- Connection INDEX 2 Steel Structure Axonometry 1 Description 01 02 04 10 11 16 21 22 25 30 39 48 54 3 Structural Drawings 4 Loads Analysis, Design & Check of secondary beam 5 Design & Check of other structure - Roof - Floor - Roof Truss - Cantilever - Border Secondary Beam - Floor Truss - Pillar

DESCRIPTION

The project consists in a mixed-use building made by circular ring with a height of 13.5 meters (2 stories, pilots in some parts for entrance). The upper level is for museum, it's an open space with some double height from the ground foor but without partitions due to the function light, and circulation reasons. The lower level is mainly for offce, commercial, cantin, and reception of the museum.

Because of the height, the pillars are used: STEEL CIRCULAR HOLLOW PILLAR (d=60mm, also considering architectural reason).

The roof secondary beams are IPE330, (they are dimensioned considering the heavist slab, for worker's mantainance of the building, with a live load of 0.5 KN/m2).

While the foor secondary beams are IPE 360. The border secondary beam IPE330 are adopted. The cantilever on the edges we use IPE360 where under concentrated loads.(they are dimensioned considering the heavist slab, the functon of muswum, with a live load of 5 KN/m2).

For roof truss, we use pairs of combination of UPN 65 (each profle) for all horizontal members, all vertical & diagonal members: pairs of L 50 (each profle).

For foor truss, all horizontal members: pairs of combination of UPN 100 (each profle). For all diagonal members: pairs of combination of L 60 (each profle). For all vertical members: pairs of combination of L 50 (each profle).

The connection of cantilever and border secondary beams happends through a steel plate welded to the end of the section of the border secondary beams then bolted to the fange of the cantilevers. While the connection of truss elements are fllet welded with each other.

