SHOWCASING AND CELEBRATING OTAGO AND SOUTHLAND’S ENGINEERING AND MANUFACTURING SECTOR

SHOWCASING AND CELEBRATING OTAGO AND SOUTHLAND’S ENGINEERING AND MANUFACTURING SECTOR

Every engineering company in this part of the world has a unique story. This publication is all about getting those stories out to a broader audience, SOREC founder Gareth Evans says.

He first imagined the Southland + Otago Regional Engineering Collective in 2017 when he arrived in Dunedin as CEO of Farra Engineering, a company with a 160 year history.

Seeing the common issues faced by engineering firms in the region, including a shortage of skilled labour, Gareth began thinking about collaborative solutions.

‘‘I felt that if the whole sector was starting to struggle, it was best for us to work together,’’ he says. ‘‘I went out and found other people who were willing to try something a bit different.’’

With some government funding and support from local MPs and members of the engineering community, it took well over a year of work from the steering committee before SOREC was launched in late 2019. Over $7 million in business capability grants were facilitated during this early period, as well as the establishment of the SOREC Academy.

While the initial concept for SOREC was to attract engineering work to the region, it soon became more about creating a pipeline of skilled labour to meet the demands of the existing industry.

As a result, the Academy was launched, as a gateway for young people into the engineering industry, and developing them to fit its specific needs.

‘‘When we were doing the feasibility study, we quickly realised the constraint wasn’t the market, it was the labour force,’’ Gareth explains. ‘‘So we pivoted pretty quickly. That required building deep relationships with schools so they would trust us to look after their kids.’’

An important step was the appointment of James Bracewell as SOREC Skills Partnership Manager.

‘‘The main thing was getting someone onboard fulltime who could really drive the skills and apprenticeship pathways,’’ Gareth says. ‘‘Having someone committed to that has made all the difference.’’

Another game changer has been the more recent partnership with Business South. After proving that the SOREC concept was strong enough on its own merits, the organisation considered who could help them grow the model during its next stage.

Business South CEO Mike Collins says it made perfect sense for them to team up for the benefit of the engineering sector in the region.

‘‘SOREC were doing a lot of great work around advocacy, training, events, and networking,’’ he says. ‘‘Business South did a lot of that already, so I thought through economies of scale we could work in partnership to provide those services with SOREC.’’

The partnership began late last year, with SOREC’s administrative functions being supported by the Business South team. Gareth Evans has joined the Business South board, while James Bracewell now works with the team based in the Dunedin office.

‘‘Being based in the office enables James to work together more closely with our apprenticeship programme, and other programmes we support,’’ Mike says. ‘‘They’re now organising events and collaborating a lot closer than would have happened if this partnership hadn’t come together.’’

On Thursday April 18, the SOREC Summit 2024 will be held at the Trades Training Centre in Dunedin. The second such event that the organisation has held, the summit will focus on future proofing manufacturing and engineering companies in Otago and Southland.

Because of the timing, Mike says this publication is a great way to highlight what is going on across the south in those industries.

‘‘The whole rationale behind it is really to showcase all the amazing stories,’’ he says.

‘‘It is hard sometimes to get people to open up and tell their story, but we wanted to give them a platform to speak about their experiences, the challenges and the great achievements. And to celebrate the whole engineering and manufacturing community.’’

Farra Engineering CEO Gareth Evans first envisioned SOREC in 2017.

Farra Engineering CEO Gareth Evans first envisioned SOREC in 2017.

We are passionate about ensuring the sustainability of engineering in our regions, an incubator for industry to work together to grow and share the ‘pie’.

Let us know how we can help you and your company by answering this SOREC, Business South Survey: Scan the QR code.

www.powerhousewind.co.nz

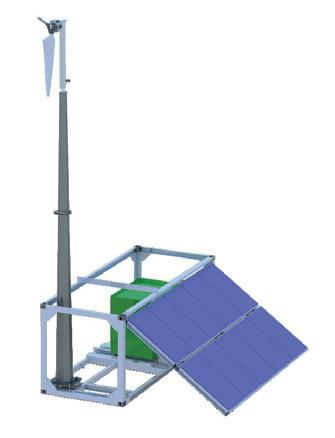

Powerhouse Wind stands at the forefront of renewable energy innovation in rural Aotearoa, delivering an unmatched combination of wind and solar energy solutions through their flagship products: the PowerCrate® and Thinair™.

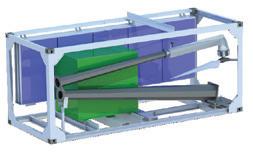

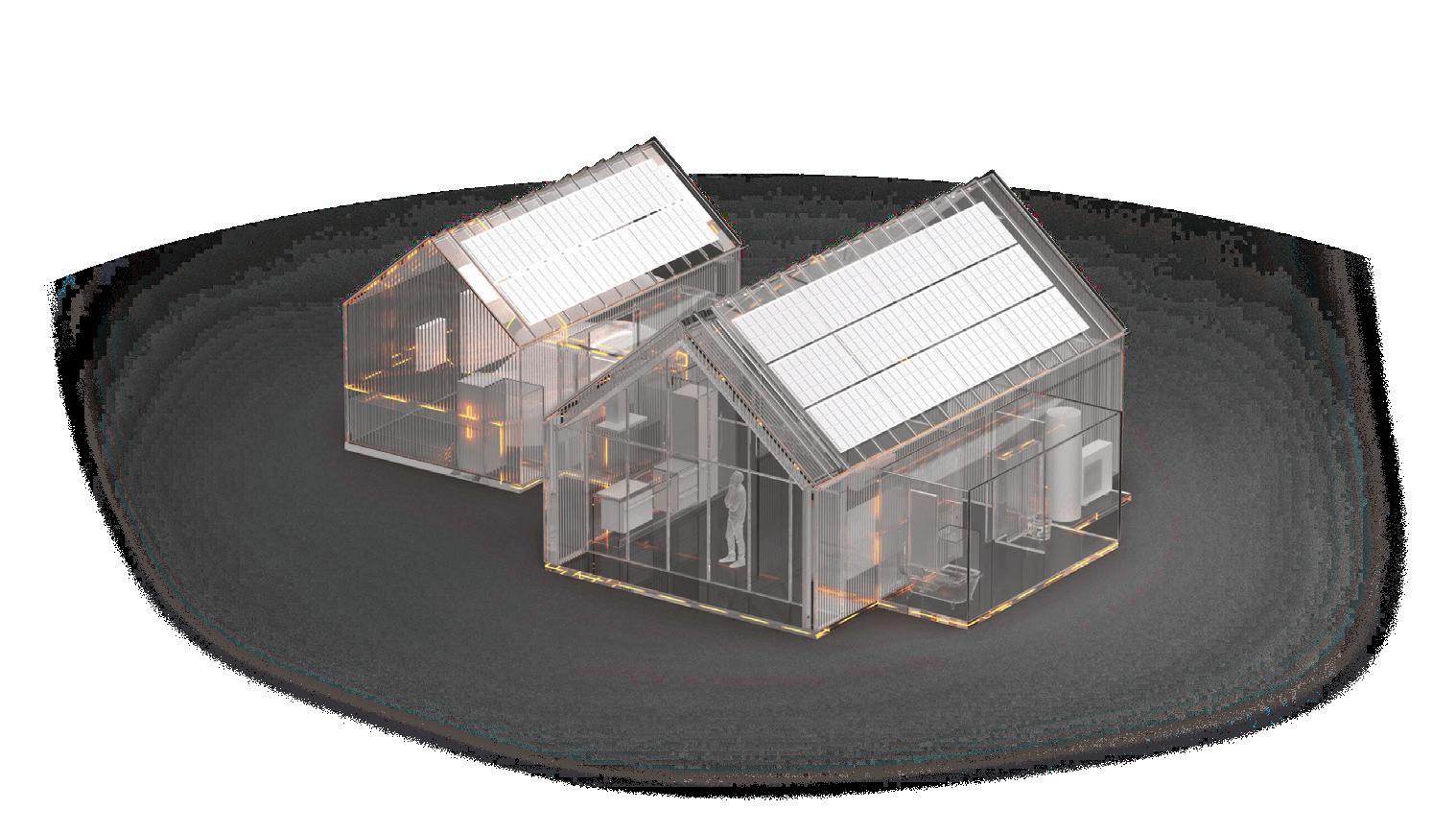

PowerCrate is a first-of-its-kind hybrid renewable energy module, integrating wind and solar power in a turnkey energy module for all seasons.

