CONSTRUCTION, QUARRY & RECYCLING MAGAZINE PLANT & CIVIL JUN-JUL 2024 www.plantandcivilengineer.com £4.95 €6.95 IN ASSOCIATION WITH & ISSN 2041-7829 mcsharrytrack.com I Tel: +353 90 6629500 EXCLUSIVE DEALER - Rep. of Ireland & N. Ireland NEW NAME FOR RENOWNED EXCAVATOR AND UNDERCARRIAGE DEALER.

NEW NAME FOR RENOWNED EXCAVATOR AND UNDERCARRIAGE DEALER.

Golda Burrows General Sales Manager

Emma Cowan Editor

Martin Elliman General Manager

Joel Byers Production Manager

Rachel Clarke Accounts Administration

Helen Beggs Chief Operating Officer

Plant & Civil Engineer is Published by:

4 SM (NI) Ltd, The Old Coach House, 12 Main Street, Hillsborough BT26 6AE

CONTACT Golda: 07724 192032 or Martin: 07985 887171

Email: golda@4squaremedia.net

Email: martin@4squaremedia.net

COPYRIGHT NOTICE:

I’m writing my comment on the day the Belfast Telegraph published the 2024 Top 100 most profitable companies. I was interested to discover that 19 companies were from the sectors Plant and Civil Engineer reports on (almost one-fifth of the list).

Terex GB (Dungannon and Omagh) ranked third on the Top 100 list, outperformed only by our two pharmaceutical giants, Randox and Almac. Other ‘plant and civil’ companies included McCloskey Engineering, Dungiven (24), Toubkal/Strickland, Coalisland (51), Whitemountain Quarries (Breedon Ireland) (60) Edge Innovate NI, Dungannon (64) and CDE Global, Cookstown (87). Tyrone appears to breed world-leading plant and equipment experts!

This edition has a lot inside, including crushing and screening, the McSharry Track rebrand, 50 years of Creagh Concrete and much more.

If you’re going to Hillhead, look out for Golda and Martin from the PCE team. It would be a great chance to catch up and you are guaranteed to be treated to one of Marty’s one-liners!

Looking forward, we’re planning features on materials handling, insurance, ADTs and metal recycling in our August-September edition. On that note, both Clearway Metal Recycling and Regen Waste Holding were in the Top 100. Our features are a great way to showcase your business and expertise, so get in touch with us.

You can keep up to date every day with all the industry news 24/7 at www.plantandcivilengineer.com. Of course, you should also be getting our weekly newsletter which is emailed out every Tuesday; if not, do subscribe on our website so you don’t miss out. It’s free!

Emma Cowan Editor

Mobile: 07921 787686

Email: pceeditor@4squaremedia.net

3 PLANT & CIVIL ENGINEER News 32 40 53 59 70 Spotlight On Crushing & Screening Heavy Haulage Plant Hire contents PLANT & CIVIL JUN-JUL 2024

material in this publication is copyright, including advertisements which have been prepared for advertisers. No part of it may be reproduced in any way whatever

stored in electronic retrieval systems without the written permission of the publishers. We are a completely independent voice and are not connected to any Institutes or Associations within the industry. Our aim is to publish accurate, specific and dedicated information, targeting each sector of the industry, throughout Ireland. The publishers cannot be held responsible for any inaccuracies supplied by the contributors. All rights reserved.

© Plant & Civil Engineer 2023. All

or

Plant & Civil Engineer

4SM (NI) Ltd is part of the North West News Group

comment 45 ENTER NOW

PLANT & CIVIL CONSTRUCTION, QUARRY & RECYCLING MAGAZINE AWARDS2024

COVER: NIALL, MICHAEL AND FINTAN McS HARRY.

New self-cleaning Reflux Bucket for excavators from Tyrone inventor

This June sees the launch of a very practical innovation for excavators from Northern Ireland company DUFab Equipment Ltd. The new product is a ‘Reflux Bucket’ attachment, which is patented and going into production for sale.

The Reflux Bucket, designed to make digger work faster and more efficiently, is the brainchild of John McElduff, owner of DUFab and a man well known for his practical innovations.

The Reflux Bucket is a self-cleaning bucket, with a clear hitching design that enables the bucket to self-clean with every lift. “I’ve seen buckets jam and get clogged many times and this design will do away with the problem, saving time, speeding productivity and generating fuel savings,” explains John. “It’s a self-cleaning plate that attaches to the front linkage pin, with a hydraulic piston attached to the back pin. The result is an excavator

bucket that cleans itself hydraulically with every dig-and-deposit action.”

DUFab currently has one Reflux Bucker on demonstration and the company is open to sales and re-orders.

For more information, contact John McElduff of DUFab Equipment on M: 07834 083303 or E: info@dufab-equipment.com. Visit https://www.dufab-equipment.com/ or view on Facebook at https://www.facebook. com/profile.php?id=61552628610550

New 2-Tonne Takeuchi Tool-Carrier

The latest addition to the 3-Series range is a new 2-tonne TB320 mini excavator.

The new TB320 is a mini excavator/tool-carrier designed for multi-attachment use that offers an exciting development in the mini excavator domain. It comes with proportional control on auxiliary 1 & 2, 3rd auxiliary pre-piped for quick hitch and an optional 4th aux as a factory fitted option. With excellent 40l/min flow rate this new 2-tonne is adaptable for a variety of hydraulic attachments including: mulchers, flails, augers, post knockers and tilt-rotators, typically used by landscape contractors and groundworkers. With increased engine power and excellent breakout force (17.0kN/ 9.1kN), this 2-tonne

mini delivers power performance when required. The long arm, heavy counterweight and longer track frame add to stability when digging deep (2370mm).

The TB320 has new 3-series styling both inside and out, including LED lighting, Bluetooth, DAB, and spacious operator

station with excellent footwell visibility for trench work.

With a compact design and dimensions, it’s safe to trailer tow and easy to transport to and from site. The expanding track frame from 980-1370mm gets access in the most confined spaces. With matching pin and link dimensions to the TB216 the new TB320 is a compatible addition to the fleet.

Holly Cooke Marketing Manager “The new 2-tonne TB320 combines both a mini and multi attachment tool carrier. The increased flow rate gives it greater power and productivity on site.

The 3-Series line-up now extends right across the range from 2 to 10 tonne. Get an update at Hillhead Stand S2.”

news 4 PLANT & CIVIL ENGINEER Martin Elliman e. martin@4squaremedia.net m. 07985 887171 GET IN TOUCH

Tax Credit Specialist Momentum Group invests in Irish market

Bangor-based specialist tax consul ting firm Momentum has announced a £500,000 expansion into the Irish market. Momentum’s specialist service helps companies to maximise R&D tax relief credit, capital allowances and land remediation relief

The consultancy already has an established client base in Ireland and the investment in Dublin city centre office space will allow it to maximise service to Irish companies.

The latest Irish Revenue Commissioners statistics published in 2021, reveal that Irish companies have claimed over €1.29bn in R&D Tax Relief.

The lion’s share of the R&D spend (77%) was from large enterprises (>250 employees), while SMEs accounted for 23% of the spending.

Founded in 2009, the Momentum Group has a strong track record of working with businesses across multiple sectors in Ireland, Northern Ireland and other parts of the UK and managing director,

Tom Verner, believes the time is right to strengthen links and expand further in the Irish market.

Expertise To Help Smes Release Revenue

“We already work with a range of Irish businesses, so it is right that we establish a real presence in the Republic of Ireland,” Tome Verner said.

“Ireland’s SMEs need support to help the country become a

global economic powerhouse in technology and this investment, over three years, is evidence of our commitment to providing that expert support.to help these businesses save time and money by identifying, analysing and optimising R&D opportunities.

“Often, SMEs are deterred by the complexity of putting a claim together and knowing what does or doesn’t qualify for relief.

Momentum a proven track record in generating significant financial benefit for businesses through R&D relief had has the expertise and knowledge to maximise benefits for companies.”

Tom continued: “The Government’s Impact 2030 strategy seeks to put the full spectrum of research, development and innovation at the heart of addressing some of the country’s biggest challenges. To support this strategy, the Irish Government has made some headline changes to the R&D Tax Relief scheme such as increasing the rate to 30%.

“Despite the incentives, it’s clear SMEs are still not availing of tax credits in sufficient numbers, while the larger companies, who have the resources to devote to making claims for their qualifying R&D expenditure. If the Irish Government is to realise its ambition to make Ireland an R&D powerhouse, more needs to be done to encourage smaller businesses to invest in innovation and to claim for the work they are doing.”

IPS Ireland New Sole Irish Distributor for Xenith Height Aresta Safety Products

Established in 2013, IPS Ireland has evolved into Ireland’s largest supplier of access platform parts, service, crane pads and workshop consumables and supplies. The company has recently partnered up with UK-based Xenith Heights as an exclusive distributer of their full range of Aresta safety products. The aim of the new deal will be to increase its market penetration and customer satisfaction across the island of Ireland. Xenith Heights is a UK based industrial firm that focuses on the design, manufacturing, and supply of fall arrest equipment and safety harness for work-at-height tasks including scaffolding and renovation projects. Aresta Safety provides technical solutions to protect workers from falls and other risks associated with heights, ensuring their health and safety while on the job.

