Workshop Manual

LM732

TELEHANDLERS

RepairManual

DocumentN°.87474474A(I--2008)

THISWARNINGSYMBOLACCOMPANIESIMPORTANTMESSAGESINVOLVINGYOURSAFETY.

Readthesafetyinstructionscarefully,andfollowtheprecautionsrecommendedinorderto avoidpotentialrisksandsafeguardyourhealthandyoursafety.

YouwillfindthissymbolinthetextofthisManualwiththefollowingkeywords: WARNING-Cautionsintendedtoavoidunsuitablerepairoperationswithpotentialconsequences forthesafetyofthepersonperformingtherepair.

DANGER-Warningsspecificallyindicatingpotential dangersforthesafetyoftheoperatororofother personsdirectlyorindirectlyinvolved.

IMPORTANTWARNINGS

AllmaintenanceandrepairoperationslistedinthisManual mustbeperformedexclusivelybytheServiceNetwork oftheManufacturer,complyingstrictlywiththeindicationshereinandusingtheprescribedspecialtoolswhere indicated.

Anypersonperformingserviceoperationsdescribedin themanualandfailingtoabidestrictlybytheinstructions becomessolelyresponsibleforany consequentialdamagethatcouldoccur.

TheManufacturerandallorganizationsinthedistributionchainassociatedwiththeManufacturer,includingnational, regionalandlocaldealersthoughnotexcludingothers,declineallliabilityfordamagesattributabletoabnormalities intheoperationorresponseofparts and/orcomponentsnotapprovedbytheManufacturer,usedintheservicing and/orrepairofaproductbuiltor marketedbytheManufacturer. Inanyevent,nowarrantyofanydescriptionisofferedonorapplicabletotheproductbuiltormarketedbythe Manufacturer,inrespectofdamagesresultingfrom abnormaloperationorresponseofpartsand/orcomponentsnot approvedbytheManufacturer.

AVOIDACCIDENTS

Mostaccidentsandinjuriesthatoccurinandaroundfactories,onfarms,inthehomeorontheroads,arecaused byfailuretofollowsomesimpleandfundamentalruleregardingprecautionaryproceduresandsafety. Accordingly,INTHEMAJORITYOFCASES,ACCIDENTSCANBEAVOIDED:itissufficientsimplytoforesee thepossiblecauses,andexercisethenecessarycautionandprudence.

Whateverthetypeofequipment,andhoweverwelldesignedandbuilt,itisnotpossibletoeliminatetheriskof accidentcompletelywithoutadverselyaffectingcertain essentialfeaturesinstrumentalinprovidingreasonable levelsofaccessibilityandensuringsmoothoperation.

Acarefulandprudentoperatoristhebestinsuranceagainstanyaccident. Thecompleteobservanceofthissimplerulewillofitselfbesufficientinavoidingmanyseriousaccidents. Thisruleis:neverattemptanycleaning,lubricationormaintenanceoperationwiththemachineinmotion.

WARNING

Beforecommencinganykindofmaintenance,adjustmentorrepairworkonmachinesequippedwith attachmentsoperatedhydraulically,mechanicallyorbywireropes(suchasfrontloaders,dozers, scrapers,etc.)makecertaintheattachmentisloweredandrestingontheground. Iftheattachmentneedstobeintheraisedpositioninordertogainaccesstoonepartofthemachine oranother,itmustbesupportedintheraisedpositionbyseparateequipment,andnotheldwiththe machinecontrols.

MODELDESIGNATIONS

Themodelsmakinguptherangeoftelescopichandlers(Telehandlers)describedinthismanualareidentified inthetextbyreferencetothemaximumreachoftheboom.

Thevehicleslistedbelowmaynotbeavailableinallcountriesoronallmarkets.Foruptodateinformationon allmachines,consultyourauthorizeddealer.

SECTION55–ELECTRICALSYSTEM

Diagram7:Tip--overpreventionsystem/roofwiper53

Diagram8:Heater,radio/trailersocket/interiorlight55

Diagram9:Air--conditioning

GENERALINSTRUCTIONS

IMPORTANTNOTICE

AllmaintenanceandrepairoperationslistedinthisManualmustbeperformedexclusivelybytheService NetworkoftheManufacturer,complyingstrictlywiththeindicationshereinandusingtheprescribedspecialtools whereindicated.

Anypersonperformingserviceoperationsdescribedinthemanualandfailingtoabidestrictlybytheinstructions becomessolelyresponsibleforanyconsequentialdamagethatcouldoccur.