1

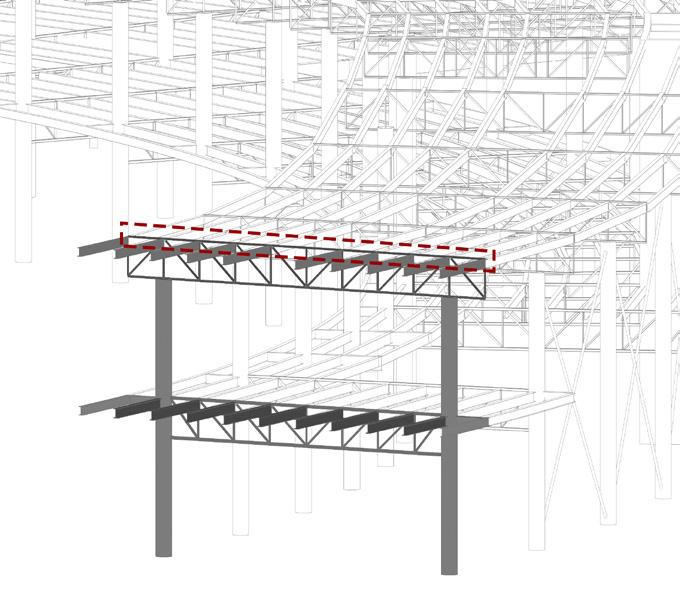

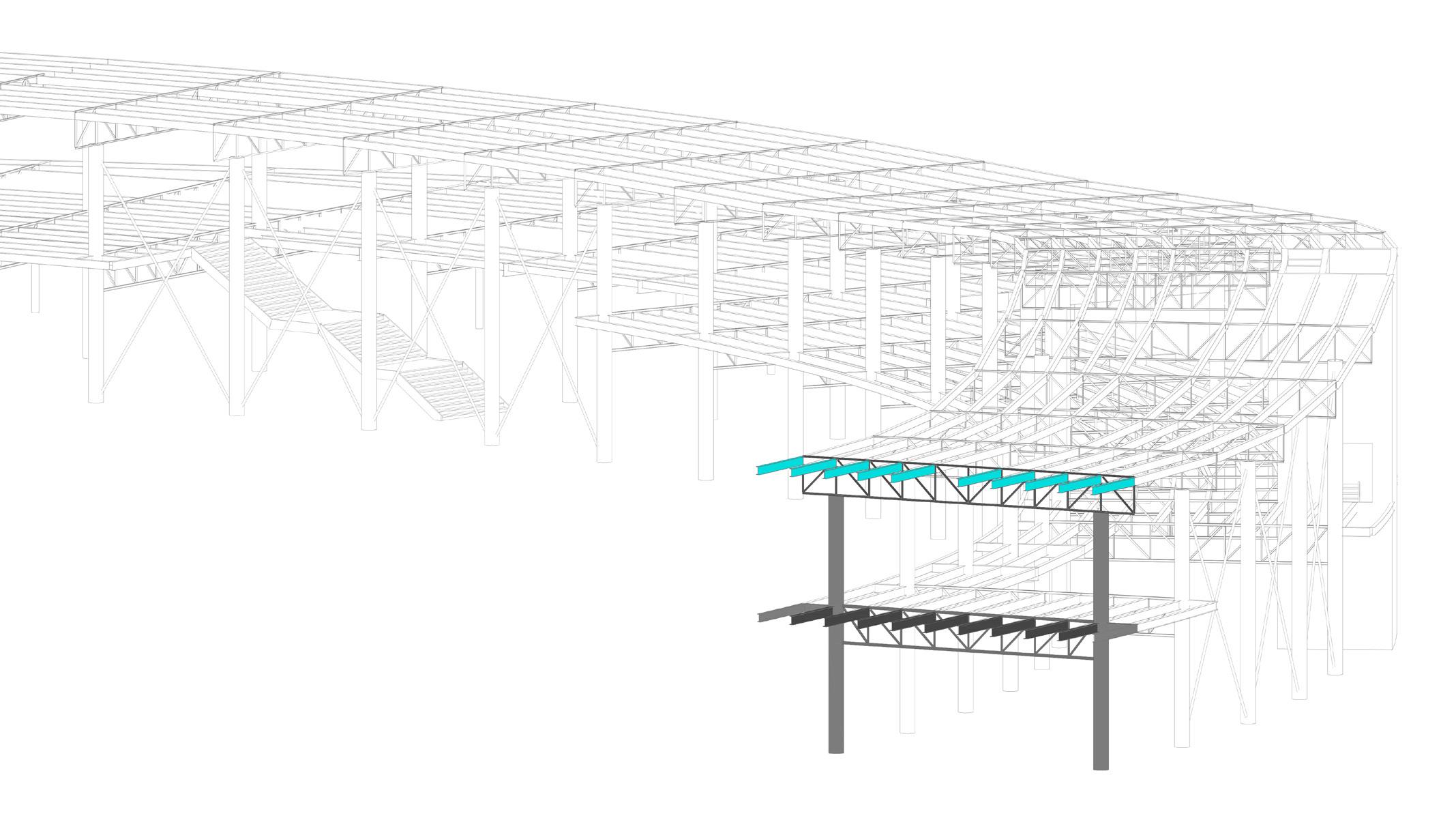

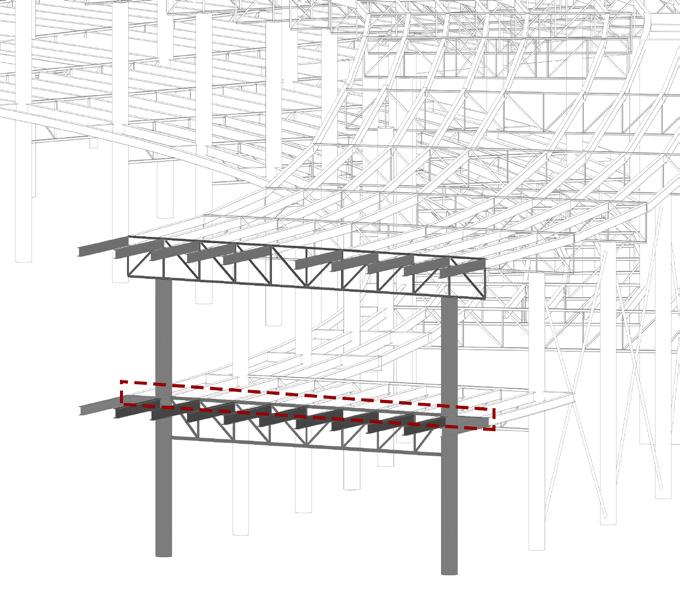

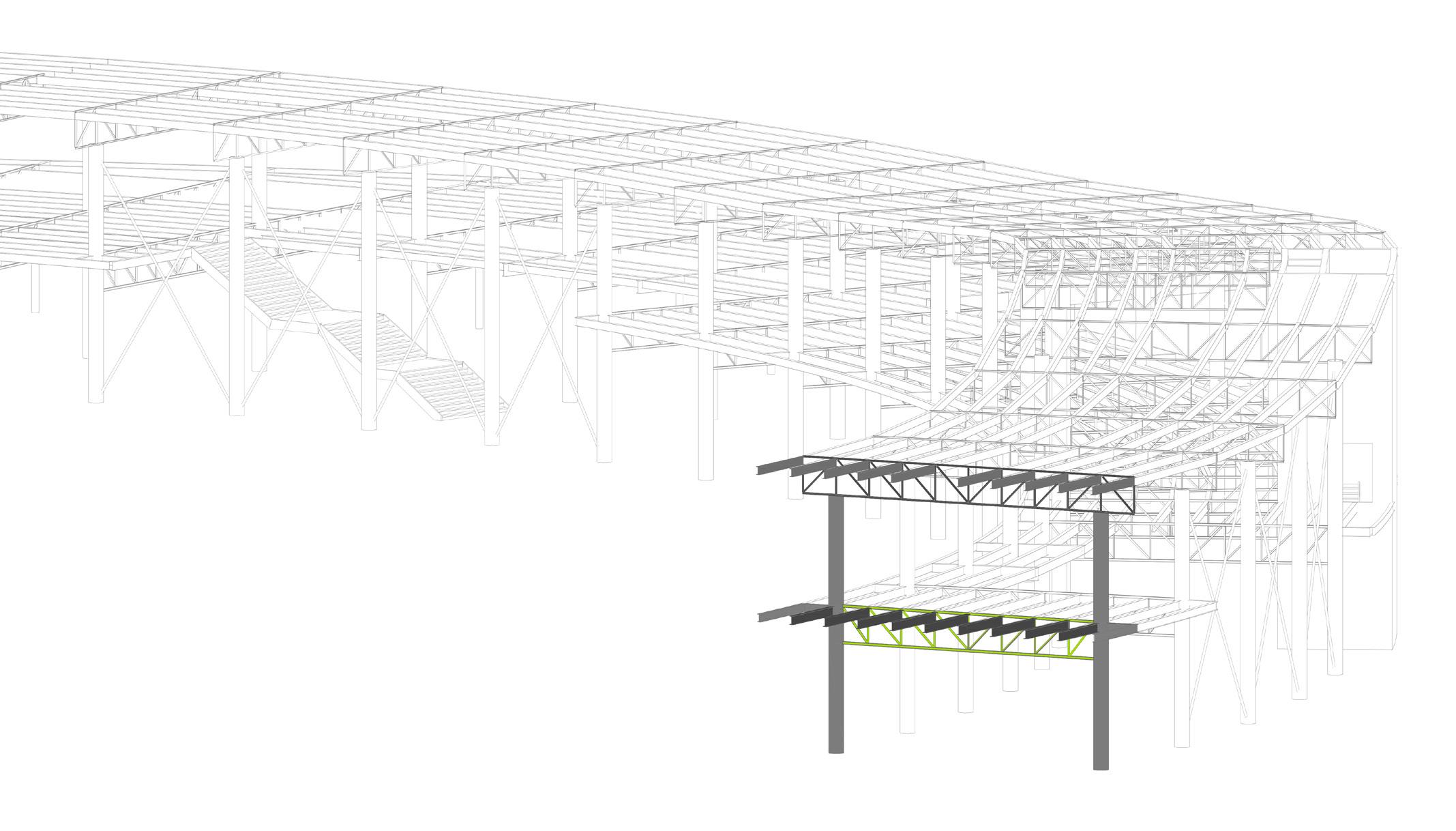

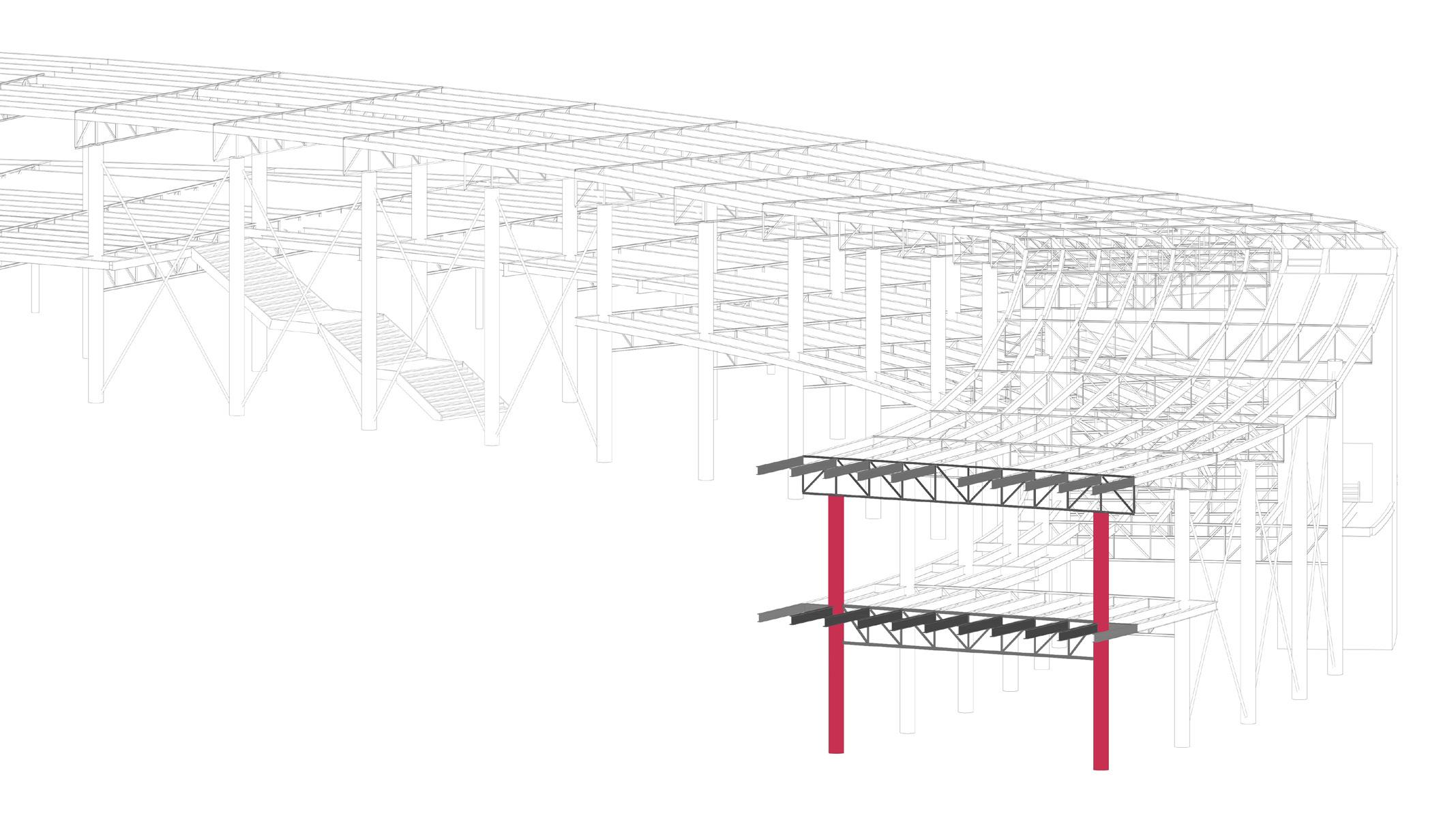

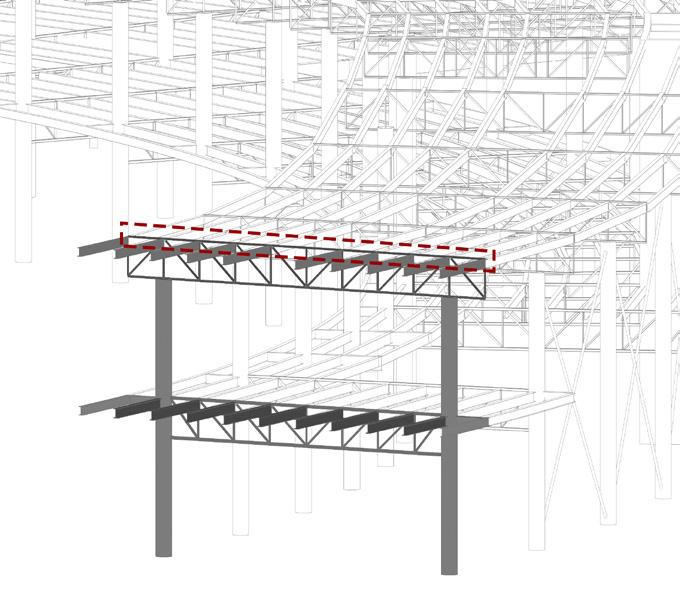

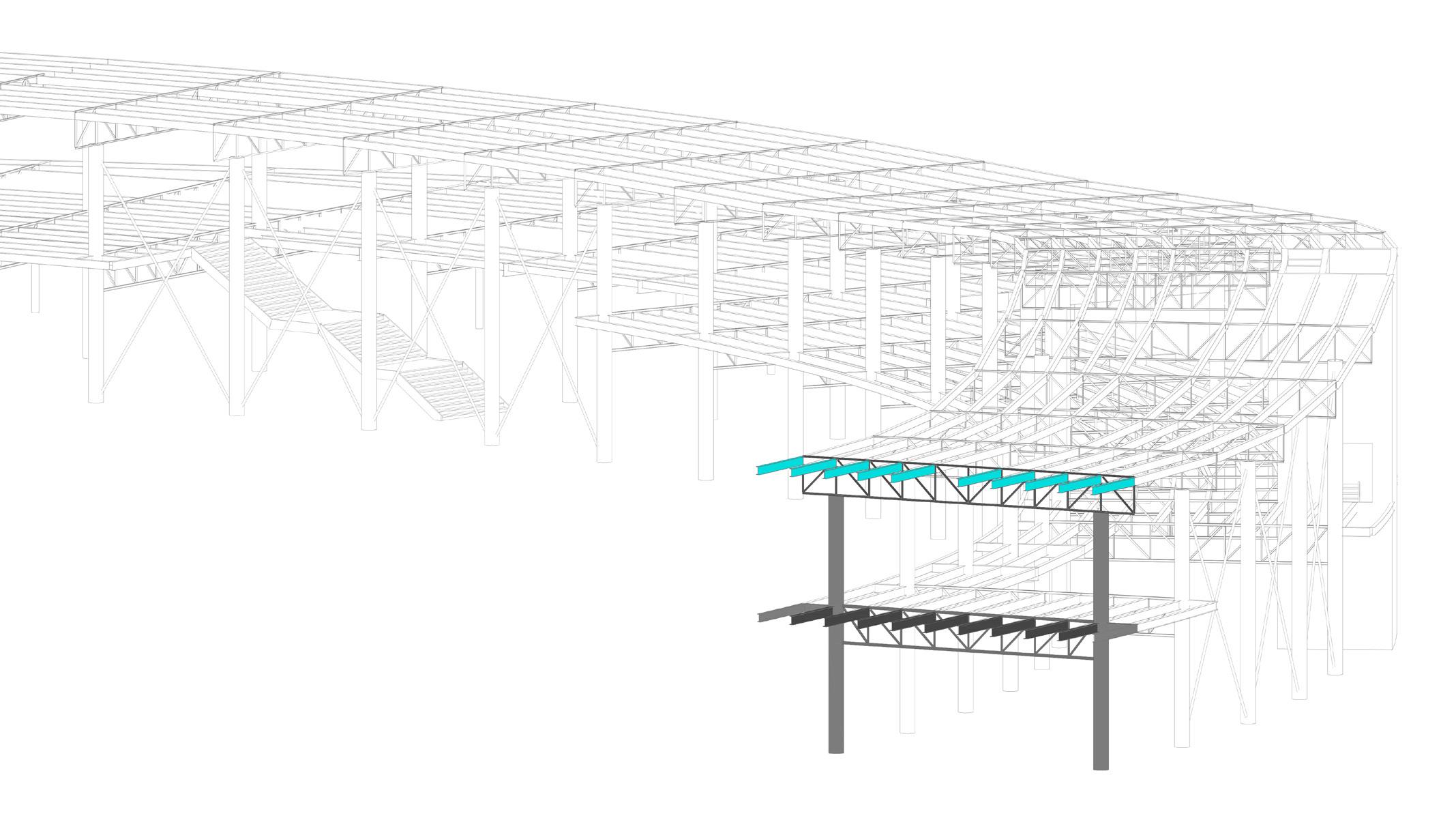

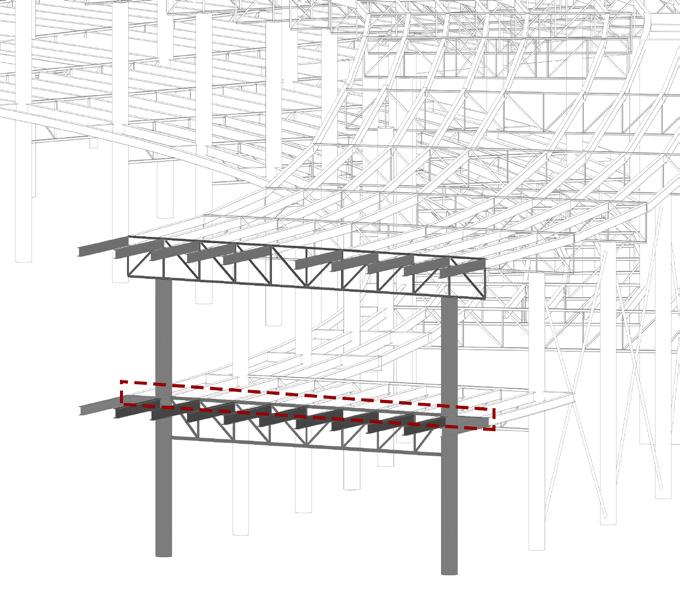

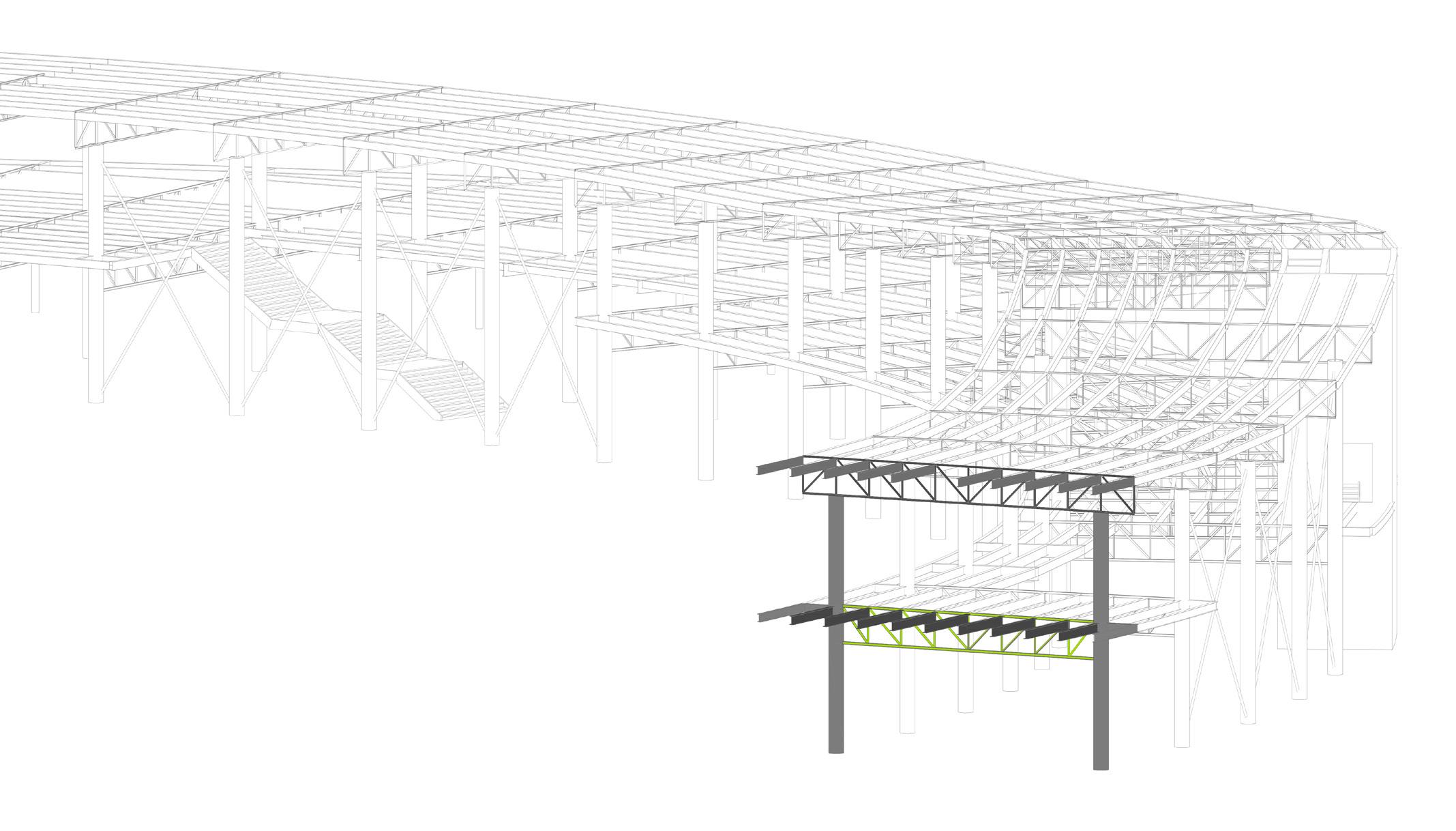

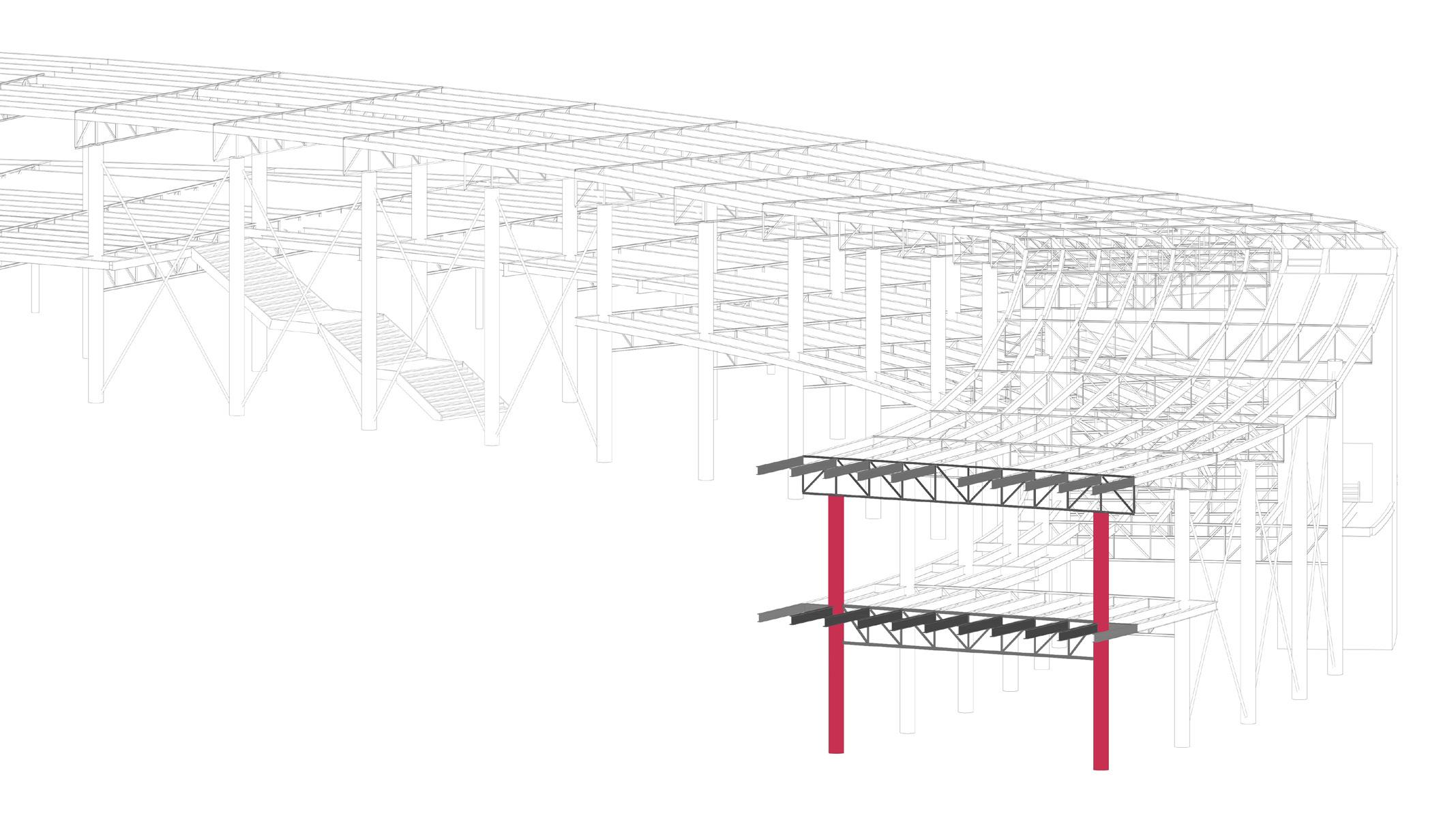

STEEL STRUCTURE AXONOMETRY

2

ROOF TRUSS - UPN 65/ L 50

FLOOR TRUSS - UPN 100/ L 60/ L 50

SECONDARY BEAM ON ROOF - IPE 330

SECONDARY BEAM ON FLOOR - IPE 360

SEONDARY BEAM ON BORDER - IPE 330

CANTILEVER - IPE 360

PILLAR - Hollow section d=610mm

3

STRUCTURAL DRAWINGS

4

FIRST FLOOR

GROUND FLOOR

5

6 SECTION

FIRST FLOOR 2

FIRST FLOOR 1

GROUND FLOOR 2

GROUND FLOOR 1

7

ROOF

SECTION OF EACH SEGMENT

8

PLAN OF EACH SEGMENT

CALCULATION PLAN

FIRST FLOOR

FIRST FLOOR

GROUND FLOOR

GROUND FLOOR

9

LOAD ANALYSIS, DESIGN & CHECK OF SECONDARY BEAM

10

Loads Computation

G2 Non Structural Permanent Loads

From the criteria for collaborating slabs:

G2 Non Structural Permanent Loads: 2.8 KN/m2

Q1 - Live loads

Live loads of roof (maintenance): 0.5 KN/m2

11

Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground 239 2.77907 Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade 120

ROOF

Q2 - Snow loads

Mi is the shape factor

Qsk is the ground snow load

Ce is the snow exposure factor

Ct is the thermal factor

Qs=Mi*Qsk*Ce*Ct=0.8*1.5*1*1=1.2KN/m2

G1 - Structural loads (Collaborating slab)

G1 - Structural loads (Collaborating slab) = 0.15m * 13KN/m3 = 1.95 KN/m2

Ultimate limit state fundamental combination

