Part number 84425026

2nd edition English

April 2011

Replaces part number 87492450

INTRODUCTION

PRIMAR Y HYDRAULIC POWER SYSTEM

LIGHTING SYSTEM

ELECTRONIC SYSTEM

F AUL T CODES

AXLES, BRAKES AND STEERING

FRONT AXLE

WHEELS AND TRACKS Wheels

FRAME AND CAB

FRAME Primary frame

FRAME POSITIONING

FIELD PROCESSING

SEEDING Mechanical system

SEEDING Electronic system

SEEDING Air system

SOIL PREP ARA TION Planting

Advice

Foreword

FRAME - Safety signs

Basic instructions

T orque

T orque – Hydraulic T ubes and Fittings

Dimension

W eight

Product identification

Product identification

Advice

All repair and maintenance works listed this manual must carried out only qualified dealership strictly complying with the instructions given; and whenever the special Anyone who carries out the above operations without complying with the procedures shall responsible for the subsequent

The manufacturer and all the organizations it’ s distribution including - without limitationlocal reject any responsibility for damages due the anomalous behavior parts and / components not approved the manufacturer including those used for the servicing repair the product manufactured marketed the manufacturer any warranty given attributed the product manufactured marketed the manufacturer case damages due anomalous behavior parts and / components not approved the manufacturer

The information this manual - - date the date the publication. the policy the manufacturer for continuous Some information could not updated due modifications a technical commercial well suit the law regulations dif ferent case refer your Sales and Service

Foreword

T echnical Information and ICE

This information this manual has been structured using the Integrated Coding Environment ICE the way which technical information created, stored and retrieved the T echnical Information Database.

ICE coding classifies all information three

The first category the the second category the Information T ype and the third category the Product:

• LOCA TION - the function the that the piece technical information going describe e.g. Fuel tank.

• INFORMA TION TYPE - the piece technical information that has been written for a particular component function the Capacity would a type T echnical Data that would describe the amount fuel held the Fuel

• PRODUCT - the model that the piece technical information written for

Every piece technical information will have those 3 categories attached Y will able use any combination those categories find the right piece technical information you need resolve that customers concern his machine.

That information could be:

• the description how remove the cylinder head

• a table specifications for a hydraulic pump

• a fault code

• a troubleshooting table

• a special tool

How Use this Manual

This manual divided into Sections. Each Section then divided into Chapters. Contents pages are included the beginning the then inside every Section and inside every Chapter alphabetical Index included the end a Chapter Page number references are included for every piece technical information listed the Chapter Contents Chapter

Each Chapter divided into four Information types:

• T echnical Data (specifications) for all the hydraulic and

• Functional Data (how works) for all the mechanical, electrical, hydraulic devices, components, and

• Diagnostic Data (fault codes, electrical and hydraulic troubleshooting) for all the mechanical, electrical, hydraulic and

• Service data install) for all the hydraulic and

Sections

Sections are grouped according the main functions systems the Each Section identified a letter C The number Sections included the manual will depend the type and function the machine that the manual written for . Each Section has a Contents page listed alphabetic / numeric order . This table illustrates which Sections could included a manual for a particular

PRODUCT

T ractors

V ehicles with working arms: skid

Mounted equipment and

PNEUMA ELECTRICAL ELECTRONIC SYSTEMS A

POWER PRODUCTION B

POWER TRAIN C

TRA VELLING D

BODY AND STRUCTURE E

FRAME POSITIONING F

T OOL POSITIONING G

WORKING ARM H

INTRODUCTION

SECTION

A -

B - Power Production

C - Power T rain

D - T ravelling

E - Body and Structure

Electronic Systems

F - Frame Positioning

G - T ool Positioning

H - W orking Arm

J - T ools and Couplers

K - Crop Processing

L - Field Processing

DESCRIPTION

This Section covers the main systems that interact with most the functions the includes the central parts the hydraulic, electrical, electronic, pneumatic, lighting and grease lubrication The components that are dedicated a specific function are listed the Chapter where all the technical information for that function

This Section covers all the functions related the production power move the machine and drive various devices. the case a pulled - type this Section covers the power take - f function where power provided from the towing

This Section covers all the functions related the transmission power from the engine the axles and internal external This Section also covers the power take - f function where power provided the pull - type machine and additional Process Drive

This Section covers all the functions related moving the machine, including tracks, wheels, steering and braking. covers all the axles; both driven axles and non - driven including any axle

This Section covers all the main functions and systems related the structure and the body the including the the the operators cab and the The functions related the positioning the machine frame are included Section F , Frame Positioning.

