Winter Winter

F eaturing Goshen County

F eatured Goshen County Operations Introducing Goshen County

Valley Video Hay Markets

Dinklage Feedyard

McNamee Auction Company

Z&W Mill

Bar X Ranch

SS Ranch Company

Bear Creek Rubs

Ken Haas Angus

21st Century Equipment

McClun’s Lazy JM Ranch

Cattle County Video

Eastern Wyoming College

Pleasant Valley Greenhouse

Dirt Road Wife Photography

Ellis’ Harvest House

Ochsner Roth Cattle Company

G Bar H Genetics

Doug Booth Family Angus

Torrington Livestock Markets

Bear Mountain Beef

Booth’s Cherry Creek Angus

Although one of Wyoming’s smaller counties, Goshen County is a powerhouse in ag production

The Wyoming Livestock Roundup is happy to highlight farms, ranches and agribusinesses of Goshen County in our 2025 Winter Cattlemen’s Edition.

Located on Wyoming’s eastern border with the sprawling grasslands of Nebraska to the east, Platte County to the west, Laramie County to the south and Niobrara County to the north, the long, rectangular county of Goshen spans 2,225.39 square miles with a population of 12,642.

Although Goshen County is Wyoming’s fourth smallest, the fertile soil, availability of water and favorable climate make it a powerhouse in agricultural production.

The area’s climate is semi-arid, characterized by more moderate temperatures than other parts of the state, with around 14 inches of annual rainfall and an average 34 inches of snow each winter.

The availability of water is the primary reason Goshen County is so productive.

The North Platte River is the lifeblood of the county, and with the help of extensive irrigation infrastructure, provides a consistent source of water for large-scale agricultural production.

Continued on next page

Goshen County agriculture

As of 2022 Census of Agriculture data published by the U.S. Department of Agriculture’s (USDA) National Agricultural Statistics Service (NASS), Goshen County is home to 736 farms, and land in farms totals 1,256,152 acres.

Of the county’s agricultural land, 953,886 acres are classified as pastureland; 241,931 acres are classified as cropland and 19,037 acres are classified as woodland.

Six percent of land in farms – or 80,336 acres –are irrigated.

The county’s fertile soil has the ability to produce a

plethora of crops. According to NASS, all hay and haylage, at 60,428 acres, is the number one crop grown in the area, followed by corn for grain at 19,022 acres; wheat for grain at 12,183 acres; barley for grain at 4,435 acres and corn for silage at 3,142 acres.

Other important crops grown in the area include sugarbeets, sunflowers, potatoes and dry beans.

The area’s ability to grow ingredients needed in livestock feed, as well as the close proximity to the state’s largest cattle auction – Torrington Livestock Markets, LLC. – makes it no surprise Goshen County leads the state in cattle production. NASS reports

Goshen County is home to 109,449 cattle and calves.

The rest of the county’s livestock inventory includes 6,869 sheep and lambs; 2,208 horses and ponies; 1,259 layers; 858 goats; 127 broilers and other meat-type chickens; 36 pullets and 16 hogs and pigs.

Additionally, NASS reports Goshen County accounts for 13 percent of the entire state’s agricultural sales, with the total market value of agriculture products sold topping $204,618,000.

The majority of these sales come from livestock, poultry and poultry products at $153,593,000 – with the sale of cattle and calves totaling $149,644,000 – while the remaining $51,024,000 comes from

the sale of crops.

State rankings

With this, Goshen County leads the state in market value of agricultural products sold and is therefore ranked first in agricultural importance to Wyoming’s economy.

The county boasts numerous other top five rankings in the state and never falls below the top 18 across the board.

According to NASS, Goshen County ranks first in total livestock, poultry and poultry products, as well as first in the production of cattle and calves.

The county ranks second in horses, ponies, mules, burros and donkeys and total crops produced, as well as third in grains, oilseeds, dry beans and dry

peas and nursery, greenhouse, floriculture and sod.

Additionally, Goshen County ranks fourth in fruits, tree nuts and berries; eighth in poultry and eggs; 15th in sheep, goats, wool, mohair and milk and 18th in hogs and pigs.

Information in this article was compiled from Goshen County’s official website and USDA NASS. Hannah Bugas is the managing editor of the Wyoming Livestock Roundup. Send comments on this article to roundup@wylr.net.

THREE MILE CREEK RANCH

Lusk, Niobrara County, Wyoming

7,162± total acres; 5,882± deeded & 1,280± State lease acres. Live water, multiple improvements.

$8,675,000

Clark & Associates at (307) 334-2025

SPIEGELBERG SPRINGS RANCH

Laramie, Albany County, Wyoming

6,281± total acres; 5,019± deeded, & 1,262± State lease acres. Live water via Spring Creek & Sand Creek, 89± acre private lake

Reduced to $4,950,000

Mark McNamee (307) 760-9510 or Cory Clark at (307) 334-2025

OW RANCH

Lusk, Niobrara County, Wyoming

5,387± total contiguous acres; 4,107± deeded & 1,280± State lease acres. Over 3 miles of year round creek. Exceptional hunting.

$5,500,000

Clark & Associates at (307) 334-2025

2092 ROAD 220

Cheyenne, Laramie County, Wyoming

35± acres with 5,947 sq. ft. fully custom brick home with 4 bedrooms, 3.5 baths and 3 car garage. Adjacent to TT&T Equestrian Arena. Brokerowned property.

