Link Product / Engine

Speedrower® 200 [YEG675001 - ] Middle East Africa

Speedrower® 200 [YEG675001 - ] Latin America

Speedrower® 200 [YEG675001 - ] Asia Pacific

Speedrower® 200 [YEG675001 - ] Australia New Zealand

Speedrower® 240 [YEG675001 - ] Asia Pacific

Speedrower® 240 [YEG675001 - ] Latin America

Speedrower® 240 [YEG675001 - ] Middle East Africa

Speedrower® 240 [YEG675001 - ] Australia New Zealand

F4HE9687

F4HE9687

F4HE9687

F4HE9687

F4HE9687

F4HE9687

F4HE9687

F4HE9687

Engine

INTRODUCTION

[10.001] Engine and crankcase

[10.202] Air cleaners and lines

[10.206] Fuel filters

[10.216] Fuel tanks

Fuel injection system

T

urbocharger and lines

[10.254] Intake and exhaust manifolds and muf fler

Engine cooling system

Fan and drive

Front axle system

[25.310] Final drives

Rear axle system

rear axle

Hydrostatic drive

T ransmission and steering hydrostatic control

Hydrostatic transmission

Pump and motor components

Brakes and controls

[33.1 10] Parking brake parking lock

Hydraulic systems

Hydraulic systems

Main lift system

[35.105] Charge pump

[35.220] Auxiliary hydraulic pump and lines

Reservoir , cooler , and filters

Combination pump units

Header attachment height system

Header attachment tilting system

Header reverser drive

Head and header hydraulic drive

Steering

[41.101] Steering control

Cab climate control

Air conditioning

Electrical systems

[55.000] Electrical system

[55.019] Hydrostatic drive control system

V and (HV AC) control system

Harnesses and connectors

[55.640] Electronic modules

[55.DTC] F AUL T CODES

operator seat Cab Cab interior

Cab doors and hatches

Personal safety - Hydraulic system safety

Personal safety - Maintenance safety (*)

Safety rules - Ecology and the environment (*)

Personal safety - not operate tag (*)

T orque - Minimum tightening torques for normal assembly (*)

T orque - Standard torque data for hydraulics (*)

Basic instructions - Shop and assembly (*)

Hydraulic contamination

Capacities

Maintenance chart - Recommended operating temperature range

General specification

Product identification - Product Identification Number (PIN) (*)

Part identification - Engine serial number

Product identification - Machine orientation

Foreword - Important notice regarding equipment servicing

200

240

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution including - without limitationlocal reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer . any warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The manufacturer reserves the right make improvements design and changes specifications any time without notice and without incurring any obligation install them units previously and illustrative material herein are accurate known time publication but are subject change without case refer your NEW HOLLAND Sales and Service

Foreword - Note the dealer

Company policy

Company policy , which one continuous reserves the right make changes design and cations any time without notice and without obligation modify units previously built.

All data given this book subject production Dimensions and weights are approximate only and the illustrations not necessarily show windrowers standard

Parts and accessories

Genuine NEW HOLLAND parts and accessories have been specifically designed for NEW HOLLAND

W e would like point out those "NONGENUINE" parts and accessories have not been examined and released NEW HOLLAND The installation and use such products could have negative fects upon the design istics your machine and thereby fect its safety NEW HOLLAND not liable for any damage caused the use "NONGENUINE" NEW HOLLAND parts and

Lubrication

Adequate lubrication and maintenance a regular schedule vital maintaining your T o ensure long service and ficient follow the lubrication and maintenance schedules outlined this The use proper fuels, oils, grease and filters, well keeping the systems clean, will also extend machine and component

NOTICE: Always use genuine NEW HOLLAND replacement oils and filters ensure proper filtration engine and hydraulic See your NEW HOLLAND dealer for additional oil

Safety rules

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation not could result minor moderate injury

T O FOLLOW

Machine safety

NOTICE: Notice indicates a situation that, not avoided, could result machine property damage.