This innovation is vital for rural and remote areas where traditional grid connections are unreliable or nonexistent. PowerCrate is a sustainable energy solution for remote construction and telecommunications, lifestyle blocks and agriculture; it is an energy resilience solution in an increasingly uncertain climate.

Powerhouse Wind is particularly

proud of Thinair - New Zealand’s only commercial small wind turbine, a testament to more than a decade of dedicated development and testing. Featuring an elegant single-bladed design with a patented teetering hub, it exemplifies their commitment to robust, fit-for-purpose solutions for New Zealand and its gusty winds.

Powerhouse Wind leverages Dunedin’s engineering ecosystem for manufacturing while ensuring nationwide field service. Recent successes include the deployment of PowerCrates across the South Island and dynamic showcases at major agricultural events. They will next feature in the Sustainability Hub at Fieldays® in Mystery Creek, Hamilton.

Powerhouse Wind plans to expand production in response to growing global demand for energy resilience, and is inviting investment and business partnerships, as they solidify a pivotal role in rural energy transition.

www.ceneng.co.nz

A deep passion for farming and a continuous drive to support the agricultural industry in innovative ways are driving local firm Cen Eng Ltd to new heights of excellence.

The Omakau based company is passionate about farming and constantly on the lookout for new ways to support the industry.

Specialising in machinery repair, product design, and the execution of complex projects, Cen Eng prides itself on delivering services that are both reliable and efficient.

The company boasts well-equipped workshops that enable swift and effective in-house repairs and manufacturing of parts.

This capability, paired with their fleet of mobile vehicles, ensures that customer operations remain uninterrupted, providing vital support precisely when and where it’s needed.

The diversity of skills within the Cen Eng team allows them to offer a broad spectrum of solutions, catering to a wide range of customer needs.

One of the key aspects that sets Cen Eng apart is the presence of Chartered Mechanical Engineer Steve Hore, whose expertise enables the design of bespoke solutions tailored directly to customer specifications.

This personalised approach, combined with the company’s proven track record in maintaining essential community services like water supply, underscores Cen Eng’s unique position in the industry as a provider of critical, customized engineering solutions.

• Hybrid energy—wind, solar, and diesel integrated with Li-ion batteries for energy security throughout the year.

• Transportable and deployed in less than two hours for permanent or temporary power.

Contact us today to learn how we can boost your resilience.

NZ PRODUCT ACCELERATOR www.nzproductaccelerator.co.nz

In the ever-evolving landscape of technology and innovation, the NZ Product Accelerator (NZPA) aims to supercharge the research and development processes of local companies.

In crowded tech fields, companies face many challenges and opportunities.

For those seeking meaningful change and unlocking new possibilities, the NZPA serves as a trusted partner, providing a unique blend of expertise, resources, and support.

With a focus on connecting industry with research expertise, NZPA empowers companies to solve industry problems and boost productivity, through targeted connections with the academic and science research community.

Comprising a network of over 100 researchers from nine academic and governmental research organisations, they aim to apply their deep wells of R&D experience to actual market problems.

One shining example of this process can be found in a collaboration between NZPA and world leading manufacturer Fisher & Paykel Appliances (F&PA).

The journey began with F&PA's recognition of the urgent need to confront climate change and reduce carbon emissions.

They established a Carbon Zero Smart Home R&D Institute to tackle the subject, then started to look for partners. They turned to NZPA for guidance and support, and together embarked on a transformative journey to identify research capabilities aligned with the vision of decarbonisation.

The result was a ground-breaking collaboration with GNS Science, a

renowned partner within NZPA's network, to address the challenge of enhancing thermal insulation performance.

But the collaboration doesn’t stop there. While GNS acts as the lead organisation, they are able to collaborate further with internal teams from F&PA, and also postdoctoral, PhD, Masters and undergraduate student researchers to maximise talent being applied to the problem.

This broad spectrum approach helps identify both short term wins and longer term step changes that can drive real changes in reducing energy consumption and the carbon footprint of temperaturecontrolled appliances.

The project has garnered $700,000 in funding for the first year, with the expectation that the project will continue for several years.

What sets the collaboration apart was the seamless integration of F&PA's industry insights and application knowledge with NZPA's expertise in connecting industry with research expertise.

Through NZPA's Enterprise Engagement Model, F&PA was assigned a project lead to guide them through every stage of the R&D process—from scoping to project team identification, contracting, deployment, and ultimately, the delivery of project objectives.

As part of the engagement process, NZPA facilitated connections between F&PA and a diverse range of stakeholders, both within and outside its network.

These connections were instrumental in enabling the project and driving collaboration across multiple streams of work, each focused on exploring the fundamentals of reducing heat transfer and applying them to temperaturecontrolled appliances.

The impact of this collaboration extends

far beyond the confines of individual projects, catalysing broader economic growth and prosperity.

By fostering a culture of innovation and entrepreneurship, F&PA and NZPA are stimulating job creation, attracting investment, and positioning New Zealand as a hub for sustainable technologies and practices.

This project highlights a goal embedded in the heart of everything the NZPA does.

At the core of its vision lies a commitment to fostering the growth and success of New Zealand's distinctive technology companies, empowering them to thrive in competitive global markets.

Through strategic partnerships and collaborative projects, NZPA is catalysing innovation and propelling New Zealand to the forefront of technological excellence.

This approach is rooted in inclusivity and collaboration, recognising that the most impactful solutions emerge from diverse perspectives and expertise.

By bringing together stakeholders from across the spectrum of industry, academia, and government, they create a vibrant ecosystem where ideas flourish and innovation thrives.

This collaborative ethos enables NZPA and their partners to tackle complex challenges with agility and creativity, leading to breakthroughs many of which have far-reaching implications.

One of NZPA's key strengths lies in its ability to support technology companies at every stage of their journey, from inception to market success.

Through targeted mentorship, funding opportunities, and access to cutting-edge resources, entrepreneurs and innovators are empowered to turn their ideas into reality.

By providing a supportive environment for experimentation and iteration, NZPA enables companies to rapidly iterate and refine their products, accelerating their path to market success.

Another spoke to NZPA's success is its ability to leverage strategic partnerships and collaborations to maximise impact.

By forging alliances with industry leaders, research institutions, and government agencies, they are able to tap into a wealth of expertise and resources, amplifying the effectiveness of the initiatives.

These partnerships enable projects to access cutting-edge technologies, stay abreast of emerging trends, and identify new opportunities for growth and innovation.

By harnessing the collective ingenuity and creativity of New Zealand's brightest minds, NZPA is paving the way for a future where innovation knows no bounds.

Contacts:

Steve Wilson

Chair, NZPA Board steve.wilson.findlay@gmail.com

Mark Taylor

NZPA Co-Director mark.taylor@auckland.ac.nz

Mark Jones

NZPA Co-Director mark.jones@auckland.ac.nz

Brian McMath

NZPA Business Manager b.mcmath@auckland.ac.nz

Raechel Laing

NZPA Otago/Southland raechel.laing@otago.ac.nz

FARRA ENGINEERING

www.farra.co.nz

Engineering has been the family business since 1863 at Farra Engineeering.

For 160 years, this family-owned firm has evolved from humble beginnings as tinsmiths to become New Zealand’s oldest and most versatile engineering company, owned by descendants of the original founders Janet and Joseph Farra.

Today, Farra Engineering employs a robust team of 130 professionals, including 15 apprentices, and has made significant strides in gender diversity and youth employment within the engineering sector.

The company’s commitment to local talent development is underscored by its academy that nurtures new engineers, offering them opportunities to work on global projects.

Farra’s diverse portfolio encompasses design,

machining, sheet metal, stainless and heavy fabrication, and powder coating.

Supported by an ISO9001 quality system, the firm’s capabilities are unmatched in New Zealand, enabling it to tackle complex engineering challenges and deliver world-class solutions from Dunedin to the global market.

A beacon of innovation and adaptability, Farra has continuously reinvented itself to meet the demands of changing markets. This spirit of evolution is evident in their pioneering projects and products, such as the Compact Duo, a patent-pending mobile access solution designed for façade maintenance of high rises.

Farra’s engineering expertise extends to creating the largest linkage Building Maintenance Units in the Southern Hemisphere, and it proudly holds the distinction of being the first in New Zealand to achieve certification for the International Welding Standard EN 15085.

