12 minute read

BIM workflows

Reality capture for BIM reshaping industry practices

An explosion is underway in the use of visual data collected and used in near-real-time for construction, as Randall S. Newton reports.

Aris Market Square is a mid- we haven’t been able to do before,” says scanning is largely due rise tower currently under Joe Jones, a senior project manager with to the new affordability construction in Houston, Austin Commercial. “This is a game- of UAVs, as well as software Texas, an upscale residential/ changer for us.” advances that make photocommercial building adjacent to a histor- graphic imagery useful as a ic downtown park. Scan-to-BIM explosion source of site data alongside –

In a high-growth city like Houston, this Aris Market Square is just one example or sometimes replacing – laser could be just one more tower going up, of an explosion in the use of reality data point cloud scan data. but this particular project is breaking captured and used in near-real-time for Scan data in BIM is used in ground for its leading-edge use of visuali- construction. It may be far removed from three ways: design, construction, sation technology for construction. what most industry professionals think and asset management. The rea-

General contractor Urban Oaks of as BIM, but for construction compa- son scan-to-BIM is currently Builders and subcontractor Austin nies, building imagery scanning offers a booming in construction is twoCommercial are working with fold, says Tom Greaves, chief technology firms 3DR and Autodesk to automate construction management. Using 3DR’s ‘‘ A new era of drone scanning with fast marketing officer of DotProduct and a 13-year veteran of the AEC scan-data SiteScan and a Sony R10C cam- data turnover answers construction’s business in a variety of era, the contractors used an need for good data quickly roles. Unmanned Aerial Vehicle (UAV) – a drone – to take hundreds of photos of the building’s concrete ’’ “Construction needs a good answer now,” says Greaves. “A good structure, roof and exterior as it went up. fast return on investment and reaps divi- answer today is better The photos were then processed using dends in saved time, increased efficiency than a great answer a SiteScan and Autodesk ReMake to create and increased job-site safety. week from now.” a 3D model to prepare visualisations Real-time scan for construction man- The new era of such as textures and wireframe views. agement is just one use case in the new drone scanning with

As a result, instead of having construc- area of scan-to-BIM technology. fast data turnover tion crews climb up and down scaffold- Terrestrial (tripod-mounted) laser scan- answers coning to conduct quality control checks, ners have been around for years, but their struction’s project managers can take updated drone high prices and complicated operation need for photogrammetric scans and apply them have made them useful only on very large to the model. projects with plenty of room for teams to

“This technology allows us to collect collect data from many angles. data in an urban environment in a way Today’s rapid adoption of

The contractor in charge of construction for Aris Market Square in Houston is using scan data to monitor construction in near-real-time (Source: Autodesk)

Would you be able to walk the plank in the vertigo-inducing WorldViz demo?

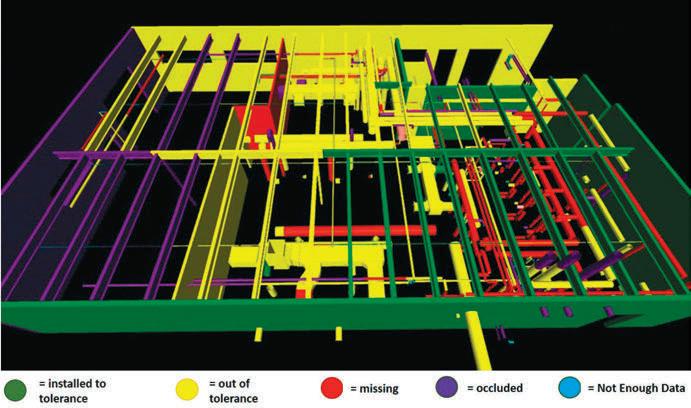

good data quickly. “If you Skur uses existing laser with both existing models Sometimes, this means just use scan data can capture as-found and scanning hardware and its and other forms of visual as a representation, and sometimes, it use it against the design proprietary software to quickly turn point clouds information. Third, move means extracting geometry features from model quickly, you have into actionable design and to data ‘consumption’ scan data for use in design. something.” construction data. (Source: Skur) where the data is repur- Huie says the widespread adoption of

Design products like posed, translated and edit- scan data is “driving us to make extra Revit, MicroStation, ArchiCAD and other ed for specific tasks along the design- investment.” Bentley recently released an architectural BIM tools are labour-inten- build-operate continuum. Fourth, use the update to its ContextCapture software, sive, notes Greaves – and labour-intensive data for business decisions. which allows both laser point clouds and also means time-intensive. Construction Along the way, the ‘reality’ level of the photos to be integrated into one data managers are familiar with the idea of data matches the use case. Sometimes, all model. Bentley’s Fredericque expands on throwing labour at a job to compress time, that is needed is a visualisation of how what the near future holds: but design doesn’t work that way. much land will be impacted by construc- “There is a coming fusion of sensor

