11 minute read

Laser scanning for verification

Verity, a new software tool that compares point clouds against design & fabrication models, is put through its paces by architect Jacob Down on a live project at the University of Exeter’s Penryn Campus in Cornwall, UK

In construction and architectural ditional methods of construction and with manufacturing processes, some limited material palettes. They understood degree of dimensional variability is their craft and could adjust their work as inevitable. It will occur even when required to overcome any irregularities. operatives are fully trained, have plenty Today, construction is complex: a netof experience and go to deliberate work of relationships, procurement methlengths to achieve the specified sizes and ods, critical paths, trades and specialist dimensions stipulated by drawings, subcontractors, utilising a myriad of conspecifications and BIM models. struction techniques and manufacturing

More often than processes, varying not, this variability is from prefabricated down to the physical About the author precision engineering limitations of opera- to more traditional tives and tools of Operating from his forms of onsite conmaterials used, conPorthminster struction. cluded research Studio in St. Ives, Cornwall, [overAs a result, active undertaken decades looking the raw review of as-built ago by the atlantic swells and progress onsite, in British Research complex weather order to identify misEstablishment (BRE), systems] St. Ives aligned or out-of-tola leading building science centre. This Architect Jacob Down focuses on the production of multi-disciplinary and technologically evolutionary works derived from erance elements, is an extremely valuable led to the formulation his studies at the Bartlett School of exercise. It is no surof BS 5606:1978 – Architecture and his unique interactions prise then that it Code of Practice for with this natural environment. seems to be growing Accuracy in Building, in popularity with which was later contractors that are revised to become BS 5606:1990 – Guide looking to de-risk their projects by identito Accuracy in Building. The guide aims fying mistakes and dimensional variabilito provide advice on how to avoid prob- ties before they become costly errors. lems of inaccuracy and dimensional vari- This trend has been driven by developability inherent in construction. ments in software and the growing acces-

Historically, buildings were relatively sibility of 3D laser scanning through lower simple, constructed by craftsmen using tra- cost scanners like the Leica BLK 360.

However, the actual verification process that cross-checks an as-built point cloud produced from a laser scan with the geometry of a BIM/fabrication model has typically been a somewhat manual exercise. It is usually undertaken as a ‘sense check’ in only a few critical locations and visualised in plan or section, resulting in limited verification in only one or two planes.