G1 Structural Loads: 1.95 KN/m2 * 1.3 = 2.535 KN/m2

G2 Permanent Loads: 2.779 KN/m2 * 1.5 =4.168 KN/m2

G total: 2.535 + 4.168 = 6.7 KN/m2

Q1 Live loads: 0.5 * 1.5 = 0.75 KN/m2

Q2 Snow loads: 1.2 * 1.5 = 1.8 KN/m2

Q total: 0.75 + 1.8 = 2.55 KN/m2

G+Q at ULS: 6.7 + 2.55 = 9.25 KN/m2

SLS

G1=1.95 KN/m2

G2=2.779 KN/m2

G total=4.729 KN/m2

Q1=0.5 KN/m2

Q2=1.2 KN/m2

Q total=1.7 KN/m2

G total+Q at SLS=6.43 KN/m2

P=6.43*1.5 m=9.645 KN/m

(SLS)

Span of loading area of unit: 1.5 m

fd = 9.25 * 1.5 = 13.875 KN/m

13.875 KN/m (ULS)

12

Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade

DESIGN OF SECONDARY BEAM ON ROOF

) efection

(SLS) P=9.645 KN/m

5*PL4/(384*EI)=L/250 (Italian code)

Imin=250*5*PL4/(LE*384)=(250*5*9.645*75003)/(210000*384)=1.00917*108 mm 4 =1.00917*104 cm 4 IPE 330

2)

(ULS) P=fd=13.875 KN/m2

Mmax=PL2/8 W=Fd S275

Wmin=M/fd=PL2/8*fd=(13.875*75002)/(8*275)=2.66069*109 mm 3

=266.069 cm 4 IPE 240

So we choose IPE 330

13

ROOF BEAM SECONDARY IPE 330

CHECK OF SECONDARY BEAM ON ROOF

teel profle IPE 330 S275

Height

Width

Thic ness fange

Thickness of Web

R radius

Area

Weight for unit length

Inertia moment

Resistance plastic modulus

q=(Q1+Q2)*Length of loading unit Area =(0.5+1.2)*1.5=2.55 KN/m

g=(G1+G2)*Length of loading unit Area =(1.95+2.779)*1.5=7.09 KN/m

Ala C/tf=[160-11.5-(2*18)]/ (2*11.5)=4.89 <= 10 class 1

Anima d/tw=[330-(2*11.5)-(2*18)]/7.5=36.1 <= 72 class 1

DISPLACEMENT CHECK

Maximun displacement is equal to :

max=5*(gt+g+q)L4/(384*EI)=5*(0.49+7.09+2.55)*75004/(384*210000*16270*104) =12.21 mm <=30 mm (L/250)

Displacement due to live load: 2=5*qL4/(384*EI)=5*2.55*75004/(384*210000*16270*104)=3.07 mm <=25 mm (L/300)

The chec is satisfed.

