SER VICE MANUAL

W50C

W50C

W60C

W70C

W70C, W80C

W50C CWL W50C TIER 4 T OOL CARRIER

Link Product / Engine

W50C CWL W50C TIER4 Z - BAR

W60C

W70C CWL W70C TIER4 Z - BAR STD

W70C CWL W70C TIER4 HIGH SPEED

W80C CWL W80C TIER4 Z - BAR STD

W80C CWL W80C TIER4 HIGH SPEED

Engine

INTRODUCTION

[10.001] Engine and crankcase

[10.216] Fuel tanks

Four-Wheel Drive (4WD) system

Drive shaft

Front axle system

Powered front axle

[25.102] Front bevel gear set and dif ferential

[25.108] Final drive hub, steering knuckles, and shafts

Rear axle system

Powered rear axle

Rear bevel gear set and dif ferential

Planetary and final drives

Final drive steering and shafts

Hydrostatic drive

[29.100] T ransmission and steering hydrostatic control

Brakes and controls

Hydraulic service brakes

10] Parking brake parking lock

Front axle brake

Hydraulic systems

[35.000] Hydraulic systems

[35.300]

[35.106]

Main control valve

Pilot system

Auxiliary hydraulic valves and lines

High flow hydraulics

Hydraulic hand control

Hydraulic travel system

Front loader arm hydraulic system 1

Front loader bucket hydraulic system

T ool quick coupler hydraulic system

Frames and ballasting

[39.100] Frame

[39.140] Ballasts and supports

Steering

Steering control

Hydraulic control components

Cylinders

Cab climate control

[50.100] Heating

[50.200] Air conditioning

Electrical systems

Electrical system

Harnesses and connectors

Front axle control system

V and (HV AC) control system

W arning and instruments

[55.DTC] F AUL T CODES

Front loader and bucket

Arm

[90.150] Cab

Hydraulic contamination

Basic instructions - How use the maintenance standard and precautions

Basic instructions - Precaution for disassembly and assembly

Basic instructions - Electrical equipment precautions

Consumables

Product identification - Machine components

Product identification

Basic instructions - Important notice regarding equipment servicing

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution chain, including - without limitationnational, regional, local reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer any case, warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The information this manual - - date the date the the policy the manufacturer for continuous Some information could not updated due modifications a technical commercial type, changes the laws and regulations dif ferent countries.

case refer your NEW HOLLAND CONSTRUCTION Sales and Service

Basic instructions - Shop and assembly

Shimming

For each adjustment select adjusting shims and measure the adjusting shims individually using a eter , then add the recorded not rely measuring the entire shimming which may the rated value shown each

Rotating shaft seals

For correct rotating shaft seal

proceed follows:

Before assembly , allow the seal soak the oil will sealing for least thirty Thoroughly clean the shaft and check that the working surface the shaft not

Position the sealing lip facing the

NOTE: W ith hydrodynamic take into consideration the shaft rotation direction and position the grooves that they will move the fluid towards the inner side the

Coat the sealing lip with a thin layer lubricant (use oil rather than Fill the gap between the sealing lip and the dust lip double lip seals with grease.

Insert the seal its seat and press down using a flat punch seal installation not tap the seal with a hammer

While you insert the check that the seal perpendicular the When the seal make sure that the seal makes contact with the thrust

T o prevent damage the seal lip the position a protective guard during installation

O - ring seals

Lubricate the O - ring seals before you insert them the This will prevent the O - ring seals from overturning and which would jeopardize sealing ficiency

Sealing compounds

Apply a sealing compound the mating surfaces when specified the Before you apply the sealing compound, prepare the surfaces directed the product container .

Spare parts

Only use CNH Original Parts NEW HOLLAND CONSTRUCTION Original Parts.

Only genuine spare parts guarantee the same quality , and safety original they are the same parts that are assembled during standard production. Only CNH Original Parts NEW HOLLAND CONSTRUCTION Original Parts can fer this

When ordering spare parts, always provide the following information:

• Machine model (commercial name) and Product Identification Number (PIN)

• Part number the ordered which can found the parts catalog

Protecting the electronic and / electrical systems during charging and welding

T o avoid damage the electronic and / electrical systems, always observe the following practices:

Never make break any the charging circuit connections when the engine including the battery

Never short any the charging components

Always disconnect the ground cable from the battery before arc welding the machine any machine

• Position the welder ground clamp close the welding area

• you weld close proximity a computer then you should remove the module from the

• Never allow welding cables lie near , across any electrical wiring electronic component while you weld.