According to Ian McIntyre, Sales at Xenith Height, “This new partnership with IPS Ireland is an exciting prospect as they have excellent service capability, which really fits with our aim to increase our offering to Ireland’s customers, with a

local approach and premium service. Customers in Ireland will be able to benefit from improved product availability, as well as faster delivery times.”

Commenting on their recent partnership, Gary Power, parts manager at IPS Ireland said, “We are excited toa be moving forward with this new endeavour as this will enhance the high-quality products we provide and give customers access to additional products and services. We are confident that our partnership with Xenith Heights will provide our customers with outstanding quality safety products and exceptional customer service, achieving strong supply chains. Our ambition is to drive industry growth by delivering reliable safety products and providing after-sales services to existing and new customers.”

news 6 PLANT & CIVIL ENGINEER

Momentum Group directors pictured in Dublin. From left; operations director Steve Morley, business development director Simon Huntley, financial director Jayne McKee and managing director Tom Vernor.

PLANT & CIVIL FOLLOW US ON

Trevor Lambe and Gary Power, IPS Ireland, Ian McIntyre (centre) Xenith Heights.

Each solution we supply from Volvo Construction Equipment, including the ground-breaking Electric models; Volvo Penta engines; Sennebogen material handlers; and Kohler engines comes with a nationwide team of qualified service engineers, a next-day parts delivery system and an all-island branch network.

OVER 50 YEARS OF MOVING IRELAND California Heights Chapelizod t:+353 1 616 1000 Cork Sallybrook, Glanmire Co.Cork t:+353 21 482 1288 Galway Carnmore West Oranmore, Co.Galway t:+353 91 790 722 Portadown Seagoe Industrial Area Portadown, Co. Armagh t: +44 28 38 337 222 D20 YH76 T45 H778 H91 FWF6 BT63 5QE SERVICE SERVICE AVAILABLE 364 DAYS OF THE YEAR ORDER ONLINE 24/7

www.patodonnell.com

MINORE™ Introduces Transformative Mineral Solutions To Protect Resources

Specialist in sustainable mineral solutions, MINORE™ has extended its portfolio, advancing a suite of innovations to help organisations protect valuable resources, aid biodiversity, and green construction. Operating in the new, and rapidly growing, sustainable material management sector, MINORE™ now has three key strands to its business. Expertise incorporates mining existing mineral deposits using sustainable techniques for use in cement and brick and green landscapes; repurposing discarded minerals into new product formulations; and developing bespoke biodiversity solutions. Founded in 2012, its roots trace back to the 1950s as a mining and quarrying family business. Established on an old, disused Victorian brickworks and ash pit in West Yorkshire, this provides a unique environment for MINORE™ to produce bespoke mineral and soil formulations. Its processes involve using existing mineral deposits and carefully selected, discarded materials from waste, construction and demolition projects, and collaborating with product formulators. Ultimately, it

will restore its brownfield site to natural habitat and open space, whilst providing support for biodiversity net gain projects.

Biodiversity

solutions

Over recent years, MINORE™ has undertaken extensive research and development into manufacturing and blending minerals for a variety of applications. Its bespoke solutions are designed to improve soil preservation, water management solutions, carbon

capture, and support biodiversity projects, for regenerative agriculture, horticulture, and green construction sectors amongst others. MINORE’s approach is guided by new strategies and legislation around preserving the natural environment and resources, including Biodiversity Net Gain Regulations introduced this year. Additionally, it offers opportunities for local developers to purchase biodiversity net gain habitat units within the Wakefield and South Elmsall area, as part of its brownfield restoration project. This will transform an area identified under the Biodiversity Metric as poor condition medium distinctiveness to good condition, turning an old landfill site into an ecosystem where wildflowers and insects will thrive.

Mineral repurposing

MINORE™ mine, recycle and manufacture sustainable mineral solutions for green construction products, industrial and consumer markets. Its extensive portfolio includes recycled soils, stony cohesive fill material, pipe bedding, and primary clay and ash products.

One year on, Metso UK distributor, McHale plant sales reports

‘better than expected’ beginning

One year to the month since their appointment as Metso Lokotrack distributors in the UK took effect, McHale Plant Sales will exhibit at the ScotPlant and Hillhead to meet as many customers as possible with a simple message of ‘thanks’ for the welcome their arrival on the UK scene it has received.

Over the 12 months since April 2023, the company has established a headquarters depot at Tamworth and a Scottish base on the east side of Edinburgh.

According to their Business Development Director, Darragh O’Driscoll “mindful that we began with a blank canvas, we are exceedingly happy with the picture that has emerged.”

Recruitment, which is ongoing, has seen key appointments made in sales management

and equipment sales, parts, stores and distribution, as well as in administration and customer communications, in-house machine maintenance and repair and mobile field service engineering roles.

“On the personnel side, we have an expanding and committed team, all totally focused on building the business and delivering the best service we can for customers” O’Driscoll said.

“In the important areas of parts availability and supply, our depots are well stocked and supported by an efficient UK-wide distribution structure. So too in tech-support where our team of mobile service engineers continues to expand,” he added.

news 8 PLANT & CIVIL ENGINEER

PLANT & CIVIL www.plantandcivilengineer.com

New project aims to revolutionise tunnel infrastructure installation with robotic AI

A consortium of mechanical and civil engineering, and robotic automation industry leaders, including Tunnel Engineering Services (UK) Ltd (TES), i3D robotics (i3D), the Manufacturing Technology Centre (MTC), Costain, and VVB Engineering, has developed the first robotic and AI solution set to revolutionise the installation of mechanical and civil services in tunnels. Traditionally, installing these services in tunnels is hazardous, labour-intensive and timeconsuming. The prototype Automated Tunnel Robotic Installation System (ATRIS) can autonomously select brackets, locate where they need to be mounted along a tunnel wall, and install them. In doing so, the automated solution can improve on-site health and safety by reducing the risks associated with manual labour at the tunnel work face, for example, working at height in confined spaces, and hand-arm vibration experienced by workers during installation. Once fully developed, the final system can be deployed in tunnel construction for a variety of sectors including transport, water and energy. It is expected to increase productivity by 40% due to faster installation, reduce installation costs for new mechanical and electrical (M&E) systems by 30%, and cut construction plant movements by 40% to decrease embodied carbon.

The 22-month project, partly funded by Innovate UK’s Smart grant, was led by TES, which developed the initial concept in partnership with the consortium. Leveraging its expertise in robotics and automation, MTC spearheaded the design and manufacture of the robot’s end effectors. i3D developed crucial visualisation software for precise navigation, whilst Costain and VVB provided industry knowledge and expertise in tunnelling and fit-out requirements.

Alan Worsley, Design and Project Manager at Tunnel Engineering Services (UK) Ltd said: “TES has over many years designed and manufactured Mechanised Tunnelling Machines and special purpose equipment for the construction industry. Over this time, innovation has been at the forefront of our business, and the need for automation

in traditionally manual M&E fit-out techniques has led us to develop ATRIS and make it commercially viable for the market. We believe the system can offer a safer, more costeffective and sustainable solution for future infrastructure projects.”

Steve Nesbitt, Chief Technologist for the Built Environment at MTC, said: “Like many sectors, construction has faced labour challenges over the past few years which has driven greater interest in using robots, beyond manufacturing and logistics, to address these issues. By contributing our expertise to this project, we are paving the way for construction companies to adopt technology for greater control and structuring of on-site works, making infrastructure delivery safer, more productive, and more sustainable.”

Dr Jon Storey, Lead Engineer at i3D, said: “Developing an automated system to install infrastructure in tunnels has been a long-standing ambition for the construction sector. ATRIS has moved us significantly closer to that goal. The use of stereo vision with machine learning and robotics to place bolts precisely on a curved surface is an unprecedented achievement, with potential applications beyond the construction sector, such as nuclear decommissioning and defence.”

Lee Bateson, Mechanical and Engineering Manager and Robotics Lead at Costain, said: “Teaching the robots to learn seemingly simple tasks – such as how to avoid cross-threading the screws that go into the sockets – has been hugely fulfilling, thanks to the consortium’s collaborative spirit. Whether it’s carbon reduction, increasing productivity or improving workforce health and safety, this is transformative technology that will have enormous benefits for the customers that we build tunnels for.”

Nicholas Beedle, Group Operations Director at VVB Engineering, said: “Tunnel works historically are expensive to build and maintain, and in the higher risk bracket for safety during construction and operation. It is important that ongoing improvements are made to address both of these issues. The development of the robotic AI solution is a step towards solving both of these industry challenges.”

Hamm Compactors awarded with a German Design Award Special Mention

The HC 110(i) – HC 250(i) compactors from Hamm receive the accolade of “Special Mention”, awarded to outstanding examples of design.

