23 minute read

FRONT COVER

Repairs

P&O Ferries’ vessel in A&P Tyne

Advertisement

P&O’s ro/pax ferry Norbay has recently undergone a drydocking and repair at A&P Tyne which included the removal and overhaul of the vessel’s stabilisers. During the vessel’s 12 days in dock, A&P’s team removed, dismantled and cleaned the stabilisers as well as worked closely with P&O’s ship contractor to replace the seals, before the units were re-assembled, filled with oil, tested and refitted.

Despite the short time in dock, A&P was also required to carry out a comprehensive array of other checks, repairs and renewals. Work included replacing 80 hull anodes and the port side belting, measuring the propeller shaft wear down, overhauling the lower hold operating cylinders and forecastle aft mooring winch and testing the rudder pressure, as well as replacing the lower hold lid hinge pins and the exhaust gas pipe above the funnel deck with new steel.

Mike Wappet, Marine Director for A&P North East said, “Due to a change of schedule we had only six days’ notice of the intent to dock so our team had to ready themselves quickly. Some additional steel work was also required as part of the class survey which made the schedule tight, however we moved to 24 hour working to ensure we met the undocking deadline and maintained the highest standards of marine engineering and fabrication.”

Meanwhile, A&P Falmouth welcomed a record number of vessels during October as the facility repairs, refits and maintains some nine vessels and all three drydocks.

A total of five vessels will use A&P Falmouth’s drydock facilities, two of which will be double dockings. Kahrs Bereederung’s 9,313 dwt containership Samskip Express entered Dock No. 2 for a series of hull repairs from grounding damage, followed by Tarmac’s City of Chichester dredger, which undergoes standard

The Commodore Goodwill in A&P Falmouth maintenance and repairs each year. Dock No. 3 will welcome Serco tugs SD Careful and SD Deborah simultaneously for their standard drydockings, while Dock No. 4 will play host to Condor Ferries’ 11,166 gt ro/pax ferry Commodore Goodwill as part of its Commercial Partnership Agreement with A&P.

Three RFA vessels - RFA Mounts Bay, HMS Tamar, HMS Trent and P&O Ferries’ ro/pax ferry 28,138 gt Pride of Burgundy - will undergo refit work, general maintenance and mobile repairs while alongside in Falmouth.

Andrea Sabbion, Business Development Director at A&P Falmouth said, “October will be a very busy month for A&P Falmouth as we have a full house of ships and all aspects of our facility will be in constant operation.

“The arrival of ro/pax vessels, containerships, dredgers, military vessels and tugs shows the diversity of our expertise and facilities. This also reflects the strength of our order book and a degree of pent up demand caused by COVID-19. Careful pre-planning and schedule management has enabled us to counter some of the challenges of the last few months, particularly in relation to the supply of critical spare parts.

“The team has also adapted quickly to our new stringent HSEQ measures to mitigate the risk of COVID-19 and keep our clients safe. It’s thanks to them that we’ve been able to remain operational for our clients during this time.”

Strong 2020 at Cammell Laird

Merseyside’s Cammell Laird has reported a strong 2020 despite the challenges of COVID-19 – with its construction hall, workshops and drydocks in continuous use since the start of the year.

Speaking about operating during a global pandemic, the CEO of Cammell Laird, David McGinley said, “Despite the restrictions and challenges of the last few months, the needs of our clients have not changed, and we have seen consistent demand for our engineering expertise and on-site facilities. The team has shown fortitude, commitment and agility throughout, which has been instrumental in keeping clients’ vessels operational and maintaining our reputation for engineering excellence.”

Notable projects include the on-going transformation of the unique 6,767 gt cargopassenger ship RMS St Helena, as she becomes a mobile hub for the Extreme Electric SUV racing series. Cammell Laird is also preparing for the start of the next ferry season, which will see the return of all four Calmac-owned ro/pax ferries for their annual maintenance periods.

Focusing on Cammell Laird’s roster of defence work, the yard has welcomed the first of the Royal Navy’s Type 45 class of destroyer to Birkenhead. HMS Dauntless is undergoing her Power Improvement Programme (PIP), which will improve the resilience of the power and propulsion systems by replacing two diesel generators with three new systems and modifying the high voltage system.

Cammell Laird is also in the final stages of a 10-month programme of equipment upgrades and general repairs and maintenance for RFA’s replenishment Tidesurge, the third of the RFA Tideclass tankers, as part of a Through Life Support (TLS) contract to maintain nine RFA vessels over the next 10 years.