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property damage. The word Notice used address practices not related personal safety .

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a step, other information the The word Note not intended address personal safety property

Safety rules

General safety rules

Use caution when operating the machine Raised full tanks and other loads will change the center gravity the The machine can tip roll over when near ditches and embankments uneven surfaces.

• Only skilled operators who are familiar with all the controls and harvesting techniques should use the recommended operate cultivated land with slopes greater than % ( ° ) uphill and

• necessary , when driving downhill change into a lower gear before starting the Machine must stopped downshift into a lower gear

Never permit anyone other than the operator ride the

Never operate the machine under the influence while otherwise

Pay attention overhead power lines and hanging High voltage lines may require significant clearance for safety

Hydraulic oil diesel fuel leaking under pressure can penetrate the causing serious injury

• NOT use your hand check for Use a piece cardboard paper

• Stop remove key and relieve the pressure before connecting disconnecting fluid

• Make sure all components are good condition and tighten all connections before starting the engine izing the

• hydraulic fluid diesel fuel penetrates the seek medical attention immediately

• Continuous long term contact with hydraulic fluid may cause skin cancer . A void long term contact and wash the skin promptly with soap and water

Keep clear moving parts. Loose clothing, jewelry , watches, long hair , and other loose hanging items can become entangled moving

W ear protective equipment when appropriate.

NOT attempt remove material from any part the machine while being operated components are

Make sure all guards and shields are good condition and properly installed before operating the Never operate the machine with shields Always close access doors panels before operating the

Dirty slippery and platforms can cause Make sure these surfaces remain clean and clear

A person pet within the operating area a machine can struck crushed the machine its NOT allow anyone enter the work

Raised equipment and / loads can fall unexpectedly and crush persons Never allow anyone enter the area underneath raised equipment during

Never operate engine enclosed spaces harmful exhaust gases may build

Before starting the sure that all controls are neutral park lock

Start the engine only from the operator ’ s the safety start switch the engine can start with the transmission gear not connect short across terminals the starter Attach jumper cables described the Starting gear may cause death serious injury

Always keep all and Slow Moving V ehicle (SMV) emblem clean provide the best possible visibility while operating the machine.

Operate controls only when seated the operator ’ s except for those controls expressly intended for use from other

Before leaving the machine:

Park machine a firm level

Put all controls neutral park lock

Engage park use wheel chocks

Lower all hydraulic equipment header ,

T

urn f engine and remove key

due exceptional you would decide keep the engine running after leaving the operator ’ s then the following precautions must followed:

Bring the engine low idle

Disengage all drive

W ARNING

Some components may continue run down after disengaging drive systems.

Make sure all drive systems are fully

Failure comply could result death serious injury .

Shift the transmission into

Apply the parking

General maintenance safety

Keep area used for servicing the machine clean and dry Clean spilled

Service machine a firm level surface.

Install guards and shields after servicing the

Close all access doors and install all panels after servicing the not attempt clear obstructions make adjustments the machine while motion while the engine

Always make sure working area clear other persons and pets before you start operating the

Unsupported hydraulic cylinders can lose pressure and drop the equipment causing a crushing not leave equipment a raised position while parked during unless securely

Jack lift the machine only jack lift points indicated this

Incorrect towing procedures can cause When towing a disabled machine follow the procedure this Use only rigid tow

Stop the remove key and relieve pressure before disconnecting connecting fluid

Stop the engine and remove key before disconnecting connecting electrical

Scalding can result from incorrect removal coolant

Cooling system operates under Hot coolant can spray out a cap removed while the system Allow system cool before removing When removing a cap turn slowly allow pressure escape before completely removing the

Replace damaged worn tubes, electrical

exhaust and hydraulic lines may become hot during T ake care when servicing such components. Allow surfaces cool before handling disconnecting hot components. W ear protective equipment when

When follow this instructions the Always disconnect the battery before welding the Always wash your hands after handling battery

Wheels and tires

Make sure tires are correctly not exceed recommended load Follow instructions the manual for proper tire inflation.

