14 minute read

Las Vegas 2017

Autodesk University part 1

At the first Autodesk University in Las Vegas under new CEO Andrew Anagnost, delegates got a taste of the company’s vision and focus for its current and next generation of products. Martyn Day of AEC Magazine attended the event

Autodesk CEO Andrew Anagnost, on stage with Esri president Jack Dangermond, discussing a collaboration which aims to put GIS and BIM at the centre of projects Autodesk University in Las Vegas is probably the biggest CAD event of the year, attended by over 10,000 customers, developers and resellers and hosted in one of Las Vegas’s vast casino hotels. The four-day event offers classes from key Autodesk staff, as well as high-level product experts, along with selected keynotes from the Autodesk top brass and its most innovative customers.

Former CEO Carl Bass generated an explosion of development at the company, firmly switching it from a reliance on 2D products to a range of 3D tools, 3D printers, cloud-based apps, high-end CNC machining, mobile applications, educational software, biotech and even social media.

Under Bass, the company also started its transition from charging customers traditional perpetual software licenses with added annual maintenance charges, to suites of subscription-based products.

Routes to market also started to change, with Autodesk selling more direct and relying less on its army of VARs (value added resellers). The company actively engaged with the resurgent ‘maker’ movement and established BUILD spaces for their activities at major offices (including San Francisco, Toronto, Boston and Portland).

After a run-in with investors who joined the board of the company, an agreement was reached in which Bass stepped down as CEO. A prolonged search for an external or internal replacement ensued, and in June 2017, Autodesk’s board gave the job to the company’s chief marketing officer and senior vice president of business strategy and marketing, Andrew Anagnost.

Anagnost is a 20-year Autodesk veteran who previously worked at NASA Ames Research Center. Under Bass, he served as architect and leader of Autodesk’s business model transition, moving the company to today’s softwareas-a-service (SaaS) model.

Unfortunately, in this reshuffle, Anagnost’s main competitor for the top job, Amar Hanspal, another long-term Autodesk employee and senior vice president of products (that is to say, the executive pretty much in charge of all product development), chose to leave the company.

With Autodesk currently in an income trough, a side-effect of moving from perpetual licence sales to subscriptions, Anagnost has not wasted much time in reorganising the company, adopting a ‘three horizons for innovation’ methodology. The first horizon (H1) is for incremental, successful products (AutoCAD, Inventor, Revit); H2 is for next-generation core businesses (Fusion, Forge); and H3 is for future growth engines (Machine Learning, Artificial Intelligence, Bio and so on).

The consequences of this new strategy have been profound. Many software developments that had failed to gain traction or that were costing more to deliver than they were bringing to the company in terms of revenue have been designated ‘end of life’. These include many iOS applications that are no longer developed, with the exception of Sketchbook Pro.

And, at the time of writing, the company has announced plans to cut some 13 percent of its workforce, or 1,150 jobs. Anagnost says that every penny saved from these lay-offs will be reinvested in the company’s digital infrastructure and construction focus.

For customers, one of the key benefits that they might see from the organisational changes underway is the removal of vertical market silos. For many years, Autodesk has tried to get its software suite to ‘speak the same language’, so that information can be shared seamlessly between each application. Industry silos inhibit these efforts, but a flat structure, combined with the cloud-based Forge back end could help Autodesk to finally achieve its unified data nirvana.

Anagnost’s keynote This year’s Autodesk University was the first time Anagnost could publically deliver his vision of the future of design technology and the company’s key areas of focus for the next few years.

Previous keynotes from Autodesk CEOs have tended to look much further out into the realms of science fiction, rather than on near-term deliverables. Anagnost, in contrast, gave an insightful address on the benefits that automation will bring to society and on how it will change jobs and the nature of work. While many people are concerned about robots in the workplace and the prospect of Artificial Intelligence replacing knowledge jobs, Anagnost pointed to data from past revolutions, which without exception, led to the creation of new jobs. In the case of the digital revolution, for example, the introduction of the PC was seen as a threat to secretaries, but the reality was that personal processing power made

many new jobs possible.

Anagnost argued that robotics and Machine Learning (a branch of Artificial Intelligence) should not be feared, but instead embraced. At the same time, however, the existing workforce should look to re-educate and upskill, in order to make the most of this opportunity.

In the field of design, Autodesk is leading this AI charge, with projects like Dreamcatcher and generative tools like Dynamo, which help engineers and designers create high-quality designs, guaranteed to meet customer needs every time. In other words, AI-powered design tools hold out the promise of enabling design teams to create more designs in less time.