Reduced to $1,350,000

Mark McNamee at (307) 760-9510

GOSHEN COUNTY FARM

Torrington, Goshen County, Wyoming

521.78± acres with 420± acres under three pivots with wells. Improvements include grain bins and 1,440 sq. ft. Morton home.

$2,700,000

Cory Clark at (307) 334-2025

HAT CREEKS BREAK RANCH

Lusk, Niobrara County, Wyoming

1,775± deeded acres. Scenic draws, excellent hunting, and custom built improvements.

$3,175,000

Clark & Associates at (307) 334-2025

Fertile cropland – Goshen County boasts 241,931 acres of fertile cropland responsible for the production of hay, corn, wheat, barley, sugarbeets, beans and potatoes. Visit USA Parks photo

Leading cattle county – Goshen County leads the state of Wyoming in beef production, with an inventory of 109,449 cattle and calves. Geology of Wyoming photo

Goshen County History

Well-worn trails led

the establishment of Wyoming’s agriculture-dominated Goshen County

The North Platte River is a major tributary of the Platte River, which branches off of the Missouri River in southeast Nebraska and winds through the Cornhusker State before heading southwest to central Wyoming.

Back in the day, the historic trails used by settlers

moving west – including the Oregon and Mormon trails –shadowed the North Platte River, and present-day Goshen County laid in the crossroads of these paths.

In the 1850s, this route was used by regularlyscheduled stagecoaches carrying passengers and U.S. mail west, as well as the short-lived Pony Express which hauled mail from Missouri to California.

In the early 1860s, transcontinental telegraph lines were installed along the route, and in the late 60s, the Cheyenne-Deadwood stage coach line ran through the county to gold fields in the Dakota Territory.

Evidence of the bustling transcontinental traffic through Goshen County is evident in the wagon ruts, place names and historic landmarks that remain today.

One of these is the name Goshen County itself, although the whereabouts of its origin come from two different stories.

Some suggest the area is named after Goshen Hole, a valley south of Torrington, originally called Goshés Hole after an early Native American warrior or a French trapper.

Others believe the county is named after Egypt’s fertile Land of Goshen outlined in the Bible’s 45th chapter of Genesis because of its highly-fertile soils and semiarid climate which makes it a powerhouse for agriculture production.

Early ranching

Agriculture has been an integral part of Goshen

County throughout its rich history.

Cattle production began as early as the 1850s, when Fort Laramie Post Sutler Seth Ward supposedly left a small herd of cattle out on the open range during the winter of 1852-53. Surprised they survived, Ward continued the practice, which was later adopted by other ranchers settling in the area.

About 15 years later, the Fort Laramie Treaty of 1868 required Native American Tribes in the area to restrict hunting to north of the North Platte River. White settlers began moving cattle herds across the plains north of Cheyenne, along Chugwater Creek and the Laramie River.

The first permanent breeding herd was started by W.G. Bullock and B.B. Mills at Fort Laramie.

Other pioneer ranchers in the area included John Hunton, Hiram Kelly, John Kessler, Charley Coffee and Philip Yoder. The Union Cattle Company and Swan Land and Cattle Company were the area’s largest early ranches.

Cattle production continued, and in 1934, the Torrington Livestock Commission was started by the Petsch family of Scottsbluff, Neb. The commission later became Torrington Livestock Markets, Inc. in 1989, which is now the largest auction in Wyoming and one of the largest in the country, selling cattle from the nine-state region and attracting buyers from across the nation.

Today, Goshen County produces more cattle than any other Wyoming county.

According to the 2022 Census of Agriculture, published by the U.S. Department of Agriculture’s (USDA) National Agricultural Statistics Service (NASS), Goshen County is home to 736 ag operations and 109,449 cattle and calves.

Early farming

The North Platte River was also critical in the formation of Goshen County’s prolific farming industry, and in the beginning, settlers used water from the North Platte, Rawhide Creek and Horse Creek to irrigate their fields.

The first water right was claimed from Rawhide Creek in 1881.

Then, the Reclamation Act of 1902 provided funding for irrigation projects across 20 Western states, and revenue generated from the sales of semi-arid public lands was used for the construction and maintenance of these irrigation projects.

Newly-irrigated lands

Fort Laramie – Originally established as a private fur trading fort in 1834, Fort Laramie evolved into the largest and best known miliary post on the Northern Plains before it was abandoned in 1890. National Parks Conservation Association photo

would then be sold, and the revolving funds were used to support more projects.

Through $10 million in funding, nearly 250 miles of the interstate and Fort Laramie canals were constructed.

By 1947, the Fort Laramie canal on the south side of the North Platte provided water for 53,000 acres, and those who used this water established the Goshen Irrigation District. On the north side of the river, the canal provided water for 15,000 acres, and water users created the Lingle Water Users Association and the Hill Irrigation District.

In Hawk Springs, water drawn from Horse Creek was used by those in the Horse Creek Conservation District for 10,300 acres. Later, farmers and ranchers began drilling wells for irrigation water and to fill stock water tanks.

Today, irrigated and dryland farming still dominate in Goshen County, with farmers growing a variety of wheat, dry beans, barley, corn, potatoes, hay, sunflowers and sugarbeets.

By the early 1950s, the county boasted 13 grain and bean elevators and six potato docks.