14

h b tf tw r A gt Iy Ix Wpl 330 160 11.5 7.5 18 62.6 0.49 788 16270 713 mm mm mm mm mm cm 2 N/mm cm 4 cm 4 cm 3

Acting shear and bending moment

VEd =(1.3gt+1.3g+1.5q)*L/2=(1.3*0.49+1.3*7.09+1.5*2.55)*7.5/2=51.29 KN

MEd =(1.3gt+1.3g+1.5q)*L2/8=(1.3*0.49+1.3*7.09+1.5*2.55)*7.52/8=96.18 KNm

Shear resistance

VpLRd=Arfy/(3-2*rM0)=[A-2b*tf+(tw+2r)*tf]*fy/(3-2*rM0)

=[6260-2*160*11.5+(7.5+2*18)*11.5]*275/(1.05*3-2)=465.767 KN

VEd <= VpLRd

Bending bearing capacity

McRd=WpL*fy/rM0=713*103*275/1.05=186.73 KNm

96.18 KNm (MEd) <= 186.73 KNm (McRd)

The chec is satisfed.

15

FLOOR

Loads Computation

G2 Non Structural Permanent Loads

From the criteria for collaborating slabs:

G2 Non Structural Permanent Loads:

Q1 - Live loads ive loads

(Cat. C3, museum)

16 Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 0.007 Sceed 6 18 Eps insulation 250 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 0.0129 Onyx solar panel 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 8 Eps insulation 200 10 Concrete deck Air igloo membrane 0.0129 Reinforced concrete foundation slab 40 24 Sceed Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 2 4.8 0.008385 0.96 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 0.007 Sceed 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade

KN/m2

of foor : 5

2.565 KN/m2

2.76 2.565 Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 Weight of envolope Roof Internal double skin facade Mid floor pilotis 210 195 120

G1 Structural Permanent Loads

G1 Structural Permanent Loads: 0.195

Q1 - Live loads

Ultimate limit state fundamental combination

G1 Structural Loads: 0.195 KN/m2 * 1.3 = 0.25 KN/m2

G2 Permanent Loads: 2.565 KN/m2 * 1.5 =3.85KN/m2

G total: 0.25 + 3.85 = 4.1 KN/m2

Q1 Live loads: 5 * 1.5 = 7.5 KN/m2

G+Q at ULS: 4.1 + 7.5 = 11.6 KN/m2

Span of loading area of unit: 1.5 m

Fd = 11.6 * 1.5 = 17.4 KN/m

SLS

G1=0.195 KN/m2

G2=2.565 KN/m2

G=2.760 KN/m2

Q=5 KN/m2

G+Q=7.76 KN/m2

Interaxis:(G+Q)*1.5=11.64 KN/m

17

ive loads of foor :

KN/m2

5

KN/m2 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Mid floor pilotis Ground External double skin facade Material Thichness mm Density KN/m3 Alluminium 3 27 Bituminous 5 0.007 Sceed 6 18 Eps insulation 250 10 Vapor barrier 5 0.007 Collaborating slab 150 13 False celling gypsium panel 20 4.5 Total 389 / Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Air 16 0.0129 Onyx solar panel 10 24 Total 666 / Concrete resin flooring 70 24 Insulation support 100 8 Vapor barrier 5 0.007 Collaborating slab 15 13 Eps insulation 200 10 False celling gypsium panel 20 4.5 Total 230 / Concrete resin flooring 60 24 Insulation support 15 8 Eps insulation 200 10 Concrete deck 200 24 Air igloo membrane 650 0.0129 Reinforced concrete foundation slab 40 24 Sceed 80 18 Total 1245 Glass 6 24 Air 15 0.0129 Glass 4 24 Air in between 600 0.0129 Glass 15 24 Gas argon 16 0.017841 Onyx solar panel 10 24 Total 666 Total weight KN/m2 0.081 0.000035 0.108 2.5 0.000035 1.95 0.09 4.72907 0.144 0.0001935 0.096 0.00774 0.36 0.0002064 0.24 0.8481399 1.68 0.8 0.000035 0.195 2 0.09 4.765035 1.44 0.12 2 4.8 0.008385 0.96 1.44 10.768385 0.144 0.0001935 0.096 0.00774 0.36 0.000285456 0.24 0.848218956 Weight of envolope Roof Internal double skin facade Mid floor pilotis Ground External double skin facade

17.4 KN/m

DESIGN OF THE SECONDARY BEAM OF FLOOR FLOOR BEAM SECONDARY

) efection

P=11.64 KN/m2 (at SLS)

P 4/(384*EI)=L/250 (Italian code)

Imin=250*5*PL4/(LE*384)=(250*5*11.64*75003)/(210000*384)=121791295 mm4 =12179.1295 cm 4 IPE 360

Mmax=PL2/8 W Fd S275

Wmin=PL2/8*fd=(17.4*75002)/(8*275)=444886.36 mm

18

So we choose IPE 360

2)

3=444.886 cm 4 IPE 270

IPE 360

CHECK OF SECONDARY BEAM ON FLOOR

teel profle IPE 360 S275

Height

Width

Thic ness fange

Thickness of Web

R radius

Area

Weight for unit length

Inertia moment

Resistance plastic modulus

q=(Q1+Q2)*Length of loading unit Area =5*1.5=7.5 KN/m

g=(G1+G2)*Length of loading unit Area =(0.195+2.565)*1.5=4.28 KN/m

Ala C/tf=[170-12.7-(2*8)]/(2*12.7)=5.562 <= 10 class 1

Anima d/tw=[360-(2*12.7)-(2*18)]/8=37.325 <= 72 class 1

DISPLACEMENT CHECK

Maximun displacement is equal to :

max=5*(gt+g+q)L4/(384*EI)=5*(0.57+4.28+7.5)*75004/(384*210000*16270*104) =15.8845 mm <=30 mm (L/250)

Displacement due to live load: 2=5*qL4/(384*EI)=5*7.5*75004/(384*210000*16270*104)=9.04 mm <=25 mm (L/300)

The chec is satisfed.

19

h b tf tw r A gt Iy Ix Wpl 360 170 12.7 8 18 72.7 0.57 1043 16270 1019 mm mm mm mm mm cm 2 N/mm cm 4 cm 4 cm 3

Acting shear and bending moment

VEd =(1.3gt+1.3g+1.5q)*L/2=(1.3*0.57+1.3*4.28+1.5*7.5)*7.5/2=65.8312 KN

MEd =(1.3gt+1.3g+1.5q)*L2/8=(1.3*0.57+1.3*4.28+1.5*7.5)*7.52/8=123.43 KNm

Shear resistance

VpLRd=Arfy/(3-2*rM0)=[A-2b*tf+(tw+2r)*tf]*fy/(3-2*rM0)

=[7270-2*170*12.7+(8+2*18)*12.7]*275/(1.05*3-2)=530.87 KN

VEd <= VpLRd 65.8312 <= 530.87

Bending bearing capacity

Rd/Wpe fyd=275/1.05=261 MPa

MRd=fyd*Wpe =261 MPa*1019*103 mm3=265.95*106 Nmm=265.95 KNm

Wpe=1019 cm3

MEd <= MRd 123.43 KNm <= 265.95 KNm

20

DESIGN & CHECK OF OTHER STRUCTURE

21

BORDER SECONDARY BEAM

Q1=5 KN/m2

G1=0.195 KN/m2

G2=2.565 KN/m2

ULS

G1=0.195*1.3=0.25 KN/m2

G2=2.565 KN/m2*1.5=3.85 KN/m2

Q1=5*1.5=7.5 KN/m2

GFV=GF F*1.5=418995 KN/m

(Facade load in ULS-interaxis)

interaxis: 1.5 m/2=0.75 m

Fd=(G1+Q1+G2)*0.75 m+GFu

=8.7 KN/m+8.7 KN/m=12.89 KN/m=P

SLS

G1=0.195 KN/m2

G2=2.565 KN/m2

G=2.760 KN/m2

Q=5 KN/m2

Fyd=(G+Q)*0.75 m=5.82 KN/m

12.89 KN/m

22

P BORDER SECONDARY BEAM IPE 330

DESIGN OF BORDER SECONDARY BEAM

) efection P fyd (SLS)=5.82 KN/m

P 4/(384*EI)=L/250

Imin=250*5*P*L4/(L*E*384)=250*5*5.82*75003/(210000*384)=60895647.3 mm4 =6089.5647 cm4

IPE 300

2) Bending moment P (ULS)=8.7 KN/m

Mmax=PL2 W Fd

Wmin=PL2/(8*fyd)=8.7*75002/(8*275)=329573.864 mm3=222.49 cm3

IPE 220

But we adopt IPE 330 for architecture reason.

CHECK OF FACADE SECONDARY BEAM

teel profle IPE 330

ness fange Thickness of Web

radius

Weight for unit length

moment Resistance plastic modulus

Ala C/tf=[160-11.5-(2*7.5)]/ (2*11.5)=5.804 <= 10 class 1

Anima d/tw=[330-(2*11.5)-(2*18)]/7.5=36.93 <= 72 class 1

KN/m

23

Height Width

R

Area

Inertia

q=5*0.75=3.75

g=(0.195+2.565)*0.25=2.07

gF=2.793

Thic

KN/m

KN/m

h b tf tw r A gt Ix Wpl 330 160 11.5 7.5 18 62.61 0.49 11766.89 713.15 mm mm mm mm mm cm 2 N/mm cm 4 cm 3

DISPLACEMENT CHECK

Maximun displacement is equal to : max=5*(gt+g+q)L4/(384*EI)=5*(0.491+2.07+3.75)*75004/ (384*210000*11766.89*104)

=15.1787 mm <=30 mm (L/250)

Displacement due to live load: 2=5*qL4/(384*EI)=5*3.75*75004/(384*210000*11766.89*104)=6.25 mm <=25 mm (L/300)

The chec is satisfed.

