ANNIVERSARY MAGAZINE

Barend Löbker:

Koot:

CONTENT COLOPHON This is a publication of Fresh Publishers Stevinweg 2, 4691 SM Tholen Copyright © 2022 All rights reserved Editing Thijmen Tiersma, Blauvelt Tuinbouwvertalingen Design Viola van den Hoven Photography Simon Voogt, Thijmen Tiersma, Vortus Acquisition Thijmen Tiersma Print Tinto Media No part of this publication may be reproduced without prior written permission from the publisher. The editors accept no liability for any inaccuracies. Simon Voogt’s life on the road Fluence LED at Vahl Advice in bell pepper cultivation

from youngest consultant to owner Henk

consultant is going to sell knowledge This is the Vortus team page 2 page 24 page 14 page 10 page 30 page 18 01 04 03 02 05 #

It’s an enormous pleasure for me to present you with this booklet. This publication marks a special event, namely the 40th anniversary of Vortus BV.

40 years since we first started helping you to the next level with our consultancy services. We’ve been working with leading companies in international greenhouse horticulture for 40 years. We’ve travelled these 40 years alongside you, and we’ve taken a few knocks together on the way. In the early 1980s, when Simon Voogt and Henk Koot launched Vortus BV, the world was also in the grips of an energy crisis. The slogan at the time was, ‘gas prices up, greenhouse horticulture down’.

We currently find ourselves facing a similar crisis, but we will overcome this hurdle again, even if we do occasionally wonder... How?

My thanks go out to the Vortus team that ultimately forms Vortus BV. We would never have managed to get this far without this group of ‘hard-headed’ people. In an uncertain, rapidly changing world, it’s important to hold firm and not be swayed by whichever way the wind happens to be blowing. We must stand our ground, while at the same time responding decisively to new developments at the right moment. That means selecting and embracing the new developments that are important for our customers, if not necessarily for ourselves.

For 40 years, our greatest strength has been our independence. Considering the only thing we sell is our expertise, we are able to let our customers know what’s the best path to take. Our ultimate goal is, and will always remain, to make sure that our customers are satisfied because they’re doing business profitably.

In these difficult days, it can be particularly difficult to stand firm without being called old-fashioned. There are lots of new developments which could be commercially interesting for all kinds of companies if they were applied. These developments are often accompanied by well-intended ‘independent’ advice. It’s exactly here that we see it as our task to pick out those developments that benefit our customers, so that we can move forward together.

After all, we can also thank our existence to a new development that was of great benefit to our customers, namely using rockwool as a growing medium. It allowed production to advance considerably. The lack of expertise among growers about this development was the impetus behind Vortus BV.

Hopefully, immersing yourself in the fantastic stories in this booklet will inspire you to stop and think how we overcome difficult periods time and time again.

Barend Löbker,

FOREWORD

Simon Voogt’s life on the road: “If I stay healthy, I’ll retire in five years”

At the end of 1982, Simon Voogt’s Peugeot had travelled some 22,000 km (14,000 miles). The founder of consul tancy firm Vortus visited lots of growers in the first year, and continues to do so to this day. The ‘semi-retired’ crop consultant still follows developments in horticultu re closely, currently from his home in Tucson, Arizona. A story about his career, the origins of Vortus, travel, and growth country Mexico.

Simon Jan Voogt was born on 8 July 1948 in Rozenburg, the Netherlands, into a family of horticulturists. His father Pieter and his wife had ‘one of the larger greenhouses in the village’ near Rotterdam, where they grew all kinds of crops, including tomatoes. It was hard work. His two older brothers later became horticulturists, but Simon took a different path. ‘My father said, “Go and study. You can’t earn anything in horticulture.”’

Teachers

Het reizende leven van Simon Voogt

Simon Voogt’s life on the road

Simon ended up at the horticultural high school in Naaldwijk. He also studied at the University of Wagenin gen, where he specialised in soil sciences and earned titles in botany and chemical analysis. At the time, Simon was already working at the Naaldwijk Research Station, where he had started out in 1968 as a researcher. ‘I saw and heard a lot, and learned so much from great teachers such as Cees Sonneveld and Joost van der Ende. At the time, I also had a lot of contact with Dick Klapwijk of the physiology department, who taught me much about plant physiology. I can now see that working there for more than 10 years until I left in 1979 laid the foundations for my later work as a cultivation consultant.’

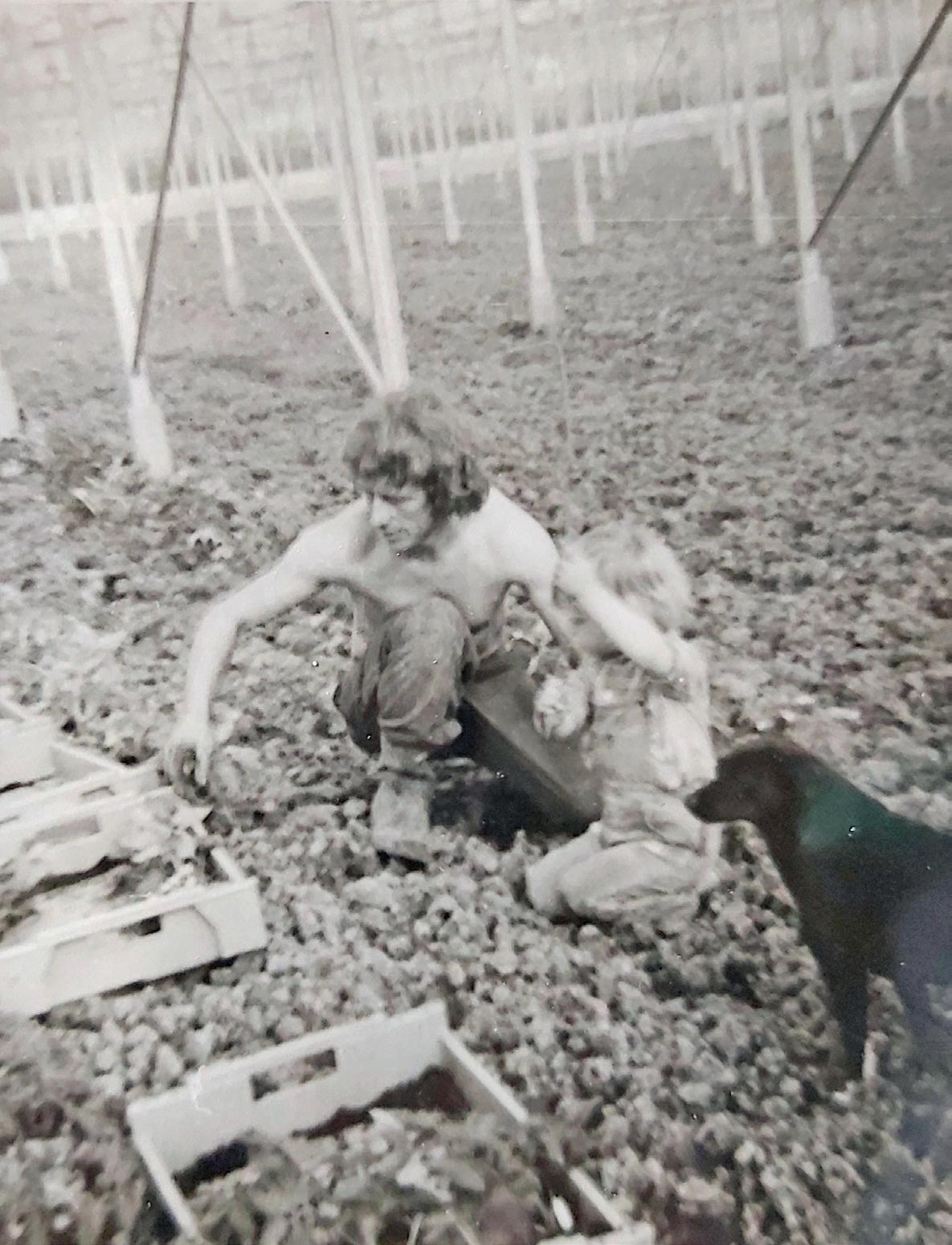

The greenhouse of Simon Voogt’s parents in Rozenburg

The greenhouse of Simon Voogt’s parents in Rozenburg

2 | Simon Voogt’s life on the road

01

In the early days, I used to fly from Amsterdam to New York every three weeks

Pioneers

In 1979, Simon started working as a cultivation consultant for supplier Brinkman. It coincided with the period when growers were switching from cultivating in soil to cultiva ting on substrate. ‘I had already had the honour of helping growers make the switch during my time at the research station. Pioneers back then included tomato growers Kees Damen and Jan van Zijl from Wateringen and Kwintsheul, and Jacob Bijl from Maasdijk. The first cucumber grower to grow on rockwool on a large scale was Wil Haket in the Delfgauw-Pijnacker region.’ During his time at Brinkman, Simon also travelled frequently to Drenthe and Groningen. ‘Many growers in Erica and Klazienaveen also made the switch, followed later by colleagues in Hoogeveen and Sappemeer. I travelled to these areas extensively to give presentations on the subject at study clubs.’

