of machinery are impacted.

The smart sensor fits to the assets surfaces, collecting and transmitting data via smartphone or gateway to a secure cloud service. Advanced algorithms analyze the data to provide real-time insights into the condition and performance of monitored assets. The asset to be monitored is chosen during commissioning. All components of a powertrain can be monitored via one portal — either individually or as part of the complete powertrain.

The sensor handles applications in hazardous areas and harsh environments. Its enclosure is designed to withstand high vibration levels and protects om total dust ingress (IP66/67). The sensor is certified for ATEX, IECEx and NEC 500. DW

ABB www.abb.com

22 November 2022 www.designworldonline.com DESIGN WORLD

OVER 25 YEARS’ EXPERIENCE WITH MANUFACTURING AND SOURCING OF MATERIAL, SUB-ASSEMBLIES AND FULL TURNKEY PRODUCTS.

• PRODUCTS: We offer component manufacturing, engineering, sourcing, custom component manufacturing. Kingway offers components and subassemblies all the way to full box builds.

• LOGISTICS: Kingway can help develop a custom Logistics plan to meet your needs including Expedited Air Freight, Sea Freight and Domestic Warehousing.

• VISION STATEMENT: Kingway Electronics offers Direct Sourcing and Customized Logistics Management by utilizing our 25 plus years of relationships and experience to deliver better Pricing, Shorter Lead Times with the Goal of Maximizing our customers profitability.

kingway-usa.com (330) 205-4904

FULLY CUSTOM OEM

STANDARD TO

SOLUTIONS

Crucial temperature control in pharma manufacturing

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

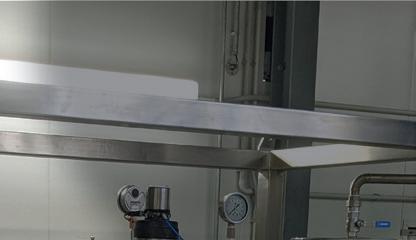

The line produces pharmaceutical pellets containing the active ingredients in capsules.

Design Notes 24 November 2022 www.designworldonline.com DESIGN WORLD

HRS Heat Exchangers

have helped a leading Australian pharmaceutical company expand its production capacity by supplying a bespoke system that controls the temperature of solution materials used in capsule manufacturing.

Mayne Pharma commercializes branded and generic pharmaceuticals in several product areas. Its manufacturing facility is in Salisbury, South Australia, approximately 12 miles om Adelaide, where it produces tablets, capsules, liquids, and creams.

Capsules are a popular method of drug delivery, made of a two-piece dissolvable outer shell containing miniature pellets which carry the active ingredients. The pellets are prepared using a fluid bed dryer to reduce moisture content and are sometimes spray-coated with a solution containing key ingredients. The spraycoating solutions use an alcohol-based formulation to ensure correct mixing and maintenance of the fundamental chemical properties. The solutions must be prepared and applied within a tight temperature range.

Mayne Pharma wanted to expand and upgrade its existing production capacity for capsule production by adding a third fluid bed dryer and the associated equipment while also improving temperature regulation to its existing lines. HRS Heat Exchangers was asked to provide a quotation for a hot water heater to support the new line but quickly realized that a turnkey package offering active heating or cooling as required would provide a much better solution.

“The alcohol for the solutions is drawn om our outside tank farm,”

a spokesperson for Mayne Pharma explained. “One of the issues with the old systems was that on hot days the factory had to wait for the alcohol to cool down before mixing the solutions, which could sometimes take hours. The HRS solution means that we can actively cool it if we need to. Alternatively, if we bring in the alcohol on a cold day, we can heat it up, as necessary.”

The solution produced by HRS is a heater/cooler with the ability to reduce hours of cooling time to less than 60 minutes. Due to space constraints in the existing factory and the requirement to connect various pieces of equipment, the unit was supplied on a compact skid with integrated controls and automation of both heating and cooling processes. Other challenges faced by HRS Engineers were uncertainties about heat transfer in the existing tanks and having to overcome unknown pressure losses in a small jacket annulus which would otherwise affect the performance of the unit.

The HRS unit uses two K Series multipass corrugated tube heat exchangers to maintain solvent temperature at 77 °F or 68 °F as required. The hot water loop is composed of one heat exchanger, a centrifugal pump, safety features, and the necessary ancillaries such as a pressure gauge, temperature transmitter, and manual valves.

“The service water is recirculated in a closed loop with the selected solution tank to heat the solvent om 59 °F to the target temperature,” said Ella Taghavi, Technical Sales Engineer at HRS Heat Exchangers. “The process is controlled by temperature transmitters and an autonomous

DESIGN WORLD www.designworldonline.com November 2022 25

Ella Taghavi, Technical Sales Engineer at HRS Heat Exchangers.

control system, and given the importance of the temperature in the process, product temperature is also monitored via a secondary control loop with transmitters located on each solution tank.”

Moreover, the cooling section is designed to maintain the product temperature at the targeted set point. Incoming service water om a buffer tank is cooled using chilled water at 42-50 °F om elsewhere in the factory using several passes through the second heat exchanger. “The tank jacket service water is recirculated in a closed loop with the selected solution tank to cool the solvent om 104 °F to the target set temperature of 77 °F or 86 °F,” said Ella. Again, temperature transmitters control the process via an autonomous control loop.

Despite the Covid-19 pandemic, the process of manufacturing, installing, and commissioning the unit ran smoothly, taking less than six months om the order being received to the unit being fully operational. “Covid-19 meant that we weren’t able to undertake Factory Acceptance Testing (FAT) at HRS’s manufacturing facility in Spain, but as it was such a straightforward job, we wouldn’t have insisted on this anyway,” said the spokesperson.

“We undertook the commissioning on site with remote support om HRS’s Engineer Ella Taghavi in Melbourne, but apart om a couple of phone calls, nothing else was required.” DW

Design Notes

26 November 2022 DESIGN WORLD THE RIGHT STAMPING. THE RIGHT WASHER. RIGHT NOW. REQUEST YOUR FREE 2023 Catalog & Calendar bokers.com(800) -WASHERS

WILL BE THERE. For over 100 years, nearly every industry across the globe has trusted Boker’s to provide quality components, world-class service and on-time delivery.

multi-

corrugated

HRS www.hrs-heatexchangers.com

BOKER’S

The HRS uniT uses two K Series

pass

tube heat exchangers to maintain solvent temperature as required.

1. 2. 3. 4. Balls

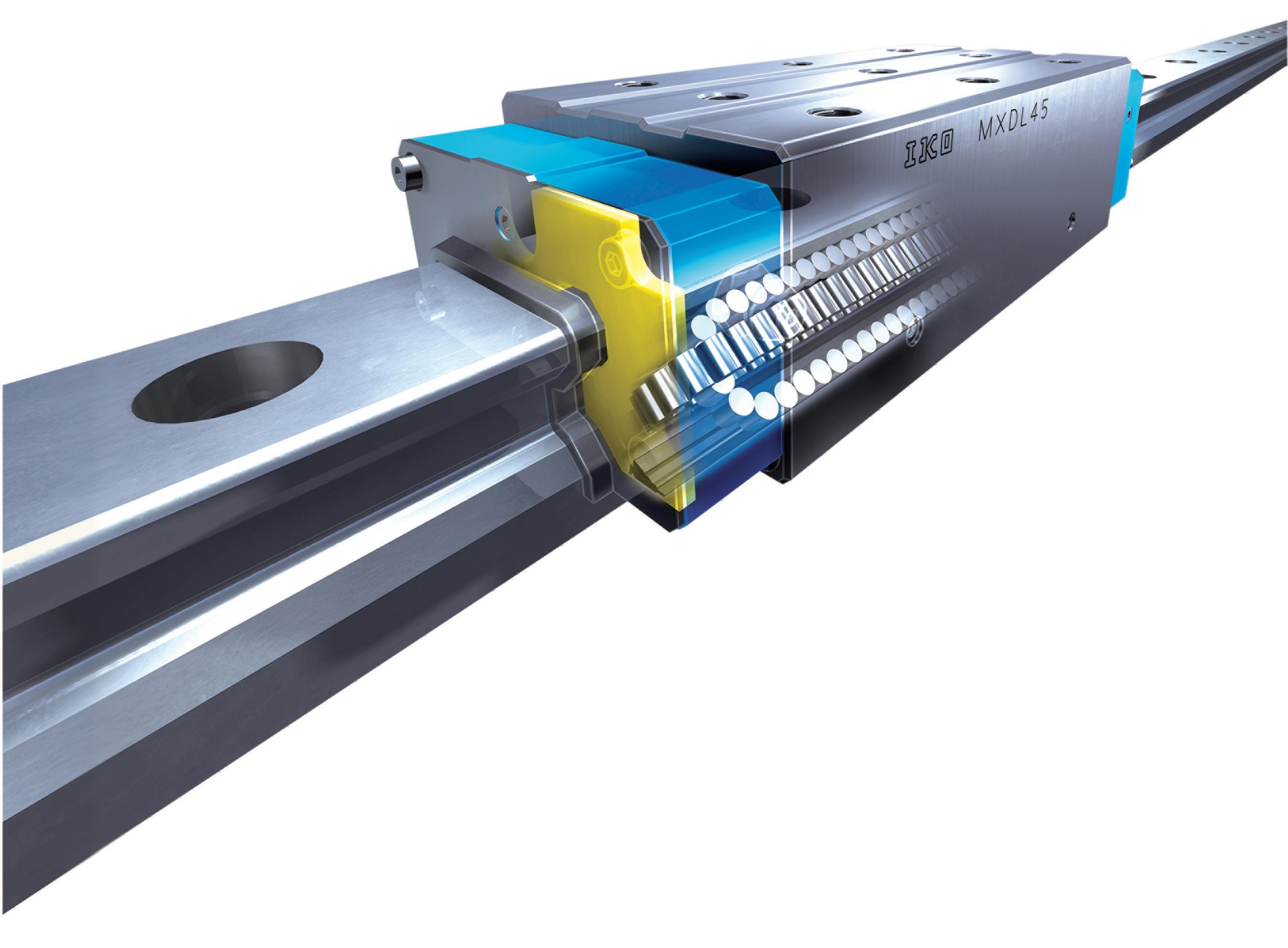

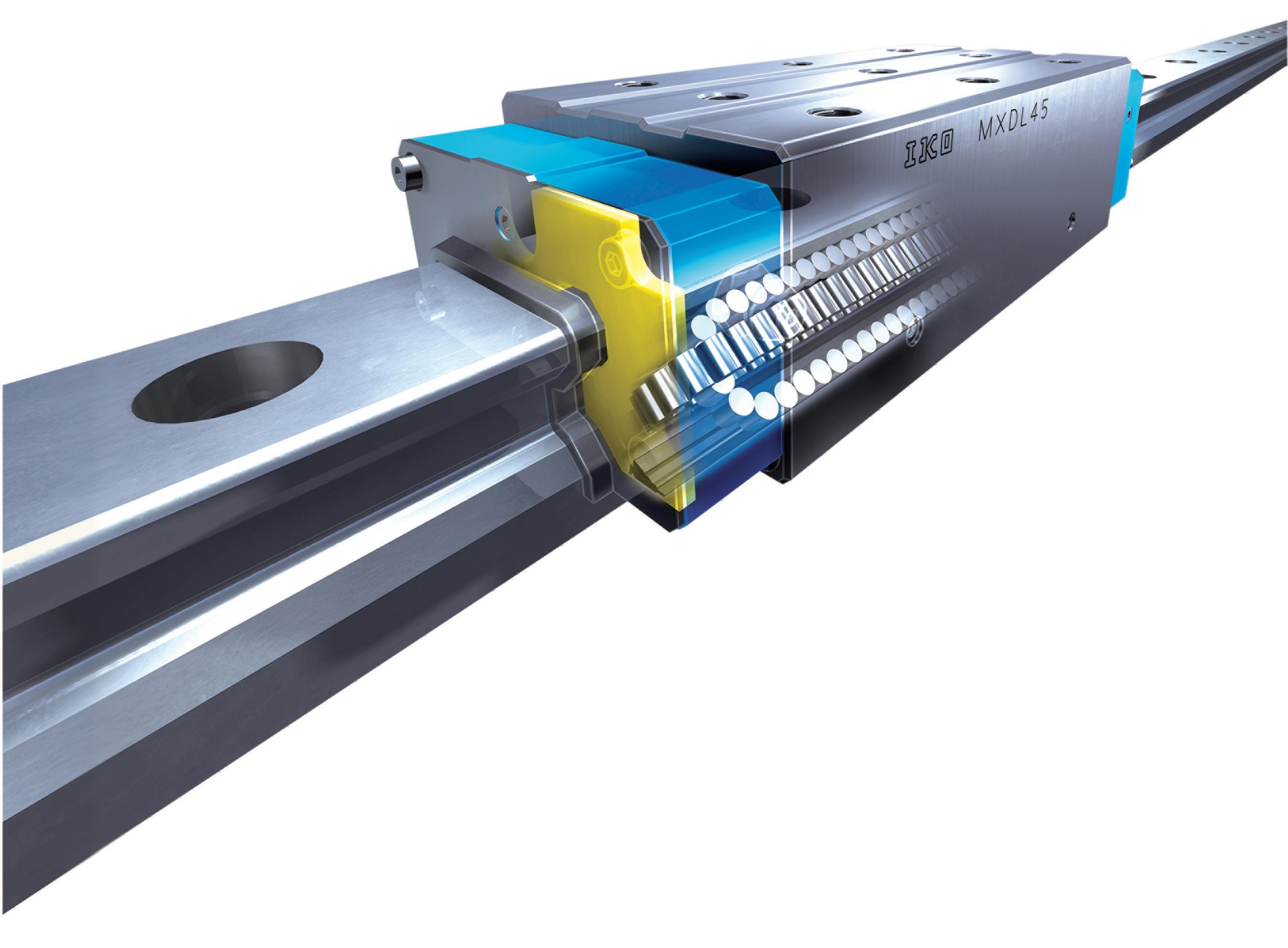

and rail for optimum stability Single, U-shaped rigid steel rail and base can be one-end supported Four ball circuits (not just two) for moreload and accuracy Circuits positioned closer to base for more stability.