SHIMS

Selecttheshimsforeachadjustment,measuringthemonebyonewithamicrometerandthenaddingtogether thevaluesmeasured:Donotrelyonthemeasurementoftheentirepack,whichcouldbewrong,orthenominal valueindicatedoneachwasher.

SEALSFORROTATINGSHAFTS

Forcorrectinstallationofthesealsonrotatingshafts,observethefollowingprecautions:

--priortoinstallation,soakthesealsforatleasthalfanhourinthesameoiltheywillbeexposedtoinoperation; --cleantheshaftthoroughlyandmakesurethatitsworkingsurfaceisundamaged; --directtheliptowardthefluid;inthecaseofahydrodynamiclip,theribsorgroovesmustbepositioned, relativetothedirectionofrotationoftheshaft,insuchawayastopropelthefluidtowardtheinsideofthe seal;

--smearthesealinglipwithafilmoflubricant(oilispreferabletogrease)andinthecaseofdoublelipseals, packthegapbetweenthesealinglipandthedustlipwithgrease; --insertthesealinitsseat,andpresshomeusingapunchwithaflatcontactface;neveronanyaccountstrike thesealwithahammerormallet;

--whenpressinghometheseal,makecertainitisinsertedperpendicularlyinrelationtotheseatand,once inplace,makecertainitisincontactwiththeshoulder,wherespecified; --topreventthelipofthesealbeingdamagedbytheshaft,interposesuitableprotectionmediaduringthe installationofthetwoparts.

O--RINGS

LubricateO--ringsbeforeinsertingthemintherelevantseatstopreventthemtwistingandrollinginthecourse ofinstallation,asthiswouldadverselyaffecttheirsealingaction.

SEALANTS

MatingsurfacesmarkedXmustbesmearedwithasealingcompoundrecommendedbytheManufacturer,or asuitableequivalent. Beforeapplyingthecompound,preparethesurfacesinthefollowingmanner: --removeanyencrustationswithametalbrush; --degreasethesurfacesthoroughlyusingthedegreasingagentrecommendedbytheManufacturer,ora suitableequivalent.

BEARINGS

Wheninstallingbearings,theringsshouldbe: --heatedto80° 90°Cbeforeshrinking(inner)ontotheshaft; --cooledbeforedriving(outer)intotheseat.

ROLLPINS

Wheninstallingrollpins,makesurethatthecutisfacinginthedirectionofthemechanicalforcebearingonthe pin. Spiralrollpins,ontheotherhand,canbefittedwithanyorientation.

NOTESONSPAREPARTS

Useonly genuinesparepartsguaranteedbytheManufacturer. Genuinesparepartsaretheonlyonesensuringthesamequality,thesamelifeandthesamesafetyasthe originalequipment,sincetheyarethesameasthoseinstalledinproduction. Onlygenuinepartsfromthemanufacturerensurethisguarantee. Ordersforsparepartsmustincludethefollowingindications: --modelofthevehicle(commercialdesignation)andchassisnumber; --typeandnumberoftheengine; --partnumberfortheitemordered,obtainablefromthe“Microfiches”orthe“SparePartCatalogue”,onthe basisofwhichallordersareprocessed.

NOTESONTOOLS

ThetoolsrecommendedbytheManufacturerandillustratedinthisManualare: --studiedanddesignedspecificallyforservicingvehiclesofthisrange; --requiredinordertoensureareliablerepair; --carefullyengineeredandstringentlytestedtoprovideeffectiveandlonglastingequipment. Rememberalsothatwhenproperlyequipped,therepairmechaniccan: --operateunderoptimumtechnicalconditions; --achievethebestresults; --savetimeandeffort; --workinsaferconditions.

WARNING

Thewearlimitsindicatedforsomeitemsmustbeconsideredasrecommendedvalues,butnotabsolutely binding.Theindications“front”,“rear,“right”,“left”refertothedifferentpartsasseenfromapositionsittingin thedriverseatandfacinginthenormalforwarddrivedirectionofthevehicle.

HOWTOMOVEAVEHICLEWITHOUTBATTERIES

Thecablesoftheexternalpowersupplymustbeconnectedexclusivelytotherespectiveterminalsofthepositive andnegativecablesonthevehicle,usingefficientclampsthatwillprovideasecureandstablecontact.Switch offallelectricalloads(lights,wipers,etc.)beforeproceedingtostartthevehicle.Shoulditbenecessarytocheck theoperationofthevehicle’selectricalsystem,thismustbedoneonlywiththepowersupplyconnected;Having completedthecheck,switchoffallloadsanddeactivatethepowersupplybeforedisconnectingthecables.