The company’s success is also recognized through numerous awards, including the Grand South Business Awards for Excellence in Manufacturing and the HERA Welding Technology/ Quality Education award.

Farra’s projects have left an indelible mark on the global stage, with over 200 access machines exported for use in some of the world’s most iconic buildings, including the award-winning Quay Quarter Tower.

Farra stands out in the industry for its ability to solve complex problems and produce high-quality products in demanding environments.

As Farra Engineering looks to the future, its 160-year legacy of innovation, quality, and community engagement continues to drive its success, making it a cornerstone of New Zealand’s engineering landscape and a valuable partner for global projects.

www.covermarq.co.nz

It is a banner year for the canvas fabricators at Covermarq in Dunedin, celebrating its 30th birthday.

Founded in 1994 the company has grown into one of the city’s premium producers of canvas and PVC products.

Specialising in tailor-made solutions, the company caters to both commercial and residential clients, ensuring that every product is uniquely crafted to meet specific needs and preferences.

The foundation of Covermarq’s enduring success lies in its commitment to using only high-quality materials coupled with outstanding workmanship.

This dedication is reflected in the company’s comprehensive range of services, from truck and boat covers to

sunshades and custom sandpit covers, all designed with precision and care.

Distinguishing itself from competitors, Covermarq boasts a team of fully qualified Canvas Fabricators and stateof-the-art machinery, including two HF welders and eleven sewing machines. This enables the delivery of a vast array of products, showcasing their versatility and expertise in the industry.

As a respected member of the Advanced Textiles Association NZ, Business South, and as a Farmlands Card Partner, Covermarq’s reputation for excellence extends well beyond its local community.

The company’s professional offerings include everything from commercial awnings to residential deck canopies and recreational shade sails, solidifying its position as a leader in custom canvas solutions.

www.enterpriseupholsterers.co.nz

Enterprise Upholstery stands as a testament to the enduring value of traditional craftsmanship in the modern world.

With over 60 years of experience, this family-owned local business in Dunedin has become synonymous with top-quality workmanship in the upholstery industry. Offering a wide range of services including reupholstery, foam sales, upholstery supplies, fabric supply, furniture repairs, and custom headboards, along with the convenience of pick-up and delivery, they cater to both commercial and domestic furniture needs.

What truly sets Enterprise Upholstery apart is not just their comprehensive service offerings but their deeprooted commitment to excellence and

personalized customer service. The friendly and helpful staff go above and beyond to provide free quotes, advice, and tailored solutions, ensuring no job is too big or too small for their dedicated team.

Their track record of success includes long-standing collaborations with other local businesses, such as a sixty year partnership with commercial furniture manufacturer Metalon, continuous partnerships with interior designers like that with The Workroom based in Wanaka, and various local school fit-outs. These achievements underscore their capability to handle a diverse range of projects, reflecting their versatility and expertise in the field.

As one of the few remaining upholstery businesses in Dunedin, Enterprise Upholstery preserves the craftsmanship and values of a bygone era while staying abreast of contemporary design trends.

From a modest team of eight in 2002, to employing over 150 employees at their purposebuilt Green Island factory and head office, Escea has built a successful manufacturing business during a time when many Dunedin manufacturers left the city. This locally owned and operated enterprise has always remained steadfast in its commitment to its founding values, despite its growth and international success.

Specialising in crafting worldclass fireplaces, including indoor and outdoor gas and

wood products, Escea has firmly established itself as a market-leader in the fireplace industry. With distribution channels spanning New Zealand and exporting to Australia and North America, the company’s dedication to continuous improvement and customer focused innovation has led to their global success.

Founder and CEO Nigel Bamford’s vision of producing industry-leading fireplaces in Dunedin remains unchanged – with access to a skilled local workforce, Escea fosters in-house talent ranging from Product Designers and Engineers to Customer Support,

Marketing Teams and world class manufacturing operators.

This in-house strategy allows Escea to work smarter and faster. Proximity between teams allows them to adapt quickly to feedback in the market, deliver product solutions faster, and easily bring new ideas to life – without the typical delays and challenges of working with offshore teams and manufacturing facilities.

“It’s this unrelenting focus on always doing our best and constantly improving that makes our team so good at what they do,” says Bamford. This dedication has certainly

contributed to the longevity of the business and the longstanding reputation of the Escea brand.

And it’s not just fireplaces that this approach extends to – its charitable arm, the Fire for Life initiative, reaches out to touch the lives of those in need across the globe.

The Fire for Life Cooking Stove is a portable, lightweight, and safer alternative to traditional open fire cooking methods in the developing world. Escea designed the stoves to require less fuel, emit less smoke, and significantly reduce the risk of accidents. The project took its

first steps towards making a difference in Syrian displacement camps, in partnership with ReliefAid, and in 2023, was recognised with three awards at the NZ Best Design Awards. To date, Fire for Life has helped over 5,000 families, and for Escea, this is only just the beginning.

From its roots in Dunedin to its impact on the global stage, this company’s journey is a powerful local story that demonstrates how businesses can leverage innovation and local talent not only to thrive commercially, but also to effect meaningful change in communities worldwide.

Ask an engineer how to build a bridge and there’s a good chance they’ll come back to you with a formula for a sturdy build.

Ask them the best way to handle another

Drew and Laurel step in to bridge this gap, working one-on-one and delivering group workshops/trainings that teach their clients in how to apply their unique behavioural frameworks and models. Armed with frameworks designed to enhance communication, leadership, and teamwork, they specialise in guiding

They may be small, but the impact Dunedin Sheet Metals has with its clients is anything but.

Specialising in a broad spectrum of metalwork services, this company has carved a niche for itself with its

This includes a 4 metre long guillotine, a CNC 4 metre 200 ton press and a CNC turret punch, great for repetitive products like their signature meterbox line.

At the heart of their ethos is a love for tackling challenging and intricate projects.

This enthusiasm for complex tasks not

www.wae.co.nz

WAE Engineering Limited, with its roots deeply embedded in the heart of Otago, New Zealand, has emerged as a beacon of innovation, reliability, and growth in the engineering sector.

Since its inception in 1985, WAE Engineering has transformed from a modest workshop with just three employees to a powerhouse of over 100 dedicated professionals spread across five strategic locations in Waikouaiti, Dunedin, Palmerston, Balclutha and Oamaru.

This expansion is not just a testament to the company’s growth but also its commitment to serving a broad spectrum of industries throughout Otago and beyond with unparalleled expertise and efficiency.

At the core of WAE Engineering’s offerings are comprehensive structural and mechanical engineering services.

These encompass plant maintenance cover, engineering design, and the ability to build and install complex machinery

and structures.

A notable aspect of the company’s operations is its Cranes and Access Equipment division, which seamlessly integrates with the engineering teams to deliver end-to-end project solutions.

This synergy ensures that projects are not just conceptualised but also executed with precision, adhering to the highest standards of quality and safety.

What sets WAE Engineering apart is its ability to manage a wide array of projects across Otago, thanks to its extensive network of branches.

From Palmerston to Balclutha, the company’s presence ensures that it can swiftly respond to clients’ needs, providing timely and effective solutions.

The Engineering Supply stores located in Palmerston and Balclutha further enhance this capability by ensuring that necessary materials and tools are always at hand, significantly reducing turnaround times for repairs and maintenance.

Being a BOC distributor for gas and consumables adds another layer of efficiency and convenience, making WAE Engineering a one-stop-shop for its clients.

This distinction highlights the company’s foresight in not just meeting immediate project needs but also addressing the ancillary requirements that are critical for the seamless execution of engineering tasks.

The journey from a small workshop to a leading engineering firm is a source of pride for WAE Engineering. This growth narrative is punctuated by significant achievements and milestones that underscore the company’s expertise.

Projects such as the structural steel fabrication and installation for new builds in Dunedin, earthquake strengthening for iconic locations, and intricate installations for the mining industry showcase WAE Engineering’s capacity to handle complex engineering challenges with finesse.

What truly differentiates WAE Engineering in a competitive landscape is its comprehensive service offering.

The company is not just an engineering firm; it is a holistic solution provider that brings together design, fabrication, fitting, crane operations, access equipment, and transport under one umbrella. This integrated approach ensures that clients receive streamlined, efficient, and cost-effective solutions tailored to their unique requirements.

Beyond the technical and operational excellence, WAE Engineering is deeply rooted in the local community.

As a family-owned and operated business, it places immense value on local engagement, employment, and development.