Actuator–Greater Loads, Precision & Rigidity...All In Less Space Why our single axis ball screw slide guide bests the competition:

have 4, not just 2, points-of-contact to guide block

BG

New king pin and thrust bearings save costs for forklift company

Edited by Mike Santora • Managing Editor

When a South A ican forkli rental company was seeking reduced downtime, expenditure, and fewer equipment repairs, they contacted Vesconite Bearings about its king pin and thrust bearings.

This is according to brothers Jacques and Van Rhyn , who, together with their father, Japie du Plessis, supply forkli s to clients in the agriculture, uit, and wine industry through JP Fork Truck Rental, a family-owned and operated company.

In the forkli hire industry, clients o en say, “rev it like a rental,” indicating that rental machines are used intensively since maintenance and repair costs are allocated to the rental company.

In extreme cases, clients li loads that exceed the capacity of the machine, causing the rear wheels of the forkli to li and then drop, o en causing damage to the axles.

“It caused severe damage to the rear axles, and we would have to collect the forkli om our clients to do the repairs and send some of the parts to an engineering workshop to have them fixed,” said Van Rhyn. “And it used to cost a lot of money,” he added.

This was before the rental company moved to Vesconite low- iction wear-resistant king pin bushings and thrust bearings for the main pivot point on the rear axle.

The Vesconite parts replaced the conventional needle roller bearings for the king pin and the thrust bearings.

Design Notes 28 November 2022 www.designworldonline.com DESIGN WORLD

Van Rhyn also said that Vesconite king pin and thrust bearings do break in some instances, but in most cases, they only deform slightly.

“If the part has deformed, it usually is an indication of impact, and the bushing is either replaced or shimmed and can be used again,” he said.

Jacques, who has completed a Ph.D. in mechanical engineering, commented that the rental company appreciates the new king pin and thrust bearings’ hardness while still being ductile enough not to crack or shatter under impact.

“It can withstand a lot of wear. It is hard and, at the same time, not brittle,” he noted.

The ability to withstand high axial loads and stress is particularly important in forkli thrust bearings due to the weight of the machine’s counterweight, which needs to absorb impact and not crack or shatter.

The brothers explained that conventional thrust ball bearings

Quantifying the savings from this upgrade is di cult, but the downtime has been significantly reduced, which has led to savings in maintenance and transport costs.

were used before the introduction of Vesconite’s plain bearings.

With a ball bearing, the contact between the axle and stub-axle is multiple point loads (contact with the balls) ,and, in the case of a severe impact, the ball bearings shatter or even push outwards, breaking the bearing housing. This causes the steering plates and the stub-axle to bend and the stub-axle to rub up against the axle resulting in extreme wear on the components.

Quanti ing the savings om this upgrade is di cult, but the downtime has been significantly reduced, which has led to savings in maintenance and transport costs.

“Re-occurring bearing failures were eliminated, which means that these parts are now on a preventive maintenance schedule instead of corrective or failure maintenance schedule,” said Jacques.

“This has saved a significant amount of downtime and inconvenience for both our clients and ourselves,” he noted.

JP Fork Truck Rental is so impressed with the new parts that it has installed Vesconite mast liners and trunnion bearings in addition to king pin and thrust bearings in about 80% of its fleet of more than 80 forkli s.

It also expects to have all its machines fitted with new parts by the end of this year.

“Clients are happier when you don’t have downtime on your machines,” said Van Rhyn. “This is not an issue anymore.”

DW

Vesconite Bearings www.vesconite.com

DESIGN WORLD www.designworldonline.com November 2022 29

For demanding measurement tasks, the IF2001/USB interface module is available, which also supports the RS422/USB signal conversion.

Laser triangulation sensors for a range of applications

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

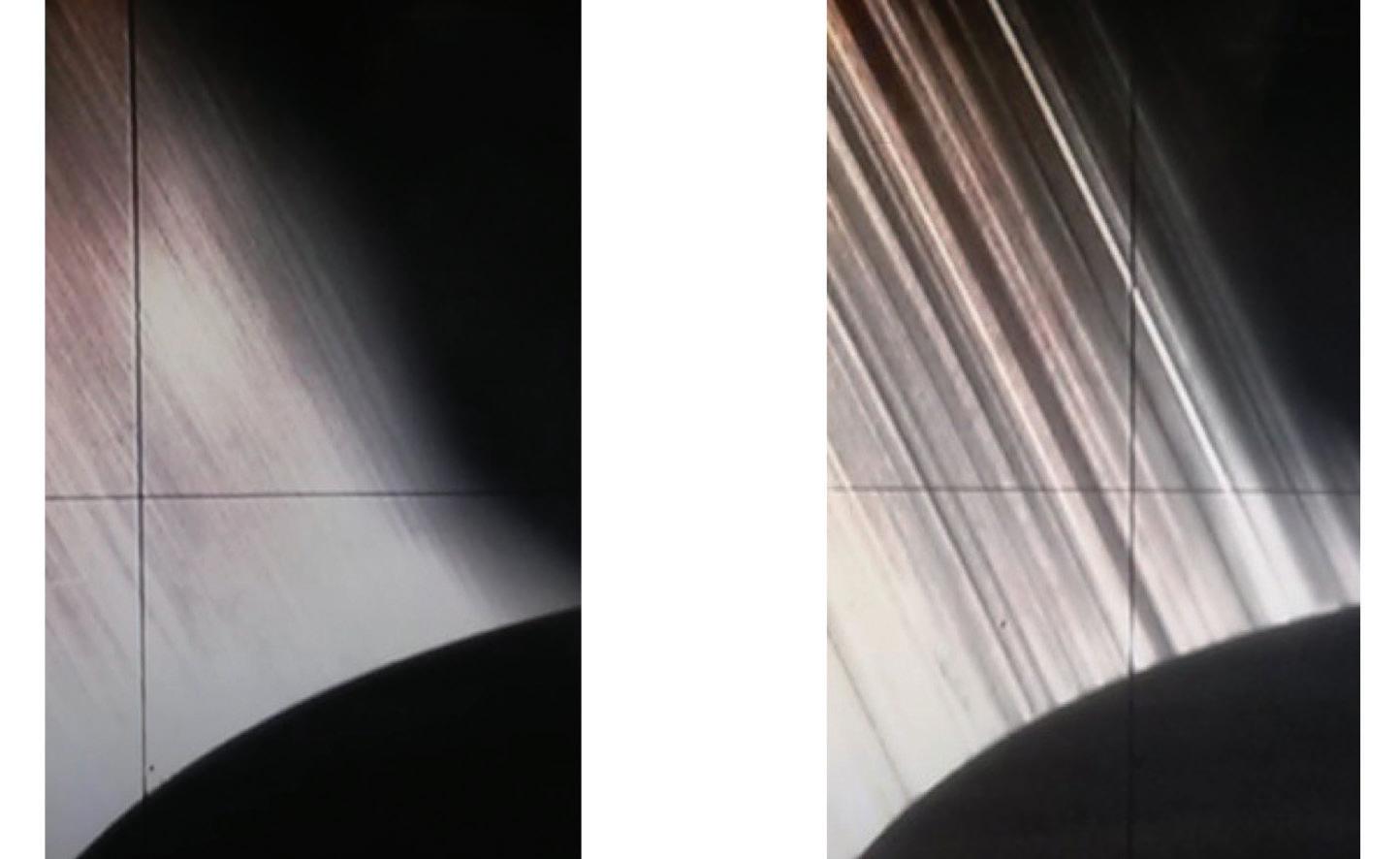

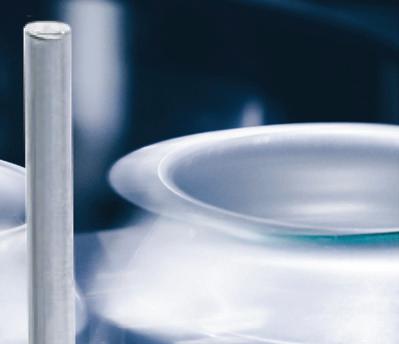

The compact optoNCDT 1420LL laser sensors perform precise distance measurements on metallic and structured surfaces. The sensor projects a small laser line onto the measuring object, compensating for any interference. This ensures stable and reliable measurement values. The sensors are used whenever standard laser point sensors reach their limit.

The optoNCDT 1420LL laser sensors work with a small laser line rather than a laser point. This allows them to measure accurately even on rough, diffuse, and shiny metallic surfaces. Their laser line ensures optical averaging and compensates for irregular surfaces. They achieve reliable, highly precise measurement values on rough surfaces, defects, recesses, and holes. The optoNCDT 1420 LL models are available with measuring ranges of 10, 25, and 50 mm.

The standard model has a glass cover pane to protect the receiver unit. In addition, the optoNCDT 1420 series sensors can also be equipped with a protective film to prevent external influences om causing damage to the cover glass and unwanted reflections. The film avoids scratches and streaks, which increases signal stability.

The IC2001/USB single-channel converter cable is available as an additional accessory. It establishes a USB connection to the sensors via RS422. The advantage is a costeffective connection solution for permanent installation. The unshielded cable allows a maximum data rate of 1 MBaud.

For demanding measurement tasks, the IF2001/USB interface module is available, which also supports the RS422/USB signal conversion. DW

Micro-Epsilon www.micro-epsilon.com

30 November 2022 www.designworldonline.com DESIGN WORLD Design Notes

INFRASTRUCTURE ENGINEERING

FLUID

INTERNATIONAL

POWER EXPO MARCH 14-18, 2023 LAS VEGAS, NV, USA The International Fluid Power Exposition (IFPE) is the place where engineers meet to: “ There’s no other show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.”

IFPE only happens once every three years! REGISTRATION OPENS EARLY AUGUST See why IFPE is the can’t-miss fluid power

of

Learn

Discover solutions current suppliers can offer

your

challenges. Find

partners

suppliers

CONNECT WITH TOP MANUFACTURERSCO-LOCATED WITH CONEXPO-CON/AGG (two shows, one price) Including Bosch Rexroth , Danfoss Power Solutions , Parker Hannifin , Poclain , IFM Efector , Hawe Hydraulik , Husco , and 375+ more! Join your

these OEMs: ∙ Caterpillar

∙ Volvo Construction Equipment ∙ Liebherr ∙ CASE Construction Equipment ∙ Komatsu ∙ John Deere Construction ∙ Doosan Bobcat ∙

∙ LBX

#1 Trade

&

for Fluid Power, Power Transmission, and Motion Control

KEN ROSENBECKER SALES MANAGER NORTH AMERICA | WIPRO

event

2023!

more at IFPE.com

to

unique

new

among

pushing the envelope on what fluid power can do.

peers from

Inc

KOBELCO Construction Machinery USA

Company Spark new ideas with in-depth technical conversations with other engineers. The

Show

Conference

Internet of Things

The benefits and challenges of real-time manufacturing data collection

Bill Dykas • Senior Product Manager of Telit IoT Platforms • Telit

Because data collection is the foundational element of the Internet of Things (IoT), it stands to reason that the quality of manufacturing data analytics is proportional to an organization’s data collection capacity. For a large majority of manufacturers, however, real-time data collection presents a major challenge, which is why many Industrial IoT projects fail to deliver at scale. Considering the disparate and numerous machines and devices that make up the manufacturing ecosystem (sensors, robotics, cameras, and more), it’s not surprising that real-time, low-latency data collection is complex. Add to this the fact that many organizations make the mistake of looking past the data collection stage while planning IIoT projects. Yet, failing to consider processes and tools for distributing and transforming data prevents organizations om realizing the value data brings. Better data can help businesses increase process e ciency, including eliminating unplanned downtime with predictive maintenance, reducing costs and risks to workers, meeting regulatory requirements, and creating new business models.

