Advanced Engineering. Prototyping. Product Development. Micro-Manufacturing. Learn More at Resonetics.com

Medical equipment requires flawless performance, every time. That’s why so many Bodine products drive everything from complex diagnostic machinery, patient lifts and beds, to medical stirrers and centrifuges. Our gearmotors, motors and controls provide the efficient and reliable power needed for applications when second-best is simply not an option.

Visit bodine-electric.com for more Information

bodine-electric.com • info@bodine-electric.com • 773.478.3515 (USA)

EDITORIAL

Executive Editor Chris Newmarker cnewmarker@wtwhmedia.com @newmarker

Managing Editor

WEB DEV/DIGITAL OPERATIONS

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Jim Hammerand jhammerand@wtwhmedia.com

Senior Editor Danielle Kirsh dkirsh@wtwhmedia.com

Pharma Editor Brian Buntz bbuntz@wtwhmedia.com

Associate Editor Sean Whooley swhooley@wtwhmedia.com @SeanWhooleyWTWH

Editorial DirectorDeviceTalks Tom Salemi tsalemi@wtwhmedia.com

VP Lifesciences Mary Ann Cooke mcooke@wtwhmedia.com 781.710.4659

CREATIVE SERVICES

VP of Creative Services Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

DeviceTalks Tuesdays is a weekly virtual event that brings the insights and energy of our in-person events to your desktop.

Each DeviceTalks Tuesday will kick off with a quick briefing from the editors of MassDevice and Medical Design and Outsourcing. These presentations will give attendees insights on what trends will be moving medtech in the days to come.

Be sure to check back frequently as new live events continue to be added.

WATCH devicetalks.com

Digital Media Manager Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

Web Dev./Digital Production Elise Ondak eondak@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Rep Tracy Powers tpowers@wtwhmedia.com

Customer Service Rep JoAnn Martin jmartin@wtwhmedia.com

Customer Service Rep Renee Massey-Linston renee@wtwhmedia.com

Customer Service Rep Trinidy Longgood tlonggood@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator Matthew Kulkin mkulkin@wtwhmedia.com @WTWH_Matt

Webinar Manager Matt Boblett mboblett@wtwhmedia.com

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

WTWH Media, LLC 1111 Superior Avenue, 26th Floor Cleveland, OH 44114 Ph: 888.543.2447 Fax: 888.543.2447

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Production / Marketing Designer Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

EVENTS

Events Manager Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

Videographer Manager Bradley Voyten bvoyten@wtwhmedia.com @bv10wtwh

Videographer Garrett McCafferty gmccafferty@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com FINANCE Controller Brian Korsberg bkorsberg@wtwhmedia.com

MEDICAL DESIGN AND OUTSOURCING (ISSN 2164-7135) is published 6 times per year: (January, March, May, July, September, November) by WTWH Media, LLC, 1111 Superior Ave., 26th Floor, Cleveland, OH 44114.

PERIODICALS POSTAGE PAID AT CLEVELAND, OH AND ADDITIONAL MAILING OFFICES.

POSTMASTER: Send address changes to Medical Design & Outsourcing, 1111 Superior Ave., 26th Floor, Cleveland, OH 44114.

Medical devices have never been more complex than they are today.

They’re getting smaller, smarter and safer. They’re more effective, intuitive and sustainable. Medical device companies manufacture some to last longer — and then redesign others for just a single sure-fire use.

Device developers have more options than ever: advanced materials, cutting-edge components and new technologies like 3D printing, artificial intelligence and robotics that lend a helping hand in the operating room and on the production line.

It’s also never been harder to go it alone.

Collaboration is more important than ever, and we at Medical Design & Outsourcing are proud to help with our latest Medical Device Handbook. We’ve tapped our in-house expertise — along with technical professionals and leaders at major medical device OEMs, contract manufacturers, suppliers and partners — to offer actionable information and advice to help medical device designers and engineers break new ground.

In this edition, we’ll once again cover a wide range of topics: components, drug delivery, manufacturing, machining, molding, materials, product design and development, regulatory, reimbursement, software, intellectual property, sterilization services and tubing. All of these articles will also be available online at wtwh.me/ handbook, along with content across all of those categories from previous handbook editions.

To highlight just a few articles, MDO readers of this year’s handbook will:

• Hear Medtronic CEO Geoff Martha, Abbott Medical Devices EVP Lisa Earnhardt and ResMed CEO Mick Farrell discuss how medtech companies can take advantage of healthcare ecosystems;

• Get tips from Boston Scientific for keeping production lines staffed and running despite the global labor shortage;

• Understand the blood clot science behind Johnson & Johnson’s Embotrap stent retriever for thrombectomies to treat ischemic strokes;

• Learn how DermaSensor designed a handheld device for earlier detection of skin cancer;

• Confront and conquer the challenges of developing devices for cardiac ablation;

• Consider the future of artificial intelligence in medical devices with regulatory and reimbursement experts from the industry and FDA.

Outsourcing. Enjoy — and thanks for

American-made Interpower® North American 5-15, 5-20, 6-15, and 6-20 hospital-grade cords, and international hospital-grade cords provide the correct amperages and voltages for vital medical equipment requiring correct amperages and voltages such as portable CT Scanners and X-ray machines, medical-grade treadmills, ECMO machines, and ventilators.

When designing and manufacturing hospital-grade products worldwide, it’s essential to know the medical requirements of the country of export—select hospitals in Australia, Canada, Denmark, Japan, and the United States have proprietary requirements. All Interpower hospital-grade cords are manufactured to the highest standards. Interpower hospital-grade cords come with NEMA hospital-grade plugs bearing the “green dot,” and surpass UL 817 (18.2.4.1) and C22.2 No. 21-14 requirements for hospital-grade power cords and cord sets.

“We test more than the standards require for our own benefit,” Interpower Product Development Manager Ron Barnett said. “We do so because it lends better reliability to our design.”

• World-class customer service

• Value-added services such as lengths, colors, & packaging

• No minimum order or dollar requirements

• Quantity price breaks

TOR ALDEN leads SteriPack’s usercentered product development group as global VP of design, human factors and development. His expertise focuses on over 30 years of the design, development, research, and human factors of medical, life science and consumer healthcare products. Alden earned his bachelor’s degree in industrial design from Syracuse University and received his Master of Science in management of technology (MOT) from Stevens Institute of Technology.

JOHN BANKS, assembly operations manager at Beacon MedTech Solutions, oversees the manufacturing operations of all products in the Life Sciences portfolio to ensure on-time delivery and quality standards compliant to ISO 13485, ISO 9001 and cGMP. He brings 10-plus years of experience in both technical and leadership roles within the medical device and biopharma industries to help companies accelerate success in the market.

LISA BARTAKOVICS is the senior director of global regulatory affairs and quality at Avery Dennison Medical (ADM), overseeing regulatory affairs including FDA 510(k) submissions of combination products, Class III Design Dossier approval and international product registrations. She is also responsible for the quality system and quality performance, including document control system standardization and bestprocess implementation across ADM's three manufacturing sites in Mentor, Ohio; Turnhout, Belgium; and Longford, Ireland.

DAVID DEVINE is the business development manager, Medical, Branson Welding and Assembly at Emerson. Devine earned a degree in mechanical engineering from the University of Dayton, where he began his career with Emerson as a manufacturing engineering co-op in Sidney, Ohio. He has spent six years with Branson Welding and Assembly, starting as a sales engineer.

DANIEL FRIEDRICHS, Ph.D., leads development engineering efforts at Minnetronix Medical for the commercialization of surgical energy devices including in vivo electroporation systems and other energy-based medical, surgical, and drug-delivery therapies. He is named on more than 35 patents and has worked with an extensive network of clients seeking to commercialize a wide array of technologies.