Working with Henk

Simon met Henk Koot at Brinkman. ‘Henk first worked at supplier Codri, which later merged with Brinkman. That meant Henk automatically came under my wings. Cor Brinkman asked me at the time if I could work well with Henk. I knew I certainly could, as we already knew each other well from the meetings at Naaldwijk Research Station. Henk was an information officer, and every week his group would meet with the researchers, including myself. I noticed at the time that he was a person with a wide range of expertise, who was also able to ask a lot of relevant questions.”

Need for advice

Just like Henk, whose thoughts on the matter can be found in his story later in this booklet (from page 30), Simon eventually realised that what he wanted was to visit growers in a sales role. He’d also had enough of the bureaucratic life at the research station, with ‘all its rules’. Vortus was founded in 1982. ‘I’d already built up a consi derable network at the research station through giving lectures and attending study evenings. Even back then I was asked a lot of questions, which made me realise the deep need for consultancy services.”

Going into business

Vortus was Simon’s first company. ‘Henk became my first consultant, but we quickly expanded to seven consultants. Rien Rodenburg, who I knew from my period in Naaldwijk, was the second consultant to be hired. He was working in the north of the Netherlands, where growers were swit ching to cultivation on substrate. The soil in the area was peat-rich and difficult. It was only logical that Rien would

Simon Voogt’s life on the road

Simon Voogt in the greenhouse at Hein Lansbergen

Simon Voogt’s life on the road

Simon Voogt in the greenhouse at Hein Lansbergen

3

|

join us.’ Daan Boonman joined the team as a pepper specialist in the Westland area of the central Netherlands. ‘I wanted somebody specialised in that crop.’ Tineke Goe bertus was a spokeswomen in Bleiswijk. ‘I already knew her, and she turned out to be very interested in joining us.’

Symptoms of deficiencies

Vortus was soon able to count on seven consultants following the recruitment of Bram Noordam and Wout Hogendam, acquaintances from the time at Brinkman. All seven were specialists in fruit vegetable cultivation, as Vortus continues to be to this day. In contrast, Simon had always conducted a lot of research on gerbera. ‘I thought it was an interesting crop, because it quickly showed symptoms of any deficiencies. Later on, I also supervised lots of companies with their gerbera crops, and continued with this work as soon as I started Vortus. Hein Lansber gen from Delfgauw was one of the growers I advised. He was the first to switch to cultivation on substrate on roller

tables. In retrospect, it all went a bit too fast, so it didn’t work out. Even so, Hein was a good grower, a good friend, and he enjoyed sport. We cycled a lot together.’

Feeding schedules

The nutritional approach when growing gerberas is com pletely different to that required when growing tomatoes, peppers or cucumbers, Simon soon learned. ‘Gerbera is sensitive to a lack of manganese and iron, so very specific nutrients have to be used to keep these crops green. I tried out lots of schedules.’ The schedules created by Simon for all kinds of crops are still encountered around the world to this day. ‘They have, of course, been refined over the years.’

Hard lesson

Gradually, he discovered that different schedules were ne cessary in countries outside the Netherlands. ‘In climates with lots of sunlight, for example, the evaporation in Janu

| Simon Voogt’s life on the road

Henk Koot and Simon Voogt

Vortus had their office in this building in the early years

4

ary and February is much higher than in the Netherlands. Here in Arizona, 3,000 watts at the beginning of March is normal. This means there’s a danger that because the wa ter supply increases, the supply of fertilisers also increa ses. At some point, however, a threshold is reached, as too much isn’t good either. That’s another thing I had to learn the hard way in the beginning. The potassium levels for tomato and cucumber schedules for the Netherlands were too high for international cultivation, which caused pro blems with calcium absorption. I ran into these problems in Arizona and Mexico. The next problem was blossom end rot. It was a hard lesson, but I now know the right way to go about things.’

A look across the pond

In his first year, Simon worked from home in Rozenburg. ‘Henk came to my house every week for a meeting.’ A year later, the company moved into an office in Maassluis. ‘That was a lovely building on Veerstraat. From 1983 onwards, the whole group met there every week.’ Later on, Vortus moved to another building in Schiedam. ‘Schiedam was slightly more central for everyone, and easier to reach.’ As time passed, Simon also started advising growers in North America. ‘In the early days, I used to fly from Amsterdam to New York every three weeks. I wanted to check things out there first. From New York, I flew on to Ontario, where I supervised all kinds of projects and built a large network of contacts. Large companies such as Windset and Hou welings already existed, and I used to visit them.’

Emigration

In 1993, Simon emigrated to British Columbia, where he set up Vortus Greenhouse Consultants. ‘I had managed to establish lots of contacts with some large companies quickly, so I decided to settle there permanently.’ His

approach to extensive travel is pragmatic. ‘My job is ex tremely interesting, but at the end of the day plants don’t move, so you have to go to them. That means travelling to see things, and I was the person in the group willing to do that. It’s something I’ve got no regrets about and which still fascinates me, although I do consider travel itself mainly as a necessary evil.’

9/11 11 September 2001; Simon will always remember 9/11. At the time of the attack on the Twin Towers in New York, he was supervising a project for Houwelings in California. ‘I helped them set up the project, and provided advice for 17 years. At the time, I was flying every two weeks from Vancouver to Los Angeles. Around 9/11, I flew first class as a gold member, thanks to all the miles I had accumulated through so much flying. I met my second wife, an Ame rican flight attendant, on that flight. My first wife wasn’t enjoying Canada much after we emigrated. In retrospect, that flight was my best ever.’

Arizona

Simon moved from British Columbia to California with his second wife in 2004. Natural disasters had already forced Simon and his wife to evacuate three times. ‘Twice, wildfires came very close, and the third time there was an

Simon Voogt’s life on the road |

Lighting in a tomato greenhouse in Owatonna where Simon Voogt is a consultant

In retrospect, that flight was my best ever

5

6 |

Simon Voogt’s life on the road

Simon Voogt still works as an consultant in this greenhouse in Owatonna

6 |

Simon Voogt’s life on the road

Simon Voogt still works as an consultant in this greenhouse in Owatonna

enormous mudslide which buried 23 people. Their bodies were never found.’

That was reason enough for Simon and his wife to consi der moving, and they decided on Arizona in 2019. ‘I was already familiar with the weather due to my work. I worked a lot with Johan van de Berg of Eurofresh. He started the company with Wil van Heyningen, at the time owner of the largest greenhouse horticulture company in the United Kingdom. I could write a book about that time. Unfortuna tely, the company, which grew rapidly in the small town of Willcox in Arizona and covered an area of 110 hectares (272 acres), closed its doors. A lack of people who wanted to work in the greenhouses finished them off.’ Simon remembers Johan making a deal with the local prison. ‘Prisoners were sent to work in the greenhouses, but they turned out to be extremely poorly motivated and had no respect for hygiene. The crops were infected with viruses. We tried to keep production going with intercropping, but to no avail.’

Sawdust

From the moment Simon first set foot on the other side of the Atlantic, he was impressed by a number of growers in Ontario. ‘Companies such as Houwelings and Windset were already large and well established back then. They used sawdust. as substrate, which they obtained from the extensive local timber industry. However, they soon found growing in sawdust was problematic, because its qua lity deteriorated rapidly as soon as it got wet and warm. It would start fermenting, and its moisture levels would deteriorate.’

Unique combination

Growers decided to switch to cocopeat and rockwool. Simon imported some Dutch expertise. He had already set up Vortus Greenhouse Consultants in Canada in 1993, and Voogt Greenhouse Consultants that same year. ‘With the right feeding schedules, growers managed to incre ase production by 30 to 40%.’ Simon believes that the products supplied by growers in Canada from May to Sep

tember are unbeatable. ‘From 1 May, the days are much longer than in the Netherlands. 18 hours of high intensity light is unbeatable. They also have access to excellent water; truly unique rainwater from the mountains, very low in bicarbonate, and low in chlorine and sodium. It might be cold outside, but with the windows closed crops grow very well, and this keeps CO2 levels in the greenhouse high. This combination of light, water and CO2 gives amazing results. It’s easy to produce 3 kg of tomatoes per square metre per week for weeks on end, until the end of August, when the nights start getting longer and the re’s not enough light. You can’t actually grow there from November to January unless artificial lighting is used, but that’s expensive.’