In the 1920s, Holly Sugar Company built a factory in Torrington – one of five factories in the state.

In 1926, the first year of operation, the factory processed 21,000 tons of beets. Although a large figure at the time, this number is slight in comparison to the 745,000 tons processed in 2012 by the Western Sugar Cooperative, which took over Holly Sugar in 1943.

After 95 years of production, Western Sugar’s Torrington factory closed in 2018.

Early towns

The first permanent settlement in Goshen County was Fort William, a trading post built in 1834 near the junction of the Laramie and North Platte rivers.

Here, Fur Traders Robert Campbell and William Sublette established and built the original wood stockade buildings, which later became known as Fort Laramie.

After the original structures deteriorated, employees of the American Fur Company built a new post in 1841 and named it Fort John, although many still used the popular name of Fort Laramie.

The fort offered a place for weary travelers heading west to rest and replenish their supplies.

In 1849, Fort Laramie was purchased by the U.S. government and operated as a military post, where it grew in size and importance, becoming the principal military outpost on the Northern Plains before it was abandoned in 1890.

Situated on the banks of Horse Creek, LaGrange is another one of Goshen County’s oldest communities and is named after Stage Coach Driver Kale LaGrange.

Supposedly, LaGrange claimed water rights for the area in 1883 and platted the townsite in 1889.

Wyncote was established around 1900, but because the Union Pacific (UP) Railroad was unable to obtain enough land for the townsite, land to the east was donated to create the town of Lingle instead. This town was named after Financer Hiram D. Lingle.

In 1911, Gov. Joseph Carey officially declared the formation of Goshen County, and the county’s government was organized in January 1913.

At this time, the town of Torrington became the official county seat.

The UP Railroad influenced the creation of several more towns in the area, including Huntley, Cottier, Yoder, Hawk Springs and Veteran.

In the 1860s, Jim Moore claimed and settled near one of the last watering holes south of Lusk, and nine years later, he was the owner of the second largest cattle operation in the Wyoming Territory.

His brand, the J Rolling M, inspired the name of Jay Em, which was a bustling center of commerce throughout the 1920-30s.

Today, there are only a few residents in Jay Em, and the town center is mostly vacant.

Jesse Yoder, the head of the Goshen Townsite Development Company, is the namesake of smalltown Yoder.

His hopes were to combine the two settlements of Springer and Lacy Corners into one town located beside the UP Railroad which passed close by his ranch. The town thrived and quickly established real estate offices; grocery, hard-

ware and dry goods stores; a bakery and a creamery.

In 1922, a schoolhouse was erected and a newspaper started publishing weekly.

In 1925, Yoder was home to more than 500 people, as well as three new drugstores, two barber shops, a hotel, a bank, several churches, a doctor’s office, a community hall, a telephone office, a rooming house and a livery stable.

Yoder became the county’s business and trade center for a short time. However, by 1970 the population decreased to 100 and the town has remained quiet to this day.

In 1920, the town of Veteran was also established, named for a military program which allowed returning World War I Veterans and their families to qualify for an 80-acre irrigated plot

of land.

Today, the majority of Goshen County’s population lives in the county seat of Torrington and agriculture remains one of the most predominant industries in the area, ranking first in the state for total market value of ag products sold at a whopping $204,618,000.

Information in this article was compiled from the Wyoming Historical Society, Geology of Wyoming, Goshen County’s official website and USDA NASS. Hannah Bugas is the managing editor of the Wyoming Livestock Roundup. Send comments on this article to roundup@wylr.net.

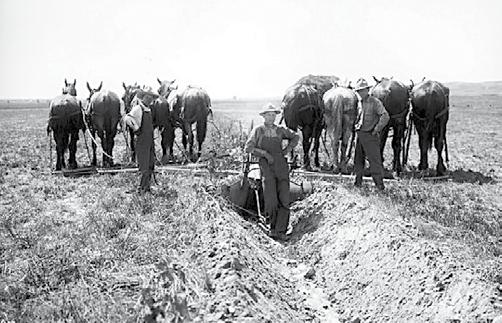

Early irrigation – Goshen County’s close proximity to the North Platte River has helped ranching and farming thrive for centuries. Here, workers take a break from ditching an alfalfa field near Lingle in 1912. Wyoming State Archives photo by J.E. Stimson

Holly Sugar factory in Torrington in 1928. Homesteaders Museum photo

Agriculture powerhouse – Supposedly named after Egypt’s fertile Land of Goshen from the 45th chapter of Genesis in the Bible, Goshen County’s prolific soils and close proximity to water make for a powerhouse in ag production. Pictured are Weimer and Maxene Denny with a load of recently harvested sugarbeets near Veteran circa 1930. Homesteaders Museum photo

Valley Video Hay Markets

Hay is a necessary commodity for most ranches and dairies, and many farmers make a living growing hay to fill these needs.

Bringing hay growers and buyers together is an important part of agriculture, and something Barry McRea does very well.

Barry started his hay market 24 years ago. He wasn’t a farmer or a rancher himself, but he realized there was a need for hay brokers who could help people find good hay when they needed it, as well as a way for hay growers to have a dependable market for their crops.

He also knew of a number of local farmers who could supply the hay.

“At the time, the internet was pretty new so we started

putting on internet video auctions for hay,” Barry shares. “Back then, there wasn’t a lot of competition for this, so it was relatively easy to establish customers.”