TONY KAUFMAN is new business ventures lead for the Medical Materials & Technologies Business at 3M and has more than 24 years of medical device design, development and manufacturing experience. Kaufman is Lean Six Sigma Black Belt certified, has utilized finite element analysis modeling in various ways to solve challenges and accelerate product development, and holds a degree in biological systems engineering from the University of Nebraska-Lincoln.

MATT KNUTSON is vice president of manufacturing operations at Donatelle, where he is responsible for production, manufacturing engineering and automation, quality, maintenance and facilities. Knutson has designed, implemented and overseen implementations of both fixed automation and flexible automation systems throughout his career.

RICHARD LANDRY, director of operations at Beacon MedTech Solutions, applies decades of plastic injection molding and contract manufacturing expertise to oversee all manufacturing operations. Working with a cross-functional team, Landry elevates customer programs through particular expertise in engineering and operations management, with an emphasis on quality, training and continuous improvement.

ROBBIE LONG is a senior technical applications engineer with Fictiv and has a long history of working in prototyping and digital manufacturing. Long attended the University of West Georgia and is based in Atlanta.

MATT LOWE, chief product and marketing officer at MasterControl, is a medical device expert with experience in product development and product management at Ortho Development Corp and Bard Access Systems, a subsidiary of BD. Lowe has launched more than a dozen medical devices, has five patents issued, wrote an FDAcleared 510(k) and managed a multisite, multiyear postmarket clinical study for orthopedic devices.

ARJUN LUTHRA is the commercial director at Biointeractions, an R&D company specializing in biomaterial coatings for devices, instruments and implants. The portfolio of multi-action materials confronts chronic challenges such as thrombus formation, infections, device-related complications and other biocompatible challenges.

GAURAV MANCHANDA, medical market development director at Formlabs, launched and leads the medical division for the 3D printing company, where his goal is to advance 3D printing in the healthcare industry by combining clinically validated 3D printing technology, in-house QA/RA expertise, accessible pricing, and a wide range of materials. Manchanda leads 3D printing market development in priority segments including medical devices, pointof-care, orthotics and prosthetics, medical education, and the life sciences.

GREGORY MONTALBANO is the principal of MIDI, a turnkey product development consulting firm specializing in the design and development of medical, biotech, life sciences and home healthcare devices and systems. With 30-plus years of experience, Montalbano has serviced clientele ranging from startups and emerging companies to Fortune 500 organizations representing industry segments from both domestic and international markets.

ZACHARY MURNANE is a senior research and development applications manager for Honeywell’s Spectra business, which produces Spectra MG Bio, an ultra-high molecular weight polyethylene (UHMWPE) fiber. He has more than ten years of experience leading manufacturing and new product development initiatives within Fortune 500 companies, most recently with a focus on expanding the use of UHMWPE within the medical industry.

JAY NOBLE heads Integrated Computer Solutions’ global team of engineers, leveraging his more than 25 years of experience leading global software engineering and professional services teams in the medical, military and industrial spaces. He holds a B.S. in computer science from the University of Massachusetts in Lowell, an M.S. in computer science from Boston University and an MBA in international business from Suffolk University in Boston.

PHILIP REMEDIOS is principal and design director at BlackHägen Design, an R&D consultancy focused on medical device innovation. He has a background in design and engineering and is a named inventor on over 35 patents.

ANDREW (A.J.) TIBBETTS is a shareholder in the Intellectual Property & Technology practice group in Greenberg Traurig's Boston office. Formerly a software engineer, Tibbetts works with organizations large and small, serves on the board of MassMEDIC and guides digital health efforts for MassBio.

FLORIAN SOLZBACHER is the cofounder and chairman of Blackrock Neurotech and professor and chair of the Department of Electrical and Computer Engineering at the University of Utah. A leading authority on chronically implantable sensors for electrophysiological and chemical biomarkers, Solzbacher drives the technological vision for Blackrock with a focus on restorative tech for neurological conditions.

STEPHANIE VAN NESS is associate director of marketing and chief storyteller at Integrated Computer Solutions, writing about user experience design and innovations in technology, from gesture-controlled medical devices and extended reality-powered surgical training simulators to autonomous truck fleets. Her work has appeared widely in medical device and software publications. She holds a journalism degree from Boston University.

COMPONENTS:

How fluorescent signals could allow for deeper sensor implants in the brain; How the Utah Array is advancing BCI science; 5 steps to help medical device makers deal with semiconductor shortages

In vivo electroporation is an engineering solution for drug and gene delivery; How Qnovia aims to use inhaled therapeutics for smoking cessation

Best practices when outsourcing medical injection molding; Two strategies for managing labor shortages at Boston Scientific; Leverage automation to get ahead of supply and demand; 5 questions to ask when transitioning from medtech product development to manufacturing; Affordable 3D-printed medical devices reach commercialization; Three considerations for reshoring your medical device components and assemblies; Is there a better way to weld medical wearable components?

MATERIALS:

How antimicrobial coatings of the future will better prevent infections; Small but mighty medical fiber: Minimally invasive surgery demands new materials; Braiding technology options for innovative biomedical textile structures

PRODUCT DESIGN & DEVELOPMENT: 3 critical starting points for medical device design usability research; Medtronic’s Design for Reliability and Manufacturability after the reorganization; This smart, dissolving pacemaker communicates with sensors on the body for remote patient monitoring; 4 ways to usher in next-gen medical device design; How to center patients when designing distance care medical devices

REGULATORY, REIMBURSEMENT, STANDARDS & IP: Navigating MDR’s newly charted waters; The future for AI in medical devices; IP for healthtech AI; Staying on the compliant side of change control regulations

SOFTWARE: Pushing the boundaries of brain-computer interface software; Meticulous software testing can save the lives of medical device users

STERILIZATION SERVICES: FDA reports sterilization challenge progress as EPA takes aim at EtO emissions

TUBING:

How Medtronic designed the next generation of GI bleeding treatment; Design challenges to overcome when developing cardiac ablation devices

PRODUCT SPOTLIGHT AD INDEX

Medtech leaders discuss how to get the most out of a burgeoning healthcare ecosystem.

DermaSensor’s innovative device could save lives with early skin cancer detection capabilities.

The founder of Johnson & Johnson MedTech’s stroke science research arm explains the science of blood clots and how that influenced the Embotrap’s design.

CYROLITE® has been working in hospitals and labs for more than 40 years. Thanks to their excellent properties, our high-performance acrylics are perfect for use in a wide range of medical devices. CYROLITE® is highly transparent and easily processed into intricate parts. It can be reliably sterilized using most common methods and is BPA- and DEHP-free. This has impressed both patients and healthcare professionals alike: CYROLITE® meets the requirements of USP Class VI, ISO 10993-1, and REACH. You can find more details at www.cyrolite.com.

Medical Design & Outsourcing is excited to release the winners of our annual Leadership in Medical Technology program. Since we announced the nominees in our January 2022 issue and online, our user community has voted on what companies they feel best exemplify medical technology leadership in 14 categories. We are happy to celebrate the winners here.

Founded in 1990, Isometric’s success begins and ends with our people. Isometric is ISO 13485 certified with two adjacent facilities, Class 7 cleanrooms, and over 95 employees.

With unparalleled micro manufacturing capabilities, Isometric provides 100% in-house:

• Micro 3D Printing

• Micro Tooling

• Micro Molding

• Micro Automated Assembly

• CT Scanning

A global micro solutions leader, Isometric serves high precision medical market segments such as diabetes, ENT, ophthalmic, cardiovascular, neurovascular, orthopedic, drug delivery–and more. Isometric’s numerous micro solutions include micro fluidics, molded needles, catheter tips, sensors, transdermal patches, life science disposables, and neurovascular implant devices. Driven by ambition for innovation, Isometric’s team of experts use our internally developed Microns Matter® risk mitigation process to successfully meet tolerances and bring your micro parts to validation faster.

