10 minute read

Driveline & Brakes

HARROP ENHANCED FORD PX RANGER

Two differential upgrades for enthusiasts are now offered by Harrop

Harrop Engineering has taken its mission to deliver industry leading powertrain and driveline products to the Automotive Aftermarket and applied it to the popular Ford PX Ranger platform; creating a suite of performance products for enthusiasts to relish. Harrop’s engineering and design prowess were recognised by 4x4 Australia when its PX Ranger development vehicle was crowned the inaugural 2016 Custom 4x4 of the Year, as voted by readers. This achievement and the continued sales performance of the PX Ranger nationally was a key driver for further product development by the Harrop Engineering team. Fast forwarding to today, Harrop now offers two differential upgrades for enthusiasts with a helical gear design Truetrac LSD and industry leading ELocker. The Harrop Eaton Truetrac differential operates as a standard or open differential under normal driving conditions, allowing one wheel to spin faster or slower as necessary. When a wheel encounters a loss of traction or the terrain changes, the gear separation forces take effect and transfer torque to the high-traction wheel. The helical-shaped gears mesh with increasing force until wheel spin is slowed or completely stopped. When the vehicle exits the low traction situation, the differential resumes normal operation. Harrop also offers an electromagnetic actuated ELocker, its market leading selectable locking differential for off-road use. Similar to the Truetrac the ELocker operates as a standard or open differential under normal driving conditions but is switched activated to a fully locked differential, capturing 100 percent of the available torque and sending it equally to both ends of the axle as required. To complement the differential range, Harrop also supplies Diff Rebuild Kits for customers requiring an overhaul at the time of upgrade. Further to this, Harrop has recently developed a Charge Air Intercooler Kit for the PX Ranger with a 28 percent larger frontal surface area and 75 percent thicker core than the OEM unit. This upgrade addresses a known deficiency in the factory plastic tanks which can fail on vehicles with performance upgrades in particular with higher boost applications. The Harrop Charge Air Intercooler features cast aluminium tanks welded to the core for a robust solution designed to handle the higher boost loads without the fear of cracking the plastic tanks or leaking through the seal area of the plastic tank and aluminium core. Harrop’s inhouse testing on its Ford PX Ranger development vehicle saw Intercooler temperatures remain constant over extended test cycles, compared to the OEM intercooler which had over a 65 percent increase in temperature (from 33 degrees Celsius to 55 degrees) over a 100 second drive cycle. Harrop’s Charge Air Intercooler will also be available to suit the range of 2.0L powered Ford Ranger and Raptor models late in 2021. Harrop Performance and 4WD products are available for order from stockists and dealers across the country. For more information, please visit www.harrop.com.au or contact the Harrop customer service team on 1300 HARROP.

NEW SPINDLE GREASING TOOL

From Terrain Tamer

Terrain Tamer explains that it is not uncommon for the inner spindle / CV driveshaft bearing / bush to fail prematurely, due to being starved of lubricant, as it cannot be greased without the spindle being removed. The new Terrain Tamer Spindle Inner Bearing / Bush Greasing Tool, or ‘Spindle Greasing Tool’ for short, has been created as a solution to this problem. The tool allows greasing of Toyota spindle bushes, without needing to remove the spindle or wheel hub. After removing the drive flange, free wheel hub and bearing adjustment lock nut, the tool fits on the threaded end of the spindle. Grease is then pumped between the spindle and the drive shaft. A rod inserted in the steering knuckle filler plug hole will show the grease level. Terrain Tamer says molybdenum grease is recommended for this application. Compatible with all Toyota threaded spindles, Terrain Tamer says the bearings’ longevity is greatly extended when using the Terrain Tamer Spindle Greasing Tool.

ACS TALKS CLUTCH BLEEDING PROCEDURES

New clutch bleeding video released for Holden Rodeo, Colorado and Isuzu D-Max

Australian Clutch Services has recently launched a video on the clutch bleeding procedure for 2007-2012 4JJ powered Isuzu D-Max and Holden Rodeo/ Colorado Models. The bleeding procedure was investigated by the technical support team at Australian Clutch Services after feedback from customers due to some difficulty in bleeding the system. It was discovered that it can be difficult to encourage the fluid behind the slave cylinder piston in these applications due to the location of the bleeder port in relation to the inlet from the master cylinder. “We are always looking for ways to provide the technical support necessary for our customers to efficiently install the product,” Australian Clutch Services Mechanical Engineer, Stewart Furze, said. “We had several instances where customers called our technical support team with difficulty in bleeding the clutch hydraulic system in 4JJ powered Holden and Isuzu applications, so we were able to test this on a vehicle in our research and development facilities here in Adelaide to help diagnose the problem and produce a video to help guide customers through alternative processes.” The slave cylinder in these models has an electronic actuator behind the piston that allows the line to be restricted for reduced fluid flow. This, combined with the location of the bleeder port and inlet port, can cause air to be trapped behind the piston in the slave cylinder. The best way to resolve the issue that we found was to clamp the line off, force the piston back and then carefully reverse bleed the slave cylinder until enough fluid has been added to allow for conventional bleeding techniques to be used,” Stewart said. “Our video goes through this process and we believe this will help customers save time and effort with the installation.” Australian Clutch Services offers replacement slave cylinders for this application under its ClutchPro brand as well as reverse bleeders to complete the job if required. “We offer a comprehensive range of complete clutch kits, hydraulics and components for these vehicles and can also offer a range of reverse bleeder tools if the customer requires these,” Stewart said. The ClutchTech technical video series by Australian Clutch Services is one of the most popular clutch specific video series available and can be found on the Australian Clutch Services YouTube channel. With over 50 videos covering a range of technical guides and procedures, this video series is ideal for those looking for detailed but simple explanations on clutch installation procedures. The videos are also linked via QR code with applicable technical service bulletins provided in each kit. For more information, please visit the Australian Clutch Services YouTube channel or www.australianclutch.com.au