Although it was a new concept, Barry generated a lot of popularity, gaining customers across much of the U.S.

With the ability to line up buyers and sellers, Barry’s video hay market was able to help farmers and ranchers in many states who needed hay, especially in drought years.

Barry says, “2012 was a big year, with drought across large areas. We shipped a lot of hay to Texas, Oklahoma and New Mexico. Our usual market for dairy hay is eastern Colorado, but our business soon expanded and we built up a lot of buyers.”

Local growers

During the past 20-plus years, Barry’s business has primarily been based on about 40 growers within a 50-mile radius of Torrington.

“Since the beginning, I’ve pretty much used the same growers in this small area to send hay all across the country. Those farmers have always been able to supply the alfalfa we’ve needed,” he says.

“I may sell hay for about 100 different growers during any given year, but I have about 40 of my favorites who have been working with me for 24 years,” he adds.

Farmers in eastern Wyoming have the ideal climate and irrigation water to grow really high-quality alfalfa.

“It’s great to have so many growers nearby because I don’t have to travel all across the U.S. to find hay,” Barry notes. “I just buy it here within a 50-mile radius in our area, and it is generally some of the highest-quality hay in the nation.”

Barry notes hay from the local growers he works with is usually very consistent in quality as well.

He also shares, on years when there is an over-supply of hay, he gets approached by even more sellers looking for someone to buy.

“But I have to stay loyal to my reliable sources,” he states. “The growers know me, and a big part of selling something across the U.S. to various buyers is that growers know they will get direct payment from me.”

Nationwide buyers

According to Barry, a lot of hay sold through his auction goes to dairies, while a fair amount also goes to ranchers, especially those south of Torrington.

However, he notes this changes a little every year, depending on weather, hay prices and geographic regions.

“Generally, there is someplace around the country where there’s a dry spot and hay production and pasture are in short supply,” he states. “Sometimes it’s Texas. Sometimes it’s Iowa. A few years ago, two-thirds of the hay we shipped out went to Montana. Generally, though, there’s always a need.”

He continues, “Ironically, this year has probably seen the lowest demand for hay in the 25 years I’ve been doing this. The hay

“I am the one who has to fight the battles and make sure we get payment from the buyers,” he adds. “My growers are assured they will get paid. My job is to locate the hay, do the tests, find a buyer and guarantee payment. Most of this business is based on loyalty and trust.”

inventory finally became so high, prices are down in spite of many drought areas around the West. Everyone over-produced alfalfa last year, so the areas that are dry this year still had a stockpile and hay was generally available.”

Another situation Barry has faced this year is a lower demand across the board for hay because cow numbers are down. This is the lowest the national cow herd has been for over seven decades.

“Cattle numbers are lower than many people realize, and the demand for hay consumption on ranches is quite a bit less than it would have been a decade ago or so. Feedlots have less inventory of cattle, so they are feeding less hay this year,” he explains.

“The dairies are also feeding a bit less because all of the commodities including corn, soybeans, cottonseed and cotton hulls, etc. are cheaper. A lot of these commodities are also closer – with less transport cost –to the dairies and feedlots,” he adds. “They are closer and cheaper, so all around, hay consumption has been lower this year.”

Despite this, Barry’s business continues to benefit growers. He notes he will start selling first cutting alfalfa in July and continue to sell hay throughout the year.

“It’s always been a big benefit to them, to keep moving their product through many different marketing times,” he says.

To get hay to buyers across the country, Barry utilizes several trucking companies – two local trucking firms in the area for closer hauls and a local dispatcher who uses back-

haul trucks to take hay out on their backhaul.

“This year, oddly enough, about 70 percent of my sales went south to Texas or east to Iowa,” he shares. “I used backhaul trucks for those since both those hauls average at least 500 to 600 miles either east or south.”

“Our local market consists of either ranchers or the dairy market in the Greeley, Colo. area, so I use local truckers for those short hauls,” he adds.

It all fits together, with a networking system and team effort.

Quality assurance

To ensure the hay he brokers is of the highest quality, Barry requires hay be tested.

“I get a list of all of the hay and its test results,” he explains. “This makes it easier to match it up with the buyer’s needs, whether it be ranch hay, dairy hay or feedlot hay.”

The matchup also includes hay sampling and testing to make sure the hay meets the needs of a certain stockman.

“I make a full circle in the 50-mile radius and take samples from all of my haygrowing clients’ alfalfa and send them in to laboratories for testing,” he says. “Then, from those samples and test results, I can make a fit.”

Barry does this all by himself, with the help of one employee.

“I have a great bookkeeper,” he states. “I am very fortunate to have efficient bookkeeping for this business. She works out of her house and takes care of all our records. When the farmers weigh their hay, all records are e-mailed directly to my office and she takes care of it. Payments to those

growers are made weekly.”

“We used to use the mail for all of this, but now we use direct e-mail for the weigh tickets, payments, etc. which makes it much more efficient,” Barry continues.

“So, I have one bookkeeper, two local trucking companies and a dispatching outfit I use all the time for the backhaul trucks going back out of this part of the country,” he explains. “It’s turned out to be a great system. We weren’t smart enough to think of all of this when we first started, but we always made it work and made improvements when we could.”

Additionally, Barry’s oldest son Brock McRea built and updates his website.