The world trusts Sava’s mechanical cable to power tomorrow’s surgical robots and endoscopic instruments. That’s a fact.

For over 50 years, Carl Stahl Sava Industries has been a staple in the manufacture of world-class surgical robotic, endoscopic device, implantable and wearable mechanical cable and assemblies. Using materials such as tungsten, stainless steel, nitinol, titanium and more, Sava has taken the time and invested greatly in perfecting the ultrafine cables powering the motion systems of the world’s most advanced surgical marvels.

Working alongside the most trusted names in contract manufacturing and surgical instrumentation innovation, Sava has a deep bench of experts with decades of collaborative experience.

Trelleborg Healthcare & Medical helps pharmaceutical and medical device companies improve patient quality of life by partnering in all stages of development, from concept to serial production to create engineered polymer solutions for demanding applications. Trelleborg’s global footprint is backed by experts with 30+ years of industry experience and a portfolio of capabilities, including micromolding, process automation, silicone extrusion, drugeluting solutions, silicone and thermoplastic molding and over-molding, multicomponent molding, device assembly, and silicone dipping and coating. Trelleborg’s Rapid Development Center helps medical device companies navigate and accelerate the development process from concept to market launch.

Rotor Clip is a globally recognized manufacturer of high-quality retaining rings, spiral rings, wave springs and hose clamps. Companies across a broad range of industries rely on Rotor Clip products, value-added services and expertise to build reliable and safe equipment for virtually any application.

Rotor Clip operates in the US, UK, Germany, China, and the Czech Republic - providing worldwide service to its customers. Recognized worldwide, Rotor Clip has received numerous quality awards from major OEMs, automotive manufacturers, and distributors. Rotor Clip also produces its products under IATF 16949, ISO 9001, AS9100, ISO 14001, ISO 13485, and TISAX standards.

Stock Drive Products/Sterling Instrument (SDP/SI) makes it easier for OEMs to get their products to market by designing and delivering precision components and complex drive assemblies while managing costs and inventories. Well known as the one-stop-shop, we provide mechanical and electromechanical components, engineering development, precision manufacturing, and problem-solving customized solutions.

Established in 1950, we are a proven partner to the most recognized names in medical, aerospace, defense, and robotics industries providing innovative solutions, worldclass quality, and engineering support from concept to completion. We look forward to working with you!

Accumold began in a rented garage in 1985. Our primary focus was and still is on very small micro-sized plastic parts and components that other companies can’t produce. The original Micro-Molder® was designed to help manufacture parts with minimal waste and short cycle times for electronic component manufacturing. Although there have been many innovations over the years the basic principals have remained the same and so has our commitment to micro-injection molding technologies.

Today the company now focuses on industries that require fast turn around and complex parts for high tech industries such as Micro Electronics, Micro Optics, and Medical, as well as new emerging markets and technologies.

TRACO Electronic AG , is a Swiss company with headquarters in Baar, Switzerland. TRACO markets its products worldwide under the registered trademark TRACO POWER. As a leading power supply specialist with more than 35 years’ experience we are dedicated to the design and manufacturing of high quality DC/DC and AC/DC power conversion products with an emphasis in medical approved solutions.

The standard product offering in medical grade power solutions includes 15~850 watt AC/DC power supplies in open frame, fully enclosed or encapsulated models and 1~60 watt DC/DC converters with PCB mounting.

With over 100 years of experience, Boker’s has earned the reputation as a stamping leader. They deliver precision stampings in a complete range of sizes: flat blanking and piercings up to 12” x 12” (flat) with thicknesses from .005” to .190” (varies by material) and draws up to 3” deep and 8” in diameter.

With numerous inside diameters, thicknesses and over 2,000 commonly specified and hard-to-find material options— including various types of steel, aluminum, brass, copper, nickel silver, plus non-metallic materials such as PTFE, polyester, fiber and nylon— whatever your requirements, if it can be stamped, Boker’s can turn it into the part you need.

Boker’s also delivers a wide selection of standard and nonstandard washers, spacers and shims. With over 32,000 stock tools, and outside diameters of .080” to 5.140” along with a variety of inside diameters, you have millions of fl at washer possibilities.

All stampings, washers, spacers and shims are available in short, medium and long runs with a 100-piece minimum.

Boker’s also offers 3D printing for prototyping, complete Statistical Process Control (S.P.C.) capability, inhouse tooling, and “Dock-to-Stock” and “Just-in-Time” programs.

Nitto Kohki USA, Inc. designs, develops, engineers, and continuously improves high quality air compressors and vacuum pumps for applications like medical devices, laboratory equipment, applied robotics and environmental sensing equipment.

Nitto Kohki’s unique linear free piston design has one moving part per pump— the piston. The result is a pump with exceptionally reliable performance in tough medical applications. The linear free piston concept enables Nitto Kohki pumps to be smaller and lighter than conventional aerators, allowing designers greater flexibility in system design.

Hobson & Motzer’s world-class facilities offer the most advanced technology in metal transformation and assembly. With more than 100 years of precision manufacturing experience, we have the capabilities and infrastructure to deliver on critical projects. Our commitment to lean and continuous improvement results in superior quality, as well as exceptional supply chain performance and customer satisfaction. Our extensive tool design and engineering expertise drives repeatability and efficient production. We offer precision rapid prototyping and project-based support, from concept to completion. Medical device components include endo-mechanical, electrosurgical, pharmaceutical, ophthalmic blade blanks, custom electrical contacts, and more.

ElectroCraft, Inc. is a global provider of dependable, application-engineered fractional-horsepower motor and motion products. The ElectroCraft Powering Innovation custom manufacturing services cover the following products: AC motors, PMDC motors, brushless DC motors, stepper motors, servo motors, gearboxes, gearmotors, linear actuators, drives, servo drives and integrated motor drives.

Our products are found in thousands of different applications within industrial, commercial and consumer product markets. While ElectroCraft provides a wide array of standard products with many configurable options, we have built our brand on custom OEM solutions that meet the precise performance, cost and quality our customers require.

For OEM Customers who are unsatisfied with having to design around inflexible off-the-shelf products, our technical knowledge and cusomizable product families provide for a design experience which results in motor and motion systems that provide superior reliability and performance at the lowest possible cost.

Chamfr is a female-owned medical device component marketplace founded 5 years ago by 3 co-founders who saw an unmet need in the industry. Engineers needed fast access to components for early stage development but were frustrated by long lead times and lack of accessibility to medical-grade components for early stage development.

At Chamfr, we are not a single company trying to push our products. Instead, we give medical device engineers access to a wide range of in-stock components and technologies for prototyping to spur the development of innovative medical devices. This allows design engineers to launch their products faster by being able to iterate without long lead times and high-cost minimum orders. With 3000+ components, from over 30 different suppliers, all in-stock and ready to ship, Chamfr is kind of like an Amazon for medical device components.

One of the biggest advantages of buying on Chamfr is transparency. You see who you are buying from so when it’s time to source long term supply, you know exactly where to go and can be confident that you have medical-grade supplier and traceability for your DHF.

COMSOL is a global provider of simulation software for product design and research to technical enterprises, research labs, and universities. Its COMSOL Multiphysics® product is an integrated software environment for creating physics-based models and simulation applications. A particular strength is its ability to account for coupled or multiphysics phenomena. Add-on products expand the simulation platform for electromagnetics, structural, acoustics, fluid flow, heat transfer, and chemical applications. Interfacing tools enable the integration of COMSOL Multiphysics® simulations with all major technical computing and CAD tools on the CAE market. Simulation experts rely on COMSOL Compiler™ and COMSOL Server™ to deploy applications to their design teams, manufacturing departments, test laboratories, and customers throughout the world.

Kirsh Senior Editor

Kirsh Senior Editor

Fluorescent sensors are typically used to label and image a variety of molecules to give a unique glimpse inside living cells. However, the method has been limited to cells grown in a lab dish or in tissues closer to the surface of the body because the signal from the sensors are lost when implanted too deeply in the body.