Continuous learning

Simon is currently supervising a few projects where lighting is used, although he is now in a ‘semi-retired’ capacity. In 2020, Simon stopped with Voogt Greenhouse Consultants. He had already sold all his shares in Vortus in The Netherlands to Barend Löbker in two stages in 2006 and 2007, and his shares in Vortus in Canada to Tine ke Goebertus and Willem Vesseur. The projects Simon still visits are near Minneapolis. ‘It’s very dark between September and March, so they illuminate crops with HPS and LED. That’s something new, so I find it very interes ting. I visit them every month. It’s extremely cold, and can even reach -300 Celsius. It’s like stepping into an industrial freezer,’ Simon laughs. ‘It’s very different to Arizona, but the project is fascinating, so I enjoy going there.’

Winding down

It typifies the cultivation consultant who’s always on the go. ‘Growing plants is the most interesting thing in the world. Unlike humans, plants don’t lie. They show you exactly what’s happening, as long as you know how to read them. Over the past 40 years, I’ve learned quite a bit about that, and what you can and can’t do with a plant.’ Despite his fascinating job, Simon has now set a date when his work as a crop consultant will come to an end. ‘If I stay healthy, I’ll stop in five years’ time when I turn 79.

Simon Voogt’s life on the road |

If I stay healthy, I’ll stop in five years’ time when I turn 79

7

|

Simon Voogt’s life on the road

In recent years, I’ve been trying to spend more time at home. My wife supports me in everything I do, and I have to keep her happy, I’m ready to start winding down.’

Mexico, a growth country

Over the next five years, Simon expects the horticultural sector in Mexico in particular to expand enormously. ‘The country gets plenty of sun, and labour is cheaper than in the USA. Just like Spain and Morocco compete with the Netherlands, Mexico is competing with the USA. Large American growers are facing astronomical energy prices, and labour is also scarce and expensive.’ In recent years, Simon has built up lots of contacts in Mexico through a good Mexican friend from Tucson who runs a large tomato and cucumber distribution centre. ‘With the growth that the horticultural sector is enjoying in Mexico, I now found where I live is convenient and relatively close. I think that I’ll continue to visit the country a lot, even with advances such as autonomous growing. That’s something I firmly believe in, but I also think people will still have to be present in the greenhouse to check the plants. No

technology can compete with that.’ Simon’s friend knows his way around Mexico and speaks the language. ‘He’s a great help to me, you can’t get anywhere without speaking Spanish.’

Desert

Simon lives with his wife and dog in the middle of the desert in Arizona. Henk grows grapes at home in Rotterdam, but that would be impossible for Simon to do in his spare time in the dry, hot climate. ‘I’ve got a lot of cacti here, which can look after themselves most of the time. I tried growing tomatoes in a vegetable garden, but they burned immediately when the weather was hot. Instead of gardening as a hobby, I like to walk the dog outside in the morning.’ Simon still enjoys cycling. ‘While visiting one of my daughters, who lives and works in the French Alps, I once saw the peloton of the Tour de France pass by. That was amazing to behold, from behind a glass of beer. These days in Arizona, I do try to find flat areas when I can cycle. After all, I’m not 20 anymore, but fortunately I do still feel healthy. I still enjoy everything I do.’

8

FDG Lease congratulates Vortus with its 40th anniversay Growing is always better together Congrats to Vortus from team De Ruiter!

AAB NL CONSULTANTS ENGINEERS ESTATE AGENTS T. +31 (0)174 637 637 WWW.AABNL.NL AAB congratulates Vortus on its 40th Anniversary Engineering your sustainable growth Enza Zaden congratulates Vortus with its 40th anniversary.

Barend Löbker: from youngest consultant to owner

‘Our work will always be human work’

The work of a crop consultant might sometimes seem a bit technical, but in fact it’s a very social profession. It’s precisely this personal touch that keeps popping up in the story of Barend Löbker, who was first employed by Vortus in 1999 and has been owner and director since 2007.

Barend joined the consultancy in May 1999, a date that’s easy for him to remember, as it was the year his son was born. ‘I already knew Vortus through my father’s company. Simon Voogt and Daan Boonman, one of the ‘wise old hands’ with us at the moment, used to visit my father in the pepper and tomato greenhouse when he was a Vortus consultant.’ Barend grew up in those greenhouses; like so many others, he was ‘born in the greenhouse’, in a manner of speaking. When Vortus was looking for a new consul tant, Barend’s name was floated. ‘Daan gave Tineke Goe bertus the tip, and we sat down at the table together not long afterwards. We quickly reached agreement. I wanted to give advice, but not sell products. It was this very idea that was at the root of Vortus’ origins, so we were immedi ately on the same page.’

Before moving to Vortus, Barend worked for a supplier, just like Simon (story in this magazine from page 2) and Henk Koot (story from page 30). In Barend’s case, the supplier was Maasmond. ‘The company no longer exists. I was a plant protection consultant. We used to give advice, but that wasn’t our main task; selling products was. However, I liked giving advice more, so when Vortus invited me to join them, I jumped at the chance.’

Emigration

Tineke, who had interviewed Barend for his job because founder Simon had already settled in the United States, also moved to North America in 1999, but in this case Canada. That meant Barend was able to take over Tineke’s customer portfolio in the western Netherlands. ‘Each consultant had their own area and customers.’ At the time, Vortus had six consultants; Tineke, Daan, Henk, Simon, Rien Rodenburg and John Potters.

Barend’s stint travelling around growers in the west of the Netherlands was a short-lived one. In early 2000, growers in the Northern Netherlands began expanding in size significantly. ‘In that time, building greenhouses with a size of 30,000 to 50,000 m2 was a serious business. Simon asked me to deal with the region.’ Barend remembers driving up there with his wife to have a look around, and

10 | Barend Löbker: from youngest consultant to owner

Barend and dad Art plant tomatoes

02

go house-hunting at the same time. ‘We found a place in Emmen. We still live in the city, close to the greenhouse horticulture areas in the area.’ Barend ‘emigrated’. ‘We fol lowed in the footsteps of all the growers who moved east to set up companies in Drenthe. Rien was already in the region. I spent a lot of time with him in the beginning, until his work took him to Asia.’

Put to the test

That was back 2001, and Barend took over Rien’s custo mer portfolio too. His customers in the west of the Netherlands were transferred to a colleague. ‘I still have one customer from back then, a grower in Waddinxveen who I still visit.’ Thanks to the rapid growth among his new customers, Barend immediately found himself inundated with work. When he thinks back to his early days as a consultant, Barend realises that growers were actually putting him to the test. ‘You had to show what you could do, that’s how it was. The grower knew perfectly well what they wanted, but acted ignorant in my presence to see what I would come up with. That’s how they tested me. It’s also important to have the courage to admit it if you don’t know something, and you can always ask about things afterwards. We still give that advice to new consultants.’

Barend first got to know all the ins and outs of cucumber cultivation after he moved to the north. ‘A lot of things were completely new to me, so I learned a lot back then. I was honest about my inexperience, and if I needed any help I called Henk or one of our other consultants. That meant I could give sound advice and build up trust among customers. That trust is perhaps the most important aspect of our work.’

Taking the plunge

After a number of years working at Vortus, Barend started to get itchy feet. His father was a grower, so doing busi ness was in his blood, he explains. ‘I wanted something for myself. In 2006, I summoned up the courage and asked Simon if I could take over the business.’ Just like Barend’s job interview, it was a fairly short conversation. ‘We quickly reached agreement. In retrospect, I think Simon was relie ved that I came forward. He was already in the USA and everything was running smoothly here, so he was less in volved with the Netherlands. I acquired part of the shares. I can still remember signing the deed on 13 July 2007.’

A year later, in 2007, Barend took the plunge again. ‘This time, I bought the rest of the shares. From that moment on, I was owner and director. On the same day that Henk left his job as consultant, we signed the papers at a notary. It was a big change. I was the youngest consultant at Vortus, and suddenly the owner. That took some getting used to for all of us, but it has never caused any problems. It wasn’t as if I suddenly wanted to turn everything upside down. I think I’m like Simon in that I’m fairly level-headed

about our profession, and don’t get swept up by every hype that comes along. We’ve always said that we’re here to serve growers. It might sound a bit dull, but it’s the truth of the matter.’

Cautious with innovation Innovations and new technology have to work in the grower’s favour. ‘That takes time, and sometimes it turns out that something new isn’t necessarily better.’ Barend mentions ‘Het Nieuwe Telen’, an initiative in the Nether lands about using new insights to improve cultivation, as an example. It’s not about technology, but a new way of growing. ‘There are lots of useful elements within the concept, but I don’t think growers should have to do everything differently all at once.’ He cites the work of his father, who currently has a volunteer job in the Westlands Museum. ‘The greenhouses in the museum still rely on the same principles as the much taller, more modern greenhouses currently in use. You put plants inside, and they have to yield the best results possible. Over the years, we’ve started to look at things more from the perspective of the plant.’