The company’s commitment to fostering a stable, loyal workforce is evident in its approach to career progression, with many of its skilled tradespeople having started as apprentices within the company.

The company’s success stories,

such as the fabrication of trays for 21 dump trucks, the removal and installation of massive gantry cranes, construction and project management of a new Blast Freezer in North Otago, and being the preferred supplier for maintenance work across various sectors, highlight its versatility and capacity to deliver on a broad spectrum of engineering challenges.

Looking forward, WAE Engineering remains dedicated to its mission of being the service provider of choice in the region.

With a clear focus on innovation, community engagement, and sustainable growth, the company is poised to continue its legacy of excellence, reliability, and comprehensive engineering solutions.

Whether it’s a complex mechanical installation, structural fabrication, or a critical maintenance task, WAE Engineering stands ready to meet the challenges of today and the opportunities of tomorrow, reinforcing its position as a leader in New Zealand’s engineering landscape.

20 years ago, the business has grown to become a one-stop-shop for all things hydraulic.

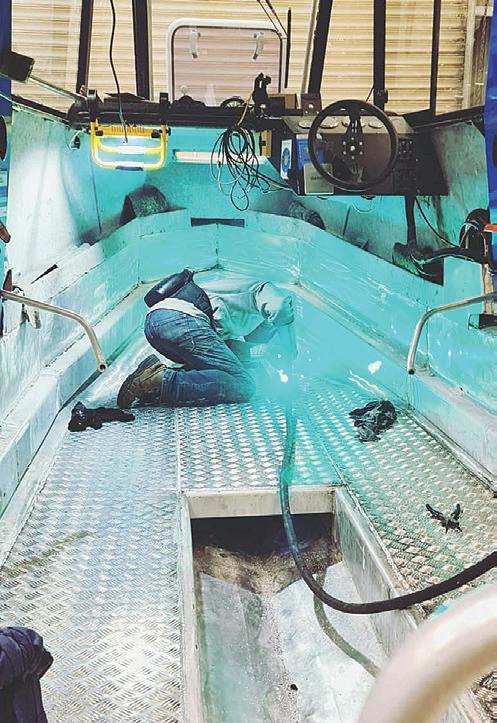

With a focus and strength rooted in repairing and designing hydraulic machines of all sizes, Hydraulic Services & Repairs Ltd stands tall as the go-to expert in Dunedin.

Whether it’s a massive industrial rig or a compact hydraulic system, they’ve got it covered.

Nothing is too big or too small for them; they thrive on finding solutions where others see challenges.

Their recent success stories speak volumes, including the complete rebuild of an 875 Tigercat with a Waratah head – a testament to their unwavering commitment to excellence. Having started as a one-man-band over

From hose fit-ups and repairs to machining new rams and parts, they handle it all with precision and expertise. With over two decades of experience and a team dedicated to exceeding expectations, they deliver unparalleled service and industry knowledge.

Clients benefit from the partnerships which they maintain with world-class companies like RYCO and Palfinger, ensuring top-quality equipment and service.

Added to this, comprehensive consumer and mechanical guarantees, along with a robust Health & Safety program, provide peace of mind to their clients.

STEELSteel fabrication isn’t merely an engineering process for Dunedin Engineering firm Zeal Steel.

Instead it is an opportunity to expand the horizons of the art of fabrication.

While architectural metalwork and ironworks are their bread and butter, a recent project allowed them to add some steel to the cultural fabric of the community.

In 2023 they were proud to be involved in the fabrication of a corten sculpture commissioned by mana whenua-owned consultancy Aukaha. The sculpture is a tohu whenua (landmark) that tells the Waitaha story of Kōpūwai, a giant ogre with a pack of two-headed dogs.

Designed by Ōtākou’s Ephraim Russell as part of a partnership between mana whenua and Transpower, the tohu whenua was installed near Oturehua, overlooking the Otago Rail Trail. This project demonstrated Zeal Steel’s approach to its clients, acting as a functioning engineering ideas incubator.

Collaborating with other engineering companies and cutting-edge suppliers, they bring technology and creativity together to transform concepts into reality.

By pooling their expertise in technologies such as cutting processes, laser, plasma, guillotine, and brake pressing, Zeal Steel shows its strength in fabrication and assemblage of these component parts to create bespoke engineering solutions for its clients.

Founded in Invercargill in 1978, Sheet Metalcraft has always been locally owned and operated. While initially they were purely doing light sheetmetal work, over the decades the company has evolved significantly, operating across four workshops in the city. Now their repertoire includes; design, light/medium fabrication, project management & large contingent of onsite maintenance across Southland including building, plumbing roofing & cladding.

Among the large team there are staff members who have been with the company for over 40 years. As the team has grown they have made a real focus on home & work life balance

and really enjoy when the team gather together with their families to celebrate throughout the year. “They all embrace a commitment to our core values of high quality products, delivered on time which makes us very proud.”

Having invested heavily in modern CNC technology, including 3D scanning, Haas Barfeed Lathe & Haas 4 axis Machining Centre, Laser cutter, Waterjet cutter capable of cutting any material up to 165mm thick, and a large Router cutter.

The CNC laser cutter is the most advanced cutting system in the Southland region. Capable of loading and unloading up to four tonnes of material unmanned, it creates greater efficiencies and enables tighter delivery schedules to be met.

Sheet Metalcraft are also particularly proud of their new 3D scanning capabilities. Essential for the modelling and creation of complex 3D components, it also aids them in measuring and verifying existing site dimensions and environments.

The continuing development of the company has largely been through seizing opportunities as they emerge, and a desire to continually offer their customers more.

Nathan is determined that they’ll keep embracing technological advancements in the engineering industry.

‘‘We’ll continue pushing the boundaries of what we can build, and challenging the team,’’ he says. ‘‘Our focus is on not saying ‘no’, we engineer solutions when tasked with near impossible

requests. We love exceeding our own, and our client’s expectations.’’

As was the case with an international award-winning door project offers a great example of Sheet Metalcraft Ltd’s broad range of strengths.

A collaboration with Hyndman Taylor Architects and RBJ Construction, the impressive bespoke pivot door weighing 350kg was an excellent test of Sheet Metalcraft’s diverse offering.

Up against international competition, it won the FritsJurgens Best Exterior Pivot Door category in 2022, with the jury noting that ‘‘we chose this door because of its pure design’’.

Sheet Metalcraft managing director Nathan Barker says it exhibited what the company can do in the realm of architectural

fabrication.

‘‘It showed the scope of what we can do in-house,’’ he says. ‘‘That was a pretty cool project to be internationally recognised for.’’

Although they can complete complex projects of all sizes inhouse, one of the great benefits of being Invercargill based is the ability to collaborate with other companies in the region.

‘‘One of the good things about doing work in Southland is the ability to collaborate on larger projects if needed,’’ Nathan says. ‘‘There’s a genuine level of trust and an ability for people to collaborate here.’’

With this strong commitment to collaboration, innovation, and quality, Sheet Metalcraft remains a beacon of engineering excellence in the southern regions.

Jemtec Limited, trading as Edwards Engineering, is a cornerstone of innovation and expertise in the engineering sector.

Located in the heart of Balclutha within the Rosebank Industrial Park, Jemtec’s extensive facilities are a centre of engineering excellence, offering a broad spectrum of services that encompass the manufacturing of new heavy vehicles, alongside comprehensive repairs and modifications to all heavy machinery.

Proudly, Jemtec is not just an ordinary engineering firm; it is an all-encompassing hub where vast knowledge meets unparalleled skill. The company prides itself on its ability to fulfil clients’ requests with precision and efficiency, leveraging a talented team that thrives on challenges.

A recent highlight for Jemtec was the

recognition of a new build for Millers Flat Transport, which garnered the “Truck of the Month” accolade in NZ Trucking Magazine, underscoring the company’s commitment to excellence and innovation.

What sets Jemtec apart is its versatility in handling repairs, modifications, and new builds of heavy vehicles and general engineering tasks, facilitated by a spacious workshop that caters to a variety of projects.

The company’s recent acquisition of Edwards Engineering marks a new chapter, retaining its legacy staff and quality craftsmanship while integrating cutting-edge technologies such as CNC machinery, CAD designing, and a dedicated hydraulic area.

This strategic expansion not only honors the legacy of Edwards Engineering but also propels Jemtec into the future, ensuring it remains a premier destination for engineering solutions.