A team of Massachusetts Institute of Technology engineers have developed a photonic technique that dramatically improved the fluorescent signal. The researchers showed that sensors could be implanted as deep as 5.5 cm in the tissue and still provide a strong signal. Improved signaling could help fluorescent sensors to track specific molecules inside the brain or other tissues deep within the body for medical diagnosis or monitoring drug effects.

“If you have a fluorescent sensor that can probe biochemical information in cell culture, or in thin tissue layers, this technology allows you to translate all of those fluorescent dyes and probes into thick tissue,” said the lead author on the study, Volodymyr Koman.

Wavelength-induced frequency filtering

Traditionally, scientists use different kinds of fluorescent sensors — including quantum dots, carbon nanotubes and fluorescent proteins — to label molecules inside the cells. The fluorescence of the sensors can be seen by shining a laser light on them. However, the method does not work in thick, dense tissue or deep within tissue because tissue emits some fluorescent light called autofluorescence, which makes implant signals weak.

“All tissues autofluoresce, and this becomes a limiting factor,” Koman said. “As the signal from the sensor becomes weaker and weaker, it becomes overtaken by the tissue autofluorescence.”

The MIT researchers modulated the frequency of the fluorescent light emitted by the sensor so it could become more easily distinguishable from tissue autofluorescence. Called wavelength-induced frequency filtering (WIFF), the method uses three lasers to create a laser beam with an oscillating wavelength. (continued on page 32)

MIT engineers have developed a photonic technique for fluorescent sensors that could improve sensor signals deep in the body.Image courtesy of the Massachusetts Institute of Technology Danielle

Oscillating beams are shined on the sensors and cause fluorescence emitted by the sensor to double its frequency, according to the researchers. The signal can then be easily picked out from the background’s autofluorescence. The researchers reported they enhanced the sensor signal-tonoise ratio more than 50-fold.

its usability, the team focused on glioblastoma. Patients with this aggressive form of brain cancer typically undergo surgery to remove as much as the tumor as possible and then receive chemotherapy to eliminate the remaining cancer cells.

“We are working on technology to make small sensors that could be implanted near the tumor itself, which can give an indication of how much drug is arriving at the tumor and whether it’s being metabolized,” said Michael Strano, senior author of the study and the Carbon P. Dubbs professor of chemical engineering at MIT. “You could place a sensor near the tumor and verify from outside the body the efficacy of the drug in the actual tumor environment.”

The researchers suggest the method could be used to monitor the effectiveness of chemotherapy drugs. To demonstrate

When the cancer drug temozolomide enters the body, it is broken down into smaller compounds, and the MIT team designed a sensor to detect the compound known as AIC. They found that they could place the implant as deep as 5.5 cm within an animal brain and could read the signal from the sensor even through the animal’s skull.

The researchers suggest the sensors could also be used to detect molecular signatures of tumor cell death. The WIFF method could be used to enhance the signal from other types of sensors, including carbon-nanotube-based sensors that detect hydrogen peroxide, riboflavin and ascorbic acid.

“The technique works at any wavelength, and it can be used for any fluorescent sensor,” Strano said. “Because you have so much more signal now, you can implant a sensor at depths into tissue that were not possible before.”

The MIT team hopes to continue the research using a tunable laser to create the signal and improve the technique even further. They are also working on sensors that are biologically resorbable and do not need to be surgically removed.

The research was funded by the Koch Institute for Integrative Cancer Research and Dana-Farber/Harvard Cancer Center Bridge Project with additional funding from the Swiss National Science Foundation, the Japan Society for the Promotion of Science, the King Abdullah University of Science and Technology, the Zuckerman STEM Leadership Program, the Israeli Science Foundation and the Arnold and Mabel Beckman Foundation.

The study was published in the journal Nature Nanotechnology.

This gold-standard brain-computer interface technology is creating a platform for better patient outcomes.

Brain-computer interface (BCI) science has seen exciting advances and heightened public attention in recent years, and for good reason. The promise of BCI for individuals with paralysis is monumental: To intuitively restore communication, control external devices, and provide the independence that many able-bodied people take for granted.

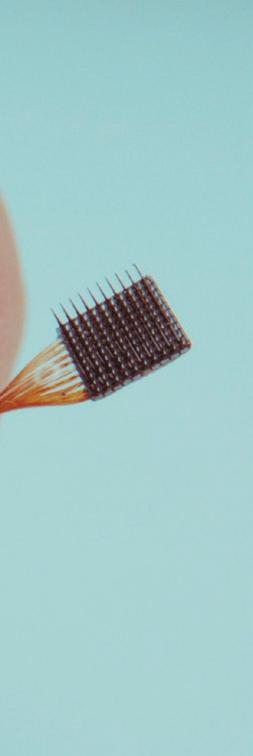

Sitting at the core of today’s BCI innovation is a tiny device that has quietly powered advances in the field for decades: the Utah Array.

Studied in humans since 2004, this bundle of microelectrodes, also known as the NeuroPort Array, remains the only FDAcleared high-channel microelectrode platform that can record signals from individual neurons and that is used in BCI applications for movement disorders. In clinical studies, it has been successfully surgically implanted in the brain tissue of patients with paralysis

for up to eight years (and counting) to record movement intentions and restore physical sensations, resulting in life-changing applications for the patients.

Because of its extensive safety and efficacy profile and the quality of neural data it gathers, the Utah Array is often considered the gold standard of BCI technology. But it’s more than just a useful research tool — the Utah Array is driving BCI innovation and unlocking practical, clinical solutions for patients with paralysis.

What is the Utah Array?

The Utah Array is a high-channel count microelectrode array invented by Richard Normann at the University of Utah. Initially intended for applications in visual prosthesis, over time it became widely adopted by the neuroengineering community as the gold standard tool for basic and applied research.

The array gathers neural signals from up to 100 channels per device, and it’s the only BCI implant with documented long-term stability and safety in humans. It has been studied in dozens of patients for a total of more than 30,000 days, demonstrating groundbreaking performance.

The Utah Array has earned commercial FDA clearance for monitoring electrical activity in the brain for 30

days or less, and Blackrock is pursuing clearance for long-term implantation, which will enable commercialization of the BCI platform as a clinical therapy. In studies where Investigational Device Exemptions have allowed implants to remain in place chronically, the Utah Array has been shown to successfully restore function in patients with paralysis and ALS for up to eight years so far. Research is underway to examine how the Utah Array could potentially treat chronic pain and other neurological conditions.

A modified version is used in efforts to restore hearing. Ultimately, the Utah Array is best thought of not as a single device but a family of devices and form factors and as the core of a larger platform and workflow.

Blackrock is actively working with partners to design processes that result in optimal outcomes post-operation (such as avoiding tissue damage or immune response to the implant) and ensure long-term patient safety and higher quality of life.

(continued on page 36)

Neurotech uses its Utah Array in its brain-computer interface to sense brain signals.

(continued from page 34)

Because the Utah Array has been proven to work safely and effectively for years on end, the Blackrock team has turned its attention to making its BCI commercially available as a medical device, bringing the technology out of the lab and into patient homes.

The Utah Array has a few key performance features:

• 100 active electrode channels per implant; can be customized up to 1,024 channels

• Typical configurations include four to six devices (400-600 electrodes)

• Ability to reliably pick up signals from both individual neurons and a summation of high-resolution signals

• Variety of connector types for acute or chronic recording

• Electrode site metal options: iridium oxide or platinum

• Standard electrode lengths: 0.5-1.5 mm (research) or 1.0-1.5 mm (clinical)

The Utah Array’s largest advantage over other BCI electrodes currently in development is its longevity and safety. No other neural implant used in BCI applications has a comparable safety and efficacy profile demonstrated over years of clinical research. In terms of safety, the Utah Array has had no FDA-reported serious adverse events related to the implant since it was first implanted in humans in 2004.