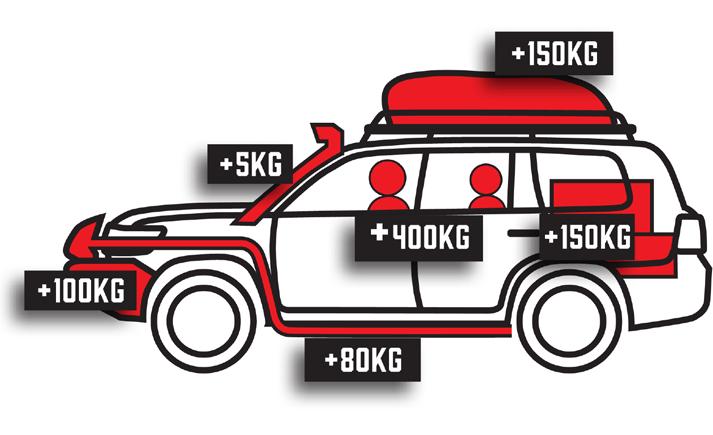

COPING WITH EXTRA KILOS?

Disc Brake Australia’s range of 4WD performance brake products can help

Every outdoor enthusiast and 4WD owner knows how quickly additional weight can add up with bullbars, rear bars, tyre swing outs, rock sliders, roof racks and other accessories all contributing to an increased Gross Vehicle Mass (GVM). Add to that the luggage in the boot and on the roof and a bunch of people, and before you know it you have almost put an extra tonne of weight on your vehicle (always make sure not to extend the legal GVM). If you then decide to tow along an unbraked trailer, you are looking at the next three quarters of a tonne. So, your vehicle’s brakes are now dealing with an extra 50 percent plus of weight that need to be stopped. Disc Brakes Australia (DBA) says that whilst most OE-fitted brakes will do a reasonable job with the extra load, there are two aspects that determine the need for a brake upgrade: (a) are your brakes technically capable of handling the extra load, and (b) considering every metre counts, would shortening your stopping distance be of value? In theory, a GVM increase should have no impact on your stopping distance, assuming all other conditions remain unchanged, and the brakes can handle the extra weight. However, in reality the load sensitivity of most tyres in their typical operating range is such that the friction coefficient decreases as the load increases, which means less friction between the tyres and the road leads to a longer stopping distance. A brake upgrade can help compensate for this. Larger brake diameters, surface design (slotted, drilled, etc.) as well as the pad friction composition all increase braking performance, which will not only help you make up for the additional metres, but can even reduce your stopping distance compared with the original equipment. This brings us back to point (a) above – are your current brakes capable of handling the extra weight? DBA says that with higher weights, higher thermal energy is created during the braking process, which your standard brakes might not be able to dissipate adequately, especially when brakes are applied over a prolonged period. The result will be brake fade and eventual brake failure. DBA says this is where it has the upgrade ‘combo’ for your vehicle, stating that its 4000 Series rotors offer superior braking performance under the heaviest conditions thanks to the patented Kangaroo Paw ventilation vane design, high carbon cast-iron material, Thermal Stability Profiling (TSP) treatment, and unique thermographic paint markings. 4000 Series rotors are available in various surface configurations, with the popular T3 tridirectional slots facilitating additional dust and gas dissipation. The 4000 Series rotors are perfectly complemented by DBA’s range of Xtreme Performance brake pads. Scorched for optimal performance, this low-metallic, low copper friction material offers superior performance across the full temperature spectrum. Application-specific NVH shims and slots facilitate low noise and maximum drive comfort. For more information, visit www.dba.com.au or contact DBA via sales@dba.com.au or 1800 730 039.

TYK-9070SMFST EXEDY SAFARI TUFF CLUTCH KIT

For the Toyota Hilux and Fortuner GUN Series

With the popularity of 4x4 dual-cab utes at an alltime high, Exedy says it has recognised that the market for upgraded clutch solutions is also on the rise. It says that with the GUN series Toyota Hilux being undisputedly the king of sales in this segment, Exedy understood it was essential to offer a dependable performance solution to meet this market demand. The result is the Exedy Safari Tuff TYK9070SMFST. Tried and tested, the Exedy Safari Tuff TYK9070SMFST is designed as a direct replacement for the original clutch and flywheel system found in 1GDFTV powered Hilux and Fortuner models with six-speed transmissions. The clutch kit includes the following items and for ease of replacement, has been designed to be compatible with original factory fixtures: • Conversion Single Mass Flywheel • Safari Tuff Clutch Cover • Safari Tuff Clutch Disc • Clutch Release Bearing • Spigot/Pilot Bearing • Alignment tool The TYK-9070SMFST is only the latest addition to the Exedy Safari Tuff range which in recent times has seen other popular dual-cab ute applications such as the PX Ford Ranger / UP Mazda BT-50, MQ/MR Mitsubishi Triton and RG Holden Colorado models introduced to the range. Going bush or towing?

Exedy Safari Tuff clutch kits reportedly have you covered with parts engineered to provide the increased torque capacity, smooth engagement and optimum durability to help get you there. As an Original Equipment Manufacturer, Exedy says you can be assured its Safari Tuff clutch kits are made from high-quality premium materials developed through Exedy’s 70-year history of manufacturing and motorsport experience. Exedy Australia says it is globally known for providing the broadest range of clutches. It says the Exedy Safari Tuff range is the first port of call for those drivers looking to upgrade their clutch, “offering a range that stands up best to the toughest challenges while delivering the best driving experience.” For more information, visit www.exedy.com.au