SAFETYRULES

PAYATTENTIONTOTHISSYMBOL

Thiswarningsymbolaccompaniesimportantmessagesinvolvingyoursafety.

Readthesafetyinstructionscarefully,andfollowtheprecautionsrecommendedin ordertoavoidpotentialrisksandsafeguardyourhealthandyoursafety. YouwillfindthissymbolinthetextofthisManualwiththefollowingkeywords:

WARNING --Cautionsintendedtoavoidunsuitablerepairoperationswithpotential consequencesforthesafetyofthepersonperformingtherepair.

DANGER --Warningsspecificallyindicatingpotentialdangersforthesafetyofthe operatororofotherpersonsdirectlyorindirectlyinvolved.

AVOIDACCIDENTS

Mostaccidentsandinjuriesthatoccurinandaround workshopsarecausedbyfailuretofollowsome simpleandfundamentalruleregarding precautionaryproceduresandsafety.Accordingly, INTHEMAJORITYOFCASES,ACCIDENTSCAN BEAVOIDED:itissufficientsimplytoforeseethe possiblecauses,andexercisethenecessarycaution andprudence.

Whateverthetypeofequipment,andhoweverwell designedandbuilt,itisnotpossibletoeliminatethe riskofaccidentcompletely.

Acarefulandprudentmechanicisthebestinsurance againstanyaccident.

Thecompleteobservanceofthissimplerulewillof itselfbesufficientinavoidingmanyserious accidents.

DANGER. Neverattempttoclean,lubricateor maintainamachinewiththeenginerunning.

SAFETYRULES

GENERAL

◊ Followthespecifiedmaintenanceandrepair procedurescarefully.

◊ Donotwearrings,wristwatches,jewellery,and looseorhanginggarments,suchas:ties,torn clothing,scarves,unbuttonedorunzipped jacketsthatcouldbecomecaughtandentangled inmovingparts.Wearpropersafetyclothingand protectivegear,forexample:non--slipfootwear, gloves,safetyglassesorgoggles,hardhats,etc.

◊ Donotperformanyserviceoperationonthe machinewithpersonsoccupyingthedriverseat, unlesstheseareauthorizedoperatorsassisting withtheworkinhand.

◊ Neverattempttooperatethemachineorits attachmentsfromanypositionotherthanseated inthedrivingposition.

◊ Neverperformanyoperationonthemachine withtheenginerunning,unlessindicatedinthe manual.

◊ Shutofftheengineandmakecertainthatthere isnopressureinthehydrauliccircuitsbefore removingcaps,covers,valvesetc.

◊ Allserviceoperationsmustbeperformedwith theutmostcareandattention.

◊ Step--laddersandaccessplatformsusedinthe workshoporinthefieldmustbeconstructedand maintainedinaccordancewithaccident preventionregulations.

◊ Disconnectthebatteriesandtagallcontrolsto signalthatservicingisinprogress.Immobilize themachineandanyattachmentthatmustbe lifted.

◊ Donotcheckorrefillfueltanks,ortopup batteries,orusestartingfluidwhensmokingor nearanakedflame,sincethefluidsinquestion areflammable.

◊ Brakesareinactivewhenreleasedmanuallyfor servicingpurposes:inthissituation,keepthe machineundercontrolusingwheelchocksor similardevices.

◊ Thegunofthefillerhosemustalwaysremainin contactwiththetankfillerpipewhenrefuelling. Maintainthiscontactthroughouttherefuelling operationsoastoavoidanypossibilityofsparks beinggeneratedwiththebuild--upofstatic electricity.

◊ Whentowing,useonlythedesignatedhitchpoints. Exercisecarewhencouplingtrailedloads:Make surepinsand/orlocksaresecurebeforepulling. Stayclearofdrawbars,cablesorchainsunder load.

◊ Tomoveamachinewhenbrokendown,usea traileroralow--loader,ifavailable.

◊ Whenloading/unloadingamachinefroma transportvehicle,selectalevelsurfaceaffording firmsupporttothewheelsofthetruckortrailer. Anchorthemachinesecurelytothebedofthe truckortrailerandlockthewheelsasspecified bythecarrier.

◊ Useonlyapprovedgroundedauxiliarypower sourcesforheaters,chargers,pumpsandsimilar equipmenttoreducethehazardsofelectrical shocks.

◊ Liftandhandleallheavypartswithlifting equipmentofsuitableratedcapacity.

◊ Bewareofbystanders.

◊ Neverpourgasolineordieselfuelintoopen, wideandlowcontainers.

◊ Neverusegasoline,fueloilorotherflammable liquidsascleaningfluids:useonlyproprietary non--flammableandnon--toxicsolvents.

