8 minute read

AVZ Minerals

AVZ MINERALS A monstrous lithium project in the DRC

Advertisement

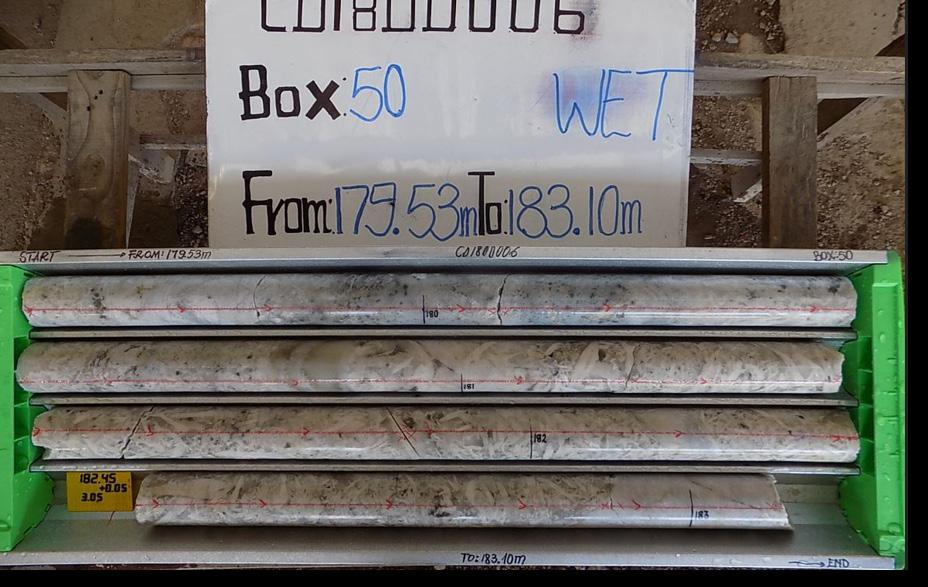

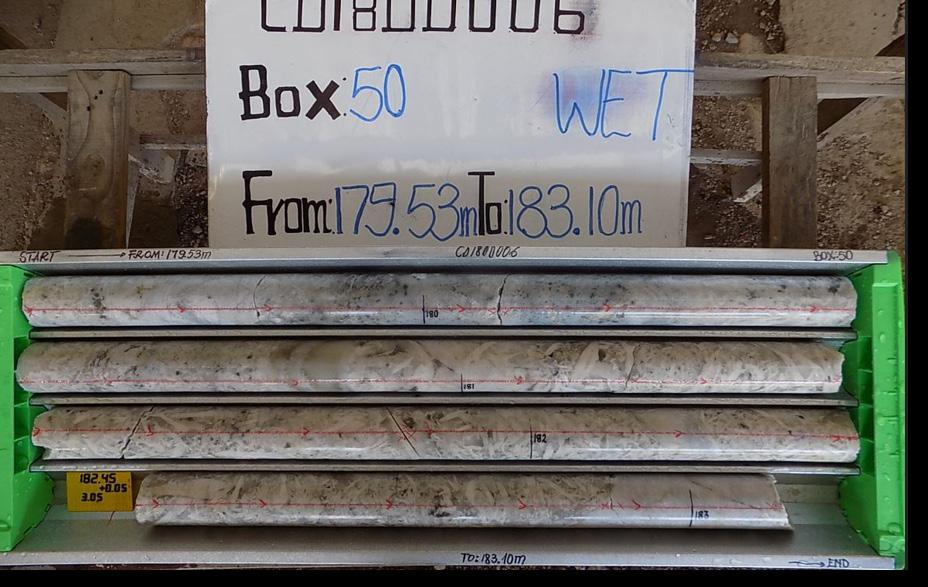

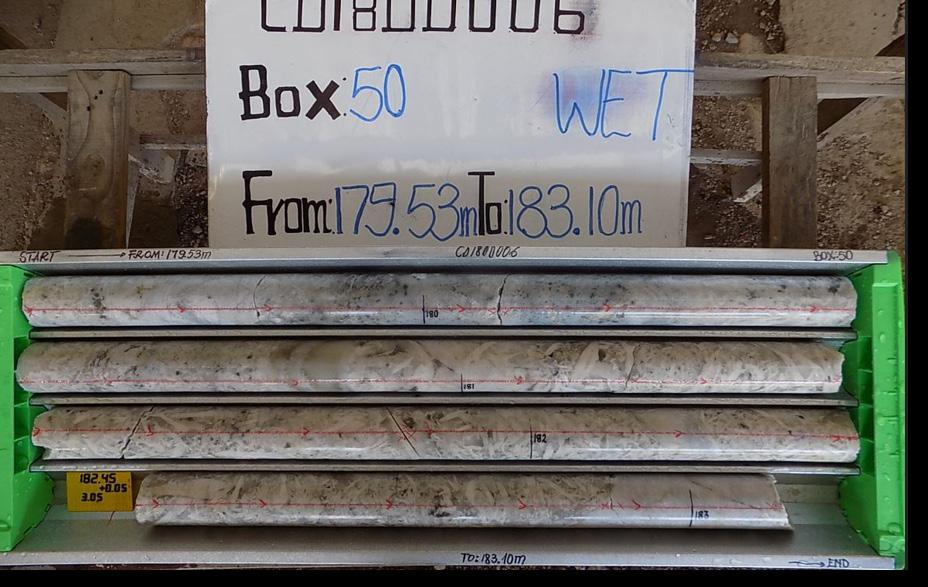

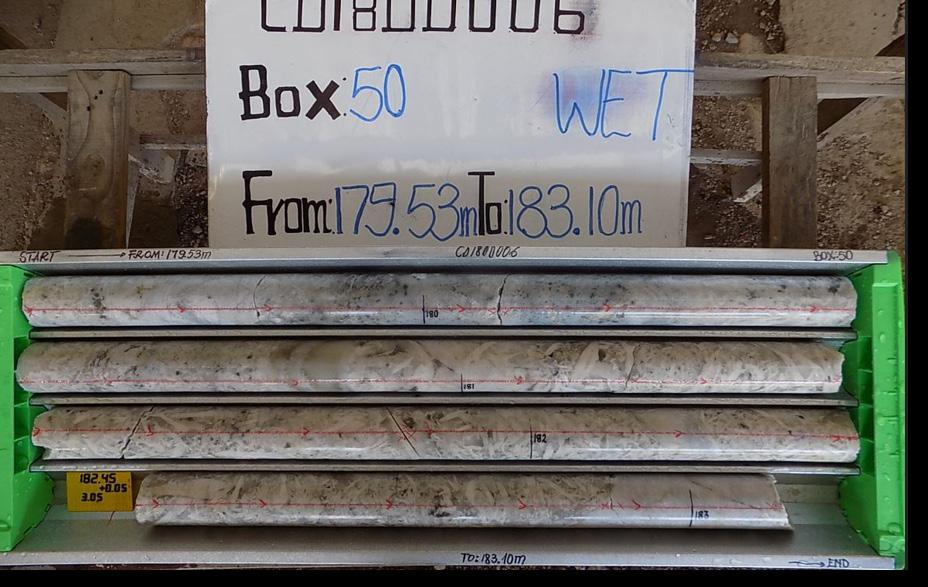

AVZ Minerals’ 60%-owned Manono Lithium and Tin Project in the Democratic Republic of Congo (DRC) was recently christened the ‘Escondida of lithium’ by the Chinese Ministry of Land and Agriculture after they learned of the potential size of the resource. “We’ve only drilled a small portion of the total project area and are extremely excited that we have a 400 million tonnes (Mt) JORC resource at 1.65% lithium,” says AVZ’s managing director Nigel Ferguson. The Manono resource also includes additional tin and tantalum credits, making it one of the largest undeveloped spodumene projects in the world.

