22 minute read

The CDE conundrum

Current common data environments have a number of shortcomings. What needs to happen for them to better support efficient information-sharing in our industry, asks Paul Wilkinson?

When it comes to defining a common data environment, or a CDE, confusion abounds. If we want an ‘official’ definition, we might look to the UK Avanti Project, which ran between 2001 and 2005 and drove the development of BS 1192:2007. This describes a CDE as, “a repository, [...] a project extranet or electronic data management system.”

Two years later, PAS 1192-2:2013 defined a CDE thus: “A single source of information for any given project, used to collect, manage and disseminate all relevant approved project documents for multidisciplinary teams in a managed process.” This could take the form of “a project server, an extranet, a file-based retrieval system or other suitable toolset.”

In other words, at different times, the industry has talked about documents and file repositories on one hand and data management systems on the other, as if they were the same thing.

“In looking to move away from clunky reliance on emails and attachments, which was simply a digitisation of a clunky paper process, we seem to have confused our aspirations to share data and manage BIM processes, with specifications about exchanging files,” says Turner & Townsend BIM consultant Shaun Farrell. “As a result, our processes often tend to focus on manually exchaning, checking and approving file-based deliverables.”

Farrell believes that CDEs should be more integrated with the authoring platforms used to create information – not just BIM tools, but also other digital tools including Microsoft Office, Oracle Primavera and costing and estimating platforms, giving seamless support for time-based simulations, cost and asset/ operational management data.

However, he recognises that industry inertia, current information management practices and the widespread familiarity of managing documents and folders make this a challenge.

Evolution, not revolution In the last issue of AEC Magazine, I outlined how, since 2011, the UK industry focus on BIM has offered a wealth of opportunities to software-as-a-service (SaaS) providers specialising in construction collaboration. Most of these now provide a CDE as part of this service, to enable the sharing of modelbased information and related workflows by teams looking to comply with the UK BIM Level 2 requirements. These include Aconex, Asite, Autodesk BIM360, Bentley ProjectWise, GroupBC and Viewpoint. But the shift to providing CDEs has been an evolution, not a revolution.

When Farrell digs into the detail of CDE use, he says, compliance with the BS 1192:2007 process (see box below, The BS 1192 process in a nutshell) is pretty patchy, often breaking down at the very first ‘check, review, approve’ gateway.

Most of the current crop of CDE platforms do not handle the transition from ‘Work In Progress’ (WIP) to ‘Shared’ particularly well, he says, due to lack of integration with the authoring platform and the fact that few authoring platforms integrate with collaboration platforms, except when they are vendor-specific solutions designed to do exactly that. “Designers are making some key early decisions here, and yet we are often only capturing the final output from their

The BS 1192 process in a nutshell

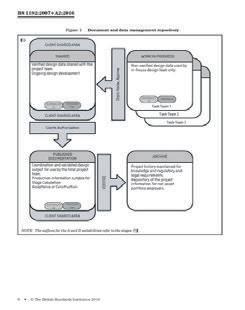

BS 1192:2007 outlined a four-step process following the life history of information. This starts with initial design ‘Work in Progress’ (WIP), then progresses through ‘Shared’ to ‘Published’, with any outdated or superseded information going to ‘Archive’.

Typically, WIP-stage information is only viewable by those involved within a company, but it still needs to be captured in the CDE as it will be subject to checks and approvals that might need to be audited later.

Once WIP is ‘Shared’, other members of the design and construction team can see the information – it might be used for coordination and clash detection, for example – and once these processes are completed, it may be ‘Published’. This means the work now constitutes a specific client deliverable: a planning application, a construction status document, model or drawing are common examples.

A lot of information is also given ‘Client Published’ status, meaning it becomes part of the client’s asset information system.

decision-making, then uploading that deliverable to the CDE. I’ve yet to see many CDEs that allow source information and references to be tracked and linked back to WIP. Clear and auditable change management between information exchanges is still a human activity, or specialist platform-based activities based on file-by-file comparison, rather than information progress over time.”

One solution that potentially bridges the gap is Opentree’s Cabinet. Teessidebased Opentree provides an internal document management application that connects via APIs to several CDE platforms (Viewpoint, Aconex and Viewpoint are among early partners), allowing the sharing of CAD, BIM, MS Office and other files. Importantly, Cabinet enables sharing of both files and their related metadata, and then ensures metadata is synchronised if, for example, a Revit model’s suitability status is changed.