Jared Sim says one of the best things about studying engineering at Otago Polytechnic | Te Pūkenga is the programme’s focus on industryrelevant, real-world learning.

“I much prefer being able to do practical work rather than just sitting in a lecture hall all day,” he says, adding that the decision to enrol in a Bachelor of Engineering Technology (Electrical) was something of a “nobrainer”.

“Even though I still have a little bit of work to do before I complete my degree, my advice to others contemplating studying engineering would be to focus on more practical work rather than theoretical lectures.

“It’s what will help you in real life and it’s also what people in industry are really looking for from a graduate.”

Interested in engineering from a young age, Jared says being able to study and remain close to family in Dunedin was another compelling reason to choose Otago Polytechnic | Te Pūkenga.

And his decision has paid off. Although he still has to complete one paper and an exam to gain the degree, Jared has secured a job at Dunedin firm United Machinists, which designs and manufactures precision components for a range of aerospace, electronics, automotive, medical, and marine applications.

Specialising in Mechatronics Engineering, Jared was offered a job at United Machinists during his first semester of study at Otago Polytechnic | Te Pūkenga.

And he’s still there.

“I work at United Machinists as a Manufacturing Process Engineer. My main job is as the operator and programmer of our coordinate measuring machine,” he explains.

“I’m also working on a ‘flipper/ robot’ system at United Machinists. I developed it as part of my final-year project at Otago Polytechnic | Te Pūkenga. The aim is to provide the coordinate measuring machine with ‘lights-out capability’, which basically means it frees up an operator from repetitive, mundane tasks and enables them to do more interesting work.”

RED BOOM ENGINEERING

www.redboom.co.nz

The establishment of Red Boom Engineering was the culmination of a business dream for Mosgiel man Rodney Anderson.

He had cut his teeth in a number of industries, including mining work in Australia, logging, excavation, farming, and even loading top dressing aircraft, but owning his own business had been a long held aspiration.

This goal came to fruition in 2022 with the establishment of Red Boom Engineering.

Today the company goes from strength to strength, specialising in crafting custom truck decks, trailers, and agricultural equipment, while also tackling unique side projects including outdoor furniture and fire pits.

What sets Red Boom apart is not just its bespoke engineering solutions but the personal touch and expertise Anderson brings.

His extensive experience in a variety of industries equips him with a rare insight into his clients’ needs, making Red Boom a sought-after partner for businesses and individuals alike.

The company boasts state-of-the-art equipment, such as Kemppi Welders and Siegmund welding tables from Germany, allowing for precision and easily

repeatable products of the same design. Anderson’s proficiency in Computer Aided Design (CAD) further enhances the company’s capability to deliver custom projects to exacting standards.

Red Boom’s success stories, including handling overflow work for other companies due to the scarcity of great engineers, underline its excellence and the high demand for its expertise and facilities.

Until the first lockdown, United Machinists owners Alex and Sarah Ramsay had been the drivers of their own change.

“Our immediate thoughts were, ‘we’re done for now’,” Sarah says. “We’d launched a multimillion-dollar facility to double our production. That demand dropped to zero, and based on customer forecasts was going to stay below 50% for the indefinite future.”

But once they picked themselves up off the floor, they saw an opportunity. They launched a nationwide market research campaign, aiming to talk to New Zealand manufacturers that contract manufactured offshore.

“The common message was that while New Zealand quality was excellent, service - particularly the ability to communicate and meet delivery expectations - was poor,” Sarah says.

On the back of this feedback, they developed real-time customer schedules, which as far as they know remains the only example of a CNC machine shop doing so in Australasia.

Sarah also dusted off her writing skills and started penning opinion pieces on LinkedIn and

the company’s email newsletter. These not only promoted United but advocated for industry.

While existing customer demand was down through 2020 and into 2021, United attracted new customers to off-set the dropparticularly within the medical and aerospace sectors.

In 2021 a previous customer returned to full production volumes, putting capacity, particularly in quality inspection, under pressure.

United hired a graduate from Victoria University, with help from Callaghan Innovation’s Student Experience Grant.

“That was the catalyst for a culture change from CNC Machine Shop to advanced manufacturer,” Alex explains.

By introducing internal automation skills and a project that spanned robotics, CMM programming, and 3D printing of fixtures, the wider company looked at other areas in the manufacturing process that could have manufacturing process innovations applied.

“We now have two full-time manufacturing process engineers, Callum Scott and Jared Sim, both Otago Polytechnic graduates,” Alex says.

These are entirely new roles which drive the process innovation in the company.

Over summer, United also had two full-time interns. Canterbury University mechanical engineering student Hayden Elliot worked on a 3D printing and engraving project for aerospace, while Otago University Computer Science student Daniel West worked on automating several data entry processes.

Non-traditional approaches to traditional problems are the theme of the company’s latest venture, anodizing.

“Anodizing is a huge problem for us and many in New Zealand. There’s a real shortage of capacity and it is the very final process on a high value component. Currently we package up all our aluminum work, send it to the central North Island, and have them send it back once it’s coated, we inspect it, and then invariably send it Northwards again for final delivery to the customer”.

It’s an inefficient, risky, and slow process – with potential for damage to parts through handling, not to mention being heavy on transport carbon emissions.

United hasn’t just gone for any ordinary anodizing tank solution. They have had an advanced anodizing line with full digital controls and monitoring designed and built by United States company Technic. Manufacturing Process Engineer Callum Scott will be working on a project to fully automate the line.

“This hasn’t been done in New Zealand before. We know of multi-million-dollar operations overseas, but for such a low-cost low volume service that’s just not feasible. If we have the best

gear, a controlled environment and get our data right, there’s no reason we can’t automate the process entirely”, explains Callum.

As for what’s next, Sarah says that once the anodizing is up and running they’ll be looking at how to commercialise the concept further.

They also plan on doing their aerospace AS90:100 accreditation this year, to raise their accreditations to suit their growing Australian and hopefully USA Aerospace clients.

TEMPLETON ENGINEERING

www.templetonengineering.co.nz

With over a century of work in the Wanaka community under its belt, Templeton Engineering remains uniquely placed to meet local engineering needs.

Founded in 1906, the company has been an integral part of the community for 115 years, and prides itself on providing a friendly ear for their clients problems.

Potential customers are encouraged to pop in and discuss their needs face to face with the engineers, with no job too big nor small for the team. Their reputation for superior customer service and for getting things done has grown from the deep ties of heritage Templeton Engineering shares with the wider Wanaka community.

Customers today can expect exactly the same brand promise that the firms first customers could expect in the early 20th century; a high standard of work at a fair price.

Today this work encompasses a full range of engineering services from working on structural steel for architectural housing and architectural fabrication through to farm equipment, haulage machinery and general and mechanical engineering.

Founder James Templeton started as a blacksmith and wheelwright on the Lake Wanaka waterfront in 1895, before moving to Albert Town and opening the doors of Templeton Engineering in 1906.

Today it is acknowledged as the oldest domestic customer of the Bank of New Zealand

and remains an integral part of the Albert Town business community, a fact highlighted by its square on the Wanaka edition of the Monopoly board game.

The Templeton family has remained involved with the company throughout the years, with James’ great great

Adhesion Sealing stands as a distinguished subcontractor in the construction industry, renowned for its expert services in sealant application, waterproofing, and membrane solutions. With a particular emphasis on remedying leaking basements, and the application of sealants and membrane decking and roofing, Adhesion Sealing shines in delivering tailored, high-quality outcomes for new builds and repair projects.

Since 1987, the company has cemented its reputation in Dunedin through the deployment of a wide range of products, meticulously chosen to address diverse challenges.

This dedication is bolstered by a team of skilled applicators whose expertise ensures excellence in every task.

grandson Garry Templeton still working for the firm. He ran the company from 1996, before handing the reins over to the husband and wife team of Matt and Sarah Read in 2021.

The Reads are excited to guide Templeton Engineering into the future, while remaining proud

of the local heritage behind the firm.

Between Garry and Matt they bring 60 years of engineering expertise to bear in conjunction with their crack team of tradesmen and engineering staff to solve their customers’ problems.

Pride in their work is evident through notable projects such as the resin flooring for the Mosgiel pool surrounds and a significant warm roof system for the new Polytech Trades Building. Success in waterproofing leaking basements across the city further underscores their mastery and reliability.

Adhesion Sealing distinguishes itself from competitors through its comprehensive product selection and a steadfast commitment to quality, driven by a philosophy that no single product fits all situations.