For more information about Valley Video Hay, visit valleyvideohay.com or call Barry McRea at 308235-5386.

Changing with the Times

Dinklage Feedyards adopts new technology, doubles in capacity

Three and a half miles east of Torrington on the north side of Highway 26, sits Dinklage Feedyards.

Over the last quarter century, the operation has grown into a 30,000-head feedlot.

Capacity

When Dinklage purchased the feedyard from Continental Grain Company in the 90s, it looked a little different than it does today. By adding additional pens and building a new feed mill, the company increased the capacity to nearly double what it originally was.

“It’s a nice size,” said Yard Manager Rondel Carman. “It’s still small enough it gets the personal touch, yet big enough to operate from an economic standpoint.”

The feedyard sources 75 to 80 percent of the grain they feed within the local valley in western Nebraska and eastern Wyoming. In years like 2024, when production is lower than normal, sometimes the grain will come from as far away as the Dakotas.

Dinklage is a finishing feedyard, meaning they fatten cattle which then go directly to market. This means as yearlings come off of grass in the fall, things get busy at the yard.

At any given time, there are 13 to 15 employees on the job, and there are 20 full-time employees.

Changes and innovations

Rondel has been at the feedyard in Torrington for over 30 years, first with Continental Grain Company and then with Dinklage when they bought the operation in 1997. He has seen the ebbs and flows of the industry and has marked the passing of time with the evolution of technology.

What was once done with pen and paper is now tracked via computers and cellphones.

Every feed truck is equipped with GPS and its own computer screen, monitoring rations and giving drivers the ability to take notes as they go which can be instantly accessed by others.

“The biggest change over the years is the technology. Every doctoring facility has scales on the chutes and computers right beside them. All of the cattle have an electronic identification tag in them, so we track every animal individually,” explains Rondel.

“It is the same way on the milling side of it. Back in the day, it took three or four guys to run a feed mill. Today, it’s 100 percent automated,” Rondel adds.

These days, all of the equipment is monitored by computers and if something goes wrong, it sends Rondel a text to let him know. He jokes when the internet goes down, it is hard to get things done.

Challenges Rondel says a big reason many aspects of the job, especially the feed mill, have transitioned to technology is because it is hard to find people who want to do the work. He admits it’s been a challenge to find people who want to get up every morning and spend the day horseback riding through pens and looking at cattle or working in the feed mill.

Just like producers, Mother Nature is a constant tribulation for the feedyard. As a business that is based on production performance, a winter storm is more than just an inconvenience when time is money.

“Cattle today have been

sitting here on feed all fall. The conditions are good. Cattle are comfortable. Cattle are performing amazingly. But if we get a foot of snow, it can turn it upside down for us in a hurry,” explains Rondel. “We spend a lot of money and time cleaning it up when it does happen to try to keep the cattle on track, but it still hurts.”

Dinklage Feedyard is always taking new customers. For more information, visit dinklagefeedyards.com

Tressa Lawrence is a corresponding writer for the Wyoming Livestock Roundup. Send comments on this article to roundup@ wylr.net.

Lot 19 • 3229L • #4848684 • 9/9/23

PRIME PLUS X ORACLE X PLATINUM 123PRO, 43HB, 79GM, 13CED, -1.3BW, 83WW, 126YW, 30MILK, 12HP, 8CEM, 13ST, 1.01MB, 0.24RE, $20,0962$P, $91$R Got Marbling? Check this bull out!

82WW, 137YW, 32MILK, 12HP, 9CEM, 12ST, 1.16MB, 0.78RE, $27,386$P, $118$R Big Time $Profit Prospect!!!

Lot 9 • 3862L • #4885996 • 8/26/23

IDENTITY X PREMIER X IMPRESSIVE 158PRO, 91HB, 67GM, 18CED, -3.3BW, 90WW, 141YW, 29MILK, 15HP, 13CEM, 18ST, 0.62MB, 0.23RE, $14,215$P, $59$R Rare Identiy Son from the Della Cow Family!

Lot 33 • 3225L • #4848676 • 9/8/23

PRIME PLUS X ORACLE X PLATINUM

142PRO, 72HB, 70GM, 15CED, -3.2BW, 77WW, 118YW, 30MILK, 12HP, 9CEM, 18ST, 1.01MB, 0.41RE, $24,303$P, $127$R Marbling, Calving Ease and Profit!

Lot 14 • 3701L • #4928814 • 10/27/23

JUMPSTART X EDGE X CHATEAU 92PRO, 42HB, 50GM, 14CED, -2.1BW, 76WW, 123YW, 27MILK, 13HP, 9CEM, 13ST, 0.49MB, 0.32RE,

Growing operations – Over the last quarter century, the Torrington division of Dinklage Feedyards has grown into a sprawling 30,000-head capacity feedlot. Courtesy photo

Locally-sourced feed – The Torrington division of Dinklage Feedyards sources 75 to 80 percent of the grain they feed from locals in eastern Wyoming and western Nebraska. Courtesy photo

A family affair –McNamee Auction Company is a familyoriented business, owned and operated by Michael and Jonette McNamee, their two children and their respective families.

Pictured from left to right are Georgia, Creighton and Jace McNamee, with baby Thurston coming soon; Michael and Jonette McNamee and Mikayla, Rhen, Korby and Jory Zurcher.