Upgrades to this vessel included the installation of four new 40m long exhaust systems, complete with new structural steel. A series of precision lifts were required to transfer the new exhaust system, including its 3.5 tonne silencers, into the engine room via the vessel’s funnel. The team is also upgrading the fire main (HPSW) and making improvements to the ballast water treatment system.

Parts of the vessel’s Azimuth bow thruster will also be replaced, the preparation for which involved digging a 5 m pit to accommodate the 4 m diameter thruster tunnel as it is removed prior to changing out the 5 m main support tube. While in the drydock, the sea valves, rudders and propellers will also be inspected and serviced.

The former Project Director for the RFA Tideclass tankers at Cammell Laird (now with Type 45 PIP), Tony Scaife said, “Working to the vessel’s design intent and using our experience from the previous Tideclass vessels, we are delivering a complex programme of work to a very high standard. It’s testament to the depth of our experience and project management skills, as well as our relationship with the Ministry of Defence, that we are able to do that.”

RFA Tidesurge is expected to depart Cammell Laird in December before her sistership, RFA Tideforce arrives in early 2021. Other ongoing defence projects include wave-class fast fleet tanker RFA Wave Knight, which is nearing the end of a £14m refit programme of upgrades, servicing and refits.

The St Helena arrives on Merseyside

RFA Wave Knight arrived at Cammell Laird in March, following a six-month deployment in the Middle East and spent eight weeks in Cammell Laird’s Dock No. 5, before being moved to the South Berth West Basin. The programme includes hull and tank surveys, service, inspection and repair of the mooring winches, renewal of the cargo tank PV valve pipework, refurbishment of the ABEAM RAS rig equipment, a repaint of the vessel’s hull and super structure and renewal of the flight deck coating.

Newbuilding projects of note during 2020 have included achieving a series of important milestones in the construction of RRS Sir David Attenborough – the research ship that will transform how ship-borne science is carried out in the Polar Regions.

Cammell Laird has tested and commissioned the vessel’s lifeboats and power systems and most recently, the water mist fire protection system. Work is now focused on readying the vessel for sea trials in October, which includes commissioning and testing the marine propulsion systems as well as checking the vessel’s scientific underwater sensors and deployment mechanisms.

During the past six months Cammell Laird has also bolstered its senior management team, with new appointments spanning operational, health, safety, environment and quality (HSEQ), procurement and commercial roles.

Linton Roberts, Cammell Laird’s former Group Technical Director of Sales has been appointed as Director of Operations, while Kevin Peart, formerly Group HSEQ Director of A&P Group, has been appointed as Director of HSEQ for both Cammell Laird and Atlantic and Peninsular Marine Services. Former Head of Procurement, Jane Bryan assumes the role of Director of Procurement, Steve Gibney acts as Interim Director of HSEQ and Neil Harden joins as Director in the commercial team from engineering consultants, M J Quinn.

Busy times at Remontowa

The successful drydocking of four Germanmanaged containerships on the X-Press Feeders service, - Hamburger Lloyd’s 15,952 dwt Baltic Fulmar Baltic Petrel, and Baltic Shearwater and Nordic Hamburg Shipmanagement’s 13,031 dwt X-Press Elbe have recently been completed by Poland’s Remontowa, Gdansk. The Baltic Petrel and Baltic Shearwater left the shipyard with changed names – SCA Tunadal and SCA Munksund respectively. The scope of repairs for the X-Press Feeders vessels was similar and comprised traditional class renewal repairs.

Vessels from the Wilson shipmanagement fleet are a common sight in Remontowa. In the last three years, the yard has repaired over 20 ships from this Norwegian shipowner, of which nine were completed during this year (2020). In recent months, these have included the general cargo vessels Wilson Alster, Wilson Mass and Wilson Weser. The last of the fleet that left Remontowa quite recently was the 8,301 dwt Wilson Nice. Work on this vessel included hull and cargo hold maintenance, including painting, and main engine overhaul.

Verder Rederij’s 8,669 dwt LPG tanker Coral Parensis was recently in the yard for her fourth Special Survey, including drydock work and steel and pipe renewal.

At the end of August, Exmar’s 26,616 dwt LPG tanker Bastogne left the shipyard after completion of standard class renewal, installation of an Alfa Laval BWM system and the gas detection system, and main engine overhaul.