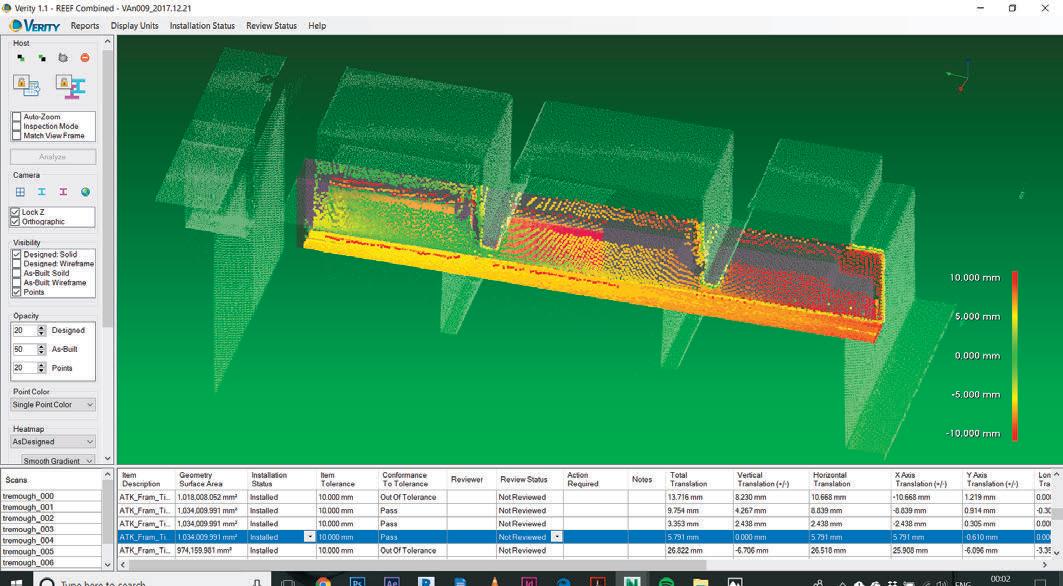

Automated verification with Verity Verity is a fully integrated software plugin that utilises advanced algorithms to automate the verification process within Autodesk Navisworks. Developed by ClearEdge3D, it compares the 3D laserscanned point cloud of as-built work onsite with the corresponding asdesigned BIM/fabrication model, in order to produce clear visual outputs that illustrate deviations of elements. It also supports the preparation of detailed reports for circulation with the design team. This

is an automated process, pulling the selected point cloud and as-designed elements from Navisworks into Verity in order to analyse the data and produce a concise table of results, based on a predetermined tolerance range.

Information displayed for each analysed element includes data on item description, surface geometry area, installation status, item tolerance, detailed transition and rotation, but most notably, its conformance to tolerance, stating whether or not it falls within the stipulated tolerance range.

Following the analysis, Verity offers a number of tools to review and interrogate the data, and even amend geometry to reflect the as-built point cloud, by moving as-designed elements to as-built positions at the click of a button.

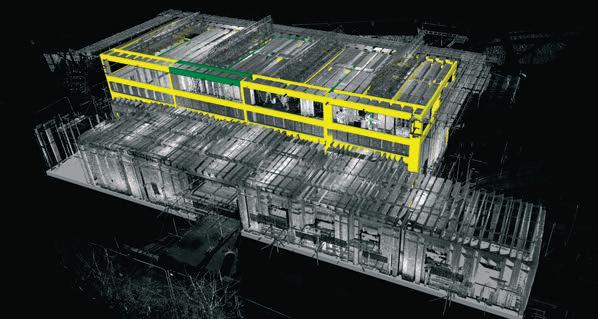

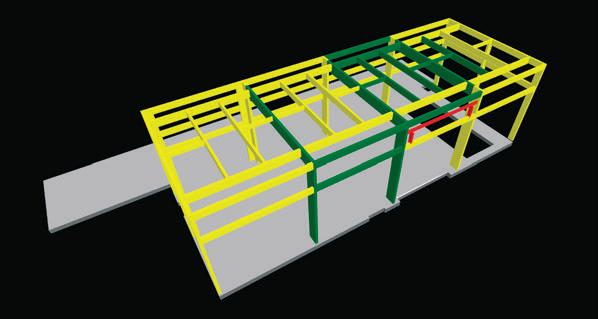

Verity in action on the REEF Project In order to better understand Verity’s processes, workflow and potential, we put the software through its paces on a The 267 sqm timber cloud of the structure as a fully live project onsite at the frame REEF Building registered Autodesk Recap file. University of Exeter’s Penryn was 3D laser scanned by 3DMSI It was fundamental that the Campus in Cornwall, UK. point cloud included all the

The REEF Building (an acronym for individual scan locations and therefore Renewable Energy Engineering Facility) had not been unified, as well as being is a 267 sqm (GIA) timber frame building positioned to the coordinates of the correbeing constructed by Kier Construction sponding BIM model. along with Poynton Bradbury Wynter Both point cloud and as-designed BIM Cole Architects. model were appended to Navisworks

The glue-laminated primary and sec- with non-structural timber elements ondary timber frame structure, prefabri- hidden for clarity. The remaining timber cated timber wall panels, roof joists and structural elements and the as-built roof deck were designed and erected point cloud were then selected and onsite by a timber frame specialist. The pulled into Verity using the ‘Add to design information was issued to the Verity’ [Selected Node] tool and design team in conventional DWG format appeared as itemised elements in table and Poynton Bradbury Wynter Cole form within the Verity window. Architects modelled the key structural At the click of the ‘Analyze’ button and elements within their as-designed BIM input of the tolerance required, the user model for coordination. can sit back and let Verity do its magic.