Those who don’t know better might think that Vortus is a bit conservative, but Barend says that nothing is further from the truth. ‘I wouldn’t call it that. We do embrace new technology, and innovation is a good thing, in fact it’s es sential. 20 years ago, screens were a rarity, but now there are sometimes three in a single greenhouse. However, the basic principle remains the same; the plant has to grow well, and greenhouse crop yields have to be optimal. That was the situation when Vortus started all those years ago, and it was the situation preceding it. Maybe we’re just a bit more cautious when it comes to innovation.’

Barend Löbker: from youngest consultant to owner

A young Barend lining boxes with paper

11

|

Advice for everyone

On the subject of innovation and renewal, a partnership with greenhouse builder Kubo stands out. This partner ship has been ongoing since 2014, and was extended in 2019 with a handshake at the international horticultural trade fair GreenTech in Amsterdam. Vortus advises gro wers who invest in one of Kubo’s new, semi-closed Ultra Clima greenhouses. ‘It’s in everyone’s interest that things go smoothly in a new installation. That’s how our part nership, in which we retain our independence, should be seen. We’ve frequently come across all kinds of situations where we could link our advice to products, but that’s something we deliberately avoid.’

Barend cites an example from the Vortus customer base. ‘We advise both plant propagators and growers. There’s a commercial relationship between them, in that the grower buys plants from the plant propagator. As you’d expect, plant propagators have sometimes asked us to recom mend their plants to growers. We never do. We want to work alongside the grower and plant propagator to make the best possible product, but we work for multiple plant propagators. For this reason, if we get such a request from a plant propagator, we always advise growers to consi der the plants of several plant propagators. At the end of the day, the grower decides. It has always been, and will continue to be, a personal choice which we don’t want to influence.’

Maintaining emotional distance

According to Barend, Vortus has its own vision of horti cultural developments, and attracts customers who share that vision. ‘Our profession is personal. We have to click with our customers, with the growers. The grower looks for an consultant they trust and get along with, and we do the same vice versa, perhaps without even realising it. There is occasionally friction, of course. You have to be able to keep each other on your toes, and not just tell someone what they want to hear. Equally, you have to maintain some distance as an consultant, because otherwise there’s a danger that you’ll get swept up in the grower’s emotions.’

These kinds of emotion come to the forefront when problems arise in cultivation. For example, everyone understands that a virus in a crop is very distressing, and the consultant is also affected. ‘One of our consultants

Barend in a greenhouse with cucumbers

Barend in a greenhouse with cucumbers

Feelings can’t be expressed in numbers or algorithms

once said that a customer’s problems kept him awake at night. In itself, excellent, because it reveals deep personal involvement. However, it’s not good for a consultant to lose sleep over such things. At times like these, it’s nice to work as a consultant in a team where you can talk about problems. That’s another lesson learned from Henk and Simon. In a group, a solution that nobody has thought of can come from an unexpected source via a colleague.’

A consultant can’t keep things locked up in their head It’s rewarding for consultants to come across different challenges in each greenhouse, together with the grower. Finding solutions is satisfying. In these times of increasing competition, a customer sometimes asks a consultant not to share company secrets outside the greenhouse. ‘It’s nothing new. 20 years ago, I was given a NDA to sign, a declaration of exclusivity. That doesn’t work in our profes sion. You can’t lock up ideas in your head. Our job is to see a lot, draw general lessons from what we see, and apply those lessons elsewhere, in everyone’s interest.’ Keeping a balance is important, of course. ‘Sometimes, you come across things that are too personal. In these cases, ‘what happens in Vegas stays in Vegas’.

The 40th anniversary of Vortus and the growth that the company has continued to experience since its foun dation is evidence enough that paid consultancy work has earned its right to exist. But what about the futu re? Barend has noticed that the number of companies providing advice has increased in recent years, which he calls a ‘positive development’. ‘Sales representatives are describing themselves as a “consultant” more and more frequently on their business cards. That’s fine, especially internationally, where suppliers are also reacting to growth in the horticultural sector, and there’s a big demand for expertise. Consultants play an important role here. We in the horticultural sector as a whole often work together nationally and internationally, with everyone doing their bit for a project. That requires independent advice. That’s how we came into existence, and that’s how we will continue to exist.’

Human work

According to Barend, all kinds of advances underway in horticulture, such as autonomous cultivation, robotics or the involvement of investors, continue to require advice and guidance. He’s not worried that the rapid inroads being made by new technology will mean people, inclu ding the consultant, disappear from the greenhouse. ‘My granddad did everything by hand, my dad witnessed the introduction of climate computers, and now the techno logy for autonomous cultivation is advancing really rapidly.

We’re keeping a close eye on these trends, and regularly discuss them with specialists. Putting the technology to one side for a moment, what we’re ultimately interested in is what the grower thinks. They’re the ones who have to work with this technology in practice.’

By no means all the innovations that are presented make it into practice. ‘That also used to be the case with technology trialled at testing stations, which is why I don’t think that our work is suddenly going to be digitised. It’s great, of course, that growers can now use new systems to control multiple greenhouses at the same time from a single location. We also use modern technology in our work, and can now control certain aspects remotely. We can also contact customers via video conferencing. In my opinion, however, people often have a natural tendency to hide the very worst. That means the least attractive corner of the greenhouse isn’t visible during a video call, yet this is the area that could profit most from some attention. Fortunately, growers are still happy to see us turn up, and that isn’t something that’s going to change anytime soon. Feelings can’t be expressed in numbers or algorithms. Our work remains human work.’

Vortus extends its partnership with greenhouse builder Kubo. Wouter Kuiper and Barend Löbker shake hands at GreenTech Amsterdam 2019

Barend Löbker: from youngest consultant to owner |

Vortus extends its partnership with greenhouse builder Kubo. Wouter Kuiper and Barend Löbker shake hands at GreenTech Amsterdam 2019

Barend Löbker: from youngest consultant to owner |

13

in bell

cultivation

The rubbish bag is no longer needed: 40 years of advice in bell pepper cultivation

Nursery A. Ammerlaan in Bleiswijk has been a customer ever since cultivation consultant Daan Boonman, now in his early 60s, joined Vortus. Daan has been visiting the bell pepper growers since December 1987, but this au tumn will mark the last time. That’s not because Daan’s retiring, but because grower Ard sold his company to a fellow bell pepper grower. We’re at the office of the bell pepper cultivation company in Wilgenlei in Bleiswijk in late May, where we briefly shake hands with grower Ard who’s about to leave on an afternoon excursion with colleagues. We stay to discuss the past, present and future of pepper cultivation with Daan and his colleague Ruud van den Berg.

Daan and Ruud have a long shared history in pepper cultivation, which started when Ruud was still a grower. In 2011, he and his brother Mark harvested the last crop of yellow peppers in the greenhouse in Groendalseweg in Bleiswijk. Ruud then worked as a manager in horticul ture for several years, until he let slip to Daan that he was ‘looking for something else’. A chat with Vortus director Barend Löbker followed, and he was invited to attend the celebration of Vortus’ 35th anniversary. There, Ruud, who at the time was not yet employed by the company, met Arie Ammerlaan, the father of grower Ard. Sadly, he passed away last year and will miss Vortus’ latest anni versary, although Ard, Daan and Ruud will be present. All three men are pepper specialists, but they’re also ‘connec ted’ in a different, coincidental way. Ruud: ‘I currently live in a new house on the spot where Arie Ammerlaan once started growing in ‘Bleiswijk village’.’ Daan: ‘I was already a

03 14 | Advice in bell pepper cultivation

Advice

pepper

consultant there.’ In 2007, the bell pepper growers Ammer laan moved to Wilgenlei, and Daan went with them. Now, 15 years later, Ruud is also in the office next to the green house and sorting area that span more than 6 hectares. These days, however, he’s no longer there as a grower, but as a Vortus consultant.

Daan: ‘Ard was one of the first to call me after he comple ted the sale of his company last summer. He wanted to tell me personally, before I heard about it from other growers. That shows the kind of relationship you build with custo mers. Besides being consultants, we sometimes also act as confidential counsellors for growers, and we talk about much more than cultivation. We discuss social personal matters, investment plans, environmental issues, you name it. Growers ask us for our opinion.’ It’s something that Ruud also recognises. ‘As a grower, you’re shaped by your experiences’. In Ruud’s case, this included being forced to stop after a number of difficult years following expansion of the company. Ruud continues: ‘Cultivation is the basis of conversations as a consultant, but there are plenty of customers with whom I discuss other subjects. That’s makes the work interesting I also work with very different types of people.’

Rockwool

Daan graduated from the horticultural high school in 1983. ‘I got my diploma on 1 July, and I had already landed a job by 15 July. That’s how quickly things moved. Daan started working for Dutch government at Kring Westland, in which several regional growers shared insights and also had one cultivation consultant. ‘By coincidence, I soon became responsible for some of the bell pepper growers in the region. As a consultant, I followed plenty of courses, but that was the time when I really learned about pep per cultivation in practice.’ Given his origins on a farm in

Zeeland, Daan was no stranger to cultivation, but peppers were new to him.