In the past, Autodesk has tended to focus on the manufacturing space, with the development of products like Fusion. that was never intended. Quantum is, in Autodesk’s applications have been writBut Anagnost stressed that he has an fact, a range of services that will be added ten as services, which sit on the cloud expanded view of where Autodesk to Forge and BIM 360, with some of the backbone. These would include DWG, should be focusing next. In some ways, underlying collaboration capabilities rendering, document management, anallinking the past vision of manufacturing being made available to other Autodesk ysis tools, import export, data translawith a future vision of digital construc- products. AEC Magazine hopes to bring tion, reality capture, 3D print optimisation, where the company’s AEC tools are you more information on what has tion, generative design and so on. heading, could drive the next generation become of Quantum and the technologies Through APIs, these underlying serof building through digital fabrication. we have written about in the not-too-dis- vices become accessible to developers, This is a much more balanced view for a tant future. who can mix and match them to quickly company that has its eyes on so many When it comes to Forge, much time and create bespoke applications with commarkets. As a result, attendees from the effort at Autodesk has been spent, with plete file fidelity and easy expansion not construction space were given a lot more little to show. This year’s Autodesk only to Autodesk services, but also food for thought than in previous years. University, by contrast, was dramatic in through webhooks to other services, such

Never one to mince his words, terms of the number of application devel- as Dropbox. These capabilities are also Anagnost told AutoCAD LT users that opers who had embraced the Forge envi- open to Autodesk customers, who can they should not bet the future of their ronment. In the past, Autodesk devel- develop applications for their own company on 2D. The message was clear: if oped products such as AutoCAD, with bespoke solutions. they do, they are betting on the wrong APIs (application programming interfac- Autodesk continues to flesh out thing. Instead, he urged customers to es) that developers would use to access Forge’s capabilities. In March 2018, the explore the value that comes with prod- data created in these programs to per- company will add a range of ‘IO’ capabilucts and services delivered on a subscrip- form tasks such as rendering, document ities – AutoCAD IO, Revit IO, 3ds max tion basis, rather than stick IO. These are headless (interon perpetual licenses. That makes sense: Autodesk is now developing new ‘‘ By getting rid of its silos, the company now faceless) cloud versions of desktop applications and will enable developers to access, machine learning functionality that can only be accessed better resembles the flat structure of its new, edit and create entities in models and drawings that are via the cloud. Older products, cloud-based applications and hopefully, it will stored on Autodesk’s cloud now taken off maintenance, will not benefit from new finally get interoperability nailed services. The promise is that this will fundamentally functions like this. Project Quantum & Forge management, symbol libraries, raster-to’’ change the way that thirdparty applications work, relying less on desktop applications and For those who have followed our articles vector conversion and so on. With each more on data and where it resides. It is on Autodesk’s Project Quantum closely, application, we had a different API that an additional incentive for customers to this year’s Autodesk University may have required the presence of the software to move to cloud products, such as BIM come as something of a disappointment. operate. Additionally, if you really want- 360, where storing data in the cloud can Quantum was only mentioned once and ed to create a complete, tailored applica- open up new possibilities to leverage only then to say that it would be included tion, you would have to license the model analysis and machine learning. in BIM 360. It turns out that by mention- underlying application (the original ver- That doesn’t mean that desktop appliing Quantum and ‘productifying’ the sions), which was very expensive. cations are going away. Authoring tools term, Autodesk became sensitive that it Forge is a total rethink of this. Key will still be required but, over time, was creating demand for an application components that are common to there will be more benefits to storing

project data on the cloud for collaborative workflows.

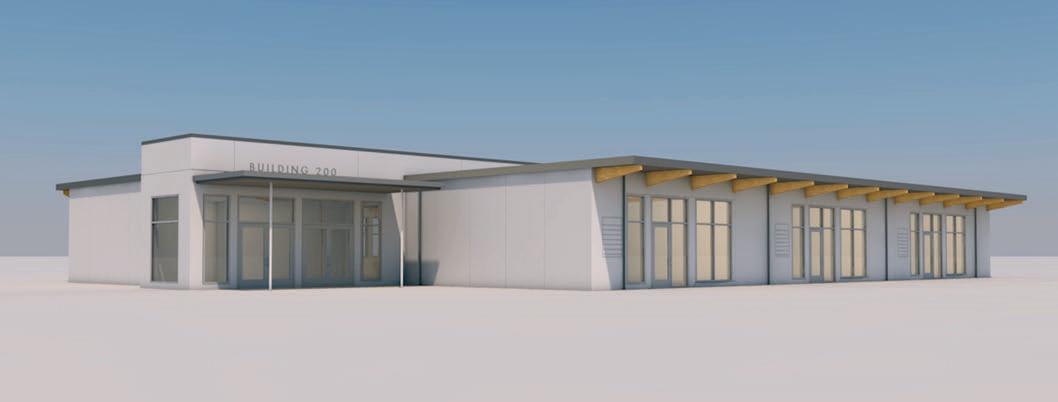

Forge Fund invests in construction To help developers get on board and start working in the Forge environment, Autodesk previously announced a multimillion dollar fund. The lion’s share of this, however, went towards the manufacturing space. With the new focus on construction, Autodesk has systematically invested in a number of start-ups this year, including SmartVid.io, ManufactOn and Project Frog.

At Autodesk University, the company announced the fourth investment in five months, by leading the funding round for Assemble Systems. This company provides a SaaS platform that consumes BIM models, drawings and point clouds, enabling construction professionals to condition, query and connect the data to key workflows.

Tools cover bid management, estimates, project management, scheduling and finance, in view of the way that adoption of BIM and cloud technologies continues to accelerate across the construction industry. Assemble Systems will integrate its technology with Forge and will strengthen BIM 360’s pre-construction data management, quantification, estimation and other associated workflows.