It’s vital to recognize that real-time data collection doesn’t stop at collection. It must be managed, distributed, and transformed to give businesses full benefits. One of the most limiting factors lies with the existing communications standards. Many manufacturers rely on

Open Platform Communications (OPC), which has been a key interoperability standard since 1996. Although useful, this aging standard by itself can’t keep pace with today’s changing needs. OPC is the standard approach for supervisory control and data acquisition (SCADA) and human-machine interface (HMI) systems to interface with programmable logic controllers (PLCs). The original OPC specification was tied to the Microso Windows operating system (OS). OPC Data Access (OPC DA) and Microso definitely took connected manufacturing a significant step forward. However, using OPC DA in today’s manufacturing climate poses several challenges. OPC’s underlying technology is so aligned with Microso that it isn’t compatible with many other technologies. As OSs like Linux become prevalent in manufacturing, companies relying on OPC DA can find their interoperability plans thwarted.

Manufacturers need a better way to connect their organizations and make the most of the IoT revolution considering that not every machine has an OPC interface nor is every machine network connected. To quickly establish connectivity om shop floor to top floor, and their ecosystems, there is a clear need for developing and improving the device drivers and their ability to read the data and collect it om multiple mediums, including audio and video.

This data collection technology must be smart enough to know what to do if the system in which it is connected is o ine. It must also be able to store and forward the data to distribute it in a cost-effective and e cient manner. The data must then be transformed to ensure transparency and accessibility all while in context within the business process.

Most important, businesses need the flexibility to change how data are collected depending on the use case and environment — and without the need for developers to build custom code to create the interfaces connecting diverse components. With the right technology, manufacturers can mask the complexity of connecting the factory or plant floor

32 November 2022 www.designworldonline.com DESIGN WORLD

Manufacturers need a better way to connect their organizations and make the most of the IoT revolution considering that not every machine has an OPC interface nor is every machine network connected.

to IT systems, as long as the solution is flexible and agile enough to collect data when needs change.

It doesn’t take years to prove the value of operational data and what it can do for businesses. Some systems are capable of launching projects in a matter of weeks, acting as the edge intelligence. When operating on multiple hardware platforms, these systems are capable of growing a library of hundreds of device connection drivers — with industrystandard connection so ware like OPC UA and DA and device-specific native drivers — that can read and write directly to enterprise systems. The edge logic engine transforms the data without the need to write custom code.

These IIoT systems are the backbone of digital transformation, with 5G accelerating this transformation by eliminating cabling and enabling ultra-reliable, mission-critical wireless communications. By improving realtime data collection capacity, especially when IoT benefits are becoming business necessities, the entire supply chain — om the creation of raw materials to finished products and right down to last mile delivery — is elevated to a new level. Most important, when real-time data collection capacity is optimized, the promise of IIoT will become a reality. DW

Telit www.telit.com

Sense

Since 1999 Quantum Devices has been known for innovation in encoder manufacturing and customization to match requirements. Let our engineers assist in your sensor design. Utilizing our own silicon foundry, we fabricate our own photodiodes. Then we build from the ground up, with design and manufacturing on-site allowing us to offer application-specific products.

Being vertically integrated and producing each critical element of our product line in-house, enables us to: Accommodate new business; Create drop-in replacements for hard-to-find or custom encoders; and Quick-turn prototypes.

WHAT DO YOU THINK?

Connect and discuss this and other engineering design issues with thousands of professionals online

DESIGN WORLD November 2022 33

Incremental Encoders 608.924.3000 quantumdev.com Better Design. Better Performance. Made in Barneveld,

USA Visit our online store. All orders ship within 48 hours.

the Difference.

WI

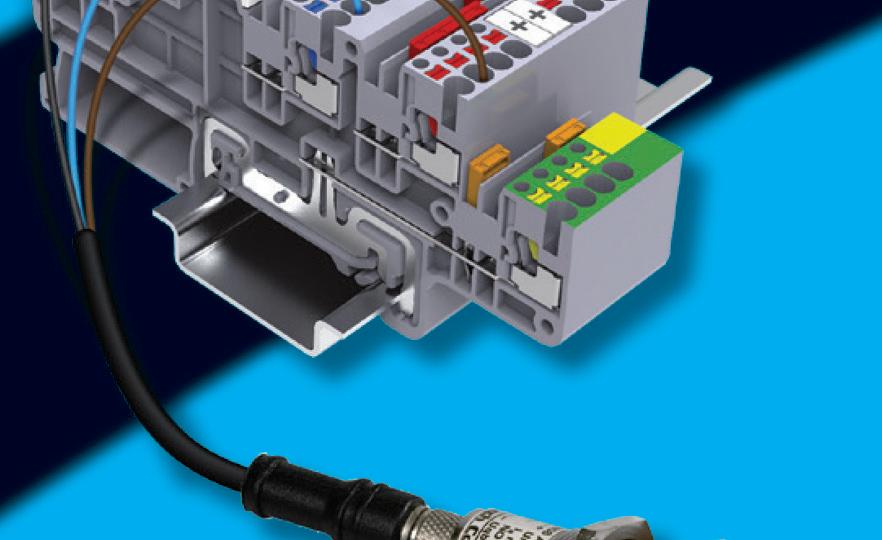

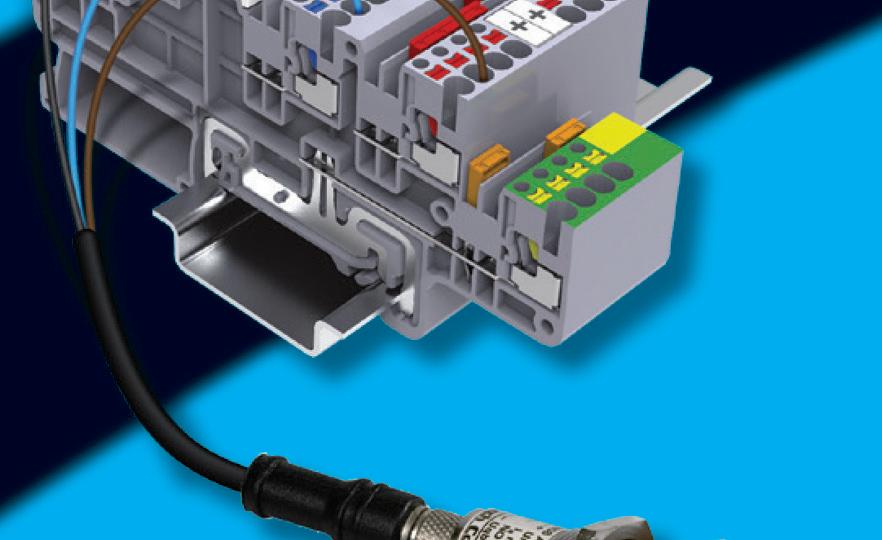

CAN-to-Fiber converters extend communications up to 40 kilometers

The ICF-11711 Series of CAN-to-fiber converters is for applications that involve long distance data transmission. When used in pairs to connect two CAN 2.0 or two CAN-FD devices or networks, ICF-11711 converters extend transmission distance by 2 kilometers (1.25 mi.) on multi-mode fiber or as much as 40 kilometers (24.85 mi.) on single-mode fiber, regardless of the CAN baud rate. The converters will transmit at data rates up to 1 Mbps in CAN interfaces and up to 5 Mbps in CAN-FD interfaces

Baud rates limit the transmission distance of a CAN system, as stated in the ISO 11898 standard. The faster the baud rate, the shorter the maximum transmission distance. ICF-11711 converters overcome this limitation, making it possible to deliver the expected baud rates over long communication distances.

Because industrial networking devices are usually deployed inside space-limited cabinets, these DIN-rail mounted converters measure 1.19 x 2.76 x 4.52-in., and come with 2 kV isolation and 2 kV surge protection for CAN port. Protected in a rugged, IP30 rated metal housing, the converters have an operating range of -40 to 75°C to help overcome harsh communication environments. An optional wall mounting kit is available. To make multiple device

configurations easier, Moxa CAN-tofiber converters have a DIP switch to change interfaces between CAN and CAN-FD. In addition, there is an auto baud-rate setting function for the CAN interface that eliminates the need to perform configurations. Also, in the event a communication error occurs, the user can check the built-in LED indicators to identi whether the error occurred in the CAN or fiber connection.

ICF-11711 converters can be used in a range of CAN (Controller Area Network) applications including factory automation, building automation, aircra and aerospace as well as in electrical vehicle (EV) charging stations. For instance, since CAN has been adopted as the bus for the internal batteries of electrical vehicles, these converters can enable the collection of valuable information, such as charging status and energy usage, om each electric vehicle and provide billing information to the vehicles’ owners, based on when and how much power supply their EV were charged with. DW

Moxa www.moxa.com

WHAT DO YOU THINK?

Internet

Things 34 November 2022 www.designworldonline.com DESIGN WORLD

of

and discuss this and other engineering design issues with thousands of professionals online

Connect

Antennas support Wi-Fi 6E

This line of 6 GHz, Wi-Fi 6E capable sector antennas suit indoor and outdoor applications such as large arenas and stadiums.

Wi-Fi 6E sector antennas offer high performance and throughput while supporting equencies om 2.3 GHz to 7.2 GHz. They feature 17 dBi to 20 dBi gain, 65° and 90° coverage and 2x2 MIMO port options for increased speed, versatile coverage, and less interference.

These antennas ship with universal radio brackets for easy installation and are shorter than 40-in., adhering to universal zoning compliance. They also feature Type-N connectors, 1200 MHz of extra bandwidth availability, and dual slant +/- 45° polarization.

Using these sector antennas with the extra 1200 MHz available in the 6 GHz Wi-Fi 6E band allows users to reach speeds up to 1 to 2 Gbps. The antennas work on 2.4 GHz and 5 GHz networks available today and allow future-proof network capabilities without a need for antenna changes. DW