For Ruud, however, things were different. He was already familiar with his father Dick’s greenhouses when a small boy. Dick first grew tomatoes, but switched to growing peppers ‘when intercropping became too much for him’. This was the mid-1980s, the period in which growing on substrate became popular in pepper cultivation. Daan: ‘That was a massive advance for bell peppers. The advan tages were countless: fewer soil diseases, no more soil disinfection. Growers switched rapidly, quickly convinced of the advantages of growing on rockwool. As is still the case today, a grower who invests takes a risk, but those who did so at the time took some big steps forward. Eve ryone saw that, so others quickly followed. I now think that those who didn’t follow either didn’t have the opportunity to do so or lacked an entrepreneurial spirit.’

Ruud’s father did make the switch. ‘I think that within a few years, virtually everybody stopped growing peppers in soil.’ For growers, it meant a real advance and much cleaner cultivation according to Ruud, with ‘rockwool slabs and plastic on the ground’. ‘The days when my father had to work at night disinfecting the soil were over.’ Ruud might be a cultivation consultant these days, but he still remembers which variety his father grew at the time. ‘Ma zurka, by Rijk Zwaan. Those peppers were really big.’

Hybrid varieties also emerged at the same time as cultiva tion on substrate, says Daan. ‘There were lots of open pol linated varieties in the 1970s and 1980s, and growers with their own varieties. They cultivated to produce peppers, but used the most attractive plants with the best peppers to generate their own seed.’

Daan and Ruud in the greenhouse at nursery A. Ammerlaan in Bleiswijk

Daan and Ruud in the greenhouse at nursery A. Ammerlaan in Bleiswijk

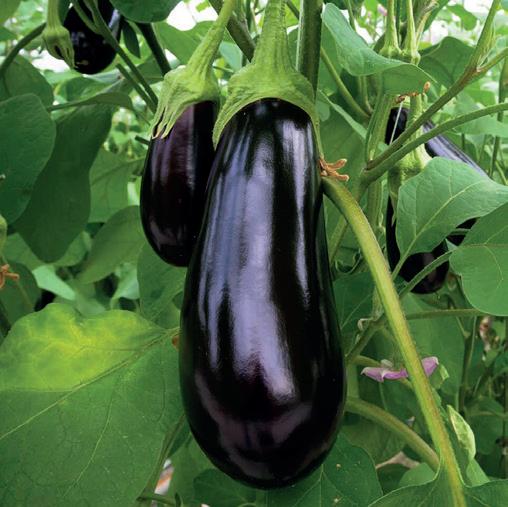

The move to cultivation on rockwool was not limited to bell peppers, other fruit vegetables soon followed. Daan: ‘Cultivation on rockwool was highly beneficial for peppers, but for aubergines it offered even more advantages. At the time, roughly the same area was used for both crops in the Netherlands ‘ Ruud: ‘The aubergine root could fulfil its function much more efficiently on rockwool.’ Cucumber and tomato growers also switched to the new system, and high-wire cultivation also gained popularity. Daan: ‘This required higher greenhouses for tomatoes. Growers without the infrastructure required sometimes switched to bell peppers.’

Screen cloth

Daan can’t remember the first grower he visited in De cember 1987 as a brand new Vortus consultant. ‘I signed the contract on 1 December, and the day after I visited the first growers. I took over the portfolio of Eef Maassen, who had started his own cultivation company. After about 10 days, I had already visited a big group.’ Ruud: ‘You’re right there Daan, it was a very big group. Back then, there

were still lots of growers.’ With the growing popularity of substrate cultivation, pepper cultivation started to grow rapidly in the Netherlands. Daan: ‘Originally, peppers were cultivated under fixed plastic or foil. From these humble beginnings, cultivation was further refined. First, movable foil, which was used at the beginning of cultivation and no longer needed after 6-8 weeks to save energy, to movable screen cloth and now even double screen cloth.’ These days, two screens hang in the greenhouse at grower Ard. It was something that had been considered when he had a new greenhouse built in 2007. Daan: ‘I remember Ard toying with the idea back then, but I wasn’t convinced. I mainly wondered how much energy Ard thought he was going to save.’ He smiles. ‘The screen cloth has already been in place for about 10 years. We were talking about it recently.’

Daan refers to the energy crisis. ‘The greenhouse was pre pared for the installation of a double screen while it was being built, and now we can reap the benefits.’ Ruud: ‘A double screen is virtually standard equipment these days,

16 | Advice in bell pepper cultivation PEPPER CULTIVATION | harvest and cultivation area Source: CBS GREENHOUSE HORTICULTURE | surface area and number of companies in the Netherlands HARVEST in mln. kg HARVEST in m2 NUMBER companies SURFACE in acres 2017 370 2005 2969654 2199741 6262441 931000 2005 119 146 268 67 2017 1319355 2018 3114935 2042040 7417460 1426722 2010 74 77 182 53 2010 1311 2018 415 2019 2570494 1334291 6334624 1390828 2015 65 44 148 64 2015 1504 2019 430 2020 3143917 1340389 8496517 2340909 2020 70 38 133 98 2020 1532 2020 440 2021 3114204 1531666 9041708 2593658 2021 71 38 141 105 2021 1628 2021

and not just for peppers, but also for growing tomatoes, for example. Growers used to worry about dense screens causing moisture problems, but now you see screens eve rywhere. Growers use much less energy these days. You no longer find heating tubes with a maximum temperature of 60 or even 650 Celsius among the peppers. Thanks to new cultivation methods, much lower temperatures can now be used. Growers can still achieve the desired tempe ratures in the greenhouse with tubes kept at a lower, more

uniform temperature. That reduces temperature peaks during the night, while still achieving the desired tempera ture over 24 hours.’

Crisis

Since the autumn of 2021, the energy crisis has been a recurring topic when Daan and Ruud talk to growers. Ruud: ‘A grower’s office has the greenhouse climate data on one computer screen, and the rising gas and electricity prices on another. It’s a sign of the times. I recently told my wife that having a history from my time as an independent grower is useful. This era is demanding a lot from growers, and some are finding it difficult to cope psychologically. You have to listen to them carefully, inform them as best you get, and share your thoughts, especially about the short term.’ Even though it’s already late May, it’s impos sible to even think about the 2022/2023 season, believe both cultivation consultants firmly. Ruud: ‘So many factors remain uncertain.’ Daan: ‘Many growers don’t know their sowing and planting dates for the coming season yet.

A grower’s office has the greenhouse climate data on one computer screen, and the rising gas and electricity prices on another. It’s a sign of the times

17Advice in bell pepper cultivation |

Name: Barend Löbker Position: Owner Vortus bv and cucumber, tomato and organic consultant Employed since: 01-06-1999

Name: Daan Boonman Position: Bell pepper, tomato and propagation consultant Employed since: 01-12-1987

Name: Marinus van der Lugt Position: Bell pepper, tomato, aubergine, propagation and herb consultant Employed since: 01-12-2000

Name: Judith van Dijk Position: Office Manager Employed since: 01-09-2016

Partnership with Sweet Pepper Consultancy

This is the Vortus team

18 | This is the Vortus team #

Name: Ruud van den Berg Position: Bell pepper and cucumber consultant

Name: André Becker (Germany) Position: Tomato and cucumber consultant Employed since: 01-11-2018

This is the Vortus team

Name: Ton Peters Position: Bell pepper, cucumber, propa gation and organic consultant Employed since: 01-08-2019

Name: Pieter van Staalduinen Position: Tomato and cucumber consultant Employed since: 01-03-2020

Name: Tineke Goebertus Position: Vortus greenhouse consultants Inc. Canada Employed since: 01-08-1989

19

|

Normally, 80% of growers will have planned this by now: plant at the end of November or early December, then harvest until about mid-October. It used to be a fixed pat tern, but not anymore. We cultivation consultants at Vortus already said to each other last autumn: “We’re about to learn a lot. Things that we’ve never seen or done are about to happen. We might have to question accepted know ledge that has never been open to discussion before.”’

This is not the first ‘crisis’ that Daan or Ruud have expe rienced. ‘Look at how much the price rises in the early 1980s would cost in today’s money,’ they say, giving an idea that a crisis, and especially an energy crisis, is nothing new. After thinking about some of the major and minor hurdles bell pepper cultivation has overcome in the Netherlands, ‘lean years’ and ‘low prices’ were mentioned, along with the years following 2008. Daan: ‘Periods like that are decisive. To put it bluntly, it was survival of the fittest. Many growers were forced to close their doors, and only the strongest companies were able to continue.’ These were also the years in which companies rapidly in creased in size. Ruud: ‘Maybe 10% every year. My brother and I also expanded when we got the chance.’