◊ Whenusingcompressedairforcleaningparts,use safetyglasseswithsideshieldsorgoggles.

◊ Limitpressureto2.1bar,inaccordancewith localandnationalregulations.

◊ Donotruntheengineinenclosedareaswithout properventilation.

◊ Donotsmoke,useanakedflameorcause sparksintheimmediatevicinitywhenrefuelling orhandlingreadilyflammablematerials.

◊ Donotuseanakedflameasalightsourcewhen lookingforleaksorcarryingoutinspectionson themachine.

◊ Movewithextremecarewhenworkingunderthe machine,andonoraroundthemachine.Always wearprotectivesafetyequipmentasindicated: hardhat,goggles,safetyfootwear.

◊ Whencarryingoutinspectionsthatrequirethe enginetoberunning,enlisttheassistanceofan operator,whoshouldremaininthedriverseat throughoutandkeepthemechanicinsightatall times.

◊ Foroperationsoutsidetheworkshop,setthe machineonlevelground,ifpossible,and immobilizethewheels.Ifworkonaninclineis absolutelynecessary,immobilizethemachine initially,thenmoveittolevelgroundassoonas thiscanbedonewithareasonablemarginof safety.

◊ Bewareofchainsorwireropesthatarepinched andbent:donotusethemforliftingortowing. Alwayswearsuitablythickgloveswhenhandling chainsandropes.

◊ Chainsmustbefirmlysecured:makecertainthe couplingisstrongenoughtoholdtheenvisaged load.Theremustbenooneinthevicinityofthe coupling,chainsortowropes.

◊ Theareawheremaintenanceoperationsare carriedoutmustalwaysbekeptCLEANand DRY.Clearupanypuddlesofwateroroilspills immediately.

◊ Donotpileupoilyorgreasyrags:theserepresent aseriousfirehazard.Alwaysplacetheminametal container.

◊ Beforesettingthemachineoritsattachmentsin motion,check,adjustandlockthedriverseat.

87474474A --01--2008

Also,makecertainthereisnoonewithinthe rangeofactionofthemachineorits attachments.

◊ Donotcarrylooseobjectsinpocketsthatmight fallunnoticedintocompartmentsinternallyofthe machine.

◊ Wearproperprotectiveequipmentsuchas safetygogglesorsafetyglasseswithside shields,hardhat,safetyshoes,heavygloves whenmetalorotherparticlesareliabletoflyor fall.

◊ Ifrepairsinvolveweldingortorch--cutting,wear theproperaccidentpreventionequipmentforthe purpose:tintedgoggles,hardhat,overalls, weldingglovesandboots.Darkglassesshould alsobewornbypersonsotherthanthewelder, whenstandingneartheweldingorcuttingarea. NEVERLOOKATTHEWELDINGARC WITHOUTSUITABLEEYEPROTECTION.

◊ Wireropeswillfraywithprolongeduse:always wearsuitableprotectivegearwhenhandling them(heavygloves,gogglesetc.).

◊ Handleallpartscarefully.Keephandsand fingersawayfromnarrowgaps,gearsormoving parts.Alwaysuseandweartheappropriate protectivegear,suchassafetygoggles,gloves andsafetyshoes.

STARTING

◊ Donotruntheengineinenclosedareasnot equippedwithventilation systemsofsufficient capacitytoremoveexhaustgases.

◊ Donotplacehead,body,limbs,feet,handsor fingersneartofansorbeltswhenthese componentsareinrotation.

ENGINE

◊ Beforeremovingtheradiatorcap,unscrewvery slowlytoreleasepressurefromthesystem.The levelofcoolantmustbetoppeduponlywiththe engineatstandstill,orifwarm,turningoverat idlespeed.

◊ Donotrefuelwiththeenginerunning,especially ifhot,asthiswillincreasetheriskoffireinthe eventoffuelbeingspilled.

◊ Neverattempttocheckoradjustfanbeltswhen theengineisrunning. Neveradjustthefuelinjectionpumpwiththe machineinmotion.

◊ Neverlubricatethemachinewiththeengine running.

◊ IMPORTANT:Accordingtodirectivesno. 2000/25/ECoftheEuropeanUnionandno.40 CFRPart.89oftheU.S.,itisprohibitedto tamperwiththeengineinanyway,includingthe downloadofnon--certifiedsoftware.Any tamperingwithanengineorwithitsfuelfeed systemnotpermissibleunderthecurrent specificationswillmean: inlegalterms, thattheengineislongerin

compliancewithstatutoryregulationsor protectedbyinsurance,andwarrantyonthe engineandfuel systemisinvalidated;depending onwhatisdeclaredinthecertificates,the customercouldbefacedwithveryhighcoststo restoretheenginetoitsoriginalcondition; inengineeringterms, possibleoverloadingof enginecomponents;theriskofearlyengine wear,duetotheexcessiveloadoncomponents andtotheuseofcontaminatedoil.Onlypersons approvedbytheManufacturerareauthorizedto carryoutrepairsonthefuelsystem.Such repairscanbecarriedoutonlyusingthe specificationssuppliedbytheManufacturer.