The 11 – 25 t models impressed the jury of experts with a thoughtfully designed platform concept, quiet and eco-friendly operation, innovative cab design and a high level of user-friendliness.

The internationally recognised German Design Award is one of the most coveted prizes on the design scene. It recognises major design trends and

honours exceptional product design, communication design and architecture. The jury is made up of experts recognised in the field of design, from twelve different nations and a variety of sectors, who

set very high standards when it comes to selecting the award winners.

Dr Axel Römer, Head of Development and Construction at Hamm AG, expressed his delight after the award was announced: “We are hugely proud of this award, because it’s a recognition of our commitment to exceptional design and highlights the innovative prowess of our products.” With this recent accolade, the compaction specialists now boast a collection of more than 40 design awards.

news 10 PLANT & CIVIL ENGINEER

GRAB EVERY OPPORTUNITY

NOTICE: ALWAYS FOLLOW WARNINGS AND INSTRUCTIONS PROVIDED BY THE MANUFACTURER.

JCB LAUNCHES BIGGEST X SERIES CRAWLER EXCAVATOR WITH 370X

JCB unveiled its biggest and most powerful model yet – the new 370X –at a special press event held at the JCB world headquarters in March.

The heavy-duty earthmover was heralded as bringing industry-leading levels of productivity, durability, and reliability to the 35-40 tonne sector.

Plant and Civil Engineer’s Martin Elliman attended the event and was blown away by the sheer size of the JCB 370X. “There were other new products launching at the event, but the JCB370X dominated the show and we were delighted to get a special report by Dan Gilkes outlining his first test drive of the machine,” said Martin. Other products unveiled at the prestigious event included new electric models in the 3 tonne site dumper range, new additions to the ride on tandem roller range, EU Stage V compliant versions of its large platform skid steers, of key improvements to the JCB backhoe loader range, the launch of two 2.5-tonne mini excavators, the 25Z-1 is a zero tailswing model and the 26C-1, the JCB Raptora brand-new tilt rotator designed specifically for the JCB Hydradig, together with an expansion of the Hydradig range of wheeled tool carriers. Last but not least, was the announcement of a new partnership between. JCB and Leica Geosystems, part of Hexagon, to offer factory-fitted 2D and 3D-ready semi-automated excavator control solutions known as INTELLIGRADE. Now back to the biggest beast in the new product line-up, the JCB 370X

KEY FEATURES OF THE JCB 370X:

• A machine designed from the ground up with proven X-Series DNA built in

• Ability to move 4.5 tonnes more material per litre of fuel than competitive models

• Stage V/T4F 240kW (322hp) diesel engine delivering 14% more power

• New JCB UX user interface, with 10” colour touchscreen display and controls

• Increased hydraulic pressures boost performance in hard digging

• Extended service intervals for improved total cost of ownership (TCO)

• Uprated undercarriage and heavy counterweight deliver maximum stability

excavators 12 PLANT & CIVIL ENGINEER

MORE OF EVERYTHING

Paul Swallow, Business Head – Excavators, said: “With more power, increased strength and durability, reduced fuel consumption and lower ownership costs, the JCB 370X is a major step forward for customers in the 35-40 tonne class. With fantastic operator comfort and control, the 370X delivers a heavy-duty excavator solution for markets around the world.”

EXCEPTIONAL PERFORMANCE

The JCB 370X is powered by the latest Cummins L9 diesel engine, which is certified as EU Stage V and EPA Tier 4 Final compliant. This 8.9-litre, six-cylinder, engine boasts a 14% power increase over the outgoing JS370, with 240kW (322hp) available at just 1,700rpm. The engine delivers this maximum power within a reduced operating rev range, to increase fuel economy and reduce overall noise levels. A Tier 2 common-rail engine is available for non-legislative territories.

The latest generation Kawasaki tandem hydraulic pump operates with an increased 350 bar pressure, rising to 380 bar during power boost cycles. Combined with a latest generation valve block and hydraulically-operated cooling fan with reversing function, this contributes to classleading efficiency. The 370X is capable of moving up to 4.5-tonnes more material

per litre of fuel and up to 86 tonnes per hour more than competitors in testing. All major structures and components have been designed with additional performance and productivity in mind. A heavier counterweight contributes to

excavators 13 PLANT & CIVIL ENGINEER

added stability, while larger structures cope with the additional forces.

Increased service pipework diameters and raised hydraulic pressures result in more power at the dig end, which has been redesigned with cast boom foot and hydraulic ram pivot points for additional strength and longevity.

The 370X is supplied with a 6.45m monoboom, with a choice of 2.63m, 3.23m and 4.03m dippers. Optional heavy-duty dippers have additional crush bars and reinforcement to cope with arduous applications.

Bucket pin diameter has been increased and the machine can be fitted with a new JCB dual pin quickhitch, to pick up 90mm or 100mm attachments. There are also new 2.1m3 XHD and 2.34m3 XHD buckets available, plus JCB will offer a new HM330T hydraulic breaker specifically for the 370X.

OPERATOR COMFORT

As with all X-Series machines, the 370X benefits from the JCB Command Plus ROPS cab. As well as being one of the largest excavator cabs on the market, with 2.86m3 of volume, the Command Plus cab benefits from a heated air suspension seat and a reduced 69dB in-cab noise level.

The cab is further improved with a new 10” touchscreen monitor with a new user interface called JCB UX, while the switch panel incorporates more customisable hot keys, allowing further personalisation for the operator. Climate control, a radio with DAB option, keyless start and twin cameras for

added visibility are all standard equipment.

The JCB UX interface has up to 25 user profiles, which can all be customised with the ability for operators to set the joystick configuration to meet their individual requirements. Mobile phone connectivity has been improved with phonebook integration via the monitor. The machine is exceptionally easy to use and help guides are available within the monitor, along with ‘how to’ videos, covering all of the features of the JCB UX system.

TOTAL COST OF OWNERSHIP

The 370X delivers real-time monitoring of all fluid levels on the in-cab display The machine also benefits from extended service intervals, with hydraulic intervals doubled to 2,000 hours. Engine coolant service in

now required at 3,000 hours, while the air filter element intervals are extended up to 2,000 hours. The machine boasts three work modes to optimise digging, lifting or economy. Auto-stop and Auto-Idle engine functions are also standard, to reduce fuel consumption during idling, further boosting TCO.

The 370X is available with a range of options, to tailor the machine to an individual customer’s requirements. These include auxiliary hydraulic circuits with up to 15 attachment settings and a premium heated and cooled operator’s seat. LED lights are now standard, with options available to increase to up to 14 LED work lights. The machine can also be offered with the JCB 2D and 3D-ready INTELLIGRADE system, providing machine control solutions to enhance productivity, accuracy and safety.

A bird’s eye 360° camera system, integrated within the 10” display, can also be offered, along with high visibility, all-round handrails.

The 370X follows the styling and design first seen on smaller X-Series JCB excavators, with robust doubleskinned steel service doors and tube-in-tube bolt-on handrails.

www.dennisons.co.uk/jcb

14 PLANT & CIVIL ENGINEER

excavators

Evoquip appoints new business development manager

EvoQuip, a leading global supplier of compact crushing and screening equipment, has announced the appointment of Christian Ebner to the position of Business Development Manager for Latin America. Christian will be responsible for sales and distribution growth of the brand in South America and Mexico.

Christian brings a wealth of expertise to his new position, having graduated from the prestigious University Austral de Chile with a degree in Mechanical Engineering. He then spent 20 years in Sales and Marketing roles, achieving remarkable success. Christian has also forged strong ties within the international

community, having worked closely with the British embassy in recent years.

Speaking about the appointment, Barry O’Hare, Business Line Director of EvoQuip said: “We are delighted to welcome Christian to the team. With his diverse experience and keen understanding of market dynamics he is an invaluable asset to helping us achieve EvoQuip’s expansion strategies. Latin America is a key market for us, and Christian’s deep understanding of the region, coupled with his passion for the brand, will be instrumental in driving our business forward.”

Christian will be based out of Chile and can be contacted at christian.ebner@terex.com

McHale Plant Sales appoints company manager UK

Metso distributor, McHale Plant Sales has taken a further step in building its UK management team with the appointment of James Cliffe to head its operations in Tamworth and Edinburgh. Hugely qualified in the field of aggregates production, quarrying and concrete products manufacturing, Cliffe joins McHale Plant Sales in the role of Company Manager UK.

Before joining McHale, he held managerial appointments within CRH and its Roadstone subsidiary, including that of National Mobile

Crushing Division manager and Huntstown Quarry Location Manager – one of the two largest and busiest quarries in the Roadstone network which, combined, delivered a total extraction volume of 500,000 tonnes of material per month.

Resident in Dublin, Cliffe is a native of Dungarvan in Co. Waterford. A MSc, BSc and BEng graduate of Cork and Waterford Institutes of Technology and the University of Derby. His qualifications include a Masters in Construction Project Management, an Honours in

New MD for Takeuchi UK

Construction Management & Engineering, and a Batchelors Degree in Civil Engineering. In addition to CRH and Roadstone management development programmes, he has completed industryspecific studies in Asphalt and Paving, Concrete, Quarry Management, and Minerals Extractives.