Diseases and pests are other notorious obstacles to growth in the sector, with Daan mentioning the fungal black root disease (diporotheca rhizophila). ‘In the late 1990s and early 2000s, this was a problem that many growers, but certainly not all of them, had to deal with. Growers used to collect drain water in the ground. After it passed through the slab, it entered a collection system, which was sometimes above ground but as often as not the old, existing drainage system. The fungus contami nated the water, which caused problems.’ The men can also vividly remember viruses, such as the sweet pepper mosaic virus, and the appearance of harmful insects such as the sweet pepper weevil in 2012, the thrips, and more recently the stink bug and louse. Ruud: ‘A lot of companies were sterilised.’

Mobile phone

It’s precisely at such times that Daan and Ruud like to be there for their customers, although on some occasions it’s better to stay out of the way for a while, as is made clear by the two examples they give when asked about moments that they won’t forget any time soon. Daan recalls an event back in 1990. ‘I can still remember events on a stormy day back then as if I was still there. On the day in question, in late January, I was visiting a grower in Westland. It was about 3 pm, I think, and quite a lot of gla zing had been blown out, so he sent me home. I couldn’t do anything at that moment, and we decided to speak on the phone in the evening. Anyway, I set off home. At 7 pm, the phone rang at my home in Steenbergen, but I wasn’t there, because I didn’t make it home until 10 pm. I couldn’t believe what I saw underway: uprooted trees, overturned trucks, blocked bridges. The phone network was com pletely overloaded, and all this time my worried wife with two young children was waiting for my return. I’ve had a mobile phone with me ever since. The first phone I bought was this big,’ Daan smiles, as he sketches an enormous box in the air with his hands.

Ruud also remembers the stormy period well. ‘Entire greenhouses were razed to the ground.’ Daan: ‘I think about 10 storms passed over the Netherlands in successi on, from the end of January to February.’ By the time Ruud became a consultant, mobile phones were already univer sal. He visited a grower as a brand new consultant in early February 2018. ‘When I arrived, the grower was standing there with a roll of bubble wrap in his hands. His facial expression said enough. About 600 panes of glass had been blown out by a whirlwind. I greeted the grower, wis

| Advice in bell pepper cultivation

20

hed him luck, and left quickly, as he obviously had other priorities. Moments like these leave a lasting impression. The grower even had to re-sow some areas, and could only replant much later than normal. I think I did the right thing at the time. What we sell is expertise and experience. Fortunately, the grower is still a customer.’

Personal bonds

Looking to the future, Daan and Ruud still expect to pay many more visits to greenhouses. Daan: ‘We often start in the greenhouse, then have a chat over coffee. When Covid-19 first broke out, I worked from home 4 days a week. These days, everything is possible, such as accessing climate computers with the grower’s consent or video calls, but the feeling isn’t quite there and it’s more difficult to pinpoint problems in cultivation. For me, there’s only one

solution: go into the greenhouse and look around.’ Laughing, he continues: ‘That meant I quickly got fed up with working from home because of Covid. If growers didn’t mind, I started visiting them again, that’s what I wanted.’ Ruud agrees. ‘I also returned to visiting greenhouses before long. I did one round of customers in Germany remotely over two days, but then I went back to the previous methods. I think that’s also our strength: looking, smelling, feeling, listening and sharing thoughts on site.’

Daan cites another piece of history. During his time as a consultant working for the Dutch government, there were lots of reorganisations. ‘There was even talk of privatising the consultancy. At the time, the first private consultants also emerged, including Vortus. Government information has always been free of charge, there was no table of fees. One of the downsides was the high turnover of staff, so growers couldn’t rely on a fixed consultant, which is what they wanted. Private agencies offer more certainty in this respect.’ From an economic point of view, it might sometimes make more sense to have a single consultant visit all the growers in a region, but that isn’t how Vortus works. Daan: ‘It’s precisely because of the bond that you have or build up with a grower that you put in the hours to solve a problem. That can mean spending more time

than planned, which messes up your daily schedule.’ Ruud nods: ‘That happens, but in my experience other growers understand. If things are going well, a visit can be concluded more quickly. But when it’s the other way around on another day, there’s space for some special attention.’

Rubbish bag

Many years ago, a grower once jokingly referred to Daan as ‘a pastor’. ‘He said: “You’re just like the pastor. When you arrive, I have to confess what I’ve done wrong, and then you lecture me on what I have to do in the coming period.” This anecdote is already pretty old. In the past 20 years, I’ve seen a lot change. The days when I set up a company’s climate computer with the grower’s consent are long gone. That would involve standing behind such a climate computer the size of a cigarette machine, and turning the knobs.’ Ruud recognises the image. ‘That is becoming increasingly unimaginable. The average grower now has much more in-house, and also has in-house specialists in all kinds of areas.’ The cultivation consultants no longer always deal directly with the grower, as larger companies often employ managers. Daan, laughing: ‘I’ve got customers with multiple sites, where sometimes you have to be a bit diplomatic to raise issues and get things done.’ Ruud: ‘Then you say: “Go and talk to so-and-so”, in the hope that

In the hall at the bell pepper grower’s current location, there are still photos of the site where Ard’s father used to grow.

In the hall at the bell pepper grower’s current location, there are still photos of the site where Ard’s father used to grow.

He said: ‘You’re just like the pastor

Advice in bell pepper cultivation |

21

you can enlighten people. Our work needs people skills.’ Daan nods: ‘Some customers call us frequently, others rarely or never. But if the latter do call, then you know they need you there yesterday, because they have a real problem.

Thanks to modern mobiles, cultivation consultants always have a camera at hand, so rubbish bags for cuttings are no longer necessary. Daan: ‘In the past, you could easily visit about seven or eight growers a day, and at the end of such a day I’d have a rubbish bag full of plant material. Wherever you came across something, you took a cutting or a sample. Then we would discuss our findings in meetings.’ This is typical of the experiences of consultants who visit many places. Little has changed in that regard. Ruud: ‘If Epsom salts have accidentally ended up in the A-bin somewhere, you hear about it. It’s a mistake that still happens.’

Daan and Ruud list 7 advances in bell pepper cultivation over the years:

1 The greenhouse has changed: higher, lighter, larger surface, different lengths and widths.

2 Due to the large sizes of companies, there are many more workers present.

3 Lots of modern tools, from picking systems to internal transport, and from electric carts to path registration.

4 Much more interest in biological control.

5

The basis of fertilisation hasn’t changed! The way drain water is used is the main factor that complicates or hinders fertilisation.

6 Peak production in 1985 was 20 kg/m2 Today, the figure is 35 kg/m2

7 Blossom end rot affecting quality is no longer a prominent problem. Fruit rot, on the other hand, is more prominent.

22

| Advice in bell pepper cultivation

BLUE RADIX CONGRATULATES VORTUS ON ITS 40TH ANNIVERSARY! +31 (0)180 203 203 - info@oxin-growers.nl oxin-growers.nl Oxin Growers congratulates Vortus with its 40th anniversary

Cucumber grower still opts for LED: ‘This looks like what you have in your head’

‘Walk on, turn right and then down that hallway.’ In the background is the sound of sorting cucumbers. We enter the office and meet growers André and Kees Vahl at the main location in IJsselmuiden.

When we are having a cup of coffee, Dries also walks by. The three of them form the management of the cucumber nursery, which also has an organic cultivation location for tomatoes and peppers just down the road and a branch in Germany. It is mid-April, cultivation is in full swing eve rywhere. Not much later Leo Lansbergen of Fluence joins in and, having just returned from a visit to growers in the United Kingdom, Barend Löbker also joins. This completes the ‘team’ behind the cucumber growers’ decision to opt for LED lighting.

In the autumn of 2019, Barend and Leo met for the first time with grower Kees. How did that happen?

Barend: ‘I had the opportunity to speak in Austin, USA, in October 2109 at the PHOTOx Summit organized by Fluence. I was asked to tell about my experiences with lighted cultivation. I did that together with Ep Heuvelink of Wageningen University & Research. The university conducted trials with full LED lighting in cucumber. I had followed those tests. I ran into Leo at the event. He was really just employed by Fluence.’

Leo: ‘That’s right, it was literally my first week. We got talking. The event was about full spectrum LED lighting. Barend already knew this from tests, he said.’

Barend: ‘It was at WUR in Wageningen that I first saw cu cumbers grow normally under LED lighting that year. That had never really worked until then. Anyway, I hadn’t seen it yet. With full LED it worked in that test.’

04 24 | Fluence LED at Vahl

Fluence LED at Vahl

The Vahl brothers had also been working on their own experiments with lighting for some time at the time.

HPS fixtures were already installed in part of their greenhouse. Trials with LED lighting had also been carried out. Didn’t like them?

Kees: ‘We have tested several times with LED lighting in our cucumber cultivation. Each with a red-blue spectrum. That was not easy for us every time. As a result of those tests, we had actually already written off LED in cucumber. Until Barend called. He said: ‘Kees, I’ve now seen some thing that you should give another chance. This looks like what you have in your head.’ Then I called Leo anyway.’