Always disconnect the negative cable from the battery when charging the battery the machine with a battery charger

NOTICE: you must weld the unit, you must disconnect the battery ground cable from the machine battery . The electronic monitoring system and charging system will damaged this not

Remove the battery ground

Special tools

W ARNING

Reconnect the cable when you complete

Battery acid causes burns. Batteries contain sulfuric acid. A void contact with skin, eyes clothing. Antidote (external): Flush with water . Antidote (eyes): flush with water for minutes and seek medical attention immediately Antidote (internal): Drink large quantities water milk. not induce vomiting. Seek medical attention immediately . Failure comply could result death serious injury

The special tools that NEW HOLLAND CONSTRUCTION suggests and illustrate this manual have been specifically researched and designed for use with NEW HOLLAND CONSTRUCTION The special tools are essential for reliable repair The special tools are accurately built and rigorously tested fer ficient and longlasting operation.

using these repair personnel will benefit from:

• Operating optimal technical conditions

• Obtaining the best results

• Saving time and fort

• W orking safe conditions

Safety rules

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

used with the safety alert indicates a hazardous situation not could result minor moderate injury

F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation not could result machine property

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information which clarifies steps, procedures, other information this manual.

Throughout this manual you will find the word Note followed additional information about a other information the manual. The word Note not intended address personal safety property damage.

Personal safety

Carefully read this Manual before proceeding with refuelling other machine

Repairs have carried out only authorized and structed staf specific precautions have taken when welding when using mallets heavy mers.

Not authorized persons are not allowed repair carry out maintenance this machine. not carry out any work the equipment without prior

Ask your employer about the safety instructions force and safety

Nobody should allowed the cab during machine maintenance unless a qualified operator helping with the maintenance

necessary move the equipment carry out pairs not lift lower the equipment from any other position than the operator ’ s seat.

Never carry out any operation the machine when the engine running, except when specifically indicated.

Stop the engine and ensure that all pressure relieved from hydraulic circuits before removing caps, covers,

All repair and maintenance operations should carried out with the greatest care and

Service stairs and platforms used a workshop the field should built compliance with the safety rules

Any functional especially those fecting the safety the should therefore rectified immediately .

DANGER

Unexpected movement!

Make sure parking brake applied. Secure machine with wheel chocks. Failure comply will result death serious injury .

D0013A

Before performing any work the attach a maintenance progress This tag can applied the left - hand control lever , safety lever cab door

TULI12WEX2004AA 1

TULI12WEX2005AA 2

Emergency

prepared for emergencies. Always keep a fire guisher and first aid kit readily Ensure that the fire extinguisher serviced accordance with the ufacturer ’ s

SMIL12WEX0174AA 3

Equipment

W ear close fitting clothing and safety equipment appropriate for the job:

• Safety helmet

• Safety shoes

• Heavy gloves

• Reflective clothing

• W weather clothing working conditions the following personal safety equipment should hand:

• Respirators (or dust proof masks)

• Ear plugs acoustic ears protections

TULI12WEX2008AA 4

• Goggles with lateral shield masks for eyes protection not wear unbuttoned flapping clothing such torn open jackets shirts with open zips which could get caught into moving

Engine - Radiator

Never leave the engine running enclosed spaces without proper ventilation which able evacuate toxic haust Keep the exhaust manifold and tube free from combustible not refuel with the engine especially this increases fire hazard case fuel

Never attempt check adjust the belts when the gine

Never lubricate the machine with the engine

TULI12WEX2009AA 5

Pay attention rotating components and not allow anyone approach these areas avoid becoming

Hands, clothing tools getting caught the fan blades transmission can cause violent hemorrages and generate conditions grave danger For this reason avoid touching approaching all rotating moving

A surging spray the coolant from the radiator can cause serious burns and

Before checking the coolant shut - f the engine and allow machine cool down the radiator and Slowly unscrew the cap release any residual

necessary remove the cap while engine wear safety clothes and then loosen the cap slowly relieve the pressure gradually

When checking the oil and coolant use lights and lamps explicitly designated explosion proof. these types lamps are not fires explosions may occur

Hydraulic systems

Jets fluids under pressure can penetrate the skin ing serious

A void this hazard relieving pressure before ing hydraulic other

Relieve the residual pressure moving the hydraulic control levers several

T ighten all connections before applying

T o protect eyes wear a face shield safety

Protect your hands and body from possible jets fluid under

Swallowing hydraulic oil a severe health hazard.

