SER

Contents

INTRODUCTION

Hydraulic systems

[35.744] Seeding and planting hydraulic circuits

Wheels

[44.530] Carrying and transport wheels

Electrical systems

Harnesses and connectors

[55.404] External lighting

Metering system

Metering mechanical drive

Product metering

Platform, cab, bodywork, and decals

[90.1 18] Protections and footboards

Safety rules

Basic instructions

Basic instructions

T orque

Basic instructions

Special tools

General specification Dimension

Conversion factors

Product identification

Ear

Gloves.

BAIL14SE00801AA 1

SEM19101776 2

SAFETY FEA TURES FOUND THE MACHINE

Support stands: provide safe support the front part the machine when performing maintenance and

BAIL14SE00801AB 3

Safety chains: avoid lack control over machine case accidental disengagement between the bar the Seeder and the drawbar the tractor they limit the descent the lift arms and the drawbar

Decals: there are decals with warnings about the jor safety risks and with technical instructions such metering

Platforms (footrests) and protections: they should not used during machine operation; only for filling and

Row lift cylinder locks: provide safety against the ering the planting rows when transporting the chine and performing When you start disconnect these

BAIL14SE00801AC 4

BAIL14SE00801AE 5

BAIL14SE00801AD 6

W ARNING NOTES USED THIS MANUAL

NOTE: This word indicates special technical instructions not can cause malfunction and eventually , damage the

A TTENTION: This word indicates special technical instructions not can cause damage the machine and even risk injury .

A TTENTION: This word indicates special technical instructions not can cause damage the chine and imminent risk injury , and even

Displacement transportation the machine

cases where the machine needs moved another location perform maintenance observe rules such as:

• Prefer the use trucks transport the especially when comes public

For transporting the machine towing with the tractor:

• Seek information about what allowed and the order recommended the local traf fic

• For operations performed default the current the consequences must borne the operator

When displacement with the tractor allowed:

• Use alerting such slow vehicle approved the current local traf fic Keep these devices clean and good condition.

• Practice speeds compatible with the road conditions and traf but never exceeding MPH (20 / Reduce the speed considerably when the surface

NOTE: not transport the machine loaded: supply the seed the planting

• Use the brake pedals the tractor for a smooth

• careful with the power crossing points restricted width and other

• Never allow people the machine while moving

For maintenance services performed with the Seeder coupled onto the tractor .

For many maintenance especially those performed the convenient leave the Seeder coupled the tractor ensure the firmness and stability the addition:

• Remove the ignition key

• Engage the first gear and actuate the parking

• Put a sign next the tractor panel:

UNDER MAINTENANCE NOT OPERA

7

BAIL14SE00801AF

When removing, reinstalling moving heavy assemblies

• Always use appropriate devices attach and lift whole and / heavy

• Never stand under suspended safe the lifting equipment may be, not worth running the risk!

• Check that the devices used have the necessary pacity and that they are perfect storage and ing

BAIL14SE00801BA 8

Safety recommendations follow when performing maintenance the Seeder

NOTE: The following recommendations are specific the maintenance work the Seeder , the workshop the

For safety information related the handling chemical fertilizers and see the

• Keep the machine properly supported: Always lower both support stands and install the locking latches the lift See the item features found the machine", and not support the machine improvised objects which can collapse under the load. also not work the machine supported only a hydraulic

• equipped with row not forget lower was necessary leave them ensure a complete locking.

• Especially , when handling parts that have a cutting edge, such the lagged and coulter disks, use priate

SEM19101778 9

• With the engine running: not touch enter the seed fertilizer box and not perform any repairs and also not access the supply

• not wear loose clothing, blankets loose hair (if jewelery such bracelets and necklaces: moving parts could pull and tear such with a risk serious injury!

• Understand the procedure before performing fer this manual when necessary

• Prolonged exposure loud noise can cause hearing damage. Use ear protectors such as: noise dampers and

• Operating the equipment safely requires your full A void using headphones while operating the

• Use original parts only Similar apart from promising the functioning the also pose safety hazards.

• Use appropriate tools and not accept provisations and refer this manual whenever sary . Improvisations constitute a potential safety Special precautions should taken when using trical T o loosen and tighten use the correct size and pattern (millimetric) tools.