KP Performance Antennas www.kpperformance.com

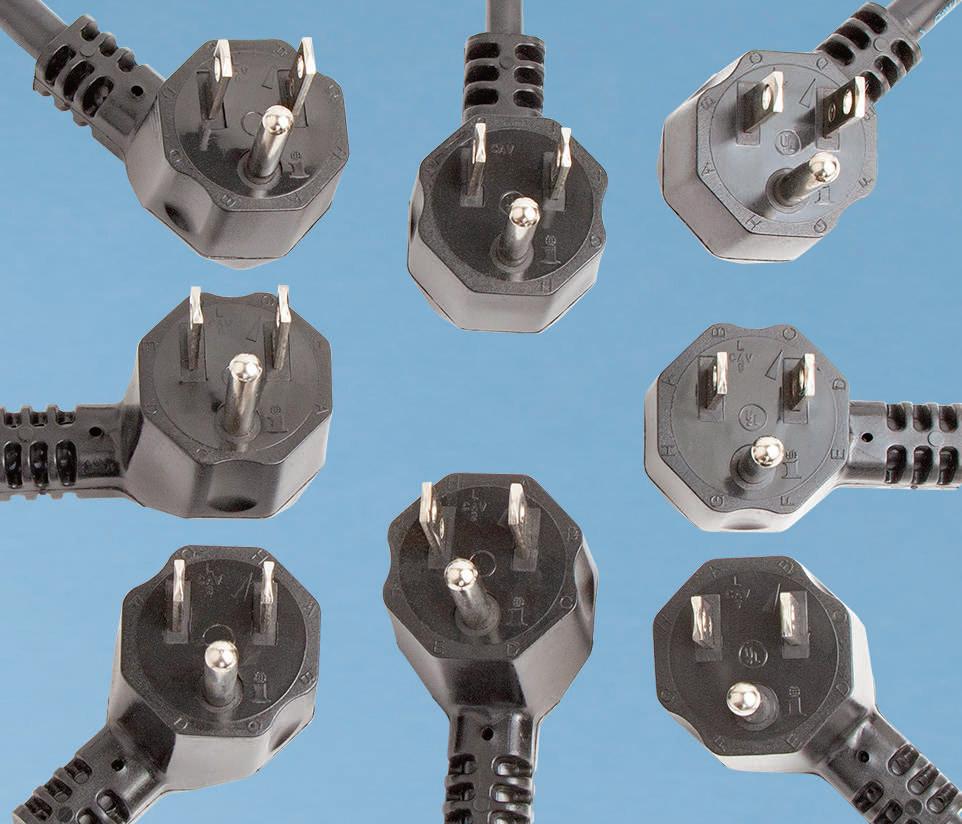

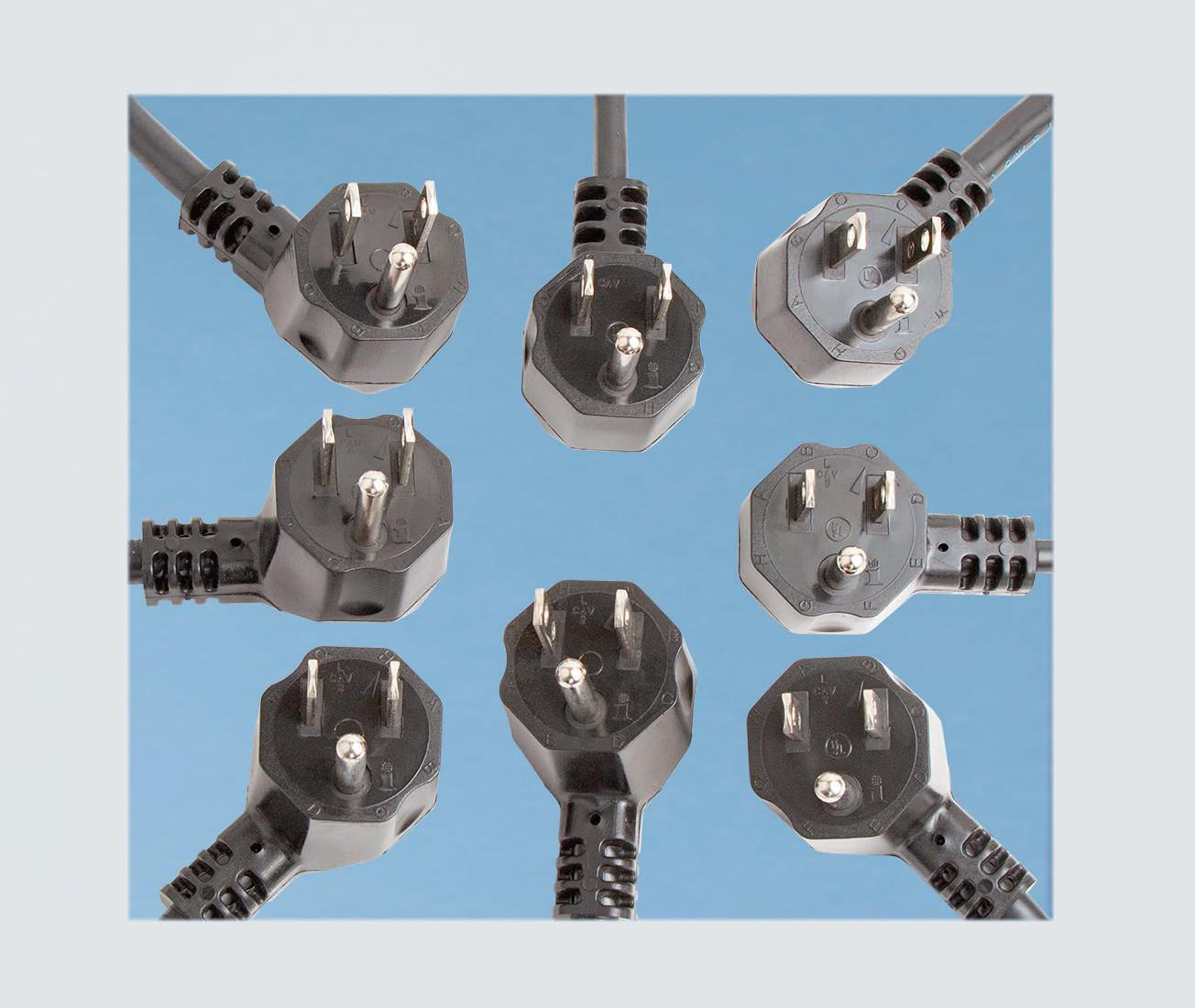

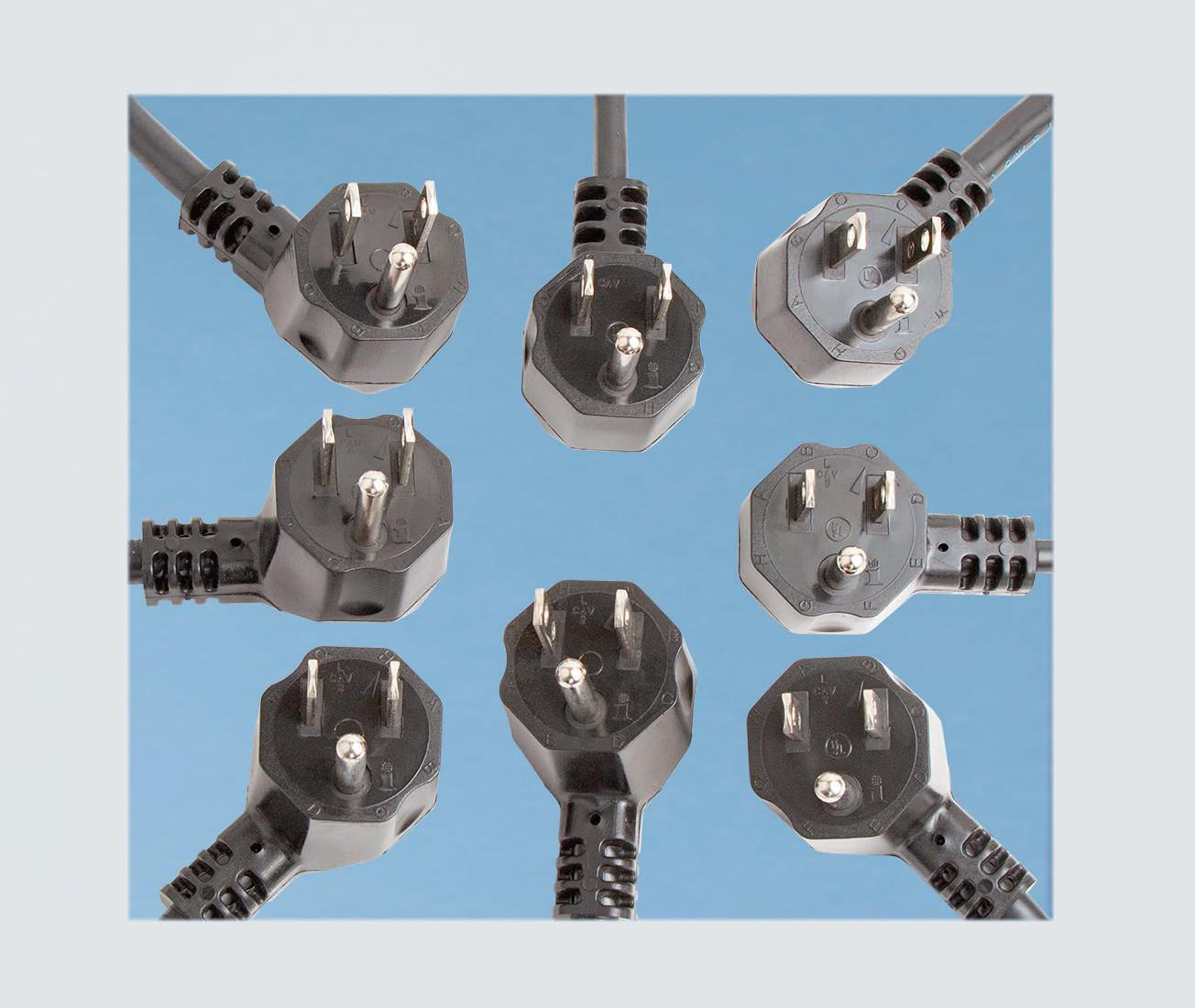

Angled NEMA Cords Made in the U.S.A!

Interpower® offers 8 different angles of the NEMA 5-15 cord. When limited space between equipment and the power connection make cord direction critical, an angled cord minimizes the space between connectors reducing the strain on both plug and cord. Different cord angles provide multiple options on how a cord can plug into extremely tight angles—maximize the minimum space confining your cords!

• Manufactured & shipped in Lamoni and Oskaloosa, Iowa

• No minimum order requirements

• World-class customer service

® ®

Toll-Free Phone: (800) 662-2290 E-mail: info@interpower.com

Business Hours: 7 a.m.–6 p.m. CST Order Online! www.interpower.com

DESIGN WORLD www.designworldonline.com November 2022 35

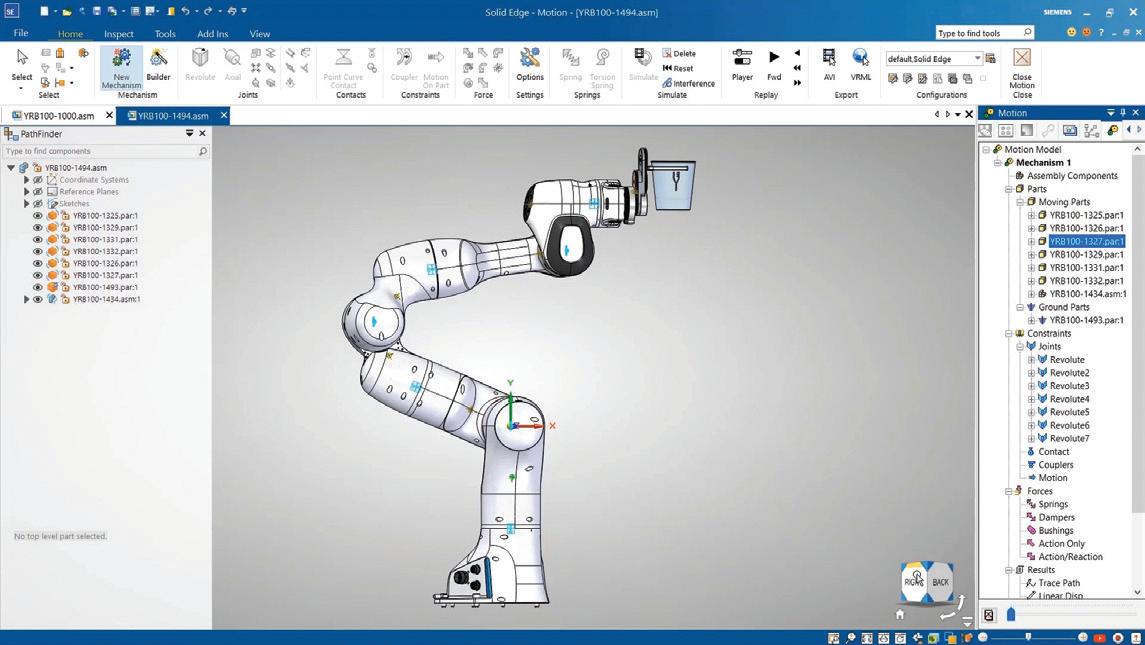

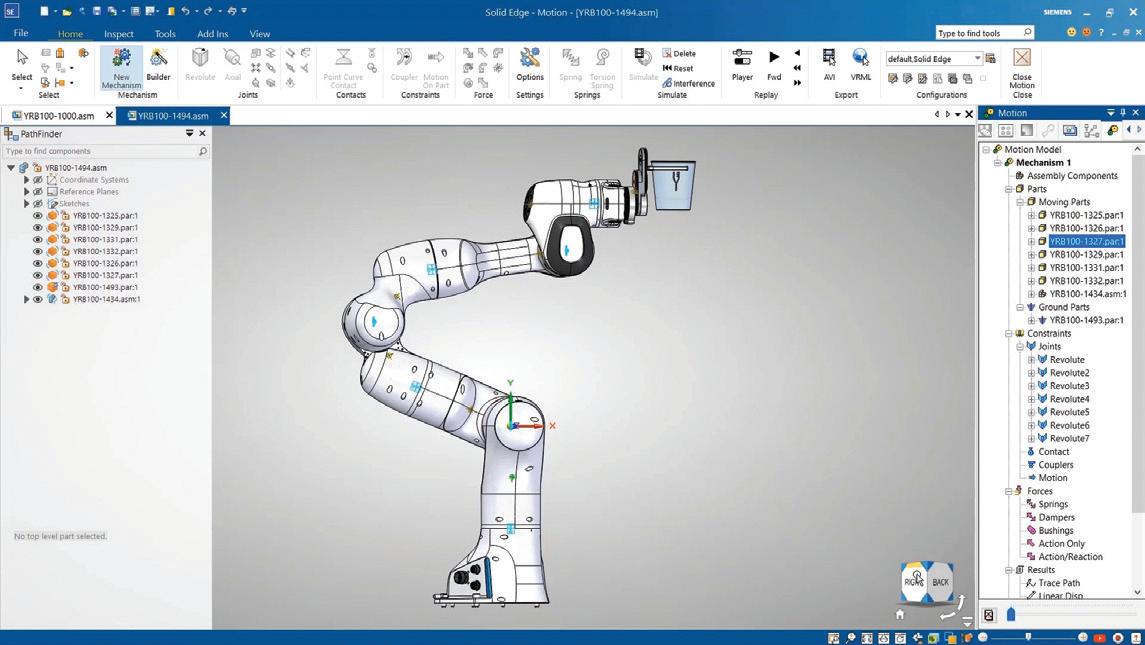

Siemens boosts collaboration and performance with Solid Edge 2023

The latest release of Solid Edge so ware for product design, engineering and manufacturing, brings a new streamlined user experience, greater interoperability with the Siemens Xcelerator portfolio and greater capability and collaboration across many industry workflows.

In addition, Solid Edge will have new licensing options to better meet the changing business needs of small and medium-sized manufacturers, providing greater flexibility, more value and, with Xcelerator Share, greater collaboration and speed.

Solid Edge’s new look and feel brings a modern update to include more intuitive ways of working, greater personalization options and improved modeling workflows. Updates to the geometry definition tools in Solid Edge include synchronous technology applied to traditional ordered history-based parts and parts created using convergent modeling (using generative design or om 3D scans) can be used in simulations without the need for additional conversion.

Solid Edge 2023 also unlocks the power of design data while future proofing customers’ work – data om Solid Edge can be transferred between other solutions in the Siemens Xcelerator portfolio, including NX Mechatronics Concept Designer (MCD) and Process Simulate. Solid Edge 2023 also leverages Siemens’ leadership in Model Based Definition (MBD), with a new Solid Edge Advanced PMI add-on that delivers high-quality consistent dimensioning for downstream applications that can take advantage of 3D annotated product data models.