ELECTRICALSYSTEMS

◊ Shoulditbenecessarytouseboosterbatteries, remembertoconnectbothendsofthebooster cablesasspecified:(+)with(+)and(--)with(--). Avoidshort--circuitingtheterminals.THEGAS RELEASEDFROMBATTERIESISHIGHLY INFLAMMABILE.Whenrechargingbatteries, leavethebatterycompartmentopentoimprove ventilation.Nevercheckthebatterychargeby improvising“jumpers”withmetalobjectsplaced acrosstheterminals.Avoidsparksornaked flamesanywherenearthebatteries.Refrain fromsmokingtoavoidtheriskofexplosion.

◊ Beforeanyworkiscarriedout,makesurethat therearenofuelorcoolantleaks:eliminateany suchleaksbeforeproceeding.

◊ Donotrechargebatteriesinanenclosed environment:makecertainthereissufficient ventilationtopreventtheriskofaccidental explosionsoccurringduetotheaccumulationof gasesgeneratedduringrecharges.

◊ Alwaysdisconnectthebatteriesbeforedoing anyworkontheelectricalsystem.

HYDRAULIC SYSTEMS

◊ Fluidescapingunderpressurefromaverysmall holecanbealmostinvisible,andprojectedwith sufficientforcetopiercetheskin.Accordingly, useapieceofcardboardorwoodtosearchfor suspectedpressureleaks.NEVERSEARCH FORLEAKSWITHBAREHANDS.Ifescaping fluidshouldpenetratetheskin,seekmedical adviceimmediately.Seriousinfectionorallergic

skinreactionscandevelopifpropermedical treatmentisnotadministeredstraightaway.

◊ Whensystempressuresmustbemeasured,use theproperinstruments.

WHEELSANDTYRES

◊ Makecertainthattyresarecorrectlyinflatedto thepressureindicatedbytheManufacturer. Checkperiodicallyforpossibledamagetorims andtyres.

◊ Whencorrectingtheinflationpressure,standto onesideofthetyreatasafedistance.

◊ Checktheinflationpressureonlywiththe machineunladenandwiththetyrescold,to avoidanerroneouslyhighgaugereading.Never usereconditionedwheelcomponents,asabadly welded,brazedorheat--treatedrepaircould weakenthestructureandleadtofailure.

◊ Neveruseatorchtocutorweldawheelrimwith thetyrefittedandinflated.

◊ Beforeremovinganywheel,immobilizethe machinefrontandrearonallhubs.Having jackedupthemachine,positionsolidstands underneathtopreventitfalling,inaccordance withcurrentsafetyregulations.

◊ Deflatethetyrebeforeattemptingtoremove objectslodgedinthetread.

◊ Neverinflatetyreswithflammablegases;this couldproduceexplosionsandcauseinjuryto bystanders.

REMOVALSANDREFITMENTS

◊ Liftandhandleallheavypartswithlifting equipmentofsuitableratedcapacity.Make certainthatpartsaresupportedbysuitable slingsandhooks.Usetheeyeboltsprovidedfor thepurpose.Lookoutforpersonsstandingnear theloadbeinglifted.

◊ Handleallcomponentswithgreatcare.Never placehandsorfingersbetweenonepartand another.Alwaysweartype--approvedsafety gearandclothing:glasses/goggles,glovesand industrialfootwear.

◊ Donottwistchainsorwireropes.Alwayswear protectivegloveswhenhandlingropesorchains.