“Our phone- and tablet-based solutions tion. Sometimes, the scan data has to types and sizes, and rapid adoption; it is let you capture the geometry of a newly installed pump room say, in a few minutes,” says Greaves. “A few minutes later, become the foundation for creating design data, because it is the most cost‘‘ People buy a transformative technology. The short time it will take to create 3D models the point cloud can be compared to the BIM either on the jobsite or in the stakeholders’ offices. The small files (<40 MB) effective and fastest way from idea to design model. “We look at scan-to-BIM scanners that create great will change how people manage and process infrastructure projects.” from DotProduct scanners let project as much bigger than creat- point clouds – managers make swift coordination deci sions without waiting for specialist sur vey crews or CAD modellers.” ing actionable geometry,” says Bentley’s David Huie, a product marketing manager but they don’t want point Straight to the geometry Much of the use of scan data for building information and 20-year Bentley veter- clouds, they focuses on the ability to refReality modelling an. “The paradigm of scan want vectors. erence or provide context, Bentley Systems has been assembling a set of scan-to-BIM tools in recent years, mostly by acquisition. Benoit data to geometry is not [always] the ideal use.” For understanding They want data in a format they but there is also a big market for turning point clouds or photos into geometry for Fredericque is a senior product line man- brownfield environments, already use direct use inside a BIM ager in charge of scan technology, which for communicating design Mark Senior, authoring tool. Arithmetica the company refers to collectively as ‘reality modelling’. intent or construction progress, or to represent 3D for Arithmetica started as a small software house to serve London’s “We look at scan-to-BIM from the workflow point of view,” says operations, scan data is many times preferable to ’’ film industry, but has found itself in the middle of BIM. Fredericque. First, acquire the data with repurposing BIM data created by design- Arithmetica’s PointFuse can take point scanning or photography. Second, con- ers and engineers. cloud data or photogrammetry from vert it to data, and generate what Bentley “Add CAD data to go to the highest drones and generate 3D vector geometry. calls a ‘reality mesh’, an overlay for use degree of intelligence,” says Huie. The software can identify natural break

lines across the object’s geometry, making it possible to select, investigate and extract features like doors, walls, windows and other building elements. It allows building specialists in areas such as mechanical, electrical and plumbing to work with captured data without conversion to a 3D geometry format.

In its current form, PointFuse does not automatically classify geometry, but its developers see that as the logical evolution of the product.

“BIM isn’t really just about 3D models,” notes Will Tompkinson, a US-based consultant who helps AEC clients implement PointFuse. “BIM is a workflow for documenting what is to be on site.”

“We streamline the point cloud conversion experience,” adds Mark Senior, business development manager at Arithmetica. “People buy scanners that create great point clouds – but they don’t want point clouds, they want vectors. They want data in a format they already use.”

From extraction to verification For several years, ClearEdge3D has published the EdgeWise portfolio of software, designed to automate the extraction of features from point cloud data. It started with intelligent identification of piping for process and power plants, then expanded the software’s capabilities to recognise other building elements. It now has a suite of products that extract a variety of features that can be added to a BIM model much faster than by manual methods.

Construction services firm 3DIS recently created a complete as-built Revit model of a newly constructed building at Kettering University in Flint, Michigan. Typically, such a job would require one day of laser scanning, a half-day registering the scans, five days of modelling in

Would you be able to walk the plank in the vertigo-inducing WorldViz demo?

AutoCAD to draw features A team from Severn requiring remediation or from the scan data, and two Partnership needed two weeks to gather the point cloud data other attention. days of tracing in Revit. necessary to build a Revit “Construction verification

Using EdgeWise model of the Royal Institute could be seen as one of the Building, 3DIS eliminated the modelling step in of Chartered Surveyors headquarters. (Source: Severn Partnership) missing links in the BIM chain,” says Michael AutoCAD and reduced how Johnson at Plowman long it took to get to Revit data by 55%. Craven, a leading UK survey firm that “What used to take days to process can has been testing Verity. “There is an now be completed in hours,” says Nick evolving need for a software tool that can Bobbitt of 3DIS. automate the process of verifying con-

The newest product in the EdgeWise struction progress and accuracy.” line is Verity, software for construction Verity data can be viewed in Autodesk verification, which is sold in the UK by Navisworks or Revit. Excitech. The software verifies accuracy of as-built construction against a design Irregular geometry in Revit model. ClearEdge3D claims commercial Revit has a reputation for being difficult construction routinely spends 5% of a to work with for irregular objects and project’s actual cost on fixing “poorly unusual design flourishes. The latest ediconstructed and out-of-tolerance work.” tion of Scan to BIM software from Verity is designed to shortcut the process ImaginIT Technologies offers a new way of finding out-of-spec work early, by com- to deal with unusual elements. Items like paring current as-built scan data to the built-in art objects (think gargoyles) or original design model, flagging problems intricate wainscoting can be scanned at high resolution. The resulting data can be extracted and converted to a Revit library object for placement in a model. Scan to BIM is an add-on to Autodesk Revit; it works inside the product, creating a natural familiarity to the process of bringing scan data into Revit as model elements. In addition to modelling intricate objects, the latest version of Scan to BIM automates the recognition and extraction of wall batches from a point cloud. Midwestern Consulting is a US-based civil engineering consulting firm special-

ising in large building construction projects. As its customers migrated from AutoCAD to Revit, they noticed a simultaneous increase in the number of times laser cloud scan data was being modelled first in AutoCAD, then again in Revit.