In the colours of Unity Line, the 15,950 gt ro/pax ferry Copernicus, ex Puglia has been in operation since 2018. She is the sistership of the Galileusz, also belonging to Euroafrica Shipping Lines. Copernicus called at Remontowa for a class renewal along with maintenance works, the major part of which was the steel and pipe works including modification of the BWM system. She operates on the winouj cie (Poland) – Trelleborg (Sweden) route.

The 61,204 dwt tanker Tavropos, owned by Greece’s Pleiades Shipping Agents recently called at Remontowa for the installation of an Erma First BWM system, steel and pipe work, anchor-mooring and mooring lifts repairs, and main engine and cargo pump overhaul. The hull maintenance will include 100% sandblasting and new paint system.

During the last visit of Exmar’s 9,965 dwt LPG carrier Temse during 2018, the key point of the repair works was the BWM system installation. This year, she underwent a class renewal, extended by several other important items in the work schedule, including overhaul to the booster pump assembly, main engine overhaul and hull painting.

Atlanship SA’s 34,426 dwt containership Chiquita Express was in Remontowa for the installation of an Alfa Laval BWM system. The additional task was the repair of 28 hatch covers.

Another chemical tanker of the Norwegian shipowner Odfjell, the 16,121 dwt Bow Condor has undergone repairs in Remontowa. In addition to the class renewal, steel work in the ballast tanks and hull maintenance and painting had been carried out. In addition an Alfa Laval BWM system was installed. Chemical tankers from this shipowner systematically visit the shipyard.

Two chemical tankers from Norway’s Stenersen AS, Bergen, the 16,607 dwt Sten Baltic and her sistership Sten Nordic called at Remontowaa for the installation Alfa Laval BWM systems. Out of this Norwegian shipowner’s 18ship fleet, we had repaired seven vessels with an orange hull in the last three years.

Amoretti Armatori’s two chemical tankers, the 2,698 dwt sisterships Frances Wonsild and

The Chiquita Express in Remontowa, with the hatch covers on the quayside

Sarah Wonsild once again use the facilities at Remontowa. The main scope of work included class renewal and the overhaul of the main engines.

OSM Ship Management’s 20,209 gt car carrier Höegh Caribia called Remontowa for drydocking and general repairs. This is the fourth car carrier from this owner repaired in the yard over recent months. The scope of work on-board this vessel included drydocking and alongside work, including steel work and hull maintenance, which included full sandblasting.

At the end of September, Van Oord’s 18,900 m3 trailing suction hopper dredger Volvox Amalia was drydocked in Remontowa.

River cruiser repair at SMS Lowestoft

UK’s SMS Group has refitted Woods Silver Fleet’s river cruiser Silver Sturgeon in Lowestoft and fabricating its new Central London facility, Woods Quay, in Lowestoft. Work on both the Silver Sturgeon and Woods Quay were safety undertaken during lockdown. Both projects are now complete with Woods Quay recently hosting the launch of the newly rebranded Uber Boat by Thames Clippers.

Thames Clippers vessels were built by The

The Silver Sturgeon undergoing refit in SMS Lowestoft DMC delivers nozzles to super trawler modification project

SMS Group’s sister company - The Wight Shipyard in Cowes – another example of buying and building British. Referencing the Woods Quay project Nicholas Warren, Commercial Director commented, “The support of Woods, and their faith in buying and building British during these challenging times really is fantastic.

“As is its new facility - it’s COVID-secure, offers customers the combined and truly unique proposition of tailored events spaces, boating and bespoke lunches. Geared up for both ‘family bubbles’ and more formal/corporate events, the facility is a genuine game changer for the Thames. We truly appreciate their custom and wish them the very best of luck with what remains of the summer season. Each and every business is enduring difficult times at the moment.

“That said the way that both Woods and Thames Clippers have ‘future-proofed’ its respective businesses by making the right investments and the right time gives both the industry and Londoners a sense of security. The Thames is becoming an increasingly special, first class, part of London and we’re both pleased and proud to be part of that everexpanding community.”

Tom Woods, the Managing Director of Woods Sliver Fleet, added, “We have made significant investments in the last 24 months - the annual Silver Sturgeon refit in Lowestoft, and our new Woods Quay, being two examples. Woods Quay is a wonderful space. We’re determined to offer the best, high-end, experience on the Thames whilst at the same time ensure economic pricing, and a ‘family bubble’ model focusing on food, fun, and boating. Our intent is also to offer our corporate customers a totally bespoke, customisable, entertaining and event space. It’s the best London has to offer, and its right on the waterfront”

DMC delivers large nozzles for DSAm modification

Holland’s Damen Marine Components (DMC) has delivered two large 19A nozzles to Parlevliet & Van der Plas for its fishing trawler, the Margiris. The vessel is one of the largest of its type in the world. She has recently undergone a modification project at Damen Shiprepair Amsterdam (DSAm).

