EVAPORATOR

L1 L2 L3

Use Bubble Curve for Subcooling

PSIG

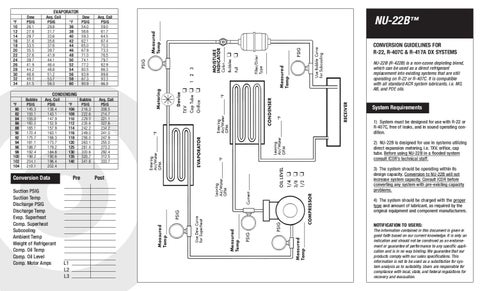

System Requirements 1) System must be designed for use with R-22 or R-407C, free of leaks, and in sound operating condition.

❑ ❑ ❑

3) The system should be operating within its design capacity. Conversion to NU-22B will not increase system capacity. Consult ICOR before converting any system with pre-existing capacity problems.

1/4 3/8 1/2

OIL LEVEL

Measured Temp

PSIG

COMPRESSOR

Current

PSIG

Measured Temp

NU-22B (R-422B) is a non-ozone depleting blend, which can be used as a direct refrigerant replacement into existing systems that are still operating on R-22 or R-407C. It is compatible with all standard ACR system lubricants, i.e. MO, AB, and POE oils. RECEIVER

Leaving Air/Water GPM

°F

CONDENSER

Measured Temp

Filter/Drier Type

❑ ❑ Full

Color Bubbles

°F

MOISTURE INDICATOR

Entering Air/Water GPM Leaving Air/Water GPM Use Dew Curve for Superheat

CONVERSION GUIDELINES FOR R-22, R-407C & R-417A DX SYSTEMS

2) NU-22B is designed for use in systems utilizing direct expansion metering, i.e. TXV, orifice, cap tube. Before using NU-22B in a flooded system consult ICOR’s technical staff.

°F

EVAPORATOR

Post

Measured Temp

Suction PSIG Suction Temp Discharge PSIG Discharge Temp Evap. Superheat Comp. Superheat Subcooling Ambient Temp Weight of Refrigerant Comp. Oil Temp Comp. Oil Level Comp. Motor Amps

Pre

PSIG

Conversion Data

1 2 3

Avg. Coil PSIG 208.5 214.7 221.1 227.6 234.2 241.0 247.9 255.0 273.2 292.4 312.5 333.7

Device TXV ❑ Cap Tube ❑ Orifice ❑

°F 106 108 110 112 114 116 118 120 125 130 135 140

Measured Temp

Bubble PSIG 216.3 222.6 229.0 235.6 242.2 249.0 256.0 263.1 281.4 300.6 320.7 341.8

CONDENSING

NU-22B™

Metering

Avg. Coil PSIG 138.4 143.1 147.9 152.9 157.9 163.1 168.3 173.7 179.2 184.8 190.6 196.4 202.4

Avg. Coil PSIG 59.0 61.7 64.5 67.4 70.3 73.3 76.5 79.7 82.9 86.3 89.8 93.3 96.9

°F

°F 80 82 84 86 88 90 92 94 96 98 100 102 104

Bubble PSIG 145.3 150.1 155.0 160.0 165.1 170.4 175.7 181.1 186.7 192.4 198.2 204.1 210.1

Dew PSIG 54.0 56.6 59.3 62.1 65.0 67.9 71.0 74.1 77.2 80.5 83.9 87.3 90.9

°F 36 38 40 42 44 46 48 50 52 54 56 58 60

Entering Air/Water GPM

Avg. Coil PSIG 29.8 31.7 33.6 35.6 37.6 39.7 41.9 44.1 46.4 48.8 51.2 53.7 56.3

PSIG

°F 10 12 14 16 18 20 22 24 26 28 30 32 34

Dew PSIG 26.1 27.8 29.7 31.6 33.5 35.5 37.6 39.7 41.9 44.2 46.6 49.0 51.5

4) The system should be charged with the proper type and amount of lubricant, as required by the original equipment and component manufacturers. NOTIFICATION TO USERS: The information contained in this document is given in good faith based on our current knowledge. It is only an indication and should not be construed as an endorsement or guarantee of performance to any specific application and is in no way binding. We guarantee that our products comply with our sales specifications. This information is not to be used as a substitution for system analysis as to suitability. Users are responsible for compliance with local, state, and federal regulations for recovery and evacuation.