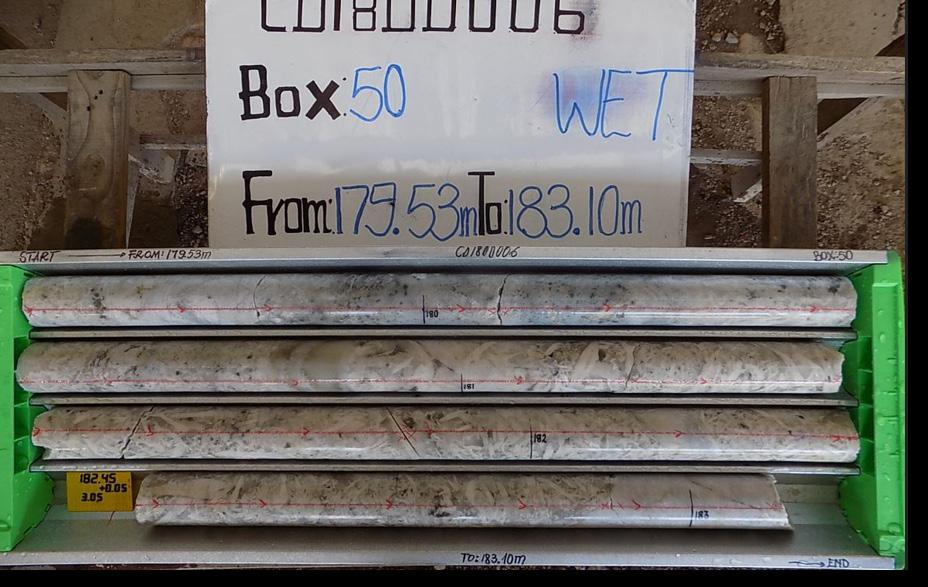

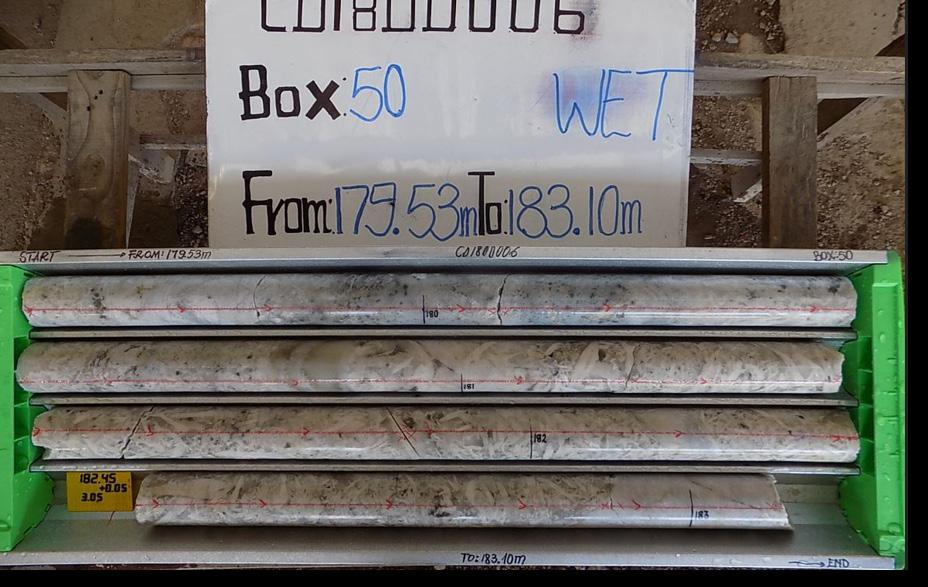

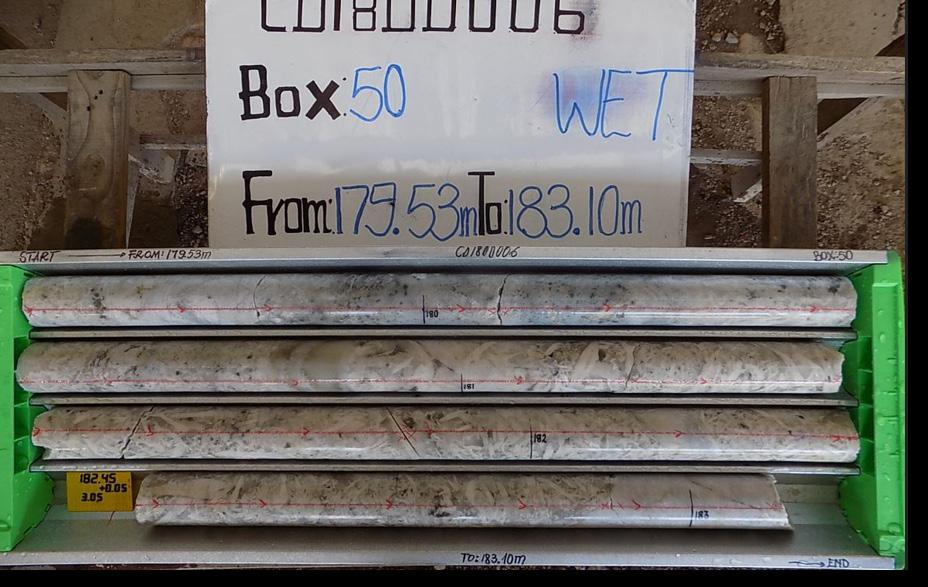

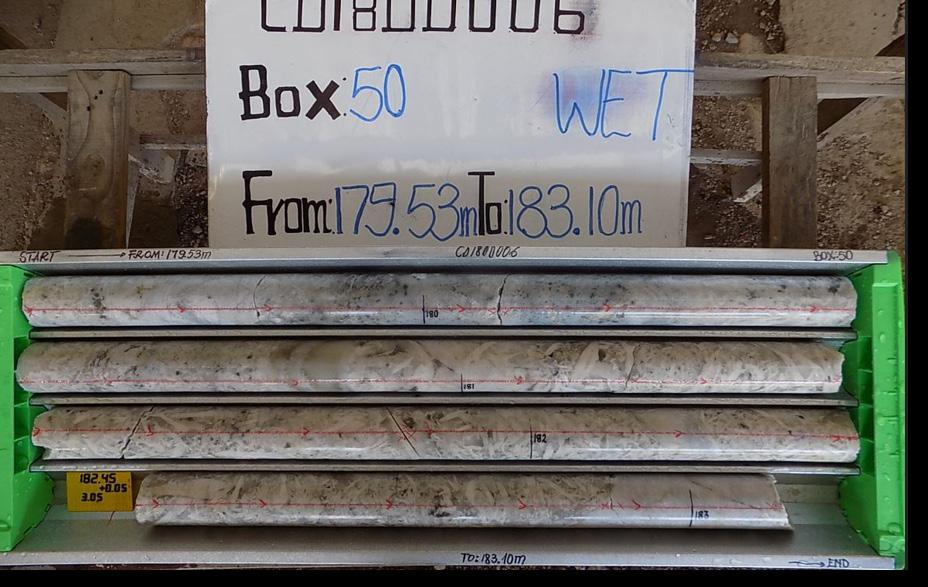

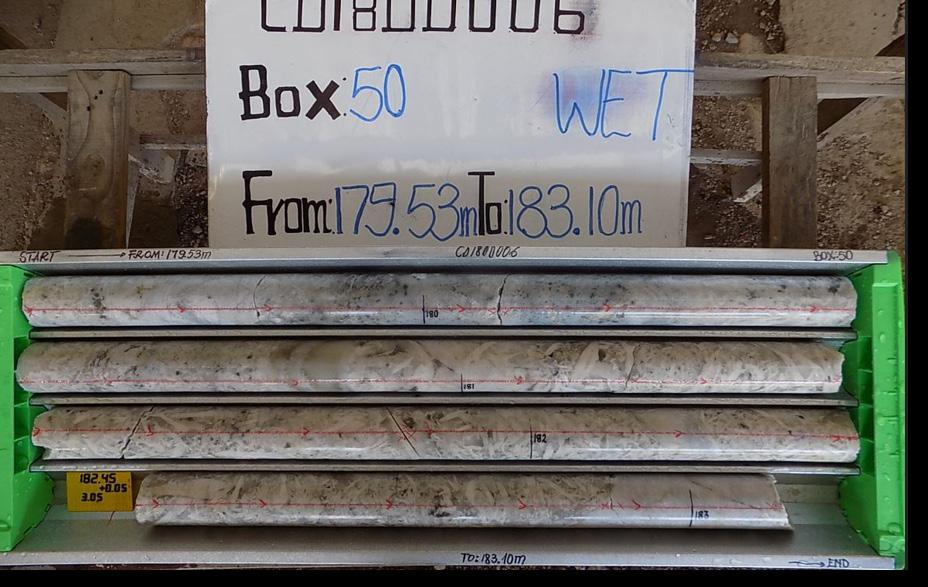

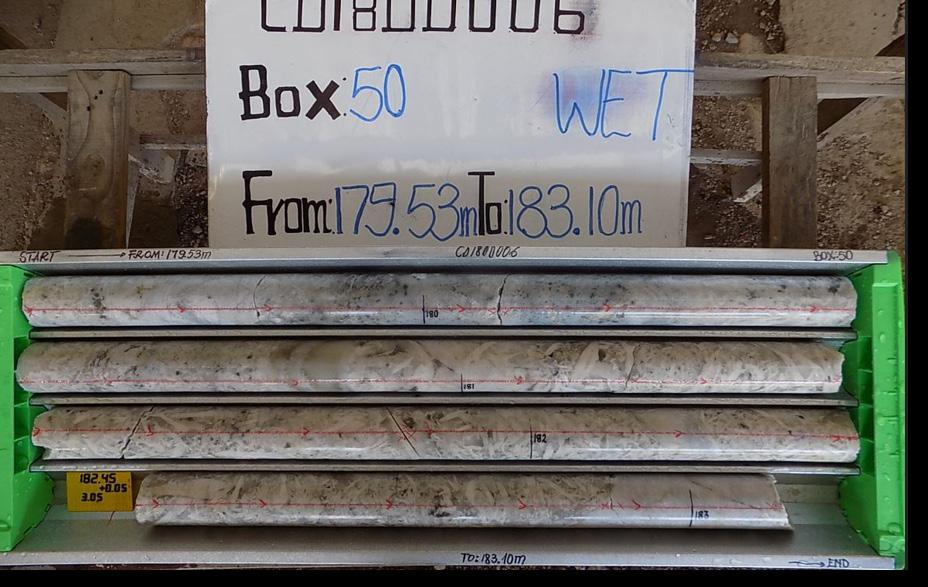

AVZ has only drilled one of six known pegmatites across the 188 km 2 project area – the Roche Dure pegmatite. Roche Dure is the ASX-listed company’s initial exploration and development focus at Manono, primarily due to the presence of historical geological data from the 1950s and 60s when the area was mined for tin.

A total of 42 vertical drill holes were made to depths of between 50 and 150 metres to produce a lithium concentrate grade of 6.8% at a 10mm crush. Since then, AVZ has drilled 86 drill holes totalling 27,466 metres.

Scoping out Roche Dure “Our exploration consultant spent two weeks mapping the whole project area. He suggested that Roche Dure was the best place to start because it was ‘low hanging fruit’. Roche Dure is just 1.6 km of the total 15.5 km strike length at Manono, so we’ve only touched approximately 10% of the entire project area.”

The Roche Dure scoping study was published to the ASX in May 2019 and contained strong economics, including a massive US$2.63 billion pre-royalties, pre-tax NPV, a 64% IRR and a three-year payback time. The scale and longevity of the project was also confirmed by the study, which was modelled on a 20- year mine life based on a 5 million tonnes per annum (Mtpa) open pit mine scenario, consuming only 25% of the resource.