At Damen’s Amsterdam repair yard, the Margiris underwent work which included bow thruster overhaul and fabrication of new bow thruster grids, piping renewal, steel tank repairs, hull cleaning and painting and fabrication and installation of a new sea chest as well as nozzle renewal.

DMC produced the nozzles at its production facility in Gdansk, Poland. From there, the nozzles were loaded onto a special transport for delivery to Amsterdam in January. On arrival,

DSAm lifted the new nozzles with chain clocks before welding them in place. The Marin/ Wageningen 19A profile can be delivered in various L/D lengths. This nozzle type is often used for vessels where reverse thrust is less important. Each of the nozzles for this project has a diameter (Ø) of 3,636 mm.

DMC produced the nozzles using its Single Weld Spinning Method – based on a single weld seam on the inner side of the nozzle. The spinning machine can produce nozzles with an inside diameter ranging from 1,000 mm to 5.3 m on the outside. Using a completely automated system, the spinning machine can handle stainless steel, duplex steel and special steel materials.

The reduction in CO2 emissions associated with nozzle use already improves vessel sustainability significantly. With the Single Weld Spinning Method this goes even further. Reduced grinding and welding, results in less energy use and less emissions. Additionally, the method saves production, which enhances DMC’s stable price/quality ratio for increased cost-efficiency. “We are very pleased to supply the nozzles for this notable vessel. Back in 2015, we delivered our 10,000th nozzle. At the time of writing this has risen to approximately 12,500 – a testament to the quality and popularity of our product range,” said Kees Oevermans, Damen Marine Components Sales Manager.

Ro/pax repairs in DSHI

Holland’s Damen Shiprepair Harlingen (DSHl) has completed a repair project on-board Rederij Doeksen’s 3,990 gt passenger/car ferry Vlieland. The vessel operates a ferry service across the Wadden Sea between Harlingen in the north of the Netherlands and the island of Vlieland.

The Vlieland required repair following a recent incident that took place as she was departing the harbour in Harlingen. As a result of the accident, the vessel’s SB engine room flooded. DSHL carried out an emergency operation, sealing the hole in the hull, before moving the vessel on to the yard for full repairs. At the yard, DSHL carried out a series of work on-board the vessel, including the removal of the main and auxiliary engines, the gearboxes and all electrical equipment and wiring – of which there is over 4 kms. Following this, the yard undertook the rebuilding of the engine room. This included re-installing the CAT 3508 main engines and Cat 3406 and 3408 auxiliary engines cpl/w generator sets that had been overhauled by PON (Caterpiller’s Holland agent).

Klaas Krook account manager product support at PON explained, “We value our relationships, most of which are long-term. When Doeksen was faced with the damage on the Vlieland, we went the extra mile. Together with our valued partner Damen, we overhauled the engines in the SB engine room, and used REMAN parts to get it done cost efficiently.”

At the same time, the yard blasted the hull and repainted the vessel. A local electrical technician company, Piet Brouwer, installed a new monitoring and safety system to the Vlieland – Rederij Doeksen having decided to take the opportunity to do so while the vessel

A&P GROUP - THE UK’S LARGEST COMMERCIAL SHIP REPAIR FACILITY

A&P operates three full service ship repair facilities located on the East and South West coasts of the UK.

A&P provides ship repair, maintenance, conversion, life extension and fabrication services to the commercial marine sector and oil & gas industry. A&P’s unparalleled track record for safe, efficient and high quality services includes the successful turnaround of passenger vessels, offshore units and green retrofit projects.

A&P NORTH EAST

A&P SOUTH WEST

A&P SOUTH WEST

DOCK NO. 2 259.1 x 39.6 M

DOCK NO. 3

DOCK NO. 4 228.8 x 26.8 M

177.7 x 26.2 M A&P NORTH EAST

DOCK NO. 1 259 x 44 M

DOCK NO. 5

DOCK NO. 6 175 x 22 M

120 x 17 M

MARINESALES@AP-GROUP.CO.UK WWW.AP-GROUP.CO.UK

Damen Shiprepair Harlingen completes repair project on-board Rederij Doeksen’s ferry Vlieland

was in drydock.