Within McHale Plant Sales UK, his priorities will include sales and management of the UK sales team, the on-going task of team building, facilities and services development at Tamworth and

Takeuchi UK have recently appointed Daisuke Yanagisawa, better known as Yana as its new Managing Director, effective from 1st June 2024.

Yana has spent the last 12 months as assistant MD, getting to know the industry in the UK. Yana will be leading the team of 25 at Takeuchi’s UK head office in Rochdale and Thatcham depot.

Daisuke Yanagisawa Managing Director says: “There’s a huge opportunity to build on the success Takeuchi UK has achieved so far, and I’m really looking forward to working with the team to grow the business significantly.

“My main focus is to take Takeuchi UK to the next level by strengthening the team. I strongly believe having the right people at the right places is the core for our growth.”

Takeuchi UK benefits from an extensive and established dealer network of 30 depots supporting customers nationwide. Takeuchi will continue to support customers by developing world-class products and listening to owners and operators.

James Cliffe.

Edinburgh, and the maintenance of close communications with Metso users, key accounts, and UK crushing sector operators generally

Customer-led innovation has always been central to the Takeuchi philosophy and developments in the New 3-Series range and New Electric models are an exciting next chapter for Takeuchi in the UK.

Takeuchi remains a major excavator supplier to the UK’s construction and plant hire industry. The excavator product range has expanded year on year, now with over 22 models between 1 to 15-tonnes.

Daisuke Yanagisawa continues: “With the recent opening of the new Aoki factory in Japan and increased productivity, our machine availability is going to be its bestever. Over the next few years, we aim to grow the Takeuchi customer base nationally. Our Dealer know-how and expertise will be critical to our ongoing success.”

The Takeuchi brand continues to be popular with contractors, plant hire and owneroperators with many investment advantages. This year Takeuchi UK will reach its 50,000th machine sale, a major milestone for the Takeuchi UK team and dealer network.

appointments 16 PLANT & CIVIL ENGINEER

Christian Ebner.

Daisuke Yanagisawa YANA Takeuchi MD.

ATTACHMENT

READY

MORE FLOW - READY TO GO

The New TAKEUCHI 3-SERIES TB320 2-tonne excavator, available in cab and canopy configurations. Designed to accommodate a wide range of attachments with 3 auxiliary ports as standard, 4th line optional. Ideal for landscapers and owner operators with increased power, hydraulic flow and proportional controls.

HIGH-SPEC CONFIGURATION

EXPANDING TRACK FRAME

PROPORTIONAL CONTROLS

TRUSTED RELIABILITY MADE IN JAPAN

ALAN MILNE TRACTORS / DIECI Newry T: 02830 821230 www.alanmilnetractors.co.uk BREENS

Cashel T: 062 61356 Ennis T: 065 684 1000 Naas T: 045 493 410 www.bfm.ie

The NEW TB320 offers maximum excavating performance in a road towable weight class.

DAWSONGROUP CLEANS UP WITH 75 IVECO EUROCARGO ROADSWEEPERS

Business to Business and asset funding specialist Dawsongroup plc has taken delivery of 75 IVECO Eurocargo 16-tonne municipality vehicles (ML160E22K), complete with Bucher Municipal sweeper bodies to add to Europe’s largest short and long-term sweeper rental fleet.

Roadsweepers might not cover huge mileage, but they need to be durable as their mission involves heavy equipment and a demanding stop/start environment.

The Eurocargo is an ideal platform for this challenging mission courtesy of its tough 3350mm purpose-built sweeper chassis which delivers excellent manoeuvrability in busy urban environments.

Dorking-based Bucher Municipal supplied and fitted the truck-mounted bodies taking full advantage of the 16-tonne GVW to create a body that is highly

functional but very robust. As a result, this vehicle’s payload is circa 6,600kg.

Each vehicle is left-hand drive with Dawsongroup fitting FORS standard safety equipment to enable each one to work in urban areas in complete safet. All vehicles are also equipped with Chapter 8 rear signage as well as 360-degree cameras to boost visibility and meet strict DSV standards.

Highly efficient 220hp Tector 7 sixcylinder diesel engines coupled to a 12-speed automated gearbox provide plentiful power and torque for this heavyduty workload while also meeting the latest Euro VI emission requirements.

Dawsongroup are no strangers to Eurocargo roadsweepers with previous vehicles recently being de-fleeted after up to four years of operation. Glen Carruthers, Dawsongroup Managing Director said:

“We have run IVECO product before so we know they are very strong and practical for these tough operating conditions. We have already seen some vehicles go out on longer-term hire with councils.

Each of these Eurocargo roadsweepers has been supplied on an IVECO Planned Repair and Maintenance service contract, helping Dawsongroup ensure maintenance costs are more predictable.

news

PLANT & CIVIL ENGINEER 18

More bang less bucks

The Liebherr-XPower range of wheel loaders returns outstanding fuel efficiency

Please contact Liebherr-Ireland for specification and availability.

Liebherr-Ireland

L 576 | 12.85 I/h* L 556 | 9.91 I/h* L 586 | 16.59 I/h* L 566 | 12.21 I/h* L 550 | 8.94 I/h* L 580 | 13.94 I/h*

01/06/22

guideline

actual average of the model’s global population in LiDAT

are subject to specific site conditions, materials, application

operator use. See how much you can save with Liebherr’s real-time fuel calculator.

* Figures taken on

are a

based on the

and

and

Unit 23N, Greenogue Industrial Estate • Rathcoole • Dublin • D24 P38P Phone +353 (1) 458 7650 • LGBSalesLIR@liebherr.com • liebherr.com Fuel efficient wheel loaders

FROM THE DESK OF: GORDON BEST,

REGIONAL DIRECTOR, MPANI

BUCKING THE TREND IN A WORLD OF UNCERTAINTY

Despite all the clatter and chaos as a fallout from geo-political uncertainty and the calling of a general election for once Northern Ireland seems to be bucking the trend. The most recent Ulster Bank PMI indicated that Business activity continues to rise amid further marked expansion of new orders and that confidence, particularly within the local construction sector the highest it has been for 7 years. Construction firms reported their highest rates of new orders in three-and-a-half years. The news that the Finance Minister, Dr Caoimhe Archibald MLA recently signed an Interim Fiscal Framework on behalf of the Executive securing a commitment from Treasury to review how the Executive is funded going forward is very welcome It provides assurances the NI Executive can plan on the assumption we will be funded at or above the 124% level of relative need in future financial years. Basically that means that for every £100 per head of public spend in England, Northern Ireland will receive £124 per head. This means a further £24 million from the Spring Budget will now be available for allocation as part of June monitoring. Any future Barnett in 2024/25 will be at this increased level meaning additional funding for public services here. Nevertheless, the budgetary position facing the Executive remains incredibly challenging

On a national level the recent MPA Economic briefing reported that UK economic conditions improved at the start of the year. GDP grew by 0.6% on a quarterly basis in 2024Q1, exiting a shallow recession at the end of 2023. A return to growth is encouraging, but it is worth noting that the economy has flatlined for much of the past two years. April marked the lowest rate of inflation for almost three years and should continue to support a gradual recovery in real incomes. However, GDP growth of around 0.5% overall in 2024 reflects the impact of past increases to interest rates, which will more broadly keep a lid on confidence to spend and invest. In terms of the national construction picture with the wider economy showing

some signs of resilience at the start of 2024, construction output faltered. Weatherrelated impacts were partly blamed for the setback, yet the underlying cause of the deterioration reflects the deeper challenges facing the sector, particularly in areas of new work over the past six months.

It remains a challenging environment for housing. An improvement in confidence at the start of the year will be difficult to sustain until the Bank of England begins to loosen monetary policy.

HEALTH AND SAFETY INSPECTIONS UNDERWAY

On the health and safety front, our Health and Safety Committee continue to work hard on behalf of MPANI members. HSENI inspectors will visit businesses to ensure that machinery is adequately guarded to prevent access to dangerous parts. The Health and Safety Executive for Northern Ireland (HSENI) has announced an inspection initiative across Northern Ireland quarries, concrete and waste premises, which will take place from May until September 2024. HSENI inspectors will be visiting these businesses to:

• ensure machinery is adequately guarded to prevent access to dangerous parts

• ensure operators have adequate procedures in place for safe isolation and lock-out of equipment

• review the measures in place so that both routine and non-routine maintenance can be carried out safely HSENI Inspectors will provide information and advice during the inspection initiative. Where significant risks are found, Inspectors may take enforcement action to achieve compliance with health and safety legislation and to ensure that the risks are properly managed.

Find out more about the machinery guarding, safe isolation and maintenance initiative

STAY SAFE, STAY OUT

As you may be aware this is the time of year when we see an increase in potential of trespassing on members sites and a greater risk of young people entering disused quarries and swimming in extremely cold water.