Acting shear and bending moment

Shear resistance

VpLRd=Arfy/(3-2 M0)=[A-2b*tf+(tw+2r)*tf]*fy/(3-2 M0) =[6261-2*160*11.5+(7.5+2*18)*11.5]*275/(1.05*3-2)=465.918 KN

Bending bearing capacity

24

VEd =(1.3gt+1.3g+1.5q)*L+1.5gF*L/2=[(1.3*0.4915+1.3*2.07+1.5*3.75)*7.5+ 1.5*2.793*7.5]/2=49.292 KN MEd =(1.3gt+1.3g+1.5q+1.5gF)*L2/8=92.42191 KNm

VEd <= VpLRd 49.292 <= 465.918 OK Rd/Wpe fyd=275/1.05=261 MPa MRd=fyd*Wpe =261 MPa*713.15*103 mm3=186.132*106 Nmm=186.132 KNm

<= MRd

MEd

OK

P2*R1=2*VED=49.292*2=98.384 KN

DESIGN OF CANTILEVER

T=P=98.384 KN

M=Mmax=P*L=98.389*1.5=147.576 KNm

max=P*L3 (3 EI) min=L/400=1500/400=3.75 mm

Imin=PL3 (3 E MIN)=98.384*103*15003/(3*210000*3.75)=140548.571 mm4

=14054.8571 cm4 IPE 360

25

CANTILEVER

CANTILEVER IPE 330

DISPLACEMENT CHECK

Maximun displacement is equal to :

max=PL3/(3EI)+5*gt*L4/(E*I)=98.38*103*15003/(3*210000*16265.62*104)+

5*0.52*15004/(384*2100001.265*104)=3.24+0.0011=3.2411<=3.75

Ved1*gt*1.3*L=0.5709*1.3*1.5=1.11325 KN

Med1=gt*1.3*L2/2=0.5709*1.3*1.52/2=0.83499 KNm

Ved2=P=98.384 KN

Med2=Mmax=147.576 KNm

Ved=Ved1+Ved2=99.49 KN Med=Med1+Med2=148.41 KNm

Shear resistance

VpLRd=Arfy/(3-2*rM0)=[A-2b*tf+(tw+2r)*tf]*fy/(3-2*rM0) =[7273-2*170*12.7+(18+2*18)*12.7]*127*151.211/(1.05*3-2)=530.87 KN

VEd <= VpLRd 99.49 KN <= 530.84 KN OK

Bending bearing capacity

=MRd/Wpe fyd=275/1.05=261 MPa

MEd <= MRd 148.41 KNm <= 265.95 KNm OK

26

MRd=fyd*Wpe =261 MPa*1019*103 mm3=265.95 KNm

Height Width

R

Area Weight

Inertia moment Resistance plastic modulus h b tf tw r A gt Ix Wpl 360 170 12.7 8 18 12.73 0.5709 16265.62 1019.15 mm mm mm mm mm cm 2 N/mm cm 4 cm 3

Thic ness fange Thickness of Web

radius

for unit length

Roof Truss

1、3: all horizontal members: P 6 (each profle)

2、4: all vertical & diagonal members: 0 (each profle)

Weight: 0.07 N/mm (single profle)

Weight: 0.058 N/mm (single profle)

27

Floor Truss

1、3: all horizontal members: P 00 (each profle)

2: all diagonal members: 60 (each profle)

4: all vertical members: 0 (each profle)

Weight: 0.01 N/mm (single profle)

Weight: 0.08 N/mm (single profle)

Weight: 0.064 N/mm (single profle)

28

FACADE

Weight of facade unit

1、 Internal skin

7.5/1.737=4.31

.3 facade unit per foor unit

Density of Glass: 2500 Kg/m3=25KN/m3

AI=1.737*6= 10.422 m2 VI=AI*0.01 m=0.10432 m3 GI=VI*25 KN/m3=2.6055 KN

2

、External skin

AE=(1.65+0.25)*6= 11.4 m2

GF=4.31*(GI+GE)=41.9 KN

VE=AE*0.025 m=0.285 m3 GE=VE*25 KN/m3=7.125 KN

29

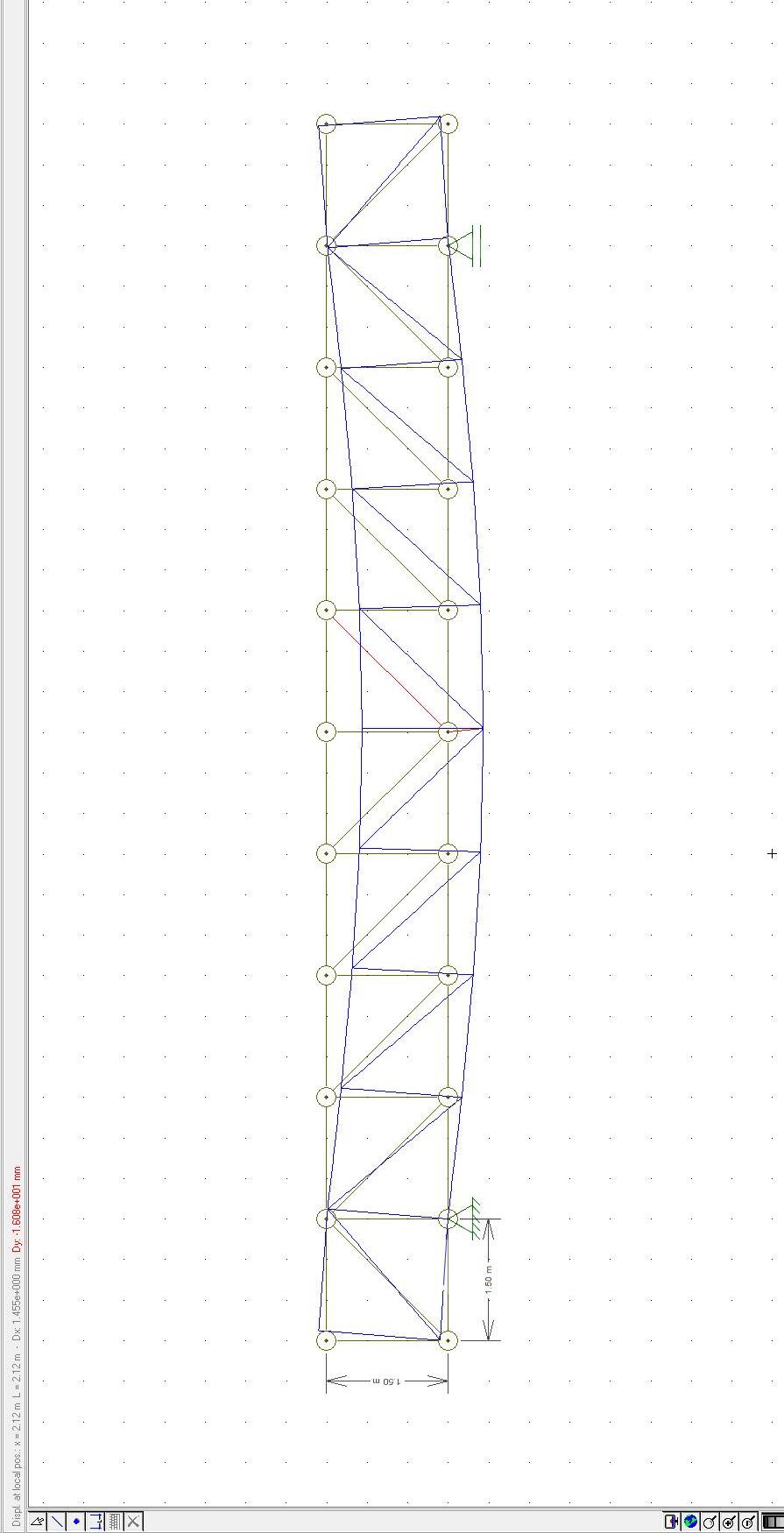

TRUSS OF ROOF

Load from facade: GF/2=20.95 KN

Load from roof layers:

Roof stratigraphy weight at ULS: 8.95 KN/m2 (calculated before)

F=8.95*1.5*7.5=100.7 KN

Total load:

GF/2+F/2=71.3 KN

F=100.7 KN

30

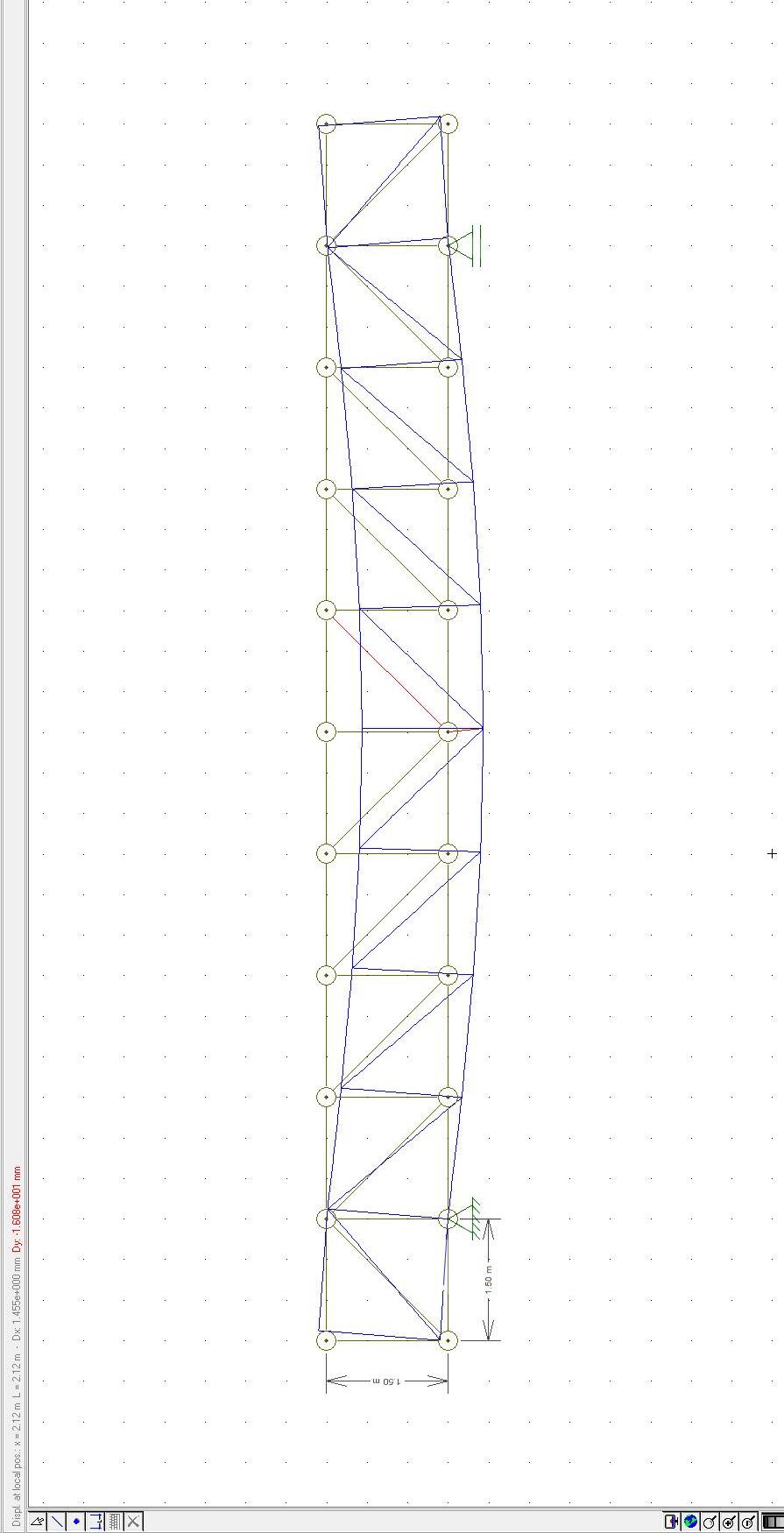

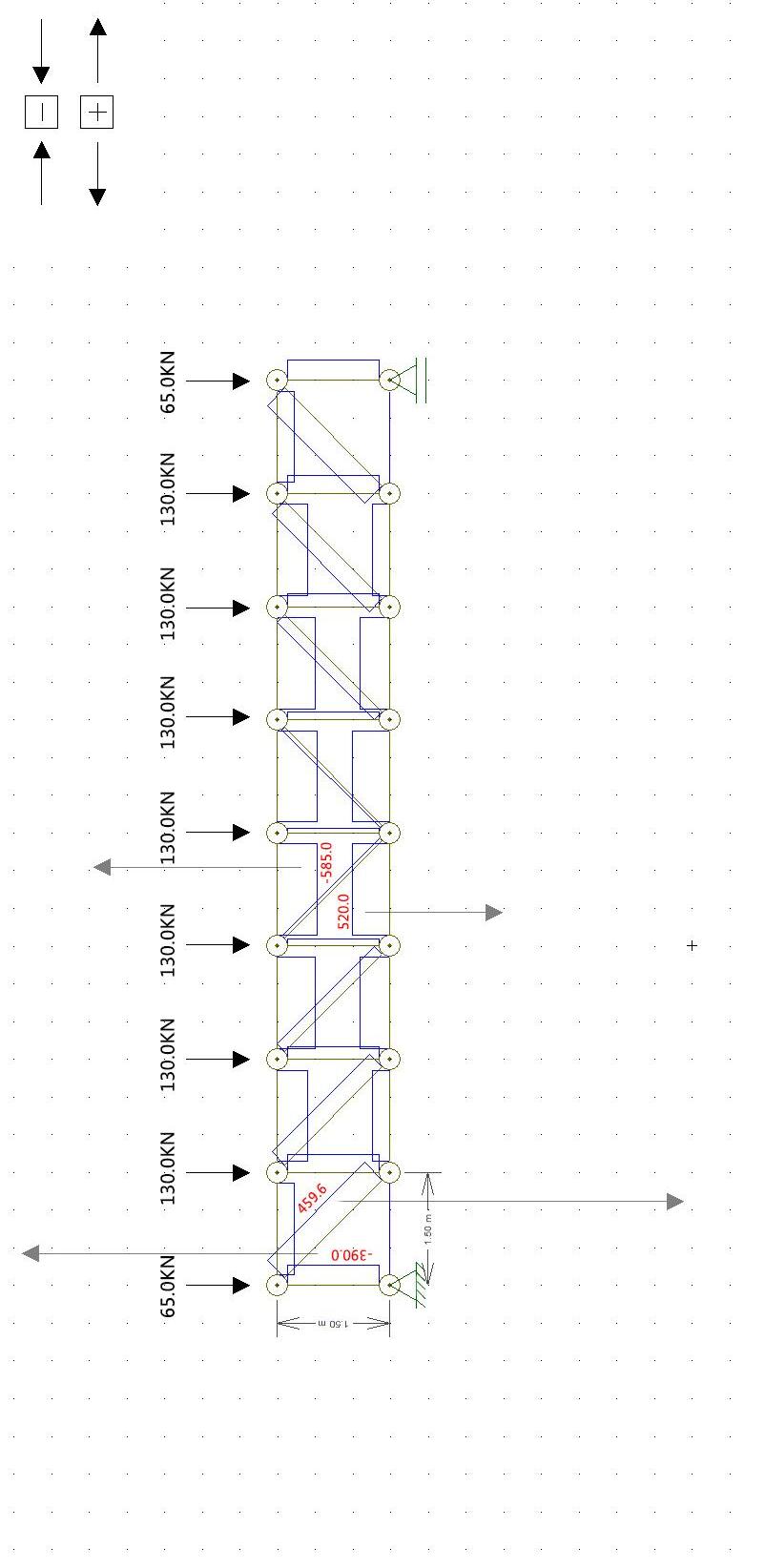

Worst for vertical compression

Worst case for horizontal member compression

Worst case for horizontal member tension

Worst for diagonal tension

T NO! M NO!

D Y =16 mm <= L/250=6*1500/250=36 mm

D Y =1.608*10 1 mm=16mm

HORIZONTAL MEMBER COMPRESSION (ROOF TRUSS) S275

Worst case for horizontal member compression from diagram

Nsd=A*fyk/rm Amin=Nsd*rm/fyk=381.9*1000*1.05/275=1458.1 mm2=14.58cm2

We choose o the minimum area of each steel profle: min/2=7.29cm2

from standard tabel, we choose P 6 steel profle 1)

Stability curve , 0.49

2)

Nsd=381.9 KN

L=1500 mm

Steel material S275

fyk=275 MPa

rm=1.05

fyd=fyk/rm=261.9 MPa

E=210000 MPa

33

4) 3) UPN 65 weight b h S (tw) t=R1 (tf) R2 (r) A d 0.07 42 65 5.5 7.5 4 9.03 34 N/mm mm mm mm mm mm cm 2 mm IX=57.5 cm4 IY=14.1 cm4 5) lassifcation of section 0. d/tw=(h-2tf-2r)/tw=(65-2*7.5-2*4)/5.5=0.76 <= 10 Class 1 c/tf =(42-7.5-2*4)/(2*5.5)=2.4 <= 10 Class 1 381.9KN 381.9KN

( fyk/Ncr)-2=[(903*2*275)/(25950*103)]-2=0.13

Ncr 2*E*Imin/L02=3.142*210000*1410*2*104/15002=25950 KN

0.

0. ( 0. ) 2]=0.5*[1+0.49*(0.13-0.2)+0.132]=0.53 ( 2 2)]=1/[0.53+(0.532-0.132)]=0.95 <= 1

Nbrd=X*A*fyd=0.95*903 mm2*2*261 MPa=447.8 KN

Nbrd=447.8 KN > Nsd=381.9 KN

The check is Ok!

34 6)

HORIZONTAL MEMBER TENSION (ROOF TRUSS) S275

Worst case for horizontal member tension from diagram

Axial force design NEd must respect: NEd/Nt*Rd <= 1

We choose 2 UPN 65 subjected to axial force Nsd=335 KN

h=65 mm b=42 mm tw=5.5 mm A=9.03cm2 d=34mm Fe 360

Where the calculated resistance to traction Nt,Rd of members should consider:

1) Gross section: NPL, Rd=A*fyk/rmo=2*903*275/1.05=473 KN

2) Section without hole:

Nu,Rd =0.9*Anet*fu/rm2=0.9*[2*(903-34*5.5)]*360/1.2=386.6 KN

NPL,Rd=473 KN > NEd=335 KN

Nu,Rd =386.6 KN > NEd=335 KN

Check OK!

So, top and bottom memeber of Roof Truss, we choose 2 UPN 65.

35

VERTICAL MEMBER COMPRESSION (ROOF TRUSS S275)

Worst case for vertical member compression from diagram

Nsd=A*fyk/rm

Amin=Nsd*rm/fyk=352.4*1000*1.05/275=13.45 cm2

We choose o the minimum area for each steel profle: min/2=6.7 cm2

from standard tabel, we choose L 50 (h=b=50 mm)

1)

Stability curve b, =0.34

2)

Nsd=352.4 KN

L=1500 mm

Steel material S275

fyk=275 MPa

rm=1.05

fyd=fyk/rm=261.9 MPa

E=210000 MPa

5) lassifcation of section 0.

d/tw=(h-2tf-2r)/tw=(50-2*8-2*7)/8=2.5 <= 10 Class 1

c/tf =(50-8-2*7)/(2*8)=1.75 <= 10 Class 1

IX=16.3 cm4 IY=16.3 cm4

36

4) 3

L

weight b h t (tw)(tf) r1 r2 (r) A d 0.058 50 50 8 3.5 7 7.41 1.5 N/mm mm mm mm mm mm mm cm 2

)

50

( fyk/Ncr)-2=[(741*2*275)/(29999.5*103)]-2=0.11

Ncr 2*E*Imin/L02=3.142*210000*1630*2*104/15002=29999.5 KN

0.3

0. ( 0. ) 2]=0.51

( 2 2)]=1/[0.51+(0.512-0.112)]=0.99 <= 1

Nbrd=X*A*fyd=0.99*741 mm2*2*261 MPa=382.9 KN

Nbrd=382.9 KN > Nsd=352.4 KN

The check is Ok!

37 6)

DIAGONAL MEMEBER TENSION (ROOF

TRUSS) S275

Worst case for horizontal member tension from diagram

L=1500*2-2

Axial force design NEd must respect: NEd/Nt*Rd <= 1

We choose 2 L 50 subjected to axial force Nsd=365 KN

h=50 mm b=50 mm t=8 mm A=7.41 cm2 d=1.5 mm Fe 360

Where the calculated resistance to traction Nt,Rd of members should consider:

1)、Gross section: NPL, Rd=A*fyk/rmo=2*741*275/1.05=388.14 KN

2)、Section without hole:

Nu,Rd =0.9*Anet*fu/rm2=0.9*[2*(741-1.5*8)]*360/1.2=437.4 KN

NPL,Rd=388.14 KN > NEd=365 KN

Nu,Rd =437.4 KN > NEd=365 KN

Check OK!