Once erected onsite, the timber frame Processing time will vary, depending the was 3D laser scanned by local surveyors quantity and complexity of data involved. 3DMSI, who delivered the as-built point Much like rendering a high-resolution

image, Verity is the sort of process you The workshop slab was found to be and review of elements within the might set up and allow to run overnight in within the ±25mm tolerance range. For Navisworks model space. the case of particularly complex projects. the timber frame, Verity found 68% of ele-

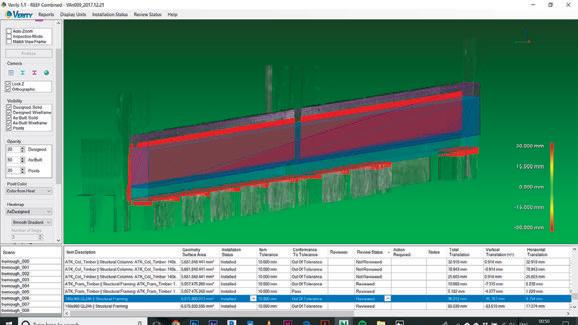

The REEF project analysis of the erect- ments [64 individual elements] to be ‘Out Results in detail ed timber frame was undertaken with a of Tolerance’, 7% [five elements] to be ‘Not In the REEF Project analysis, the five eletolerance of ±10mm, the tolerance stipu- Found’, and 25% [17 elements] within tol- ments that Verity identified as missing lated in the specialist timber frame draw- erance, achieving a ‘Pass’. were highlighted in red. These timber ings and as stated as ‘normally achieva- Results can then be pulled back into members had been coordinated to supble’ in BS 5606:1990 for timber structural Navisworks using the ‘Export Verity port the track-and-spring mechanism for frame-columns and timber components. Properties To Host’ function, which col- the sectional industrial door. At the time On a Dell XPS laptop with Intel Core i7-6700HQ CPU, 16GB RAM and 512GB SSD Verity took 23 minutes and 6 ‘‘ Variability in construction may well the 3D laser scan was undertaken, these elements were yet to be installed and Verity successfully identified their seconds to complete this analy- be inevitable, but understanding and absence, clearly illustrating sis, which consisted of a total of 68 elements, with the point cloud containing nine individumanaging that variability is crucial to a project’s success this back within the Navisworks model space. Furthermore, Verity has the al scans. On completion, Verity opens a Summary Report giving a graphical overview of the results, our-codes the elements back in the ’’ ability to visually interrogate each analysed element, log the ‘Installation Status’ and input additional clearly displaying the percentage of ele- Navisworks model with a green, red, yel- information like ‘Action Required’, ments that ‘Pass’, or were ‘Out of low, or black to match the graphical out- ‘Reviewer’, or ‘Review Status’ within Tolerance’, ‘Not Found’, or ‘Occluded’. put of a ‘Pass’, ‘Not Found’, ‘Out of Verity itself. By highlighting the element

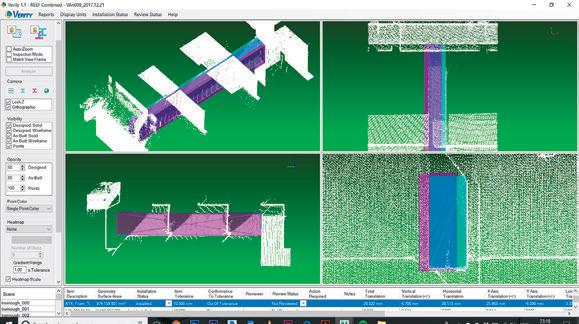

An additional analysis was also Tolerance’ or ‘Occluded’, respectively. from the table, Verity will zoom in on the undertaken for the ground floor slabs, This is a great function for those who instance displaying the as-designed based on the BS 5606:1990 tolerance of wish to use the power of Verity’s geometry in purple, the point cloud as ±25mm for variation from the target advanced algorithms but avoid getting series of white points [which can be togplane for non-suspended floor slabs sucked into the detail of the analysis, gled to the original host colour], and the before laying of screed. because it enables quick identification generated as-built geometry in cyan.