T ires are heavy Handling tires without proper equipment could cause death serious injury

Always have a qualified tire technician service the tires and a tire has lost all take the tire and wheel a tire shop your dealer for Explosive separation the tire can cause serious injury

NOT weld a wheel rim until the tire completely Inflated tires can generate a gas mixture with the air than can ignited high temperatures from welding procedures performed the wheel Removing the air loosening the tire the rim (breaking the bead) will NOT eliminate the This condition can exist whether tires are inflated The tire MUST completely removed from the wheel rim prior welding the wheel

Driving public roads and general transportation safety

Comply with local laws and

Use appropriate lighting meet local

Make sure SMV emblem

Lift implements and attachments high enough above ground prevent accidental contact with road.

When transporting equipment machine a transport trailer , make sure properly sure the SMV emblem the equipment machine covered while being transported a trailer . aware overhead structures power lines and make sure the machine and / attachments can pass safely under

T ravel speed should such that complete control and machine stability maintained all

Slow down and signal before turning.

Pull over allow faster traf fic

Follow correct towing procedure for equipment with without

Fire and explosion prevention

Fuel oil leaked spills hot surfaces electrical components can cause a fire.

Crop bird flammable material can ignite hot

Always have a fire extinguisher near the machine.

least once each day and the end the day remove all trash and debris from the machine especially around hot components such engine, transmission, exhaust, battery , etc. More frequent cleaning your machine may necessary depending the operating environment and

least once each day , remove debris accumulation around moving components such bearings, pulleys, belts, cleaning More frequent cleaning your machine may necessary depending the operating environment and

Inspect the electrical system for loose connections frayed Repair replace loose damaged not store oily rags other flammable material the

not weld flame cut any items that contain flammable Clean items thoroughly with non - flammable solvents before welding flamenot expose the machine burning

Promptly investigate any unusual smells odors that may occur during operation the machine.

General battery safety

Always wear eye protection when working with not create sparks have open flame near battery

V entilate when charging using enclosed

Disconnect negative ( first and reconnect negative (

When welding the disconnect both terminals the battery not smoke near a battery

When using auxiliary batteries connecting jumper cables start the use the procedure shown the ator ’ s not short across

Follow manufacturer ’ s instructions when storing and handling

Battery and related accessories contain lead and lead W ash hands after This a California Proposition

Battery acid causes Batteries contain sulfuric A void contact with Antidote ternal): Flush with water Antidote (eyes): flush with water for minutes and seek medical attention immediately Antidote (internal): Drink large quantities water not induce Seek medical attention ately

Keep out reach children and other unauthorized persons.

Instructional seat safety

Passengers are not permitted ride the

The instructional seat used only when training a new operator when a service technician diagnosing a

When required for the purposes training only one person may accompany the operator and that person must seated the instructional

When the instructional seat the following precautions must followed:

• Machine should driven only slow speeds and over level

• A void driving highways public

• A void quick starts

• A void sharp turns.

• Always wear correctly adjusted seat

• Keep door closed all times.

Operator presence system

Y our machine equipped with operator presence system prevent the use some features while the operator not the operator ’ s

The operator presence system should never disconnected the system the system must

Power T ake - Off (PT

O - driven machinery can cause death serious injury Before working near the O shaft servicing clearing the driven put the O switch the disengage stop the and remove the key