This model provides for annual production of 1.1 Mt at a minimum of 5.8% lithium. However, Ferguson tells RGN it would be difficult for the company to justify flooding the market with Manono product so AVZ plans to recalibrate the annual production down to 750,000 tonnes of concentrate, which puts throughput at 4.5 Mtpa.

“This still allows AVZ flexibility in terms of feeding new clients by increasing production,” said Ferguson. “We retain the ability to ‘turn’ up production to supply new customers if we want to.”

A credible offtake partner AVZ is working towards securing its first customer for the lithium produced at Manono and is hopeful it will be Chinese lithium chemicals producer Yibin Tianyi Lithium Industry Co after the two struck a strategic investment deal in November.

The deal will see Yibin Tianyi take a AUS$14.1 million share placement in AVZ for 12% of the company along with a commitment to ‘negotiate in good faith’ a binding offtake agreement for lithium products from the Manono Project.

Yibin Tianyi is currently building a 25,000 tpa lithium hydroxide plant in China that should be completed by June. They plan several staged expansions to further increase hydroxide production to about 100,000 tpa, making Yibin Tianyi one of the largest hydroxide suppliers in China.

“They have said that by the end of their four-phase plant expansion they will need approximately 750,000 tonnes of material. If they turn to us and say, ‘we need all of it’, then we can certainly supply it,” says a confident Ferguson.

A phased processing approach AVZ has its own plans for processing the spodumene ore from Manono but it will take a phased approach, commencing first with Dense Media Separation (DMS) – a simple process which can produce up to 6.3% lithium oxide without the need for flotation.

Meeting with the President of the DRC

The company will then consider a two-phase addition of a flotation circuit followed by a hydroxide circuit, although further test work is required to match the flotation cells to the exact characteristics of the Manono ore.

“We are aware of the problems some players have had in Western Australia by going straight into DMS, flotation and hydroxide plant production all in one go so we need to be careful and understand how we progress.

“One idea we have is to maintain the 750,000 tpa throughput and use the rest of the production to feed into a 25,000 tpa hydroxide plant for other clients that want the material for battery manufacturing in the automotive space, but also for power banks and storage.” The DRC is perhaps the single most important player in the growing battery metals revolution with around 60% of the world’s cobalt – a vital component in mobile phones, laptops, tablets and electric vehicle batteries – produced in the central African country.