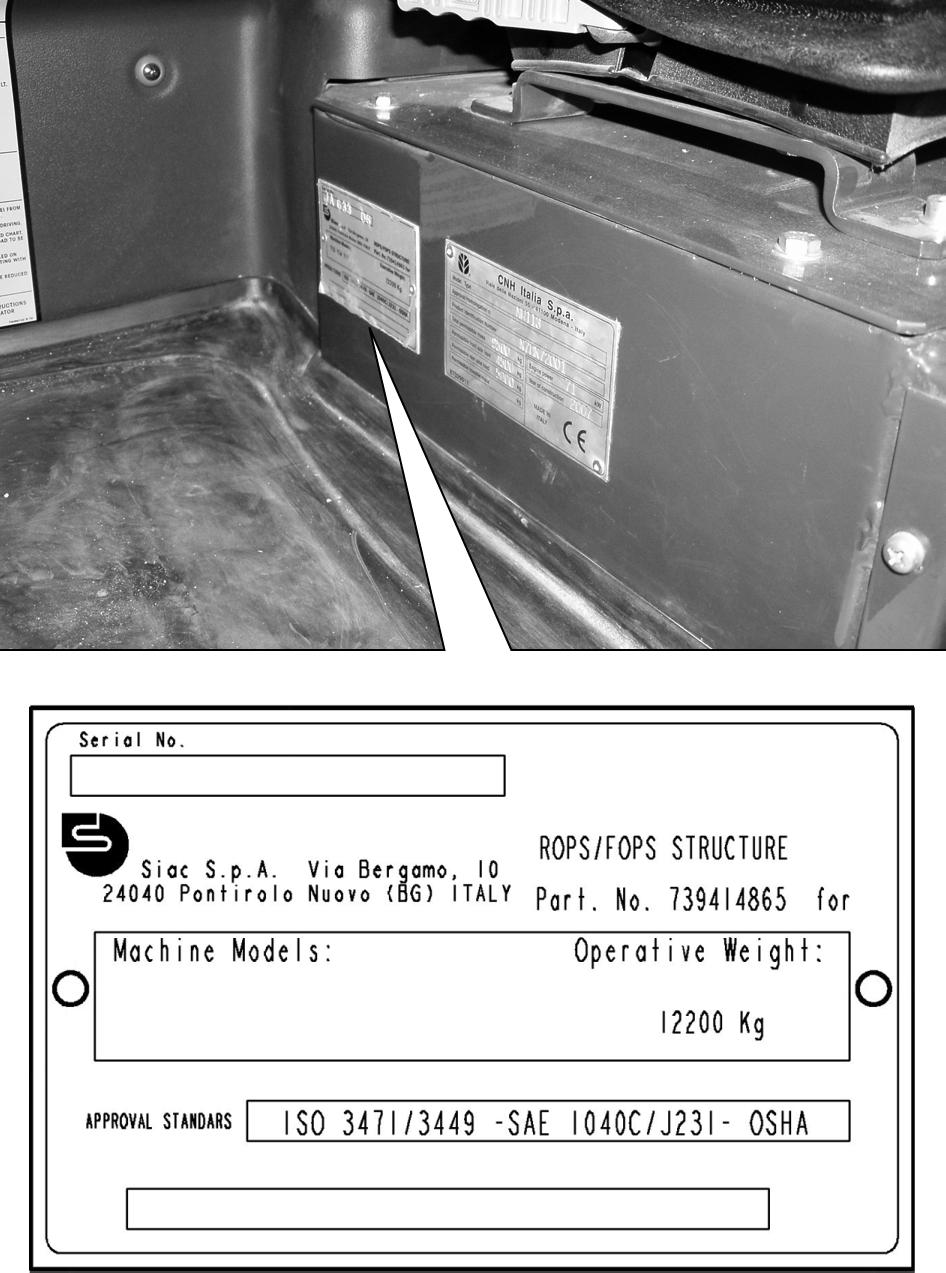

PRODUCTIDENTIFICATION

TheTelehandleranditsmaincomponentsare designatedusingvariousnumbersandletters allowingidentificationofthemachinebytheService network.Thefollowinginformationgivesthelocation ofidentificationdataplatesandofnumbersstamped onthemachine,providingvariousexamplesofthe detailsthatcanbefound.

CHASSISNUMBER

Thechassisnumberisstampedonthefrontofthe machine,onthetoppartofthemainframe,right handside.

NOTE: Whenorderingsparepartsorrequesting maintenanceonthemachine,theDealermayaskfor thechassisnumberandfortheidentification numbersofthecomponentsinvolved.These numbersarealsorequiredasanaidtoidentification ofthemachineintheeventoftheft.Keepthemina safeplace.

VEHICLEIDENTIFICATION DATAPLATES

Themachineidentificationdataplateislocatedatthe frontoftheseatwell.Recordthedetailsofyour machinebelow.

TECHNICALTYPE/MODEL

VEHICLECHASSISN

IDENTIFICATIONOF74kW TURBOCHARGEDENGINE

Theengineidentificationdataislocatedontheright handsideofthecrankcase.Recordtheinformation inthisspace,toallowquickreferenceincaseof necessity.