An engineering challenge that Blackrock and other BCI companies face is how to increase channel count and/or develop other higher-density arrays. At this point in time, the Utah Array remains the highest density recording electrode long-term tested in humans. In animal research, no higher channel count array has chronically demonstrated the ability to work reliably in cortex with comparable lifetimes.

In addition, there is a risk-reward tradeoff with higher-density electrodes. Electrode count should always be driven by application needs, which in turn are

determined by customer needs and physiology. Many neuroprosthetics and communication tool applications that interface with motor intent perform well with hundreds-to-one-thousand electrode channels. More channels may cause additional injury to tissue that is harder to heal without adding significant performance benefits. A higher concentration of electrodes alone may not automatically lead to better-performing applications.

Furthermore, the electrode array is only one key component in an entire system and value chain. A keen understanding of the use case, clinical and caretaker workflows, surgical procedures, electronics, firmware and software design and user interfaces — combined with advanced algorithms and machine learning approaches — enables the performance that users experience in the field. That allows them to translate thought-to-text with speeds approaching able-bodied people (150 characters per minute) and to control a computer or mobility devices, allowing patients to truly regain independence and function.

Some use cases do require higher channel count, such as applications for memory and vision. For these applications, Blackrock has developed novel electrodes with 10,000 channels and beyond.

While Blackrock engineers are developing higher-density electrodes that optimize the risk-reward tradeoff, the near-term opportunity of the Utah Array is its application as a medical device. In its current form, the Utah Array powers a BCI platform that, once available in a commercial medical device, will change the way paralysis and neurological disorders are treated.

The Utah Array is the tiny component that is already fulfilling this life-changing promise. And it’s just the beginning.

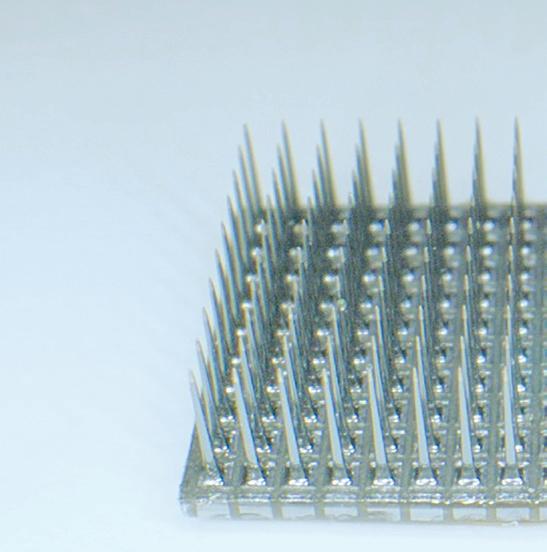

Today’s product designs for medical equipment require smaller and smaller components that are extremely durable and meet rigorous tolerance specs. Minimally invasive components deliver huge patient care advantages by shrinking the size of devices ranging from minimally invasive biopsy cutters to catheters. As advancements in minimally invasive surgery continue, biomedical engineers will continue to demand reliable, high-precision components with ever-decreasing physical dimensions and complex design structures.

Metal alloy components continue to be called upon to meet these rapidly evolving needs, but traditional manufacturing techniques struggle with shrinking dimensions and intricate structures. Using machine tools to fabricate small components is expensive, difficult and time consuming. Even more significant are the issues machine tools have in producing large numbers of small parts with consistent tolerance quality.

Micro-metal injection molding (MicroMIM) is the solution to these issues. It delivers the highest manufacturing quality while meeting specifications for extremely small components with complex geometries. MicroMIM also creates production efficiencies, yielding highly consistent production runs and a lower cost per part.

MicroMIM technology was developed to meet requirements for metal components with extremely small size specifications. While the average mass of a conventional MIM component is 15-20 grams, MicroMIM is defined as the molding of components that are less than 1 gram or have critical features that are less than 100 microns. Some current MicroMIM parts are as small as a few tenths of a gram.

At this micro scale, tight tolerances and complex geometries are almost impossible to achieve in a production environment with standard machining technology. In addition to variability in quality, the machining cycle times are long and the costs are high, both for unique tooling and metal alloy scrap.

MicroMIM is currently being used to facilitate the production of extremely small, complex-shaped metal components with outstanding mechanical properties. When implemented with well-designed molds, material choices, and mold flow characteristics, this manufacturing method creates production efficiencies and results in little wasted material. It offers a huge leap in component design freedom by eliminating the inherent restrictions of a machining approach and ultimately yields highly consistent production runs with a lower cost per part.

Additionally, MicroMIM produces microscale medical device components with much greater feature definition, smoother surfaces and superior quality than can be achieved using machining tools. A further benefit is the elimination of weld lines that impact product quality. These advantages enable lifescience OEMs to implement advanced engineering concepts and achieve consistently high levels of product quality.

Today’s MicroMIM medical equipment applications include:

• Robotic surgical micro components

• Implantables

• Catheter components and sacrificial cores for stent production

• Staples and stapling anvils

• Laparoscopic and suturing jaws

• Minimally invasive biopsy cutters and graspers

• Dental surgery

• Drug delivery systems

Advances in minimally invasive surgery will inevitably continue, with tremendous benefits for patient care. Smaller and smaller components will be required, challenging both design and production teams. You can position your teams ahead of the curve by adding MicroMIM capabilities to your portfolio.

In addition to expanding design engineering freedom, MicroMIM delivers major business advantages. Because it is a highly repeatable process, with consistent results, production runs can ramp up quickly to support critical new product introductions. This is in stark contrast to machine tool production, where each individual component has a statistically significant likelihood of unacceptable dimension variations. The batch production of microcomponents also facilitates assembly flexibility for the final devices where they are used.

Cost savings with MicroMIM give additional support to profitability. Traditional manufacturing requires high up-front investments in tooling and fixturing to produce parts with tight tolerances. MicroMIM is a cost effective alternative, with lower set-up costs as well as a lower marginal cost-per-piece during production. MicroMIM’s reliable product quality during production runs also drastically reduces manufacturing scrap, driving further overall cost reductions.

As stated, further developments in medical device technology are coming and quickly. Incorporating MicroMIM into sustainable supply portfolios now can give life science OEMs a leg up when the next cutting edge designs hit the market. Read our MIM design guide to learn more about the MIM process and to determine if your components are a good fit for this technology.

Nick Eidem is the director of business development for Advanced Powder Products, one of the country's leading Metal Injection Molding and 3D Metal Printing companies. Nick has over 10 years of experience in manufacturing sales. To learn more go to https://advancedpowderproducts.com/.

Medical device manufacturers are increasingly pessimistic about the supply of semiconductors, according to a Deloitte survey of the industry.

Some said they’ve slowed down or halted manufacturing operations after depleting their semiconductor inventories, and nearly 80% of survey respondents reporting extended lead times, with some stretching more than a year.

“More than 75% of our most-recent survey respondents said that their customers have turned to alternative types of treatment for their patients,” Deloitte’s Stephen Bradley and Bill Murray wrote in a recent report. “As a result, some hospitals and health systems are looking into alternate products, new usage strategies or treatment options.”

The Advanced Medical Technology Association (AdvaMed), which continues to push for the medical device industry to be prioritized for chip supplies, commissioned the survey to follow up on a similar survey conducted in July 2021. At that time, medical device companies said it was getting harder to obtain semiconductors, but many said they had enough inventory on hand to manage and that they had figured out temporary solutions.

A lot has changed since then. Russia’s invasion of Ukraine, for example, jeopardized Ukraine’s neon gas supplies, which are used in lasers that build the microscopic circuits in semiconductors. And Russia itself is one of the top

exporters of the palladium used in chips. Chips — once plentiful and cheap — are also now more expensive to move due to higher fuel costs and decreased shipping capacity, and some chip buyers are hoarding to protect against continued supply chain issues, Deloitte noted.