• W ork dry , clean and ventilated

• Whenever possible and necessary , clean the chine before performing maintenance: the operation becomes safer , with better quality Remove accumulations grease, oil and debris, which apart from hindering they represent potential sources fire

• Remove all tools and unused parts before starting the same way , analyze the work performed and remove parts protections allow easier making this work safer , more productive and with ity

• not perform repairs areas with transmission (chains and gears) when the machine running; risk mutilation!

SEM19101779

SEM19101760 1 1

BAIL14SE00801AG

SEM19101784

• Close all safety devices before starting the This will prevent other materials from getting tangled shafts and other moving parts the

• Keep away from the articulated parts the such row

• not walk the ladders platform the machine when the tractor

T ire calibration:

• Never exceed the recommended pressure seat the edges the tire the rim.

• Replace the tire presents any Replace the rim you observe any sign cracks, wear , deformation severe

• Make sure all the air was removed prior removing the tire from the

• Make sure the tire properly seated the rim during its filling.

• T ire replacement can dangerous and must performed trained personnel with proper tools and

• Never stand front top during the mounting a

• When removing and installing use suitable dling equipment for the weight involved. available, use a safety cage perform this type

SEM19101786

SEM19101761

Care taken with hydraulic systems and fluids under pressure general

• Fluids escaping under pressure can penetrate the skin, causing injury and serious poisoning; fluids injected into the skin must surgically removed soon they may cause

• T o check for use a piece paper not body parts.

• accident see a doctor immediately

• W ear protective gloves and goggles when working with hydraulic

A void fires

• Keep a fire extinguisher and a first aid kit always hand also Keep emergency numbers for doctor , ambulance, hospital and firefighter near the

• Never allow open flame welding near flammable solvents and other!

• not smoke the work There always the risk fire due the wide range flammable

• When remove any flammable products from near the area welded, such fuels, solvents

Chemicals and the Environment

• Being exposed come into contact with chemical decals and can harmful your

• Protect yourself from the waste gases chemical products derived from the treatment

A TTENTION: See a doctor immediately you notice symptoms poisoning such abdominal profuse chest blurred vision and nonreactive T ake the container , the label the suspected chemical Manufacturers these products provide a phone number for contact any time

BAIL14SE00801AH

BAIL14SE00801AJ

• Before disposing used fluids and always remember the environment: not pour spill these products the ground water , place them tainers that could cause

• Dispose paints and other products equately , established the existing environmental legislation. Many these products may fer recycling

BAIL14SE00801BC

Conditions the workplace

• the workshop: separate and organize used and discarded parts; the first opportunity , take them collection points for All materials, including tires, currently have recycling alternatives.

• not allow the floor the workshop get drenched with oil; this cause for slipping and apart from compromising the appearance the Remember: organization the mirror quality for the professional who works

• Provide the necessary illumination the work necessary , use a portable safety light for working places hard reach and / with lack good light.

Regarding the portable aware the insulating conditions both the electric power cable and the lamp itself: the heat the cables not properly insulated poor quality and accidentally broken bulb are factors that may cause burns a

W

elding work

• Use the proper PPE for this activity: mask, gloves and a leather

• case electric welding: always seek connect the negative electrode near the point

• Only perform welding well ventilated areas avoid the concentration toxic gases and dust.

• Before remove the thus preventing the formation toxic gases and dust. you cannot remove the use appropriate mask protect against the inhalation toxic When sanding surfaces, especially with paint, also wear a

you use a solvent remove the not forget wash the area with soap and water before welding: fire hazard!

SEM19101776

Basic instructions

HITCH THE MACHINE ONT O THE TRACT CAUTION

T ransport hazard!

Always connect a safety chain between the machine and the implement. Only use a safety chain with a strength rating equal greater than the gross weight the implement.

Failure comply could result minor moderate injury .

CAUTION

A void injury!

Handle all parts carefully not place your hands fingers between Use Personal Protective Equipment (PPE) indicated this manual, including protective goggles, gloves, and safety footwear

Failure comply could result minor moderate injury .