This year again MPANI and HSENI have circulated a joint “Stay Safe Stay Out” letter to all school principals across Northern Ireland asking them to share this important safety message with their teachers, pupils and parents. As an indicator of the success of this we have received letters from

essential materials sustainable solutions

20 PLANT & CIVIL ENGINEER

Gordon Best, MPANI

parents and calls from teachers praising this initiative and asking for more information and a number of school presentations.

NI DE-CARBONISATION PLAN

As mentioned before MPANI are signed up partners in the Innovate UK funded NI De-carbonisation Plan. We are currently holding workshops in all 11 Council areas for industry to learn more about how this Innovate UK-funded industrial de-carbonisation initiative can help them.

Led by Invest NI, the project is a consortium of stakeholders including Manufacturing NI, Mineral Products Association, Ulster University, Queens and all 11 councils.

The IDNI Portal is now up and running and can be viewed at IDNI | Home There have now been 8 Council presentations with the next one at Newry and Morne Council on the 19th June.

ADJUSTMENT TO THE BITUMEN INDEX

Following over 18 months of negotiations with BCIS and other stakeholders as a result of a significant divergence between Heavy Fuel Oil and Bitumen prices that meant that the monthly R10/15 index used in an number of DFI maintenance contracts was not reflective of the monthly movement of bitumen prices and required an agreed corrective by BCIS who manage and produce the indices on behalf of Government.

DfI have now put in place a process to agree an adjustment to the R10/15 Bitumen Index affecting a number of contract types including asphalt resurfacing. Papers have gone to senior DfI officials and the Minister, not seeking permission, but informing them of this adjustment. It is planned to have the whole process, and financial rebates completed by the end of June.

MINISTERIAL MEETING

On Wednesday 1st May, I was part of an NI Business Group delegation who met with Finance Minister, Caoimhe Archibald. The group highlighted concerns about the pressures we face and discussed contributions to the recent rate relief consultation.

We made strong arguments regarding the need to retain industrial derating as a business and investment incentive, the need for difficult decisions around revenue raising, the need to prioritise investment in our water and roads infrastructure and the need to include reform of planning in any new programme for government.

CONCRETE SUSTAINABILITY AND INNOVATION CENTRE

I am delighted to inform you that MPANI are partnering with the Mid South West Council Consortium, Invest NI, Department for the Economy and South West College on the Development of a Concrete Sustainability and Innovation Centre. Concrete producers in Northern Ireland have been very successful in developing their businesses, not only do they play a key role in supporting the construction and agricultural sectors but they also export a significant amount of product to markets in ROI, GB, and in some cases further afield. There already exists a strong set of businesses which could be described as having a cluster effect in terms of their development. This development has largely been industry-led through several entrepreneurs with only piecemeal support from the government. The sector now faces the usual challenges of running a competitive business, staying at the leading edge of developments in technology to gain efficiency and in particular to deal with all of the challenges of sustainability, recruitment and retention of people, diversity and specifically decarbonisation.

South West College (SWC), is considering the establishment of a Concrete Sustainability and Innovation Centre (CSIC), to support the Concrete sector and its supply chain implement sustainable practices and decarbonise.

In this context, SWC has identified a possible source of funding through the Mid-South West Growth Deal, one of Northern Ireland’s four City and Growth Deals committed by the NI

Executive and UK Government. The proposed facility aligns with a number of their criteria in terms of Regional Economic Development, Innovation, Decarbonisation, and Levelling up.

In outline CSIC would support the further advancement of the Concrete Industry, specifically focusing on identifying decarbonisation challenges and providing solutions for this sector.

The thinking at this stage is that the facilities/ technologies, resource and knowledge available at CSIC would assist industry to explore, test and implement various solutions to decarbonisation whilst also developing the associated skills/ knowledge transfer to drive innovation and sustainability. .

It would be built around industry-led, open innovation and collaborative research, with the benefit of access to a range of knowledge partners and stakeholders, all geared to harnessing collective learning to accelerate adoption of sustainable practices. Watch this space for future developments!!!

SEE YOU AT THE FORUM

We look forward to seeing as many members as possible at our September Local Member Forum on Thursday the 19th September in the Elk Toomebridge and the 5th December in the Glenavon House Hotel Cookstown.

If you’re interested in becoming a full or affiliate member of MPANI and get access to up to date Industry news and guidance don’t hesitate to give me a call on 07876136929. It would be great to have you on board. Take care and stay safe!!

essential materials sustainable solutions 21 PLANT & CIVIL ENGINEER

www.mpani.org

NEW BOBCAT S630 AND S650 SKID-STEER LOADERS FOR EUROPE

Bobcat has launched new Stage V versions of the company’s M-Series S630 and S650 Skid-Steer Loaders, designed for use in higher regulated markets in Europe. Customers now have a wider selection in this size of machine, with a choice between the new M-Series S630/S650 models and the more advanced R-Series S66/S76 machines. This will further strengthen Bobcat’s leadership position in this size category in the European market.

The new S630 radius lift path loader combines excellent manoeuvrability in tight areas with the reach and visibility needed for applications such as dumping materials over walls, backfilling or loading flatbed trucks.

The S630 has a rated operating capacity of 1012 kg and a tipping load of 2023 kg. The S650 model features vertical lift path boom arms particularly suited to lift and carry as well as material-handling applications.

The S650 has a rated operating capacity of 1227 kg and a tipping load of 2455 kg. Both models continue to offer excellent versatility through compatibility with a very wide range of Bobcat attachments.

SUPERIOR PERFORMANCE

Delivering superior performance while adhering to strict Stage V emission regulations, both the S630 and S650 are powered by the well proven Bobcat D24 engine, featuring a Bosch Fuel Injection System. With the engine situated transversally in the S630/S650, these models have maintained their compact size, allowing the

machines to operate and turn in the same small tight spaces.

New engine technology results in lower fuel consumption for the same type of work. The first engine oil service interval has also been extended to 500 hours and improved fuel filtration means less frequent filter replacements.

The S630/S650 are also equipped with Versatile Duty Tyres as standard, that have a bi-directional design for most common mixed surfaces, which again reduces costs by improving tyre lifetime significantly.

OPERATOR COMFORT FEATURES

Bobcat offers several popular comfort features for the S630/S650 including:

• Heat or Air Conditioning option (HVAC) – keeps operators more comfortable all through the year and in all locations.

• Cloth Suspension Seat – improves the operator’s comfort all year round.

• Auto Ride Control (option) – improves the operator’s comfort and machine stability.

IN-CAB CONTROLS

The base S630/S650 models are equipped with a new Deluxe control panel offering a selection of most of the languages in Europe. Every machine is also equipped with Bobcat Telematics solutions.

The Deluxe panel reduces the risk of misuse, thanks to the keyless start function. Options such as High Flow or

2-Speed can also be locked, if necessary, and protected by passwords.

New after-treatment technology (DPF) works automatically without any interaction during normal operation. If necessary, this technology can be easily managed from the menu in the Deluxe panel, which enables the operator to monitor the machine and exhaust aftertreatment. The new automatic multi-step engine low-idle sequence in cold conditions further improves engine performance.

On machines equipped with Selectable Joystick Controls (SJC), the auto-idle feature reduces the engine speed to low idle when the joysticks are in neutral position and have not been used for about five seconds. Auto-idle allows for quieter overall operation and reduced fuel consumption.

As well as the Deluxe Panel, Bobcat Telematics and Versatile Duty Tyres, the standard features on the S630/S650 include Hand and Foot Controls, a Deluxe Cab with Side Windows and a Suspension Seat. Options include a Cloth Suspension Seat; Selectable Joystick Controls; a Deluxe Cab with Heating or HVAC; Heavy Duty Offset and Severe Duty Tyres; High Flow with Attachment Control; 2-Speed and Power Bob-tach.

The Standard Warranty has been extended to two years (2000 hours) with Protection Plus providing up to five years of coverage.

skid-steer loaders 22 PLANT & CIVIL ENGINEER

Ahead of work getting underway on the Irish Government’s proposed EUR450million upgrade of the N5 carriageway that links Dublin through the midlands to the popular tourist regions dotted along the north-west coast, lead contractor on the project, Mayo-based civil works contractor, Wills Bros of Foxford has augmented its already extensive equipment portfolio with investment in an additional number of Komatsu-branded machines, all for use on the project.

Irish civils contractor, Wills Bros gears up for major road development with ‘significant’ Komatsu purchase

SLOW SPEED SHREDDER

Described by their supplier, Komatsu distributor in Ireland, McHale Plant Sales’ chairman, Michael McHale as one of the “most significant investments” in plant and equipment made in Ireland in recent times.

Ready for Action: Pictured on site at the €450 million upgrade to the Roscommon section of the main N5 carriageway on which Wills Bros are lead contractor is a Komatsu HM4005 articulated dump truck, one of a number supplied to them by Komatsu distributor, McHale Plant Sales.

for Transport, Eamonn Ryan TD as replacement for ‘one of the most treacherous sections of primary road in Ireland’.