However, the DRC’s struggles with conflictdriven mining, human rights abuses and child exploitation at artisanal cobalt mine sites have been well documented during the last few years, leading to consumers directly pressuring tech manufacturers to clarify their supply chains all the way to source.

Conflict-free mining So, how will AVZ verify to the global lithium market that its product has been sourced

from an industrial mining operation and hasn’t been tainted by conflict mining at any stage of the supply chain?

All Manono products will conform to iTSCi standards whereby a ‘source-to-market’ trace will be placed on the material before being sealed in containers and shipped across the world.

“Once it’s tagged to international standards and sealed away it’s hard to say it’s come from anywhere else other than Manono,” Ferguson declares.

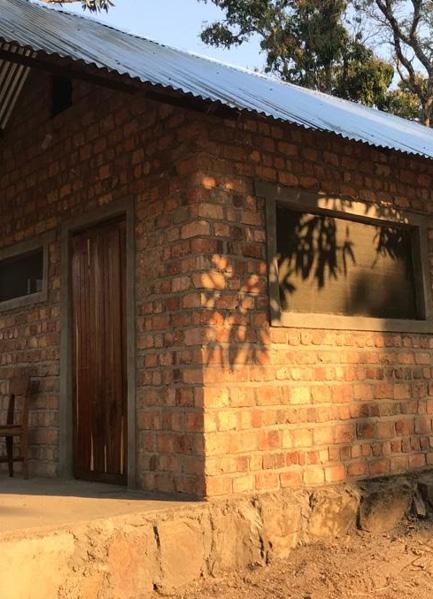

As part of AVZ’s wider commitment to the local communities and social engagement, the AVZ Foundation has also been established. The Foundation has supported a local polio vaccination for more than two years and is also funding the construction of a new school and a hospital in the local area, along with many other smaller infrastructure projects.

In addition, AVZ has safely employed more than 800 local people on a casual basis, including 320 displaced artisanal workers, while the Manono project is expected to employ up to 150 local people either directly or indirectly, supporting some 500 families.

A massive two years ahead Ferguson describes this year and 2021 as the ‘crescendo’ of AVZ’s workload at the Manono

“We’ve only drilled a very small portion of the total project area and we’re very excited by the fact that we have a 400 million tonnes (Mt) JORC resource at 1.65% lithium” Nigel Ferguson, managing director AVZ Minerals

Nigel Ferguson, managing director AVZ Minerals

Project. The definitive feasibility study is approximately 95% complete at the time of writing and should be published by the end of Q1 2020.

“Once we have the DFS out, I am hoping all of our financing will follow on the back of that. That’s going to take a bit of effort to organise but if we have Yibin Tianyi onboard it will happen quicker.

“We are talking to a couple of major financiers who are interested in participating, it’s really a case of getting them to sign on the dotted line.”

In mid-January, AVZ signed an MoU with the DRC government to investigate the feasibility of refurbishing the Mpiana-Mwanga hydroelectric power station located approximately 85 km from the proposed Manono mine site. This opportunity to power the mine from a hydroelectric plant is likely to generate significant longer-term cost savings for AVZ while also providing an environmentally cleaner alternative to the current dieselpowered option.

the designation of a Special Economic Zone (SEZ) for the Manono Project. The creation of a SEZ would generate sustainable growth and prosperity and give increased confidence to potential investors and infrastructure

developers to become involved and set up new businesses in the local area.

a j

AFRICA. IN THE PALM OF YOUR HAND.

ONLINE NOW WWW.AFRICANBUSINESSNETWORK.CO.ZA

Bushveld Minerals’ vision is to grow into a significant, low cost and vertically integrated company comprising of primary vanadium production, electrolyte manufacturing, development and deployment of Vanadium Redox Flow Batteries in the energy markets. Our value proposition includes:

• Compelling commodity market anchored to steel with burgeoning demand from energy storage market • Largest primary vanadium resource base of ~550Mt with a grade 1.58-2.02% V₂O₅ in magnetite • Bushveld Minerals owns 2 of the 4 operating primary vanadium production processing facilities, with capacity to scale up production significantly • Bushveld Minerals will offer a diversfied product offering for the steel, chemical industry and energy storage market • Bushveld Minerals vertical integration strategy into energy storage provides a natural hedge to vanadium price volatility as well as a diversified revenue stream