F orging Strong Relationships

McNamee Auction Company embraces traditional auction format, values personal connections

From growing up on a family farm and cow/calf operation in Pine Bluffs and serving as a state FFA officer back in the day, Michael McNamee has always had a soft spot for the ag industry and the people involved in it.

Today, through his business McNamee Auction Company, a live, onsite, family-oriented auction service based in the heart of Torrington, Michael is able to stay in touch with his ag roots and serve the community he has grown to treasure.

Family-oriented business

Started in 1997 by Michael and his siblings –his brother Mark and his sister Susan – McNamee Auction Company has been a family-oriented business from the beginning.

“Mark came up with the idea. He was already in real estate at the time, so he could see the potential connection between the auction business and the real estate business,” Michael explains. “He went to school, and we all started the business together. However, everybody has kind of gone their

own direction since then, and I’m the only one who’s still considered full time in the auction business.”

Both brothers still sell real estate through Clark and Associates Land Brokers, LLC, although Mark, who owns a one-third share of the company, has turned his full attention to this venture. Michael and his wife Jonette have taken over all auction company operations.

Despite the McNamee siblings’ dispersal, McNamee Auction Company continues to be family-oriented.

Michael notes his two children and their respective families – Mikayla, Jory, Korby and Rhen Zurcher and Jace, Georgia, Creighton and Thurston McNamee – are a big help with the business.

“We’re very fortunate both of the kids still help on occasion. Either Mikayla or Jace or both of them are involved with every auction,” he says. “Family was key for us from the very beginning, so we’re glad they are both still very involved with it.” Additionally, the Continued on next page

“I think the relationships we’ve built over the years with buyers and sellers and the crossover we have had in the community are all things we are very proud of.”

MICHAEL MCNAMEE

Courtesy photo

McNamees employ individual crews of anywhere from 12 to 20 people based on the size and scope of the auction.

“We’re very fortunate,” Michael reiterates. “I can’t say enough about the people we have working for us. They’ve all been with us for a long time. They are a very loyal group, and we’re lucky to have them work for us.”

Traditional auction format

Forging strong relationships with customers is another of Michael’s priorities, which is why, in a world of advanced technology and internet convenience, McNamee Auction Company has upheld the timeless in-person, onsite auction format.

In fact, the McNamees boast one of the only onsite auctions left in the country.

“And, we have a lot of success with it,” Michael states. “We’re very fortunate to have a good following of customers who attend our auctions.”

Michael admits one of the challenges he has had to overcome is countering the current trend of the “inevitable crossover to all online auctions,” and while he admits there is value in online auctions, he believes the connections made through in-person interactions during onsite auctions are invaluable.

“There are a lot of people who believe online actions are the way to go, and not that they don’t have their place, but we are going to continue to host live onsite auctions as long as we physically can,” he says.

“There is such a huge social aspect of in-person auctions, and we like to

embrace those traditions,” he adds. “If we feel we need to bring in an online audience, we can offer both. Buyers are able to participate online or bid live. We don’t do this with every auction, but if we feel it is necessary we certainly will.”

Although building a customer base to reap the rewards of holding onsite auctions was one of Michael’s greatest challenges in the beginning, he notes the McNamees’ reputation and strong relationships with repeat buyers – sometimes over 9,000 strong – are now some of his greatest accomplishments.

“We are very proud of our reputation and what we believe is a very important calling to be able to help people in a situation where they need to liquidate, regardless of what they need to get rid of,” he says. “I think the relationships we’ve built over the years with buyers and sellers and the crossover we have had in the community are all things we are very proud of.”

He continues, “We also pride ourselves on the fact we can sell just about anything. The majority of our time is spent auctioning off estate liquidations, which includes everything from equipment to personal property and everything in between.”

For more information about McNamee Auction Company, visit mcnameebrothersauctions.com or call 307-532-4976 or 307534-5156.

Hannah Bugas is the managing editor of the Wyoming Livestock Roundup. Send comments on this article to roundup@wylr.net.

Wednesday, February 5, 2025

A big help – McNamee Auction Company Owner Michael McNamee is fortunate for the loyal crew of people who help him at auctions of all types and sizes. He is especially grateful for the help of his two kids Mikayla and Jace and their growing families. Courtesy photo

Traditional auction format – Despite living in a world of advanced technology and internet convenience, McNamee Auction Company has upheld the traditional in-person, onsite auction format, allowing them to build strong relationships with their loyal customer base. Courtesy photo

Z&W Mill in Torrington opened its doors in 1940 and has been a family business since day one.

History

Frank Zimmer moved his family to Torrington in 1936 and purchased the Goshen Refining Company, which refined crude oil. He operated the refining company for a few years before closing the business down and pivoting to grain milling.

Frank saw big oil companies pushing out smaller refineries like his. He also saw high demand for steamrolled grain for local dairies to feed in their rations, and he decided to take the equipment he had from the refinery and transition it to the more sustainable business of the feed mill.

Amongst the remnants of the refining company were multiple steam boilers the mill was able to put to use generating power and utilizing steam to cook the grain when processing.

After deconstructing an existing grain elevator in Colorado and reconstructing it in Torrington, the doors of the grain mill opened for business in 1940.

Located next to the rail lines, Z&W Mill housed government grain commodities for many years. They would

store the grain and send it by rail across the country for various government programs.