36 November 2022 www.designworldonline.com DESIGN WORLD

CAE Solutions

The new Solid Edge Inspector add-on brings tools to automatically identi , label, and extract critical design and manufacturing characteristics for inspection and metrology purposes, automatically generates high-quality inspection data and reports that facilitate communication in downstream manufacturing processes.

New advanced manufacturing capabilities include new Roughing for 5-Axis Machining in Solid Edge CAM Pro, a new 4-axis Rotary Machining add-on and new wire EDM functionality. For those working at the leading edge of machining, the new Smart Machine Kits library provides easy access to standardized, professionally built machine simulation kits, enabling machinists to get up and running with full machine simulation in a action of the time typically needed.

Also introduced with Solid Edge 2023, Solid Edge SaaS brings value-based licensing combined with cloud-connected, anywhere access through Xcelerator Share. The new flexible licensing option available through a Solid Edge SaaS subscription allows capabilities to be added when needed, providing access to integrated add-ons for generative design, point cloud visualization, electrical routing, PCB collaboration, advanced simulation and much more. All of these can be easily mixed and matched with a flexible token system.

Meanwhile, product engineering data can be stored securely in the cloud and easily shared by teams and wider value chain, anywhere, anytime, on any device using Xcelerator Share. Augmented Reality (AR) capabilities can be used to see that same data in the context of the real world. DW

Siemens

Industries So ware siemens.com/solidedge2023

DESIGN WORLD November 2022 37 Millions of Springs 1-800-424-0500 CHEMICAL RESISTANCE to acids, bases and salts SPECIFIC COMPOUNDS OFFER ELECTRICAL INSULATION Volume resistivity, 75°F 1014 to 1015 ohm-cm THERMAL CONDUCTIVITY 0.5 to 2 W/(m·K) 154 Hobart Street, Hackensack, NJ 07601 USA +1.201.343.8983 • main@masterbond.com www.masterbond.com

Digital

Connecting the cloud to PLM

Onshape-Arena Connection is a new functionality that connects cloud-native Onshape product development and Arena product lifecycle management (PLM) solutions. The Connection enables product data to be shared instantly between the Onshape and Arena solutions with the click of a button, helping companies to accelerate the product development process and simpli collaboration with supply chain partners.

The Onshape-Arena Connection supports continuous, cross-functional product development that can significantly reduce costs and schedule impacts on the manufacturing

process. With the Connection, all stakeholders in the product development process – including design engineering, quality, procurement, and supply chain partners – are always working on the same version of a design. This allows for design reviews at any time and improvements to the product before investments are made in expensive manufacturing lines and tooling.

The Connection requires zero downloads, installs, or administration time and comes at no additional cost to Onshape and Arena users. DW

PTC | www.ptc.com

It’s not a web page, it’s an industry information site

So much happens between issues of R&D World that even another issue would not be enough to keep up. That’s why it makes sense to visit rdworldonline.com and stay on Twitter, Facebook and Linkedin. It’s updated regularly with relevant technical information and other significant news for the design engineering community.

CAE Solutions

rdworldonline.com

Congratulates

Watlow is a global industrial technology and manufacturing leader that provides world class engineering expertise and innovative thermal products and systems that enable customers to thrive. Watlow brings its experience to numerous industries, including semiconductor processing, energy and environmental technologies, medical, clinical and analytical and foodservice equipment, to name a few. Since 1922, Watlow has grown in product capability, market experience and global reach. The company holds more than 1000 patents and employs more than 4,200 team members working in 12 manufacturing facilities and five advanced technology and development centers in the United States, Mexico, Europe and Asia. Watlow covers 95 countries through sales and distribution offices around the world. The company continues to grow, while the commitment remains the same – to provide its customers with superior products and services for their individual needs.

www.watlow.com • 314.878.4600

Modular industrial robotics:

New kinematic simplicity for plant engineers

By Matt Prellwitz | Drive Technology Product Manager

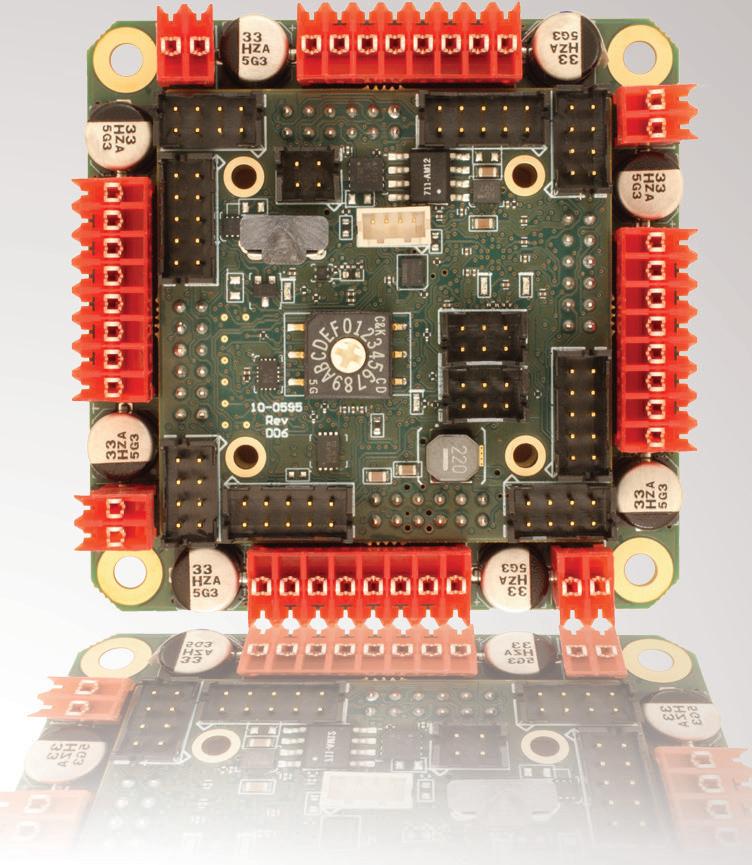

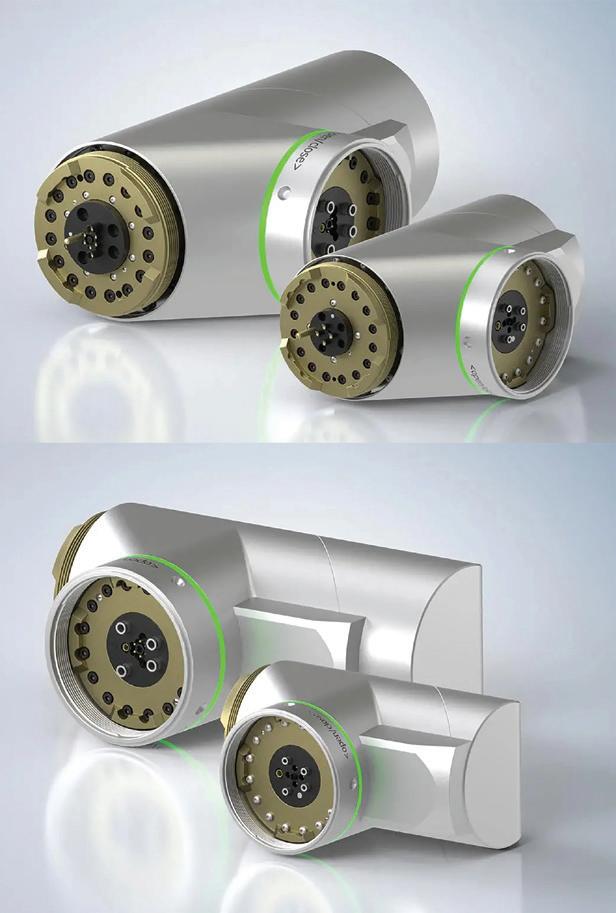

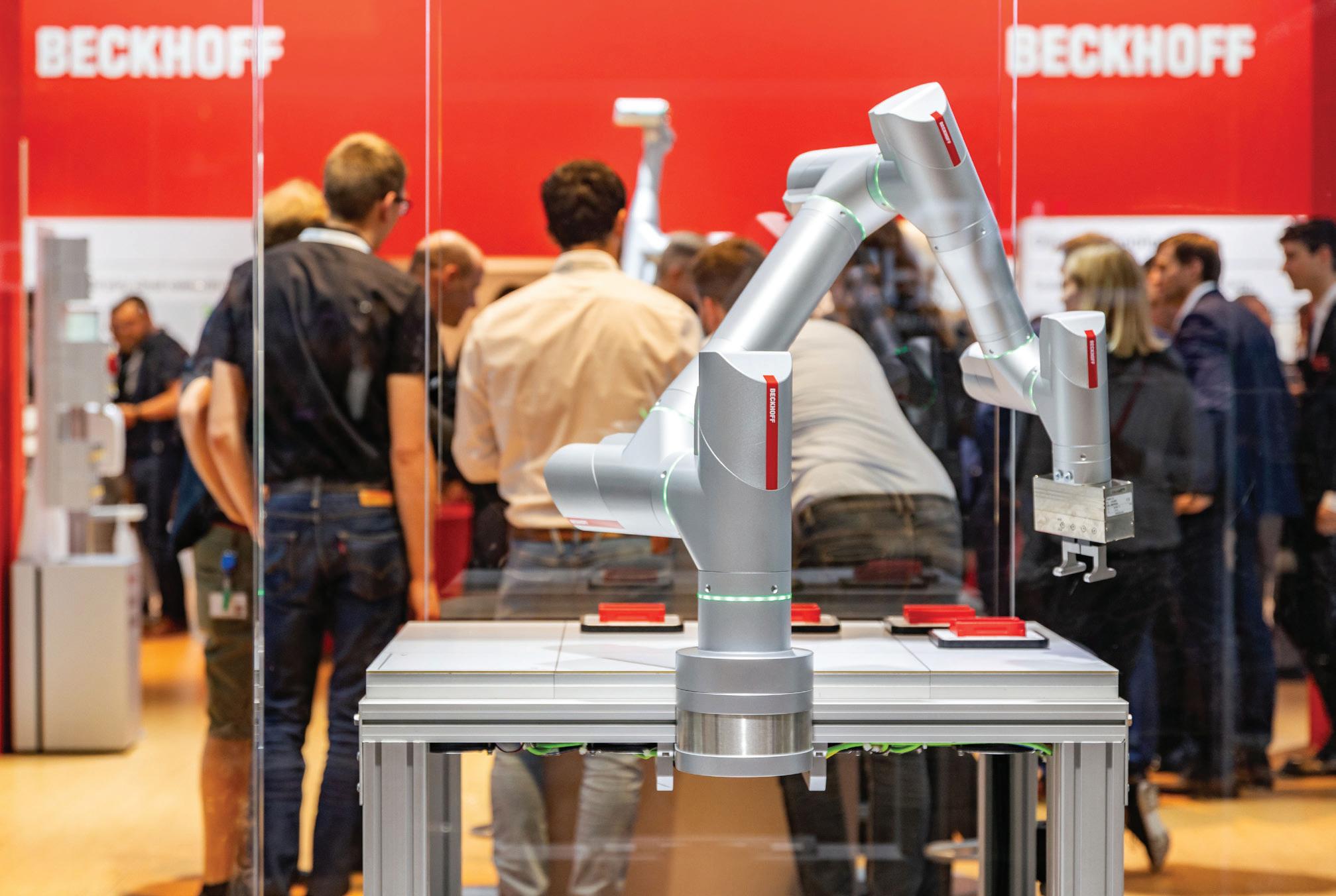

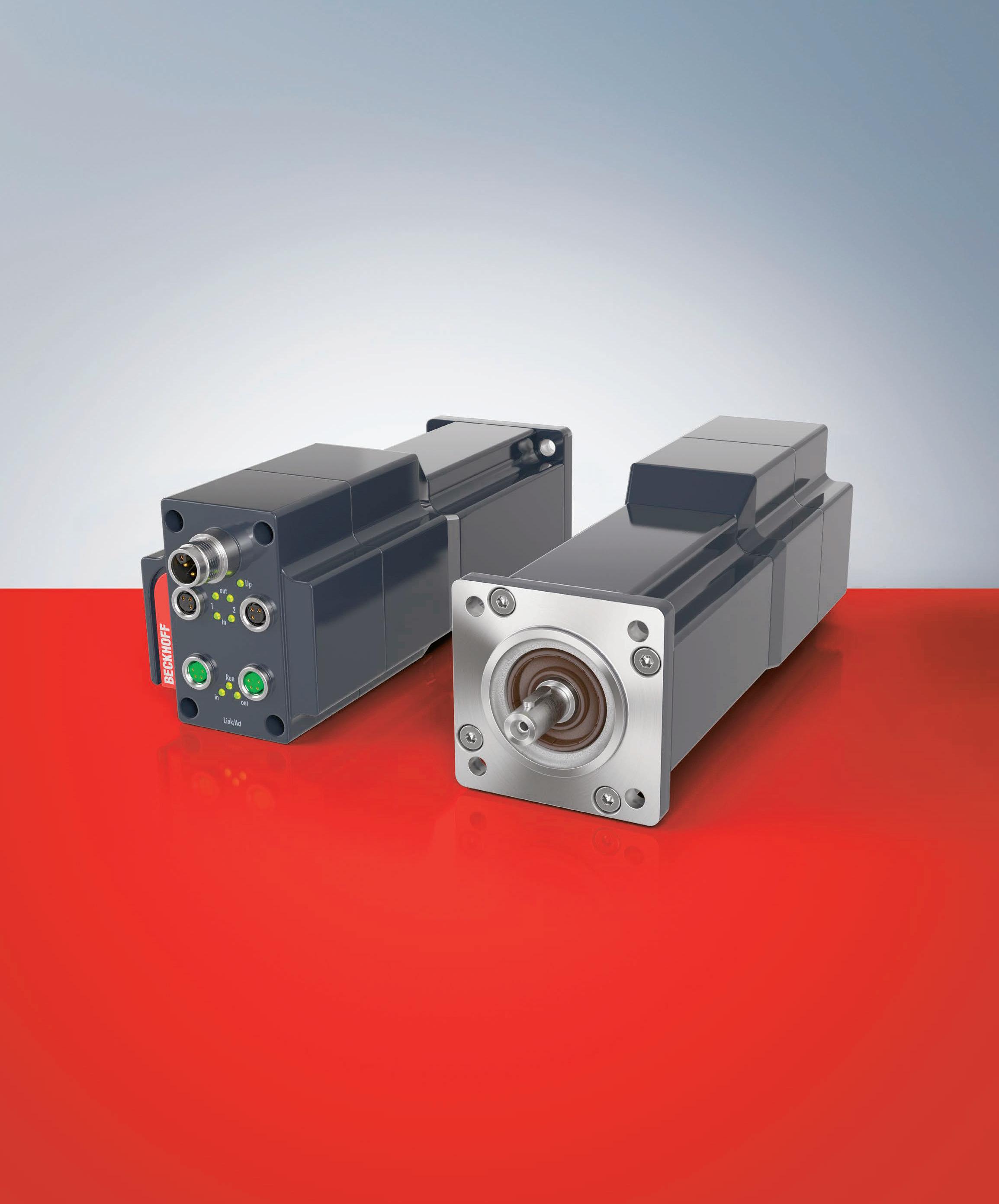

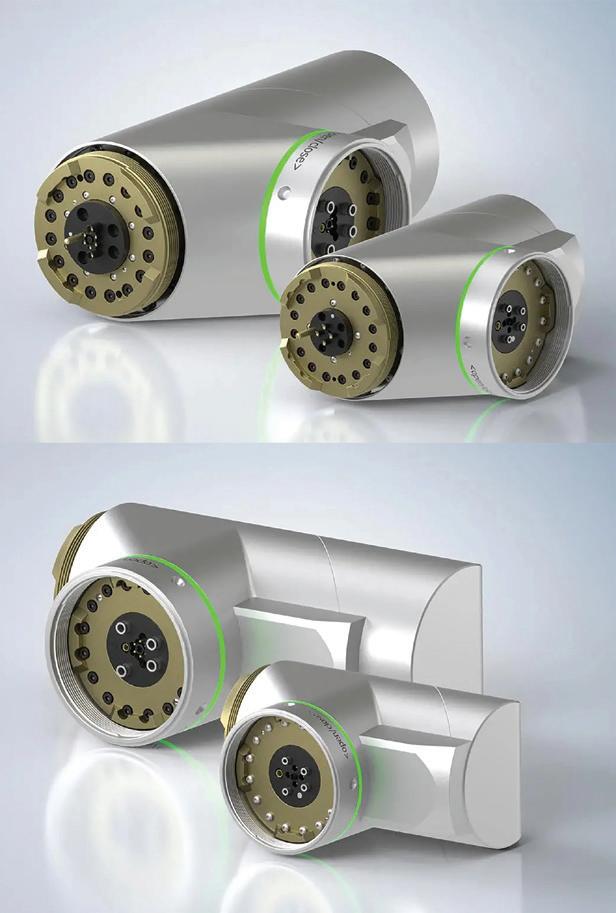

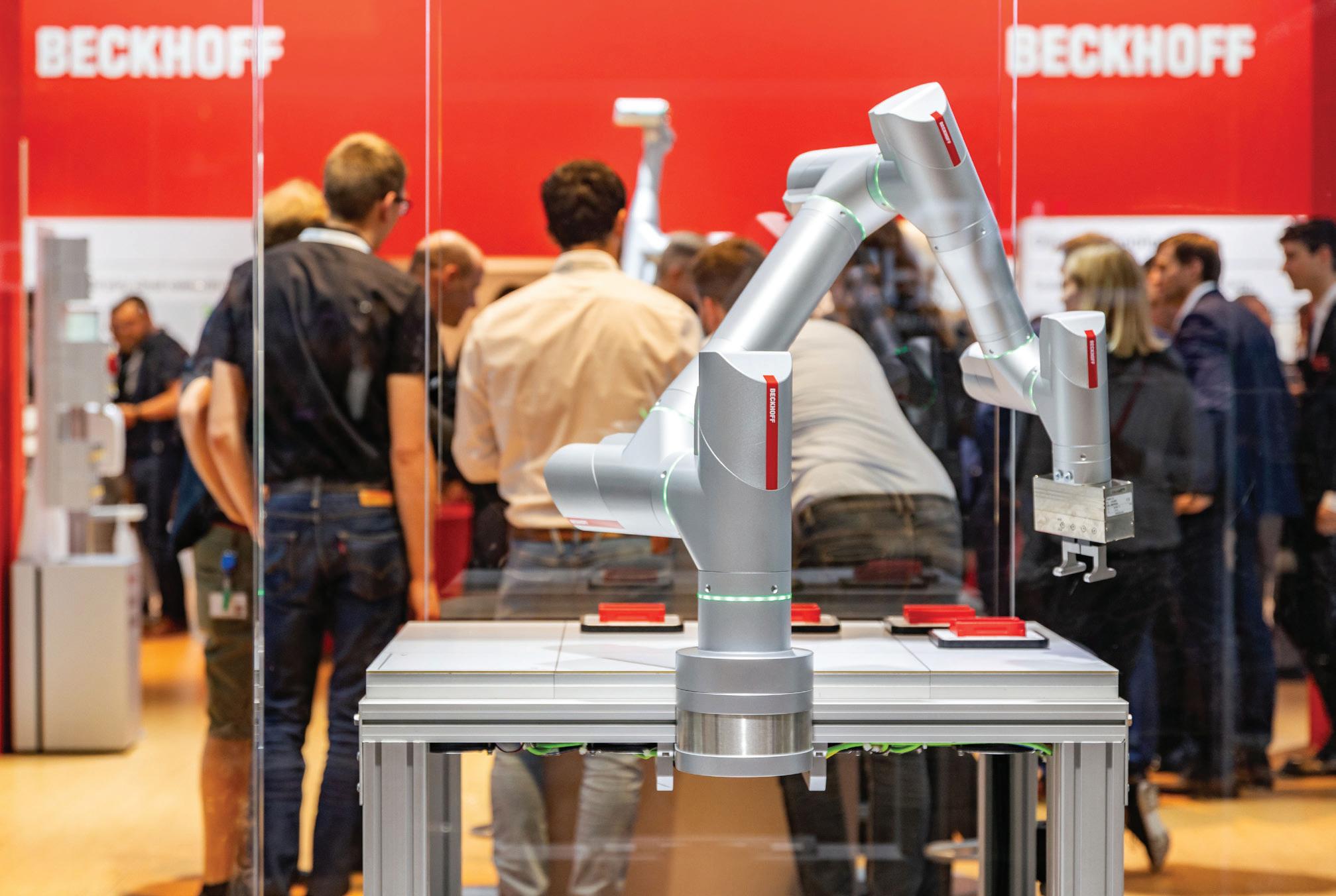

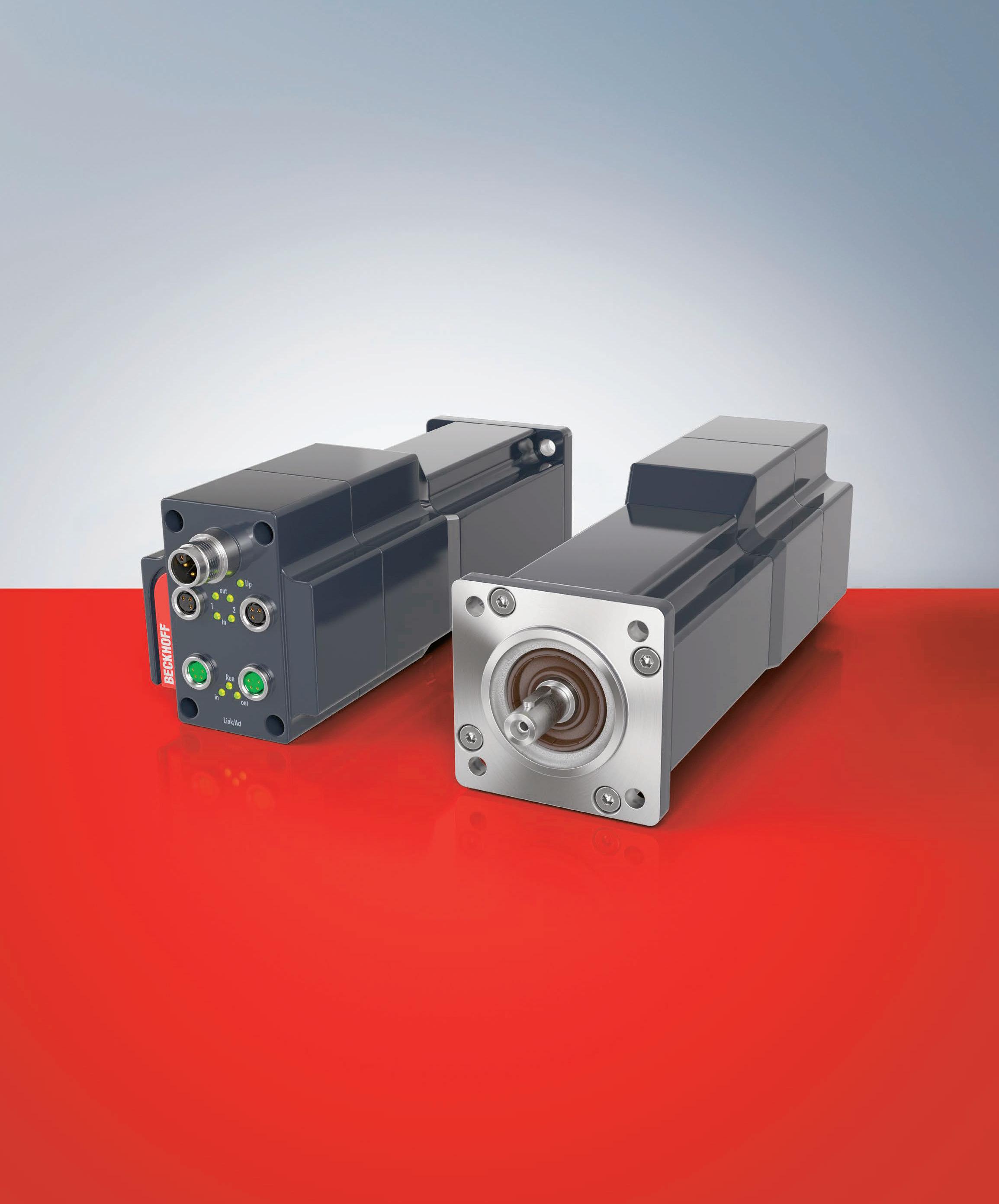

The Automation Technology for Robotics (ATRO) from Beckhoff Automation is a flexible and fully integrated multi-axis system that supports rapid robot assembly and programming.

In fact, ATRO complements other technologies in the motion supplier’s New Automation Technology product range — including PC-based control, industrial PCs, automation controllers, operator interfaces, I/O, servo drives, and motors.

Traditional six-axis serial robotics and selective compliance assembly robot arms (SCARAs) have prebuilt structures and rigidly defined motions and degrees of freedom (DOFs). In contrast, now an entirely new series of field-assemblable robots is both programmatically and physically configurable (and reconfigurable) by engineers and plant staff alike. Called Automation Technology for Robotics or ATRO, each completed assembly consists of a base

module and a unique combination of other modules (each recognized as separate EtherCAT devices by controls) to make functioning robot tables, arms, or delta assemblies.

More specifically, ATRO kinematics are built of modules from four categories.

ATRO base modules (the first upon which other modules are stacked) include a ruggedized base

40 November 2022 www.designworldonline.com DESIGN WORLD

a fully modular and easy-to-program robotics technology lets engineers and other plant personnel quickly select and connect kinematic modules to create industrial robot arms.

Now

SPONSORED CONTENT

with mounting flanges, power and networking connectivity ports, and an output media feed that begins the internal run of media through the assembly’s interior to allow limitless joint rotations. (More on this shortly.)

Active motorized modules are open-ended arm sections containing a planetary gearmotor, brake, servodrive, and control electronics in a ruggedized cylindrical housing. Ends are threaded and studded with mechanical locking Hirth joints to quickly secure to other modules in the series.