38

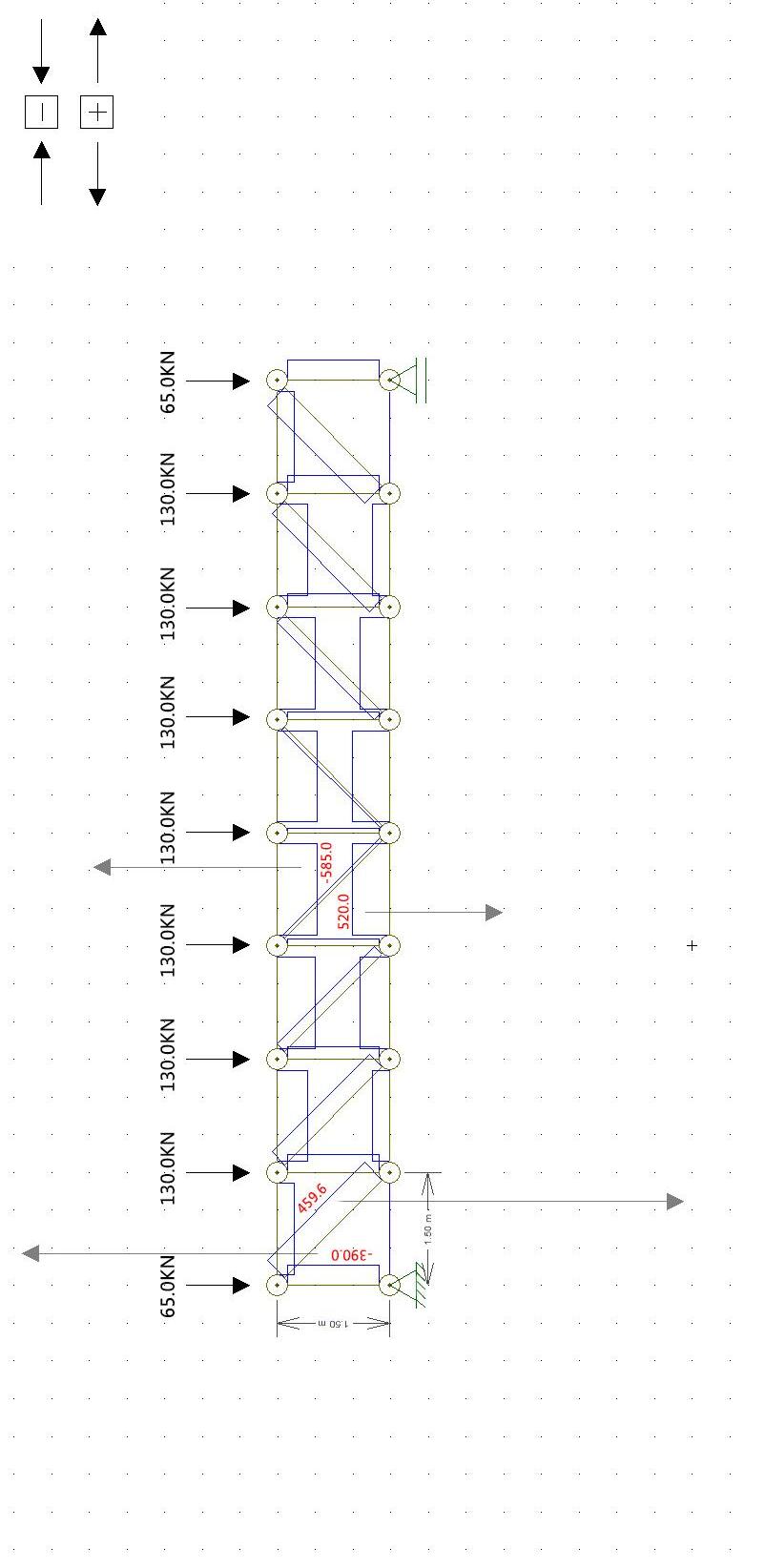

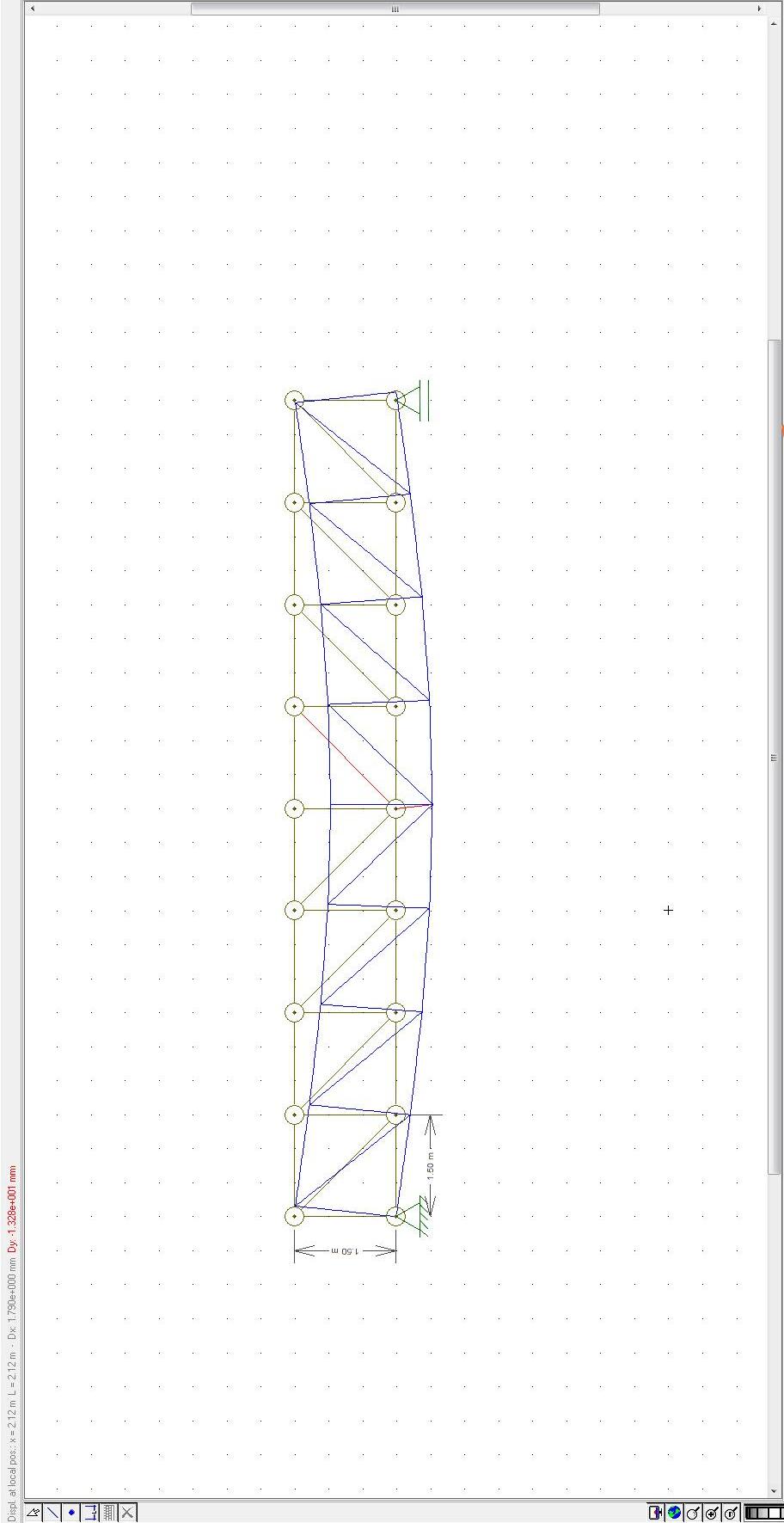

Truss of Floor

oad from foor layers (including live load):

Floor stratigraphy weight at ULS: 11.6 KN/m2 (calculated before)

F=11.6*1.5*7.5=130 KN

Total load

F=130 KN

39

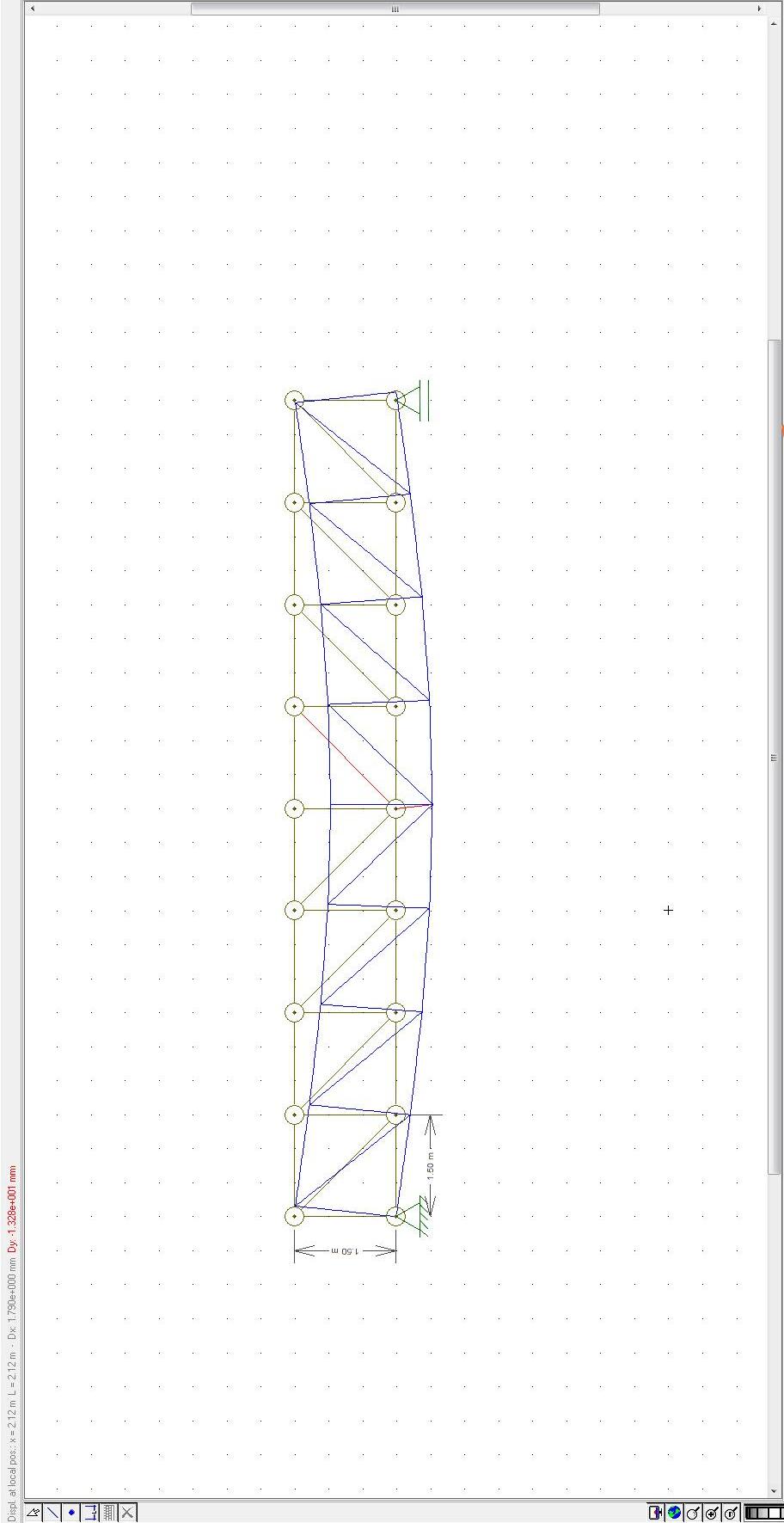

Worst for vertical compression

Worst case for horizontal member compression

Worst case for horizontal member tension

Worst for diagonal tension

T NO! M NO!

D Y =1.328*10 1 mm=13.2 mm <= L/450=6*1500/450=20 mm

HORIZONTAL MEMEBER COMPRESSION (FLOOR TRUSS) S275

Worst case for horizontal member compression from diagram

Nsd=A*fyk/rm Amin=Nsd*rm/fyk=585*1000*1.05/275=2233.6 mm2=22.34cm2

We choose o the minimum area of each steel profle: min/2=11.17cm2

from standard tabel, we choose P 00 steel profle

1)

Stability curve C, a=0.49

2)

Nsd=585 KN

L=1500 mm

Steel material S275

fyk=275 MPa

rm=1.05

fyd=fyk/rm=261.9 MPa

E=210000 MPa

42

4) 3) UPN 100 weight b h S (tw) t=R1 (tf) R2 (r) A d 0.1 50 100 6 8.5 4.5 13.5 64 N/mm mm mm mm mm mm cm 2 mm IX=206 cm4 IY=29.3 cm4 5)

0.

lassifcation of section

d/tw=(h-2tf-sr)/tw=(100-2*8.5-2*4.5)/6=12.3

> 10 Class 2

c/tf

=(50-2*8.5-2*4.5)/(2*8.5)=2.5 <= 10 Class 1

( fyk/Ncr)-2=[(1350*2*275)/(53925.4*103)]-2=0.12

Ncr 2*E*Imin/L02=3.142*210000*2930*2*104/15002=53925.4 KN

0.