Damen Shiprepair & Conversion sales manager Klaas Kuper says, “Rederij Doeksen is a long-standing client of DSHI, visiting the yard on a regular basis for the scheduled maintenance of its fleet. We enjoy an excellent relationship and are pleased to be able to assist them in getting the Vlieland safely operational again.”

Richard de Vries, manager operations at Rederij Doeksen added, “We are pleased to be able to take Vlieland back into active ferry service. We are very satisfied with the cooperation between the various parties, who have made every effort to get this job done as quickly and professionally as possible.”

Dales Marine drydocks the Glen Sannox

The first LNG ferry to be built in the UK, the Glen Sannox, completed an extended drydocking at Greenock’s Garvel Clyde Drydock on September 8th and returned to her builders at nearby Ferguson Marine at Port Glasgow for completion. The ferry is now due in service with Caledonian MacBrayne on its Ardrossan-Brodick service between April and June 2022.

While in drydock, Glen Sannox underwent hull blasting and cleaning, which saw a total of 42 tons of mussels taken, inspection of the hull coating (which was fine), as well as the replacement of the vessel’s defective bulbous bow.

Second phase of Povl Anker upgrading completed at Orskov’s

Molslinjen’s classic 1978-built ferry Povl Anker arrived at Denmark’s Orskov Shipyard in Frederikshavn on September 13th to begin the second phase of her major upgrading project. The first phase, cantered around the vessel’s passenger areas and public spaces, started in 2017.

During Povl Anker’s stay at the shipyard, expected to be completed on October 20th , the ferry will undergo modernisation of her airconditioning system, fuel oil treatment plant, upgrade of all shipboard lighting, as well as the upgrade of main engines and diesel generators and steam boiler. While in drydock the hull of Povl Anker will be repainted pebble grey, as she first appeared after delivery from Aalborg Verft 42 years ago.

The Glen Sannox in drydock

Shipyards

Appledore Shipyard to re-open

UK’s Appledore Shipyard, Barnstable, closed in March 2019 after owners Babcock said its future was not ‘secure’, despite the offer of a £60m Ministry of Defence contract, has been purchased for some £7m by the InfraStrata Group. A spokesman for InfraStrata said, “The yard’s ability to cater for smaller vessels was a market segment that cannot be ignored.”

Trade Unions have welcomed the deal and urged the government to give the yard orders.

The yard will now be operated under the name Harland and Wolff (Appledore), after the much larger Belfast site the same owner bought in December last year.

The last full ship built at Appledore Shipbuilders was a fourth 90 m offshore support vessel for the Irish Naval Service, delivered in 2018. However, the yard did build sections for the HMS Queen Elizabeth 2 aircraft carrier project after Babcock won the contract to build two such ships in 2012.

The yard’s capability is building ships up to a length of 130 m (about) 12,000 dwt. The yard has delivered around 200 vessels, the largest being HMS Scott (Length 131.0 m, Beam 21.5 m and weight 9,498 tonnes). The yard comprises a covered facility incorporating an effective site area of 18,437 m2 with a building area of 9,260 m2. This includes a building dock (118 m x 33.5 m wide). The yard can accommodate a vessel up to 10,500 dwt, max draught of 4.5 m, max air draught of 14.5 m and max lifting capacity over dock of 120 tonnes.

The yard has no repair facilities such as graving or floating docks, however, alongside berths can be utilised for such work.

Appledore Shipbuilders, Devon An aerial view of Port of Southampton

RFP process underway in Puerto Rico

The Puerto Rico Port Authority (PRPA) is looking for an operator of the drydock facility located at Pier 15, Isla Grandi, and San Juan. A Request for Proposal (RFP) process has been initiated for the operation, maintenance and repair of the shiprepair facility. The winning bidder is expected to be announced by the end of December this year.

The Puerto Rico graving dock, measuring 182.88 m x 31.1 m x 7.9 m, was built in the early 1940s for use by the US Navy and bought by the PRPA in the late 1990’s for US$11m, but hasn’t been used since 2000. It is estimated that $20m is needed to be spent on the facility to bring it back into operation.

The PRPA is looking for an operator to establish a maintenance, repair and overhaul service centre for all types of commercial vessels, as well as the fast growing number of super/ mega yachts calling in San Juan.

SMS Group moves headquarters

UK’s SMS Group, which has an enviable reputation as specialists in shiprepair, marine engineering and major fabrication projects in the commercial marine, defence, cruise and superyachts sectors, is moving its business to Western Avenue, within ABP Southampton’s footprint adjacent the King George V drydock.