Nottinghamshire-based contractor North Midland Construction recently turned to Viewpoint and Opentree to help it demonstrate PAS1192 compliance processes to its clients. “As NM Group provides both design and project delivery services, it is doubly important for us to have a strong platform to connect our backoffice information management to the daily needs of our project teams,” explains Gary Ross, head of BIM at the company. “Cabinet will demonstrate to our customers in highways, civil engineering and utilities that we satisfy the BIM process requirements they and their supply chain partners increasingly demand.”

Client ownership But should a CDE be something provided by a contractor or by a project manager? At Turner & Townsend, Farrell believes not:

“Very few of our clients are actually in already been at least one court case relat-

full potential of BIM has not yet been fully realised: “Nobody was building the platforms, and no platforms will succeed if the base data is bad. Garbage in, garbage out. BIM, particularly at Level 1, has been too focused on drawing deliverables rather than data.” Mecheri continues: “Data still isn’t a high priority for everybody; supply chain interest in data only materialises when the client demands delivery of data to agreed standards. We need more aware owners and more mature practitioners. So it’s early days for BIM. It’s a marathon not a sprint.” According to Mecheri, Invicara provides visibility of how products are incorthe construction industry – Invicara is marketed bled into systems, and operto them, the industry is often a necessary evil that as a data platform for the entire lifecycle of a building ated in buildings. It provides a data connection they have to deal with in from manufacturer right order to procure the products produced through to the asset owner-operators’ data by that industry,” he says. While the CDE needs. In January 2018, the company focus has been mainly around PAS 1192-2, announced a $10m investment from conproject delivery and multi-party informa- struction products giant Kingspan, which tion creation, this often isn’t key to the will be helping Invicara pilot solutions. company’s clients, he explains. Mecheri claims that Invicara takes a dif-

“Their ‘business as usual’ tends to focus ferent approach to the current generation on asset operations, including minor and of CDE vendors. “They come from an major works, recognising that operating EDMS background; we come from a world and maintaining built assets can repre- of data,” he says. “We start from validated sent up to 85% of their whole-life cost. So data and then enable clients to put good we need to be thinking more about, and supporting, their long-term information and ‘‘ Data still isn’t a data on top of that, and to then get actionable intelligence from their built data needs – or the needs of the people undertaking facilities management for them.” high priority for everybody; assets. As our entry point is different, so our approach to APIs is different.”

In an ideal world, a CDE supply chain Invicara provides applishould be owned by the interest in data cation programming interowner-operator, he says, with suppliers invited into it for the duration of their only materialises faces (APIs) to allow data to flow between the systems of all the participants in proinputs. “However the reality when the client ject design, delivery and is that we often have multiple CDEs, duplicating data for different businesses and demands delivery of data operation. Its first product, BIM Assure, created a plugin for Autodesk’s Revit to for different parts of the pro- to agreed share data to its cloudcess — design, procurement, standards based platform. “We are the construction, operation — and little agreement on how long these environments Anand Mecheri, Invicara CEO only vendor providing rules-based BIM data validation in the cloud. Solibri need to be set up, secured, stable and accessible.” This is a good point, because there has does BIM validation but on the desktop and the future is all about the cloud,” says Mecheri. ’’ porated into designs, asseming to a dispute involving one party block- Connecting data ing a contractor’s access to a CDE, namely A focus on data could help towards the Trant Engineering v Mott MacDonald. achievement of the ‘Digital Built Britain’

Farrell is not the only observer frus- vision. First articulated in a February trated by over-concentration on the deliv- 2015 report, this gained new impetus from ery phase. Anand Mecheri, CEO of BIM the establishment in November 2018 of a data platform provider Invicara, says the new £5.4m Centre for Digital Built Britain

at the University of Cambridge. perfect by a long way, but we’ve taken the mental and social performance is related

The centre is intended to lead the com- first step in standardising data services to how their built assets perform.” bination of BIM with the Internet of for the entire life cycle of assets, includ- Meanwhile, CDEs are, it seems, a class Things (IoT), advanced data analytics, ing service provision.” of technology compromised by industry data-driven manufacturing and the digi- Bew’s own company, PCSG, for processes still based on the exchange of tal economy, in order to enable the UK to instance, has already helped develop a files and on version and status control of plan new infrastructure more effectively, platform that enables teams to rapidly those files. build it at lower cost and operate and access open and licensed third-party Technology providers could then be maintain it more efficiently. GIS data and combine it with project- creating applications that exploit such