Midwest started using ImaginIT’s Scan to BIM to help its clients reduce the time to turn scan data into intelligent model data. On one preliminary consulting project for a large government building, Midwestern documented a 40% reduction in cost to turn as-built data into an intelligent building model. Most of the savings lay in the reduction of designer time by importing intelligent Revit assets from scan data.

Scan-to-BIM as a service Not every AEC firm wants to become an expert in gathering site data for BIM. Fortunately, there is a strong service community staying current on the technology. Severn Partnership is one of many UK firms with years of survey experience that has moved into using laser scanners and drones for gathering data and delivering BIM-ready data for clients.

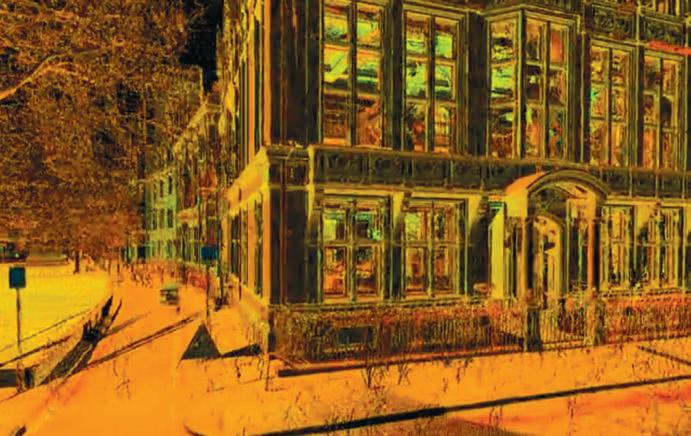

Working with the Royal Institute of Chartered Surveyors (RICS), Severn recently completed a scan of RICS’ headquarters. The Institute wanted first-hand experience in procurement, use and management of BIM data starting with the asbuilt. The historic RICS headquarters are in London’s Parliament Square, opposite Big Ben and the Houses of Parliament, comprising several different buildings that have evolved over centuries, making for a challenging assignment.

A survey team was on-site for two weeks. Some rooms were simple; others, including the Library, were filled with bespoke structural features. The Severn team turned the scan data into Revit model data with a high level of detail (LOD) factor, befitting the complexity and non-uniform nature of the RICS headquarters.

Point clouds to the cloud Point cloud files are massive; it is common for them to be measured in terabytes. Processing such behemoths can tie up the average workstation for days. A US-based start-up Skur intends to bypass desktop processing of point cloud data for BIM by taking it to the cloud.

Skur is using a proprietary process and Photogrammetry the vast parallel processing capabilities of the cloud as a way to streamline the use of scan data for rapid visualisation of large-scale environments. The goal is to make data immediately available for design review and project progress reports. Skur claims its software “can tell you not only that an object is off, but by how much and in what direction.”

The process has three steps. First, a client uploads a 3D .dwg files as a basis for comparing the design and the scan. Then the Lidar data is processed to remove unnecessary ‘debris’ that does not impact a progress study. Finally, the two are compared and analysed by the software, which outputs a variances report.

In conclusion, there are many ways that AEC firms can start to tap into scan-toBIM, but the benefits remain largely the same regardless of which one is taken: fast ROI, saved time, increased efficiency and better health and safety conditions for those working on-site.

Randall S. Newton is Principal Analyst at Consilia Vektor. He has been writing about

Photogrammetry versus laser scanning

Accuracy

Error rate

Coverage area

Usability

Software

Required equipment

Updates

Visualisation

AEC technology since 1987.

Accuracy decreases as distance increases

Manual process allows for more user error, but digital error correction is rapidly improving

Scale limits depend on specifics of camera lens and processing power

Errors more likely when dealing with reflective or transparent surfaces

Auto-extraction and meshing software not as mature but improving rapidly

Everyone has a smartphone

All improvements are on software side; no need to buy new equipment to keep up with progress

Better visual representation of textures Laser Scanning

Accuracy within .5 cm for most scanners at stated distances

Error rate is fixed based on the capabilities of the equipment

Accuracy over large spaces

Automated process after targets are placed and scanner is started; less chance for user error

Mature software for auto-extraction and meshing software for point clouds

Fixed-use laser scanners still costly; handhelds coming down in price

Generally need to upgrade physical equipment to keep up with progress

Fuzzy point cloud on highly textures/reflective surfaces