The move represents a strategic decision to move the business closer to its core customer base, and at the same time improve its geographical location. SMS Southampton is headed up by Ben Rowe and Dave Chaffers.

Ben Rowe, General Manager, said, “Since the acquisition of 2017 we deliberately, and decisively, made the decision to retain the Western Avenue site within our Estates Portfolio to ensure that when the time came we were best placed to capitalise on the benefits of this historically proven footprint.

Dave Chaffers, General Manager, added, “We’ve taken this decision now due to three very credible reasons. (One) the time is right, as a Group, and as a Business Unit, we’re trading profitably and ahead of budget. (Two) the site is perfect - it’s within the port, adjacent to a main transit route, easily accessed from the M271 - it’s close to all the ports agents, and, as Ben mentioned, the site is historically proven to be a good home for ship repairers. The actual drydock was decommissioned some years ago and is now used by ABP as a ro/ro berth.

“It makes up part of our Estates Portfolio and the location is second-to-none - it really is ideal. And (three) it coincides nicely with the planned ‘change of purpose’ at Ocean Quay - they’ll be undertaking further works of non-marine restoration which is contrary to the modern profile of SMS and that of our customers’ requirements.”

The SMS Group will be investing in both the fabrication workshop and the new mechanical workshop. The site will benefit from new signage and further investment in the offices. The location will also improve the company’s quayside presence, and its mobility with the city’s port infrastructure.

New SE Asia agent for ASRY

Bahrain’s ASRY (Arab Shipbuilding & Repair

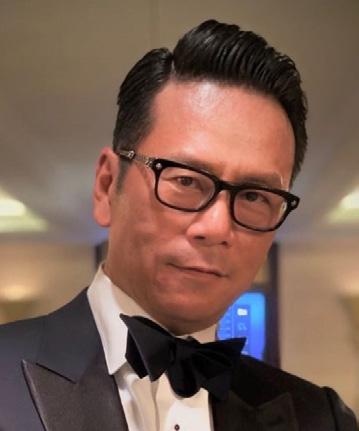

AMS’ Clayton Yu

Yard) has signed a representation agreement with Clayton Yu’s AMS to exclusively market ASRY’s products, services and facilities to the Singapore and Hong Kong shipping market.

The move comes as part of ASRY’s new management’s strategic re-alignment of its international agent’s network after following the takeover of the National Oil and Gas Authority in the Kingdom of Bahrain (NOGA) of Bahrain’s shares in the company last year.

Ahmed Aljanaid, ASRY Commercial and Business Development General Manager said of the new signing, “We are upgrading our agent network to remind our key markets, historically and going forward, of ASRY’s leading position in the regional shipyard scene. Singapore has over the years been a strong supporter of ASRY’s and we are optimistic that partnering with AMS will see the support continue and flourish in the coming years.”

Floating dock contract for Bollinger

US-based Bollinger Shipyards has announced that it will construct a state-of-the-art, floating dock for General Dynamics Electric Boat to support the construction and maintenance of the United States’ new Columbia Class of Ballistic Missile Submarines. The detail design engineering will be performed at the Bollinger facility in Lockport, Louisiana. The concept and contract design for the 18.6 m by 42.7 m drydock was performed by the Bristol Harbour Group in Rhode Island. The drydock is scheduled to be delivered to Electric Boat’s Groton Connecticut shipyard in 2024. Electric Boat is the prime contractor on the design and build of the of the Columbia Class submarine, which will replace the ageing Ohio-Class of Ballistic-Missile Submarines.

This is Bollinger Shipyards second contract awarded with General Dynamics Electric Boat. In late 2019, Bollinger Shipyards was selected to construct the 120.4 m x 30.5 m Ocean Transport Barge for Electric Boat scheduled to be delivered in 2021.

Meanwhile, Bollinger Shipyards has been presented with the 2019 ‘Excellence in Safety’ Award by the Shipbuilders Council of America (SCA) for its exceptional record of safety in the shipyard industry. Bollinger has been the recipient of the prestigious Excellence in Safety Award for 15 consecutive years – an unprecedented streak in the industry.

Shiprepair. Refit. Maintenance. Conversion. Fabrication. Specialists in Marine Fabrication & Engineering

Cammell Laird Shipyard | Campbeltown Road Birkenhead | Merseyside | CH41 9BP T: +44 (0) 151 649 6600