With some medical device manufacturers expecting the shortage to continue into 2023, Deloitte offered fi ve steps medical device companies should consider:

Deloitte’s surveys found 13% of respondents did not have a chip inventory before the pandemic, but more than 70% now say they have recently increased semiconductor inventory levels.

About half of all medical devices have at least one semiconductor, but the medical device industry’s share of global semiconductor purchases is only 1%.

Alternate suppliers can be even more effective if medical device manufacturers “build speed and flexibility into component substitutions — through planning, manufacturing, and regulatory processes” that allow for a supplier switch when needed, the Deloitte report’s authors wrote.

“More than half of our most recent survey respondents said they previously relied on a single source for 75% of their chip supply,” Bradley and Murray wrote. “All of them are now pursuing alternative sources.”

Nearly a third of survey respondents said they’ve contacted brokers, which can serve as an alternate source while protecting against counterfeit products. Deloitte said the challenge of avoiding counterfeit chips has grown for medtech firms since last year’s survey.

“Many companies are revalidating components to increase sourcing options even though the process can be cumbersome,” they said.

ResMed, in one example of agility, started shipping a new device without some of the chip-enabled features to meet immediate demand.

Deloitte said the follow-up survey found most companies have increased their visibility into multiple supply chain tiers. That helps companies spot trouble sooner and gives them more time to act.

“Digitization of the supply chain can provide visibility from the suppliers all the way to the customer and help enable a quicker response,” Bradley and Murray wrote. “Advanced analytics could enhance the ability to be more proactive in every step of the supply chain.”

With the global chip shortage expected to continue into 2023, device developers and manufacturers are taking action to keep the lines moving.

"More than 75 % of our mostrecent survey respondents said that their customers have turned to alternative types of treatment for their patients."

Reversible electroporation is the use of an electric fi eld to open pores in a cell wall, allowing transport of drugs, DNA or other “cargo” into a cell — in particular, allowing delivery of chemically large molecules and transport of DNA vaccines and customized gene therapies.

In the 40 years since its invention, electroporation has become a mainstay technique in biological sciences. Only recently, however, has wide interest taken hold when it comes to in vivo (human clinical) electroporation. Compared to other delivery vectors and carriers, electroporation stands apart as a particularly elegant engineering solution to a biologic problem, offering safe, convenient and efficacious delivery of a wide array of cargos.

Like any new technology, adoption has been slow. Companies that adapt to this new paradigm will be at the forefront of realizing the profound benefits of this technology.

In fact, electroporation-enabled gene therapies and nucleic acid vaccines are leading contenders to be paradigmshifting technologies.

Electroporation involves using an external electrical device to apply a prescribed electric fi eld to tissue. This transiently opens pores in cell walls, allowing transport of drugs, DNA, and gene therapies.

Photo courtesy of Minnetronix Medical

COVID-19 clearly demonstrated the need for quick-to-develop vaccines that can be transported without cold-chain storage. Electroporation-delivery of such a DNA vaccine is drawing wide attention and robust funding. Companies working in this space have raised significant capital, and hundreds of clinical trials are ongoing.

Diseases for which there is ongoing research into the use of electroporationdelivered therapies include a wide range of neoplasms, several viral infectious diseases and even some degenerative diseases. A sampling of these conditions includes advanced melanoma; HIV; Lassa fever; wet macular degeneration; human papillomavirus-caused cervical, head, and neck cancers; prostate cancer; certain breast cancers; and more.

With such a robust pipeline of diseasespecific agents targeting multiple types of cancers, infectious diseases, and even degenerative diseases, it is easy to see the profound health (and economic) impact this technology is bound to have.

(continued on page 42)

Why the new buzz about an old technique? Harness the potential of an existing technology for modern medicine.Minnetronix Medical

(continued from page 40)

Using electroporation as a delivery vector is quite simple. As an example, there are currently ongoing trials where a drug is administered intramuscularly with a standard hypodermic needle and syringe, then an electroporation application is performed, which causes the cells to form temporary pores, dramatically increasing the volume of that drug which ends up inside the cells.

In this case, the electroporation application involves using a separate device (that looks something like an electric toothbrush) that has pairs of needles that puncture the skin near the injection site and apply a series of electrical pulses. The process only takes a few seconds. Depending on the specifics, it can create a mild buzzing sensation for the patient but is otherwise benign.

In other devices, the injection needle is also used as part of the electroporation circuit, which makes for a more complicated delivery device but removes variability in administration.

Today’s most common in vivo electroporation applications use needle electrodes for intra-tumoral or intramuscular administration of electroporation pulses. However, research shows the ability to use “paddle” type electrodes (which don’t even need to pierce the skin) or electrodes on the surface of, for example, a flexible catheter for intraluminal or surgical applications. As electroporation matures as a delivery technology, it is likely we will see even more innovation in this space.

Developing an in vivo electroporation device requires consideration of both biologic and electro-mechanical factors. Clinical efficacy of electroporation relies on achieving specific electric field strengths, which can be influenced by varying impedance of tissue or sample. Specialized measurement equipment and protocols improve accuracy and performance, which is why an experienced design partner is invaluable. Additionally, like any medical device, such a system must be designed to be safe, effective and compliant to regulations.

Led by a former tobacco company executive, Qnovia looks to offer nicotine replacement therapy through inhaled drug delivery.

Brian Quigley spent just over 16 years at tobacco giant Altria. During his time there, he ran two U.S. business units, including the

smokeless tobacco business.

In July 2020, he joined founder and then-CEO at Qnovia (then Respira Technologies) Mario Danek as chief operating offi cer. Now CEO, with Danek as chief technology offi cer, Quigley leads the company as it looks to bring a prescription smoking cessation therapy to market.

Quigley acknowledged the potential applications Qnovia could pursue with its inhaled therapeutic technology. For now, though, the focus is firmly on pursuing FDA approval for what would be the first inhalable prescription smoking

cessation therapy. first an

“I joined Qnovia because of what I learned when I first met Mario Danek,” Quigley said in an interview. “He explained this innovation he created. He’s taken proven medical device technology and been able to imbue it with form factors for better compliance, better adoption and

better patient outcomes.”

Qnovia’s RespiRx drug delivery platform leverages a vibrating mesh nebulizer. The aerosol technology has been used to deliver therapeutics for decades, Quigley said.

However, he noted that they “really suffer” from a range of challenges. For instance, the devices are gravity-fed. This means the piece that has to pour the drug product comes into contact with the mesh itself. He called them “clunky” as they require cleaning. According to Quigley, they can

contribute to poor adherence due to the need to clean the devices.

Qnovia took the approach of miniaturizing the technology and making it work in an orientation-agnostic fashion. This helps it to deliver therapeutics in a patient-friendly way, he said.

The device features a rechargeable base unit, plus an interface for patients to track their dosing. They can follow their use regimen and capture data through the device. The device also has a prefilled drug product-containing cartridge. Quigley said the patient can stick this into the end of the device to start therapy, then replace it when needed as they move through therapy.

“It has a very familiar patient-friendly format for on-the-go treatment to deliver the drug wherever you need it and to do it effectively,” Quigley said.

Based on each indication Qnovia treats with its technology, each user would have a different use regimen, Quigley said.

Each user received a prescribed target dose based on the therapy, the treatment and the outcome, specifi cally for inhalable nicotine replacement therapy. That particular treatment has a 12-week use regimen. Quigley described it as a traditional “stepdown” model, where the patient fi rst puts down the cigarettes. Then they begin using the device, which helps them reduce nicotine use over 12 weeks before they stop using it altogether.