Mark Bew, former chair of the UK BIM specific BIM data to improve planning data services. Shaun Farrell says: “Change Task Group, is a strategic advisor to the CDBB and says: “Level 2 was all about doing the existing ‘‘ We still insist on uploading and management is the biggest challenge – we still can’t track changes easily in something a ubiquimodel better. The future is about doing something different. There is going to be a lot of inertia. The downloading files when data synchronisation is where we need to be tous as Excel for example – as evolution of our technologies has been slow. We still insist on status quo – the ‘we’ve always Shaun Farrell, Turner & Townsend uploading and downloading files done it like this around here’ – is the first hurdle to overcome. There is a general lack of understanding and decision-making (see box below, ’’ when data synchronisation is where we need to be.” Some CDE vendors are trying to faciliof why we need to change and this must Introducing GeoConnect+) tate industry change by integrating with be addressed.” However, such examples are currently other tools to cut data duplication and

Steps have already been taken; for rare. As Invicara’s Anand Mecheri says: speed up processes. Aconex and US venexample, connecting BIM and smart cit- “Construction is the biggest, most com- dor Procore, for example, are building ies thinking to create a Level 2 ‘City pack- plex and least digitised industry on the communities of technology partners conage’ of guidance. “What we will be doing planet. But data will grow in value, par- nected by APIs. Mecheri welcomes this: over the next year,” says Bew, “is gluing ticularly when asset owners start to ana- “A ‘network of systems’ must replace the our BIM and City standards together. lyse their business operational metrics idea of a single CDE application. The alignment of end-to-end data is not and see how better economic, environ- Duplication of data is a huge problem.”

Introducing GeoConnect+

Consultancy PCSG worked with Reading-based GroupBC and Ordnance Survey to develop a service called GeoConnect+, launched at the GeoBusiness event in London in May 2017.

GeoConnect+ connects BIM information with geospatial data in a way that helps large asset owners and operators manage large, disparate estates better. Datasets include OS open data, OS mapping data, land and property data, flood, river and road network data.

The map or satellite imagebased interface is accompanied by a menu of ‘layers’ that can be switched on, singly or in multiple combinations, as required. Users can, for example, view all listed buildings or sites of special scientific interest, in a specific area, and even identify the number of households, complete with addresses and postcode data, that may potentially be affected by a development.

Sussex-based regional contractor Mackley undertakes a wide range of civil engineering projects in marine and river environments. Technical services manager Trevor Mossop, said: “GeoConnect+ simplifies document access and ensures that all of the available documents, pertinent to a geotagged location, are bound together and returned from any device without reliance on understanding the search criteria. This is a massive step forward in the usability of the CDE, where accessibility and ease of use dictate buyin by staff on any project.”

geoconnectplus.com

A Q&A with Allplan

One year on from his appointment as managing director at Allplan, Richard Brotherton speaks to AEC Magazine on how AEC technology is evolving and about the company’s renewed focus on the UK and plans for the future