This insight highlights the importance of specialised solutions over generic, offthe-shelf applications.

Adhesion Sealing’s dedication to excellence, coupled with its innovative approach and seasoned experience, sets a benchmark in the industry for reliability, quality, and customer satisfaction.

At Anvil Engineers LTD, innovation isn’t just a buzzword—it’s the cornerstone of everything they do.

Nestled in the heart of North Otago and servicing the Waitaki Valley, they offer a diverse range of services, specialising in agricultural repairs, steel, stainless steel, alloy welding, and boasting a full machining workshop.

Led by workshop manager Ross Hayes, a 5th generation Engineer descended from Ernest Hayes of the Hayes Engineering Works in Oturehua, the team at Anvil Engineers inherits a legacy of ingenuity.

Their commitment to creative thinking, unparalleled customer service, and a wide array of skills sets them apart in the industry.

Established in 2019, Anvil Engineers has faced and conquered challenges, including those posed by the pandemic.

Despite these hurdles, they’ve achieved significant milestones, such as their pivotal role in the fabrication and installation of the new conveyor system at Oamaru Shingle Supplies. This success is a testament to their capability to handle large-scale projects with finesse.

But what truly distinguishes Anvil Engineers is their unwavering dedication to delivering optimal outcomes for their clients.

With a team that goes above and beyond to understand and meet customer needs, they’re not just engineers— they’re partners in progress, committed to pushing the boundaries of what’s possible.

to provide the capability to take on a wide variety of work.

Founded in 2004 by owner and general manager Mike Todd, the busy engineering firm caters for the needs of a diverse range of customers. At the core of their operations lies their dedication to innovation, precision and versatility.

Todd Engineering has been investing heavily in their workshop, people and equipment

With a fully equipped machine shop boasting cutting-edge technology, they tackle projects of all complexities.

Recent investments have included an Omax MAXIEM Waterjet Cutter and a Trumpf TruBend 3120 Press (together capable of cutting and shaping steel, stainless steel, aluminium and plastic), a Mazak CNC 5-axis Lathe, capable of machining

bespoke one-off designs to fine tolerances or manufacturing large numbers of pieces.

In 2019 Todd Engineering employed many of the recently redundant engineers from Milmech Engineering, including Operations Manager Mitch Lavender and Lead Designer Brent Walker. This expertise has allowed Todd Engineering to become a significant contractor to many meat processing sites, successfully designing,

manufacturing and installing conveyor systems and other specialised equipment.

Todd Engineering is a specialist in structural steel fabrication for the local construction industry and is a preferred supplier to many local building businesses delivering structural steelwork for industrial, commercial, and residential projects.

Another area of expertise is Industrial maintenance and overhaul where Todd

Engineering works with businesses in the mining and saw milling sectors, to design and install new equipment and maintain, repair and modify existing machinery,

As Todd Engineering looks to the future it expects its investment in new technology coupled with the expertise of its team will continue to deliver unparalleled quality and customer satisfaction.

BUSINESS DEVELOPMENT CONNECT

• Advocacy

• Export Documentation

• Training & Events

• Funding

NAVIGATE EMPOWER

EMPLOYMENT

RELATIONS HR

• Legal Advice

• HR Consultants

• Free advice via phone

WORKFORCE DEVELOPMENT & PATHWAYS

• Skill development

• Business Health Check

• Health and Safety

The SOREC Summit is a premier event celebrating the manufacturing and engineering sector in Otago and Southland. The focus of this year’s summit is future proofing the industry with talks from the best and brightest. There will be the chance to network and to have a chat with the SOREC team on how we can best help your organisation.

We are excited to announce that, along with several industry experts talking to the economy, technology, trade and people. Hon Andrew Bayly, Minister Small Business and Manufacturing, will be speaking about the future of the sector. Entrance is free, but limited spots are available. Register today!

Thu 18 April 2.00pm - 6.00pm

He Toki Kai Te Rika | Trades Training Centre, Otago Polytechnic

Looking after our Mental Health and supporting others is hugely important. Westpac Ambassador of over 10 years, Sir John Kirwan (JK) has a passion for mental health and sharing his own mental health journey with the aim of helping others with theirs.

Te Pou Ō Mata-Au, 4/6 Clyde Street, Balcutha Register at: businesssouth.outreach.co.nz/ forms/register?event=235798

Balclutha - 4 April - 9.00-10.15am

We have a wide range of Health & Safety training available. Ensuring you and your colleagues remain free from injury at work takes not only care, but specific knowledge and skills.

This course will help you to understand the Health and Safety at Work Act, and its associated regulations, to maintain a safe working environment.

Content and delivery of this programme will be aligned with the most up to date requirements of health and safety training - whatever your business.

Invercargill - 14 May, 18 June

Queenstown - 28 May, 9 April, 2 July

Oamaru - 6 May, 8 May

Dunedin - 27 May

For Trades Apprenticeship Trust can grow your team with talented apprentices who are ready to make an impact! They have people eager to learn and become a valuable member of your team. For Trades offer a seamless solution for you to host an apprentice. Benefits include access to free leadership academy (worth $1,725) or a free business mentor (worth $295). For Trades manages the apprentice administration including onboarding and payroll, can help with funding and provide full pastoral care throughout the apprenticeship. Learn more? Send an email to 4trades@business-south.org.nz

The Leadership Academy develops future Otago business leaders to be better equipped for leadership within their organisation, workplace or business. This inspirational programme is the catalyst that ignites relationship building with like-minded professional peers, fosters inspiration to take your leadership career to the next level and provides outstanding opportunities to learn from prominent leaders. This programme is led by a significant Otagobased businesses or other organisations, and participants will benefit from the opportunity to interact with the presenters and build an ongoing connection with them.

Dunedin - 3 May

Central Otago - 4 September

Don’t miss the opportunity to explore the forefront of automotive mobility, sustainability, and community at our BA5 event hosted by Cooke Howlison Toyota for an evening showcasing the latest in motoring innovation and technology. Explore our range of new models, including the ground-breaking Hilux Hybrid, all-new CH-R, and all-electric bZ4X, while gaining insights into the exciting future of Toyota for businesses

Cooke Howlison Toyota - April 24th

Meet the students and see the engineering project posters and prototypes from the year they have completed at Otago Polytechnic. This is a fantastic opportunity to see the skills of the students ready to enter the workforce.

Week of 11 November

(Open night date to be confirmed)

T-Block Otago Polytechnic

Scan this QR code to register or head to the Business South website.

It's all about understanding of industry 4.0 solutions and how this can benefit your business. Take aways;

• hands-on experience with all levels of technology

• critically analyse possible ROI and pain points

• leave with a personalised reference pack so you're ready to take the next steps in your industry 4.0 journey.

The Digital Manufacturing Challenge is catered to operators, functional and senior leaders and is a free, in-person event facilitated by expert manufacturing consultants from LMAC in partnership with Callaghan Innovation, EMA, BECA, and Technology Partners NZ Controls and Wyreframe.

Go to www.industry4.0.govt.nz/upcomingevents to register

The event will be in the West Coast, Invercargill and Dunedin in June.

If you’re in the second or third year of your engineering and/or science studies, or studying at a postgraduate level in these areas - this is a not-to-miss event!

Meet local, world-leading science and engineering firms, who could springboard your career of global adventure!

Listen to stories of recent graduate hires as they talk about their experience finding employment and kicking goals in their first year of employment. You can also speak to staff and explore career opportunities they are offering (including internships and graduate placements).

Returning in August.

https://business-south.org.nz/whats-on/mynext-adventure/

This region has a strong engineering past. According to those involved in the industry now, it also has a strong future.

‘‘Untapped potential’’ were the words that Business South CEO Mike Collins kept hearing when he spoke to local engineering firms.

Because while there is obviously a lot going on in the sector, there’s a feeling that it can be taken to a different level if the right levers are pulled.

‘‘There’s a lot of potential,’’ Mike reiterates. ‘‘Business South has been working with local business leaders, including manufacturing and engineering, who are keen to put the city and wider region on the map. We’ve come up with a draft plan of initiatives that might move the dial.’’

The southern region has a powerful heritage in the engineering and manufacturing sector. With that foundation still

being built upon, coupled with a nascent tech innovation industry, there’s much to be positive about heading into the future.

Aiding potential growth in the sector is the ease of networking and collaboration that businesses find here.