Whenever a O all guards must place prevent death injury the operator

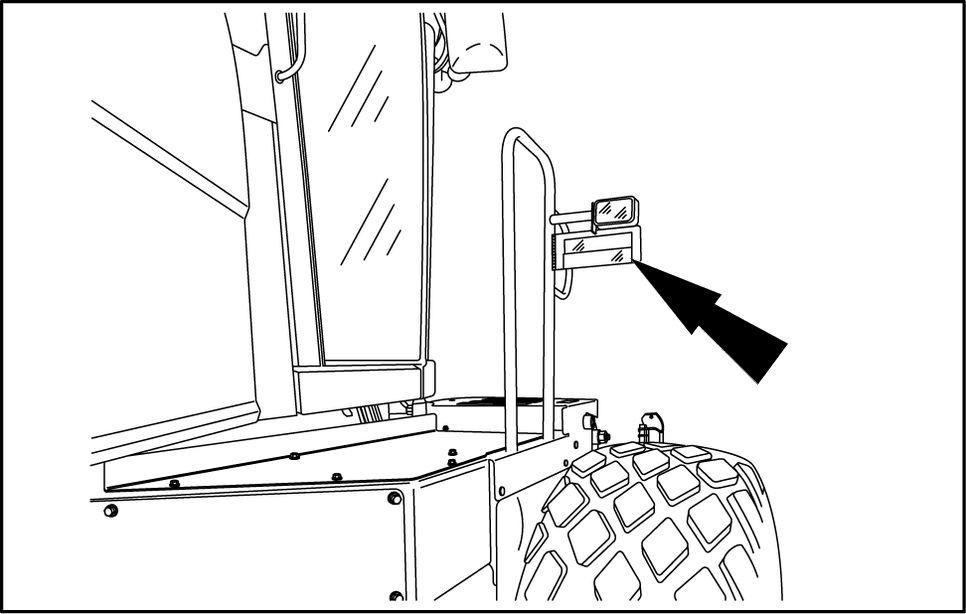

Reflectors and warning lights

Reflectors are located the handrails the areas shown Figure 1

Flashing amber warning lights must used when operating public roads.

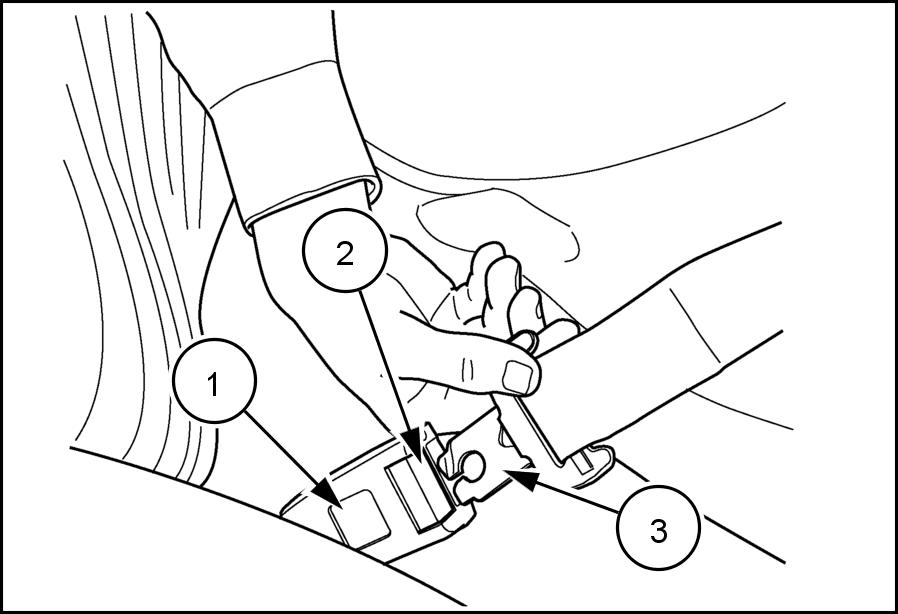

Seat belts

Seat belts must worn all times.

Seat belt inspection and maintenance:

• Keep seat belts good condition.