Barend: ‘I was barely outside when I called Kees.’

The result was not much later, so a first conversation. Didn’t that go very quickly?

Leo: ‘Yes, indeed! Fortunately, it turned out that both Vahl and Vortus were eager to share knowledge. Like us. Moreover, we were all willing to feed each other with in formation. That makes it a great example of how the entire ecosystem comes together.’

Barend: ‘Both Leo and I are cultivation technical people. This allows us to spar well together, also with Kees. We both took a piece of knowledge with us to IJsselmuiden, but it is Kees who ultimately makes the choice, together with André and Dries. They are in control.’

Kees nods. ‘For us, the cultivation consultant is someone who provides information. Someone with whom you can consult, without the cultivation consultant forcing the grower his way of growing. We must ultimately bear the responsibility. As a grower, you make many decisions every day. It’s nice to get good advice.’

Leo agrees. ‘Before I started working at Fluence as a service specialist, I worked at a breeding company and before that as a cultivation consultant. From that time I know how important communication is. I think it is just as important for an educator or consultant to use your ears as your mouth.’

Together, the men agreed to start a trial on 2000 squa re meters. But by then it was already winter. Wasn’t it already too late?

Leo: ‘No, but there was some rush to be able to include the last part of the darkest four months in the trial. It was planted on January 2. On February 3, the lamps were swit ched on in a greenhouse in which as much as possible could be controlled separately. A separate heating com partment, separate aeration and watering came in handy for this. It was not possible to administer CO2 separately and measure EC.’

Barend: ‘With the trial, learning to grow with full LED really started for us. In Kees’ greenhouse we learned what we could do with the lamps. Until then, I had mainly seen

it at WUR.’

Leo: ‘We started registering a lot from the start.’

Barend: ‘First, the plants were planted with a normal density. However, the plants grew so fast that we realised within a week that an extra stem was necessary. I had already heard about this from colleague Tineke (Goeber tus ed) of Vortus from Canada. At the same time, she ran a similar test, also in terms of design, with full LED. Fluence hung there too. Leo didn’t even know that when we first sat down at the table. I could also spar well with Tineke, just like with Kees and Leo. We saw many of the same things happen. One of the conclusions we drew was that in a fully LED-lit cultivation you needed a single plant. Not a pinched plant. Such a lamp produces so much energy that the foundation, the plant, must be very strong to be able to convert all the energy into cucumbers.’

Kees: ‘For us, that test was necessary to dare to scale up. Full LED in cucumber was something new that we didn’t just want to rely on tests at test stations. We really wanted to see it with our own eyes in our own greenhouse. When that turned out to be going well, we went for 2.1 hectares.’

What makes this full LED cultivation in cucumber so special?

Leo: ‘Based on solid test results in close collaboration with a cultivation consultant, grower and LED supplier, this became the first long-type cucumber crop grown under full-top LED in the Netherlands. What is very special is that the Vahl brothers have switched from unlit cultivation to fully LED.’

Barend: ‘For us it was a risk, once things were going well for Vahl’s cultivation, to say: ‘Full LED from Fluence is good.’ We like to remain independent as a consultancy. On the other hand, we also believe that if something is good, you should say so. That does not mean that we are no longer independent. We also serve plant propagators and growers at the same time. The same applies. He who has good plants, does well, and if we are asked, we will name what is good. The grower still has to choose for himself.’

If there was already a scenario for lighting with full LED in cucumber, it could go in the trash last winter

25Fluence LED at Vahl |

The latter also applies to the cultivation consultant with whom the grower wants to work, right?

Barend: ‘Sure. Growers got to know me through then consultant Rien Rodenburg. I was going to take over his customers.’

André Vahl, who does computer work in the cafeteria during the conversation, still remembers it well. Andre, laughing: ‘At first, Barend did not immediately reach all growers when he took over Rien’s customers. Some thought he was still too young and inexperienced. Ho wever, they soon got back to it. He was soon welcome everywhere, when they saw what he has to offer.’

Kees: ‘Cultivating is the same as getting your driver’s li cense. Ultimately, you learn the trade in practice. This also applies to information officers.’

The men discuss the shortage on the labor market and the difficulty of finding new, skilled people.

Leo: ‘When I was still at school, you could easily have sixty people in one academic year on a horticultural course Now the rinse is much thinner.’

Kees nods: ‘I see it in my daughter at school. Very few choose horticulture there. That also means that fewer new, young information officers are emerging.’

When the men sit down at the table, it’s not just about cultivation-technical matters. That much is clear. How did Kees end up in Germany as a grower?

Barend: ‘A German customer of mine had to deal with the sudden death of a manager. The other manager and owner was so shocked by this that he no longer dared to continue the planned expansion on his own. Shortly be

fore that, Kees had dropped something along the lines of ‘wanting to look abroad’. That tragic death made me think about that again. I decided to poll Kees.’

Kees: ‘A day later, after consultation with my wife, I drove that way. I ended up staying there for 5.5 years. We went to live there. I became a shareholder in the nursery in Bralitz. I still go there regularly, although I now live next to one of our locations here in IJsselmuiden. The fact that I also started growing in Germany was certainly thanks to Barend.’

In conversations about the move to LED lighting, the complete picture was extensively examined and dis cussed. Which topics were reviewed?

Kees: ‘We discussed everything prior to the project and took many things into account beforehand. Winter culti vation with lighting starts with sales. If it isn’t there, don’t start it. Nevertheless, electricity becoming very expensive was an unforeseen scenario.’ Kees refers to the energy crisis that has been making itself felt in greenhouse horti culture since last autumn. No one escapes it.

Barend: ‘We are now making the same considerations that we previously made about lighting, but now about energy. You have many variables to take into account. Plant dates, the amount of pieces you want to get... You need to have a plan for this, but in such a way that you are still flexible afterwards to react to what is going on. That is the challenge, always.’

You are used to something in horticulture, aren’t you? Kees: ‘Unfortunately yes. I still remember the Ehec crisis of 2011 well. Then we had to throw away one million

Fluence LED at Vahl

26 |

cucumbers. Precisely in the period when we were also working on the first drilling for geothermal energy. I will never forget those hectic times.’

Leo: ‘And in the end it wasn’t even the cucumbers. But yes, that only became apparent later.’ Barend, with a sense of understatement: ‘That cost a lot of money back then.’

Vahl’s geothermal activities have been mentioned. Vahl was there early.

Kees: ‘You have to keep developing, don’t you.’

Barend: ‘If father Vahl hadn’t replaced his older greenhou ses with higher greenhouses in the past, with fewer loose paths, it would have been very different now. Now there is a modern, innovative company here in IJsselmuiden. It gives the opportunity to illuminate.’

Kees: ‘Replacing the older greenhouses was a step my father took when it turned out that me and Dries were joining the company. After my father left, we invested in geothermal energy.’

Leo: ‘Innovation and sustainability, that’s what this compa ny is all about. I like that.’

Kees nods: ‘We really think like a family business. You hope that the next generation will take over and you want something good to be there. A second geothermal source is important here. That source had been coming for a while, but now it’s really here. It took longer than hoped.’

In light of the current crisis followed by: ‘Actually, we are lucky that we can always sleep.’

Has that never been different?

Barend: ‘During the time that clavibacter was on the rise in tomatoes, André really had a headache. It was at the time when Vahl also had tomatoes. In the fall. Autumn tomatoes. This was chosen because of virus pressure in cucumber.’

Kees: ‘We also had really good years with those autumn tomatoes. The tomatoes yielded good prices in those years. Until lit cultivation came up.’

Was tomato new to Vahl at the time?

Kees: ‘We had always had tomatoes as a hobby. So we knew we could do it.’

Even today, tomatoes are not completely out of sight. There is a test row in the greenhouse.

Kees: ‘As a grower, you always keep some options open. This is especially useful at this time. With what is happe ning now, an illuminated tomato cultivation could be an option. As a grower you always try to look for what no one or only a few are doing yet. It’s not easy, but you try. That was the case with autumn tomatoes, with geothermal heat and now with full LED again.’

The row of tomatoes is in the greenhouse where cu cumbers were grown on 2.1 hectares with full LED in the winter of 2021/2022. It is noticeable that the plants are relatively young.

Kees: ‘This spring, the cultivation went out early in the

Barend, Kees and Leo

Fluence LED at Vahl |

27

illuminated greenhouse and we started a new cultivation there. We hadn’t thought of that in November, but two months later we opted for this because the costs were too much for us, even with the use of geothermal heat. Elec tricity became so expensive. We then made a calculation, quickly put in a new crop, we started to use the lamps differently and in that way we got to the market early. That went well. Until we encountered a very dark period in April. Then you just didn’t want to turn on the lamps, given the cost.’