In the case of smoking cessation therapy, Qnovia has a precisely timed and delivered dose prescribed to the patient based on the number of cigarettes they used to smoke in a day. Each therapy has a specific number of activations to deliver the drug to the body to alleviate withdrawal symptoms. >>

“That kind of algorithm of the dosing, the dose control and the delivery is a function of the indication,” Quigley said. “That would be very different for any future indication. If we were working on asthma or COPD, for example, the device itself can be programmed to deliver that drug differently based on the patient needs.”

Quigley said Qnovia’s technology maintains broad potential in terms of use. That includes effective drugs already approved for delivery via a vibrating mesh nebulizer.

Each of those drugs represents billion-dollar opportunities, he says. However, patients currently have to use large, clunky or at-home nebulizers to dispense the drug, which is where Qnovia could come into play.

Additionally, Quigley pointed to the world of drug development as an opportunity. He said inhalation represents an effective way to deliver compounds to the body, particularly for respiratory disease.

Finally, he pointed to companies looking at drugs delivered in different ways. Those can be delivered with less patient friction but the same efficacy and route of inhalation.

“There’s still a lot of work to be done,” said Quigley. “That’s why we’re focusing first on the smoking cessation therapy indication. As we continue the development, we can identify and build up a pipeline of the other potential drugs we could be delivering or drugs and development that we can partner with other companies to deliver.”

Qnovia took a large step forward in September by raising a $17 million Series A funding round. Its plans include investigational new drug submission to the FDA next year, followed by Phase 1 clinical trials.

According to Quigley, the company has the capital to get through Phase 1 trials and to explore application programming interfaces (APIs) and

expansion opportunities.

“Getting through that Phase 1 human clinical trial is our next major milestone, and we’re funded to do that for sure,” said Quigley. “From there, our fate we would begin with Phase 2 studies in the back half of next year, and then move through Phase 3 in the new drug application.”

As for the future indications, Quigley said it’s hard to predict when public communications will come for those. The company’s focus remains on advancing its smoking cessation treatment.

“We’re really excited to have the support of the investors we have,” Quigley said. “We think that this technology to deliver health therapeutics has big potential. Advancing our smoking cessation application first and foremost is just a massive opportunity to improve the lives of millions of people.

“We’re excited to advance that and to continue to identify and bring to market additional indications that can help improve outcomes.”

CGI Motion standard products are designed with customization in mind. Our team of experts will work with you on selecting the optimal base product and craft a unique solution to help di erentiate your product or application. So when you think customization, think standard CGI assemblies.

Connect with us today to explore what CGI Motion can do for you.

TransMed7’s SpeedBird biopsy devices are made with injection molding, among other manufacturing processes. Photo courtesy of Fictiv

Part design, material selection, tooling and quality assurance are the keys to success.

Injection molding is known for producing high volumes of tight-tolerance parts. What medical designers may not realize, however, is that some contract manufacturers can also cost-effectively prototype functional samples for testing and evaluation. Whether it’s for singleuse devices, repeated-use devices or durable medical equipment, plastic injection molding is a versatile process that can help you bring products to market faster.

Like any manufacturing process, there are best practices for injection molding. They fall into four major areas: part design, material selection, tooling and quality assurance.

By considering what works well and working closely with an experienced manufacturer, you can avoid common mistakes that result in added costs and delays. The following sections explain what medical designers need to consider when outsourcing an injection molding project.

Design for manufacturability (DFM) is the process of designing parts so they are easy to manufacture. Parts with looser tolerances have larger part-topart dimensional variations and are usually easier and less expensive to make. However, most medical applications require tighter tolerances that those used with commercial products. Therefore, during the part design process, it’s important to work with your manufacturing partner and add the right type of commercial or precision tolerances to your drawings.

There isn’t just one type of injection molding tolerance, and omitting drawing details can result in parts that don’t fit correctly or cost too much to produce. In addition to dimensional tolerances, consider whether you need to specify tolerances for straightness/flatness, hole diameter, blind hole depth and concentricity/ovality. (continued on page 48)

(continued from page 46)

With medical assemblies, work with your manufacturing partner to determine how all the parts fit together in what’s known as a tolerance stack-up.

Tolerances vary by material, so don’t just evaluate plastics based on properties and pricing. Choices range broadly from commodity plastics to engineering resins, but these materials all have something important in common. Unlike 3D printing, injection molding can produce parts with exact end-use properties. If you’re designing pilot prototypes, recognize that you have the fl exibility to use the same material as in production. If you need a plastic that conforms to a specifi c standard, consider asking for a certifi cate of assurance (COA) to ensure that the injection molding material — not just its individual ingredients — complies.

Manufacturers mostly create injection molds out of aluminum or steel. Aluminum tooling costs less but can’t match steel tooling’s support for high volumes and precision. Although the cost of a steel mold may take longer to amortize, steel is cost-efficient across a high volume of parts. For example, if a $10,000 steel mold for a single-use medical product is amortized across 100,000 parts, the tooling cost is just 10 cents per part.

Steel tooling can also be the right choice for prototypes and lower volumes, depending on your injection molder’s capabilities. With a master die unit and frame that includes sprues and runners, leader pins, water lines and ejector pins, you only pay for the mold cavity and the core details. Family molds that contain more than one cavity can also reduce tooling costs by having multiple different designs inside the same mold.

With medical injection molding, it’s not

enough to produce good parts most of the time and then have the QA department catch any defects. In addition to tight tolerances, medical parts need a high degree of accuracy. DFM, T1 samples and post-production testing and inspection are important, but process control is essential for variables such as temperatures, flow rates and pressures. So along with the right equipment, your medical injection molder needs to be able to identify critical-toquality (CTQ) attributes.

For disposables, repeated-use medical devices and durable medical equipment, injection molding can help you bring products to market faster after alpha and beta prototyping are complete. Injection molding is known for supporting high-volume production, but cost-effective pilot prototyping is also possible. Injection molders have different capabilities, so consider making careful vendor selection an additional best practice for your next project.

Collaborative robotics and Spanish-speaking shifts are helping Boston Scientific deal with a global labor shortage.

Boston Scientific executives said two labor-shortage strategies are paying off in a big way for the medical device maker, which has around 41,000 employees across the globe.

Collaborative robotics and Spanishspeaking shifts are helping Boston Scientific deal with labor shortages in the U.S. and elsewhere.

“It’s hit us everywhere. Part of that was just general wage inflation. Although we don’t like the cost of that per se, that’s relatively easy to deal with, right? You give people raises and at least the supply continuity problem goes away,” Global Operations EVP Brad Sorenson said in a recent interview with our DeviceTalks Weekly podcast.

“The bigger issue is, however, that if we used to want to hire 200 people because we had capacity growth that we needed, we’d just put an ad in the paper and do an open house and we could hire them. That’s not the case anymore,” he continued. “Frankly, just getting enough people to work has been difficult. So we’ve undertaken a very aggressive path to try to remove the human labor dependency for things that machines can do.”

As an example, Sorenson said about 30% of Boston Scientifi c employees “look through microscopes every day and make a go/no go decision” for product quality.

“Automated machine learning has really moved the ball on a machine’s ability to do that. And quite frankly, that’s probably not the most rewarding work that our workforce is doing,” Sorenson said. “We’ve started to put in more automation in those type of places to augment our direct labor capability and in parallel undertaken a dramatic change management approach through a program we call Grow, which is really around upskilling our direct labor, creating a better career path in places that have more value add.”

He reported “really good progress” through automated visualization and cobotics, or collaborative robots that work with product technicians or engineers on the line. Such technology could augment around a third of the Boston Scientific labor force, Sorenson said. And it doesn’t mean automation will lead to layoffs. (continued on page 51)

The medical device industry obviously isn’t immune to the challenges posed by a shaky supply chain. But OEM leaders like Boston Scientific need to work doubly hard to ensure they have the supplies needed to provide devices for patient care. devicetalks.com/podcast/

(continued from page 49)

“We get the team on the bus with us,” Sorenson said. “There’s no pushback — ‘Hey robots are trying to take my job away.’ It’s, ‘I get it, you’re going to try to do the part of my job that I don’t particularly love doing every day and give me stuff that’s way more interesting and exciting so I can grow.’ So we think it’s pretty dramatic, and in some parts of the organization, we’ve made big leaps forward. We’ve been able to essentially hold labor flat while we’ve been seeing 15% to 20% increase in output.”