TROMMEL SCREENS

“When completed, it will improve road user safety, enhance regional accessibility, and better the connectivity between Dublin and the northern and western regions of the country,” Minister Ryan added.

MEDIUM SPEED SHREDDER

“Their purchase is one that underlines the status of Wills Bros as one of the finest and bestresourced civil works contractors

in Ireland, whose work is also well known through leading projects completed by them elsewhere in Europe and the UK,” McHale said.

WASTE HANDLERS

Komatsu equipment included in this latest EURO multi-million fleet enlargement are three D85PX-18 dozers, a HB365LC Hybrid excavator, two wide-track,

CBI GRINDERS

CBI GRINDERS

TROMMEL SCREENS

low ground pressure PC170 LGP excavators, and a double-digit mix of HM300-5 and HM400-5 ADTs, all of which will integrate alongside other Komatsu units within the Willis Bros fleet.

RECYCLING SCREENS

RECYCLING SCREENS

Scheduled to take up to four years to complete, the project is described by Ireland’s Minister

TWIN SHAFT SHREDDER

Welcomed by politicians and local tourist and commercial interests, the project involves the construction of approximately 34kms of new single-carriageway road that will extend from the existing N5 Ballaghaderreen Bypass to the townland of Scramoge in Co. Roscommon, bypassing the towns and villages of Frenchpark, Bellanagare, Tulsk and Strokestown. Where the route meets access points to these locations, provision will be made for pedestrian and cyclist facilities.

SHREDDING | SCREENING | HANDLING | COMPOSTING | CONVEYING

SHREDDING | SCREENING | HANDLING | COMPOSTING | CONVEYING

10 Coolmaghry Road, Donaghmore, Dungannon BT70 3 HJ

10 Coolmaghry Road, Donaghmore, Dungannon BT70 3 HJ

info@qrs.ie

info@qrs.ie

+442887767120

+442887767120

news 23 PLANT & CIVIL ENGINEER

SALES/SERVICE/HIRE

SALES/SERVICE/HIRE

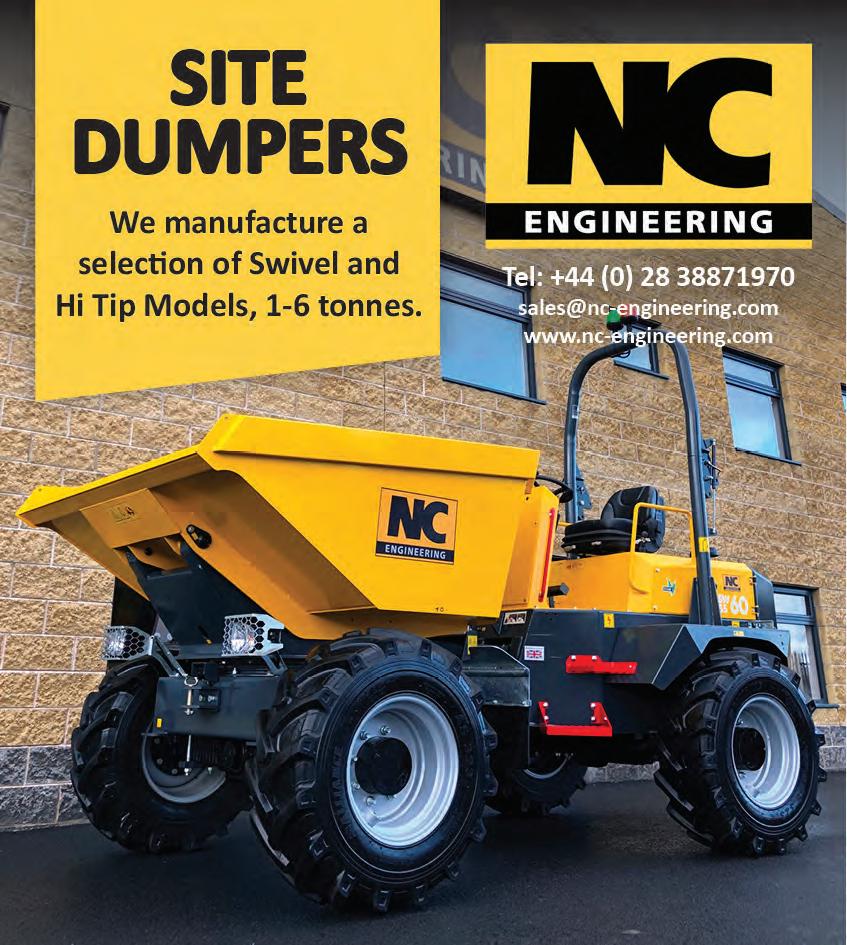

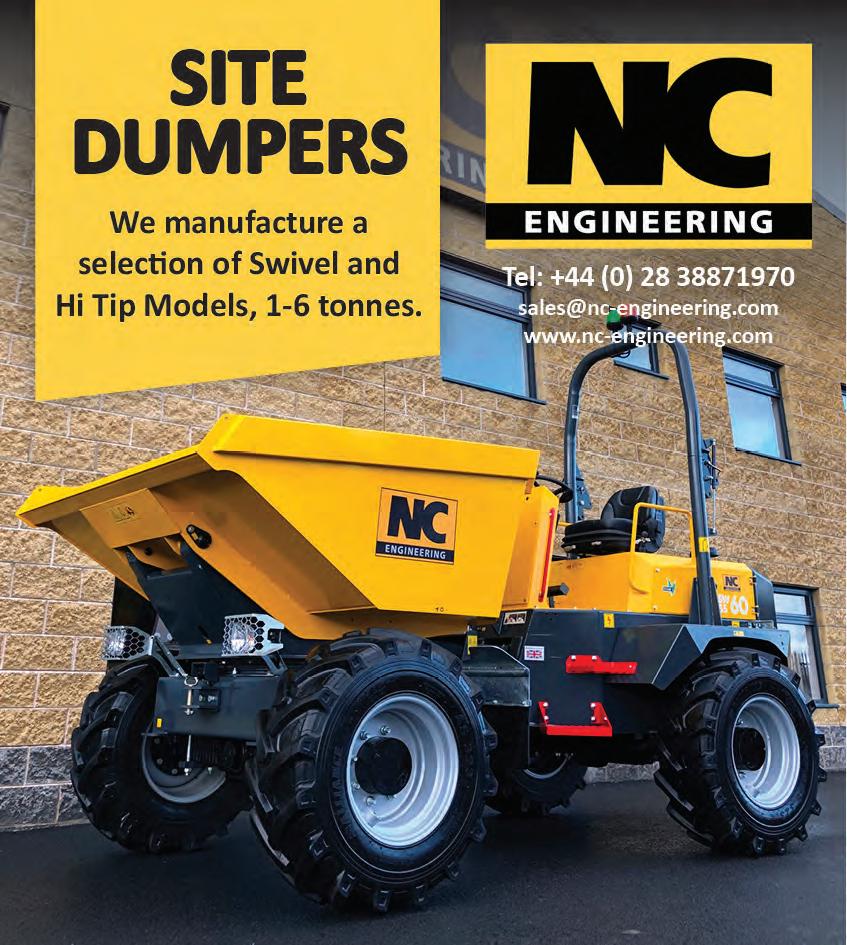

McSHARRY TRACK COMES OF AGE IN CORPORATE REBRAND

The trading name used for McSharry Bros’ track and undercarriage division has now become the company’s official name. McSharry TRACK Limited is now the trading name for the entire business.

Michael McSharry has been in business for over five decades, starting in 1970 selling agricultural tractors and incorporating as McSharry Bros (Manufacturing) Ltd in 1992. At the start of 2024, the company became McSharry TRACK. With three company directors, Michael McSharry and his sons, Niall and Fintan managing the business, which employs twenty people in all, Niall McSharry told Plant and Civil Engineer that the time was right for a rebrand.

cover story PLANT & CIVIL ENGINEER 24

The impressive forecourt at McSharry TRACK, Four Mile House, Co. Roscommon.

“McSharry TRACK has been a trading name for our undercarriage business since 2015.” Niall said. “At the time, it was useful to differentiate the track side from the plant sales side of our business.

“The decision to change our trading name to McSharry TRACK unifies the company with a strong, modern brand and consolidates the entire business under one name. It structures the ownership of the company more clearly and strengthens our presence in the market.

MCSHARRY TRACK AND BERCO SINCE 1980

Italian company Berco has a long history with humble beginnings but, over a hundred years on, it is a global leader in manufacturing undercarriage components for the most challenging applications.

The Berco brand is recognised as world-leading in its quality, innovation and commitment to providing superior parts to the mining, construction and utility sectors. As a result

they have been the preferred supplier of all the OEMs.

McSharry TRACK have been the exclusive Berco dealer for all of Ireland since 1980. That makes them the longest appointed and most experienced dealer of undercarriage parts in Ireland by some distance. It is quite a distinction and service to the industry.

Berco’s range of products encompasses everything for the undercarriage systems of all crawler machines. This includes track chains, sprockets, rollers, track shoes, idlers and tension devices.