Q: Historically, Allplan has been with Allplan. As an example, we work tracked through the entire design and strong in Germany, with its very closely with our sister company delivery process. In addition, Allplan is BIM products for architecture, Nevaris [also part of Nemetschek], and intrinsically linked to our CDE and collabengineering and facilities with our cloud CDE [common data envi- oration tool Allplan Bimplus, an open management, but less well- ronment] solution Allplan Bimplus. This platform for managing models and all known in the UK. How do your custom- way, we’re able to link associated project data ers break down by sector? to specific solutions our clients require. Allplan MD with the entire project team. We also support A: Allplan benefits from offering one Richard Brotherton has export of BIM data via platform for architecture, structural and Q: In 2017, Allplan more than 25 years of IFC4 and the open civil engineering and, while different opened a new UK experience in software BIM approach for users will naturally work with different office. Why the UK for the international maximum interoperaaspects of that platform, it provides a sin- and why now? construction industry bility. gle environment for all users. In particular, we believe we offer a unique work- A: The UK has been at and holds a degree in Civil Engineering from Plymouth University Q: Many new memflow that combines 2D and 3D processes the forefront of BIM bers of the Allplan without compromising the quality of processes and digital team, yourself includdrawings. This, in addition to our com- construction for many years and is sup- ed, have a background in structural engiprehensive solution for rebar detailing, ported through the UK government’s BIM neering and fabrication (at Tekla, CSC makes Allplan a compelling solution in initiatives. As a result, we see the UK mar- and AceCad). Should we read anything the engineering market, with over ket as a key player on the international into this, in terms of the direction in 250,000 users across the disciplines. BIM stage. I believe BIM is on the verge of which you intend to take Allplan? Our products are being used on everything from the world’s longest three-tower, ‘‘ The goal of transforming the industry and, with Allplan’s software solutions, we believe we can A: No, this domain knowledge just helps to ensure we continue to provide the cable-stayed bridge, the delivering help the industry achieve its right solutions for our clients. We, of Queensferry Crossing in Scotland, to the world’s longest tunnel, the Gothard Base Level 3 BIM is to provide goal of Level 3 BIM. Q: In the UK, we have some course, have sister companies such as SDS/2 for steel fabrication and PRECAST for concrete fabrication that work togethTunnel in Switzerland, as complete very specific industry initia- er with Allplan to ensure a comprehenwell as many landmark buildings such as the Sky Tower in Germany. traceability of every object, in tives to make BIM a country-wide standard. What developments and capabilisive solution for structural engineering. Again, these are managed seamlessly through our cloud-based CDE platform order to ties has Allplan included in Allplan Bimplus to ensure users can use Q: In the early days of BIM, support the the software to assist cus- best-of-breed tools without compromise, Allplan stood out for its focus on cost management. How has this influenced product entire lifecycle of the project. tomers to meet standards such as the UK version of COBie, for example, and enabling an effective workflow. Q: Software developers have been very development over the years? This is achieve interoperability? keen to jump on the cloud bandwagon something And how does this compare and, at AEC Magazine, we can see how A: Cost management has always been central to Allplan’s offering in countries Allplan has been able to do with what you see globally? A: The goal of delivering this helps collaboration, but we also see hurdles that must still be overcome. How does Allplan handle group working and like Germany, but in reality, for many years Level 3 BIM is to provide distributed team collaboration – and how costing processes are very regional, which makes this workflow difficult to bring to other councomplete traceability of every object, in order to support the entire lifecycle of the project. This ’’ else do you use the cloud? A: We’ve developed Allplan Share, a tries. However, it’s still very much at the is something Allplan has been able to do cloud-based collaboration tool that supheart of our thinking and we fully support for many years. The properties of individ- ports multi-user working, even when initiatives to integrate costing solutions ual drawing elements and objects can be users are in different locations. Based on

Allplan Engineering – Image courtesy of Leonhardt, Andrä and Partner, Germany

Allplan Bimplus, it opens up flexibility in your project teams and removes the obstacles associated with working virtually in the same location.

Q: Coming from the Nemetschek stable of building design products, which also includes well-known brands such as Graphisoft ArchiCAD, Vectorworks and MAXON Cinema4D, how does Allplan differentiate itself from its stablemates – particularly those that offer BIM tools such as Vectorworks and ArchiCAD? And how is the group integrating and cross-pollinating technologies from its different brands?

A: As part of Nemetschek, we are in a unique situation, as some of our offerings might be seen to compete with those of our sister companies. However, we see this competition as healthy and something that drives our technology forward. It also provides customers with choice, enabling them to choose the right tool for the right job. More often than not, we actually complement our sister companies and our combined technologies provide customers with enhanced workflows. An example of this is the work we’ve done on data exchange with SCIA Engineer, whereby a direct connection simplifies interactions between modellers and engineers considerably. This is recognised in the group as a whole, and we have a number of cross-brand initiatives underway to bring enhanced workflow to our clients on platforms such as Allplan Bimplus.

Q: Architects, in particular, seem to be broadening their tool palettes by mixing numerous products together in the realisation of their designs. What kind of capabilities does Allplan offer for collaborative open BIM working and how do you see this changing in the future?

A: Allplan Bimplus supports a CDE across both open standard formats, such as IFC and so on, and closed BIM methodologies – for example, different API and SDKs. This means that numerous applications can be utilised via this cloud technology across many stakeholders, disciplines and applications, be it for architecture, engineering, costing tools or newer technologies such as HoloLens.

Q: Many users would agree that, when creating BIM models, automated 2D output can leave a lot to be desired. That can lead to a lot of reworking to get 2D output into the state in which customers would want to see it. Some users break up the process and take their drawings into AutoCAD, which means they lose the benefits of quick changes driving new drawings. Allplan has extensive documentation editing tools; do customers accept the default option, or is documentediting of sections and elevations still a significant part of the process?