As the opportunity faded and eventually went away, it left empty buildings, and the Zimmer family saw it as an opportunity to pivot once more.

After World War II, Frank’s son Russell returned home and took over the company. He decided the buildings once used to store government grain commodities would make an excellent pellet mill.

This original mill is still in operation and is used extensively.

Although the dairies in the area dwindled, the demand for steam-flaked grain not only maintained but has risen significantly. Today, steam-flaked grain is the biggest year-round operation at the mill.

Modern day

Today, the third and fourth generations of the family are running the business.

Mary Viktorin, Russell’s daughter, and her late husband Terry took over the mill in 1992. In 2013, Shane Viktorin graduated from the University of Wyoming and came home to help his mom run the business.

As the livestock show

industry boomed in the 90s, Terry saw an opportunity. He developed his own line of show feeds which have put Z&W Mill on the map as a trusted and sought-after feed source.

The family’s Cowboy Brand Livestock Feed is manufactured at their facility in both commercial and show formulas for major classes of livestock

Thanks to an incredible network of local farmers in the North Platte River Valley, almost all grain is sourced locally.

“We have an abundance of local farmers and ranchers growing commodities we can purchase from, and then in turn, enter those commodities into the marketplace by adding value to them here at our facility for the end consumer,” explains Shane.

“Most of our grains are purchased locally. Occasionally, we have to purchase outside of the local area because Mother Nature plays a role or sometimes certain crops aren’t necessarily available for whatever reason,” he continues. “Protein is a really difficult thing to buy locally, as well as molasses, so we source those products out of the area. Our salt comes from either Kansas or Utah.”

Today, the mill employs a dozen hard-working individuals, some of whom wear many hats within the business and some who have been with the company for 20-plus years.

“We sew each individual sack by hand. It’s completed with what we call our two bunny ears. There are two loops at the top that look like bunny ears, and this is what gives the signature grain bag its look and handling feature,” Shane says. “And, we still do this all by hand.”

With over 80 years in business, Z&W Mill has become a trusted resource for farmers and ranchers from the Dakotas and Montana, all the way down to the panhandle of Nebraska and the front range of Colorado.

“What has kept us in business for as long as we have is we strive to make a very consistent, high-quality product. We also know the importance of customer service. They walk in the door and they know us and we know them, and that makes a big difference,” adds Mary.

Many of their customers have been frequenting the mill for generations. The names on the tickets in the inaugural years are the same names on many of their tickets today.

The business prides itself on being run very traditionally, with many aspects staying the same over the last eight decades.

“We take our job very seriously. We know we play a critical role in feeding the world, and we really appreciate all of our customers who have been with us over these past 80-some years,” says Shane. “It’s a really joyous thing to experience how agriculture is so deeply rooted in families and tradition, and it’s very rewarding to see the different generations of families continue to come to our business and put their faith and trust in us to provide them with a quality product.”

“Without them, we couldn’t have made it these 80-some years,” he adds.

For more information on Z&W Mills, call 307-5322347.

Tressa Lawerence is a corresponding writer for the Wyoming Livestock Roundup. Send comments on this article to roundup@wylr.net.

Courtesy photo

Quality and Efficiency

The Bar X Ranch is a multi-generational operation with a long history in Goshen County.

Kyle Kilty’s greatgrandfather Earl Vanderhei homesteaded about 15 miles west of LaGrange in southern Goshen County.

After settling the homestead, Earl went to fight in World War I, where he learned how to engineer with teams of horses.

“When he came back from the war, he started a contracting business based in Cheyenne and spent a lot of time between Cheyenne and Bear Creek between ranching and building roads,” Kyle shares. “He had registered Hereford cattle he bought from the Wyoming Hereford Ranch, where he’d built one of the dams near Cheyenne.”

Kyle’s father Kerry Kilty established the pres-

ent-day Bar X Ranch, which does not sit on the original homestead.

“My father grew up on my great grandfather’s property in Cheyenne, but after building houses in Cheyenne, he and my mother Julie moved to rejuvenate the family ranch in the early 1980s,” Kyle explains.

In 1995, Kerry’s family decided to sell the property, so he and Julie worked to scrape together enough money to buy out what they could of the ranch and the rest was sold.

“My parents ran a successful cow/calf operation, along with selling hay, putting up small square bales for horse hay and selling it in Cheyenne and northern Colorado,” Kyle adds.

Returning home At the age of 18, while attending college, Kyle’s

father passed away.

“After his passing, I took a semester off from college to help calve and get through a season before my mom dispersed the cattle herd and I went back to college,” he says.

“All through college I helped at the ranch and put up hay in the summer. I still put up small square bales

to sell hay to the customers my father had acquired selling horse hay,” he says.

“In the fall, I’d only take 12 credit hours of classes – just enough to keep my scholarship and load those classes on Tuesdays and Thursdays. As soon as Thursday classes were over, I’d go home and spend four days on the ranch, then go back

to school on Tuesday.”

Through his hard work and dedication, Kyle saved up enough to buy his own herd of cows.

“I came back to the ranch and purchased my own cows,” Kyle shares. “I started by leasing the ranch from my mother – she still owns the main part of the ranch. After I came back, I

picked up other leases from local landowners.”