DANGER

Crushing hazard! not stand place any body part between the implement and a moving tractor . Stop the tractor engine and set the parking brake before you attach cables and hoses. Failure comply will result death serious injury

• level ground, lock the machine with the support stands (1)

• With the spindle (2) lift lower the drawbar (3) until matching with the drawbar

• Back the tractor carefully and the securing with a coupling

• Install the safety chain (4) BAIL14SE00802AC 1 BAIL14SE00802AD 2

CUTTING CAP ACITY

ADJUSTMENT AND LEVELING

• T o level the turn the spindle (2)

• The machine properly leveled for planting when the frame (chassis) parallel with the ground: see dotted line the

Couple the quick coupling hoses onto the hydraulic system the tractor

NOTICE: Ensure thorough cleaning the quick couplers hydraulic cylinder Keep the plastic caps place while not use. not couple hydraulic systems with impurities the circuit into the tractor: serious damage can occur the tractor

NOTE: not drive the hydraulic system without removing the locks (5)

DRA WBAR

The drawbar (3) can raised for transportation truck and Raise the drawbar and lock the arms the drive

T o lock the drawbar up:

Disconnect and remove the spindle (2) , removing the pins (2a) and (2b)

Raise the drawbar (3) , allow the mounting the pin (2a) the hole (F) the drawbar .

Install the pin (2a) , locking the drawbar the

T o lower the drawbar , perform the above steps verse and reinstall the spindle (2)

BAIL14SE00802AG 5

BAIL14SE00802AH 6

Basic instructions

PERIODIC MAINTENANCE T ABLE

Item / Frequency

Grease all grease X Calibrate the tires

- tighten bolts and nuts general

Check the transmission chains: clean lubricate them and adjust the

For a new machine, the tightening daily , throughout the first

Perform a general washing the machine and protect the metal parts with oil X

A TTENTION: Read and follow the safety recommendations regarding maintenance contained this Section the

GREASING

• Recommended grease: Use Lithium - based grease only , NLGI - 2

• Lubricate all fittings every h daily

• There are grease fittings with dif ferent angles tate access: straight fitting 0 ° - inclined ° and °see figure.

• A void excess grease: the correct amount applied reached the time the old grease begins seep out the

• Damaged grease fittings should replaced ately avoid compromising the greasing the tive

• Before clean the grease fittings avoid the penetration dust lubricated components (bearings and

• Wheel hubs (1) : recommended that the ginning each season the hubs are cleaned and checked: replace the seals and other ponents make the adjustment the pre - load the ings (see T ransport wheel Axle - Overview (44.530) this manual) and lubricate with new

CHAINS AND GEARS

There are two dif ferent ways adjust the chains ers:

BAIL14TR00455AB 1

BAIL14SE00802AI 2

adjusted sprockets fixed pulleys (1)

• The chain, this case, works with a clearance, sured deflection "X" the longest free length the

• The "X" deflection must 1 the "L" measured between the centers the farthest

• T o loosen the sprocket support tachment (1) , - position and - attach the

3

4

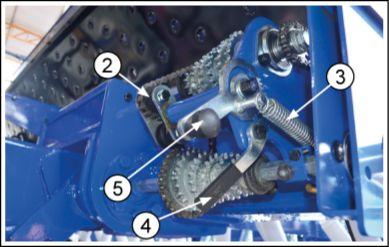

Chain adjusted spring tension

• The chain, this case, works with a slight tension the free This tension maintained and adjusted sprockets pulleys (2) , loaded springs (3)

• This type tension applied when changing the seed metering

T o adjust: loosen lock (4) and turn lever (5) until the position that corresponds the correct tension for the

After refit the lock (4)

Cleaning chains and gears

5

• Cleaning important lubrication itself, vents the accumulation which accelerates wear

The removal the old already also favors the action the new grease

• The most fective way promote a good cleaning, use a water jet under hot and / with

Lubricating chains and gears

• The lubrication must performed with

• The application oil can drops (with oiler) with a brush spray directed onto the

BAIL14SE00802AJ

BAIL14SE00802AK

BAIL14SE00802AL

NOTE: When opening (dismantle) a note the correct position the lock (6) the pins: the side with the opening should facing the side opposite the direction displacement (X) the

NOTE: This prevents any interference the chain with crop residues (such corn stalks) from causing the moval the lock (6)

NOTE: There are tools (7) with the purpose removing pins from

NOTE: Never install new links a worn out

NOTE: Always ensure the correct alignment the gears and parallelism the Misalignments cause erated wear chains and even under

NOTE: recommended off - season the chains are removed and washed kerosene diesel After that, place the chains oil bath for h and then, allow the excess oil

BAIL14SE00802BE 6

BAIL14SE00802AM 7

TIRE CALIBRA TION

• The tires must always calibrated cold.

• Frequency: weekly

• Pressure recommended: 1 - 3 bar ( - psi )

• Importance the correct pressure: apart from fecting the service life the the correct contact the Seeder tires critical for the correct grip (no avoiding failures the transmission the seed

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please