A: I believe Allplan is in a unique position: its extensive 2D drawing functionality has been in the market for many years and combined with the requirements of 3D modelling. Therefore, we don’t have to compromise on drawing quality or the 3D modelling as a number of our competitors do. We can actually work predominantly in 2D and still derive the 3D BIM model. Some applications are mainly layout tools and not created to generate deliverables for detailed reinforcement, hence the user is required to manually create 2D deliverables or use alternative systems, thus breaking BIM workflows and introducing potential errors. With Allplan, the solution is not just about creating the layout but also using familiar working methods in the 2D/3D environment to detail reinforcement, thus delivering full manufacturing data and quality production information. Even better, with Allplan, users can detail almost any shape imaginable using a wide range of bar bending codes, including BS8666.

Q: We’re seeing a current trend in which users are using CDEs to ‘data wrangle’ proprietary data into a single, synchronised environment. What are your feelings on this?

A: Engineers and architects need flexibility; they also need to deliver constructible data, which often will involve numerous software solutions to ensure that no compromise is made on the quality of the project data. Also, it is simply more efficient to use the correct tool! We therefore believe that we need to be flexible and be able to communicate with many native and open file sources. It’s the philosophy behind Allplan Bimplus to be completely open to other solutions that our clients need.

Q: Model sizes are a common problem in BIM projects, with models growing as more detail is added. What’s a typical file size for a customer project for Allplan? What kind of RAM would a typical user require and does Allplan have methodologies for breaking up models into smaller work packages?

A: Our recommended RAM requirement for a standard PC is at least 16GB. Graphic cards are also important if you wish to take advantage of 4K resolution, which is new for Allplan 2018. An overall model can be broken down into a series of structured sub models, thus enabling users to only work on the sub models they need to, even in a multi-user environment. This makes the workflow quicker, more efficient and more manageable and we believe keeps file sizes comparatively low. In reality, therefore file size does not tend to be an issue. Q: ArchiCAD has a live connection to Grasshopper. Does Allplan have any similar capabilities/workflows for computational geometry?

A: Allplan supports computational design with the import of the resultant model from the Grasshopper script.

Q: Could you give us some details on how Allplan supports parametrics?

A: Allplan is a full parametric solid modelling solution. We also have enhanced parametric intelligent objects controlled by Python called Pythonparts. An intelligent Pythonparts editor interface enables users to create their very own parametric objects and combine basic elements from pre-defined building objects – including columns, beams, foundations and stairs, for example – to create individual assemblies. In this way, recurring tasks are completed in far less time.

Q: It’s no secret that learning a BIM process can be a massive undertaking and thus a barrier to adoption for some potential users. What strategies does Allplan use in order to speed up training and keep the product from becoming excessively complicated?

A: Training is a vital element when implementing a solution such as Allplan. To maximise return on investment, training is always advised. We have a dedicated training centre in all our offices, in addition to telephone/email support from technical services and online self-help forums. All these resources help clients get up to speed as quickly as possible. We also have dedicated BIM consultants who offer both BIM consultancy courses and certification as well as BIM templates to companies and public-sector bodies. We publish an annual BIM Compendium [www.tinyurl. com/BIMComp] and invest significantly in BIM-related research at universities including the Technical University of Munich (TUM), the Leonhard Obermeyer Centre (LOC). Finally, we are of course the founders of OPEN BIM.

Q: With an increasing focus on digital fabrication in AEC, what’s Allplan’s vision in this area?

A: This is an exciting area as we see more and more technology enter the market from robots, 3D printing, even electronic bricklayers! It’s our vision to interface with such solutions, so that the BIM data created by an engineer is fully utilised downstream. We have invested in numerous projects around Machine Learning and Artificial Intelligence, which we hope to be bringing to market in the coming years.

Q: Finally, looking to the future, what technologies and processes do you think will drive adoption and improve the benefits already delivered by BIM?

A: First, we need to listen to our customers’ requirements and help them make the transition to BIM as easily as possible. This means ensuring we help them digitise core deliverables such as drawings, while introducing new workflows to support BIM adoption. And there is no doubt that cloud-based technology has its place and will continue to drive digital processes, with open collaborative platforms such as Allplan Bimplus.