0. ( 0. ) 2]=0.51

( 2 2)]=0.99 <= 1

Nbrd=X*A*fyd=0.99*1350 mm2*2*261 MPa=697.6 KN

Nbrd=697.6 KN > Nsd=585 KN

The check is Ok!

43 6)

HORIZONTAL MEMBER TENSIOND

(FLOOR TRUSS) S275

Worst case for horizontal member tension from diagram

Axial force design NEd must respect: NEd/Nt*Rd <= 1

We choose 2 UPN 100 subjected to axial force Nsd=520 KN

h=100 mm b=50 mm tw=6 mm A=13.5cm2 d=64mm Fe 360

Where the calculated resistance to traction Nt,Rd of members should consider:

1)、Gross section: NPL, Rd=A*fyk/rmo=2*1350*275/1.05=707 KN

2)、Section without hole:

Nu,Rd =0.9*Anet*fu/rm2=0.9*[2*(1350-64*6)]*360/1.2=521.6 KN

NPL,Rd=707 KN > NEd=520 KN

Nu,Rd =521.6 KN > NEd=520 KN

Check OK!

So, top and bottom memeber of Roof Truss, we choose 2 UPN 100.

44

VERTICAL MEMBER COMPRESSION (FLOOR TRUSS) S275

Worst case for vertical member compression from diagram

Nsd=A*fyk/rm Amin=Nsd*rm/fyk=390*1000*1.05/275=14.89 cm2

We choose o the minimum area for each steel profle: min/2=7.4 cm2

from standard table, we choose L 50 (h=b=50 mm) 1) Stability curve b, =0.34

2)

Nsd=390 KN

L=1500 mm

Steel material S275

fyk=275 MPa

rm=1.05

fyd=fyk/rm=261.9 MPa E=210000 MPa

5)

lassifcation of section 0.

d/tw=(h-2tf-2r)/tw=(50-2*9-2*7)/9=2 <= 10 Class 1

c/tf =(50-9-2*7)/(2*9)=1.5 <= 10 Class 1

cm4 IY=17.9 cm4

45

4) 3

L 50 weight b h t (tw)(tf) r1 r2 (r) A d 0.064 50 50 9 3.5 7 8.24 1.5 N/mm mm mm mm mm mm mm cm 2

)

IX=17.9

( fyk/Ncr)-2=[(824*2*275)/(32944.2*103)]-2=0.12

Ncr 2*E*Imin/L02=3.142*210000*1790*2*104/15002=32944.2 KN

0.3

0. ( 0. ) 2]=0.51

( 2 2)]=1/[0.51+(0.512-0.122)]=0.99 <= 1

Nb,rd=X*A*fyd=0.99*824 mm2*2*261 MPa=425.8 KN

Nb,rd=425.8 KN > Nsd=390 KN

The check is Ok!

46 6)

DIAGONAL MEMBER TENSION (FLOOR TRUSS) S275

Worst case for horizontal member tension from diagram

L=1500*2-2

Axial force design NEd must respect: NEd/Nt*Rd <= 1

We choose 2 L 60 subjected to axial force Nsd=459.5 KN

Where the calculated resistance to traction Nt,Rd of members should consider:

1)、Gross section: NPL, Rd=A*fyk/rmo=2*1110*275/1.05=581.4 KN

2)、Section without hole:

Nu,Rd =0.9*Anet*fu/rm2=0.9*[2*(1110-1.9*10)]*360/1.2=589.1 KN

NPL,Rd=581.4 KN > NEd=459.5 KN

Nu,Rd =589.1 KN > NEd=459.5 KN

Check OK!

47

h=60 mm b=60 mm t=10 mm A=11.1 cm2 d=1.9 mm Fe 360

48

PILLAR

1)

Weight of horizontal members: 0.07 KN/m

Number of horizontal members: 10

Length of horizontal members: 1.5 m

Weight of vertical/ diagonal members: 0.058 KN/m

Number of vertical memebers: 5.5

Number of diagonal memeber: 5

Length of diagonal member: 1.5*2-2

Length of vertical memeber: 1.5 m

Weight of roof truss:

G1= [0.07 KN/m *10*1.5 m+0.058 KN/m *(5.5*1.5 m+5*1.5*2-2m )]*1.3=2.8 KN

2)

Weight of horizontal members: 0.1 KN/m

Number of horizontal members: 8

Length of horizontal members: 1.5 m

Weight of diagonal members: 0.064 KN/m

Number of diagonal memebers: 4

Length of diagonal member: 1.5*2-2

Weight of vertical member: 0.064 KN/m

Number of vertical member: 3.5

Length of vertical member: 1.5 m

Weight of roof truss:

G2= (0.1 KN/m *8*1.5 m+0.008 KN/m *4*1.5*2-2 m+0.064*3.5*1.5 m)*1.3=2.87 KN

49

Self weight of roof truss (ULS)

Self weight of roof truss (ULS)

3) Self weight of cantilever IPE 360 (ULS)

Weight: 0.57 KN/m

Length: 1.5 m

G3= 0.57 KN/m*1.5 m*1.3=1.1 KN

4) Self weight of secondary beam on border IPE 330 (ULS)

Weight: 0.49 KN/m

Length: 7.5 m

G4= 0.49 KN/m*7.5 m*1.3=4.77 KN

5) Self weight of secondary beam on roof IPE 330 (ULS)

Weight: 0.49 KN/m

Length: 7.5 m

Number: 4.5

G5= 0.49 KN/m*7.5 m*4.5*1.3=21.5 KN

6) elf weight of secondary beam on foor IPE 360 ( )

G6= 0.57 KN/m*7.5 m*4.5*1.3=25 KN

50

Upper part of pillar (S275)

Nsd1=(100.7 KN*9+71.3 KN*2)/2+G1+G5+G4=553.5 KN

Nsd=A*fyk/γm

Amin=Nsd*γm/fyk=553.5*1000*1.05/275=21.1 cm2

The axial force on upper part of pillar is smaller, so we forcus on the lower part of pillars, where axial force is bigger.

51

Lower part of pillar

Nsd2=Nsd1+130 KN*7+65 KN*2+G2+G3+G4+G6

=553.5 KN+130 KN*7+65 KN*2+2.87 KN+1.1 KN+4.77 KN+25 KN=1627 KN

Nsd=A*fyk/γm

Amin=Nsd*γm/fyk=1627*1000*1.05/275=62.12 cm2

from standard table, we choose steel circular hollow section d=610 mm

1) Stability cruve a, α=0.21

2) Nsd2=1627 KN L=4.5 m

Steel material S275

fyk=275 mPa

γm=1.05

fyd=fyk/γm=261.9 mPa

E=21000 m Pa

3) t=10 mm

d=610 mm

A=188.5 cm2

I-84846.55cm2

4) Lo=βL=0.7L=0.7*4.5 m=3.15 m

52

) ( fyk/Ncr)-2=[188.5*100*275/(27628.5*103)]-2=0.36

Ncr 2EImin/Lo2=3.142*210000*84846.5*104/45002=27628.5 KN

0.

0. ( 0. ) 2]=0.5[1+0.21*(0.36-0.2)+0.362]=0.58 ( 2 2)-2]=1/[0.58+(0.582-0.362)-2]=0.96 <=1

Nb,rd=X*A*fyd=0.96*188.5*102*261=4723 KN > Nsd=1627 KN

Check is ok

53

1) Welded connection between truss memebers Fe 360

Design: Throat thickness a=5 mm

Check is ok

mm

mm

54 CONNECTIONS

L1=90

L2=210

id=t=356*103/(2*5*300)=118.7 mPa <= fu (3 w mw)=125.6 mPa

R1=(B-d)Nsd/B=15.4*Nsd/50=0.3Nsd R2=d*Nsd/B=34.6*Nsd/50=0.7Nsd L1/L2=R1/R2=(B-d)/d=3/7

55

R1=(B-d)Nsd/B=18.64*Nsd/60=0.3Nsd R2=d*Nsd/B=41.36*Nsd/60=0.7Nsd L1/L2=R1/R2=(B-d)/d=3/7 Design: Throat thickness a=7 mm L1=90 mm L2=210 mm id=t=459.6*103/(2*5*300)=109.4 mPa <= fu (3 w mw)=125.6 mPa Check is ok

2) Welded connection between truss memebers Fe 360

3) olt connection between foor secondary beam and foor cantilever

56

Design of bolts

From previous computation (Roof Load)

VED=1.3gsw*L+1.3gL+1.5g+PFtot/2

=(1.3*0.49+1.3*4.23+1.5*7.5)*7.5+20.95=151.8 KN

Choose 6 bolts

V1=VED/6=151.8/6=25.3 KN

H1=(VED/3)*(P2/P1)=(151.8/3)*(150/100)=75.9 KN

FI=(H12+V12)-2=(75.92+25.32)-2=80 KN

Choose Class 8.8 (fyb=480 N/mm2, ftb=600 N/mm2)

Fv,rd=0.6*ftb*Ares m2

Ares,min=(F1 m2)/(0.6*ftb)=(80*1000*1.25)/(0.6*800)=208.3 mm2

Choose M20, which Ares=245 mm2 > 208.3 mm2

Design of connection

do=d+2=20+2=22 mm

For distances from the edge:

e1 > 1.2do=1.2*22=26.4 mm, choose e1=65 mm

e2 > 1.2do=1.2*22=26.4 mm, choose e2=50 mm

For interenal distances:

P1 > 2.2do=2.2*22=48.4 mm

P2 > 2.4do=2.4*22=52.8 mm

P1, P2 < min(14t; 200)

choose t as thic ness of fange of IPE 330, t . mm . 6 mm

48.4 < P1 < 161, choose P1=100 mm

52.8 < P2 < 161, choose P2=100 mm

57

Check to shear force

F1=80 KN

Fv,Rd=0.6*ftb*Ares m2=0.6*800*2.45/1.25=94 KN

F1 < Fv,Rd Check is ok

Check to the hole of thinner element in connection

Bolluni interni: d=20 mm t=11.5 mm ftk=360 N/mm2 min P1/(3*do-0.25); ftb/ft min 00 (3 0. ) 600 360 min . 6 .6

. P2/do . . min . 00 . . min .66 .

K=2.5

Fb,Rd1 ftk d t m2=2.5*1*360*20*11.5/1.25=165.6 KN

2F1=160 KN < Fb,Rd1=165.6 KN Check is ok

Bolluni di Bordo:

2F1=160 KN < Fb,Rd2=163.9 KN Check is ok

58

min

min e1/(3*do);ftb/ft min 6 (3 ) 600 360 min 0. .6 0. min . e2/do . . min . 0 . . min .66 .

Fb,Rd2 ftkdt m . 0. 360 0 . . 63.

K=2.5