FRONTAXLEIDENTIFICATION

Theserialnumberandtypeoftheaxleareindicated ontheplatelocatedatthefrontoftheaxlehousing. Recordtheinformationinthisspace,toallowquick referenceincaseofnecessity.

AXLETYPE

SERIALN°

DATECODE

4x3POWERSHIFTIDENTIFICATION

Theserialnumberandmodelareprintedontheplate (1),ontheundersideofthetransmissionhousing. Recordtheinformationinthisspace,toallowquick referenceincaseofnecessity.

MODELN

REARAXLEIDENTIFICATION

Theserialnumberisindicatedonthedataplate securedtothereartransmissionhousing.Record theinformationinthisspace,toallowquickreference incaseofnecessity.

AXLETYPE

SERIALN°

DATECODE

CABIDENTIFICATIONDATAPLATE

Thecabidentificationdataplateshowstheserial numberandotherdetails,andislocatedonthefront oftheseat.Recordtheinformationinthisspace,to allowquickreferenceincaseofnecessity.

SERIALN°

DATECODE

Identificationofattachments

Awiderangeofattachmentsisavailableforthe Telehandler.

Eachattachmentapprovedbythemanufacturer carriesanidentificationdataplateindicatingthetype ofattachmentandtherelativespecifications.

WARNING

Onlytheattachmentsapprovedbythemanufacturer canbeusedonthismachine.Themanufacturer declinesallliabilityintheeventofanymodificationor adaptationbeingmadeto attachments withoutthe Manufacturer’s knowledge.

Thedetailsindicatedontheplatesmountedtothe attachmentsarethefollowing:

• Attachmenttype

• Load

• Dateofmanufacture

• Unladenweight

• Serialnumber

ENVIRONMENTALCONSIDERATIONS

Thefollowingrecommendationscanbeuseful:

• Becomefamiliarwithpertinentlegislation currentlyoperativeinthecountryofuse,andbe certainitisproperlyunderstood.

• Intheeventthatnostatutoryregulationsexist, askforspecificinformationfromthesuppliersof lubricants,fuel,antifreezeandcleaning compoundsregardingtheireffectsonhumans andontheenvironment,andhowtostore, handleanddisposeofthesesubstancessafely.

4.Avoidspillagewhendrainingoffspentengine coolant,engine,gearboxandhydraulicoils, brakefluids,etc.Afterdrainingoff,donotmix brakefluidsorfuelswithlubricants.Storethem safelyandwithoutriskuntilsuchtimeastheycan bedisposedofproperly,inaccordancewithlocal regulationsandaspermittedbyavailable resources.

5.Moderncoolantcompounds,suchasantifreeze andotheradditives,mustbereplacedeverytwo years.Greatcaremustbetakentoensurethat thesesubstancesdonotpenetratethesoil;they mustbecollectedanddisposedofinsuchaway astopresentnodanger.

6.Donotopenuptheair conditioningsystem unassisted:itmaycontaingasesthatmustnot bereleasedintotheatmosphere.Specialist HVACtechniciansusespecialequipmentto dischargeandrechargeairconditioning systems.

Usefulindications

1.Donotfilltanksfromjerrycansorusing ineffectivepressurizeddeliverysystemsthat couldcauseextensivespillage.

2.Ingeneralavoidskincontactwithallfuels,oils, acids,solvents,etc.Mostofthesecontain substancesharmfultohealth.

3.Modernlubricantscontainadditives.Donotburn contaminatedfuelsand/orwasteoilsinnormal heatingsystems.

7.Anyleaksordefectsoftheenginecooling systemorhydraulicsystemmustberepaired withmaximumurgency.

8.Donotincreasethepressureofanypressurized circuit,sincethiscouldcauseseriousfailureof systemcomponents.

9.Protecthoseswhenweldingoperationsarein progress,sinceasplashofweldmetalcan penetrateandburn,weakenandultimately pierceahosewall,causingoil,coolantetc.to leakfromthecircuit.

MAINTENANCETECHNIQUES

GENERAL

Cleantheoutsideofallcomponentsbefore proceedingwithanytypeofrepair.Dirtandabrasive dustcanreducetheefficientlifeexpectancyofa componentandresultinexpensiverepairs.

Thetimespentinpreparingandcleaningwork surfaceswillgiveresultsintermsofmakingthework easierandsafer,andthecomponentsoverhauled willbemorereliableandoperatebetter.

Usecleaningfluidsproventobesafe.Sometypesof fluidcancauseseriousdamagetoO--ringsand irritatetheskin.Alwayscheckthatsolventsare suitableforcleaningcomponents,andcarrynorisks forthehealthandsafetyoftheuser.