Assemble extracts and federates models from Revit and AutoCAD and other design systems into projects. This enables the customer to group, sort and filter data into usable construction packages, to be used for quantification, estimating, shared subcontractor views and other workflows. As design models change, Assemble checks for those changes and reports on the impact to the project quantity, cost and schedule. ESRI partnership Autodesk is now using its At the same time, the On stage at Autodesk Forge Fund to invest in more company needs to keep University, Autodesk and construction-focused firms, including Project Frog, with a an eye on delivering ESRI announced a new view to developing a cloud-based value for the subscription strategic alliance to platform to streamline design money on which it now advance infrastructure and engineering processes and optimise architectural design for relies. This year’s deciplanning and design. manufacturing sion to add even more This partnership will products to its subscripbuild the bridge between BIM and GIS tion collections, while welcome, does not mapping technologies. Combining their necessarily mean that customers will technologies, Autodesk and ESRI are derive any extra value from their particilooking to enable a broad range of pation. In our interview with Anagnost industries to gain better context by visu- back in June, he acknowledged that there alizing data of the man-made world, the were ongoing issues and asked for a year environment, its residents and the net- to really deliver on subscription value for works that weave these all together. existing customers.

Esri is a major supplier of geographic By getting rid of its silos, the company information system (GIS) software, with now better resembles the flat structure an estimated 43% share of the global of its new, cloud-based applications. market. It is headquartered in Redlands, Hopefully, it will finally get interoperaCalifornia, with annual sales of some bility nailed and its collections will start $1.1 billion. to work more like products in the Adobe

This partnership will result in the Creative suite. Meanwhile, Forge is now integration of Autodesk and ESRI tech- starting to make more sense and deliver nologies, allowing industry profession- on some of the promises that the move to als to synthesise information from both the cloud could bring. On the exhibition BIM and GIS, to enable a more connect- show floor at the event, a number of ed infrastructure. developers were showcasing Forge-

Benefits will include reductions in based applications, giving an idea of the permissions, through improved stake- type of capabilities we can expect in holder engagement; more sustainable future. We suspect this will bring a and resilient design, through enhanced renaissance to Autodesk’s developer netproject insight; and reduced risk, work and, with some very visual dragthrough improved end-to-end flow of and-drop tools in development, could materials, resource availability and open up customisation to a new generascheduling during construction. tion of users.

Conclusion Autodesk may appear to be a company in flux. Anagnost is making radical changes, while it simultaneously goes through a subscription-related trough, as well as lay-offs, and aims for a 50/50 direct sales/reseller model.

■ au.autodesk.com

In the second part of this report, we will look at core developments within Autodesk BIM360 and analyse the AEC keynote at Autodesk University, which provided insight into the company’s future vision for construction with digital fabrication.

RE-REGISTER NOW to ensure you receive your regular copy

Building Information Modelling (BIM) for Architecture, Engineering and ConstructionBuilding Information Modelling (BIM) technology and beyond

FREE subscription aecmag.com/ subscriptions

AR – from pipe dream to pipe reality

Greg Corke reports on a new Augmented Reality (AR) research and development project from Bentley Systems designed to help visualise and improve records of subsurface utility pipes

Previous research into Augmented Reality (AR) at Bentley Systems has focused on giving workers X-Ray vision to see utility pipes in 3D beneath the surface of a road. But if the exact depth of the pipes is not known, as is often the case, displaying them at the wrong depth could mislead the worker.

Bentley’s resident AR/VR expert Stéphane Côté has been leading an R&D effort to explore the benefits and practicality of displaying 2D pipes onto the surface of the road instead.

Côté’s team started by creating a reality mesh of the area using ContextCapture, then projected pipe maps vertically onto the mesh. On site, using the Microsoft HoloLens, the mesh was aligned with the physical world using pre-defined tie points.

Next, the mesh was removed, leaving difference on site and update the database pipe maps directly projected onto the accordingly. road surface. The resulting application, But what about buried pipes? Côté’s says Côté, can be used to find pipes, mark team has also been doing research into their position and quickly how to capture the exact locate valves. Côté explained that, thanks to the accuracy of ‘‘ The accuracy position of pipes every time a road is dug up for maintenance work. While both the Hololens and the of the ContextCapture is perfect for ContextCapture meshes, projecting pipe maps directaugmentation this, Côté acknowledged that the method has to be quick ly onto road surfaces might depends on the and easy so as not to delay turn out to be a reliable accuracy of the excavation work. method for displaying pipe location. pipe maps The solution was to attach some GoPro cameras to the

Of course, the accuracy of themselves, excavator boom via a custom the augmentation depends on the accuracy of pipe maps which is not rig. The videos were then fed into ContextCapture to prothemselves, which is not always great duce a mesh showing pipes, always great. But Côté explained that such a tool might also facilitate the update of pipe ’’ as well as surrounding manholes and drains. Côté concluded that this process could map records as, when it came to objects be used to progressively update pipe like manhole covers, it could clearly show maps during regular maintenance work the difference between the map and the around a city. reality. The user could then highlight the ■ bentley.com