‘‘The unique thing about the region is we are a bit of a village; everybody knows everybody,’’ Mike says. ‘‘I was talking to someone in our Young Professionals Group, who said ‘it’s so easy to get support’. The engineering and manufacturing community are just one big family of services really. A lot of innovation comes out of the place and it could be scaled up a lot more.’’

Business South has recently been having conversations with central government around what funding initiatives might look like. Some funding had already been proposed for advanced manufacturing in the region, but this has since been frozen.

Business Leaders from the region are working with Minister for Small Business and

Manufacturing Andrew Bayly on what support there may be for the sector. The government has been clear about the tight fiscal envelope that they’re currently operating in, so some strategic thought about what’s actually required is necessary.

‘‘As a business community we can continue to collaborate and to create growth in the sector and from these conversations we can then work with the government to advocate for priority investment.”

Clear career pathways for youth to enter the engineering and manufacturing sector is an obvious area to be focused upon. The SOREC Academy is a crucial

part of the future of the industry in this region, Mike believes.

‘‘Students are engaging in the programme and there are some great success stories from those who have completed the academy. The academy compliments our workforce development offerings at Business South which include For Trades apprenticeship programme, Young Enterprise Scheme and My Next Move. ’’ This publication is an aspect of addressing another opportunity the sector has. From talking to local businesses, Mike says it’s clear there are a number of success stories that would elevate the profile of the industry

and share good practice.

‘‘We’ve got a lot of great businesses here,’’ Mike says. ‘‘So it’s about bringing everybody together and putting ourselves on the map with some really good communication and storytelling.’’

SOREC founder and Farra Engineering CEO Gareth Evans is also adament that public engagement can only be beneficial in the continued growth of the engineering in the region. He’s positive about it’s bright future here.

‘‘There are a lot of companies doing really good work, and I’m confident about the sector,’’ Gareth says.

This year marks a significant milestone for transport engineering firm

TL MacLean Limited which is set to celebrate its hundredth birthday.

Established in 1924, the busy company is a cornerstone of the transport engineering sector, set to celebrate an impressive century of innovation and service this year.

Throughout its storied history, TL MacLean Ltd has established itself at the forefront of innovation, introducing Dunedin’s first portable electric welding machine in the mid-1920s. This pioneering spirit has underpinned the company’s enduring success and reputation for excellence. Today they specialise in servicing the transport industry and offer a comprehensive range of services, from design and manufacturing to chassis alterations and air suspension fittings.

Their expertise spans across creating bespoke solutions for car transporters, flat decks, crane and scaffold trucks, heavy and light-duty tipping decks, crouching trucks and trailers, flat and tipping ute decks, and more.

In addition to crafting standard transport equipment, TL MacLean Ltd excels in custom projects, including chassis alterations, lengthening and shortening wheelbases, and installing advanced components like drawbars, drawbeams, and load anchorage systems.

As TL MacLean Ltd approaches its centennial anniversary, it stands as a testament to a century of innovation, quality, and dedication to the transport industry.

Their legacy of pioneering engineering solutions continues to drive the company forward, promising another century of unparalleled service and ingenuity in the transport engineering domain.

Finding the next generation of high performance CNC machinists is crucial to the success of the industry, and is a challenge the Machinist Training Organisation New Zealand (MTONZ) is committed to meet.

Discussions among the Industry Round Table, made up of key members of the CNC industry, identified the need to establish a pipeline of high quality workers.

As a result of these discussions the not-forprofit MTONZ was created to ensure quality candidates get the support they need to thrive.

At the core of their mission is the endeavour to address the critical skills shortage and to update training qualifications to reflect contemporary demands, thereby ensuring the industry’s longevity.

It has adopted a grassroots approach towards nurturing talent and fostering a passion for CNC machining.

By engaging with schools and leading students on tours of local machine shops, they have opened up the exciting possibilities within the industry to many.

Its efforts have educated and equipped aspiring apprentices with the necessary tools to embark on fulfilling careers, with 13 apprentices already successfully placed in industry roles to date.

A significant highlight of MTONZ’s achievements is the comprehensive overhaul of the Level 3 NZQA qualifications, along with the forthcoming unveiling of a revised Level 4 qualification.

These milestones underscore its steadfast dedication to raising industry standards and ensuring that training programs are in line with the sector’s evolving needs, acting as an indispensable advocate for the CNC machining industry in New Zealand. MTONZ is driven by a genuine desire to nurture talent, innovate in training methodologies, and advocate for the advancement of the industry.

Ensuring New Zealand remains a competitive force in the global market by investing in skills that promote innovation and excellence is the ultimate goal for the organisation.

By bridging the gap between traditional training methods and modern industry needs, MTONZ is sculpting the future of CNC machining in New Zealand, securing the nation’s place as a pivotal player on the global stage for generations to come.

Dunedin’s Business Internship Programme

JobDUN is a paid internship programme that meets business need, creates high-value jobs, and retain skills and talent in Dunedin.

Startups, established firms, and not-forprofits have used JobDUN as a proven, cost-effective way to connect with Dunedin’s smart tertiary students.

It was during a work placement at Farra Engineering in Dunedin that Eva Sincock realised she loved working with metal.

Although she’d previously considered getting into the trades through building or carpentry, she hadn’t thought about engineering before.

Now she’s been in fulltime employment at Farra for a year, and is loving it.

‘‘It’s really good,” Eva says. ‘‘I didn’t think I’d like it as much as I did.”

The opportunity arose when she was studying at the now Trinity College in 2022. A work placement came up at Farra through the SOREC Academy, and she jumped at the chance.

Gareth Evans, the Farra Engineering CEO and SOREC founder, says the gateway programme sees students going to work one day a week. They learn about what it means to be in a workplace, and what the engineering industry looks like in real terms.

‘‘That meant when she finished school she already

knew that she wanted to be here and had some basic skills” Gareth says. ‘‘So we could put her straight on an apprenticeship and basically save her six months of her life.”

The programme is also great for employers, as they get to see the calibre of potential employees before bringing them onboard fulltime.

While it can be daunting for a high school student to enter the workplace, even for one day a week, Eva says it was a fairly soft landing at Farra.

There was an introductory day where she was shown around the company and introduced to people. Then over her work placement she was able to experience the different departments that Farra operates.

‘‘I loved it because I got to see the different aspects of engineering that goes on at Farra,” Eva recalls. ‘‘From the machine shop, to heavy fabrication, light fabrication, and the sheet metal side. I got to make a decision from

there of what I wanted to do my apprenticeship in.”

Having been in the gateway programme throughout 2022, she had a relatively seamless transition into an apprenticeship upon leaving school at the end of that year.

Recently Eva’s been working on the huge pit maintenance units that Farra manufactures for companies around the world. She’s also worked on projects for Emerson’s and Greggs in Dunedin.

‘‘I get to learn new things pretty much every day,” she says. ‘‘I love working with the people as well. Probably my favourite thing is going out and doing site work.”

For any high school student considering their future career, she strongly recommends the engineering industry and the SOREC Academy as an option.

‘‘If you don’t try you’ll never know,” Eva says. ‘‘I think getting into a trade is a great thing to do. I’d say to anyone who was thinking about it to just go for it.”

Applications are welcome from July 2024.

Any questions please contact:

Chanel O’Brien Enterprise Dunedin

P: (03) 474 3736

E: chanel.obrien@dcc.govt.nz

Since 2012/13, JobDUN has placed over 491 interns in Dunedin businesses

153

new jobs have been created 491

For the Dunedin based Connor Jones Group, construction and engineering are two inseparable sides of the same coin.

That’s why it prides itself on being both an engineering and a building company, a dual capability that sets it apart in the competitive landscape of Dunedin’s construction industry.

This versatility is a key aspect of their business model, enabling them to handle a wide range of projects with a level of expertise

and passion that’s rare in the field.

Co-founded by Tom Connor and Chris Jones, this mid-sized enterprise has carved out a niche for itself by offering a wide array of services, including residential and commercial new builds, renovations, government works, structural steel works, and light fabrication.

With over 25 years of combined industry experience, Connor and Jones have built a company that’s not just a business but a local institution.

Their team of 24, comprising engineers and builders who possess a genuine love for their work, embodies the company’s commitment to quality and innovation.

Among the company’s notable achievements is its recognition in the Deloitte Fast 50 awards as the fastest-growing construction company in the lower South Island, an honour it has received for two consecutive years.

This accolade is a testament to the hard work, dedication, and vision of the entire team at

Connor Jones Group.