These subsystems come in a variety of diameters, lengths, and shapes; both straight I-shape and angled L-shape motorized modules come in five power sizes. Because each active module forms a complete drive system for one robot axis, the only external components needed are a power supply and controller. It’s a structure that significantly reduces the amount of control-cabinet real estate consumed by hardware to command the robot’s DOFs.

Connection or linkage modules come in I, L, and Y shapes and allow further customization of the robot morphology. Featuring the same ruggedized housings and mechanical

Sidenote on Hirth joints

ATRO robotic arms make copious use of Hirth joints — a two-part mechanical connection named after the German engineer Albert Hirth featuring halves that engage via tapered teeth on their mating axial faces. Complemented by rotary unions for communications and power connectivity, Hirth joints are key to the quickassemble nature of ATRO arms, as they eliminate the need to finagle the linkage modules into secure coupling.

end-connection geometries as the ATRO system’s motorized modules, these serve as the movable joints of ATRO assemblies.

Finally, user-specified system modules integrate applicationspecific gripping or other end-effector functions.

With these core module options, a vast array of robotics is possible, including:

• Single-axis rotary indexing tables and two-axis trackers

• Three-axis delta robots (with supporting hardware) and four-axis pick-and-place robots

• Five-axis palletizing arms

• Six-axis serial arms

• Seven-axis robotics capable of specialty articulation for machine tending and similar tasks necessitating extension into hard-to-reach spaces inside machinery.

In some cases, the automation solution’s mechanics and part count can be reduced. ATRO’s extremely flexible structure lets it satisfy a variety of applications — even those involving payloads to 10 kg and reaches to 1.3 m.

Programming and controlling ATRO robots

ATRO features EtherCAT connectivity that complements the way in which the robot modules are commissioned and programmed via TwinCAT software. The latter features a vast model library to support standard as well as custom industrial kinematics for easier integration of robotic handlers into machine workcells. In contrast, traditional off-the-shelf SCARA and fixed serial robots are rarely a perfect fit for pre-existing or finalized workcell elements … thus complicating the setup of real-world applications.

The ATRO interface within TwinCAT supports 3D simulation of single robots to let end users build robots themselves using the base, active, and linkage modules just described. From there, virtual workpieces, trays, tables, baskets, machine access windows, imported machine CAD files, and obstacles (such as pillars, walls, and workcell fencing) in the TwinCAT GUI can be modeled to let the user define how the robot should interact with or avoid them.

Pick, turn, place, and myriad other moves can be set in the desired sequence and then exported.

DESIGN WORLD www.designworldonline.com November 2022 41 •••••••••••••••••••••••••••••••••••••••••••••••••• •••••••••••••••••••••••••••••••••••••••••••••••••• •••••••••••••••••••••••••••••••••••••••••••••••••• •••••••••••••••••••••••••••••••••••••••••••••••••• ••••••••••••••••••••

Once the controller receives the exported file, it builds the entire PLC code. Then users simply log into the controller via the GUI and click an enable button to run the robot through its motions. Coordination with advanced conveying systems and even levitating motor installations is possible, as are expansive configurations with as many as 16 ATRO robots.

Structures are simply scanned by the control software, and the TwinCAT robotic functions automatically create the corresponding control application — including a digital twin. (Where needed, the digital twin within TwinCAT can define stresses on ATRO’s mechanical components.) In-the-field teaching of ATRO systems is similarly easy; users simply grab the robot, move its connected modules through desired positions, and set the path and points via a connected HMI.

To be clear, users with different skillsets can choose from three programming options — basic routines

(for manual robot teaching), moderately sophisticated routines (for users who feel comfortable building, importing, and defining machine elements), and advanced routines for TwinCAT experts with proficiency in 3D simulation, coding operations, and line-by-line tweaking of automatically generated programming (as IEC 61131-3 structured text, ladder logic, or function-block diagrams — FBDs).

Physical system connections and communications

ATRO’s tight TwinCAT integration allows control of multiple robots via one controller. Even machine-vision image processing, machine learning, functional safety, and direct cloud integration (to support enterprise-level analysis and predictive maintenance routines) are possible. Synchronization of ATRO systems with XTS and XPlanar adaptive product handling systems within this common environment minimizes communication delays.

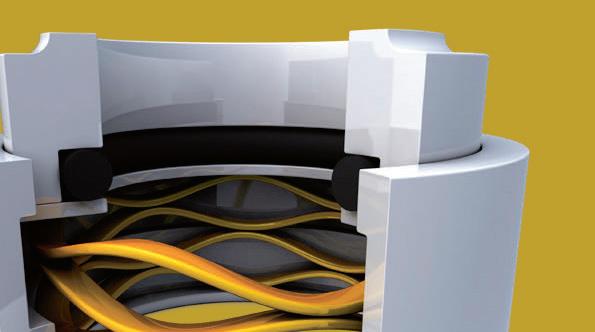

As mentioned, ATRO systems can also endlessly rotate at each joint. That’s due to:

• The gearmotor design in active modules

• Multi-turn servo-axis tracking of position

• Routing of power, communications, and other fluid media through the center of each robot module via rotary unions and Hirth joints.

The latter is particularly somewhat unique — especially as connections include four for compressed air, vacuums, water, and other fluids; EtherCAT and Gbit Ethernet; and 48-V as well as high-voltage AC power. All these connections render the ATRO capable of accepting various vendors’ end effectors and grippers (whether electromagnetic or pneumatic) which by definition are exceptionally job specific. Where might limitless joint rotation prove useful? Well, this gives ATRO

SPONSORED CONTENT

42 November 2022 www.designworldonline.com DESIGN WORLD

Beckhoff ATRO robotics are suitable for use in intralogistics, material handling, fabrication, medical assembly, and packaging applications.

systems maximum reachability as well as the ability to take especially short (read: fast) paths to reach given positions in 3D space. What’s more, it eliminates the bulkiness of cables run along the robot’s exterior as well as interfering torques so common in robots and collaborative robots (cobots).

The use of EtherCAT-standard LED communications (in the form of illuminated bands on every ATRO module) provides local diagnostics information. A module glowing blue indicates the ATRO is in teaching mode. Green indicates the module has a reliable connection and is ready to operate. Yellow indicates that an operation is being processed; red indicates the presence of an issue.

What prompted ATRO development — and emerging applications

ATRO satisfies a need for easy-toassemble custom machine-tending options, especially those requiring arms capable of reaching around obstacles within large equipment. Its customizable kinematics can also handle variable payloads and execute particularly complicated motions. Consider an application from the machine-tool industry — that of milling. Here, ATRO controls can nimbly interpolate the motion needed from the end effector to grasp, orient, and load workpieces into the machine … and then nimbly reverse the process once milling is complete.

Though ATRO systems aren’t yet certified for use as cobots, they do include 17 different drive-based safety modes, including limited speed and safe acceleration settings. The first cutting-edge ATRO permutations have taken the form of so-called octo-robots for advanced assembly and material handling applications.

Beckhoff Automation www.beckhoff.com

ATRO systems from Beckhoff adapt to tasks needing multiaxis motion. They’re also freely scalable, customizable, and expandable.

After programming, ATRO robotics use EtherCAT for direct integration into PC-based controls for automatically optimized workcells. In fact, one industrial PC can command multiple ATRO robots. Besides simplifying installation, that can also trim cost.

DESIGN WORLD www.designworldonline.com November 2022 43

for power-off considerations brakes

Motion Control 44 November 2022 www.designworldonline.com DESIGN WORLD Top 12design •••••••••••••••••••••••• •••••••••••••••••••••••• ••••••••••••••••••••••••

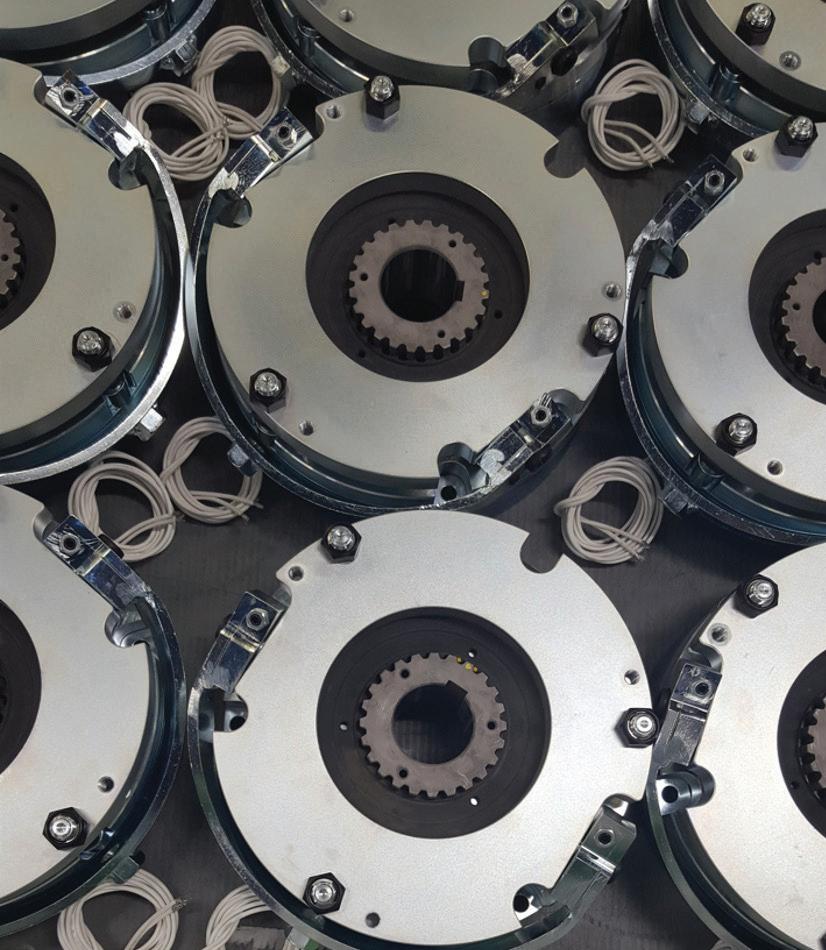

vehicles such as automatedwarehouse AGVs rely on power-off brakes for safe operation. | Vanit Jan via Dreamstime

brakes

demands fresh design approaches leveraging leading brake manufacturers’ accumulated design experience.

Key to optimizing designs for life, cost, and performance is early collaboration with the brake manufacturer.