ReplaceO--ringsandallothertypesofsealingrings everytimetheyaredisplaced.NeveruseoldO--rings orsealsandnewonestogether,whatevertheir condition.AlwayslubricatenewO--ringsandseals withhydraulicoilbeforeinstalling.

Whenreplacingcomponents,alwaysusethetool appropriatetothetypeofworkinhand.

HOSESANDPIPES

Alwaysreplacehosesandpipeswhenthesplayed endorfittingsaredamaged.

Whenanewhoseisinstalled,connectitwithout tighteningtheendsandmakesurethatitissettledin thecorrectlyposition,beforetighteningthefittings. Clipsmustbetightenedjustenoughtoholdthehose withoutpinchingthewall,andavoidrubbingcontact. Afterreplacingahoseattachedtoamovingpart, makecertainthatthehoseisnotdisturbedbythe movementofthepartinanyofthevariouspositions itcanassume.

Makesurethatnoneofthehosesinstalledis restrictedorbent.

Anyhosefittingsthataredamaged,defaced, pinchedorleakingwillrestricttheflowofoiland impairtheproductivityofthehydraulicservicesto whichtheyareconnected.Fittingsshowingsignsof displacementfromtheiroriginalcrimpedposition mustbeconsideredasalreadybroken,astheywill soonfailorbecomedetached.

Ahosewitharaggedoutersleeveallowswaterto penetrate.Asaresult,thebraidreinforcementwill corrodeunnoticedalongtheentirelengthofthe hose,resultingultimatelyinfailureofthehoseitself.

Ifahoseswells,thisindicatesthatthereisinternal leakageduetoastructuralfailure.Thiscondition deterioratesveryquicklyandwillsoonleadtothe failureofthehose.

Hosesthatarerestricted,pinched,tootautor deformedwillingeneralbereadilysubjecttointernal structuraldamagethatcanresultinalowerrateof flowandreducedoperatingspeed,andlead ultimatelytoirreparablefailureofthehose.

Unsupportedandfreelymovablehosesmustbe preventedfromcontacteitherwithoneanotheror withadjacentworkingsurfaces.Suchcontact producesarubbingactionthatwillshortentheuseful lifeofthehose.

FITTINGSWITHFRONTSEALING O--RINGS

WhenrepairingfittingswithfrontsealingO--rings,the followingproceduresshouldbeobserved.

CAUTION:NEVERDISCONNECTANDNEVER TIGHTENAHOSEORPIPEWHENUNDER PRESSURE.IFINDOUBT,MOVETHECONTROL LEVERSREPEATEDLYWITHTHEENGINE SWITCHEDOFFBEFOREDISCONNECTINGA HOSEORPIPE.

1.Loosenthefittingsandseparatethehoseor pipe,thendetachthefittingandremovethe O--ring.

2.DipanewO--ringincleanhydraulicoilbefore installingit.PositionthenewO--ringinthefitting, holdingitinplacewithvaselineifnecessary.

3.Installthenewhoseorpipeandhand--tightenthe fitting,whileholdingthehoseorpipesteadyto preventitturning.

4.Usingtwowrenchesofsuitabletype,tightenthe fittingtothetorqueprescribedforitssize.Refer tothetablefurtheronfortighteningtorques.

NOTE:toensurethataconnectionwillnotleak, itisimportantthatthefittingsaretightened neithertoomuchnortoolittle.

SPECIFICSEALINGCOMPOUNDS

Thefollowingsealingcompoundsmustbeused,followingtheindicationsgivenintheManual:

SEALANTSPROPRIETARYNAME

AnaerobicsealantLOCTITE518(gasketmaker)

RTVsiliconesealantLOCTITESUPERFLEX593,595or596 LOCTITEULTRABLUE587DOWCORNING SILASTIC732GENERALELECTRICRTV103 or108

PipesealantPST592(pipesealantwithteflon)

Lockingcompoundforboom padsscrewthreads

LOCTITE243/BLUE

TIGHTENINGVALUESFORTHREADEDFASTENERS

Checkperiodicallythatthreadedfastenersare properlytightened.

Refertothefollowingtablestodeterminethecorrect tighteningtorquewhenthreadedfastenersonthe Telehandlerarechecked,adjustedorreplaced.

IMPORTANT:DONOTusethevalueslistedinthe tableswhentheManualindicatesadifferenttorque

ortighteningprocedureforaspecificapplication.The torquevaluesareprovidedforgeneraluseonly. Makesurethatthethreadsoffastenersareclean andundamaged.

NOTE: toensurenutsandboltsareproperly tightened,atorquewrenchmustbeused.

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please