This Section covers all the main functions and systems related positioning the machine frame positioning the attachment the supporting machine

This Section covers all the functions related the final and / automatic positioning the tool once the tool positioned using the W orking Arm the machine frame.

This Section covers all the functions related the articulated single arms mounted the front rear the A working arm can have various tools and quick couplers mounted it. The tools and quick couplers are included Section T ools and

SECTION LETTER DESCRIPTION

T OOLS AND COUPLERS J

CROP PROCESSING K

FIELD PROCESSING L

This manual contains these

INTRODUCTION

This Section covers all the functions related the specific tools that mount the rear beside the The tools described here can mounted with the positioning systems side swing) listed Section G T ool This Section covers all the quick coupling systems, located between the tool and the positioning The tools used for field soil preparation and planting and seeding are

This Section covers all the functions related crop Examples crop processing include threshing, baling, cutting and

This Section covers all the field processing functions the Examples field process include fertilizer application, seedbed preparation and chemical application.

Contents

PNEUMA ELECTRICAL ELECTRONIC SYSTEMS A TRA VELLING D BODY AND STRUCTURE E FRAME POSITIONING F

FIELD PROCESSING L

Y our manual contains these The contents each Section are explained over the following

Section Contents

SECTION PNEUMA ELECTRICAL ELECTRONIC SYSTEMS

SECTION TRA VELLING

SECTION BODY AND STRUCTURE

SECTION F , FRAME POSITIONING

SECTION FIELD PROCESSING

Chapters

Each Chapter identified a letter and number combination Seeding The first letter identical the Section letter i.e. Chapter L.10.B inside Section Field Processing. The Chapter Contents lists all the echnical (how and (fault codes and troubleshooting) that have been written that Chapter for that function system the

The Chapter Index lists alphabetical order all the types information (called Information Units) that have been written that Chapter for that function system the

Information Units and Information Search

Each chapter composed information The ICE coding not included the Information Unit

Page Header and Footer

The page header will contain the following references:

• Section and Chapter description

The page footer will contain the following

Printed references found the base each page then equate

• The publication number for that Chapter

• Revision number the publication

• Publication date

• Chapter reference /

• Page number 84425026 1 1/04/201 1

FRAME - Safety signs

KEEP SAFETY DECALS CLEAN.

Wipe clean when necessary

REPLACE missing unreadable New decals are available from your dealer

T o replace decals:

Remove old decal and clean area.