Another labor supply solution came from an employee at a plant in the Midwest who suggested hiring workers who only speak Spanish, said Supply Chain VP Paudie O’Connor.

The facility already had Spanish-speaking employees from Costa Rica who had transferred. After translating documentation into Spanish, the plan worked.

“We had a couple of shifts up and running in no time,” O’Connor said. “Word of mouth in that community really helped. That is growing to be like a standard stable in that organization. About probably 25% of the workforce are only-Spanish speaking. ... It’s just phenomenal to see how it’s come together and each different community learning off each other. We’re giving Spanish classes to supervisors and engineers and anyone that wants to learn.”

With nearly $11.89 billion in annual revenue, Boston Scientific is the 12th largest medical device company in the world, according to our 2022 Medtech Big 100 ranking.

Medical device companies are competing for workers in one of the tightest-ever job markets. Meanwhile, there is pent-up demand for medical products worldwide due to increasing need along with pandemic-fueled supply chain problems.

There is a way medical device companies can overcome labor challenges and fulfill orders to take advantage of market demand. Highvolume production facilities have long relied on help from multimillion-dollar automated assembly lines and robotics. For decades, those systems were too expensive or impractical for medium- and low-production runs.

But robotic technology has advanced and expanded to the point where flexible automation makes sense for lower volumes and to bolster workforces.

Advances in robotics are helping manufacturers improve quality, fill labor shortages and promote personnel.

Many have feared advances in manufacturing would take away jobs and push more costly and fallible human workers out. However, automation systems and humans are both needed to operate manufacturing facilities efficiently, consistently and safely. Not everything can or should be fully automated, and not everything can or should be done by humans.

Flexible automation allows manufacturers to move workers off menial, repetitive tasks, and retrain them for higher-level roles that require cognitive agility and decision-making. Rather than “stealing” jobs from humans, automation and robotics can promote us.

Recently, one medical manufacturer with a product family produced through a labor-intensive, manual assembly and

insert molding process invested in new molding equipment. The team deployed an automation cell with a cobot (collaborative robot) to perform many repetitive tasks previously completed by a human operator. The switch resulted in consistent cycle times — which is key in injection molding — and a consistent level of quality with automatic separation of non-conforming parts. It also met the customer’s pricing target by reducing costs over prior models. In addition, the manufacturer’s investment helped alleviate the labor shortages it faced and enabled them to train plant floor employees for more complex tasks needed in higher-level positions.

Maximizing and optimizing resources There are generally two types of robots used for medical device production: industrial robots and cobots. Medtech

manufacturers often deploy industrial robots in automation cells. They require hard guarding and/or light curtains to prevent injuries.

Cobots can be programmed to learn multiple tasks, and with built-in controls can safely work alongside human colleagues in production. Generally, manufacturers use cobots to perform repetitive tasks that may need to be moved between jobs or work centers. Setup is quick and easy. With proper risk assessment, they do not require hard guarding. Cobots often are deployed for loading/unloading inserts into a thermoplastic or liquid silicone molding process, and automated inspection with machine vision systems or pad printing.

Cobots have revolutionized manufacturing automation costeffectiveness. Cobots are far less expensive than a full-fledged robot and easy to program. As a result, they take over menial jobs while improving precision in tedious tasks and increasing the overall safety of personnel and equipment. Before cobots came into their own, manufacturers spent much time and money designing and implementing safety systems to protect personnel and equipment from hazards. Now cobots can perform many of these tasks.

Once a cobot is programmed, assessed/tested, approved and deployed, it’s ready to handle whatever task it’s assigned. It’s possible to reassign a cobot as needed.

Deploying robots compliantly and cost-effectively Companies need to ensure internal staff or contact manufacturing partners have the knowledge and expertise to deploy and maintain their automation systems compliantly. In highly-regulated markets like the medical device industry, there are numerous, often complex regulations and international standards for automated systems in manufacturing applications. Therefore, proper automation system installation and operational and performance qualification, including process validation, are musts.

Choosing when, where and how to deploy robots requires strategic planning. The goal is to maximize operations and productivity and optimize personnel. Manufacturers should keenly focus on putting employees into roles that require cognitive agility and real-time decision-making. These roles generally are more enriching, which can

help recruiting and retention.

Take inspections, for example. Those that are straightforward, such as measuring a known feature or confirming the presence or absence of a component, can be done efficiently and effectively by robots. But that’s repetitive and often tedious work for humans. However, an inspection process to determine whether foreign material is inside a sealed package can be difficult and nuanced. All the surfaces of the part need to be assessed in all directions. A human can hold the package and tip it every which way, and put it under a microscope if they think they see something. A human has the ability to infinitely manipulate the product being inspected, whereas automation would typically follow a sequence and programming. It’s possible to achieve quality and consistency through thoughtful and deliberate deployment of automation with vision systems.

Humans are needed to design, maintain and oversee operations. This is where the labor shortages are critical and

intensely competitive. Manufacturers need technicians who are well-versed in setting up and adjusting systems and engineers with the deep expertise and knowledge to develop, qualify, troubleshoot and oversee the systems. They also need skilled personnel on the production and assembly lines who can operate and work alongside machines. All of these roles now require a higher level of training and education than the tasks that machines can now perform. Medical device manufacturers can automate many critical tasks, enabling the exact operation to be done in the same manner at the same time. Compared to a multi-shift operation with a variety of skilled human operators, they could be doing the same task, but slightly differently or vastly differently. A robot will do what it is programmed to do repeatedly and consistently. It won’t get fatigued, distracted or bored. The endgame is improved productivity to meet supply and demand, reduced risk and better allocation of resources for all involved.

Choosing a contract design or manufacturing partner begins a long, two-way relationship.

Vascular devices may need contract manufacturing services such as clean room injection molding, additive manufacturing, plasma treatment and coating or automated assembly. Photo courtesy of SteriPack

No matter what type of medical product you are designing, at one point you will be faced with deciding which design house or contract manufacturer is right for you.

OEMs through highly funded startups all face the same issues when preparing to transition from design to manufacturing.

The design-through-manufacturing cycle is getting quicker. On average, the typical product development launch is two years from concept to regulatory approval. This two-year period may initially seem like a long duration, and you might not feel an urgent need to engage a medical solution partner, letting the selection decision wait until the development cycle matures. However, time after time, we have seen a tendency to rush the development process to get to a prototype without engaging molders or manufacturers, leading to disappointment in aesthetics, assembly methods and cost.

Proper and early due diligence is especially important if you are a startup. Your organization might not yet have approved suppliers, the discipline to review past vendors, or even have experienced staff on hand. Startups are lean and fast-moving by nature. Once the startup receives its Series A or B

funding, the plan is to get to market as fast as possible. Does the company have an experienced program manager on the team that can recognize the ideal solution providers, or do you risk the pitfalls of jumping in too soon with a supplier that does not fit? Likewise, the suppliers you may target could be apprehensive about taking on the project based on volumes, investment cost and strategy to market.

There are as many medtech, diagnostic, pharma and consumer health product developers as there are specialty contract manufacturers. So let's look at the potential questions medtech designers and managers should ask when considering medical solution providers.

1. Is my contract manufacturer the proper size or scalable?

There is always a tendency for a company to overreach its growth goals. This idea relies on the assumption that a supplier with a global presence and high-volume capabilities will be safe as your production volumes grow. Even the most prominent companies fall into this trap.