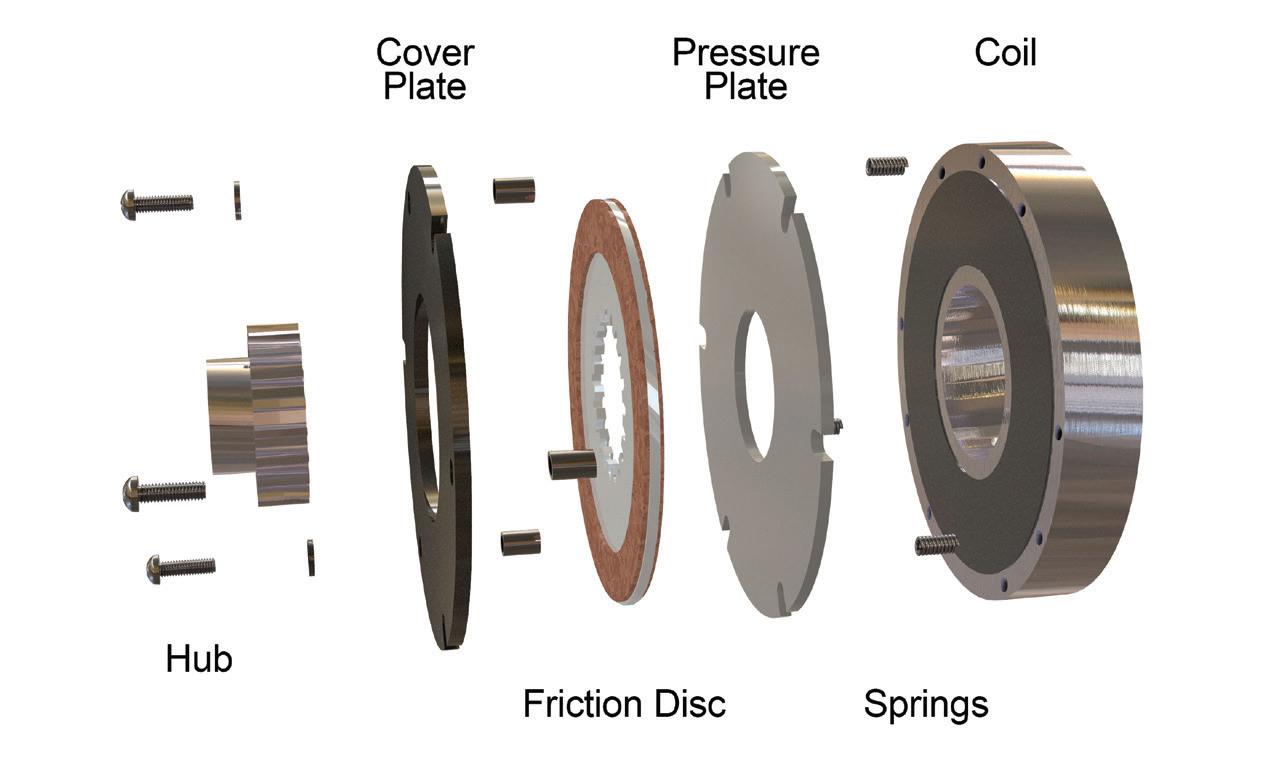

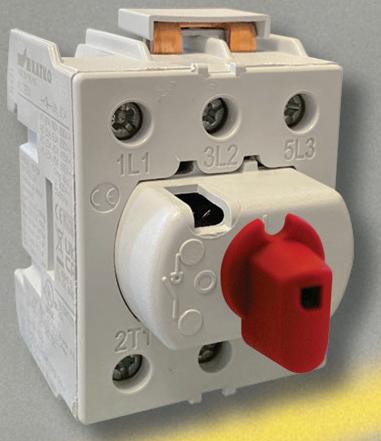

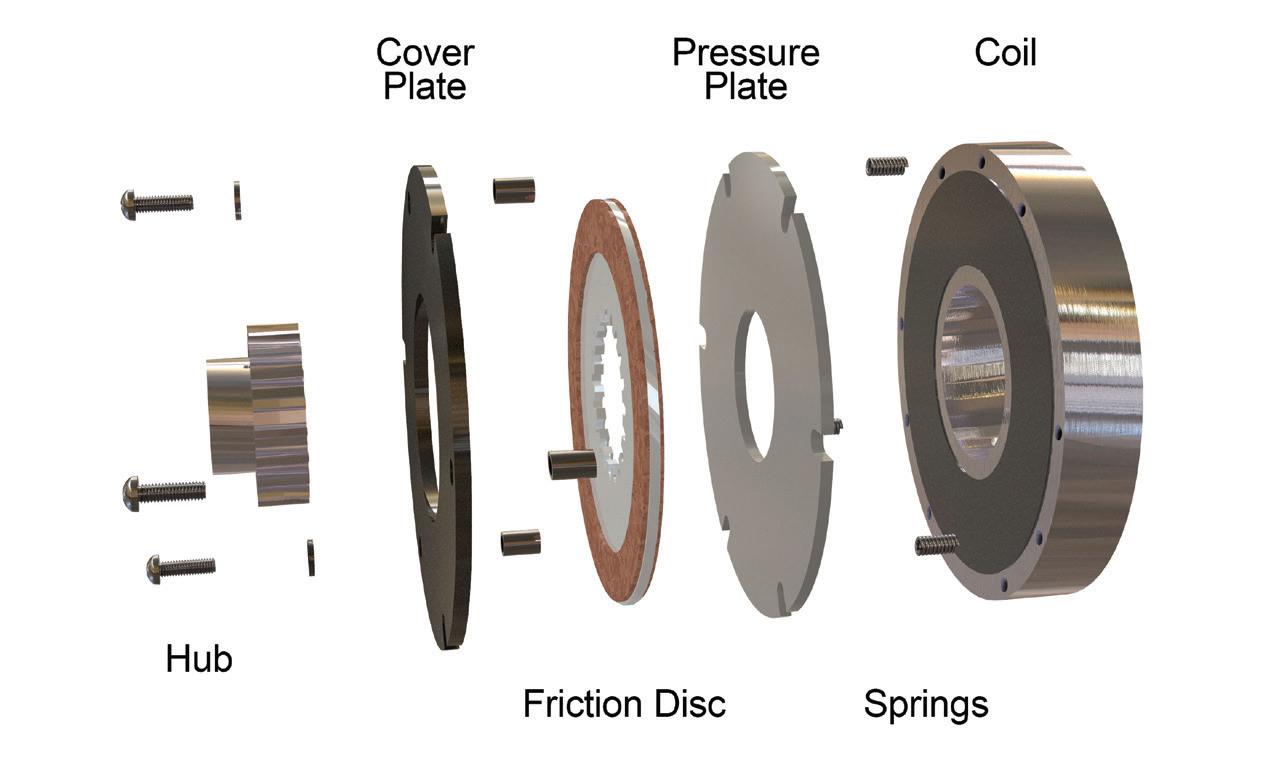

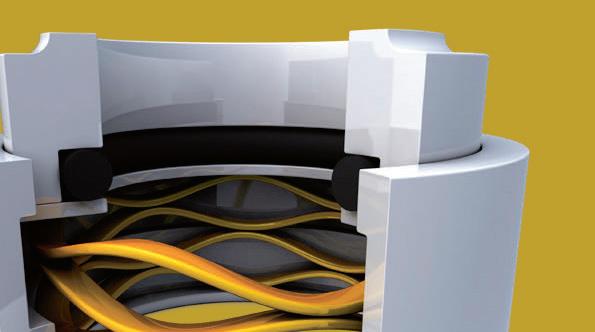

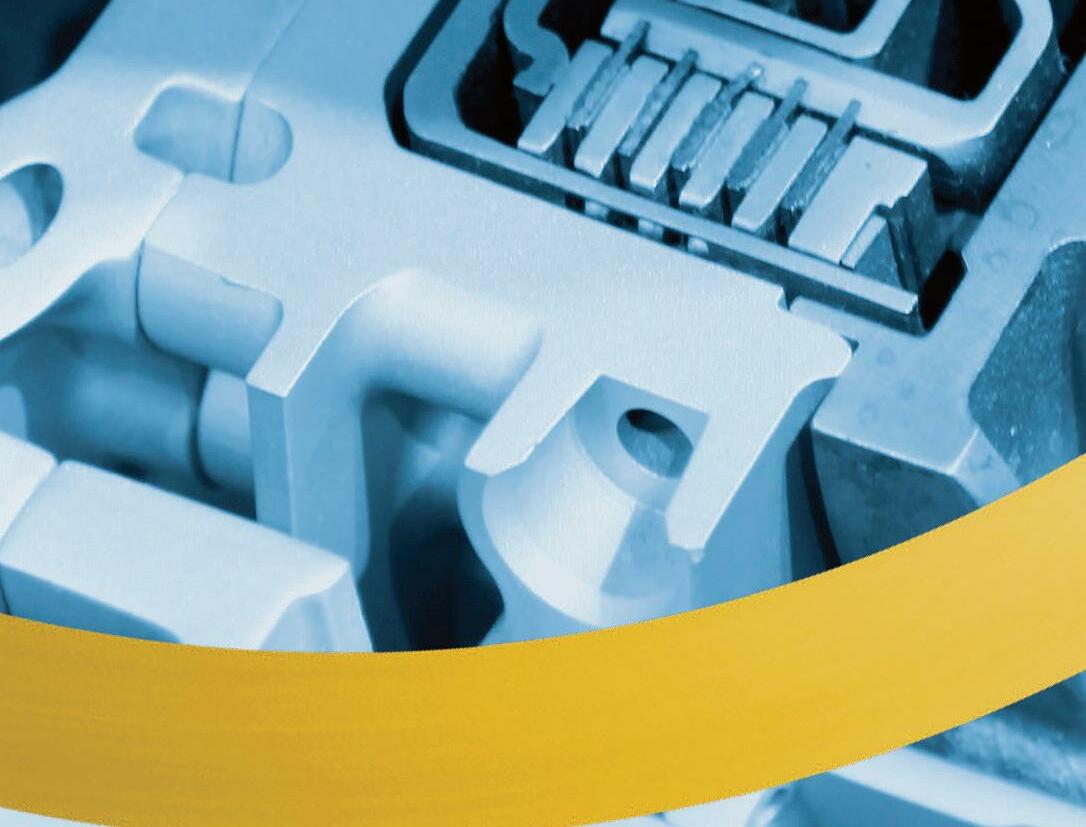

Machine designers in the motion-control industry recognize powero brakes by the following terms: Holding brakes … spring-applied brakes … failsafe brakes … parking brakes … negatively actuated brakes … and permanent-magnet brakes.

No matter what an engineer likes to call them, these brakes serve the same purposes. Most frequently, these brakes perform as safety devices by managing motion control — namely through stopping, holding, or emergency e-stop functions. They also provide accuracy or positioning.

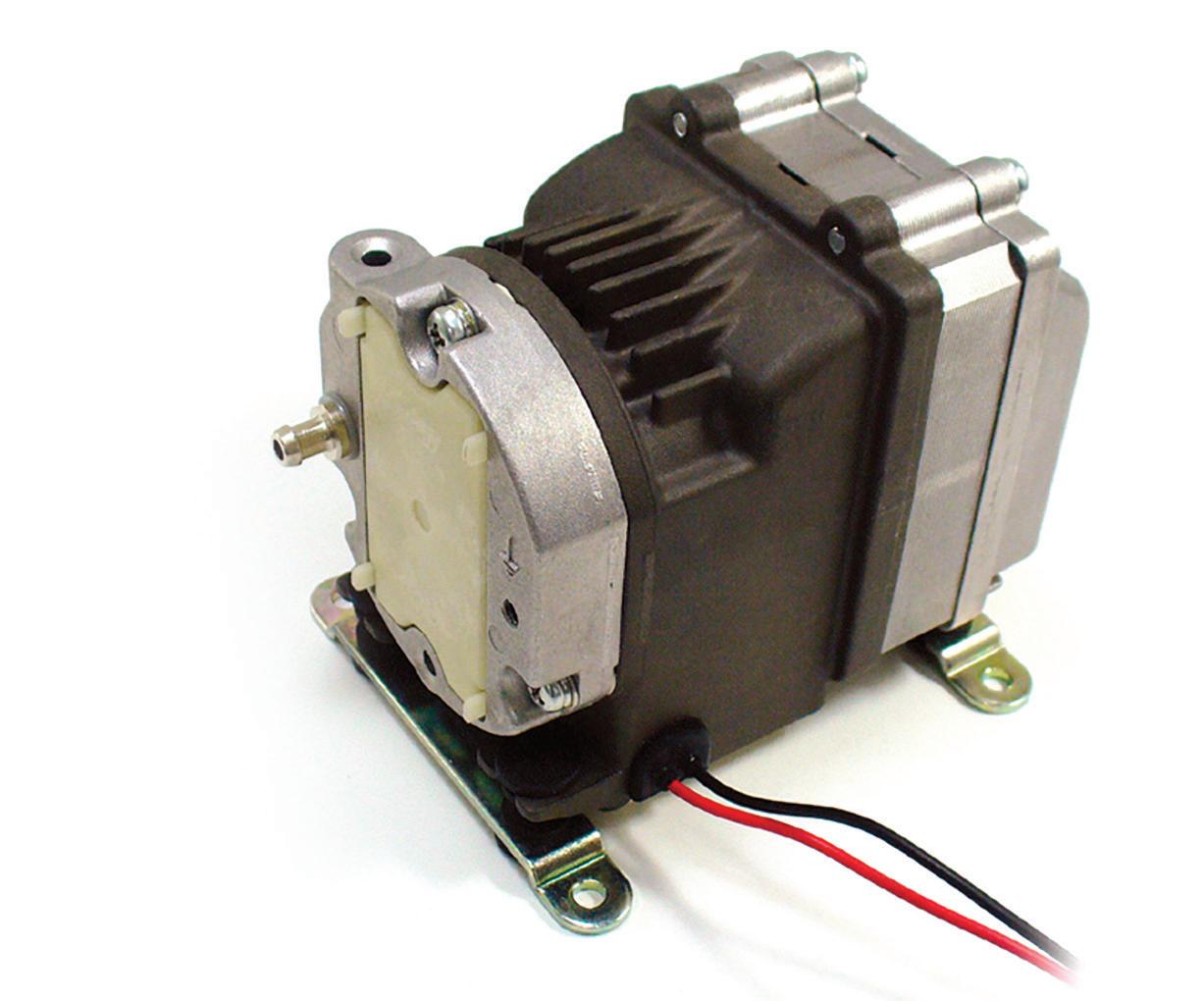

While spring-applied brakes actuate hydraulically, pneumatically, electrically, or manually, here we’ll focus on electromagnetic brakes that are electrically actuated. These are the most prevalent spring-applied brake worldwide … and the market for them is rapidly growing.

Found in a variety of applications, the most common applications for spring-applied electrically actuated brakes include servomotors, robotics, mobile robots, warehouse automation, wheel drives, hoists, elevators, doors and gates, industrial automation, surgical tools, grippers, conveyors, actuators,

automotive automation, and escalators. Now we’ll outline the top design parameters and approaches to overcome those concerns.

One: Power-off brake torque

When specifying a power-o brake, the first question to answer is: How much torque does the axis need?

The two torque ratings for brakes are static torque and dynamic torque.

On applications such as wheel drive brakes, the requirement is typically for holding only — a function that relates to static torque. Here, the motor brings the vehicle to a stop and then the

Brian Mather | Ogura Industrial Corp.

The proliferation of new applications for power-off

DESIGN WORLD www.designworldonline.com November 2022 45

•••••••••••••••••••••••••••• •••••••••••••••••••••••••••• •••••••••••••••••••••••••••• ••••••••••••••••••••••••

| Dreamstime.com

Electric

brake engages. Therefore, static torque is the primary concern here.