For McSharry TRACK, the relationship with Berco has been fruitful for both partners.

“There is a constant and ongoing demand for crawler undercarriage parts, which generates steady business. That is what attracted us to Berco in 1980 and it’s the same story today.” said Niall. “All the track parts do wear down, it’s

a simple matter of steel-on-steel, so there comes a time when they have to be replaced. This brings customers to us and it has always been of great benefit to us to offer the Berco range of parts, considering the high quality of their parts and also the support we get from Berco.”

Berco have also completed a soft rebranding in recent years and they are more focused than ever on the aftermarket.

“We now have a new range of products from Berco that are made in China that are extremely competitive on price and yet we have seen performance as good as the made in Italy parts. It is bringing more and more customers to Berco so it is good for business.” adds Niall.

The benefit for Berco in the dealer relationship is the service levels that McSharry TRACK delivers to its customers.

“Servicing and repairing a tracked machine’s undercarriage is a big job.”, explained Niall. “It requires all the old parts to be stripped out and replaced with new parts. The job is always done better by experienced fitters in a workshop environment. We are committed to doing the best possible job and our workshop facilitates that. We offer a very competitive service to supply and fit parts.”

FULL RANGE OF UNDERCARRIAGE PARTS

McSharry TRACK carries the entire range of Berco products in addition to its own McTRACK brand of undercarriage parts that includes rubber tracks. “For our McTRACK range, we started buying from manufacturers in Korea and China in 2002. All of our parts are OEM quality. By combining the Berco and

PLANT & CIVIL ENGINEER 25

Marty Donnelly organising deliveries from the roller warehouse.

cover story

Damien McGeeney and Paul Kelly, Undercarriage Team putting new Berco track chains back on this EC140EL.

NEW NAME FOR RENOWNED EXCAVATOR AND UNDERCARRIAGE DEALER.

mcsharrytrack.com Tel: + 353 90 6629500 EXCLUSIVE DEALER - Rep. of Ireland & N. Ireland

COVER: NIALL, MICHAEL AND FINTAN MCSHARRY.

McTRACK range, it means we can offer undercarriage parts from stock for every make and model of tracked machine.

WAREHOUSE, WORKSHOPS & MODERN OFFICES

“We have the largest warehouse of undercarriage parts in Ireland and we are the only dealer to also offer workshop services. So we don’t just offer parts over the counter, we also fit them and that is a big point of difference. You learn a lot, fitting parts for as long as we have done.” adds Niall. The premises at McSharry TRACK is recognised as the most impressive in the industry. It benefits from great space with a wide forecourt to present the Kobelco range and in addition to their warehouses for parts, they also have dedicated workshops for their undercarriage and Kobelco divisions. They added new offices in recent years that are finished to a very high standard. These details are all in keeping with how Michael McSharry has run his business from the start.

MCSHARRY TRACK AND KOBELCO SINCE 2014

In 2014, McSharry TRACK was awarded the exclusive, all-Ireland dealership for the

Kobelco Construction Machinery.

A Japanese company, with its manufacturing base in Hiroshima and global sales operations, Kobelco has a long heritage spanning more than 80 years. Its parent company, Kobe Steel Ltd., built Japan’s first construction machine in 1930. The 50K electric mining shovel paved the way for all future Kobelco construction machinery and set the tone for decades of pioneering technological developments.

The Kobelco range is exclusively tracked crawler excavators and cranes, so it was a natural fit for McSharry TRACK, who had also been dealing in plant sales since their very beginning.

Fintan McSharry is head of Kobelco sales and he explained that the relationship with Kobelco

has been successful. “Kobelco is extremely happy with our performance, and we are very happy with the machines. The dealership came to us after Kobelco’s partnership with New Holland ended. Essentially, we have relaunched the Kobelco brand in Ireland. We’ve grown sales year on year and gained a strong market share in the medium to large excavator categories in particular. We’ve sold well in excess of 1,000 excavators to date. Kobelco manufactures excellent machines and our customers have been impressed.”

Their customer base covers leading construction, quarry, civil engineering, utility and forestry companies. It includes Ward & Burke, Deane Public

Works, OPW, Bord Na Mona and Waterways Ireland to name a few.

“We have kept old Kobelco customers with the brand and also introduced lots of new customers to Kobelco. The fact we get repeat business speaks for itself. We make a big effort to look after the customer.” adds Fintan. This is something that we know Michael McSharry has taught his two sons very well. They also have a great team and attribute their success to the dedication and work of all their employees.

Making McSharry Track a onestop-shop for excavators, in addition to the attachment supplied by Kobelco, the Roscommon company carries the Okada range of attachments. Like Kobelco, Okada is a Japanese manufacturer of various attachments, including hydraulic breakers, demolition pulverisers, demolition crushers/ shear, recycling attachments and couplers. “Carrying the Okada range of attachments means that, whatever our customers want to use their excavators for, we have the right equipment for their job,” said Fintan.

WATCH THIS SPACE

The new McSharry TRACK brand identity will be launched soon on the company’s updated and upgraded website. www.mcsharrytrack.com

story PLANT & CIVIL ENGINEER 26

cover

Sean Doyle, Undercarriage Sales along with Eoin Gallagher and Peter Mulholland, Kobelco Parts & Service.

Full Berco undercarriage fitted to CAT 336FL.

Dromad Hire Awarded IPAF Rental Plus Accreditation

International Powered Access Federation (IPAF) Rental

Plus is a certification that ensures that Dromad Hire meets and maintains the highest standards of training, employee development, customer service, equipment rental and back-up services. It is the powered access industry’s guarantee of a high-quality rental company.

The independently Irishowned company specialises in access platform hire, general plant and tool rental, and has a new professional cleaning division, along with approved ex-rental sales. The company provides a nationwide service across the island of Ireland.

IPAF promotes the safe and effective use of powered access equipment worldwide in the widest sense – through providing technical advice

and information; through influencing and interpreting legislation and standards; and through safety initiatives and training programmes.

According to Dromad Hire’s Chief Financial Officer Marcos Simpson, “I’d like to thank IPAF for awarding us with the prestigious IPAF Rental+

certificate. Dromad puts the quality of our internal procedures at the heart of the service we provide, especially when it comes to safety. The accreditation is recognition of the effort that the team has made to ensure that our customers and contractors are assured that when they hire from us they are guaranteed excellence through the rental process, from beginning to end.”

The entire Dromad team extended thanks to IPAF for its continued commitment to providing education, training, research and promoting safe practice when working at height. A special mention is due to to Damien O’Connor and Martin Wraith of IPAF for their endless support and advice in making the process of becoming IPAF Rental+ accredited easier.

POWER MEETS PRECISION

Discover innovation at its finest with the first Tiltrotator manufacturer in the UK & Ireland. Our Tiltrotators enhance your equipment’s versatility, enabling you to take on a wider range of tasks with ease. They offer unparalleled precision and control, significantly increasing efficiency and productivity on the job site. With a Versaffix Tiltrotator, you can work more safely and effectively in tight spaces, educing the need for manual labour. Our products are compatible with 3-18 tonne machines, with an exciting 22 tonne Tiltrotator coming soon.

Our Tiltrotators: VX6 3-6 TONNE VX11 7-11 TONNE VX18 11-18 TONNE VX22 19-22 TONNE (COMING SOON)

news 27 PLANT & CIVIL ENGINEER

contact@versaffix.com www.versaffix.com

PLANT & CIVIL www.plantandcivilengineer.com

Pictured Right to Left: Clodagh McCrory (Dromad Hire), Damien O’Connor (IPAF), Sandra Bowman (Dromad Hire).

Karen McShane

President, The Chartered Institution of Highways and Transportation

CLIMATE CHANGE MEAN WE MUST CHANGE OUR LIVES

Last Autumn the impact of the Climate Crisis fully hit Northern Ireland with an estimated 1 in 300-year storm event causing flooding in our town centres in both Newry and Downpatrick. The impact ensured our town centre roads were not passable, and many businesses had to close for up to six months to conduct repairs. This month, I was asked to provide an opinion to BBC’s Spotlight NI on the impact of the climate crisis and offer a personal view on what the issues and solutions may be. just a few suggestions.

Many NI Councils have now adopted Sustainable Urban Drainage systems (SUDS) into their Local Plans and planning guidelines which is welcome but Northern Ireland is well behind other regions in the UK and it will take many years for these to have a significant impact upon the current flooding problem. The NI Assembly need to reinforce their commitment to these sustainable solutions for all new developments in Northern Ireland. Any solution will require funding and I am consciously aware that the Department for Infrastructure has a finite funding pot from which we already pay for our highway network, our water supply and treatment, our bus passes and public transport as well as maintaining our rivers. The Minister has a thankless task in seeking additional funding to bring our infrastructure up to date and dealing with maintaining resilience during these storm conditions. Without the adequate allocation of funds, we simply will not be able to maintain all our necessary services in these extreme weather events. Now is the time to invest and ensure that resilience of our key infrastructure is maintained. To address the impact of Climate change it is beholding on all of us to think about how we live our lives and to start to seek ways of reducing our impact on carbon emissions to try and slow the rate of change of the crisis.