What truly sets Connor Jones Group apart, however, is its focus on teamwork and communication.

The company boasts an in-house team of project managers, design engineers, and quantity surveyors who work closely with clients to bring their visions to life.

This commitment to keeping clients involved at every step of the process is further enhanced by the use of an innovative online construction management tool.

Using specially designed software including an app, clients can track their project’s progress, communicate with the team, and manage all aspects of their project online, ensuring a level of transparency and client satisfaction that is unparalleled in the industry.

As they continue to grow and evolve, the Connor Jones Group remains committed to delivering high-quality service and product solutions, proving that with the right mix of passion, versatility, and client focus, it’s possible to redefine an industry.

With a storied past stretching back over 34 years, OceanaGold’s Macraes operation is a testament to the evolution and resilience of the mining sector.

Now the largest active gold mine in the nation is looking for a different kind of treasure, capable new employees.

OceanaGold Macraes is not just about mining gold; it’s about mining potential.

The operation seeks individuals from a broad spectrum of disciplines, debunking the myth that mining jobs are limited to physical labor in harsh environments.

Whether it’s positions on drill rigs for those starting fresh from school or roles in accounting, planning, law, and laboratory

work for those with specialised education and skills, Macraes offers a plethora of opportunities.

This diversity in career opportunities reflects the operation’s commitment to creating a multifaceted workforce.

The mining industry is undergoing a transformation, and OceanaGold Macraes is at the forefront of this change. The company champions diversity, welcoming all into its ranks and providing them with unprecedented opportunities to thrive in a supportive environment.

At the heart of OceanaGold Macraes’ recruitment philosophy is the value placed on adaptability, learning, and a strong safety ethic.

The operation’s success is deeply intertwined with the

talents and innovation of its employees, making it a hub for those eager to tackle challenges and contribute to the legacy of New Zealand’s mining industry. With a preference for hiring locals, OceanaGold Macraes not only contributes to the regional economy but also fosters a sense of community and belonging among its workforce.

In essence, OceanaGold’s Macraes Operation is more than

Build local, sell global is the mantra for local tech hardware company Bison. Based in Dunedin on Kaikorai Valley Road, is a dynamic export manufacturer and pioneering developer of agile container handling systems.

Bison combines mechanical, hydraulic, electronic, and software technologies to produce portable lifting jacks, hoists, and the world’s only portable, certified container scales.

These innovations have propelled Bison into the global market, with its products now used in 70 countries and 95% of its revenue generated from exports.

Bison systems are used across a range of industries - including defence, energy and construction - where reliability, portability and self-sufficiency are critical. The company counts the US

military and major corporations like Lockheed Martin and GE among its clients.

Since its launch in 2016, Bison has grown from a modest start-up to a significant manufacturing operation, substantially contributing to the local economy and job market.

Its distinct direct-to-market approach facilitates close customer interactions and continuous product enhancement.

Having set up a sales office in Texas in 2020, Bison has experienced rapid sales growth in North America. The company now manufactures and ships a 40’ container load of product to its Houston warehouse every 8 - 10 weeks for sale in North America.

Recognised for its pioneering industry contributions, including a New Zealand High Tech Awards finalist nomination, Bison exemplifies innovation, growth, and global impact.

just a mining site; it’s a beacon of growth, innovation, and diversity.

Offering a wide range of career opportunities, Macraes seeks individuals from all walks of life to be a part of its continuing legacy, shaping the future of mining with each passing day.

The rich history of the Macraes region, from the early gold rushes to the sophisticated operations of today, underscores the operation’s ability to

overcome challenges through innovation and expertise. The adaptation from primitive gold extraction methods to modern technological processes has been pivotal in achieving remarkable efficiencies and innovations. This journey has not only increased gold recovery rates to an impressive 83-86% but also expanded ore processing capabilities significantly.

Providing cost effective repairs for its customers has seen Metalspray Engineering carve a unique niche for itself in the local engineering landscape.

With over 65 years of experience in the process, the Dunedin based firm has specialised in creating lasting repairs using the metalspraying process.

Metalspraying allows damaged parts to be repaired for a fraction of the cost of replacing them outright.

The process involves spraying a uniform layer of molten metal onto the surface of the part to be repaired. This is done at low temperatures to prevent distortion and stress on the repaired part.

The process can be applied to a variety of metal surfaces, including bronze, copper, aluminium and stainless steel, and even to ceramic surfaces.

Metalspray engineering have been specialists in the process ever since founder John Shanks imported the first metalspraying machine into the country in 1958.

This focus has led to earning loyal customers throughout the country and has allowed the business to expand its offerings over the years.

Today the company provides a complete range of engineering services on top of its specialist metalspraying services including design making, tool and die making, CNC milling, gear cutting, special purpose machine building, maintenance engineering and all-hours emergency engineering services.

“What I enjoy here is the size of the equipment we work on and the mentoring I receive from experienced senior heavy diesel mechanics.

As our clients are all internal, we all work together as one.”

Alex is in his first year of his Automotive Heavy Diesel Mechanic Apprenticeship at the OceanaGold Macraes Operation in the South Island of New Zealand. After completing his Automotive Level 3 certificate at the Otago Polytechnic, his four-year apprenticeship is reduced to three years, all while learning hands-on experience in his job.

“My advice would be don’t be scared or nervous, go and try something new to find what suits you.”

DANONE www.danone.com

The health of people and the health of the planet are inextricably linked in the eyes of the global food and beverage company, Danone. Now some of its local projects are helping to harmonise the delicate balance between fostering the health of people and nurturing environmental sustainability.

Headquartered in Paris, France, and with global operational sites including Auckland and Balclutha, New Zealand, Danone’s commitment to health through food resonates across 120 markets worldwide. With notable brands such as Aptamil, Karicare, and Souvenaid, and a suite of Nutricia Specialised Nutrition products, Danone’s portfolio is tailored to support the crucial first 1,000 days of life and tackle some of the most pressing health challenges faced by humanity today.

This multinational conglomerate, with over 90,000 employees, champions the cause of bringing healthier and more sustainable eating and drinking practices to the forefront of consumer consciousness.

Central to Danone’s ethos is the One Planet, One Health vision, which sees that people’s wellbeing cannot be separated from the well-being of our planet. The Biomass Boiler is the epitome of Danone’s ground-breaking Dual Project, which was committed to

over 50 years ago and expounds that corporate responsibility does not end at the factory gate or the office door.

Danone New Zealand’s Biomass Boiler

The Biomass Boiler at the Balclutha Supply Point factory exemplifies Danone’s commitment to its One Planet, One Health vision, and innovative spirit. By substituting traditional energy sources with sustainable by-products from local forestry, Danone has dramatically slashed CO2 emissions by 20,000 tonnes annually, equivalent to removing 60,000 cars from the road. This transition not only bolsters

Danone’s environmental stewardship but also ensures the production of nutritious products that contribute to a

healthier planet. The NZ$30 million investment to power the Balclutha spray drying plant entirely with renewable biomass fuel highlights its leadership in sustainable manufacturing. This initiative marks a significant milestone, positioning Danone as the pioneer of dairy spray drying plants powered by sustainable, locally sourced wood residues in New Zealand.

Soil Health Project

Moreover, the company’s engagement in the Soil Health Project, in collaboration with Synlait and AgResearch, showcases its commitment to advancing sustainable agricultural practices.

Through this five-year study, Danone aims to foster evidencebased regenerative farming

practices that enhance soil health, ultimately contributing to a more sustainable and productive agricultural industry.

B Corp Certification

A distinctive element of Danone’s corporate philosophy is its B Corp certification in Australia and New Zealand, achieved in 2022. This recognition, administered by B Lab, is awarded to companies that can demonstrate verifiable positive impact through policies and practices for employees, communities, customers and the environment. This achievement underscores Danone’s ambition to be B Corp certified across its global operations by 2025, reflecting a steadfast dedication to sustainable business practices that encompass a staggering

82.5% of its global sales already under the B Corp umbrella. Danone’s dedication extends beyond its operational boundaries, impacting communities through volunteer programs and partnerships with local organisations. What sets Danone New Zealand apart in the competitive landscape is its unwavering commitment to sustainability and employee well-being.

The Balclutha site epitomises this ethos, emphasising sustainable sourcing and manufacturing processes alongside a nurturing and inclusive workplace culture. Danone New Zealand invests in its employees’ health and wellbeing, offering comprehensive benefits such as free health insurance, gym memberships, and annual health checks.