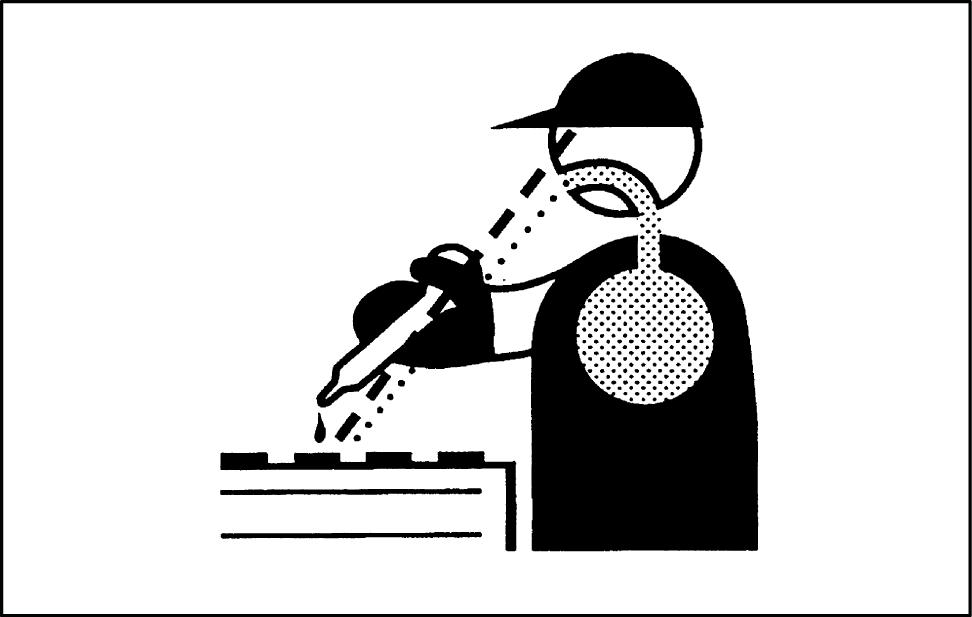

TULI12WEX2010AA 6

TULI12WEX201 1AA 7

TULI12WEX2012AA 8

When hydraulic oil has been avoid but consult a doctor a accident see a doctor familiar with this type injury immediately .

Any fluid penetrating the skin must removed within few hours avoid serious infections.

Flammable splashes may originate because heating near lines with fluids under pressure, resulting serious not weld use torches near lines containing fluids other flammable

Lines under pressure can accidentally pierced when the heat expands beyond the area immediately

Arrange for temporary fire resistant shields protect hoses other components during welding torch

Have any visible leakage repaired immediately

Discharged oil pollutes the Soak any oil that has spilled with a proper binding Sweep binding agent and dispose separately from other

Never search for leakages with fingers; use a piece cardboard and always wear

Never repair a damaged line; always replace Replace hydraulic hoses immediately detecting any damaged moist

Always store hydraulic oil the original

TULI12WEX2013AA 9

Hoses and tubes

Always replace hoses and tubes the cone end the end connections the hose are

When installing a new loosely connect each end and make sure the hose takes the correct position fore tightening the Clamps should ened suf ficiently hold the hose without crushing and prevent

After hose replacement a moving component, check that the hose does not foul moving the component through the complete range sure any hose which has been installed not kinked

Hose connections which are crushed restrict oil flow and the productivity the ponents being Connectors which show signs movement from the original position have failed and will ultimately separate completely

A hose with a frayed outer sheath will allow the water Concealed corrosion the wire reinforcement could subsequently occur along the hose length with sultant hose failure.

Ballooning the hose indicates internal leakage due structural failure. This condition rapidly deteriorates and total hose failure soon

stretched deformed hoses generally suf fer internal structural damage which can result oil a reduction the speed operation and mate hose failure.

Free - unsupported hoses must never allowed touch each other related working surfaces. This causes chafing which reduces hose

O - rings

Replace O - seal rings and gaskets whenever they are

Never mix new and old seals O - regardless Always lubricate new seal rings and O - rings with hydraulic oil before installation relevant seats.

This will prevent the O - rings from rolling over and twisting during mounting which will jeopardize sealing.

TULI12WEX2014AA

Battery

Batteries give f explosive gases.

Never handle naked flames and unshielded light sources near batteries (No smoking addressed next

T o prevent any risk observe the following instructions:

• When disconnecting the battery always nect the negative ( cable

• T o reconnect the battery always connect the negative ( cable last.

• Never short - circuit the battery terminals with metal ob-

• not grind smoke near a battery

Battery electrolyte causes severe burns. The battery tains sulphuric A void any contact with the eyes

Antidote:

• EXTERNAL: Rinse well with water , removing any soiled

• INTERNAL: A void Drink water rinse your mouth. Consult a doctor .

• EYES: Rinse abundantly with water for min and consult a doctor .

• When the electrolyte a battery can plode you attempt charge the battery you try start the engine using a booster battery Always keep the battery charged prevent the electrolyte

Provide good ventilation when changing a battery using a battery enclosed Always protect your eyes when working near a battery

Never set tools down the battery They may induce a short causing irreparable damage the battery and injuring

Never wear metal bracelets watch straps when working the battery The metal parts may induce a short circuit resulting

Dispose used batteries separately from other waste the interests environmental

TULI12WEX2015AA 1 1

TULI12WEX2016AA

TULI12WEX2017AA

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please