BRISTOL-V- BELFAST: TRANSPORT

Over the last month I have had the pleasure of visiting Bristol and SW England to look at the sustainable measures that have been

introduced to address these issues, to reduce town centre congestion and to encourage more sustainable travel and I want to compare them with what we currently do here in NI.

Like Belfast’s Glider, Bristol has introduced dedicated bus lanes with public transport priority at traffic signals so that they can run their modern, eco-friendly MetroBuses. This is also a bus-based rapid transit system that links to park-and-ride schemes that allow commuters to park their cars on the outskirts of the city and take a bus into the centre. Such a facility reduces the number of cars commuting into the city centre and helps to alleviate town centre congestion as well as lowering vehicular emissions and reducing our carbon impact.

Within our Northern Ireland cities and major towns, we need to think about where we locate our car parks and where we can provide affordable alternative public transport services. These car parks are currently located on the edge of our city centres and were always potential development sites for the future. Their development will boost the vitality

and viability of the existing centres. Within Bristol, the Council has provided further investments in public transport including enhancements to bus services, integration of ticketing and improved passenger information. Our Grand Central station will provide an enhancement but only in Belfast City Centre. Bristol has also invested heavily in cycling infrastructure to encourage more people to cycle. Like Northern Ireland, there is an increased development of cycle paths, bike lanes, and bike parking facilities together with a campaign that promotes cycling through events, information, and support for cyclists. I did note the Brompton bike hiring docks near the train station.

Within Bristol there are car clubs and shared mobility services to reduce the need for private car ownership. Car clubs provide access to vehicles on a shortterm basis, which can reduce the number of cars on the road, a bit like the system used by Belfast Bikes which allows hourly hiring. These have been approved on private land within Belfast and we have started to see them appear at our railway stations for the final miles of a journey.

However, the legislation is still not in place to allow us to allocate public road space for this essential service. We really need to campaign to have this put in place.

BRISTOL-V-BELFAST: CLEAN AIR

Bristol has also introduced a Clean Air Zone to reduce air pollution, and this is associated with charges to prevent the most polluting vehicles from entering the city centre and encouraging the use of cleaner vehicles and alternative modes of transport. These include Electric vehicles (EV’s) and unlike Belfast and Derry, Bristol city is expanding its network of electric vehicle charging points to support the transition to electric cars with incentives for businesses to install chargers. This is just a stopgap as all we have done is change the fuel in our chariots and have not really addressed how we deal with moving people and goods. However, we do need a plan in place to install the EV infrastructure until we have more viable alternatives.

from the desk of 28 PLANT & CIVIL ENGINEER

Karen McShane and Conor Spackman BBC Spotlight.

Flooding at Newry during Storm Babet.

BRISTOL-V-BELFAST:

URBAN REALM

One of the main differences that I noticed with Bristol compared to our NI cities was that they had introduced Pedestrian Zones and Significant Urban Realm Improvements. I know City Deal funding has been allocated to improvements in our Urban Realm and the Department for Communities has completed various stages of Streets Ahead, but do we yet have plans to provide more pedestrianisation schemes to make our city centres more pedestrian-friendly?

Like Liverpool and Birmingham, Bristol has already introduced car-free areas, improved public spaces, and enhanced walkability through better street design and wayfinding. These public spaces do make it possible to achieve city centre living for families as the facilities are in place for play and recreation. We need to consider the same in our towns and cities.

One of the biggest things that I noticed in Bristol City Centre was the lack of car traffic. My host told me that there are now Congestion Charging and Low Emission Zones within the city, like London. The Council have also other pilot projects related to congestion charging and low-emission zones to further discourage the use of highemission vehicles in the city centre and although proving controversial they are having a major impact on car use in the city centre. I did notice that there was good footfall to the retail units as a result and people sitting enjoying the traffic-free environment.

Alternative options for improving the viability and vitality of our town centres are under scrutiny all the time and Bristol has taken this step to address both climate action and improve the city centre environment. Such measures have not been implemented in Northern Ireland but given the difficulty in raising additional funding for infrastructure such as water supply and treatment, it may become inevitable that we see similar schemes coming forward in the future.

BRISTOL HAS ACTED, NOW IT IS TIME FOR NORTHERN IRELAND

Bristol’s Sustainable Urban Mobility Plan (SUMP) outlines a strategic framework for sustainable transport development, focusing on integrating various modes of transport, improving infrastructure, and promoting behavioural change towards more sustainable travel options. Ideally, it looks at moving people and goods rather than cars and vehicles. These proposals included Active Travel Initiatives such as walking and cycling campaigns, school travel plans, and workplace travel planning. These initiatives aim to increase the proportion of journeys made by walking and cycling and set a new ethos of how we live our lives.

As part of the Low Emission Zones and reduced vehicular traffic in the city centre the Council, as the roads authority, have been able to introduce new Smart Transport Technologies. The city is investing in realtime traffic management systems to optimize traffic flow and reduce congestion.

These technologies help manage the city’s transport network more efficiently and reduce emissions from idling vehicles. By implementing these measures, Bristol aims to create a more sustainable, efficient, and environmentally friendly transport system that reduces congestion and lowers greenhouse gas emissions.

Within Northern Ireland, we are at a stage where we cannot squeeze any more capacity onto our congested city approach roads and we need to start looking at a ‘decide and provide’ scenario where we optimise the travel modes so that we can deliver the maximum number of people rather than the maximum number of cars.

The Glider has been a real catalyst and has delivered a significant increase in use as it is easy to use, is ticketless on the vehicle and has a guaranteed journey time from the dedicated road space. The future allows this to have increased frequency so we can carry more people rather than more vehicles. This allows for increased movement along these corridors.

Is it now time for Northern Ireland to address this climate crisis and act. It is time to deliver the north-south Glider route and to start to consider what other measures we must introduce to make the future more sustainable while maintaining the vitality and viability of our town and city centres. We need to encourage our Ministers to take the brave decisions for the future of the country rather than looking at short-term election goals.

29 PLANT & CIVIL ENGINEER

from the desk of

Brunells ”The Engine Shed” now a business centre.

Control of access at “The Eye” on Glass Wharf.

Solar powered Bicycle hire at Bristol’s Temple Mead station.

Karen crossing Valentines Bridge on Bristol Canal.

Bristol’s new segregated two way cycle lanes at Redcliff.

Piletec may have proved themselves a victim of their own hiring success!

Groundforce Safety adds defibrillators to safety product portfolio

Specialist construction equipment supplier

Groundforce has taken its hire fleet of site safety products to the next level, with the introduction of (AED) iPad SP1 defibrillators. These defibrillators help contractors to provide potentially lifesaving treatment to their site personnel.

Combined with effective CPR, they are the only definitive treatment for casualties of sudden cardiac arrest (SCA).

Without immediate treatment, 95% of SCAs are fatal but delivering a shock within three to five minutes of onset increases a person’s survival chances from 6% to 74%.

The defibrillators are the latest evidence of Groundforce’s commitment to driving and improving safety standards in the industry, with initiatives such as its industry training courses and an extensive range of equipment that includes edge protection systems for excavation

support systems and ladder access platforms. Fall arrest and rescue systems, davit arm rescue systems and stretchers have also recently been added to the portfolio.

Joseph Lenihan, Director at Groundforce Ireland, said: “We believe every site, no matter how small, should have a defibrillator. We are in the business of protecting people’s lives and this new product

offering complements our existing excavation safety and rescue systems.”

30 pile extraction PLANT & CIVIL ENGINEER

PILETEC’S STRATEGIC PILE REMOVAL SOLUTION WITH THE ICE 8SG IN RESTRICTED HEADROOM

A customer was so impressed with the Diesko ICE 8SG Side Grip Hammer they supplied that they may invest in one themselves, for their fleet.

Piletec supplied the Side Grip Hammer to extract 9m U steel sheet piles which had been installed using a five-tonne crane-suspended vibrator during construction of a new motorway bridge.

THE CHALLENGE

Following the construction of the bridge, the piles had to be removed within the restricted headroom under the bridge. Other considerations which had to be taken into account before removing the piles included the ground conditions. It was necessary to ensure the vibrator was suitable to extract the piles and the customer’s excavator was compatible and had sufficient oil flow to operate the 8SG.

THE SOLUTION

To deliver the most appropriate equipment, engineers from Piletec carried out a comprehensive assessment of the site and engaged in detailed discussions with the customer.

excavators, Piletec suggested using the Dieseko ICE 8SG Side Grip Hammer. Reliable, robust and powerful, it offered an effective solution to seamlessly integrate the equipment with the customer’s 49-tonne Hitachi excavator. Piletec also collaborated on the design, fabrication and fitting of an OilQuick Coupler to the 8SG piling hammer. This customisation facilitated not only compatibility but also flexibility for the customer to switch between piling and other operations during the hire period.