Leo nods. ‘Even if you have a plan, you have to stay flexible. After all, horticulture is characterized by many fluctuations. You have to face that. A sounding board will help. That is my role, but certainly also Barend’s.’ Kees: ‘Friends of mine from other sectors don’t get it when I say that in horticulture you often don’t know exactly what you are going to earn until very late. You have good and bad years. It is important that these less good years do not occur too often in succession. And that if things go a little less, you can explain why. As long as you can do that, you’ll be fine.’

Once in the greenhouse, the new cultivation in the greenhouse with LED lamps is in full swing. Kees, Leo and Barend are walking around. Satisfied?

Kees: ‘What I find most special is that there is virtually no abortion, not even in high summer. In my opinion, you can really see the effect of LED here, especially if you use it all year round.’

Leo: ‘Many growers still have an HPS mindset. Now that they also use LED in the summer, you try to get the most out of it. We started with maximum lighting, but now that energy prices have started to rise, the focus is on optimal lighting. There is still a lot to learn about that. In the first year, the greenhouse was dimmed to radiation, now we dim on energy prices. It’s a matter of being flexible.’

Kees gives an example: ‘If I had known a month ago that the cucumbers were going away for 80 euro cents towards Easter, I would have switched on the lights. But you can’t predict that.’

Barend: ‘If there was already a scenario for lighting with full LED in cucumber, it could end up in the trash last winter. So to speak. Together we have already gathered a lot of valuable knowledge and stored it. So we really do keep the script.’

Full LED fixtures above the cucumbers at Vahl

| Fluence LED at Vahl

28

The Fluence team wishes Vortus a HAPPY 40TH ANNIVERSARY! Learn more and talk to a Fluence expert today, or visit www.fluence-led.com/case-studies @Fluence_Global © Copyright 2022 Fluence Bioengineering, Inc. GlobePlantbv|Veckdijk62b3237LVVierpolders|+31(0)181409090|www.globeplant.nl congratulates Vortus ...grownwithcare ! ontheir 40thanniversary Workingtogetherfortheplantsofthe bestquality, thatiswhatwebothstandfor.

For decades Henk Koot gave technical cultivation ad vice in the greenhouse horticulture and he visited many growers. First in government service, later on behalf of Vortus, a consultancy that he set up himself together with Siem Voogt.

Henk has been retired since 2008. Since then, ‘the real fanaticism has gone’, he says when we visit him at his home in the summer of 2021. Nevertheless, when he takes us back in time, it turns out that Henk still has the stories from then well ready. And that the grape bush is still well maintained. ‘I just removed the growing points.’

Two pipes, twelve children Henk, 79 years old, was born as a son in a family of twelve. A horticultural family in Berkel en Rodenrijs. Father had a vegetable growing business together with his brother, Gebroeders Koot. Henk experienced the cultivation of tomatoes and cucumbers, among other things. ‘I have experienced the days of growing under flat glass.’

Together with his younger brother, he was the only one of twelve children who was allowed to continue studying. Henk did that at the Mulo in Pijnacker. He also went into service, as was the case at the time. ‘After that I worked at the family business for a few months. Our company had two hectares of glass, which was large at the time. We had two chimneys, as they used to say, especially in the Westland.’

Colleagues, not competitors

His career as a consultant started for Henk in 1964. Octo ber 1st to be exact. ‘I applied for a vacancy for an assistant assistant at the Naaldwijk Research Station at the time. That was a semi-government institution. I became a civil servant and had to test run first.’ On September 1, 1965,

‘When I was introduced as a public information officer, I was lucky that I was already able to cut lettuce’

Henk at home with his

bush,

05 30 | Henk Koot: consultant is going to sell knowledge

Henk Koot: consultant is going to sell knowledge

grape

summer 2021 At the time, I don’t think that the opportunity to learn first without having to immediately turn a turnover, consultants don’t get that anymore, if at all

Henk then became an information officer. He was assig ned the Rotterdam-East district. ‘I became the successor of Ser Kamerling. Our task as information officer in a district was to bring knowledge from the Research Station to practice, to the growers.’

Each district had a study club. Knowledge transfer took place there. ‘Evenings were organized where we, as an information officer, shared information from variety trials, which we conducted ourselves, about cultivation tech niques, and lectures were also organized for which we invited specialists. Growers were then really colleagues and not competitors. It was here that the foundation of the success of Dutch greenhouse horticulture was laid.’

The information service arose from the Marshall Aid that was set up after the Second World War. The service was (partly) financed with money from the extensive aid plan initiated by the Americans. ‘Growers could then call on us for free. They called us, we went there and tried to solve their problems. If that didn’t work, we still brought in the specialist from Naaldwijk. That’s how it went.’

Being tested

Henk still remembers his first lecture as a public informa tion officer. ‘That was about lettuce varieties. In front of eighty people, I was then allowed to tell them which varie ties were good and what our results from the trials were. You should know that I was sweating pus and blood then.’

At least as exciting were the first visits to growers in his region. One of them, at the time a lettuce grower from Nieuwerkerk aan den IJssel, asked almost immediately when I got there: ‘Can you cut lettuce?’ I had to change and could start working immediately. After twenty minutes of cutting lettuce, it was time for coffee. The grower had seen enough. I turned out to be able to. I was lucky to have learned it at home. My father had also grown lettuce. Later I understood from Ser that when he introduced himself to this grower he had to help mow purslane. That is much more difficult and I could never have done it. That’s how it went back then. You were tested, but after that the ice was broken.’

Economic work

Until the mid-1970s, Henk was fully satisfied with his cul tivation technical job. This changed with the advent of the interest subsidy scheme. ‘Growers then had to have an in vestment plan in which they could demonstrate that they were going to make a profit. If the plan was good and ap proved, the mortgage interest burden for the grower could

be reduced by half.’ As a result of this arrangement, Henk had to make many investment plans and audit reports of companies from that moment on. ‘The government asked us to put much more emphasis on economics. We also had to meet more and more. I regretted that. I would much rather be involved in the cultivation.’ In 1980 Henk stopped working as an information officer in government service. He went to work for supplier Codrie, a company owned by Cor van Driel from Bleiswijk. That same year, that com pany was taken over by Brinkman. There Henk met Siem (Simon was often called that) Voogt again. He had already met him at the experimental station in Naaldwijk. ‘Siem was a researcher there. I have had lessons from him. He was a specialist in feeding schedules and with the switch from growing in the ground to growing in substrate, these became increasingly important.’

Consulting work got a face Henk did not stay at Brinkman for a very long time. ‘I soon found out that I am not a salesperson, but I can sell good knowledge.’ An example comes to mind. ‘At the time, I wor ked as a consultant for Brinkman at a horticulturist in the greenhouse. That greenhouse was full of weeds, because the soil disinfection with methyl bromide had failed. He asked me what I thought of that. I agreed with him. In my role as Brinkman’s representative, that was not ‘handy’, as I now understand. It was the time when there were many problems surrounding soil decontamination. The cultivati on had to be grown from the ground, on substrate, and for that they needed watering systems. At the time, there was a lot of demand for it and the rapidly increasing demand was not kept up with the supply. More was sold than could be installed. I therefore became a messenger of ‘bad’ news, ‘delayed news’. I hated that. I was less involved in cultivation techniques and growers started to doubt me, while I had built up a reputation as an information officer.’

Together with Siem, a separate consultancy service was set up within Brinkman in 1981, the predecessor of the current Vortus Greenhouse Consultancy. ‘In this way we gave our consultancy work a face.’ One year later, Siem took Vortus over from Brinkman. ‘He became director and I started working with him. Siem knew everything about nutrition and water and I had knowledge and experience with varieties, cultivation and climate control. That turned out to be a good combination.’

It was, as mentioned, the time of the switch to substrate. ‘At the time, people thought there were three options. Rock wool, peat bales or running water. Researchers first thought it was going to be running water, but it turned into

Henk Koot: consultant is going to sell knowledge |

31

rock wool.’ Another development was the rise of climate computers. ‘Then the computer controlled the climate. But as a grower, it was important to keep checking the con dition of the crop to make sure everything went well. That required craftsmanship.’ It was also the time of discussion about the pre-night temperature reduction. ‘It was hotly debated at the time. This was due to the advance of cli mate computers. In order to achieve the light-dependent 24-hour temperature, this could be regulated by lowering the pre-night temperature. For us it was a foregone con clusion that this was good for the crop.’

Black-on-white report

In the first five years, the team of consultants grew from two to seven people. Henk points to a crucial moment for this. ‘In those early days of rockwool cultivation, there was a bell pepper grower in Bleiswijk who had problems with his cultivation. Halfway through the season, his wife called us. Her husband was getting stressed because the cultiva tion was not going well. Advice had already been sought from all sides, but they were unable to get things up and running. Then Siem and I went by and we got things going. Among other things, the pH turned out to be much too high and the unit used by the grower was not used properly. From the moment that things started up again at that grower, that was the signal in the world that you could always knock on Vortus for growing fruiting vegetables on substrate.’