Remove the decal backing and carefully fix the decal the

Using a clean piece paper the backing work the air bubbles out from under the

REF

(1) DANGER - Keep clear machine

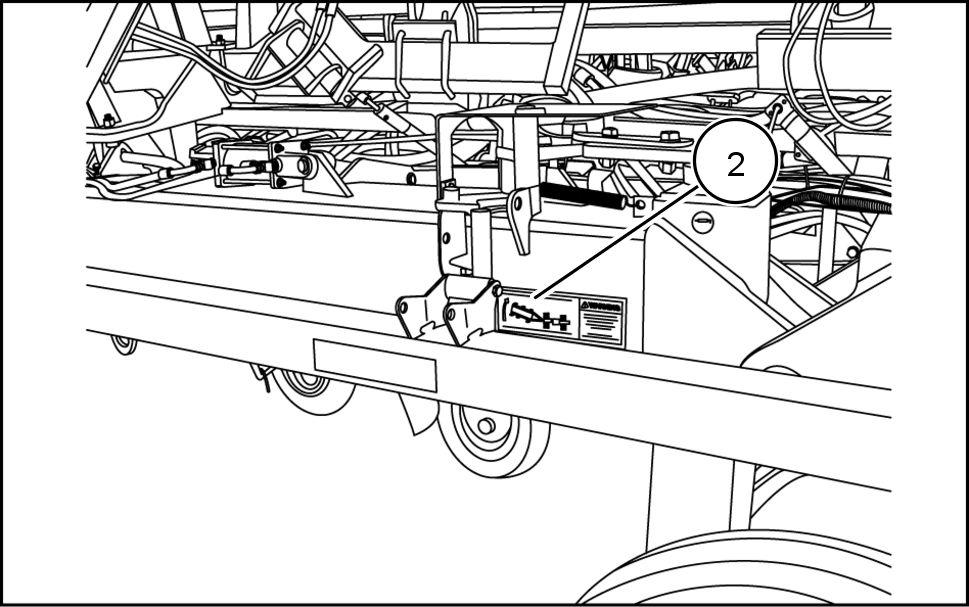

(2) W ARNING - Drill may become unstable

Decal Description

(3) Read your Operator ’ s Manual

(4) DANGER - Stay out fold zone

(5) DANGER - Rollover hazard

(6) not

(7) CAUTION - Escaping fluid hazard

(8) DANGER - Hitch upending hazard

(9) IMPOR T ANT - Latches must engaged

(10) A TTENTION - T o avoid unnecessary frame loading CAUTION - Unauthorized removal this decal will void warranty (12) W ARNING - Hydraulic accumulator contains

and oil under

DANGER

Keep clear machine when folding Mechanical hydraulic failure can allow wings W ing lock pins must installed for storage when servicing.

Quantity: 4 English: 87503980

2

3

(1) two locations each boom near wing lock pin storage

4

W ARNING

Drill may become unstable caster locks are not engaged during transport. Read

Quantity: 2

English: 87503996

(2) left and right books near locking

0687503996 5

209240S 6

Read Y our Operator ’ s Manual

Quantity:1.

English: 256147A1

06256147A1 7

(3) front hitch. 209235S 8

DANGER

Stay out fold zone. Make sure everyone clear implements before activating hydraulics.

Failure follow instructions will result serious injury

Quantity: 2

English: 87503802

DANGER

Rollover hazard. A void excessive side slopes during Failure follow instructions will result serious injury

Quantity: 1

English: 87503829

W arning - Not Ride

Quantity: 1

English: 182270A1

CAUTION

Escaping fluid hazard

Escaping hydraulic fluid under pressure can penetrate the skin causing serious injury . Relieve pressure before disconnecting hydraulic Check / T ighten all connections BEFORE applying pressure. a piece cardboard paper search for not use your ANY fluid injected into the skin, must surgically removed within a few hours GANGRENE Y RESUL T Failure follow these instructions could result minor moderate injury .

Quantity: 1

English:500.77

DANGER

Hitch upending hazard.

T o prevent hitch form rising abruptly , not unpin implement hitch exerting upward pressure the tractor drawbar . Refer Operator ’ s manual

Failure follow these instructions will result serious injury

Quantity: 2

English: 87503801

IMPORT ANT

Latches must engaged damage drill will occur .

Quantity:2

English: 87503994

T

A TTENTION

o avoid unnecessary frame casters must normal forward travel position (tires behind caster pivot) before raising lowering See Operator ’ s manual

Quantity: 2

English: 87504060

(10) center boom left and right sides, near caster .

CAUTION

Unauthorized removal this decal will void warranty Contact Overriding valves may cause machine move suddenly and unexpectedly . Damage may occur . Failure comply may result death serious injury .

Quantity: 2

English: 84260445

W ARNING

Hydraulic accumulator contains gas and oil under

Service repair must performed only trained service

Failure comply could result death serious injury .

Quantity: 1

English: 87054976

(12) accumulator mount

84425026 1 1/04/201 1