1 Green, yellow and red is used to represent ‘Pass’, ‘Out of Tolerance’ or ‘Not Found’ 2 In Verity, 3D geometry can be viewed in orthographic or perspective views, in single window or split window arrangement 3 There were a few anomalies where Verity incorrectly generated as-built geometries, including these perimeter beam elements 4 5 Colour-coded elements with and without point clouds for reference

All of these can be toggled on and off, depending on what information is required for the review. The 3D geometry can be viewed in orthographic or perspective views, in single window or split window arrangement, and be zoomed, panned and orbited like any conventional 3D model.

Through interrogation at this detail, you begin to see the subtle and more explicit variations between the as-designed geometry and generated as-built geometry, not only in the form of horizontal and vertical translations but also horizontal, vertical and sectional twist rotations.

We jumped to some of the larger anomalous discrepancies identified by Verity, where it could be seen that the software had incorrectly generated as-built geometries, which in turn was incorrectly producing some large ‘Out Of Tolerance’ results. This was the case for 12 perimeter beam elements, all located within the same junction detail.

It was clear to tell that these anomalies derived from the non-inclusion of the timber wall plates in the as-designed model during the analysis, since Verity had mistaken the underside of the wall plate from the as-built point cloud for the underside of the beam, and subsequently generated the

as-built geometry of the beam with the thickness of the wall plate lower than it should have been. This was consistent for all 12 perimeter beam elements located at that elevation with that detail.

A heat map and associated heat map scale bar can be turned on to visualise either the deviation of the generated asbuilt geometry from the as-designed, or the deviation of the generated as-built geometry from the scanned point cloud. The heat map tolerance range can be increased, beyond that undertaken by Verity in the subsequent analysis, by using a different tolerance factor. This could be very helpful in some situations, saving users from needing to re-run additional analyses where a different tolerance range may be required.

Verity also has the ability to move selected elements to their as-built locations, again via a click of a button. By selecting a single element or multiple elements from the table in Verity and clicking ‘Move Host Item To As-Built’, Verity will push its as-built geometry back into Navisworks, replacing the asdesigned element locations with the asbuilt locations.

This is a powerful function, giving the reviewer the ability to quickly produce an accurate as-built model of the constructed work onsite, which can be utilised for the duration of the project and, indeed, for the building’s onward lifecycle. Point cloud data of the as- Heat maps can be flow with the complexity and built host geometry, as-built used to visualise millimeter precision of compoheat map or as-designed heat deviations between as-built and as- nents and elements placed map can also be exported from designed within BIM models issued by Verity to native software pack- architects, engineers and other ages used by the design team to update design team members. their respective design models for an Thus, utilisation of the 3D laser scan, accurate as-built model. capturing onsite progress at a forensic

The results from Verity’s analysis can level of detail, and comprehensive analybe exported in CSV format or HTML. sis with an automated verification softThe CSV format will export the selected ware like Verity represents an extremely items from the itemised table in Verity, powerful workflow. What’s more, it’s a enabling them to viewed or shared in workflow that could be used not only by Excel. The HTML format can be exported contractors as part of their internal qualias an overall summary report of the anal- ty assurance and quality control proceysis, a table of the selected items, or a dures, but also by more savvy architects table of the selected items with hyper- and clients. linked detailed report illustrating the Verity is not intended to replace the role element’s deviations as numerical data of quality assurance or quality control and graphical heat map imagery. These reviewer, but its ability to analyse large functions, combined with the ability to amounts of detailed geometry in an autoexport the as-built point cloud data and mated manner instead facilitates the push Verity’s as-built geometry back into review of many more results to a much Navisworks, make sharing Verity’s higher degree of detail. results simple and straightforward. This, combined with its ability to update model geometry to represent the Conclusion as-built, not only provides a workflow Variability in construction may well be with greatly improved project accuracy inevitable, but understanding and man- during the construction stages, but also aging that variability is crucial to a pro- enables this newly identified accuracy to ject’s success, if clashes, rework and be passed on to end-users and facility delays are to be avoided. managers throughout the entire lifecycle

A select series of spot checks with a of a building. tape measure or total station theodolite ■ clearedge3d.com ■ pbwc.co.uk ■ 3dmsi.co.uk no longer represent a compatible work- ■ kier.co.uk ■ jacobdown.co.uk