Today, the operation is located between LaGrange and Hawk Springs, where Kyle, his wife Taryn and their two children Zoey and Lakson reside. Lessons learned Kyle notes him and Taryn have been slowly

Continued on next page

OTECO

WHEEL TRACK FILLERS

Bar X bulls – The Kilty family raises high-quality Black Angus

expanding the operation with the help of Mike Vinton, a lifelong friend who previously worked for Kerry.

“My ranching career has been a school of hard knocks because no one was there to tell me to do things a certain way or not to do something,” Kyle admits. “Lessons learned the hard way are good lessons, and honestly it’s been great.”

Kyle says over the years he tried a multitude of different things to find out what worked best for his situation.

“When we first started, we were calving in April,” he says. “Now, I’ve gone opposite of everybody else who keeps moving their calving later in the spring and summer. Instead, I now calve in February.”

Although the area gets a few cold snaps in February, Kyle says the weather is usually not too severe and proves a good month to welcome baby calves.

“April is wet. March is wet and cold and February is just cold, but cold is easier than mud,” Kyle says.

He notes the registered cows calve first, starting early in February and the commercial cows calve later.

“In the past, it was more spread out. Each month we had a different group starting. Now we try to pack everything into an eightweek stint instead of calving for four months,” Kyle adds. “Within each group, we shoot for a 45-day calving window.”

Additionally, Kyle shares ranching has been a continuous series of new adventures.

Around three years ago, the Kiltys started an embryo transfer (ET) program.

Kyle shares, although it takes years to see the result of this, he finds animal genetics incredibly exciting.

“It’s all a rush to patience,” he says. “We are constantly rushing everywhere to do everything, and then we wait.”

Inaugural bull sale

Through their expansion efforts, the Kiltys started running Black Angus cattle and will host their first bull

sale on April 12 this year at the ranch. Prior to this, all of their bulls were sold private treaty.

Kyle notes many of his bull customers are local ranchers, although he also sends a handful of bulls to Idaho every year.

“I sell them to a rancher in St. Anthony, Idaho who has a ranch in Oregon and a big forest allotment in New Mexico, but most of the bulls I sell stay here in Wyoming,” Kyle says.

He adds, “The auction will be a whole new experience. We decided to hold an auction because I wanted to bring in a sense of community. The sale will be held in the afternoon at 3 p.m. with a steak dinner to follow.”

Kyle hopes this will allow the community to come and visit for a while without having to rush back home to get something done. He hopes the sale will be more leisurely and encourages everyone to bring their families.

“I’ve also scheduled DVAuction, so the sale will be available online for people who can’t make it in person,” he says. “A local auctioneer, Lander Nicodemus, will do the sale. This is a whole new chapter and adventure for us.”

Current operations

In terms of herd management, Kyle says he tries to focus on raising efficient cattle so the Bar X Ranch runs their registered cows the same way they run their commercial cows.

The ranch is located in a wide-open area on fairly flat ground and fields and pastures are easily accessed with vehicles. Cattle can be readily moved with ATVs.

“Most of the land we run on is private property, with just a little bit of state land. The cattle are easy to move from pasture to pasture,” Kyle says.

“In the winter we take them to cornstalks and winter roughage on a farm I have north of here about 30 miles,” he adds. “We haul them there and trail them back right before calving, usually in two days. We usually overnight them

Continued on next page

“My ranching career has been a school of hard knocks because no one was there to tell me to do things a certain way or not to do something. Lessons learned the hard way are good lessons, and honestly it’s been great.”

KYLE KILTY

Northwest WY Angus Association

Northwest WY Angus Association

in a pasture about halfway between.”

Additionally, the Kiltys use an extensive ET program with a focus on topend genetics.

Calves at Bar X Ranch are sometimes retained and backgrounded, and other times, they are sold right off of the cow.

“It depends on the market,” Kyle states. “A local farmer and cattle feeder has bought our steers for the past five years, so we just do whatever fits his schedule. We are also lucky because we are close to a

reputable local auction barn and don’t have to go very far to send our cattle to market. This is really convenient because some ranchers have to haul their cattle quite a long distance.”

Kyle also says the goal at Bar X Ranch is to graze year-round, letting cows harvest their own feed as much as possible.

Most of the winter grazing is done on crop residue –everything from cornstalks to hay ground and a lot of irrigated fields – which saves on input costs for winter feed.

In summer months, the Kiltys rely on Horse Creek – the lifeblood of the ranch – to irrigate meadows and put up hay, which provides another source of income.

“Regarding the hay we put up, we generally feed half and sell half,” Kyle says. “When hay prices are high and cattle prices are low, we have an income stream from the hay. When cattle prices are high and hay is cheap, cattle are the main source of income.”

“This year will be little different,” he admits. “We are not going to sell much hay because hay is in short supply everywhere.”

Kyle concludes, “One thing I love about ranching and farming is whatever you have to do, it’s a short stint. Whether it’s haying, calving, irrigating, etc., we are not doing it for 12 months.”

“I am fortunate to have a great wife and a great family. A farm or ranch is a wonderful place for kids to grow up,” he adds.

For more information about Bar X Ranch, visit barxranch.com

Heather Smith Thomas is a corresponding writer for the Wyoming Livestock Roundup. Send comments on this article to roundup@ wylr.net.

The Kilty family – Kyle, Taryn, Zoey and Lakson Kilty are the owners and operators of Bar X Ranch, located between LaGrange and Hawk Springs. Courtesy photo