• Keep sharp edges and items than can cause damage away from the

• Periodically check belts, buckles, retractors, tethers, slack takesystem, and mounting bolts for damage and wear

• Replace all parts that have damage wear

• Replace belts that have cuts that can make the belt

• Check that bolts are tight the seat bracket

• belt attached make sure seat seat brackets are mounted securely

• Keep seat belts clean and dry

• Clean belts only with soap solution and warm water

• not use bleach dye the belts because this can make the belts

T o fasten the pull from the reel and push the tongue end (3) into the buckle end (2) until a indicates fully

T o release the push the red release button (1) the buckle and pull the tongue from the

The air - conditioning system under high pressure. not disconnect any lines. The release high pressure can cause serious injury

The air - conditioning system contains gases that are harmful the environment when released into the atmosphere. not attempt service repair the repair , recharging must performed only a trained service

Personal Protective Equipment (PPE)

W ear Personal Protective Equipment (PPE) such hard eye heavy hearing protective clothing, etc.

Not Operate tag

Before you start servicing the attach a Not warning tag the machine area that will

Hazardous chemicals

you are exposed come contact with hazardous chemicals you can seriously injured. The fluids, lubricants, required for the function your machine can They may attractive and harmful domestic animals well

Material Safety Data Sheets (MSDS) provide information about the chemical substances within a safe dling and storage first aid measures and procedures taken the event a spill accidental MSDS are available from your dealer

Before you service your check the MSDS for each used this This information indicates the associated risks and will help you service the machine safely . Follow the information the MSDS, manufacturer well the information this manual when servicing the

Dispose all fluids, filters, and containers environmentally safe manner according local laws and regulations. Check with local environmental and recycling centers your dealer for correct disposal

Store fluids and filters accordance with local laws and regulations. Use only appropriate containers for the storage chemicals petrochemical

Keep out reach children other unauthorized

Additional precautions are required for applied

Obtain complete information from the manufacturer distributor the chemicals before using

Utility safety

Make sure the machine has suf ficient clearance pass all Pay special attention overhead power lines and hanging High voltage lines may require significant clearance for safety Contact local authorities utilities obtain safe clearance distances from high voltage power

Retract raised extended necessary Remove lower radio antennas other Should a contact between the machine and electric power source occur , the following precautions must taken:

• Stop the machine movement immediately

• Apply the park stop the and remove the key

• Check you can safely leave the cab your actual position without contact with electrical stay your position and call for help. you can leave your position without touching lines, jump clear the machine make sure you not make contact with the ground and the machine the same

• not permit anyone touch the machine until power has been shut f the power

W orking heights

When the normal use and maintenance the machine requires working heights:

• Correctly use installed and

• Never use railings while the machine

• not stand surfaces which are not designated steps not use the machine a ladder , platform for working

Lifting and overhead loads

not used raised equipment a work

Know the full area movement the machine and equipment and not enter permit anyone enter the area movement while the machine

Never enter permit anyone enter the area underneath raised

Equipment and / loads can fall pectedly and crush persons underneath

not leave equipment raised position while parked during unless securely Hydraulic ders must mechanically locked supported they are left a raised position for service

Headers other lifting and handling equipment and its load will change the center gravity the This can cause the machine tip slopes uneven

Equipment and associated loads can block visibility and cause not operate with insuf ficient visibility

Mounting and dismounting

Mount and dismount the machine only designated locations that have not jump f the machine.

Make sure and platforms remain clean and clear debris and foreign Injury may result from slippery

Face the machine when mounting and

Maintain a three - point contact with steps, ladders, and handholds.

Never mount dismount from a moving

not use the steering wheel other controls accessories handholds when entering exiting the cab operator ’ s

Header lift locks

not work under the machine header unless securely blocked and / the header safety latch engaged.

Header will fall rapidly hydraulic lift system should

Rest header ground engage lift cylinder lockouts when working around raised header .

The header lift locks are engaged the left - hand side the machine pushing handle

Personal safety - Emergency exit

W ARNING

Flying objects!

Some the glass could shatter inward. Cover your head, particularly your eyes, while using the hammer . Use a shirt a jacket, your for

Failure comply could result death serious injury .

becomes impossible open the cab door , while the cab, you can use the right cab window emergency Remove the hammer (1) from the bracket the right rear post the cab. Use the pointed hammer shatter one the

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please